Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion

Abstract

1. Introduction

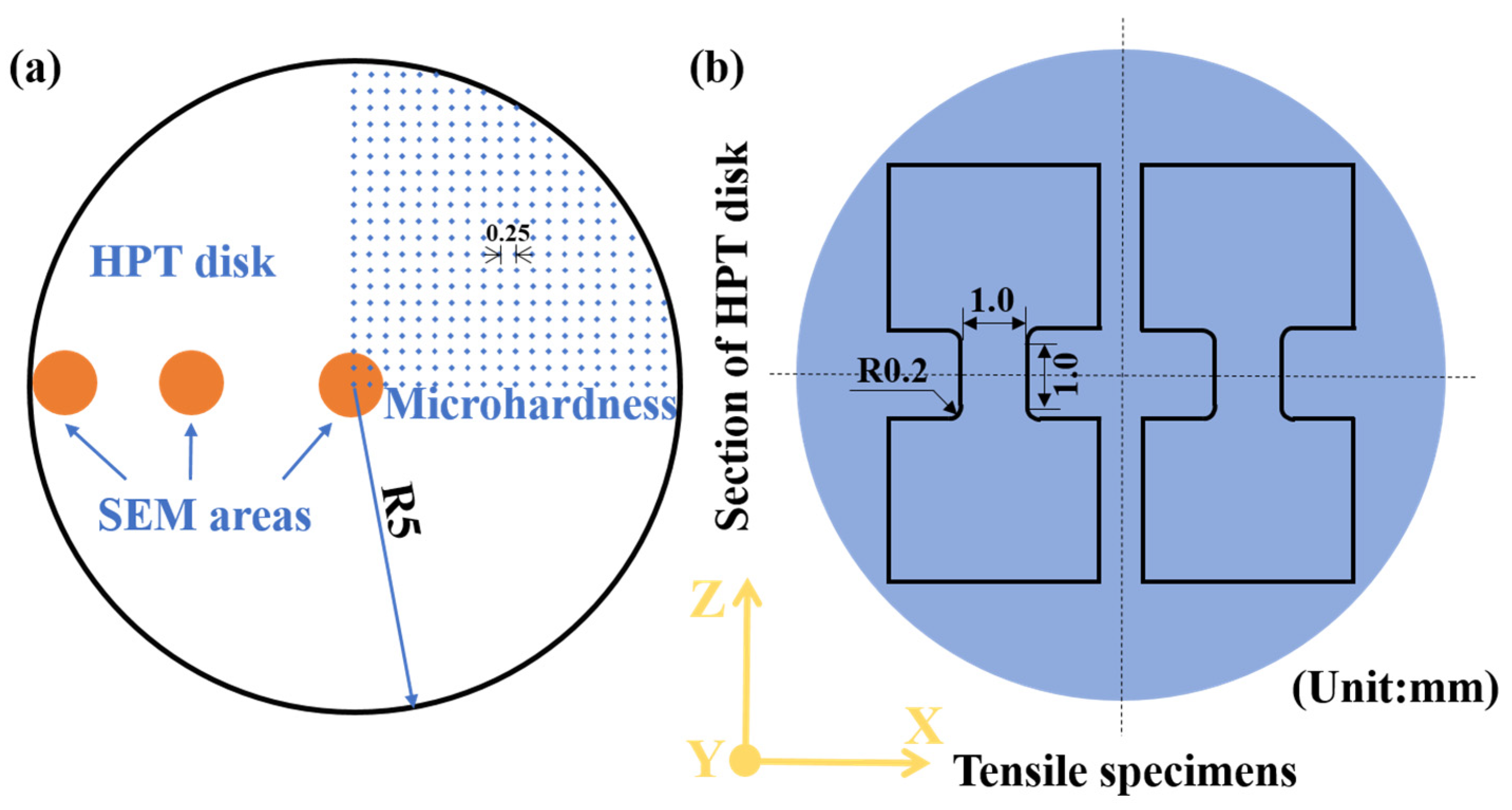

2. Materials and Methods

3. Results

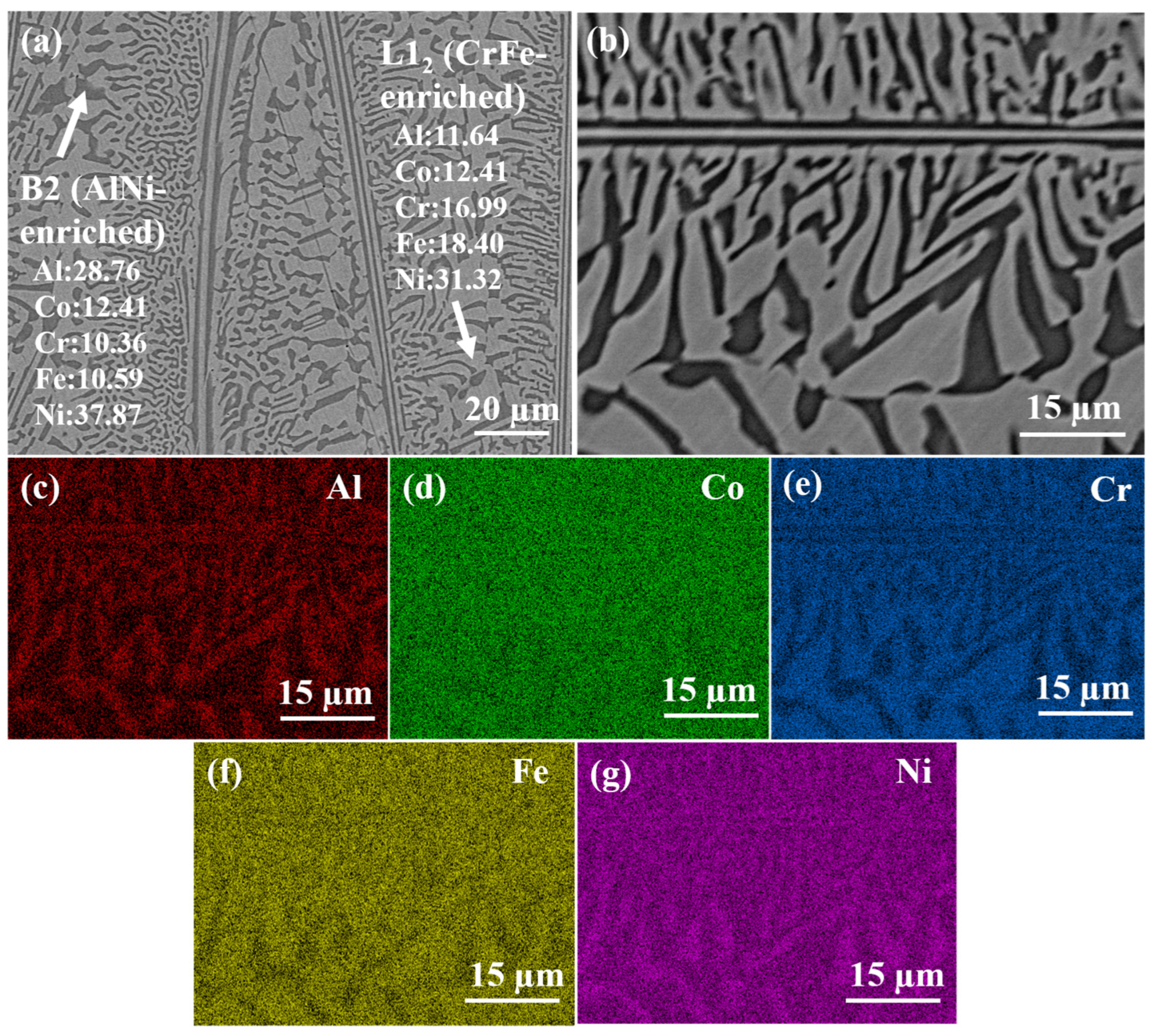

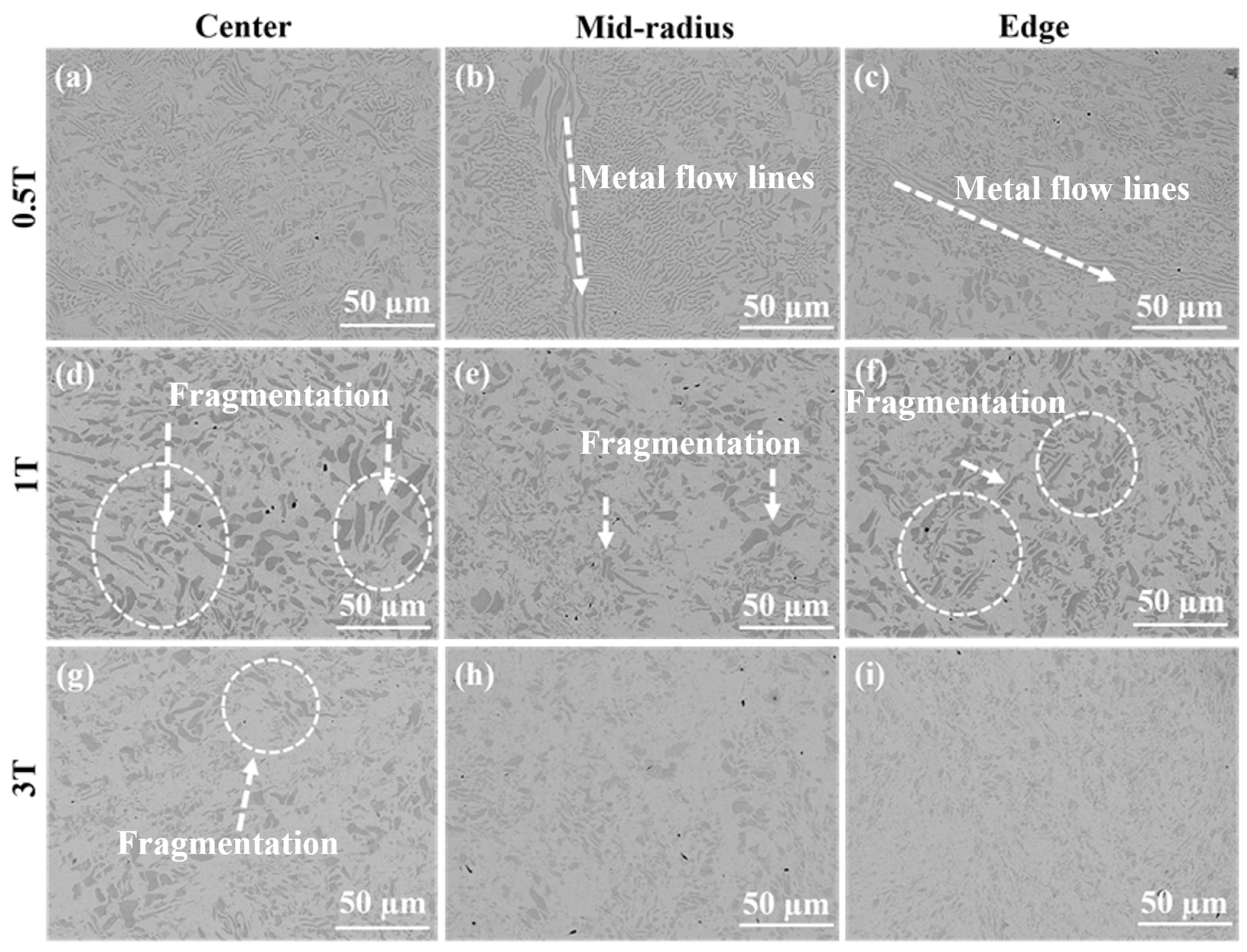

3.1. Microstructure Evolution and Phase Composition

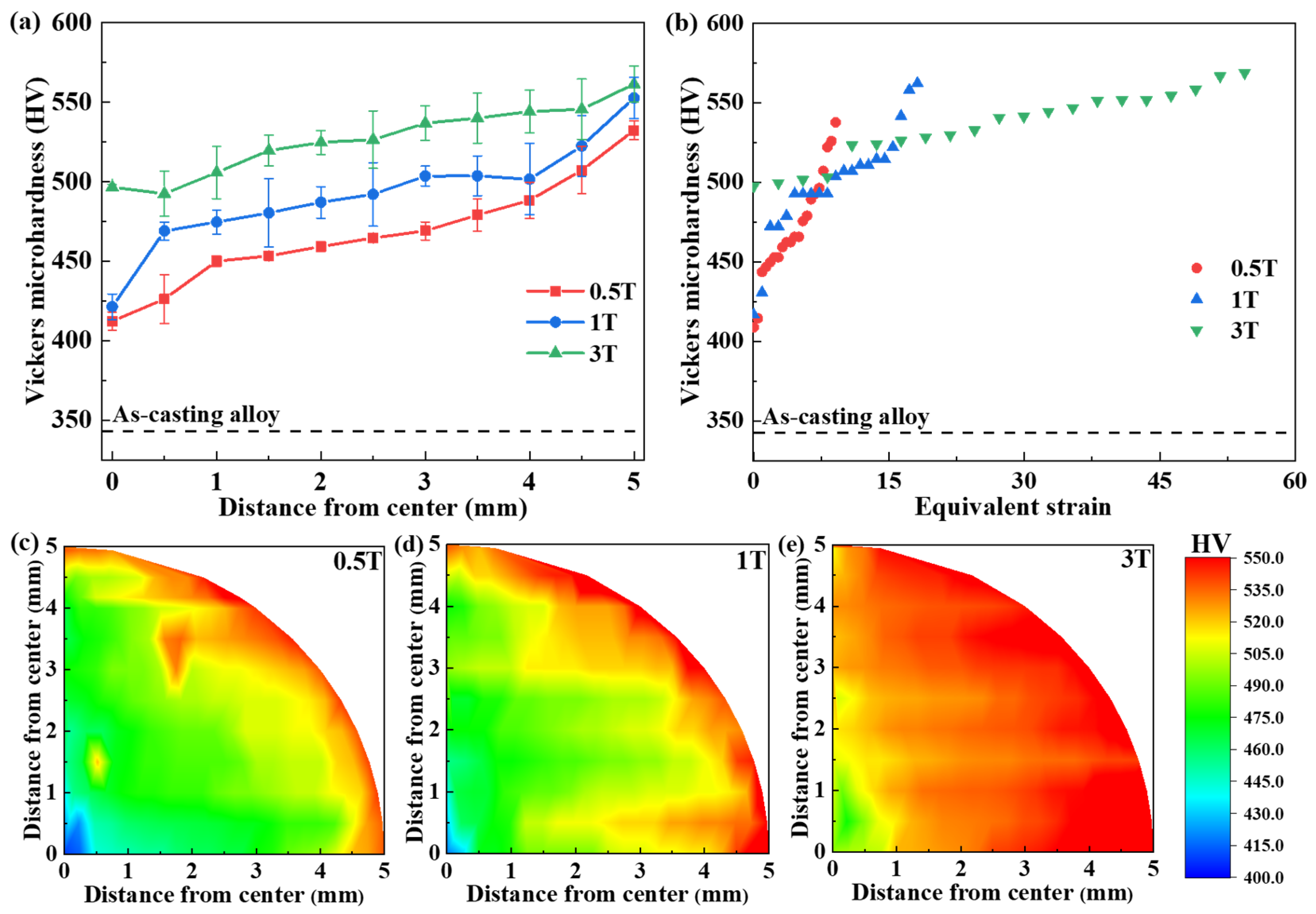

3.2. Microhardness Evolution

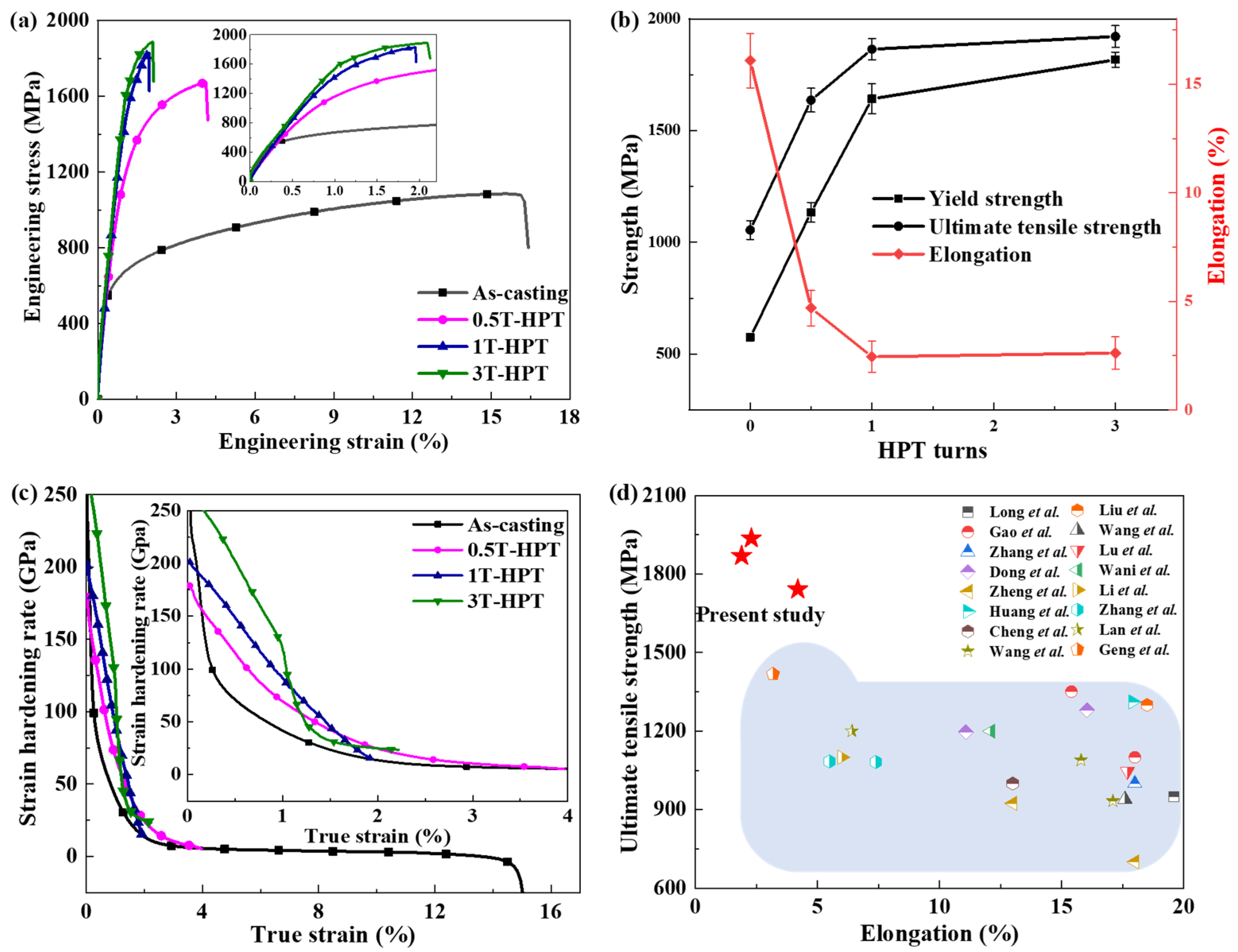

3.3. Tensile Properties

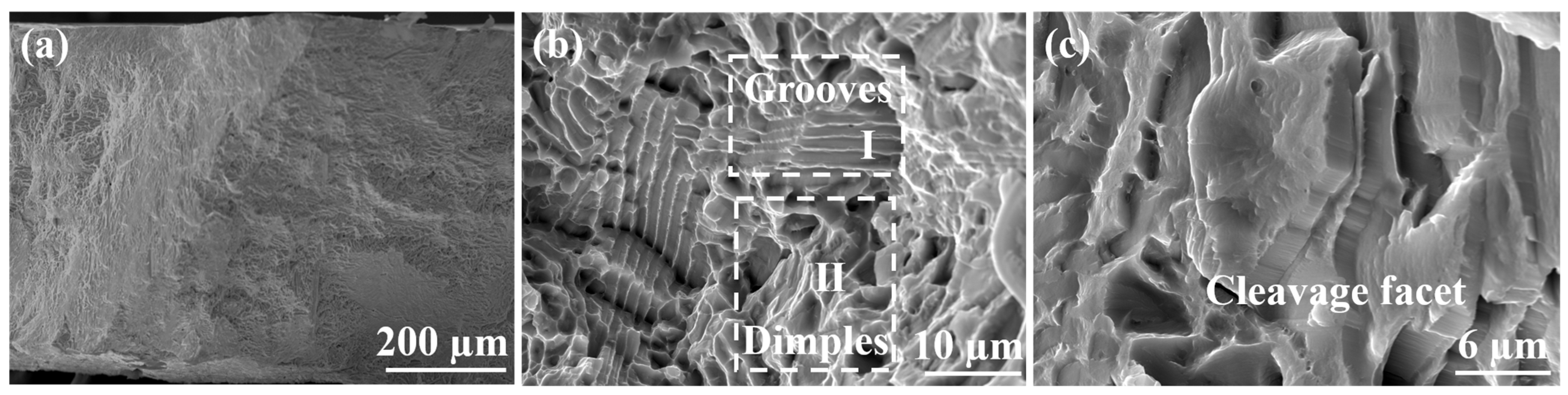

3.4. Fracture Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Jin, X.; Guo, N.; Liaw, P.K.; Qiao, J.W. Non-Equiatomic FeMnCrNiAl High-Entropy Alloys with Heterogeneous Structures for Strength and Ductility Combination. Mater. Sci. Eng. A 2021, 818, 141386. [Google Scholar] [CrossRef]

- Qi, Y.; Xu, H.; He, T.; Feng, M. Effect of Crystallographic Orientation On Mechanical Properties of Single-Crystal CoCrFeMnNi High-Entropy Alloy. Mater. Sci. Eng. A 2021, 814, 141196. [Google Scholar] [CrossRef]

- Yang, Z.; Son, S.; Ding, C.; Xu, J.; Shan, D.; Guo, B.; Kim, H.S. Effects of Current Density On the Mechanical Properties and Microstructures of CoCrFeNiMn High-Entropy Alloy. J. Mater. Res. Technol. 2024, 29, 1630–1641. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, Y.; Guo, S.; Jiang, L.; Kang, H.; Wang, T.; Wen, B.; Wang, Z.; Jie, J.; Cao, Z.; et al. A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys. Sci. Rep. 2014, 4, 6200. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Sun, Y.; Chen, N.; Luan, H.; Le, G.; Liu, X.; Ji, Y.; Lu, Y.; Liaw, P.K.; Yang, X.; et al. Simultaneously Enhanced Strength-Ductility of AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Via Additive Manufacturing. Mater. Sci. Eng. A 2022, 830, 142327. [Google Scholar] [CrossRef]

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Tailoring Nanostructures and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High Entropy Alloy Using Thermo-Mechanical Processing. Mater. Sci. Eng. A 2016, 675, 99–109. [Google Scholar] [CrossRef]

- Charkhchian, J.; Zarei-Hanzaki, A.; Moshiri, A.; Schwarz, T.M.; Lawitzki, R.; Schmitz, G.; Schell, N.; Shen, J.; Oliveira, J.P.; Waryoba, D.; et al. Unraveling the Formation of L12 Nano-Precipitates within the FCC-Phase in AlCoCrFeNi2.1 Eutectic High Entropy Alloy. Vacuum 2024, 221, 112919. [Google Scholar] [CrossRef]

- Lu, Y.; Gao, X.; Jiang, L.; Chen, Z.; Wang, T.; Jie, J.; Kang, H.; Zhang, Y.; Guo, S.; Ruan, H.; et al. Directly Cast Bulk Eutectic and Near-Eutectic High Entropy Alloys with Balanced Strength and Ductility in a Wide Temperature Range. Acta Mater. 2017, 124, 143–150. [Google Scholar] [CrossRef]

- Shi, P.; Ren, W.; Zheng, T.; Ren, Z.; Hou, X.; Peng, J.; Hu, P.; Gao, Y.; Zhong, Y.; Liaw, P.K. Enhanced Strength-Ductility Synergy in Ultrafine-Grained Eutectic High-Entropy Alloys by Inheriting Microstructural Lamellae. Nat. Commun. 2019, 10, 489. [Google Scholar] [CrossRef]

- Shi, P.; Li, R.; Li, Y.; Wen, Y.; Zhong, Y.; Ren, W.; Shen, Z.; Zheng, T.; Peng, J.; Liang, X.; et al. Hierarchical Crack Buffering Triples Ductility in Eutectic Herringbone High-Entropy Alloys. Science 2021, 373, 912–918. [Google Scholar] [CrossRef]

- He, F.; Wang, Z.; Shang, X.; Leng, C.; Li, J.; Wang, J. Stability of Lamellar Structures in CoCrFeNiNbx Eutectic High Entropy Alloys at Elevated Temperatures. Mater. Des. 2016, 104, 259–264. [Google Scholar] [CrossRef]

- Yang, Z.; Bao, J.; Ding, C.; Son, S.; Ning, Z.; Xu, J.; Shan, D.; Guo, B.; Kim, H.S. Electroplasticity in the Al0.6CoCrFeNiMn High Entropy Alloy Subjected to Electrically-Assisted Uniaxial Tension. J. Mater. Sci. Technol. 2023, 148, 209–221. [Google Scholar] [CrossRef]

- Asoushe, M.H.; Hanzaki, A.Z.; Abedi, H.R.; Mirshekari, B.; Wegener, T.; Sajadifar, S.V.; Niendorf, T. Thermal Stability, Microstructure and Texture Evolution of Thermomechanical Processed AlCoCrFeNi2.1 Eutectic High Entropy Alloy. Mater. Sci. Eng. A 2021, 799, 140012. [Google Scholar] [CrossRef]

- Wani, I.S.; Bhattacharjee, T.; Sheikh, S.; Lu, Y.P.; Chatterjee, S.; Bhattacharjee, P.P.; Guo, S.; Tsuji, N. Ultrafine-Grained AlCoCrFeNi2.1 Eutectic High- Entropy Alloy. Mater. Res. Lett. 2016, 4, 174–179. [Google Scholar] [CrossRef]

- Zheng, H.; Chen, R.; Qin, G.; Li, X.; Su, Y.; Ding, H.; Guo, J.; Fu, H. Phase Separation of AlCoCrFeNi2.1 Eutectic High-Entropy Alloy During Directional Solidification and their Effect On Tensile Properties. Intermetallics 2019, 113, 106569. [Google Scholar] [CrossRef]

- Chen, J.; Li, T.; Chen, Y.; Cao, F.; Wang, H.; Dai, L. Ultra-Strong Heavy-Drawn Eutectic High Entropy Alloy Wire. Acta Mater. 2023, 243, 118515. [Google Scholar] [CrossRef]

- Chen, X.; Kong, J.; Li, J.; Feng, S.; Li, H.; Wang, Q.; Liang, Y.; Dong, K.; Yang, Y. High-Strength AlCoCrFeNi2.1 Eutectic High Entropy Alloy with Ultrafine Lamella Structure Via Additive Manufacturing. Mater. Sci. Eng. A 2022, 854, 143816. [Google Scholar] [CrossRef]

- Wang, J.; Ke, Y.; Chen, Y.; Li, C.; Lu, T.; Liu, X.; Xu, Z.; Zhang, W.; Tang, H.; Guo, C.; et al. Microstructural Mechanisms Imparting High Strength-Ductility Synergy in Heterogeneous Structured as-Cast AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. J. Mater. Res. Technol. 2023, 27, 8119–8131. [Google Scholar] [CrossRef]

- Ma, A.; Jiang, J.; Saito, N.; Shigematsu, I.; Yuan, Y.; Yang, D.; Nishida, Y. Improving Both Strength and Ductility of a Mg Alloy through a Large Number of ECAP Passes. Mater. Sci. Eng. A 2009, 513–514, 122–127. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using High-Pressure Torsion for Metal Processing: Fundamentals and Applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Edalati, K. Superfunctional Materials by Ultra-Severe Plastic Deformation. Materials 2023, 16, 587. [Google Scholar] [CrossRef] [PubMed]

- Edalati, P.; Mohammadi, A.; Ketabchi, M.; Edalati, K. Ultrahigh Hardness in Nanostructured Dual-Phase High-Entropy Alloy AlCrFeCoNiNb Developed by High-Pressure Torsion. J. Alloys Compd. 2021, 884, 161101. [Google Scholar] [CrossRef]

- Zheng, R.; Chen, J.; Xiao, W.; Ma, C. Microstructure and Tensile Properties of Nanocrystalline (FeNiCoCu)1−XTiXAlX High Entropy Alloys Processed by High Pressure Torsion. Intermetallics 2016, 74, 38–45. [Google Scholar] [CrossRef]

- Liu, X.; Ding, H.; Huang, Y.; Bai, X.; Zhang, Q.; Zhang, H.; Langdon, T.G.; Cui, J. Evidence for a Phase Transition in an AlCrFe2Ni2 High Entropy Alloy Processed by High-Pressure Torsion. J. Alloys Compd. 2021, 867, 159063. [Google Scholar] [CrossRef]

- Duan, C.; Kostka, A.; Li, X.; Peng, Z.; Kutlesa, P.; Pippan, R.; Werner, E. Deformation-Induced Homogenization of the Multi-Phase Senary High-Entropy Alloy MoNbTaTiVZr Processed by High-Pressure Torsion. Mater. Sci. Eng. A 2023, 871, 144923. [Google Scholar] [CrossRef]

- Li, J.; Xu, J.; Wang, C.T.; Shan, D.; Guo, B.; Langdon, T.G. Microstructural Evolution and Micro-Compression in High-Purity Copper Processed by High-Pressure Torsion. Adv. Eng. Mater. 2016, 18, 241–250. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. The Significance of Strain Reversals During Processing by High-Pressure Torsion. Mater. Sci. Eng. A 2008, 498, 341–348. [Google Scholar] [CrossRef]

- Tian, Y.Z.; An, X.H.; Wu, S.D.; Zhang, Z.F.; Figueiredo, R.B.; Gao, N.; Langdon, T.G. Direct Observations of Microstructural Evolution in a Two-Phase Cu–Ag Alloy Processed by High-Pressure Torsion. Scr. Mater. 2010, 63, 65–68. [Google Scholar] [CrossRef]

- Chen, W.; Xu, J.; Liu, D.; Bao, J.; Sabbaghianrad, S.; Shan, D.; Guo, B.; Langdon, T.G. Microstructural Evolution and Microhardness Variations in Pure Titanium Processed by High-Pressure Torsion. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- Alswat, A.A.; Ahmad, M.B.; Saleh, T.A. Preparation and Characterization of Zeolite\Zinc Oxide-Copper Oxide Nanocomposite: Antibacterial Activities. Colloid Interface Sci. Commun. 2017, 16, 19–24. [Google Scholar] [CrossRef]

- Wang, L.; Yao, C.; Shen, J.; Zhang, Y.; Wang, T.; Ge, Y.; Gao, L.; Zhang, G. Microstructures and Room Temperature Tensile Properties of as-Cast and Directionally Solidified AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Intermetallics 2020, 118, 106681. [Google Scholar] [CrossRef]

- Yang, J.; Wang, G.; Park, J.M.; Kim, H.S. Microstructural Behavior and Mechanical Properties of Nanocrystalline Ti-22Al-25Nb Alloy Processed by High-Pressure Torsion. Mater. Charact. 2019, 151, 129–136. [Google Scholar] [CrossRef]

- Xue, K.; Luo, Z.; Xia, S.; Dong, J.; Li, P. Study of Microstructural Evolution, Mechanical Properties and Plastic Deformation Behavior of Mg-Gd-Y-Zn-Zr Alloy Prepared by High-Pressure Torsion. Mater. Sci. Eng. A 2024, 891, 145953. [Google Scholar] [CrossRef]

- Ikoma, Y. Severe Plastic Deformation of Semiconductor Materials Using High-Pressure Torsion. Mater. Trans. 2019, 7, 1168–1176. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, H.; Huang, H.; Yang, L.; Hu, Y.; Liang, X.; Hua, M.; Zhang, J. Strengthening Mechanism of Cocrnimox High Entropy Alloys by High-Throughput Nanoindentation Mapping Technique. Intermetallics 2021, 135, 107209. [Google Scholar] [CrossRef]

- Fatay, D.; Bastarash, E.; Nyilas, K.; Dobatkin, S.; Gubicza, J.; Ungr, T. X-ray Diffraction Study On the Microstructure of an Al—Mg—Sc—Zr Alloy Deformed by High-Pressure Torsion. Int. J. Mater. Res. 2003, 29, 842–847. [Google Scholar] [CrossRef]

- Sun, W.T.; Xu, C.; Qiao, X.G.; Zheng, M.Y.; Kamado, S.; Gao, N.; Starink, M.J. Evolution of Microstructure and Mechanical Properties of an as-Cast Mg-8.2Gd-3.8Y-1.0Zn-0.4Zr Alloy Processed by High Pressure Torsion. Mater. Sci. Eng. A 2017, 700, 312–320. [Google Scholar] [CrossRef]

- Fleck, N.A.; Muller, G.M.; Ashby, M.F.; Hutchinson, J.W. Strain Gradient Plasticity: Theory and Experiment. Acta Metall. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Kawasaki, M. Different Models of Hardness Evolution in Ultrafine-Grained Materials Processed by High-Pressure Torsion. J. Mater. Sci. 2014, 49, 18–34. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Cetlin, P.R.; Langdon, T.G. Using Finite Element Modeling to Examine the Flow Processes in Quasi-Constrained High-Pressure Torsion. Mater. Sci. Eng. A 2011, 528, 8198–8204. [Google Scholar] [CrossRef]

- Masuda, T.; Tang, Y.; Mohamed, I.F.; Horita, Z. Ultrafine-Grained AZ61 Alloy Produced by High-Pressure Torsion: Advent of Superplasticity and Effect of Anisotropy. Mater. Sci. Eng. A 2023, 879, 145240. [Google Scholar] [CrossRef]

- Shkodich, N.; Staab, F.; Spasova, M.; Kuskov, K.V.; Durst, K.; Farle, M. Effect of High-Pressure Torsion On the Microstructure and Magnetic Properties of Nanocrystalline CoCrFeNiGa(X) (X = 0.5, 1.0) High Entropy Alloys. Materials 2022, 15, 7214. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, H.; Yuasa, M.; Miyamoto, H.; Edalati, K. Corrosion Behavior of Ultrafine-Grained CoCrFeMnNi High-Entropy Alloys Fabricated by High-Pressure Torsion. Materials 2022, 15, 1007. [Google Scholar] [CrossRef] [PubMed]

- Valiev, R.Z.; Enikeev, N.A.; Murashkin, M.Y.; Kazykhanov, V.U.; Sauvage, X. On the Origin of the Extremely High Strength of Ultrafine-Grained Al Alloys Produced by Severe Plastic Deformation. Scr. Mater. 2010, 63, 949–952. [Google Scholar] [CrossRef]

- Krasilnikov, N.; Lojkowski, W.; Pakiela, Z.; Valiev, R. Tensile Strength and Ductility of Ultra-Fine-Grained Nickel Processed by Severe Plastic Deformation. Mater. Sci. Eng. A 2005, 397, 330–337. [Google Scholar] [CrossRef]

- Lugo, N.; Llorca, N.; Cabrera, J.M.; Horita, Z. Microstructures and Mechanical Properties of Pure Copper Deformed Severely by Equal-Channel Angular Pressing and High-Pressure Torsion. Mater. Sci. Eng. A 2008, 477, 366–371. [Google Scholar] [CrossRef]

- Schuh, B.; Völker, B.; Todt, J.; Kormout, K.S.; Schell, N.; Hohenwarter, A. Influence of Annealing On Microstructure and Mechanical Properties of a Nanocrystalline CrCoNi Medium-Entropy Alloy. Materials 2018, 11, 662. [Google Scholar] [CrossRef]

- Asghari-Rad, P.; Sathiyamoorthi, P.; Bae, J.W.; Shahmir, H.; Zargaran, A.; Kim, H.S. Effect of Initial Grain Size On Deformation Mechanism During High-Pressure Torsion in V10Cr15Mn5Fe35Co10Ni25 High-Entropy Alloy. Adv. Eng. Mater. 2020, 22, 1900587. [Google Scholar] [CrossRef]

- Asghari-Rad, P.; Sathiyamoorthi, P.; Thi-Cam Nguyen, N.; Bae, J.W.; Shahmir, H.; Kim, H.S. Fine-Tuning of Mechanical Properties in V10Cr15Mn5Fe35Co10Ni25 High-Entropy Alloy through High-Pressure Torsion and Annealing. Mater. Sci. Eng. A 2020, 771, 138604. [Google Scholar] [CrossRef]

- Son, S.; Asghari-Rad, P.; Zargaran, A.; Chen, W.; Kim, H.S. Superlative Room Temperature and Cryogenic Tensile Properties of Nanostructured CoCrFeNi Medium-Entropy Alloy Fabricated by Powder High-Pressure Torsion. Scr. Mater. 2022, 213, 114631. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Alexandrov, I.V.; Zhu, Y.T.; Lowe, T.C. Paradox of Strength and Ductility in Metals Processed by Severe Plastic Deformation. J. Mater. Res. 2002, 17, 5–8. [Google Scholar] [CrossRef]

- Kumar, P.; Kawasaki, M.; Langdon, T.G. Review: Overcoming the Paradox of Strength and Ductility in Ultrafine-Grained Materials at Low Temperatures. J. Mater. Sci. 2016, 51, 7–18. [Google Scholar] [CrossRef]

- Kim, H.; Ha, H.; Lee, J.; Son, S.; Kim, H.S.; Sung, H.; Seol, J.B.; Kim, J.G. Outstanding Mechanical Properties of Ultrafine-Grained Al7075 Alloys by High-Pressure Torsion. Mater. Sci. Eng. A 2021, 810, 141020. [Google Scholar] [CrossRef]

- Torbati Sarraf, S.A.; Sabbaghianrad, S.; Langdon, T.G. Using Post-Deformation Annealing to Optimize the Properties of a ZK60 Magnesium Alloy Processed by High-Pressure Torsion. Adv. Eng. Mater. 2018, 20, 1700703. [Google Scholar] [CrossRef]

- Shahmir, H.; Nili-Ahmadabadi, M.; Mohammadi, M.; Huang, Y.; Andrzejczuk, M.; Lewandowska, M.; Langdon, T.G. Effect of Cu On Amorphization of a TiNi Alloy During HPT and Shape Memory Effect After Post-Deformation Annealing. Adv. Eng. Mater. 2020, 22. [Google Scholar] [CrossRef]

- Long, X.; Li, Z.; Yan, J.; Zhang, T. Enhanced Strength-Ductility Synergy of an AlCoCrFeNi2.1 Eutectic High Entropy Alloy by Ultrasonic Vibration. J. Mater. Res. Technol. 2023, 27, 4633–4643. [Google Scholar] [CrossRef]

- Gao, X.; Lu, Y.; Zhang, B.; Liang, N.; Wu, G.; Sha, G.; Liu, J.; Zhao, Y. Microstructural Origins of High Strength and High Ductility in an AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Acta Mater. 2017, 141, 59–66. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Wang, X.; Lu, Y.; Zhou, Y.; Sun, X. The Interaction and Migration of Deformation Twin in an Eutectic High-Entropy Alloy AlCoCrFeNi2.1. J. Mater. Sci. Technol. 2019, 35, 902–906. [Google Scholar] [CrossRef]

- Dong, J.; Wu, H.; Chen, Y.; Li, P.; Zhang, F.; Wu, Y.; Hua, K.; Wang, H. Revealing the Nano-Grained Microstructure and Mechanical Properties of Electrochemical Boronized AlCoCrFeNi2.1 Eutectic High Entropy Alloy. J. Alloys Compd. 2023, 938, 168515. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, Y.; Xu, X.D.; Wu, D.; Guo, S.; Nieh, T.G.; Chen, J.H. Mechanistic Origin of Abnormal Annealing-Induced Hardening in an AlCoCrFeNi2.1 Eutectic Multi-Principal-Element Alloy. Acta Mater. 2023, 252, 118905. [Google Scholar] [CrossRef]

- Liu, Z.; Xiong, Z.; Chen, K.; Cheng, X. Large-Size High-Strength and High-Ductility AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Produced by Hot-Rolling and Subsequent Aging. Mater. Lett. 2022, 315, 131933. [Google Scholar] [CrossRef]

- Li, Y.; Shi, P.; Wang, M.; Yang, Y.; Wang, Y.; Li, Y.; Wen, Y.; Ren, W.; Min, N.; Chen, Y.; et al. Unveiling Microstructural Origins of the Balanced Strength-Ductility Combination in Eutectic High-Entropy Alloys at Cryogenic Temperatures. Mater. Res. Lett. 2022, 10, 602–610. [Google Scholar] [CrossRef]

- Zhang, X.; Li, B.; Zeng, L.; Yi, J.; Wang, B.; Hu, C.; Xia, M. Effect of Re Addition On the Microstructure and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloy. Intermetallics 2023, 154, 107808. [Google Scholar] [CrossRef]

- Lan, L.; Zhang, H.; Yang, Z.; Li, C.; Hao, X.; Wang, W.; Cui, Z. Significant Transitions of Microstructure and Mechanical Properties in Laser Additive Manufacturing AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Under Heat Treatment. J. Mater. Res. Technol. 2023, 25, 6250–6262. [Google Scholar] [CrossRef]

- Geng, Z.; Chen, C.; Li, R.; Luo, J.; Zhou, K. Composition Inhomogeneity Reduces Cracking Susceptibility in Additively Manufactured AlCoCrFeNi2.1 Eutectic High-Entropy Alloy Produced by Laser Powder Bed Fusion. Addit. Manuf. 2022, 56, 102941. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, Y.; Ding, N.; Liu, L.; Xu, H.; Xu, N.; Tian, L.; Liu, G.; Dong, D.; Wang, X. Understanding the Microstructure Evolution Characteristics and Mechanical Properties of an AlCoCrFeNi2.1 High Entropy Alloy Fabricated by Laser Energy Deposition. Mater. Sci. Eng. A 2023, 869, 144795. [Google Scholar] [CrossRef]

- He, L.; Wu, S.; Dong, A.; Tang, H.; Du, D.; Zhu, G.; Sun, B.; Yan, W. Selective Laser Melting of Dense and Crack-Free AlCoCrFeNi2.1 Eutectic High Entropy Alloy: Synergizing Strength and Ductility. J. Mater. Sci. Technol. 2022, 117, 133–145. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, H.; Zhu, Z.; Xue, P.; Wu, L.; Liu, F.; Ni, D.; Xiao, B.; Ma, Z. Dual-Phase Synergistic Deformation Characteristics and Strengthening Mechanism of AlCoCrFeNi2.1 Eutectic High Entropy Alloy Fabricated by Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2023, 150, 75–85. [Google Scholar] [CrossRef]

- Chen, X.; Xie, W.; Zhu, J.; Wang, Z.; Wang, Y.; Ma, Y.; Yang, M.; Jiang, W.; Yu, H.; Wu, Y.; et al. Influences of Ti Additions On the Microstructure and Tensile Properties of AlCoCrFeNi2.1 Eutectic High Entropy Alloy. Intermetallics 2021, 128, 107024. [Google Scholar] [CrossRef]

- Mohammadi, A.; Edalati, P.; Arita, M.; Bae, J.W.; Kim, H.S.; Edalati, K. Microstructure and Defect Effects On Strength and Hydrogen Embrittlement of High-Entropy Alloy CrMnFeCoNi Processed by High-Pressure Torsion. Mater. Sci. Eng. A 2022, 844, 143179. [Google Scholar] [CrossRef]

- Wei, Q.; Zhang, H.; Schuster, B.; Ramesh, K.; Valiev, R.; Kecskes, L.; Dowding, R.; Magness, L.; Cho, K. Microstructure and Mechanical Properties of Super-Strong Nanocrystalline Tungsten Processed by High-Pressure Torsion. Acta Mater. 2006, 54, 4079–4089. [Google Scholar] [CrossRef]

- Watanabe, H.; Kunimine, T.; Watanabe, C.; Monzen, R.; Todaka, Y. Tensile Deformation Characteristics of a Cu−Ni−Si Alloy Containing Trace Elements Processed by High-Pressure Torsion with Subsequent Aging. Mater. Sci. Eng. A 2018, 730, 10–15. [Google Scholar] [CrossRef]

- Gaikwad, S.D.; Ajay, P.; Dabhade, V.V.; Murty, S.V.S.N.; Manwatkar, S.; Prakash, U. Mechanical Properties and Microstructural Analysis of Ultra-Fine Grained Ni-Based ODS Alloy Processed by Powder Forging. J. Alloys Compd. 2024, 970, 172614. [Google Scholar] [CrossRef]

| Element | Al | Co | Cr | Fe | Ni |

|---|---|---|---|---|---|

| at.% | 16.39 | 16.39 | 16.39 | 16.39 | 34.43 |

| wt.% | 8.45 | 19.41 | 16.27 | 18.04 | 37.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Ding, C.; Yang, Z.; Zhang, H.; Ding, Z.; Li, H.; Xu, J.; Shan, D.; Guo, B. Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion. Materials 2024, 17, 2954. https://doi.org/10.3390/ma17122954

Wang F, Ding C, Yang Z, Zhang H, Ding Z, Li H, Xu J, Shan D, Guo B. Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion. Materials. 2024; 17(12):2954. https://doi.org/10.3390/ma17122954

Chicago/Turabian StyleWang, Fanghui, Chaogang Ding, Zhiqin Yang, Hao Zhang, Ziheng Ding, Hushan Li, Jie Xu, Debin Shan, and Bin Guo. 2024. "Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion" Materials 17, no. 12: 2954. https://doi.org/10.3390/ma17122954

APA StyleWang, F., Ding, C., Yang, Z., Zhang, H., Ding, Z., Li, H., Xu, J., Shan, D., & Guo, B. (2024). Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion. Materials, 17(12), 2954. https://doi.org/10.3390/ma17122954