Brittle Fracture Behavior of Sn-Ag-Cu Solder Joints with Ni-Less Surface Finish via Laser-Assisted Bonding

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Void Observation after LAB Process

3.2. Microstructure

3.3. Joint Strength and Brittle Fracture Rate

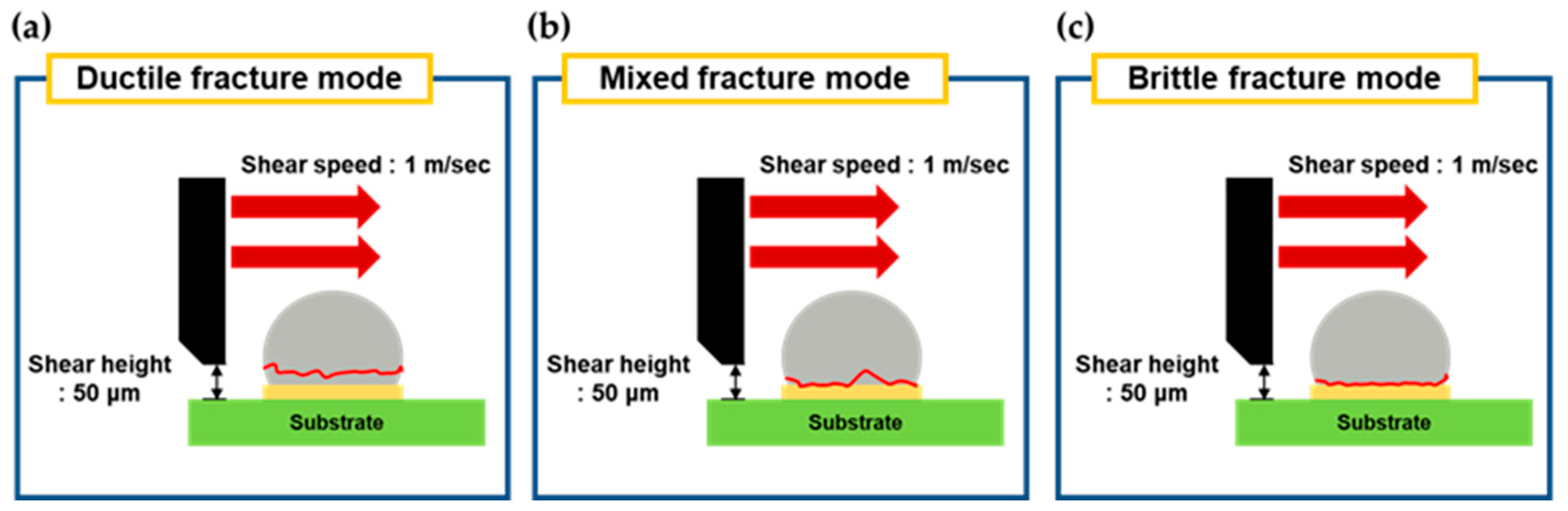

- Ductile fracture mode: 0–25% brittle fracture.

- Mixed fracture mode: 25–75% brittle fracture.

- Brittle fracture mode: 75–100% brittle fracture.

4. Conclusions

- From X-ray observation, no voids were observed in the MR and LAB 1.56 W/mm2 conditions. The void ratios increased up to 1.9% with increasing laser power.

- The IMC thickness was 3.16 μm with MR, while LAB showed thinner IMC layers, ranging from 0.69 μm to 1.5 μm as laser power increased.

- The LAB method resulted in higher shear strength than MR, with the highest strength at 1.56 W/mm2. Shear strength slightly decreased with higher laser power.

- The MR method exhibited higher brittleness than LAB, and as laser power increased, the brittleness of the LAB samples increased.

- Increased IMC thickness was correlated with higher brittle fracture rates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lau, J.H. Recent Advances and Trends in Advanced Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 228–252. [Google Scholar] [CrossRef]

- Park, J.; Kim, D.; Yoo, C.S.; Lim, T.; Chung, B.M. Development of Cost-Effective Ni-Less Surface Finishing Process for High-Speed PCBs. J. Electron. Mater. 2023, 52, 7504–7511. [Google Scholar] [CrossRef]

- Shah, K. Reliable Nickel-Free Surface Finish Solution for High-Frequency, HDI PCB Applications. J. Microelectron. Electron. Packag. 2020, 17, 121–127. [Google Scholar] [CrossRef]

- Cho, M.; Cho, J.; Kim, K.; Kim, S.Y.; Han, D.; Sung, T. Development Trend of Ni-Less Surface Treatment Technology for Semiconductor Packaging Substrates. J. Microelectron. Packag. Soc. 2023, 30, 49–54. [Google Scholar]

- Loh, W.K.; Kulterman, R.; Fu, H.; Tsuriya, M. Recent Trends of Package Warpage and Measurement Metrologies. In Proceedings of the ICEP 2016, Hokkaido, Japan, 20–22 April 2016; The Japan Institute of Electronics Packaging: Tokyo, Japan, 2016; pp. 89–93. [Google Scholar]

- Loh, W.K.; Kulterman, R.W.; Hsu, C.C.; Fu, H. Impact of Low Temperature Solder on Electronic Package Dynamic Warpage Behavior and Requirement. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 318–324. [Google Scholar] [CrossRef]

- Na, S.H.; Gim, M.H.; Kim, G.H.; Ryu, D.S.; Park, D.J.; Kim, J.Y. Reverse Laser Assisted Bonding (R-LAB) Technology for Chiplet Module Bonding on Substrate. In Proceedings of the 2022 IEEE 24th Electronics Packaging Technology Conference (EPTC), Singapore, 7–9 December 2022; pp. 414–417. [Google Scholar] [CrossRef]

- Kim, G.; Gim, M.; Na, S.; Kim, W.; Bae, J.; Ryu, D.; Park, D.; Park, K. Laser Assisted Bonding (LAB) Mechanism Study on the Effect of Flux Dipping, Stage Block Vacuum Force and Chip Attach Misalignment. In Proceedings of the 2023 IEEE 25th Electronics Packaging Technology Conference (EPTC), Singapore, 5–8 December 2023; pp. 381–386. [Google Scholar] [CrossRef]

- Na, S.H.; Gim, M.H.; Kim, C.H.; Park, D.H.; Ryu, D.S.; Park, D.J.; Khim, J.Y. Next Gen Laser Assisted Bonding (LAB) Technology. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 1991–1995. [Google Scholar] [CrossRef]

- Jang, Y.M.; Kim, Y.; Choa, S.H. Development and Optimization of the Laser-Assisted Bonding Process for a Flip Chip Package. Microsyst. Technol. 2020, 26, 1043–1054. [Google Scholar] [CrossRef]

- Alves Braganca, W.; Eom, Y.S.; Jang, K.S.; Moon, S.H.; Bae, H.C.; Choi, K.S. Collective Laser-Assisted Bonding Process for 3D TSV Integration with NCP. ETRI J. 2019, 41, 396–407. [Google Scholar] [CrossRef]

- Lee, Y.S.; Yun, C.; Kim, K.H.; Kim, W.H.; Jeon, S.W.; Lee, J.K.; Kim, J.P. Laser-Sintered Silver Nanoparticles as a Die Adhesive Layer for High-Power Light-Emitting Diodes. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1119–1124. [Google Scholar] [CrossRef]

- Joo, H.S.; Lee, C.J.; Min, K.D.; Hwang, B.U.; Jung, S.B. Mechanical Properties and Microstructural Evolution of Solder Alloys Fabricated Using Laser-Assisted Bonding. J. Mater. Sci. Mater. Electron. 2020, 31, 22926–22932. [Google Scholar] [CrossRef]

- Joo, H.S.; Min, K.D.; Lee, C.J.; Hwang, B.U.; Jung, S.B. Growth Kinetics of Intermetallic Compound Layers at the Interface during Laser-Assisted Bonding Depending on Surface Finish. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 1916–1921. [Google Scholar] [CrossRef]

- Moon, Y.H.; Joo, J.; Choi, G.M.; Lee, C.; Jang, K.S.; Oh, J.H.; Oh, Y.J.; Eom, Y.S.; Choi, K.S. Micro-Structure Analysis of Solder Joint Using Room Temperature Laser-Assisted Bonding (LAB) Process. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 590–595. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, L.D.; Hu, J.W.; Zhang, Z.J.; Huang, M.L.; Yao, H.; Li, B.X.; Zhou, X. Study on the Solid-Solid Interfacial Reaction Behavior of Solder Micro Bump Prepared by Laser Assisted Bonding. In Proceedings of the 2022 23rd International Conference on Electronic Packaging Technology (ICEPT), Dalian, China, 10–13 August 2022; pp. 2022–2025. [Google Scholar] [CrossRef]

- Lee, T.Y.; Kim, J.; Jun, S.Y.; Ahn, B.J.; Han, D.G.; Yoo, S. Interfacial Microstructure and Brittle Fracture Behavior of Sn-Based Solder on Novel Nickel-Less DEG and EPIG Surface Finishes. J. Mater. Sci. Mater. Electron. 2023, 34, 129. [Google Scholar] [CrossRef]

- Kim, J.M.; Jeong, M.H.; Yoo, S.; Park, Y.B. Effect of Interfacial Microstructures on the Bonding Strength of Sn-3.0Ag-0.5Cu Pb-Free Solder Bump. Jpn. J. Appl. Phys. 2012, 51, 05EE06. [Google Scholar] [CrossRef]

- Kim, K.H.; Koike, J.; Yoon, J.W.; Yoo, S. Effect of Plasma Surface Finish on Wettability and Mechanical Properties of SAC305 Solder Joints. J. Electron. Mater. 2016, 45, 6184–6191. [Google Scholar] [CrossRef]

- Seo, W.; Kim, K.H.; Bang, J.H.; Kim, M.S.; Yoo, S. Effect of Bath Life of Ni(P) on the Brittle-Fracture Behavior of Sn-3.0Ag-0.5Cu/ENIG. J. Electron. Mater. 2014, 43, 4457–4463. [Google Scholar] [CrossRef]

- Bachok, Z.; Abas, A.; Tang, H.F.; Nazarudin, M.Z.H.; Mohd Sharif, M.F.; Che Ani, F. Investigating the Impact of Different Solder Alloy Materials during Laser Soldering Process. Solder. Surf. Mt. Technol. 2024. ahead-of-print. [Google Scholar] [CrossRef]

- Lin, W.; Lee, Y.C. Study of Fluxless Soldering Using Formic Acid Vapor. IEEE Trans. Adv. Packag. 1999, 22, 592–601. [Google Scholar] [CrossRef]

- He, S.; Jiang, J.; Shen, Y.A.; Mo, L.; Bi, Y.; Wu, J.; Guo, C. Improvement of Solder Joint Shear Strength under Formic Acid Atmosphere at A Low Temperature. Materials 2024, 17, 1055. [Google Scholar] [CrossRef] [PubMed]

- Sweatman, K.; Nishimura, T.; Sugimoto, K.; Kita, A. Controlling Voiding Mechanisms in the Reflow Soldering Process. In Proceedings of the IPC APEX Expo 2016, Las Vegas, NV, USA, 15–17 March 2016. [Google Scholar]

- Xiong, M.Y.; Zhang, L. Interface Reaction and Intermetallic Compound Growth Behavior of Sn-Ag-Cu Lead-Free Solder Joints on Different Substrates in Electronic Packaging. J. Mater. Sci. 2019, 54, 1741–1768. [Google Scholar] [CrossRef]

- Liu, P.; Yao, P.; Liu, J. Effects of Multiple Reflows on Interfacial Reaction and Shear Strength of SnAgCu and SnPb Solder Joints with Different PCB Surface Finishes. J. Alloys Compd. 2009, 470, 188–194. [Google Scholar] [CrossRef]

- Gao, F.; Nishikawa, H.; Takemoto, T. Additive Effect of Kirkendall Void Formation in Sn-3.5Ag Solder Joints on Common Substrates. J. Electron. Mater. 2008, 37, 45–50. [Google Scholar] [CrossRef]

- Shin, A.-S.; Ok, D.-Y.; Jeong, G.-H.; Kim, M.-J.; Park, C.-S.; Kong, J.-H.; Heo, C.-H. A Study of Properties of Sn-3Ag-0.5Cu Solder Based on Phosphorous Content of Electroless Ni-P Layer. J. Korean Inst. Electr. Electron. Mater. Eng. 2010, 23, 481–486. [Google Scholar] [CrossRef]

- Tegehall, P.E. Review of the Impact of Intermetallic Layers on the Risk for Brittle Fractures in Solder Joints. In Proceedings of the IMAPS Nordic Annual Conference 2006, Gothenburg, Sweden, 17–19 September 2006; pp. 28–40. [Google Scholar]

- Morgana, R.; Sarkar, S.; Bilgrien, C.; Hunsinger, T. Effect of Voids on Thermore-Mechanical Reliability of Solder Joints. Assembly 2017, 43, 667–673. [Google Scholar]

- Yunus, M.; Srihari, K.; Pitarresi, J.M.; Primavera, A. Effect of Voids on the Reliability of BGA/CSP Solder Joints. Microelectron. Reliab. 2003, 43, 2077–2086. [Google Scholar] [CrossRef]

- Kim, D.; Hubbard, K.; Nandagopal, B.; Hu, M.; Teng, S.; Nouri, A. Effect of Voiding on Solder Joint Shock and Thermal Cycle Reliability. IPC - Printed Circuits Expo, Apex, and the Designers Summit 2006: Perfectly Cutting Edge, Anaheim, CA, USA, 8–10 February 2006; Volume 2, pp. 783–792. [Google Scholar]

- Hani, D.B.; Al Athamneh, R.; Aljarrah, M.; Hamasha, S. Shear Strength Degradation Modeling of Lead-Free Solder Joints at Different Isothermal Aging Conditions. J. Microelectron. Electron. Packag. 2021, 18, 137–144. [Google Scholar] [CrossRef]

- Yao, Y. Modeling the Mechanical Properties of Intermetallic/Solder Interfaces. Ph.D. Thesis, Northwestern University, Evanston, IL, USA, 2008. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Han, S.-E.; Lee, T.-Y.; Han, D.-G.; Park, Y.-B.; Yoo, S. Brittle Fracture Behavior of Sn-Ag-Cu Solder Joints with Ni-Less Surface Finish via Laser-Assisted Bonding. Materials 2024, 17, 3619. https://doi.org/10.3390/ma17143619

Han S, Han S-E, Lee T-Y, Han D-G, Park Y-B, Yoo S. Brittle Fracture Behavior of Sn-Ag-Cu Solder Joints with Ni-Less Surface Finish via Laser-Assisted Bonding. Materials. 2024; 17(14):3619. https://doi.org/10.3390/ma17143619

Chicago/Turabian StyleHan, Seonghui, Sang-Eun Han, Tae-Young Lee, Deok-Gon Han, Young-Bae Park, and Sehoon Yoo. 2024. "Brittle Fracture Behavior of Sn-Ag-Cu Solder Joints with Ni-Less Surface Finish via Laser-Assisted Bonding" Materials 17, no. 14: 3619. https://doi.org/10.3390/ma17143619

APA StyleHan, S., Han, S.-E., Lee, T.-Y., Han, D.-G., Park, Y.-B., & Yoo, S. (2024). Brittle Fracture Behavior of Sn-Ag-Cu Solder Joints with Ni-Less Surface Finish via Laser-Assisted Bonding. Materials, 17(14), 3619. https://doi.org/10.3390/ma17143619