Study on Low-Velocity Impact and Residual Compressive Mechanical Properties of Carbon Fiber–Epoxy Resin Composites

Abstract

1. Introduction

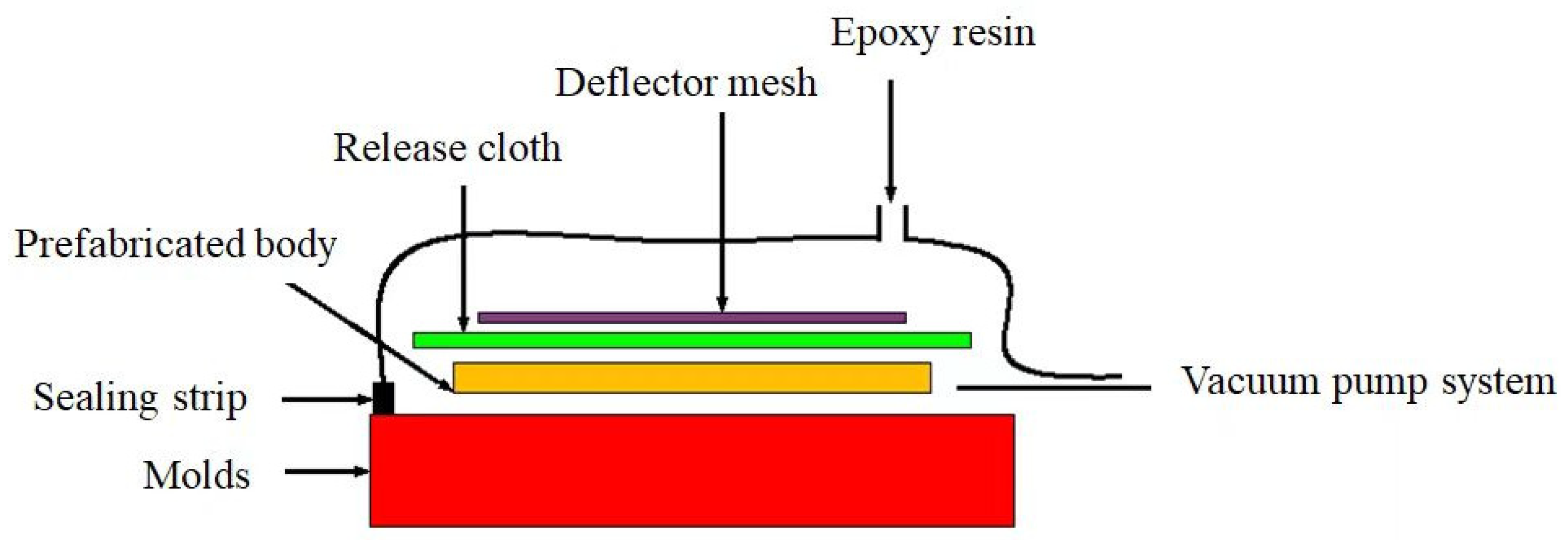

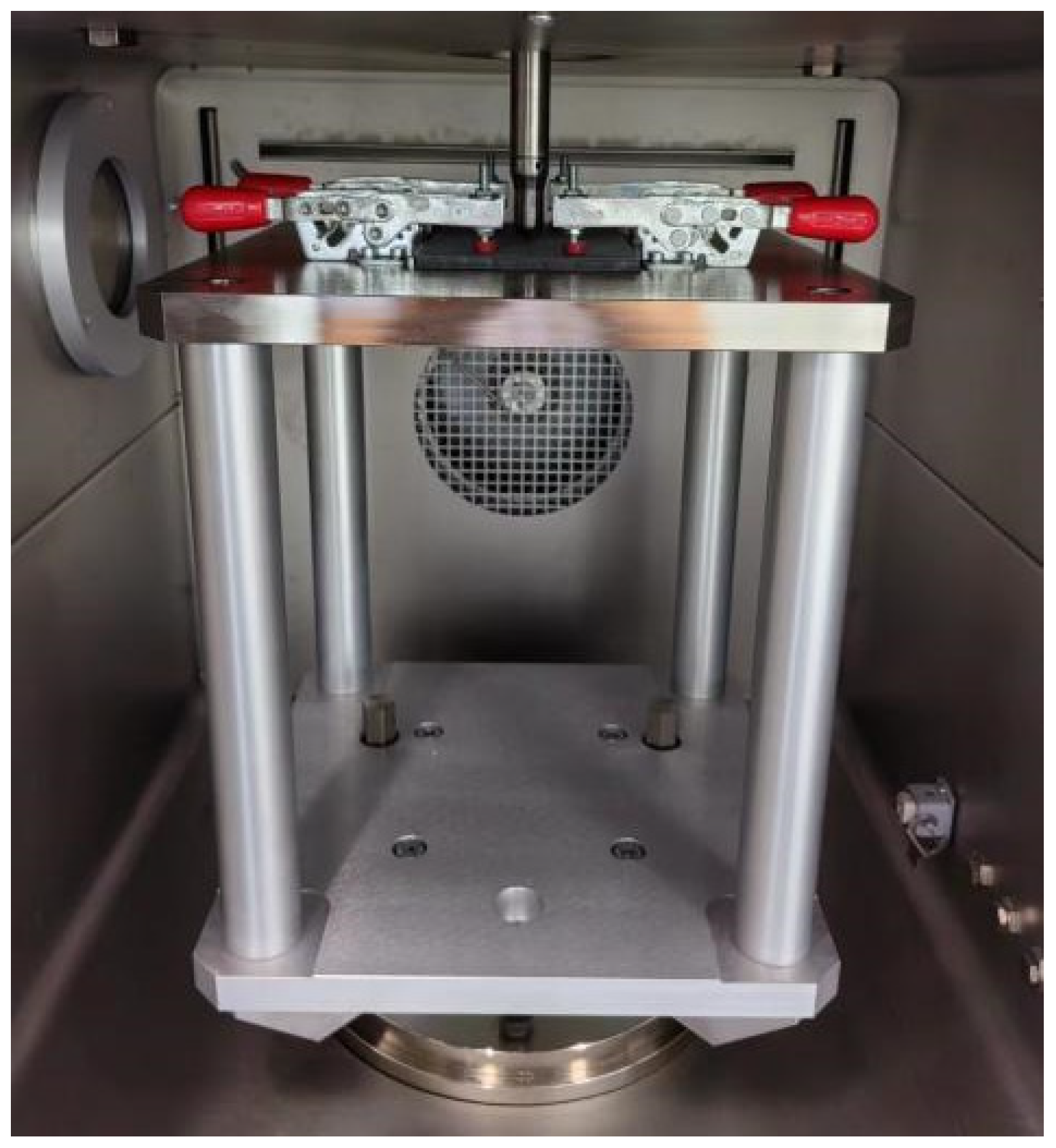

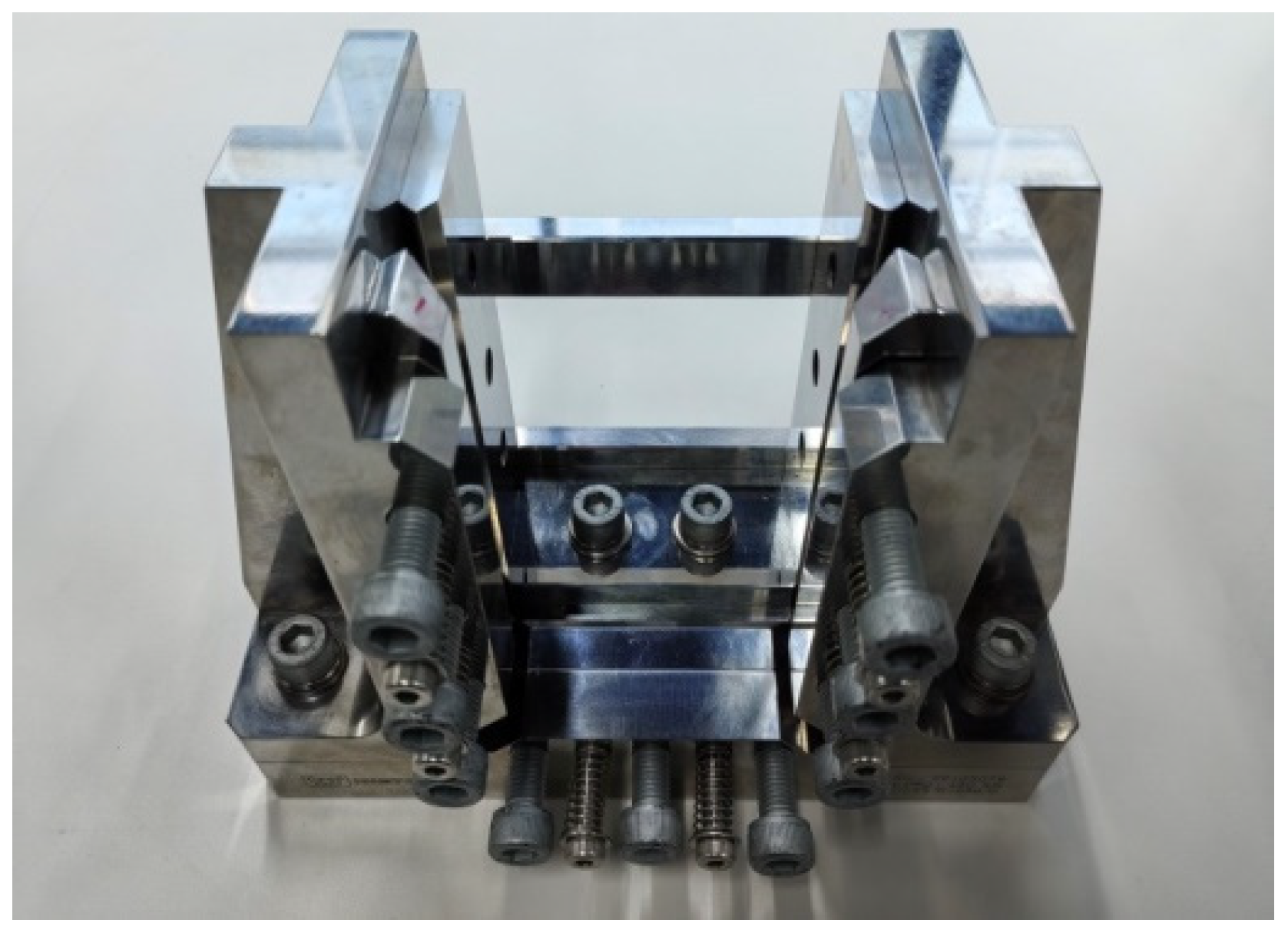

2. Materials and Methods

2.1. Materials

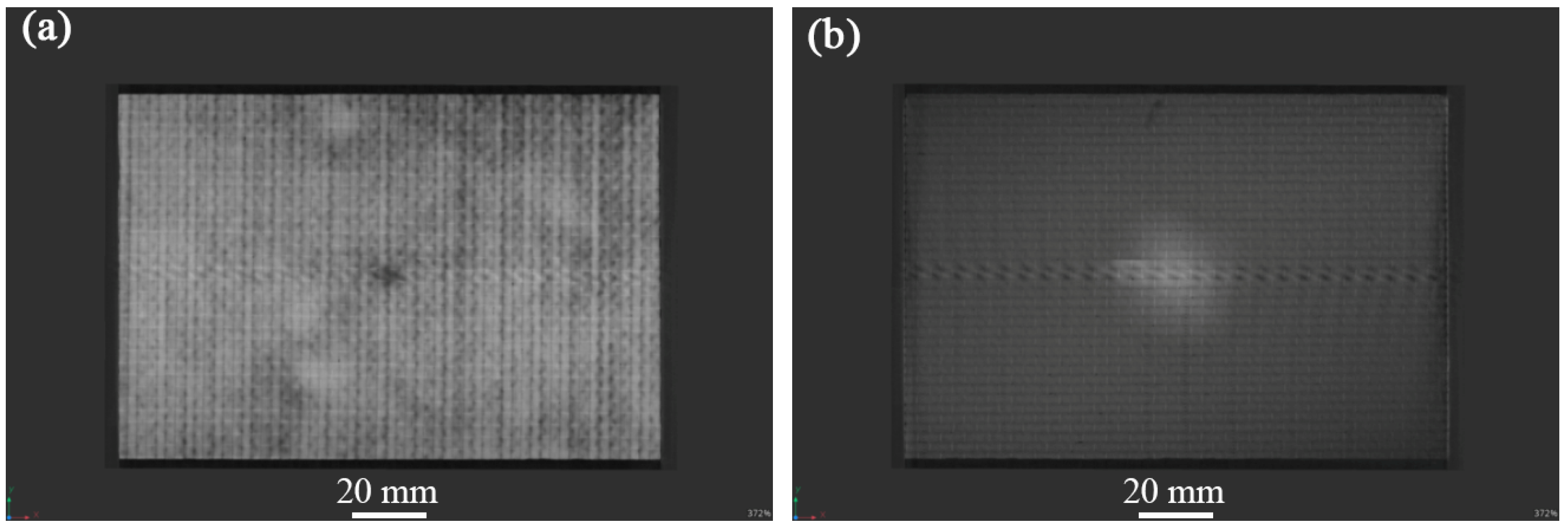

2.2. Testing and Characterization

3. Results and Discussion

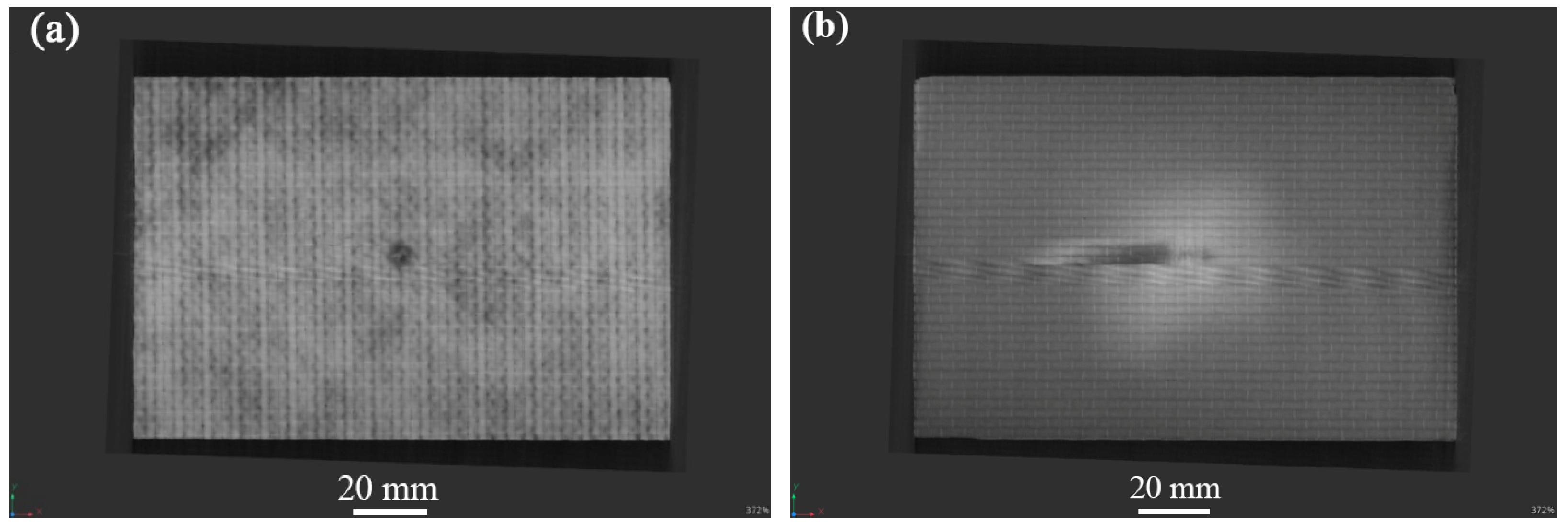

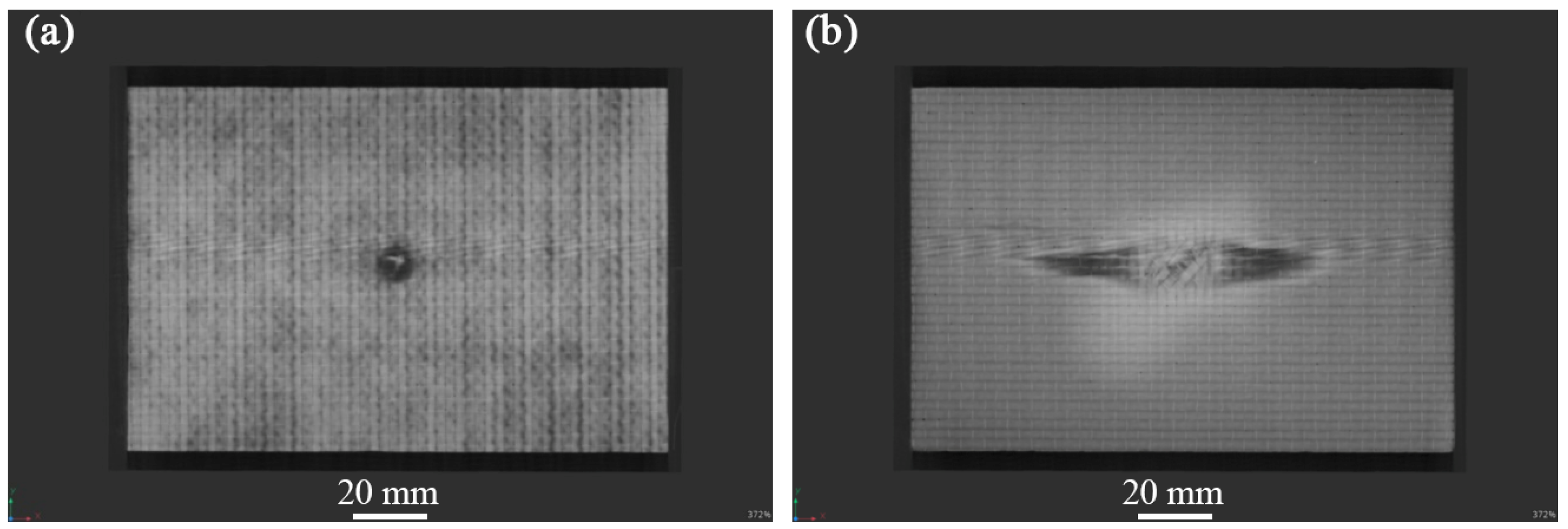

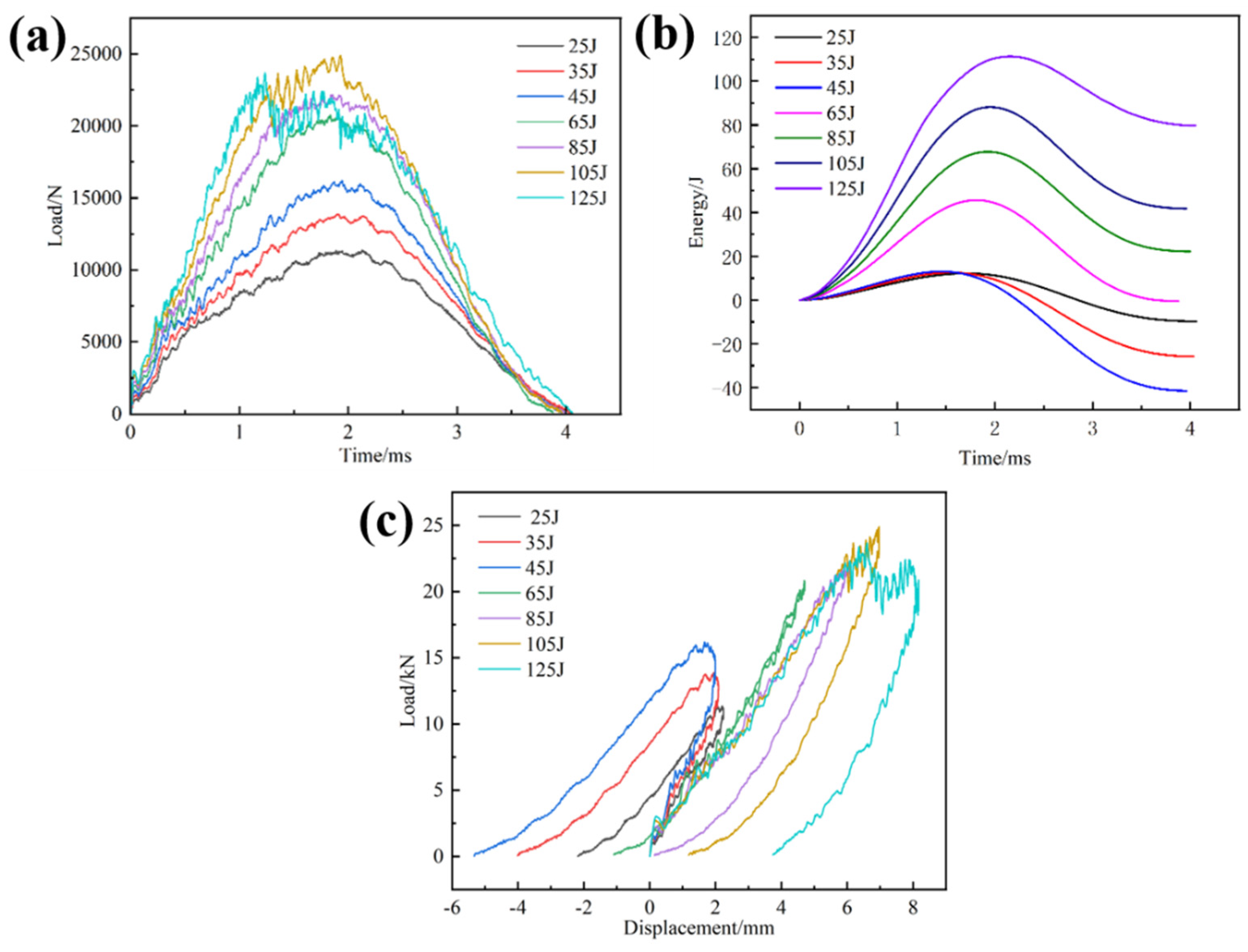

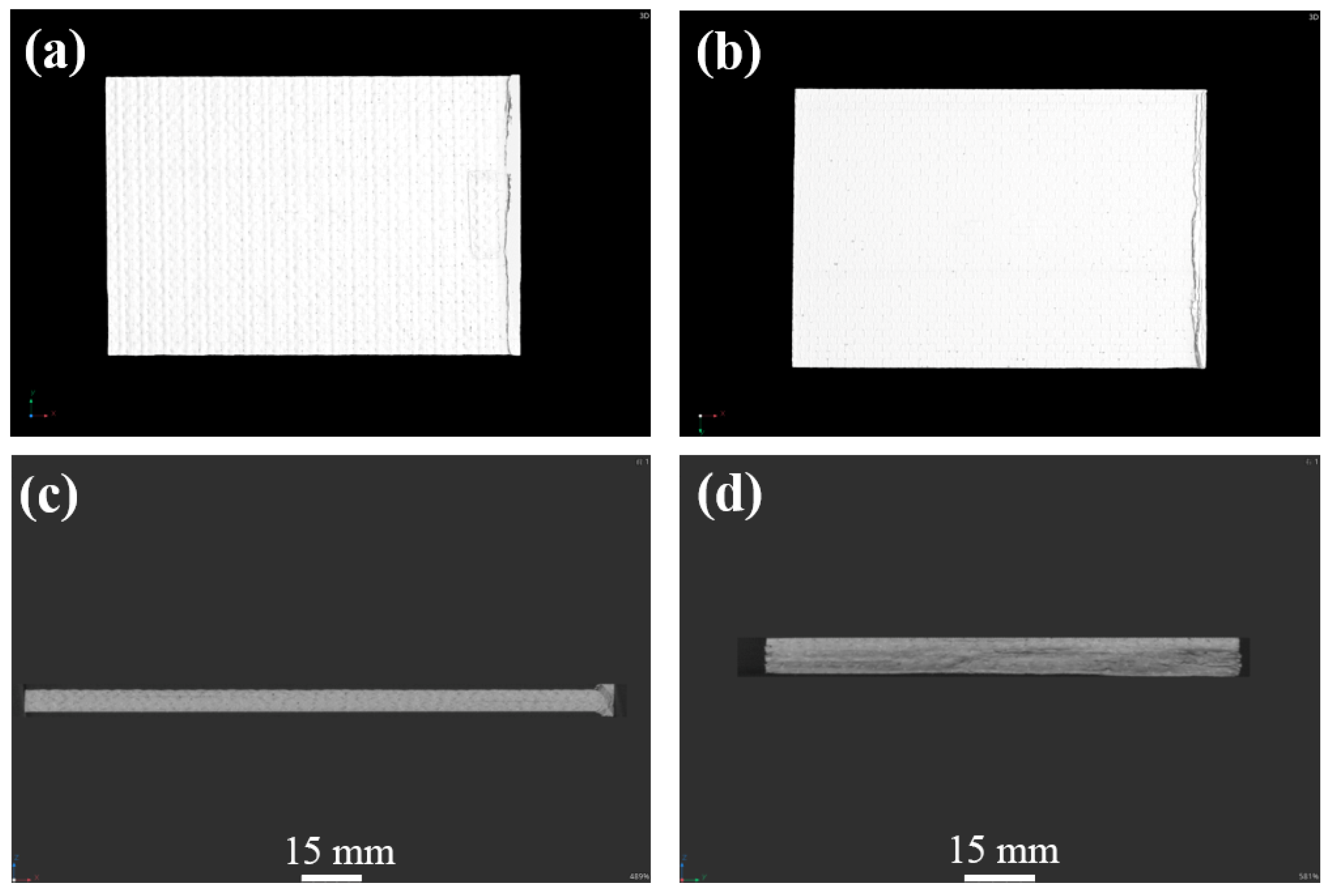

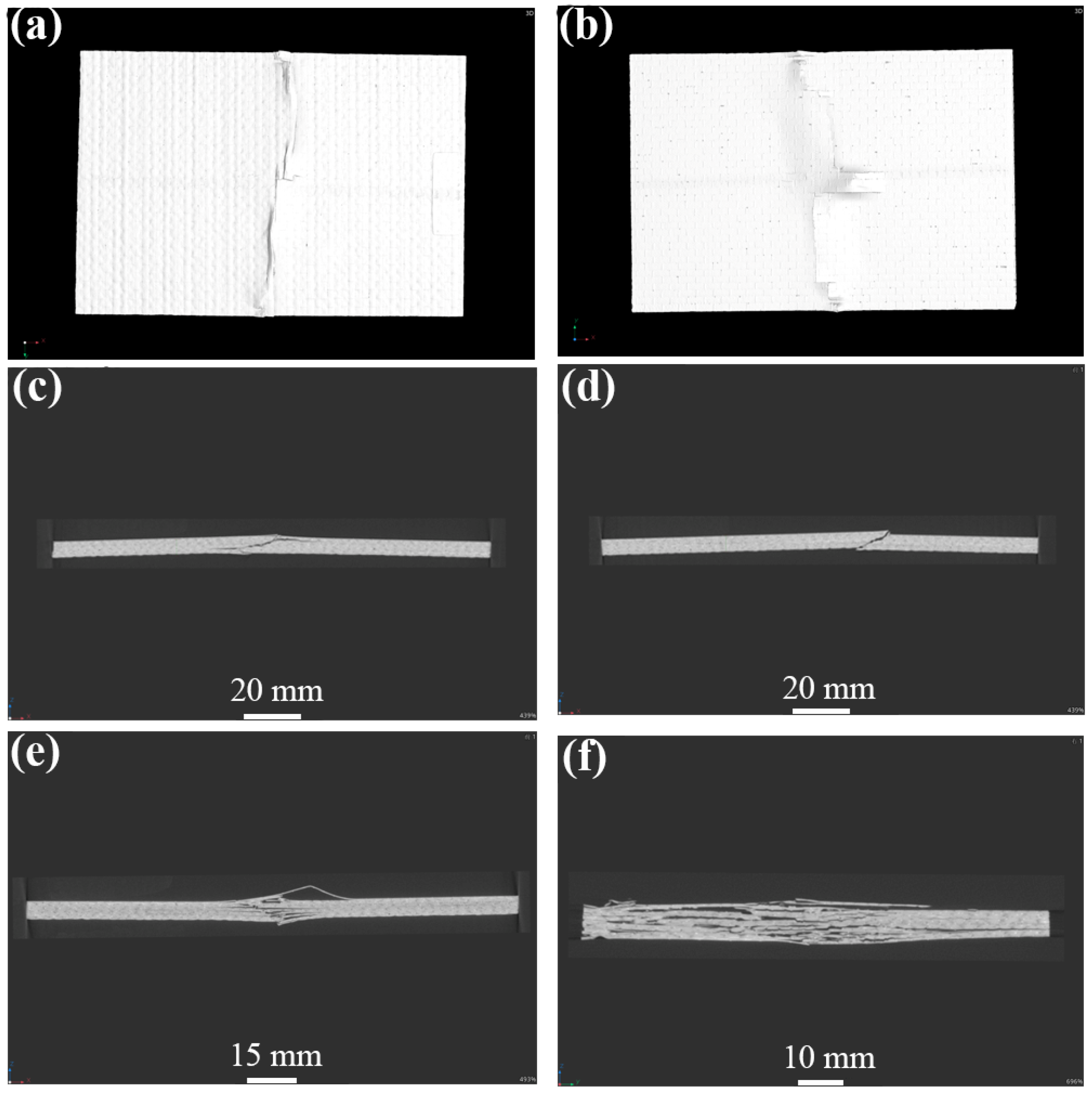

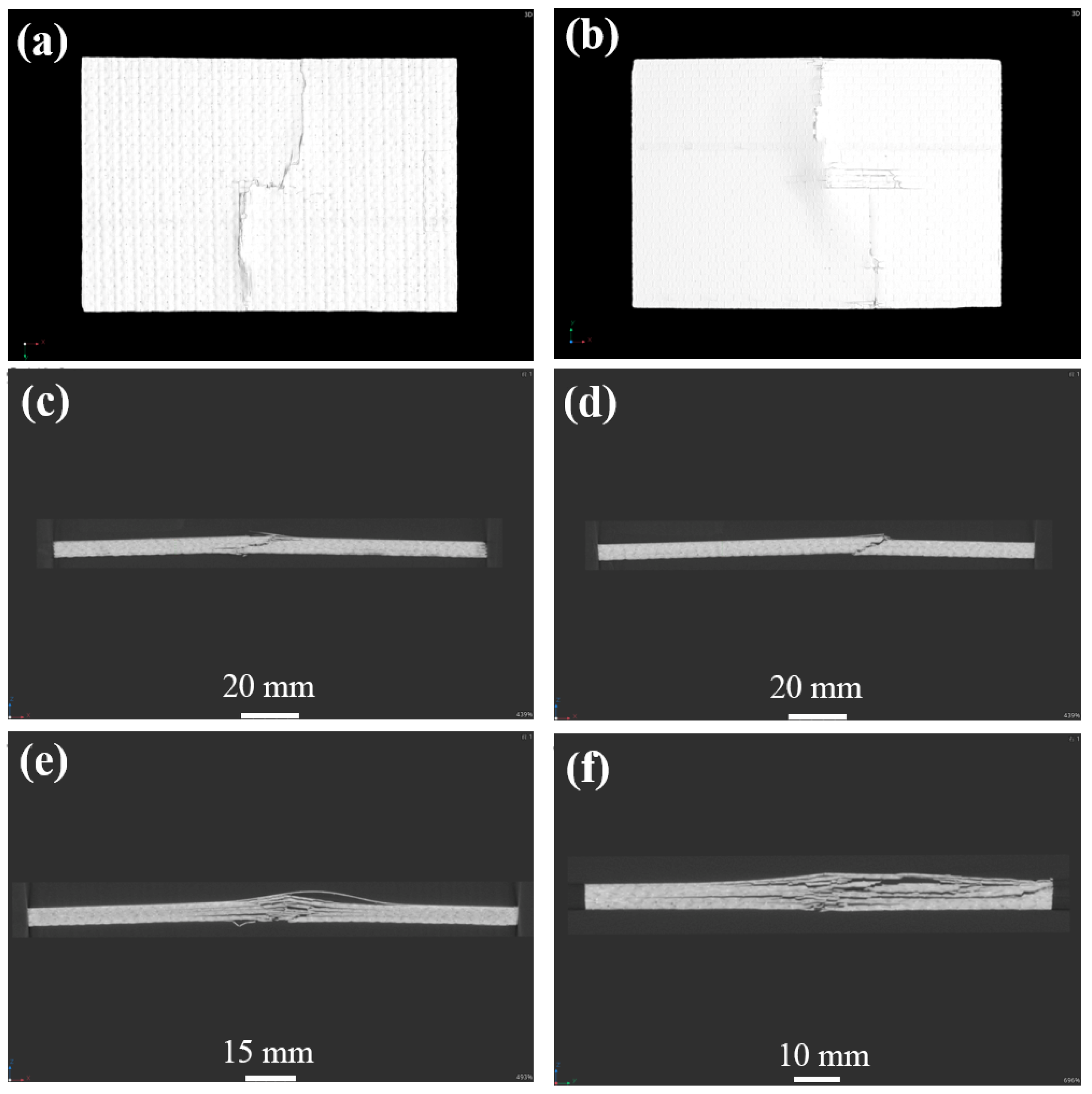

3.1. Low-Speed Impact Experiment

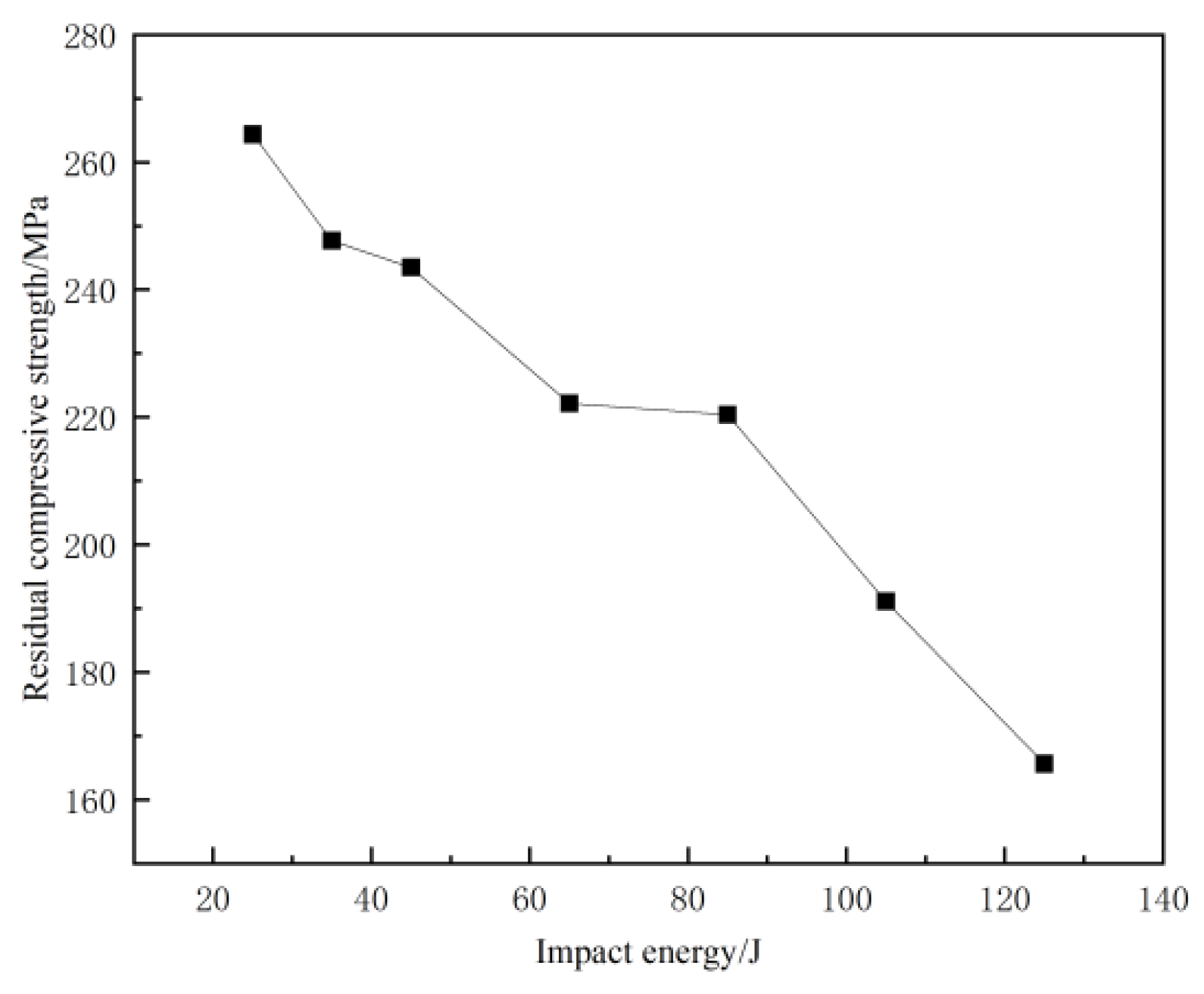

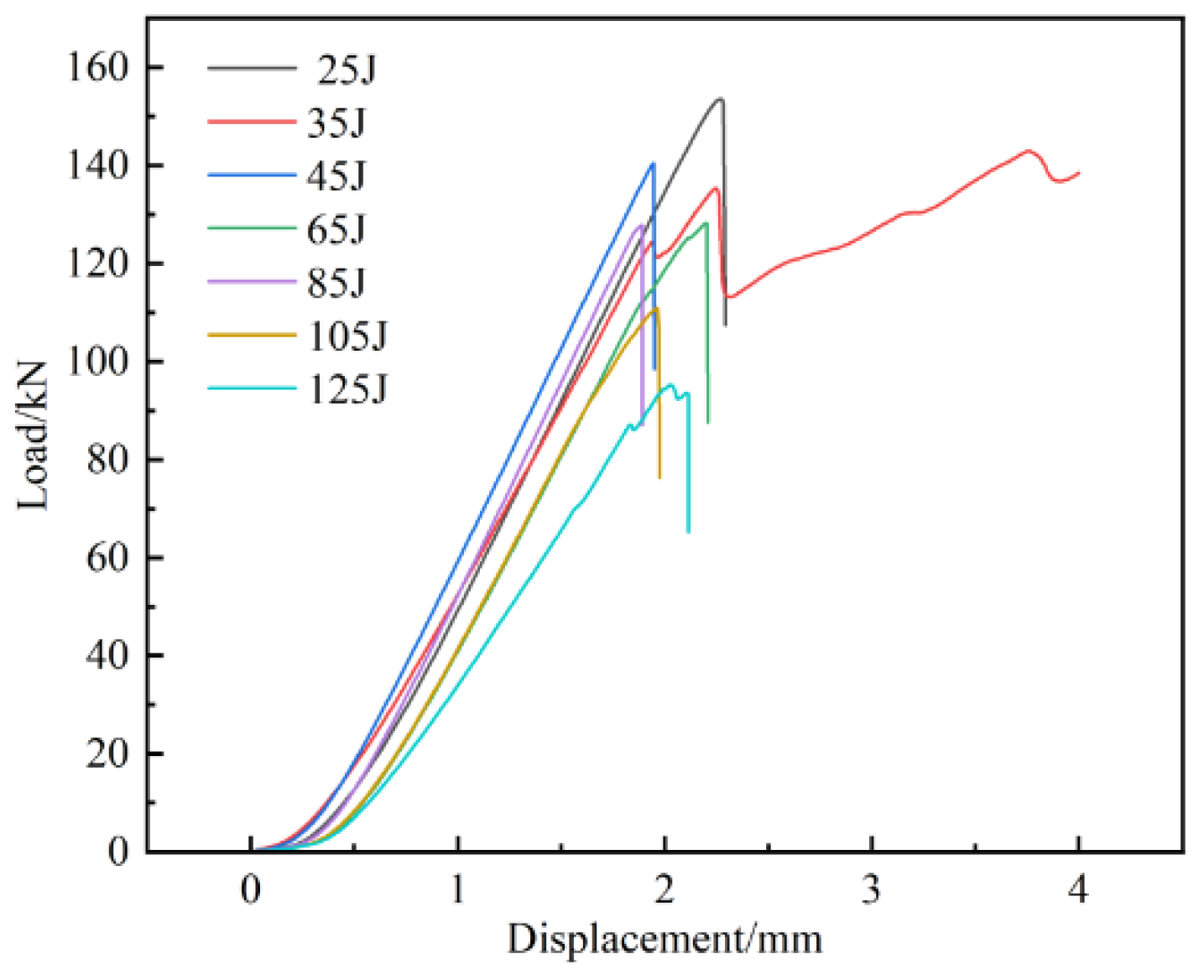

3.2. Compression Experiment after Impact

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Hou, D.Y.; Zheng, K.K.; Gao, C.H. Characterization of friction and wear of phenolic resin matrix composites reinforced by bamboo fibers of alkaline and LaCl3 treatment. Mater. Today Commun. 2023, 35, 106361. [Google Scholar] [CrossRef]

- Wu, W.J.; Zou, Y.; Li, C.H.; Li, Y.W.; Wang, Z.Y.; Chang, N.; Shi, Y.S. Effect of impregnated phenolic resin on the properties of Si–SiC ceramic matrix composites fabricated by SLS-RMI. Ceram. Int. 2023, 49, 1624–1635. [Google Scholar] [CrossRef]

- Zou, Z.Y.; Qin, Y.; Fu, H.D.; Zhu, D.; Li, Z.Z.; Huang, Z.X. ZrO2f-coated CF hybrid fibrous reinforcements and properties of their reinforced ceramicizable phenolic resin matrix composites. J. Eur. Ceram. Soc. 2021, 41, 1810–1816. [Google Scholar] [CrossRef]

- Niu, J.W.; Wang, Z.F.; Liu, H.; Ma, Y.; Pang, H.X.; Wang, X.T. Response surface optimization of pitch phase change densification using composite phenolic resin co-carbonization to prepare high performance carbon refractories. J. Anal. Appl. Pyrol. 2023, 175, 106144. [Google Scholar] [CrossRef]

- Zhu, T.Q.; Ren, Z.Y.; Xu, J.; Shen, L.L.; Xiao, C.L.; Zhang, C.; Zhou, X.; Jian, X.G. Damage evolution model and failure mechanism of continuous carbon fiber-reinforced thermoplastic resin matrix composite materials. Compos. Sci. Technol. 2023, 244, 110300. [Google Scholar] [CrossRef]

- Wang, A.N.; Xu, G.W.; Liu, X.G. Effect of polyurea coating on low-velocity impact properties of unidirectional carbon fiber-reinforced polymer composites plates. Structures 2024, 61, 106090. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.B.; Yin, B.; Li, S.J.; Jia, W.B.; Lao, D.; Wang, H.L.; Liu, J.F. New design of bismuth borate ceramic/epoxy composites with excellent fracture toughness and radiation shielding capabilities. Mater. Today Commun. 2023, 35, 106102. [Google Scholar] [CrossRef]

- Yan, M.L.; Liu, Y.C.; Jiang, W.G.; Qin, W.Z.; Yan, Y.; Wan, L.Y.; Jiao, W.C.; Wang, R.G. Mechanism of matrix influencing the cryogenic mechanical property of carbon fibre reinforced epoxy resin composite. Compos. Commun. 2022, 33, 101220. [Google Scholar] [CrossRef]

- Cugnoni, J.; Amacher, R.; Kohler, S.; Brunner, J.; Kramer, E.; Dransfeld, C.; Smith, W.; Scobbie, K.; Sorensen, L.; Botsis, J. Towards aerospace grade thin-ply composites: Effect of ply thickness, fibre, matrix and interlayer toughening on strength and damage tolerance. Compos. Sci. Technol. 2018, 168, 467–477. [Google Scholar] [CrossRef]

- Liu, H.P.; Lei, W.; Tong, Z.M.; Guan, K.K.; Zhang, H.J. Enhanced diffusion kinetics of Li ions in double-shell hollow carbon fibers. ACS Appl. Mater. 2021, 13, 24604–24614. [Google Scholar] [CrossRef]

- Ma, S.H.; He, Y.; Hui, L.; Xu, L. Effects of hygrothermal and thermal aging on the low-velocity impact properties of carbon fiber composites. Adv. Compos. Mater. 2020, 29, 55–72. [Google Scholar] [CrossRef]

- Zhu, B.L.; Wang, J.; Zheng, H.; Ma, J.; Wu, J.; Wu, R. Investigation of thermal conductivity and dielectric properties of LDPE-matrix composites filled with hybrid filler of hollow glass microspheres and nitride particles. Compos. Part B Eng. 2015, 69, 496–506. [Google Scholar] [CrossRef]

- Xian, G.; Guo, R.; Li, C.; Wang, Y. Mechanical performance evolution and life prediction of prestressed CFRP plate exposed to hygrothermal and freeze-thaw environments. Compos. Struct. 2022, 293, 115719. [Google Scholar] [CrossRef]

- Lu, Z.; Li, J.; Xie, J.; Huang, P.; Xue, L. Durability of flexurally strengthened RC beams with prestressed CFRP sheet under wete-dry cycling in a chloride-containing environment. Compos. Struct. 2020, 255, 112869. [Google Scholar] [CrossRef]

- Ouyang, S.; Li, Y.B.; Ouyang, D.G.; Li, S.J.; Xu, N.N.; Xiang, R.F. Microstructural evolution of carbon fibers by silicon vapor deposition and its effect on mullite-corundum castables. Ceram. Int. 2021, 47, 7824–7830. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, W.; Qian, X.; Su, Z.; Pham, D.-C.; Sridhar, N. Fatigue behaviour and life prediction of fifilament wound CFRP pipes based on coupon tests. Mar. Struct. 2020, 72, 102756. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Z.Y.; Pang, J.Y.; Su, L. Preparation of carbon fibre-reinforced composite panels from epoxy resin matrix of nano lignin polyol particles. J. Clean. Prod. 2023, 428, 139170. [Google Scholar] [CrossRef]

- Sun, Z.; Xiao, J.; Tao, L.; Wei, Y.; Wang, S.; Zhang, H.; Zhu, S.; Yu, M. Preparation of high-performance carbon fiber-reinforced epoxy composites by compression resin transfer molding. Materials. 2019, 12, 13. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.B.; Zhang, J.L.; Li, F.L.; Yuan, G.Q.; Zhu, Q.; Jia, Q.L.; Zhang, H.J.; Zhang, S.W. Selective laser melting of SiCp/Al composites: Densification, microstructure, and mechanical and tribological properties. Ceram. Int. 2021, 47, 30826–30837. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, Q.; Gong, Y.; Xu, G.; Qiao, W. Relationship between microstructure and dry wear behavior of compo-cast nano-SiC(p)+micro-Gr(p)/Zn-35Al-1.2Mg-0.2Sr composite under different chilling conditions. Kovove Mater. 2020, 58, 49–57. [Google Scholar] [CrossRef]

- Abakah, R.R.; Huang, F.; Hu, Q.; Wang, Y.; Liu, J. Comparative study of corrosion properties of different graphene nanoplate/epoxy composite coatings for enhanced surface barrier protection. Coatings 2021, 11, 285. [Google Scholar] [CrossRef]

- Liu, H.B.; Falzon, G.B.; Tan, W. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part B Eng. 2018, 136, 101–108. [Google Scholar] [CrossRef]

- Kumar, R.A.; Devaraju, A. A comparative investigation on cast and aging (T6) response on mechanical and dry sliding wear behavior of Al7075/SiCp metal matrix composite. Surf. Rev. Lett. 2021, 28, 2150044. [Google Scholar] [CrossRef]

- Sun, G.Y.; Yu, H.W.; Wang, Z.; Xiao, Z.; Li, Q. Energy absorption mechanics and design optimization of CFRP/aluminum hybrid structures for transverse loading. Int. J. Mech. Sci. 2019, 150, 767–783. [Google Scholar] [CrossRef]

- Song, Z.G.; Zhang, L.W.; Liew, K.M. Dynamic responses of CNT reinforced composite plates subjected to impact loading. Compos. Part B Eng. 2016, 99, 154–161. [Google Scholar] [CrossRef]

- Gu, G.X.; Takaffoli, M.; Hsieh, A.J.; Markus, M.J. Biomimetic additive manufactured polymer composites for improved impact resistance. Extreme Mech. Lett. 2016, 9, 317–323. [Google Scholar] [CrossRef]

- Li, G.; Cui, S.S. Grain modeling and finite element simulation of damage evolution for AA5182-O aluminum alloy sheet. J. Mater. Res. Technol. 2020, 9, 10559–10575. [Google Scholar] [CrossRef]

- Lei, Z.X.; Ma, J.; Sun, W.K.; Yin, B.B.; Liew, K.M. Low-velocity impact and compression-after-impact behaviors of twill woven carbon fiber/glass fiber hybrid composite laminates with flame retardant epoxy resin. Compos. Struct. 2023, 321, 117253. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Xie, J.; Zhao, X.Z.; Chen, J.L.; Li, Z.Y. Influence of void defects on impact properties of CFRP laminates based on multi-scale simulation method. Int. J. Impact Eng. 2023, 180, 104706. [Google Scholar] [CrossRef]

- Hu, S.D.; Jiang, Y.N.; Zhou, C.; Li, L.X.; Wang, X.Y.; Wang, C. Prediction and prevention of cracks in free-cutting stainless steel bar forming. Metall. Mater. Trans B. 2020, 51, 1687–1696. [Google Scholar] [CrossRef]

- Mendoza, I.; Lamberson, L. Damage tolerancing in carbon fiber-reinforced polymer (CFRP) laminates under combined impact fatigue and environmental conditioning. Compos. Part A-Appl. S. 2024, 180, 108062. [Google Scholar] [CrossRef]

- Ren, Y.Y.; Zhang, L. Impact characterization of fiber reinforced epoxy resin composites. Plast. Sci. Technol. 2023, 10, 67–70. [Google Scholar]

- Jia, Y.X.; Ao, Q.Y.; Zhang, W.Z.; Wang, T.; Liu, Y.Y.; Tian, Y. Analysis of low-velocity impact damage performance of carbon fiber composite laminate. Arms Mater. Sci. Eng. 2022, 45, 170–174. [Google Scholar]

- Zhong, Y.; Xu, M.T.; Wang, P.; Li, Y.Y. Low-velocity impact properties and failure mechanism of carbon fiber-UHMWPE fiber hybrid reinforced epoxy resin composites. Acta Mater. Compos. Sin. 2022, 39, 3202–3211. [Google Scholar]

- Yan, S.L.; Li, X.Y.; Liu, Y. Preparation of low-density polyethylene/carbon fiber composites and their properties. Plast. Sci. Technol. 2023, 51, 72–75. [Google Scholar]

- Yu, M.M.; Zhu, X.L.; Liu, X.Q.; Fang, L.; Xie, W.; Ren, M.S.; Sun, J.L. Failure mechanism and assessment of residual strength of carbon fiber/epoxy resin matrix composite laminates under multiple impacts at low velocities. Acta Mater. Compos. Sin. 2023, 40, 5359–5370. [Google Scholar]

- Sun, X.C.; Hallett, S.R. Failure mechanisms and damage evolution of laminated composites under compression after impact (CAI): Experimental and numerical study. Compos. Part. A-Appl. S. 2018, 104, 41–59. [Google Scholar] [CrossRef]

- Seamone, A.; Davidson, P.; Waas, A.M.; Ranatunga, V. Low velocity impact and compressive response after impact of thin carbon fiber composite panels. Int. J. Solids. Struct. 2022, 257, 111604. [Google Scholar] [CrossRef]

- Yang, G.D.; Zhang, J.L.; Xie, H.B.; Li, F.L.; Huang, Z.; Yuan, G.Q.; Zhang, J.Z.; Jia, Q.L.; Zhang, H.J.; Yeprem, H.A.; et al. Preparation of B4Cp/Al composites via selective laser melting and their tribological properties. Materials 2022, 15, 8340. [Google Scholar] [CrossRef]

- Pawlik, M.; Lu, Y.L. Effects of the graphene nanoplatelets reinforced interphase on mechanical properties of carbon fibre reinforced polymer–A multiscale modelling study. Compos. Part B Eng. 2019, 177, 107097. [Google Scholar] [CrossRef]

- Shao, Y.Z.; Okubo, K.; Fujii, T.; Shibata, O.; Fujita, Y. Effect of matrix properties on the fatigue damage initiation and its growth in plain woven carbon fabric vinylester composites. Compos. Sci. Technol. 2014, 104, 125–135. [Google Scholar] [CrossRef]

- ASTM D7136/D7136M-20; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM: West Conshohocken, PA, USA, 2020.

- Wang, H.H.; Qin, Z.P.; Wan, X.L.; Wei, R.; Wu, K.M. Continuous cooling transformation behavior and impact toughness in heat-affected zone of Nb-containing fire-resistant steel. Met. Mater. Int. 2017, 23, 848–854. [Google Scholar] [CrossRef]

- Siegfried, M.; Tola, C.; Claes, M.; Lomov, S.V.; Verpoest, I.; Gorbatikh, L. Impact and residual after impact properties of carbon fiber/epoxy composites modified with carbon nanotubes. Compos. Struct. 2014, 111, 488–496. [Google Scholar] [CrossRef]

- Ismail, K.I.; Sultan, M.T.H.; Shah, A.U.M.; Jawaid, M.; Safri, S.N.A. Low velocity impact and compression after impact properties of hybrid bio-composites modified with multi- walled carbon nanotubes. Compos. B Eng. 2019, 163, 455–463. [Google Scholar] [CrossRef]

- Tuo, H.L.; Lu, Z.X.; Ma, X.P.; Xing, J.; Zhang, C. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions. Compos. B Eng. 2019, 163, 642–654. [Google Scholar] [CrossRef]

- Liang, W.; Zhang, Y.F.; Zhang, L.F.; Wu, R. Precipitation behavior and strengthening mechanism of Ti micro-alloyed steel via CSP process. Mater. Res. Express. 2019, 6, 116533. [Google Scholar] [CrossRef]

- Ge, X.X.; Zhang, P.; Zhao, F.; Liu, M.; Liu, J.; Cheng, Y.S. Experimental and numerical investigations on the dynamic response of woven carbon fiber reinforced thick composite laminates under low-velocity impact. Compos. Struct. 2022, 279, 114792. [Google Scholar] [CrossRef]

- Wang, A.N.; Liu, X.G.; Yue, Q.R.; Xian, G.J. Effect of volume ratio and hybrid mode on low-velocity impact properties of unidirectional flax/carbon fiber hybrid reinforced polymer composites. Thin-Walled Struct. 2023, 187, 110764. [Google Scholar] [CrossRef]

- Damghani, M.; Ersoy, N.; Piorkowski, M.; Murphy, A. Experimental evaluation of residual tensile strength of hybrid composite aerospace materials after low velocity impact. Compos. Part B Eng. 2019, 179, 107537. [Google Scholar] [CrossRef]

- Gao, W.Q.; Zhang, C.L.; Yang, M.X.; Zhang, S.Q.; Juul Jensen, D.; Godfrey, A. Strain distribution and lattice rotations during in-situ tension of aluminum with a transmodal grain structure. Mater. Sci. Eng. A. 2021, 828, 142010. [Google Scholar] [CrossRef]

- Zhou, S.B.; Hu, F.; Wang, K.; Hu, C.Y.; Zhou, W.; Yershov, S.; Wu, K.M.; Zhang, Z.C.; Pan, X.M. Nanomechanics of retained austenite in medium-carbon low-temperature bainitic steel: A critical analysis of a one-step versus a two-step treatment. Materials 2022, 15, 5996. [Google Scholar] [CrossRef] [PubMed]

| Tensile Strength/MPa | Young’s Modulus/MPa | Elongation/% | Fineness/(g/km) | Density/(g·cm−3) | Fiber Volume Fraction/% | Thickness/mm | Diameter/μm |

|---|---|---|---|---|---|---|---|

| 4900 | 2300 | 2.1 | 800 | 1.80 | 54.5 | 0.42 | 7 |

| Mixed Viscosity/(CPS) | Glass-Transition Temperature/°C | Tensile Strength/MPa | Modulus/MPa |

|---|---|---|---|

| 250~300 | 75~85 | 65~75 | 2800~3200 |

| Specimen Number | Impact Energy/J | Residual Compressive Strength/MPa | Failure Mode |

|---|---|---|---|

| 1 | 25 | 264.37 | End failure |

| 2 | 35 | 247.70 | End failure |

| 3 | 45 | 243.52 | Valid LDM |

| 4 | 65 | 222.16 | Valid LDM |

| 5 | 85 | 220.40 | Valid LDM |

| 6 | 105 | 191.14 | Valid LDM |

| 7 | 125 | 165.62 | Valid LDM |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, X.; Wang, T.; Xue, H.; Ding, J.; Deng, C. Study on Low-Velocity Impact and Residual Compressive Mechanical Properties of Carbon Fiber–Epoxy Resin Composites. Materials 2024, 17, 3766. https://doi.org/10.3390/ma17153766

Qiang X, Wang T, Xue H, Ding J, Deng C. Study on Low-Velocity Impact and Residual Compressive Mechanical Properties of Carbon Fiber–Epoxy Resin Composites. Materials. 2024; 17(15):3766. https://doi.org/10.3390/ma17153766

Chicago/Turabian StyleQiang, Xueyuan, Te Wang, Hua Xue, Jun Ding, and Chengji Deng. 2024. "Study on Low-Velocity Impact and Residual Compressive Mechanical Properties of Carbon Fiber–Epoxy Resin Composites" Materials 17, no. 15: 3766. https://doi.org/10.3390/ma17153766

APA StyleQiang, X., Wang, T., Xue, H., Ding, J., & Deng, C. (2024). Study on Low-Velocity Impact and Residual Compressive Mechanical Properties of Carbon Fiber–Epoxy Resin Composites. Materials, 17(15), 3766. https://doi.org/10.3390/ma17153766