Effects of Resting Conditions on Tensile Properties of Acid Aggregate Hydraulic Asphalt Concrete

Abstract

Highlights

- The effect of resting time on asphalt adhesion was most pronounced in comparison to temperature and spalling agent dosage.

- A combined micro- and macro-scale investigation was conducted to ascertain the impact of varying static conditions on the tensile properties of asphalt concrete.

Abstract

1. Introduction

- We studied the variation rule of adhesion between asphalt and acidic aggregate under different temperatures, resting times, and dosages of anti-stripping agents. We analyzed the effects of static length, temperature, type, and dosage of anti-stripping agent on the adhesion between asphalt and acidic aggregates.

- We investigated the influence of resting conditions on the tensile properties of asphalt concrete. We conducted hydraulic asphalt concrete splitting tests under different static conditions such as 0, 10, 20, and 30 days and analyzed the changes in the tensile properties of asphalt concrete under different static conditions.

2. Materials and Test Methods

2.1. Raw Materials

2.1.1. Asphalt Testing

2.1.2. Aggregate Testing

- (1)

- Alkalinity modulus (M)

- (2)

- Mineral composition testing

2.1.3. Coarse Aggregate

2.1.4. Fine Aggregates

2.1.5. Fillers

2.1.6. Anti-Stripping Agents

2.1.7. Grading

- Properties of raw materials, including asphalt, coarse aggregates, fine aggregates, and fillers.

- Mineral grading.

- The amount of filler, i.e., the proportion of filler in the mineral.

- Oil–rock ratio, i.e., the ratio of the mass of asphalt in the asphalt mixture to the mass of minerals in the asphalt mixture. Mineral gradation parameters include the maximum mineral particle size Dmax, gradation index r, or coarse and fine aggregate rate and filler F. Mineral gradation was determined using the theory of the maximum dense gradation, and the recommended formula was listed as follows:where Pi is the passing rate of the sieve aperture, F is the amount of filler, with the particle size less than 0.075 mm, Dmax is the maximum particle size of the mineral, mm, di is a certain sieve size, d0.075 is the maximum particle size of the filler, and r is the grading index.

2.2. Test Methods

2.2.1. Boiling

- The aggregate particles should be selected to be free from sharp edges and with a shape that is as close to cubic as possible. They should then be cleaned and placed in an oven at a temperature of 105 °C ± 5 °C to dry the aggregate particles completely. Once this process is complete, the particles should be removed from the oven and allowed to cool to room temperature.

- A fine wire should then be used to bake the clean aggregate particles in an oven at 105°C ± 5°C for one hour.

- The dry aggregate is then immersed in heated asphalt, which is maintained at a temperature of 130 °C~150 °C for a period of 45 s. This ensures that the asphalt is completely coated with the aggregate.

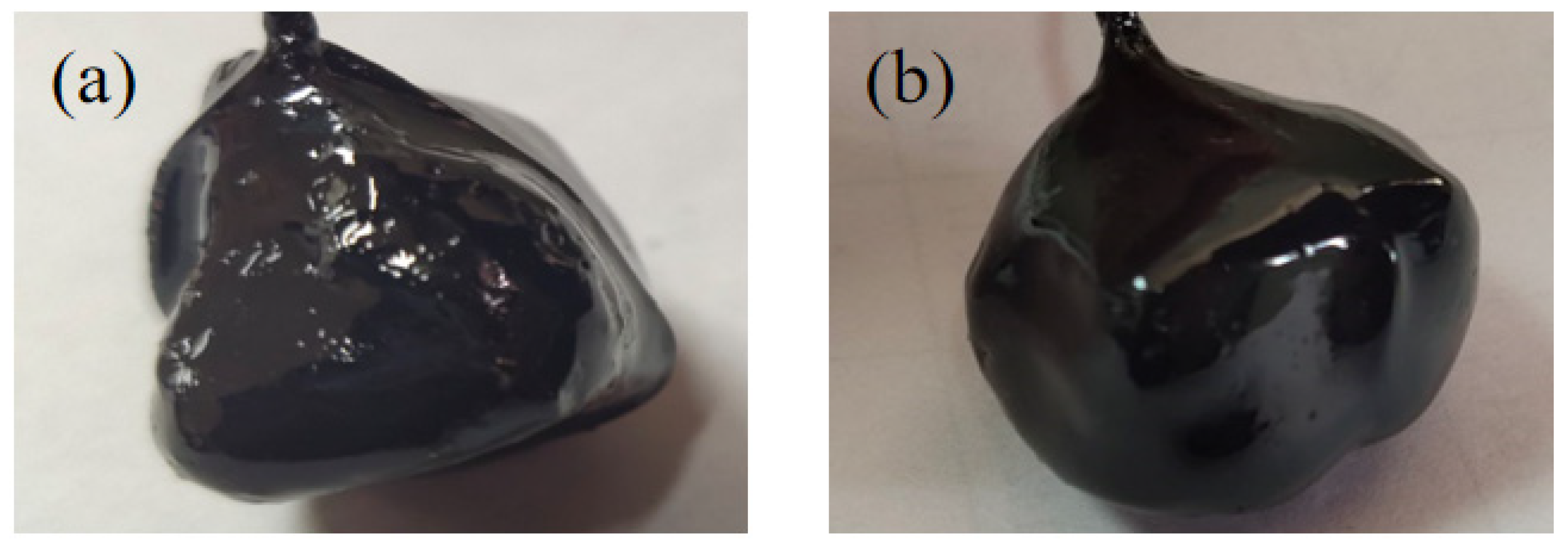

- As shown in Figure 1a, the asphalt-coated aggregate is then lifted and hung on the prepared test frame, allowing the excess asphalt to drip freely. It is then cooled at room temperature for a period of more than 15 min. A beaker of water is prepared and placed on the asbestos mesh of the heating oven. The water in the beaker is boiled using the heating oven, but the water is not allowed to boil and foam. Instead, the temperature is controlled to a state of micro-boiling.

- As shown in Figure 1b, the cooled aggregate particles covered with asphalt are lifted one by one and immersed in boiling water. Then we observed the asphalt film on the surface of the sample during the immersion process, which lasted for three minutes.

2.2.2. Cleavage Test

- The standard specimen for the splitting test was molded by the Marshall method and compacted 35 times on both sides. The diameter of the specimen mold was 101.6 mm, and the thickness of the specimen was controlled at 63.5 ± 0.5 mm. After making the specimen, the density of each specimen was measured, and the porosity was calculated. The test was carried out after 24 h of stabilization. The loading rate of the splitting test was 1.0 mm/min.

- Test temperature: 5 ± 0.5 °C.

- Test loading rate: 1.0 mm/min.

3. Results and Discussion

3.1. Results of the Boiling Method

- (1)

- Asphalt adhesion test

- (2)

- Study of the effect of resting time

- (3)

- Temperature impact studies

- (4)

- Study of the effect of anti-scaling agents

3.2. Cleavage Test Results

4. Conclusions

- In the short-term constant temperature tests at 170 °C and 180 °C, the adhesion levels of the asphalt and aggregate decreased from level 5 to 4+, 5 to 4, and 4+ to 4 when the additive amount of the anti-stripping agent (SK-A anti-stripping agent) was 0.8%, 0.6%, and 0%, respectively. In the 120 °C long-term constant temperature test, with the extension of the asphalt’s constant temperature time and the asphalt gradually aging, mixed with 0.8% and 0.6% anti-stripping agent and unadulterated anti-stripping agent (SK-A-type anti-stripping agent), the asphalt and gneiss aggregate adhesion level fell from 5 to 4, 5 to 3+, 4 to 3+, respectively. That is, whether anti-stripping agent was added or not, with the temperature increased and time extended when in the static state, the adhesion of asphalt and acidic aggregate was presented in varying degrees of decline, and the addition of anti-stripping agent can slow down the degree of attenuation but cannot change the results of the reduction in adhesion.

- Among several different resting conditions, such as the temperature, resting time, anti-stripping agent type, and dosage, the resting time exhibited the most obvious effect on asphalt adhesion.

- The mechanical properties of the two kinds of asphalt were investigated by a splitting test with respect to the factor of resting time, and it was found that the splitting strength of splitting specimens without an anti-stripping agent increased from 0.604 MPa to 0.630 MPa, 0.904 MPa, and 1.004 MPa, respectively, while the splitting displacement decreased from 1.70 mm to 1.34 mm, 1.32 mm, and 1.23 mm, respectively. The modulus of strength increased from 35 MPa to 83.31 MPa after resting for 10, 20, and 30 days, respectively. the splitting displacement of the specimen doped with an anti-stripping agent decreased from 1.49 mm to 1.45 mm, 1.20 mm, and 1.03 mm, with decrease rates of 3%, 20%, and 31%, which reflect the deterioration of asphalt concrete and the degradation of structural properties. It was deduced that doping with an anti-stripping agent could not change the tensile properties of asphalt concrete, which decreased with the increase in the resting time.

- Despite the comprehensive insight gained into the factors influencing asphalt adhesion properties, further research is required to ascertain the long-term performance alterations under varying environmental circumstances and material variables. Furthermore, it would be beneficial to investigate more effective asphalt modification methods and the application of anti-stripping agents to improve the durability of asphalt concrete.

- Currently, the water-boiling method represents the principal experimental approach for evaluating the adhesion of asphalt to aggregates. Although the area ratio was employed in this study for the assessment of adhesion, this approach may also result in significant experimental errors. Consequently, it is recommended that a more objective and precise quantitative analysis method be employed in subsequent studies to enhance the accuracy and reliability of the experimental results.

- Research should be conducted to investigate the effects of extreme climatic conditions (e.g., extreme cold, extreme heat, high humidity, etc.) on the performance of asphalt concrete, with a view to proposing corresponding design and construction strategies.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Höeg, K. Simplified material model for analysis of asphalt core in embankment dams. Constr. Build. Mater. 2016, 124, 199–207. [Google Scholar] [CrossRef]

- Hao, J.; Liu, Z.; Wang, Z. Development and prospect of hydropower project with asphalt concrete impervious elements in China. Shuili Xuebao/J. Hydraul. Eng. 2018, 49, 1137–1147. [Google Scholar]

- Al-Qadi, I.; Ozer, H.; Lambros, J.; El Khatib, A.; Singhvi, P.; Khan, T.; Rivera, J.; Doll, B. Testing Protocols to Ensure Performance of High Asphalt Binder Replacement Mixes Using RAP and RAS. 2015. FHWA-ICT-15-017;ICT-15-017;UILU-ENG-2015-2023. Available online: http://hdl.handle.net/2142/88680 (accessed on 27 April 2024).

- Zhang, Z.; Wang, K.; Liu, H.; Deng, Z. Key performance properties of asphalt mixtures with recycled concrete aggregate from low strength concrete. Constr. Build. Mater. 2016, 126, 711–719. [Google Scholar] [CrossRef]

- Motter, J.S.; Miranda, L.F.R.; Bernucci, L.L.B. Performance of Hot Mix Asphalt Concrete Produced with Coarse Recycled Concrete Aggregate. J. Mater. Civ. Eng. 2015, 27, 04015030. [Google Scholar] [CrossRef]

- Høeg, K. Asphaltic Concrete Cores for Embankment Dams. Nor. Geotech. Inst. Publ. 1997, 201, 69–87. [Google Scholar]

- Delgado, F.; Huber, N.P.; Escuder, I.; Membrillera, M.D. Revised criteria for evaluating granular filters in earth and rockfill dams. Trans. Int. Congr. Large Dams 2006, 22, 445. [Google Scholar]

- Wang, W. Developments in the design and construction of asphalt core dams. Int. J. Hydropower Dams 2010, 17, 83–91. [Google Scholar]

- Wang, W.; Heg, K.; Zhang, Y. Design and performance of the Yele asphalt-core rockfill dam. Can. Geotech. J. 2010, 47, 1365–1381. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Isomoisio, H.; Karhu, M.; Illikainen, M. Mechanical and acoustic properties of fiber-reinforced alkali-activated slag foam concretes containing lightweight structural aggregates. Constr. Build. Mater. 2018, 187, 371–381. [Google Scholar] [CrossRef]

- Yilmaz, A.; Sargin, Ş. Water effect on deteriorations of asphalt pavements. Online J. Sci. Technol. 2013, 2, 33. [Google Scholar]

- Jingjing, W.; Bureau, F.T. Research on key technologies of pavement maintenance of rural outside highway. Shanxi Archit. 2019. [Google Scholar]

- Feizi-Khankandi, S.; Ghalandarzadeh, A.; Mirghasemi, A.A.; Hoeg, K. Seismic analysis of the garmrood embankment dam with asphaltic concrete core. Soils Found. 2011, 49, 153–166. [Google Scholar] [CrossRef]

- Zheng, Y.; Kang, H.; Cai, Y.; Zhang, Y. Effects of temperature on the dynamic properties of asphalt mixtures. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 534–537. [Google Scholar] [CrossRef]

- Zhang, Y.; Höeg, K.; Wang, W.; Zhu, Y. Watertightness, cracking resistance, and self-healing of asphalt concrete used as a water barrier in dams. Can. Geotech. J. 2013, 50, 275–287. [Google Scholar] [CrossRef]

- Pszczola, M.; Jaczewski, M.; Szydlowski, C. Assessment of Thermal Stresses in Asphalt Mixtures at Low Temperatures Using the Tensile Creep Test and the Bending Beam Creep Test. Appl. Sci. 2019, 9, 846. [Google Scholar] [CrossRef]

- Wang, J.; Molenaar, A.A.; van de Ven, M.F.; Wu, S. Behaviour of asphalt concrete mixtures under tri-axial compression. Constr. Build. Mater. 2016, 105, 269–274. [Google Scholar] [CrossRef]

- Gheibi, E.; Sasanakul, I.; Sanin, M.V.; Puebla, H. Effect of Temperatures on the Dynamic Properties of Asphaltic Core for an Earth Dam. Geo-Chicago 2016, 2016, 266–275. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M.O.; Kvasnak, A.; Bausano, J.; Williams, R.C.; Worel, B. Factors Study in Low-Temperature Fracture Resistance of Asphalt Concrete. Am. Soc. Civ. Eng. (ASCE) 2010, 22. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, L.; Lei, Y.; Ma, Y.; Yan, C. Effect of the laboratory short-term aging temperature on the chemical and rheological characteristics of high modulus asphalts. Constr. Build. Mater. 2022, 314, 125569. [Google Scholar] [CrossRef]

- Islam, S.S.; Singh, S.K.; Ransinchung, G.; Ravindranath, S.S. Effect of property deterioration in SBS modified binders during storage on the performance of asphalt mix. Constr. Build. Mater. 2021, 272, 121644. [Google Scholar] [CrossRef]

- Ke, Y.; Cao, J.; Xu, S.; Bian, C.; Zhang, C.; Jia, X. Storage stability and anti-aging performance of SEBS/organ-montmorillonite modified asphalt. Constr. Build. Mater. 2022, 341, 127875. [Google Scholar] [CrossRef]

- Elkashef, M.; Harvey, J.; Jones, D.; Jiao, L. The impact of silo storage on the fatigue and cracking resistance of asphalt mixes. Constr. Build. Mater. 2022, 326, 126880. [Google Scholar] [CrossRef]

- Li, Y.-H.; Zhong, J.-X.; Huang, D.-P. Research on Influencing Factors of Asphalt Rubber Viscosity. West. China Commun. Sci. Technol. 2013. [Google Scholar]

- Yang, C.; Dang, F.; Xue, H.; Gao, J. Mechanism of structural tensile damage to concrete face slabs of high CFRDs in narrow valley regions and improvements. Shuili Fadian Xuebao/J. Hydroelectr. Eng. 2017, 36, 95–103. [Google Scholar]

- Zhao, W.; Yang, Q. Study on the applicability of asphalt concrete skeleton in the semi-flexible pavement. Constr. Build. Mater. 2022, 327, 126923. [Google Scholar] [CrossRef]

- Feng, S.; Wang, W.; Hu, K.; Höeg, K. Stress-strain-strength behavior of asphalt core in embankment dams during construction. Constr. Build. Mater. 2020, 259, 119706. [Google Scholar] [CrossRef]

- Li, Y.; Liu, J.; Liu, Y.; Zhou, H.; Wen, L.; Chen, J. Aggregate grading design of skeleton dense hydraulic asphalt concrete. Constr. Build. Mater. 2023, 365, 130031. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, W.; Yang, H.; Liu, L.; He, J. Study of stress-strain relationship of hydraulic asphalt concrete at low to intermediate temperatures based on experimental data regression. Constr. Build. Mater. 2023, 409, 134059. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, Y.; Wang, W.; Ning, Z.; Feng, S.; Höeg, K. Compressive and tensile stress–strain-strength behavior of asphalt concrete at different temperatures and strain rates. Constr. Build. Mater. 2021, 311, 125362. [Google Scholar] [CrossRef]

- Gao, J.; Dang, F.; Ma, Z. Investigation for the key technologies of ultra-high asphalt concrete core rockfill dams. Soils Found. 2019, 59, 1740–1757. [Google Scholar] [CrossRef]

- Chen, X.; Huang, B. Evaluation of moisture damage in hot mix asphalt using simple performance and superpave indirect tensile tests. Constr. Build. Mater. 2008, 22, 1950–1962. [Google Scholar] [CrossRef]

- Sengoz, B.; Agar, E. Effect of asphalt film thickness on the moisture sensitivity characteristics of hot-mix asphalt. Build. Environ. 2007, 42, 3621–3628. [Google Scholar] [CrossRef]

- Kim, S.S.; Sargand, S.; Wargo, A. A Simple Test Procedure for Evaluating Low Temperature Crack Resistance of Asphalt Concrete. Asph. Pavements 2009. Available online: http://worldcat.org/arcviewer/2/OHI/2010/01/05/H1262703117329/viewer/file1 (accessed on 27 April 2024).

- Purong, D. To Choice the Aggregate Grading of Asphalt Concrete in Hydraulic Engineering. J. Xi’an Univ. Technol. 1990. [Google Scholar]

- Bao, L.; He, M.; Wang, S.; Wu, X. Study on the Effect of Asphalt Static Conditions on the Tensile Properties of Acidic Aggregate Hydraulic Asphalt Concrete. Materials 2024, 17, 2627. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Huang, B.; Zhang, B. Experimental study on engineering characteristics of hydraulic room-temperature asphalt concrete. J. Hydraul. Eng. 2015. [Google Scholar]

- Kai, X.; He, J.; Yang, W.; Zhang, X. Analysis of Asphalt Concrete Adhesion and Long-term Water Stability. Fly Ash Compr. Util. 2018. [Google Scholar]

- Bhirud, Y.L.; Sangle, K.K.; Vaidya, O.V.; Patare, S.A. Influence of higher binder content on the splitting tensile strength and modulus of elasticity of self-compacting concrete: An experimental investigation and proposed prediction equation. Constr. Build. Mater. 2023, 398, 132478. [Google Scholar] [CrossRef]

- Ispir, M.; Ates, A.O.; Ilki, A. Low strength concrete: Stress-strain curve, modulus of elasticity and tensile strength. Structures 2022, 38, 1615–1632. [Google Scholar] [CrossRef]

- Alós Shepherd, D.; Dehn, F. Experimental Study into the Mechanical Properties of Plastic Concrete: Compressive Strength Development over Time, Tensile Strength and Elastic Modulus. Case Stud. Constr. Mater. 2023, 19, e02521. [Google Scholar] [CrossRef]

| Serial Number | Identification of Items | Unit (Of Measure) | Technical Indicators | Test Results | |

|---|---|---|---|---|---|

| 1 | Needle penetration (25 °C, 100 g, 5 s) | 1/10 mm | 60–80 | 74 | |

| 2 | Needle penetration index PI | °C | ≥−0.4 | 4.22 | |

| 3 | Elongation (5 cm/min, 15 °C) | cm | / | 85.67 | |

| 4 | Elongation (5 cm/min, 5 °C) | cm | ≥30 | 36 | |

| 5 | Softening point (global method) | °C | ≥55 | 71.56 | |

| 6 | Solubility (trichloroethylene) | % | ≥99 | 99.78 | |

| 7 | Crispy point | °C | ≤−10 | −20 | |

| 8 | Storage stability 48 h softening point Difference after segregation | / | ≤2.5 | 0.4 | |

| 9 | Flash point (open method) | °C | ≥230 | 288 | |

| 10 | Density (25 °C) | g/cm | on-the-spot survey | 1.029 | |

| 11 | Wax content (cracking method) | % | ≤2.0 | 0.9 | |

| 12 | Kinematic viscosity at 135 °C | pa.s | ≤3 | 1.3 | |

| 13 | Elastic recovery 25 °C | % | ≥65 | 95 | |

| 14 | After film oven | Mass loss | % | ≤1.0 | −0.108 |

| Needle penetration ratio (25 °C) | % | ≥60 | 71.8 | ||

| Elongation (15 °C, 5 cm/min) | cm | ≥80 | 64.17 | ||

| Elongation (5 °C, 5 cm/min) | cm | ≥20 | 18 | ||

| Elevated softening point | °C | ≤5 | 0.55 | ||

| Serial Number | Identification of Items | Unit (Of Measure) | Technical Indicators | Test Results | |

|---|---|---|---|---|---|

| 1 | Needle penetration (25 °C, 100 g, 5 s) | 1/10 mm | 60–80 | 75.67 | |

| 2 | Needle penetration index PI | °C | ≥−0.4 | 4.2 | |

| 3 | Elongation (5 cm/min, 15 °C) | cm | / | 79 | |

| 4 | Elongation (5 cm/min, 5 °C) | cm | ≥30 | 35 | |

| 5 | Softening point (global method) | °C | ≥55 | 70.1 | |

| 6 | Solubility (trichloroethylene) | % | ≥99 | 99.77 | |

| 7 | Crispy point | °C | ≤−10 | −20 | |

| 8 | Storage stability 48 h softening point Difference after segregation | / | ≤2.5 | 0.4 | |

| 9 | Flash point (open method) | °C | ≥230 | 287 | |

| 10 | Density (25 °C) | g/cm | on-the-spot survey | 1.03 | |

| 11 | Wax content (cracking method) | % | ≤2.0 | 0.9 | |

| 12 | Kinematic viscosity at 135 °C | pa.s | ≤3 | 1.3 | |

| 13 | Elastic recovery 25 °C | % | ≥65 | 95 | |

| 14 | After film oven | Mass loss | % | ≤1.0 | −0.144 |

| Needle penetration ratio (25 °C) | % | ≥60 | 89.54 | ||

| Elongation (15 °C, 5 cm/min) | cm | ≥80 | 73 | ||

| Elongation (5 °C, 5 cm/min) | cm | ≥20 | 17 | ||

| Elevated softening point | °C | ≤5 | 0.6 | ||

| Room Number | Commission Number | ωB/10−2 | ||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | MgO | CaO | Heat Loss | Alkalinity Modulus (Chemistry) | ||

| 23D161-1 | 1# | 72.25 | 4.95 | 3.52 | 2.29 | 6.84 | 2.17 | 0.18 |

| Serial Number | Sports Event | Unit (of Measure) | Design Requirements | Test Results |

|---|---|---|---|---|

| 1 | Apparent density | g/cm3 | ≥2.6 | 2.72 |

| 2 | Adhesion to asphalt | classifier: step, level | ≥4 | 4 |

| 3 | Content of needle and flake particles | % | ≤25 | 6.97 |

| 4 | Crushing value | % | ≤30 | 9.56 |

| 5 | Water absorption | % | ≤2 | 0.43 |

| 6 | Mud content | % | ≤0.5 | 0 |

| 7 | Durability (Sodium sulfate mass loss from 5 wet and dry cycles) | % | ≤12 | 4.2 |

| Serial Number | Sports Event | Unit (of Measure) | Required Indicators | Test Results |

|---|---|---|---|---|

| 1 | Apparent Density | g/cm3 | ≥2.55 | 2.71 |

| 2 | Water Absorption | % | ≤2 | - |

| 3 | Water Stability Rating * | classifier: step, level | ≥6 | 6 |

| 4 | Durability (Sodium sulfate mass loss from 5 wet and dry cycles) | % | ≤15 | 1.2 |

| 5 | Stone Powder Content * | % | <5 |

| Serial Number | Sports Event | Unit (of Measure) | Required Indicators | Test Results | |

|---|---|---|---|---|---|

| 1 | Apparent Density | g/cm3 | ≥2.5 | 2.715 | |

| 2 | Moisture Content | % | ≤0.5 | --- | |

| 3 | Hydrophilicity | --- | ≤1.0 | 0.628 | |

| 4 | Thin and soft degree | <0.6 mm | % | 100 | 100 |

| <0.15 mm | >90 | 99.7 | |||

| <0.075 mm | >85 | 86.5 | |||

| Greatest Grain Size | Gradation Exponents | Filler Amount F | Oil/Stone Ratio B | Percentage of Mass of Each Level of Mineral (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| mm | r | % | % | 19–13.2 (mm) | 13.2–9.5 (mm) | 9.5–4.75 (mm) | 4.75–2.36 (mm) | 2.36–0.075 (mm) | <0.075 (mm) |

| 19 | 0.5 | 9 | 7 | 16.17 | 12.27 | 20.11 | 14.33 | 28.12 | 9 |

| Specimen Type | Density (g/cm)3 | Porosity (%) | Maximum Splitting Strength (MPa) | Maximum Splitting Displacement(mm) | Modulus of Strength (MPa) |

|---|---|---|---|---|---|

| No anti-stripping agent | 2.418 | 0.77 | 0.604 | 1.70 | 35.53 |

| 2.412 | 1.06 | 0.630 | 1.34 | 47.02 | |

| 2.406 | 1.31 | 0.901 | 1.32 | 68.26 | |

| 2.419 | 0.78 | 1.004 | 1.23 | 81.23 | |

| Add SK-A anti-stripping agent | 2.425 | 0.53 | 0.769 | 1.49 | 51.61 |

| 2.417 | 0.86 | 0.668 | 1.45 | 46.07 | |

| 2.419 | 0.78 | 1.030 | 1.20 | 85.83 | |

| 2.411 | 1.11 | 1.071 | 1.03 | 103.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, L.; He, M.; Wang, S.; Wu, X. Effects of Resting Conditions on Tensile Properties of Acid Aggregate Hydraulic Asphalt Concrete. Materials 2024, 17, 3556. https://doi.org/10.3390/ma17143556

Bao L, He M, Wang S, Wu X. Effects of Resting Conditions on Tensile Properties of Acid Aggregate Hydraulic Asphalt Concrete. Materials. 2024; 17(14):3556. https://doi.org/10.3390/ma17143556

Chicago/Turabian StyleBao, Lei, Min He, Shu Wang, and Xinshuang Wu. 2024. "Effects of Resting Conditions on Tensile Properties of Acid Aggregate Hydraulic Asphalt Concrete" Materials 17, no. 14: 3556. https://doi.org/10.3390/ma17143556

APA StyleBao, L., He, M., Wang, S., & Wu, X. (2024). Effects of Resting Conditions on Tensile Properties of Acid Aggregate Hydraulic Asphalt Concrete. Materials, 17(14), 3556. https://doi.org/10.3390/ma17143556