Research on Alloying Elements’ Influence on CuETP-Grade Copper’s Mechanical and Electrical Properties

Abstract

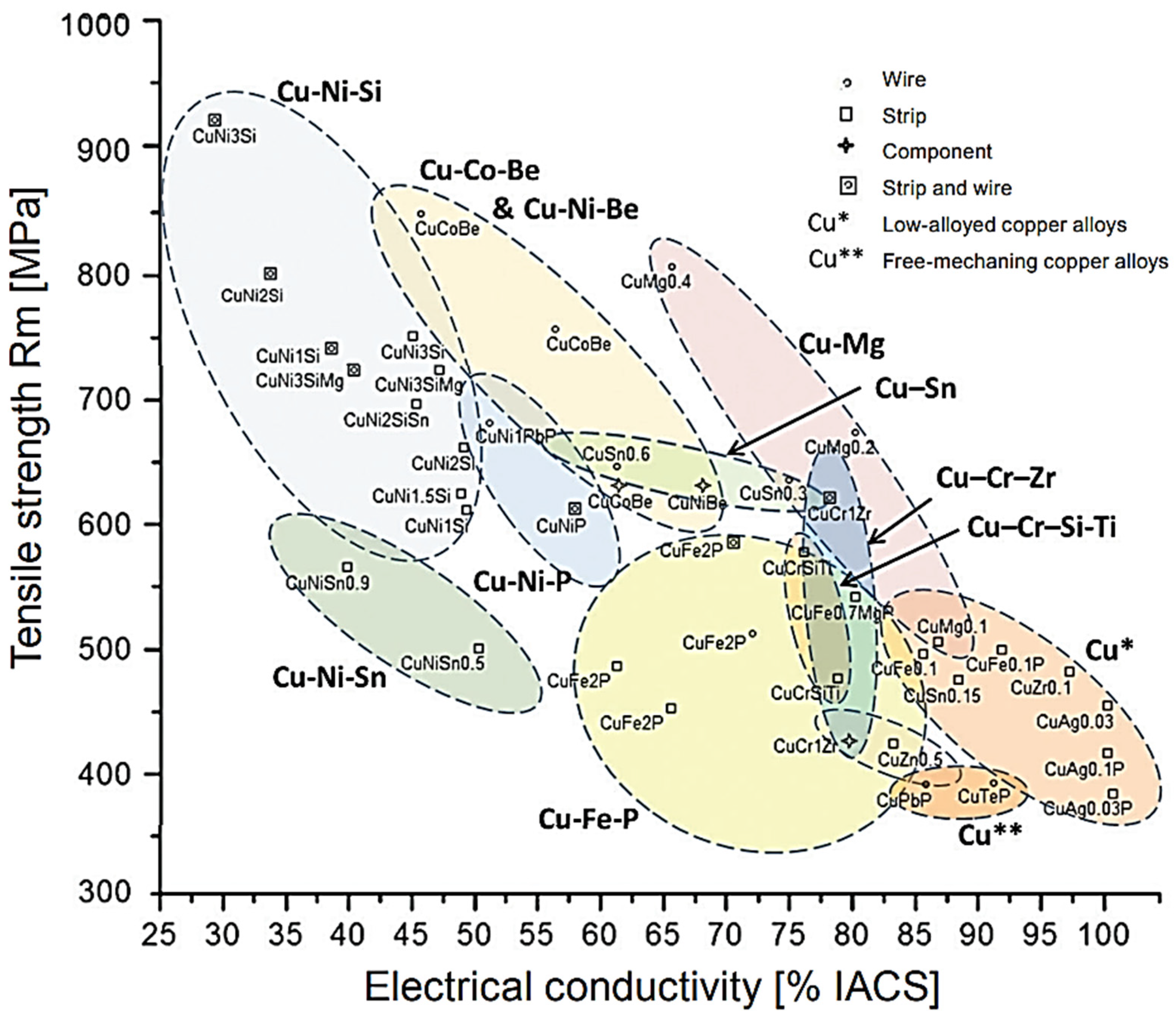

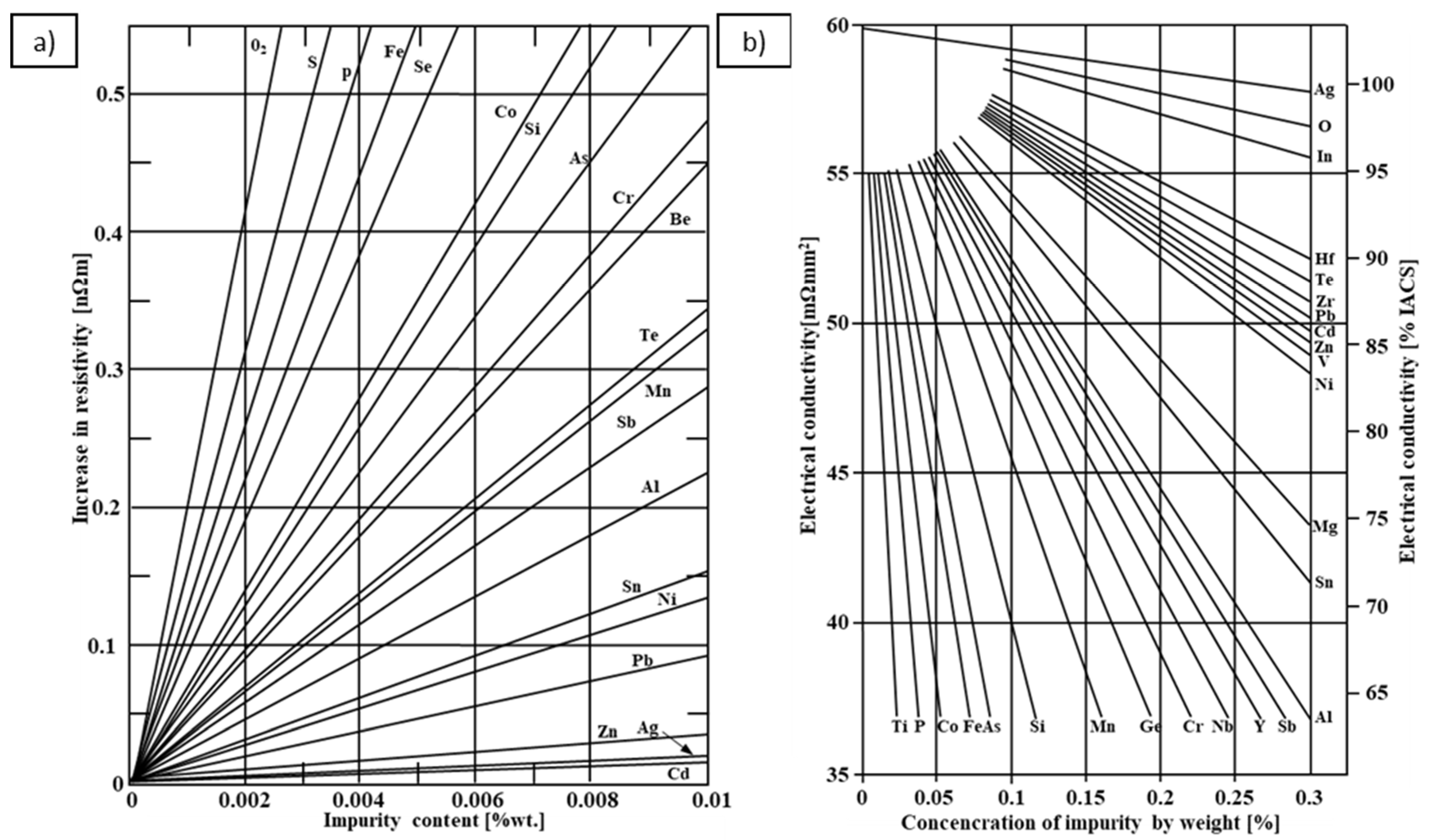

1. Introduction

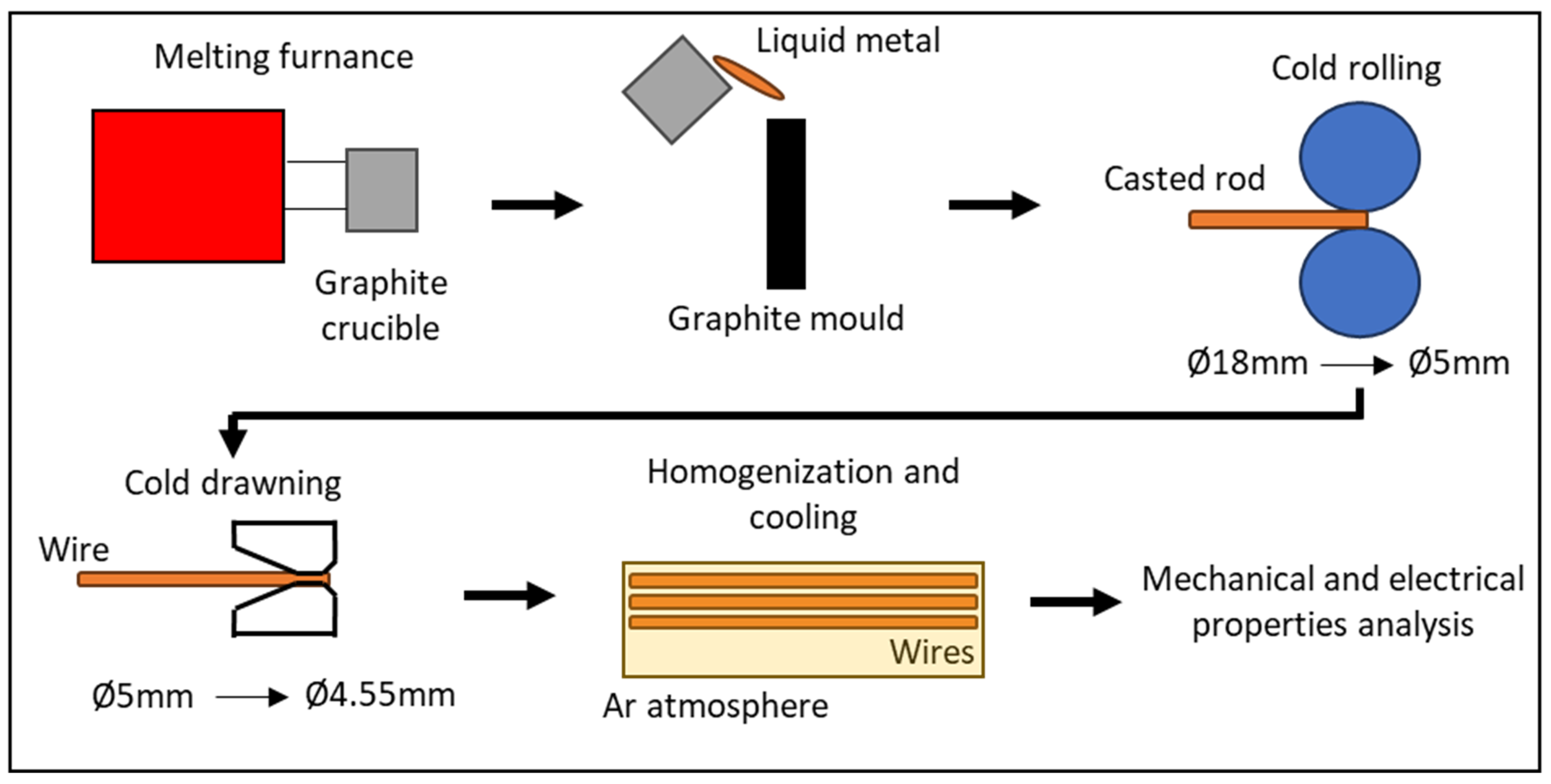

2. Methods and Materials

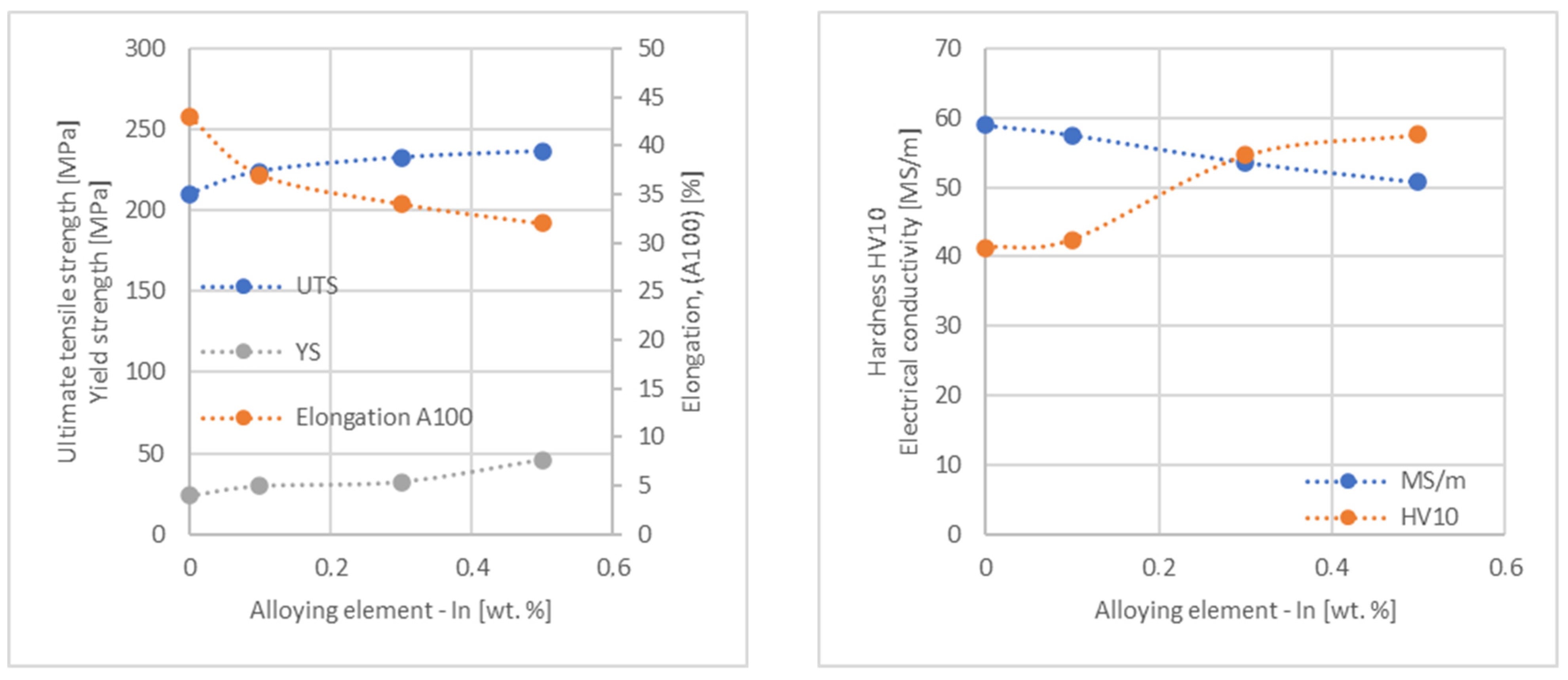

3. Results and Discussion

4. Conclusions

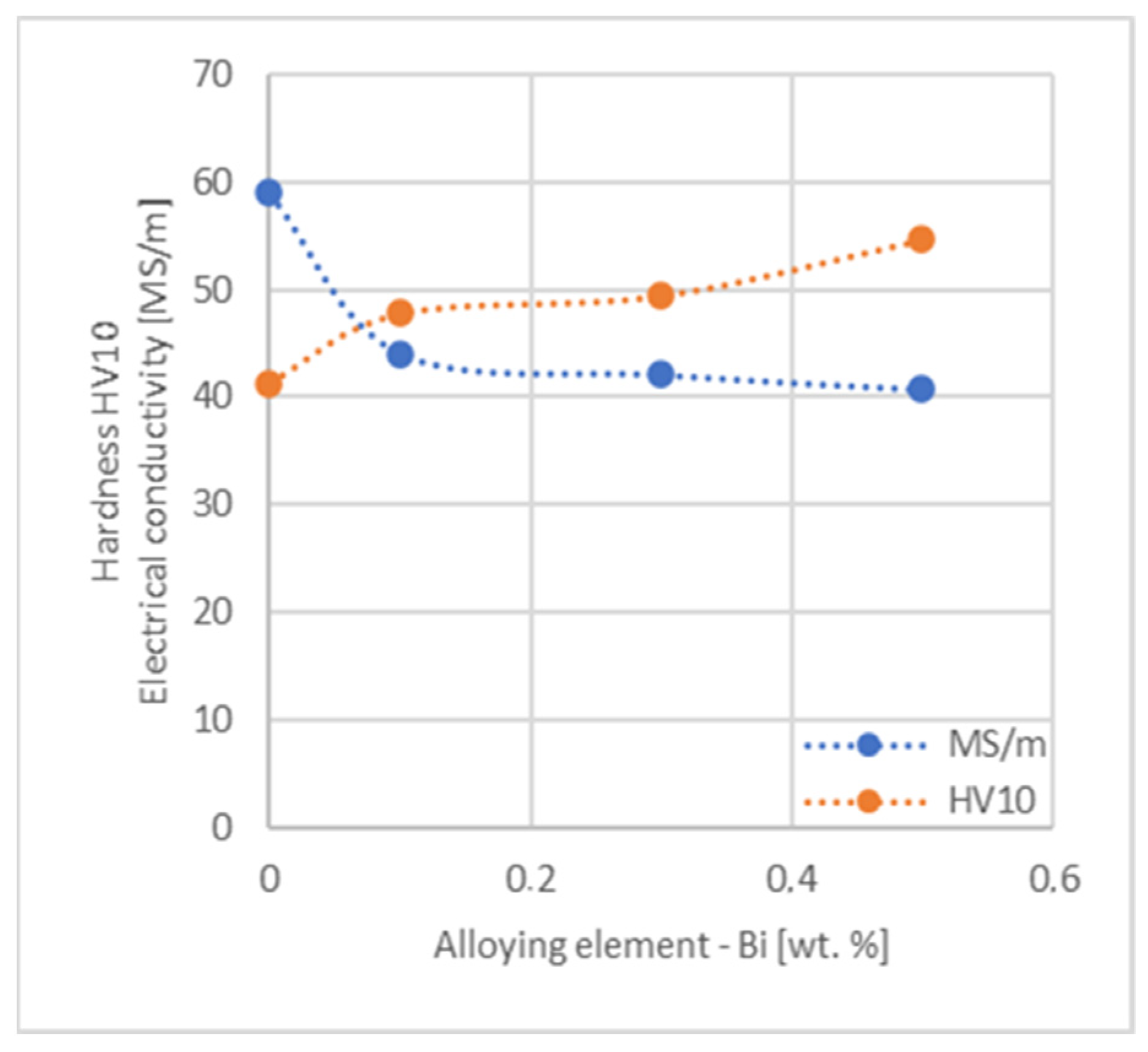

- Copper castings with the addition of Te and Bi, in all their selected contents, cannot be processed with the use of a cold metal forming process, i.e., rolling and drawing, in order to produce wires. This indicates that the cold deformability, due to the addition of Te and Bi, of this alloys is very limited.

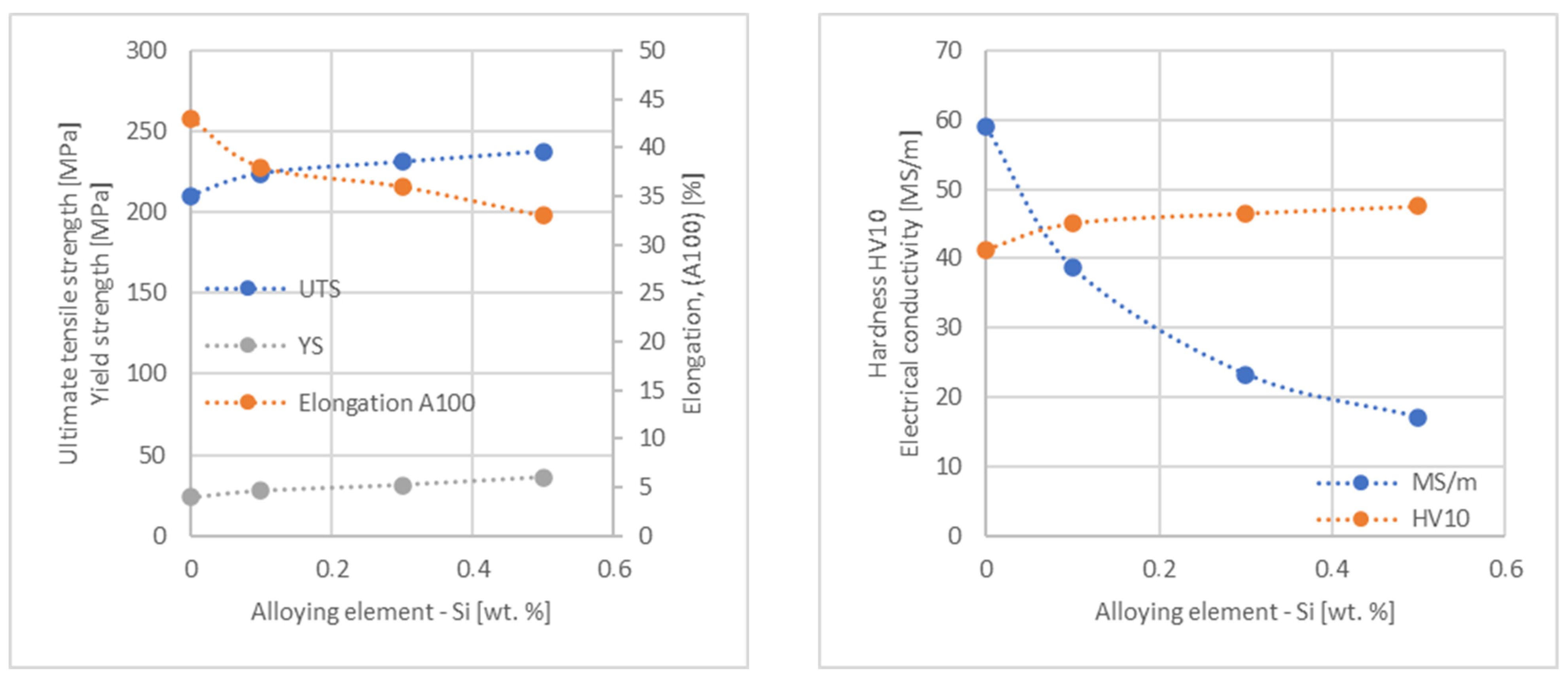

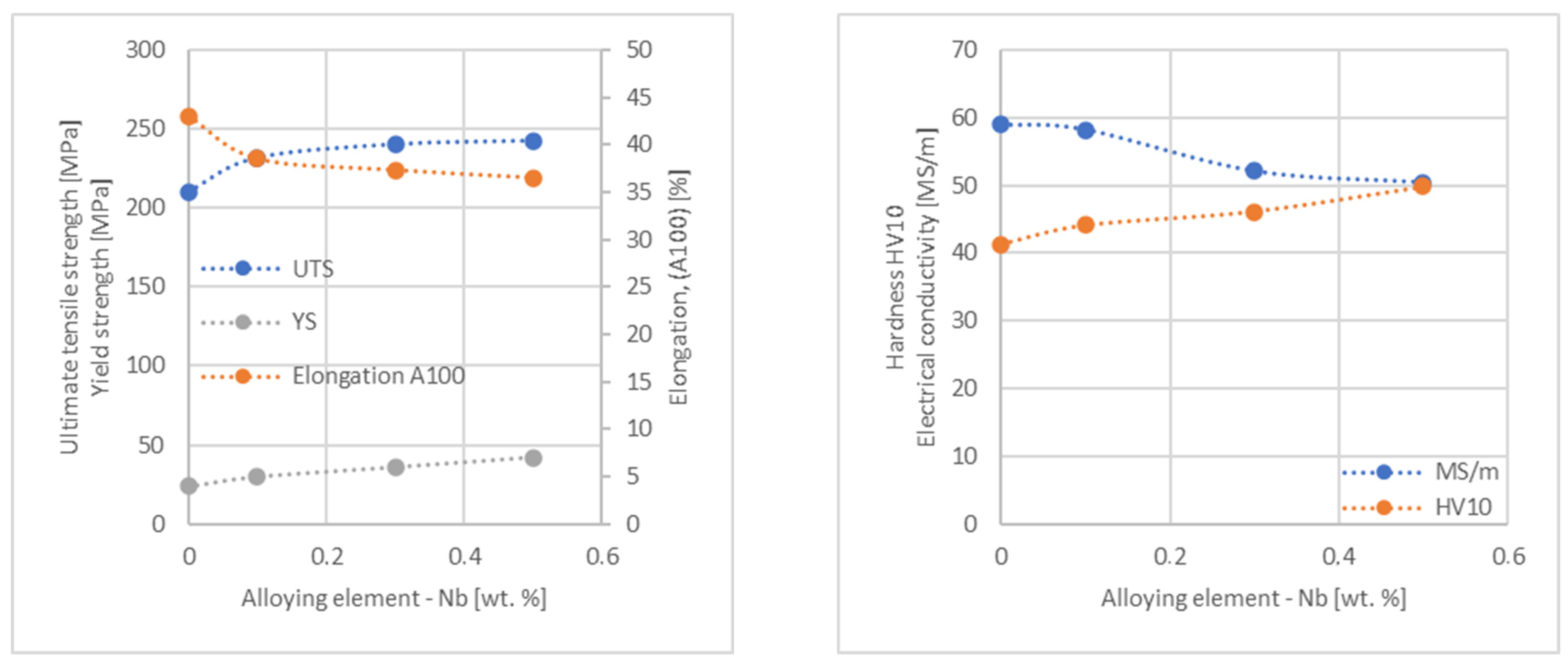

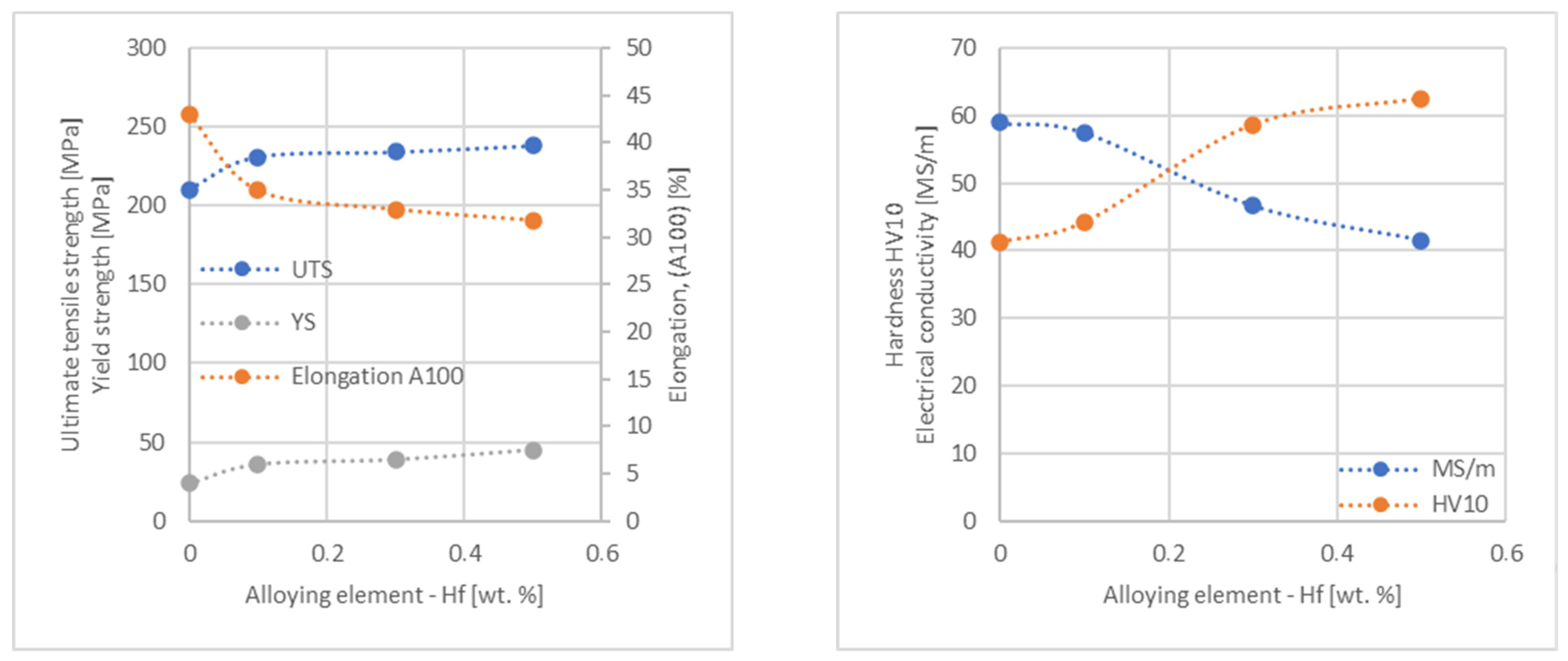

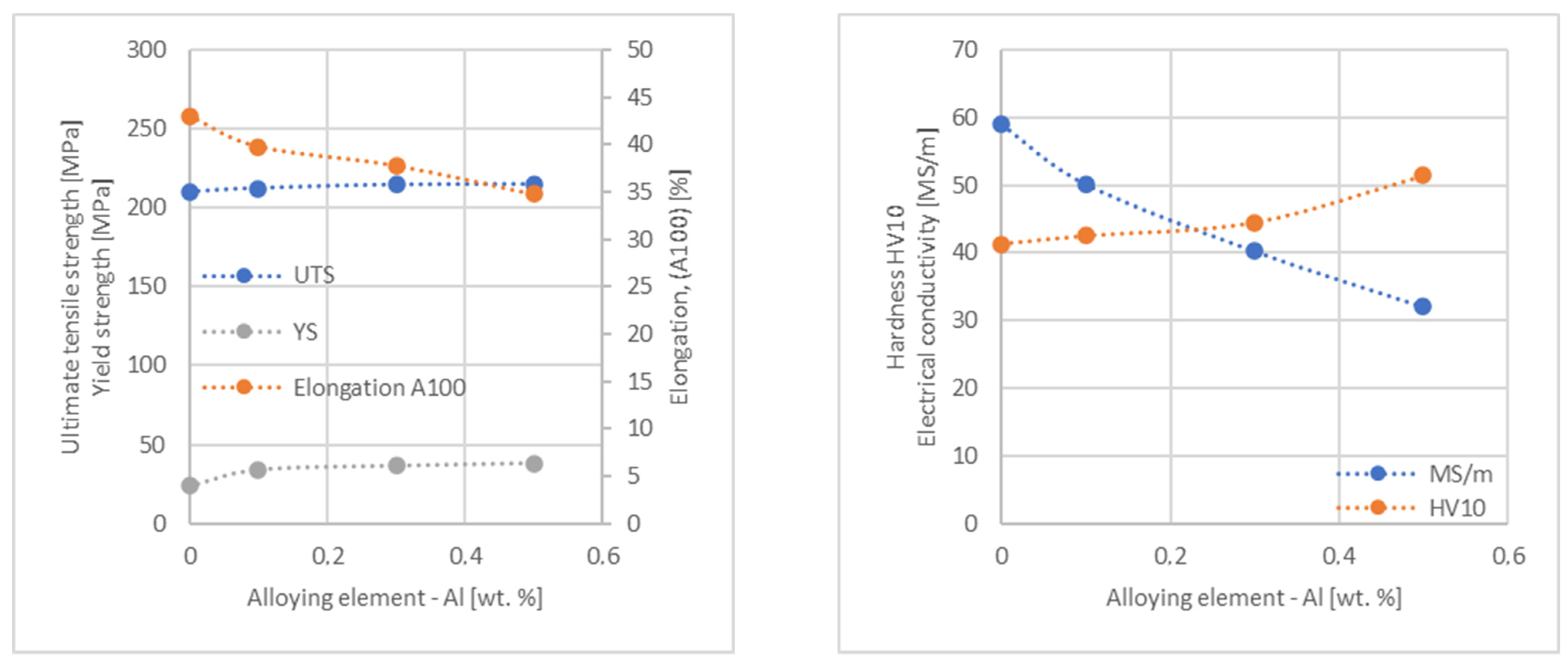

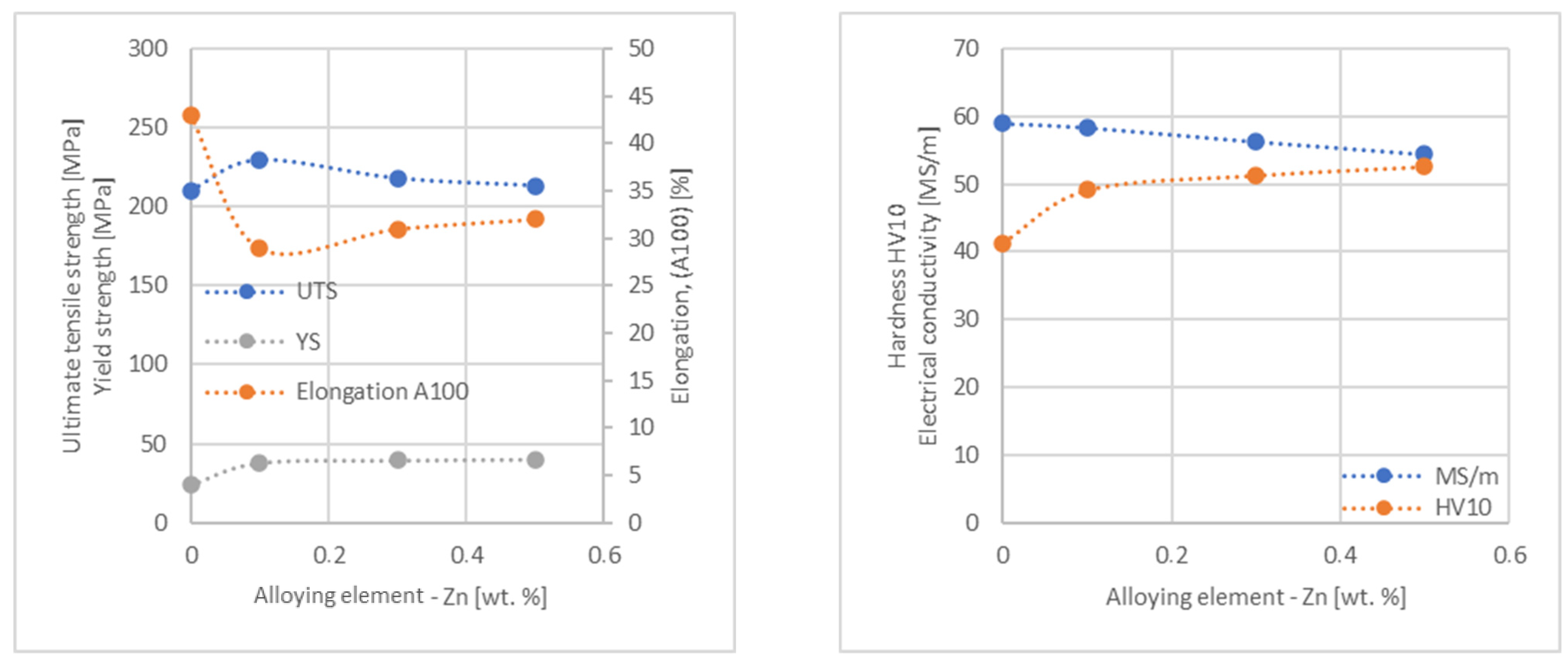

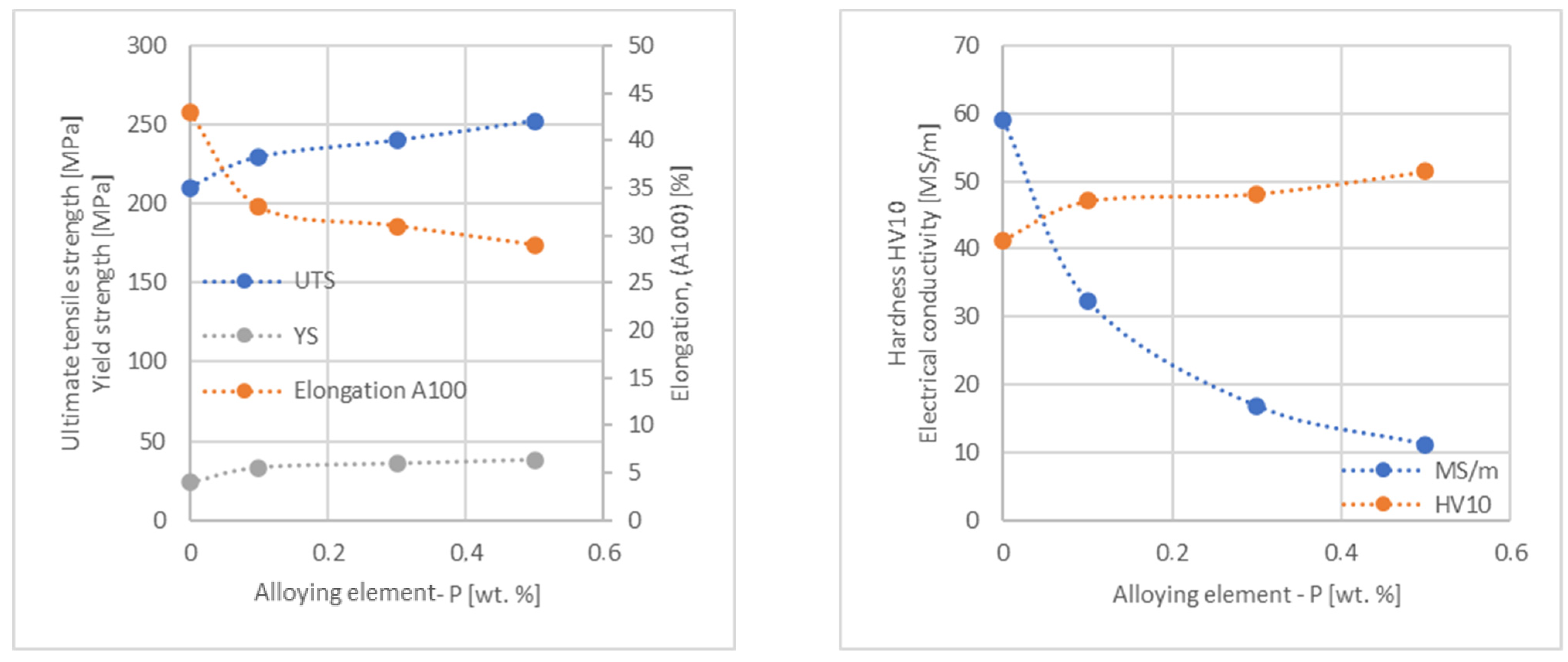

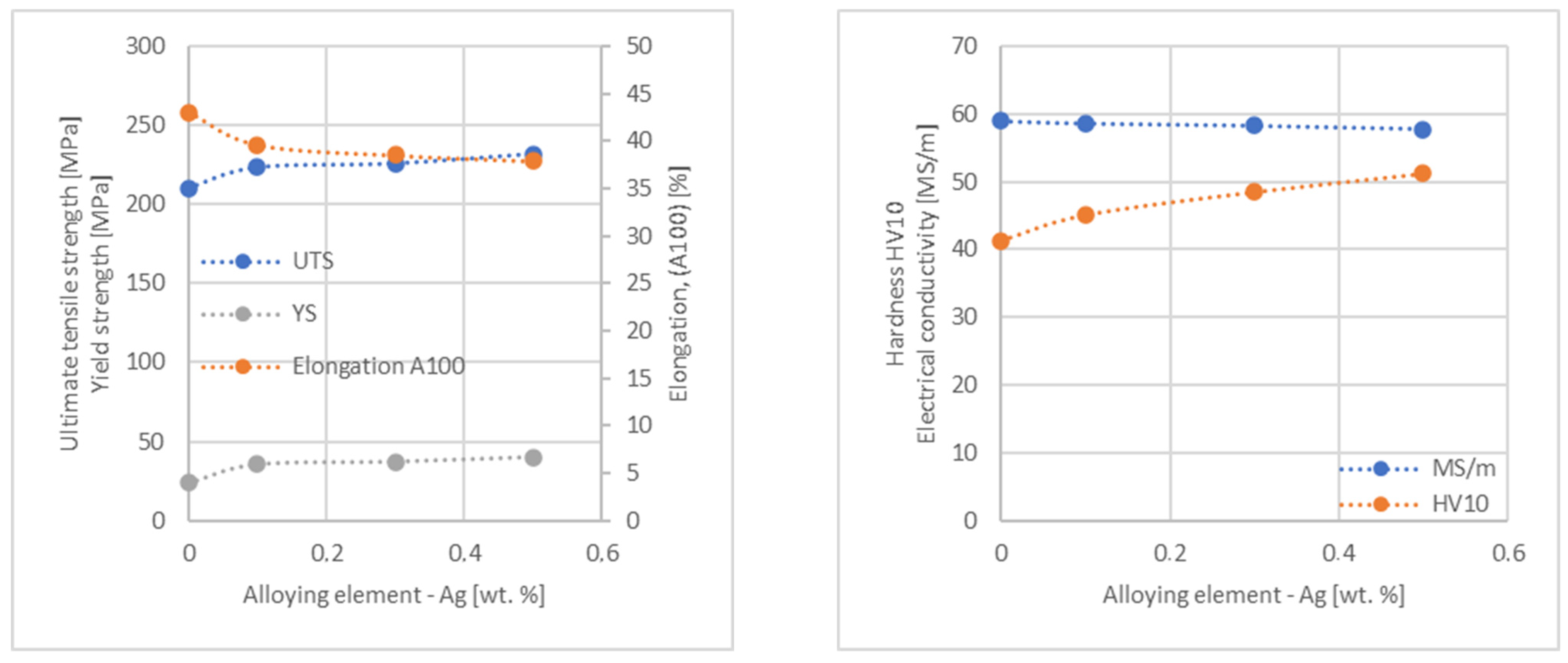

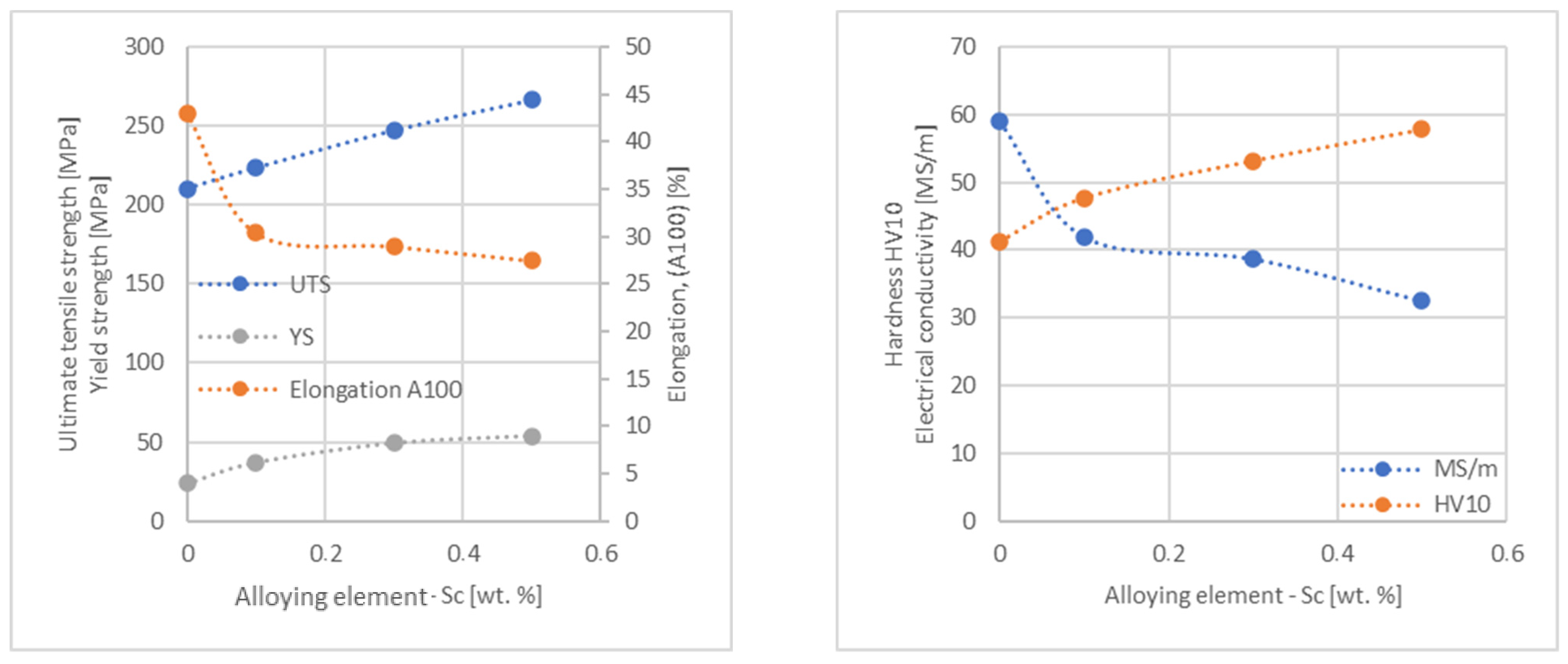

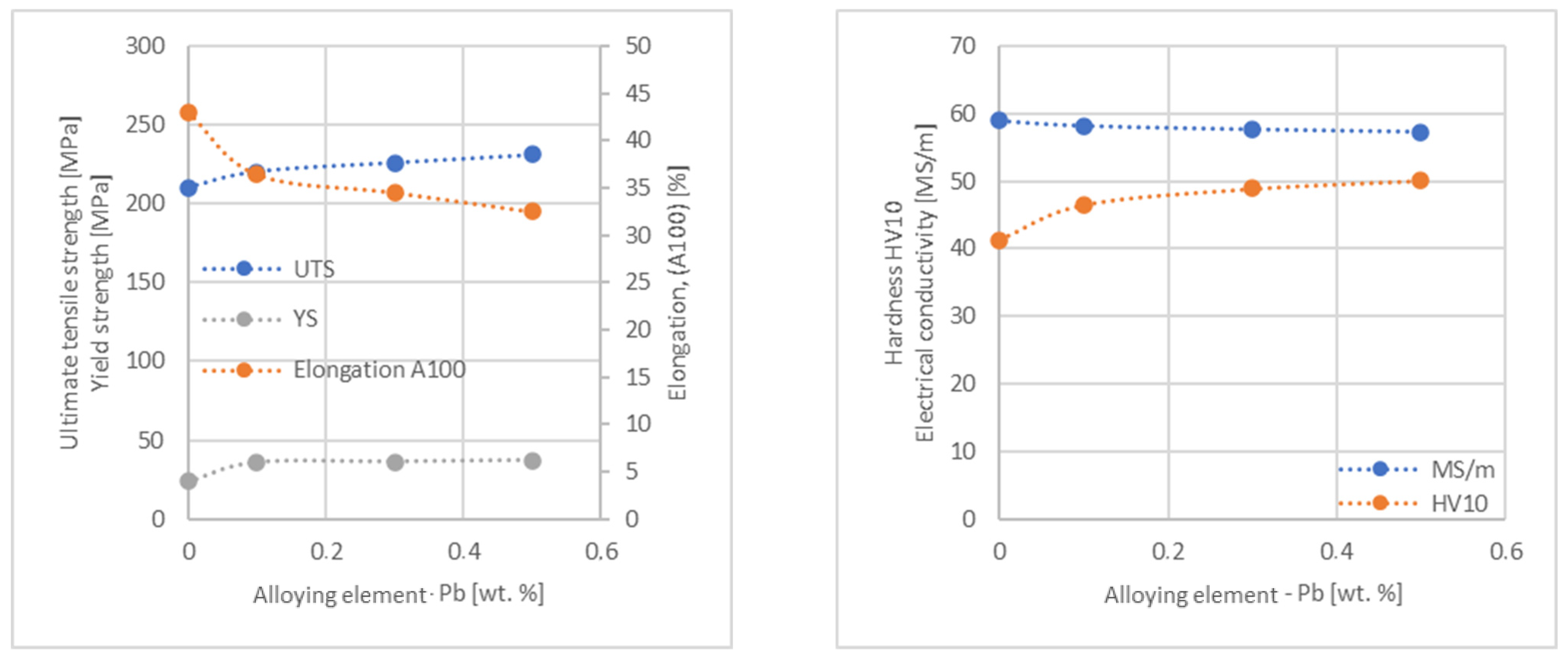

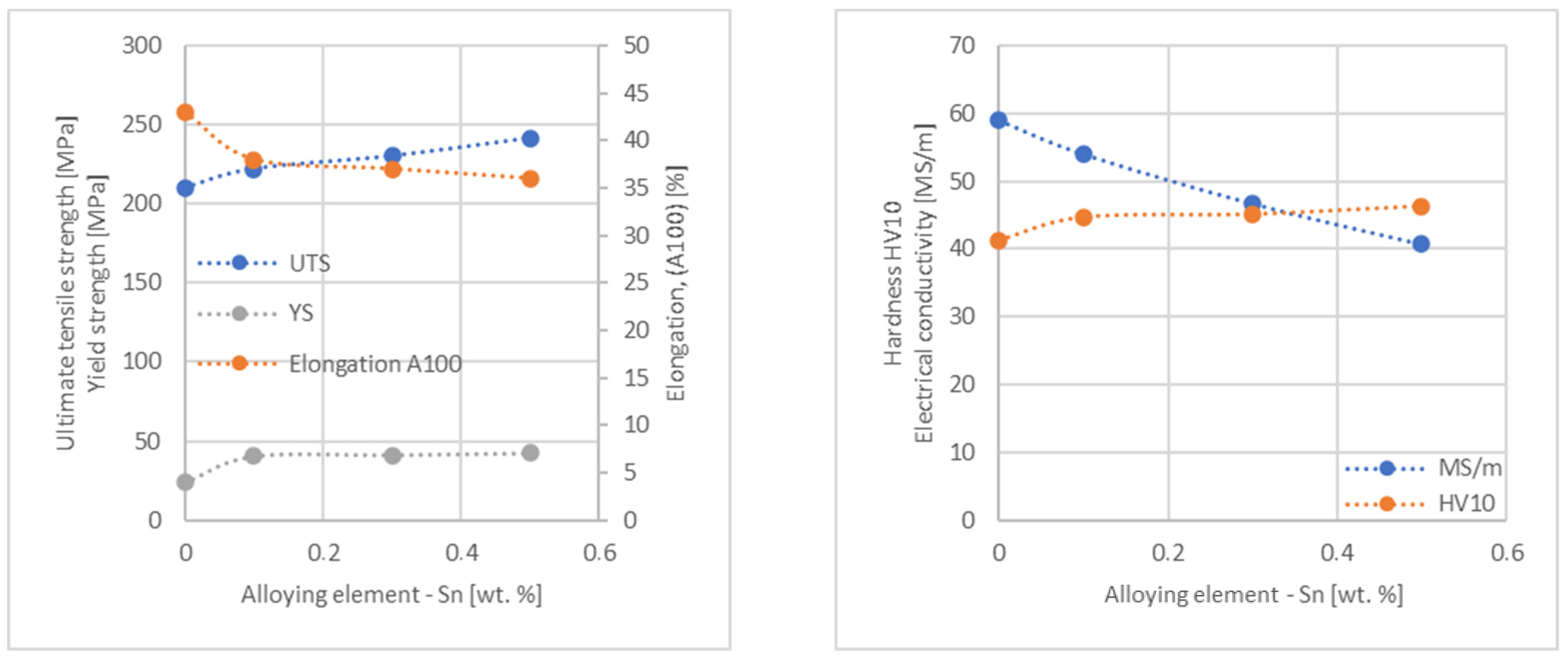

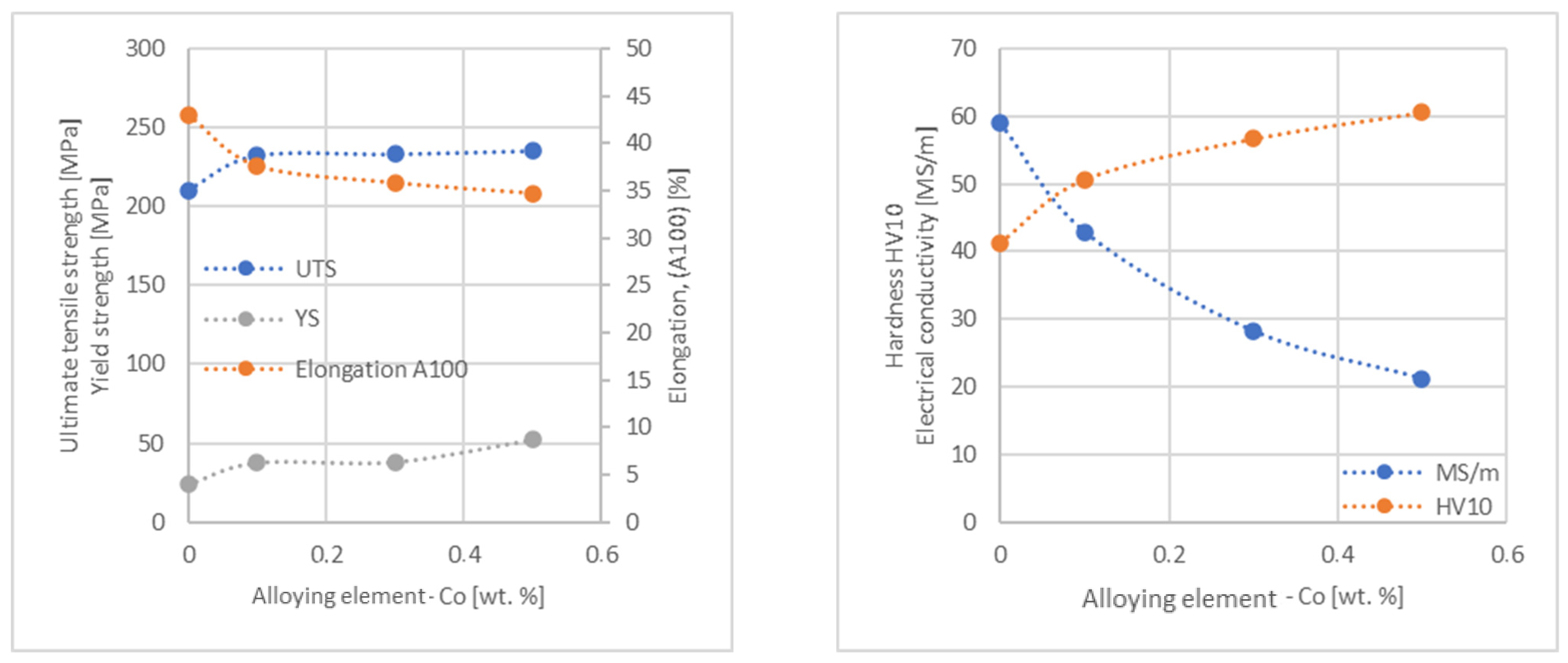

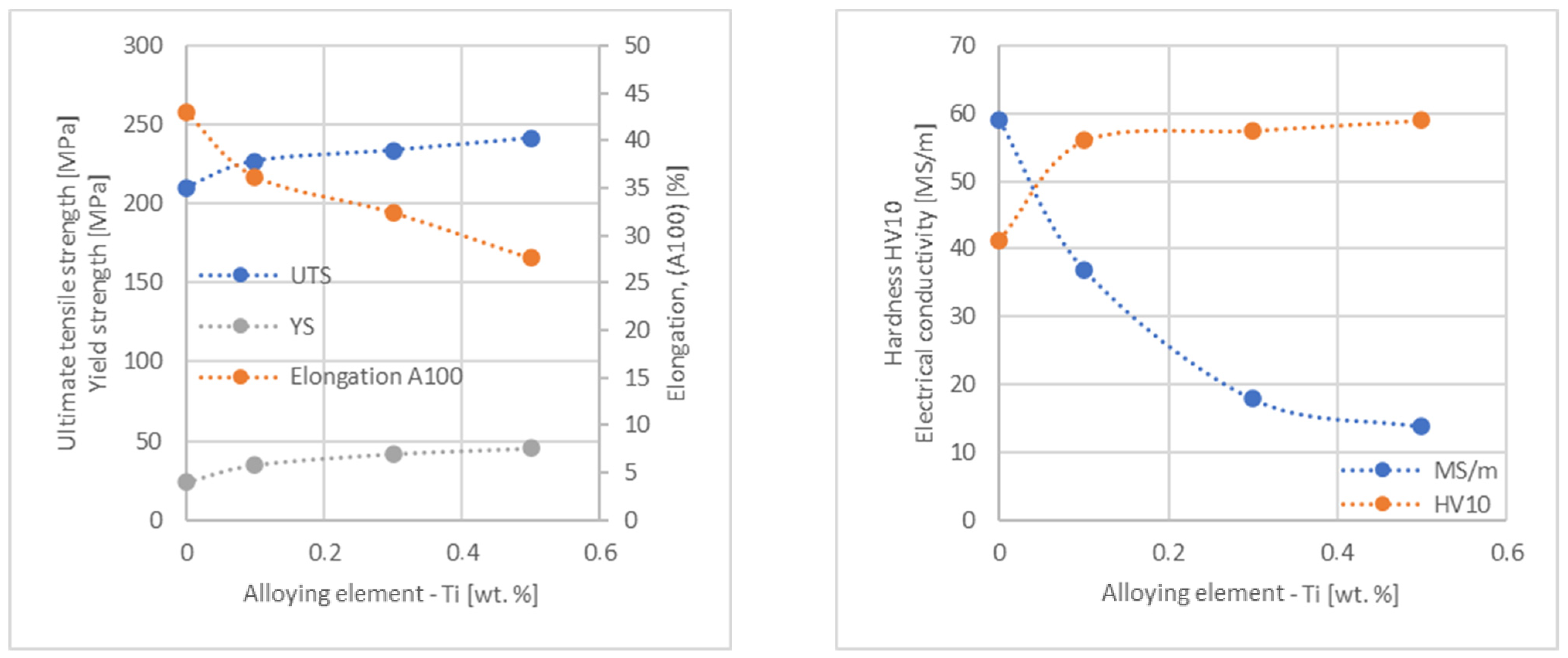

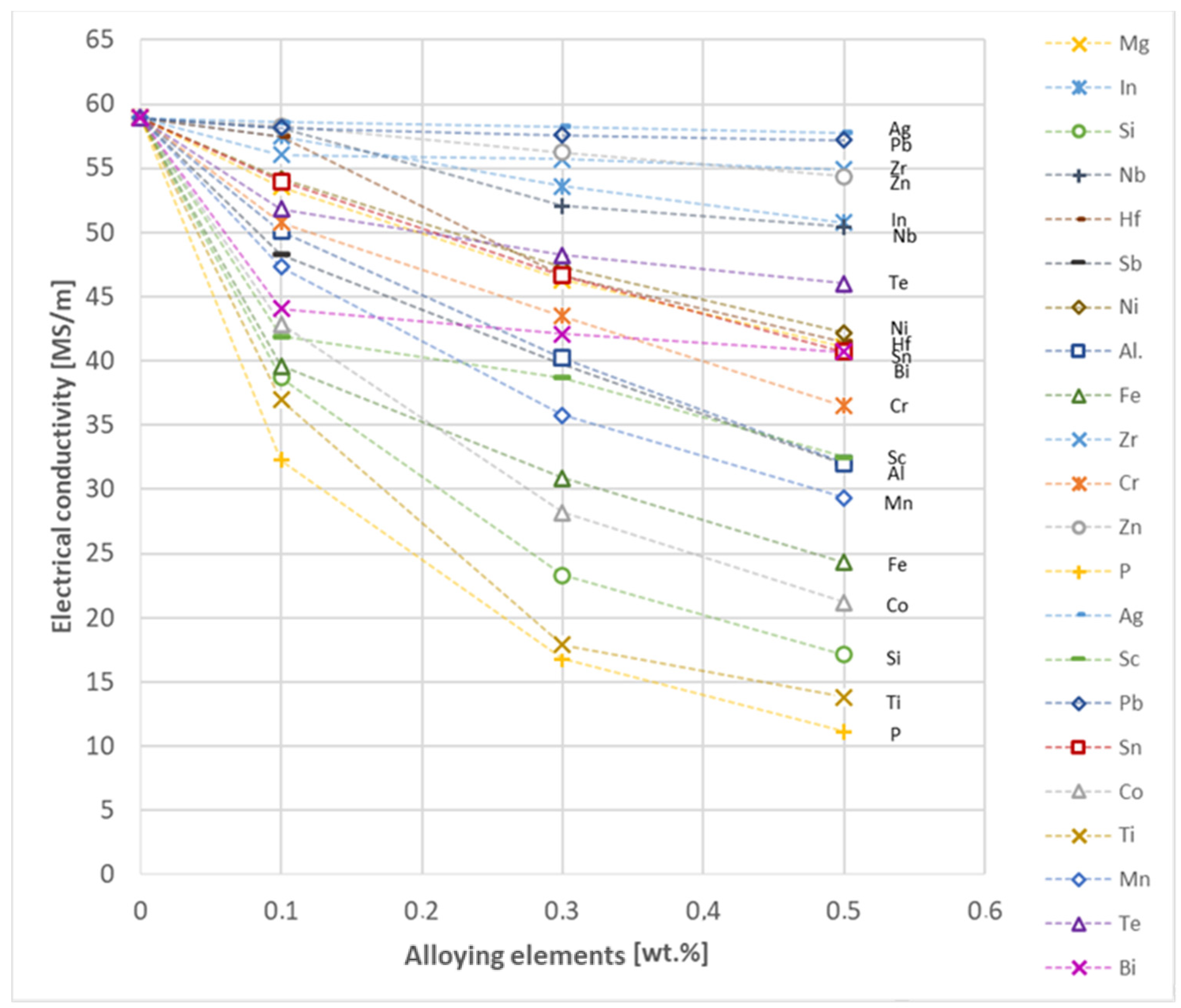

- The electrical conductivity of copper decreases, for the lowest addition of Ag and Pb to the level of 57.2 MS/m and in the case of Zr and Zn to the value of 54.4 MS/m. However, the greatest decrease was observed for P, Ti, Si, Co and Fe addition, where the electrical conductivity ranged from 11.2 MS/m to 24.3 MS/m.

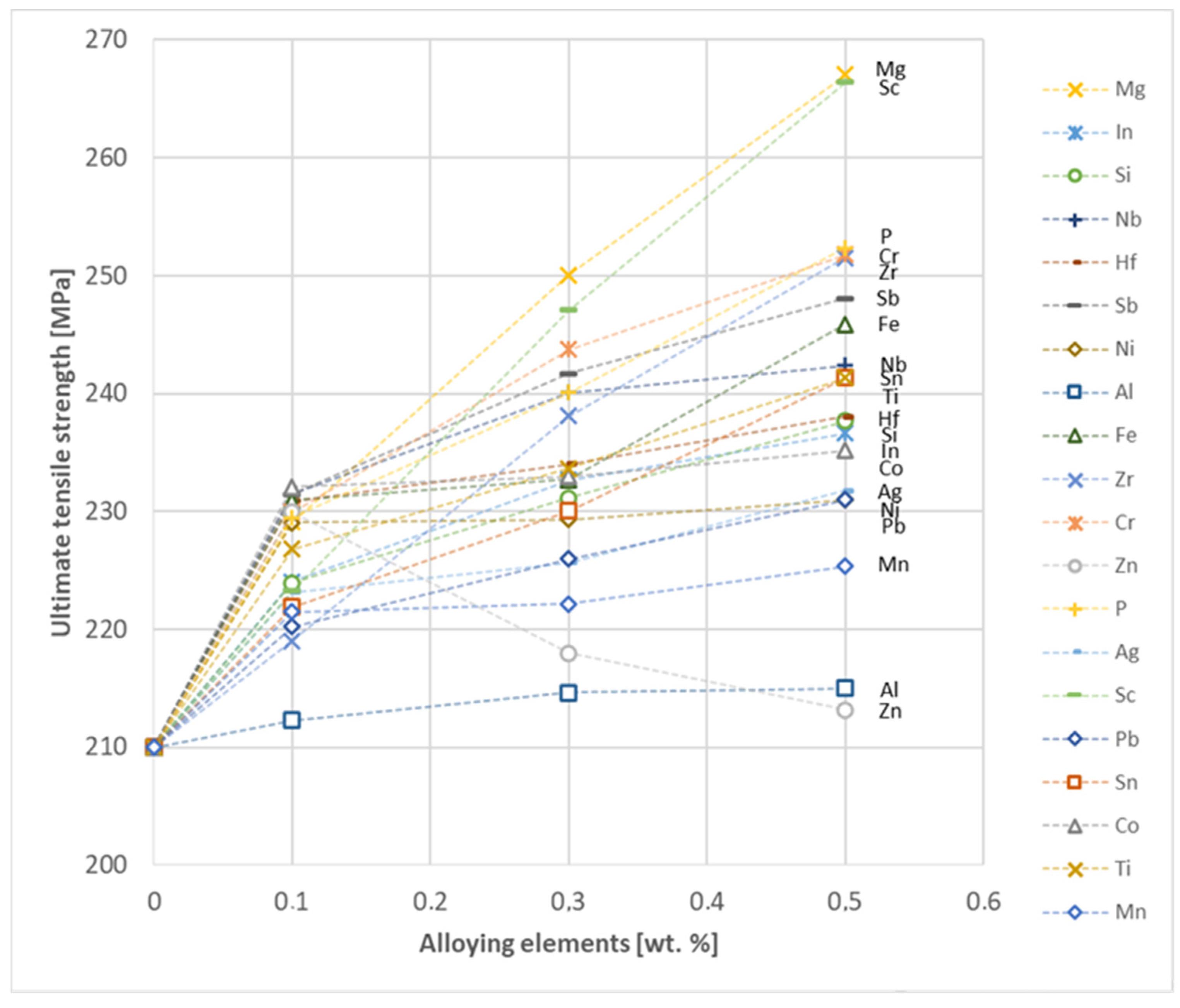

- The elements that have the greatest impact on the ultimate tensile strength of copper are Mg and Sc—the addition of 0.5 wt.% each increased the CuETP UTS to the level of 266 MPa. However, from all the tested materials, the alloying additions that have the least impact on the tensile strength of copper are Zn and Al, lowering the UTS value to 213 MPa and 215 MPa, respectively.

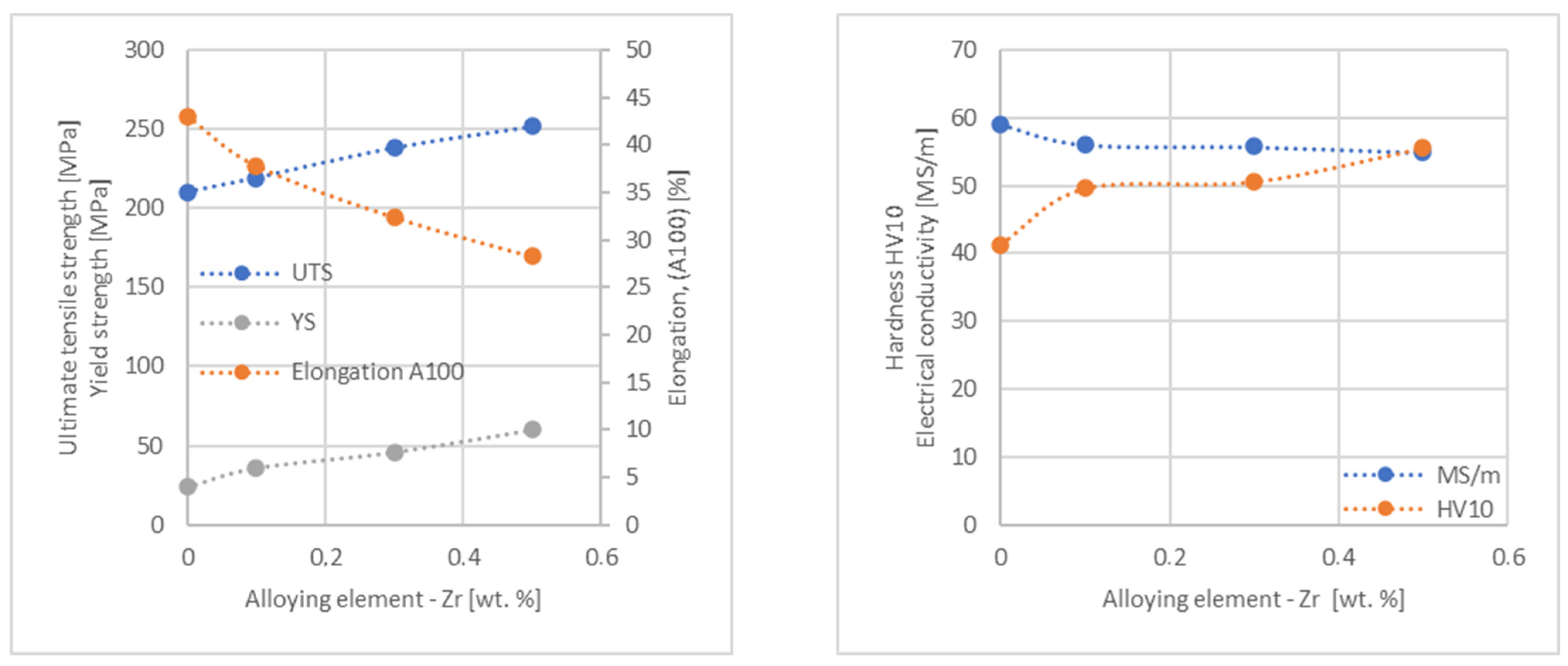

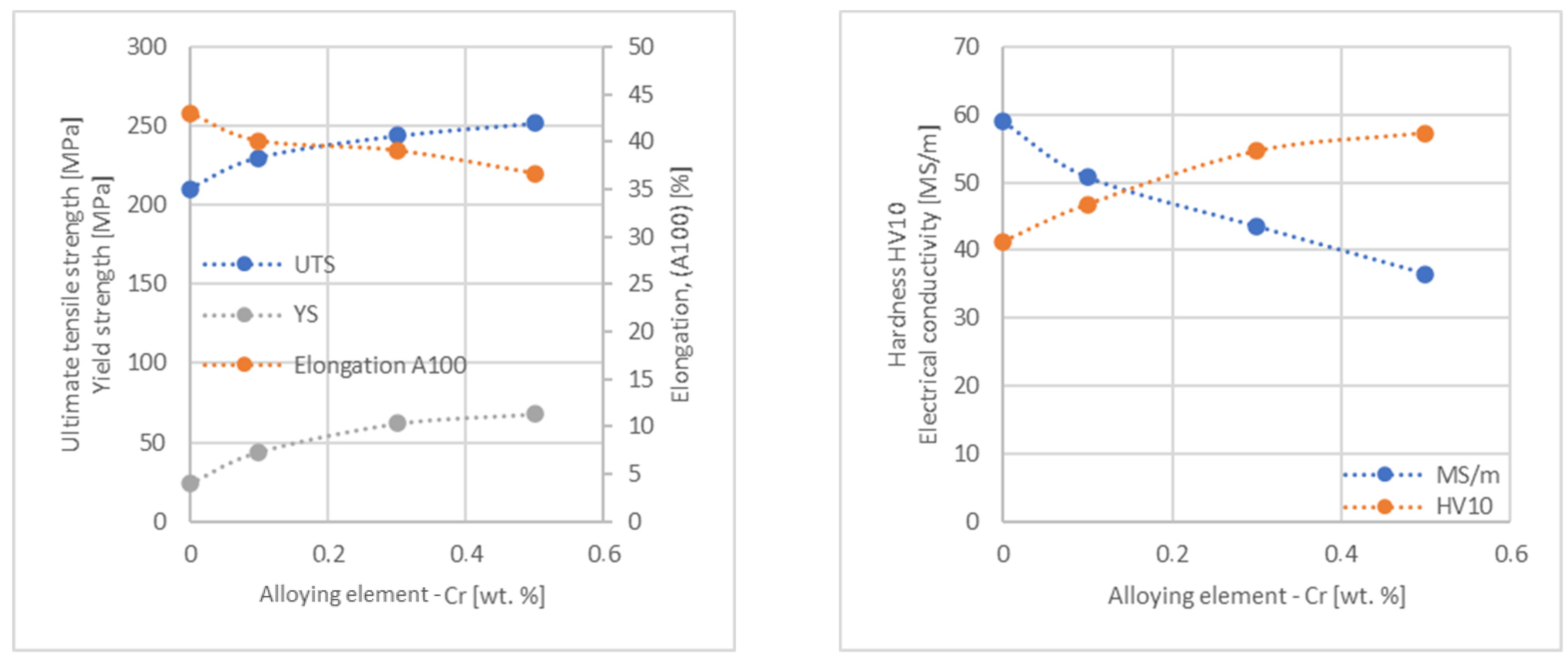

- The highest impact on the conventional yield strength of copper was found for Fe, Cr and Zr, which cause the YS to increase to a level slightly above 60 MPa. Si, Pb and Al additions have the lowest impact, with the yield strength being at the level of approximately 36 MPa.

- The addition of P, Zr, Ti and Sc to CuETP copper causes the plasticity to decrease from the level of 43% (for CuETP) down to 27.6–29%. The smallest impact on the plasticity was observed for Ag and Ni, where A100 elongation was measured at 37.5–37.9%.

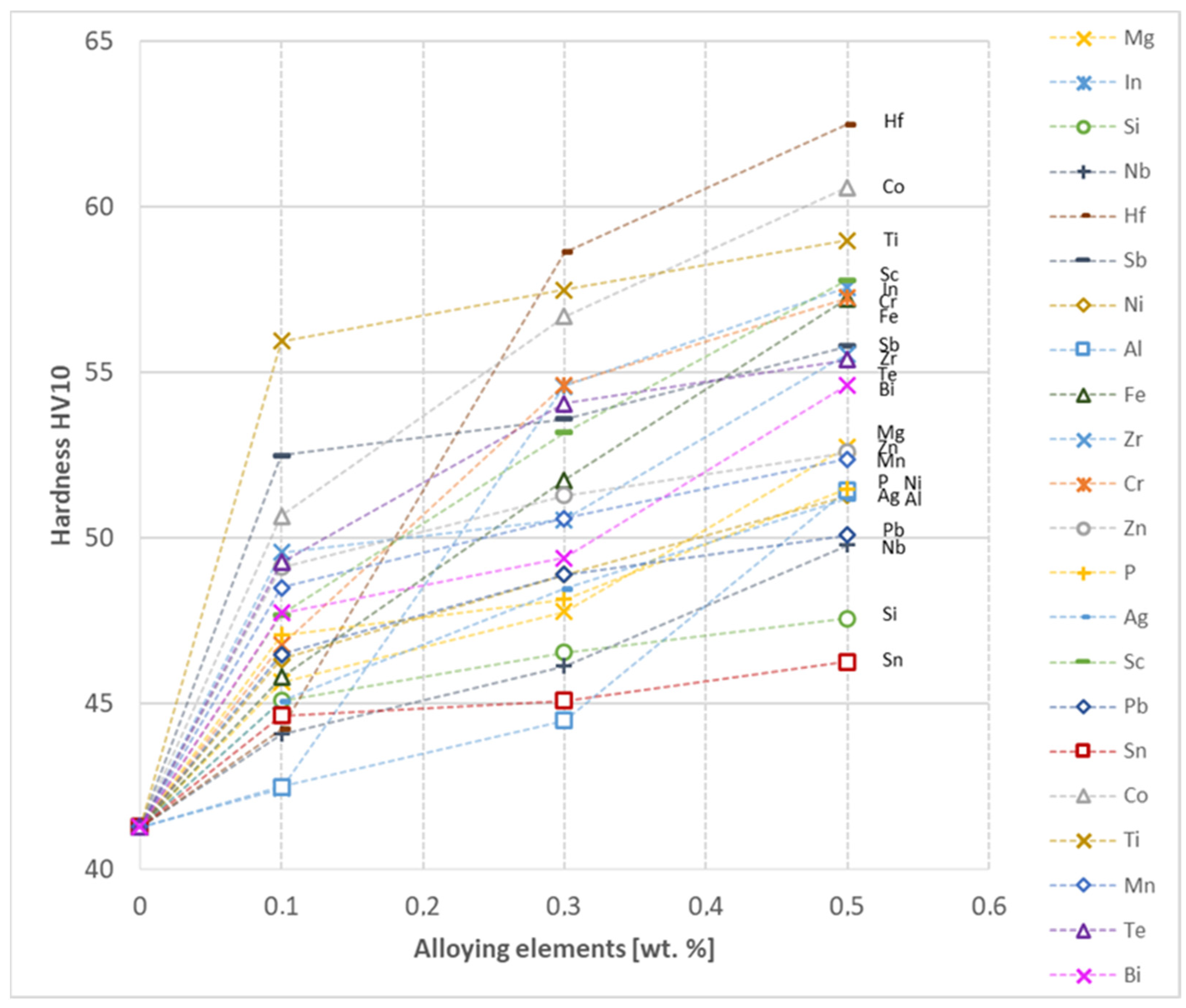

- The highest increase in CuETP hardness was obtained for Hf and Co up to 62.5 HV10 and 60.6 HV10, respectively, both for the 0.5 wt.% content. However, the smallest impact on copper hardness was observed for alloy additions such as Sn and Si, with a resulting hardness, for their highest content, of 46.3 HV10 and 47.6 HV10, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Davis, J.R. ASM Specialty Handbook: Copper and Copper Alloys; ASM International: Novetly, OH, USA, 2001. [Google Scholar]

- Warlimont, H.; Martienssen, W. Springer Handbook of Materials Data; Springer Nature Switzerland AG: Cham, Switzerland, 2018. [Google Scholar]

- Liu, P.; Tong, L.; Wang, J.; Shi, L.; Tang, H. Challenges and developments of copper wire bonding technology. Microelectron. Reliab. 2012, 52, 1092–1098. [Google Scholar] [CrossRef]

- Guo, N.; Li, D.; Yu, H.; Xin, R.; Zhang, Z.; Li, X.; Liu, C.; Song, B.; Chai, L. Annealing behavior of gradient structured copper and its effect on mechanical properties. Mater. Sci. Eng. A 2017, 702, 331–342. [Google Scholar] [CrossRef]

- Gale, W.G.; Totemeier, T.C. Smithells Metals Reference Book, 8th ed.; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Chapman, D. High Conductivity Copper for Electrical Engineering; European Copper Institute Publication No Cu0232; Copper Development Association: Brussels, Belgium, 2016. [Google Scholar]

- Rui, J.K. Electricians’ Handbook of Materials; A Pocket Reference; China Construction Industry Press: Beijing, China, 2003. [Google Scholar]

- Addicks, L. The Effect of Impurities on the Electrical Conductivity of Copper; American Institute of Mining, Metallurgical, and Petroleum Engineers (AIME): San Ramon, CA, USA, 1905; Volume 36, p. 18. [Google Scholar]

- Kurski, K. Miedź i jej Stopy Techniczne; Wydawnictwo “Śląsk”: Katowice, Poland, 1967. [Google Scholar]

- Taubenblat, P.W. Copper: Selection of high conductivity alloys. Encycl. Mater. Sci. Eng. 1986, 2, 863–866. [Google Scholar]

- Zeng, Y.; Mu, S.; Wu, P.; Ong, K.P.; Zhang, J. Relative effects of all chemical elements on the electrical conductivity of metal and alloys: An alternative to Norbury-Linde rule. J. Alloys Compd. 2009, 478, 345–354. [Google Scholar] [CrossRef]

- Sato, S.; Maki, K.; Ito, M.; Suzuki, S. Factors Affecting the Physical Properties of Electrically Conductive Copper and Dilute Copper Alloys. Mater. Trans. 2023, 64, 2039–2050. [Google Scholar] [CrossRef]

- Calatroni, S. Materials & Properties: Thermal & Electrical Characteristics. arXiv 2020, arXiv:2006.02842. [Google Scholar]

- Li, X.W.; Du, S.M.; Ma, C.H.; Shi, T.; Qi, W.; Yang, H.J. Nano-SiO2 based anti-corrosion superhydrophobic coating on Al alloy with mechanical stability, anti-pollution and self-cleaning properties. Ceram. Int. 2024, 50, 9469–9478. [Google Scholar] [CrossRef]

- Seung, Z.H.; Eun-Ae, C.; Sung, H.L.; Sangshik, K.; Jehyun, L. Alloy design strategies to Increase strenght and its trade-offs together. Prog. Mater. Sci. 2021, 117, 100720. [Google Scholar]

- Zhao, Y.-H.; Bingert, J.F.; Liao, X.-Z.; Cui, B.-Z.; Han, K.; Sergueeva, A.V.; Mukherjee, A.K.; Valiev, R.Z.; Langdon, T.G.; Zhu, Y.T. Simultaneously Increasing the Ductility and Strength of Ultra-Fine-Grained Pure Copper. Adv. Mater. 2006, 18, 2949–2953. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Mao, Q.; Liu, Y.; Zhao, Y. A review on copper alloys with high strength and high electrical conductivity. J. Alloys Compd. 2024, 990, 174456. [Google Scholar]

- Kawecki, A.; Sieja-Smaga, E.; Korzeń, K.; Majchrowska, M.; Noga, P. Research on Mechanical and Electrical Properties of Cu-Ag Alloys Designed for the Construction of High Magnetic Field Generators. J. Cast. Mater. Eng. 2021, 5, 103–107. [Google Scholar] [CrossRef]

- Chen, Y.; Ren, S.; Zhao, Y.; Qu, Y. Microstructure and properties of CuCr alloy manufactured by selective laser melting. J. Alloys Compd. 2019, 786, 189–197. [Google Scholar] [CrossRef]

- Zhao, Y.; Pang, T.; He, J.; Tao, X.; Chen, H.; Ouyang, Y.; Du, Y. Interdiffusion behaviors and mechanical properties of Cu-Zr system. Calphad 2018, 61, 92–97. [Google Scholar] [CrossRef]

- Sarin, V.K.; Grant, N.J. Cu-Zr and Cu-Cr-Zr Alloys Produced from Rapidly Quenched Powders. Metall. Trans. 1972, 3, 875–878. [Google Scholar] [CrossRef]

- Tu, J.P.; Qi, W.X.; Yang, Y.Z.; Liu, F.; Zhang, J.T.; Gan, G.Y.; Wang, N.Y.; Zhang, X.B.; Liu, M.S. Effect of aging treatment on the electrical sliding wear behavior of Cu–Cr–Zr alloy. Wear 2002, 249, 1021–1027. [Google Scholar] [CrossRef]

- Wang, W.; Kang, H.; Chen, Z.; Chen, Z.; Zou, C.; Li, R.; Yin, G.; Wang, T. Effects of Cr and Zr additions on microstructure and properties of Cu-Ni-Si alloys. Mater. Sci. Eng. A 2016, 673, 378–390. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Ahmad, T.; Zhou, C.; Xiao, X.; Wang, H.; Yang, B. Microstructures and mechanical properties of Cu–Ti alloys with ultrahigh strength and high ductility by thermo-mechanical treatment. Mater. Sci. Eng. A 2022, 835, 142672. [Google Scholar] [CrossRef]

- Tong, Y.-X.; Li, S.-Y.; Zhang, D.-T.; Li, L.; Zheng, Y.-F. High strength and high electrical conductivity CuMg alloy prepared by cryorolling. Trans. Nonferrous Met. Soc. China 2019, 29, 595–600. [Google Scholar] [CrossRef]

- Deutsches Kupferinstitut Berufsverband e. V. Low-Alloyed Copper Alloys; Deutsches Kupferinstitut: Dusseldorf, Germany, 2018. [Google Scholar]

- Franczak, K.; Kwasniewski, P.; Kiesiewicz, G.; Zasadzinska, M.; Jurkiewicz, B.; Strzepek, P.; Rdzawski, Z. Research of mechanical and electrical properties of Cu–Sc and Cu–Zr alloys. Arch. Civ. Mech. Eng. 2020, 20, 28. [Google Scholar] [CrossRef]

- Rdzawski, Z.; Gluchowski, W.; Stobrawa, J.; Kempinski, W.; Andrzejewski, B. Microstructure and properties of Cu-Nb and Cu-Ag nanofiber composites. Arch. Civ. Mech. Eng. 2015, 15, 689–697. [Google Scholar] [CrossRef]

- Rdzawski, Z.; Gluchowski, W.; Stobrawa, J.; Sobota, J. Effect of rare-earth metals addition on microstructure and properties of selected copper alloys. Arch. Metall. Mater. 2014, 59, 641–648. [Google Scholar] [CrossRef]

- Shojaei, M.R.; Khayati, G.R.; Khorasani, S.M.J.; Yaghubi, N.A. Study the failure of casted copper anode: The formation of bumps defects on the surface of the anode during casting. Eng. Fail. Anal. 2022, 138, 106426. [Google Scholar] [CrossRef]

- Pradeep, A.D.; Rameshkumar, T. Review on centrifugal casting of functionally graded materials. Mater. Today Proc. 2021, 45, 729–734. [Google Scholar] [CrossRef]

- Zhang, L.; Song, Q.; Xu, X.; Xu, Z. Process simulation of Ohno continuous casting for single crystal copper prepared from scrap copper in waste printed circuit boards. Waste Manag. 2021, 124, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Dinaharan, I.; Albert, T. Effect of reinforcement type on microstructural evolution and wear performance of copper matrix composites via powder metallurgy. Mater. Today Commun. 2023, 34, 105250. [Google Scholar] [CrossRef]

- EN 13601:2021; Copper and Copper Alloys—Copper Rod, Bar and Wire for General Electrical Purposes. ITeh Standards: Newark, DE, USA, 2021.

- Shen, Z.; Lin, Z.; Shi, P.; Tang, G.; Zheng, T.; Liu, C.; Guo, Y.; Zhong, Y. Enhanced strength, ductility and electrical conductivity of Cu–Te alloys via dynamic recrystallization and precipitation. Mater. Sci. Eng. A 2021, 820, 141548. [Google Scholar] [CrossRef]

- Singh, S.P.; Kumar, B.; Barman, D.; Kumar, P. Cu-Bi alloys with high volume fraction of Bi: A material potentially suitable for thermal surge protection and energy storage. Mater. Sci. Eng. A 2016, 677, 140–152. [Google Scholar] [CrossRef]

| Material | Element [ppm] | Not Included | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy | Symbol | Range | Cu * | Ag | As | Bi | Cd | Co | Cr | Fe | Mn | Ni | P | Pb | S | Sb | Se | Si | Sn | Te | Zn | O | Sum | |

| Cu-ETP1 | CW003A | min. | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | O |

| max. | - | 25 | 5 (1) | 2 (2) | - (2) | - (3) | - (1) | 10 (3) | - (1) | - (3) | - (1) | 5 | 15 (4) | 4 (1) | 2 (2) | - (3) | - (3) | 2 (2) | - (3) | 400 (6) | 65 | |||

| Pure Metallic Form * | Master Alloy |

|---|---|

| Mg, In, Si, Nb, Hf, Sb, Ni, Al, Fe, Zn, Ag, Sc, Pb, Sn, Co, Ti, Te, Bi | Cr–CuCr7 |

| Zr–CuZr10 | |

| Mn–CuMn50 | |

| P–CuP8 |

| Research Type | Test Stand | Number of Measurements/Samples | Final Result |

|---|---|---|---|

| Electrical conductivity | Burster Resistomat 2304 (Gernsbach, Germany) | 5 | Arithmetic average |

| Foerster SigmaTest 2.069 (Pittsburgh, PA, USA) | 10 | ||

| UTS, YS, elongation | Zwick/Roell Z100 (Ulm, Germany) | 5 | |

| Hardness | Wilson Tukon 2500 (Rolling Meadows, IL, USA) | 10 | |

| Chemical composition analysis | Spectro Spectrotest TX03 (Kleve, Germany) | 5 |

| Material and Designated Chemical Composition | Tested Main Alloying Element Content | Sample Type | Material and Designated Chemical Composition | Tested Main Alloying Element Content | Sample Type | ||

|---|---|---|---|---|---|---|---|

| Cu-Mg | CuMg0.1 | 0.11 | Wire ø4.55 mm | Cu-Cr | CuCr0.1 | 0.12 | Wire ø4.55 mm |

| CuMg0.3 | 0.30 | CuCr0.3 | 0.33 | ||||

| CuMg0.5 | 0.53 | CuCr0.5 | 0.56 | ||||

| Cu-In | CuIn0.1 | 0.10 | Cu-Zn | CuZn0.1 | 0.12 | ||

| CuIn0.3 | 0.29 | CuZn0.3 | 0.31 | ||||

| CuIn0.5 | 0.51 | CuZn0.5 | 0.51 | ||||

| Cu-Si | CuSi0.1 | 0.12 | Cu-P | CuP0.1 | 0.14 | ||

| CuSi0.3 | 0.31 | CuP0.3 | 0.46 | ||||

| CuSi0.5 | 0.49 | CuP0.5 | 0.54 | ||||

| Cu-Nb | CuNb0.1 | 0.11 | Cu-Ag | CuAg0.1 | 0.11 | ||

| CuNb0.3 | 0.33 | CuAg0.3 | 0.32 | ||||

| CuNb0.5 | 0.48 | CuAg0.5 | 0.53 | ||||

| Cu-Hf | CuHf0.1 | 0.09 | Cu-Sc | CuSc0.1 | 0.12 | ||

| CuHf0.3 | 0.27 | CuSc0.3 | 0.31 | ||||

| CuHf0.5 | 0.49 | CuSc0.5 | 0.55 | ||||

| Cu-Sb | CuSb0.1 | 0.10 | Cu-Pb | CuPb0.1 | 0.12 | ||

| CuSb0.3 | 0.26 | CuPb0.3 | 0.33 | ||||

| CuSb0.5 | 0.46 | CuPb0.5 | 0.51 | ||||

| Cu-Ni | CuNi0.1 | 0.09 | Cu-Sn | CuSn0.1 | 0.11 | ||

| CuNi0.3 | 0.30 | CuSn0.3 | 0.31 | ||||

| CuNi0.5 | 0.50 | CuSn0.5 | 0.54 | ||||

| Cu-Al | CuAl0.1 | 0.08 | Cu-Co | CuCo0.1 | 0.08 | ||

| CuAl0.3 | 0.27 | CuCo0.3 | 0.27 | ||||

| CuAl0.5 | 0.46 | CuCo0.5 | 0.46 | ||||

| Cu-Fe | CuFe0.1 | 0.07 | Cu-Ti | CuTi0.1 | 0.09 | ||

| CuFe0.3 | 0.28 | CuTi0.3 | 0.28 | ||||

| CuFe0.5 | 0.45 | CuTI0.5 | 0.47 | ||||

| Cu-Zr | CuZr0.1 | 0.08 | Cu-Mn | CuMn0.1 | 0.11 | ||

| CuZr0.3 | 0.26 | CuMn0.3 | 0.31 | ||||

| CuZr0.5 | 0.48 | CuMn0.5 | 0.49 | ||||

| Cu-Te | CuTe0.1 | 0.11 | Cast ø18 mm | Cu-Bi | CuBi0.1 | 0.13 | Cast ø18 mm |

| CuTe0.3 | 0.30 | CuBi0.3 | 0.33 | ||||

| CuTe0.5 | 0.51 | CuBi0.5 | 0.51 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franczak, K.; Sadzikowski, M.; Kwaśniewski, P.; Kiesiewicz, G.; Ściężor, W.; Kordaszewski, S. Research on Alloying Elements’ Influence on CuETP-Grade Copper’s Mechanical and Electrical Properties. Materials 2024, 17, 3020. https://doi.org/10.3390/ma17123020

Franczak K, Sadzikowski M, Kwaśniewski P, Kiesiewicz G, Ściężor W, Kordaszewski S. Research on Alloying Elements’ Influence on CuETP-Grade Copper’s Mechanical and Electrical Properties. Materials. 2024; 17(12):3020. https://doi.org/10.3390/ma17123020

Chicago/Turabian StyleFranczak, Krystian, Michał Sadzikowski, Paweł Kwaśniewski, Grzegorz Kiesiewicz, Wojciech Ściężor, and Szymon Kordaszewski. 2024. "Research on Alloying Elements’ Influence on CuETP-Grade Copper’s Mechanical and Electrical Properties" Materials 17, no. 12: 3020. https://doi.org/10.3390/ma17123020

APA StyleFranczak, K., Sadzikowski, M., Kwaśniewski, P., Kiesiewicz, G., Ściężor, W., & Kordaszewski, S. (2024). Research on Alloying Elements’ Influence on CuETP-Grade Copper’s Mechanical and Electrical Properties. Materials, 17(12), 3020. https://doi.org/10.3390/ma17123020