Improving the Mechanical Properties of Hot Rolled Low-Carbon Copper-Containing Steel by Adjusting Quenching Roll Speed

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties

3.2. Microstructure Characterization

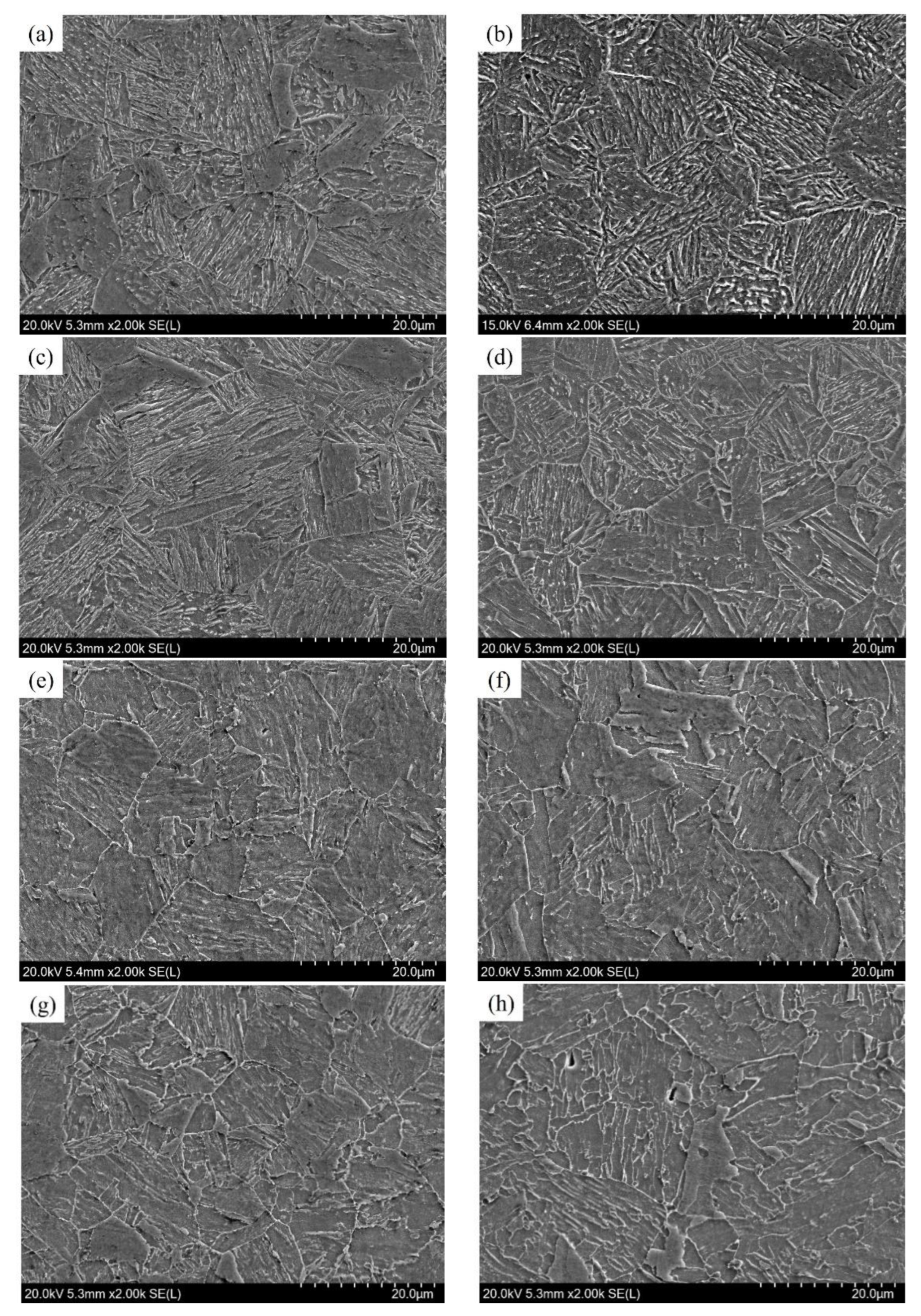

3.2.1. Prior Austenite Grain Boundaries

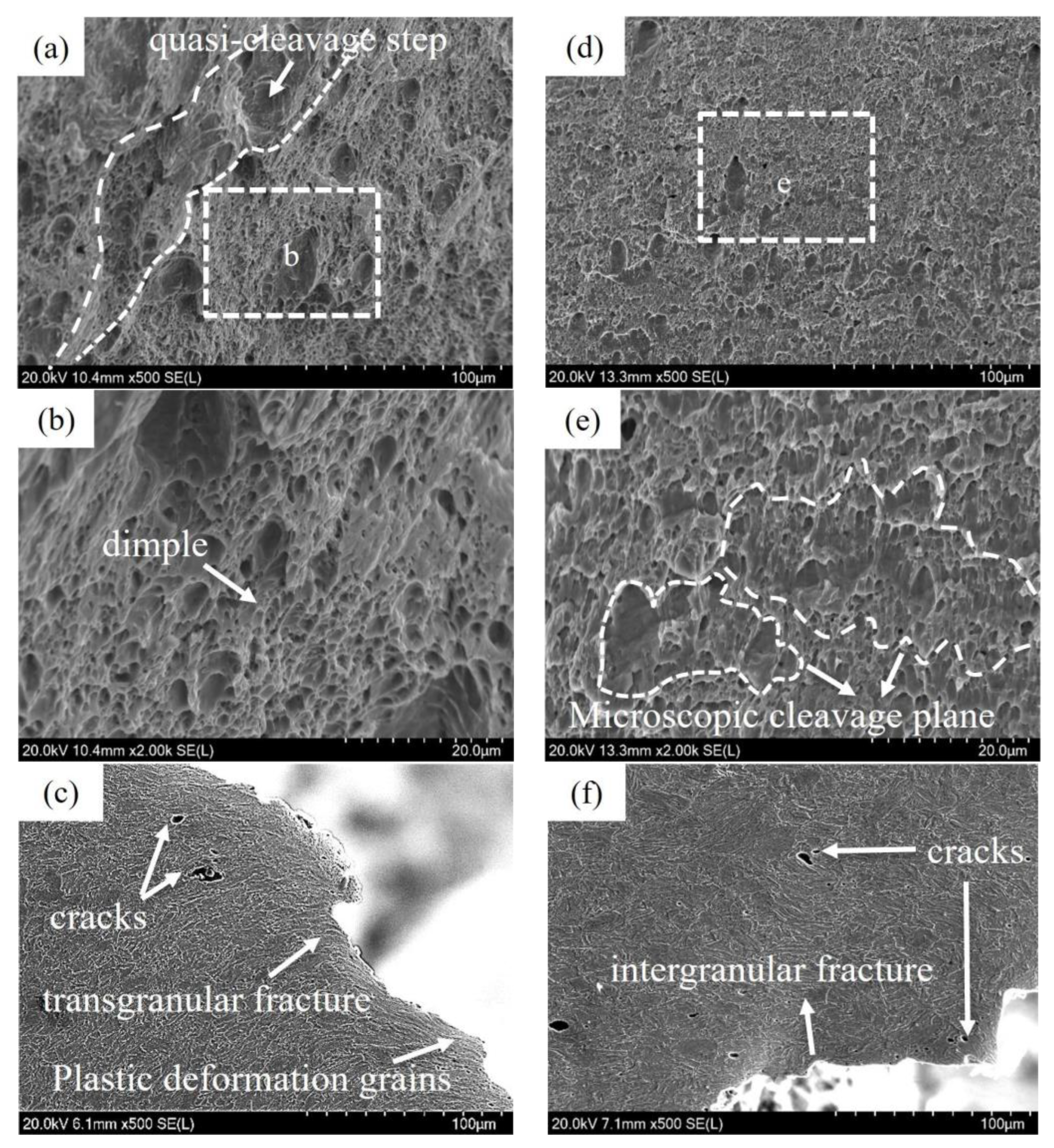

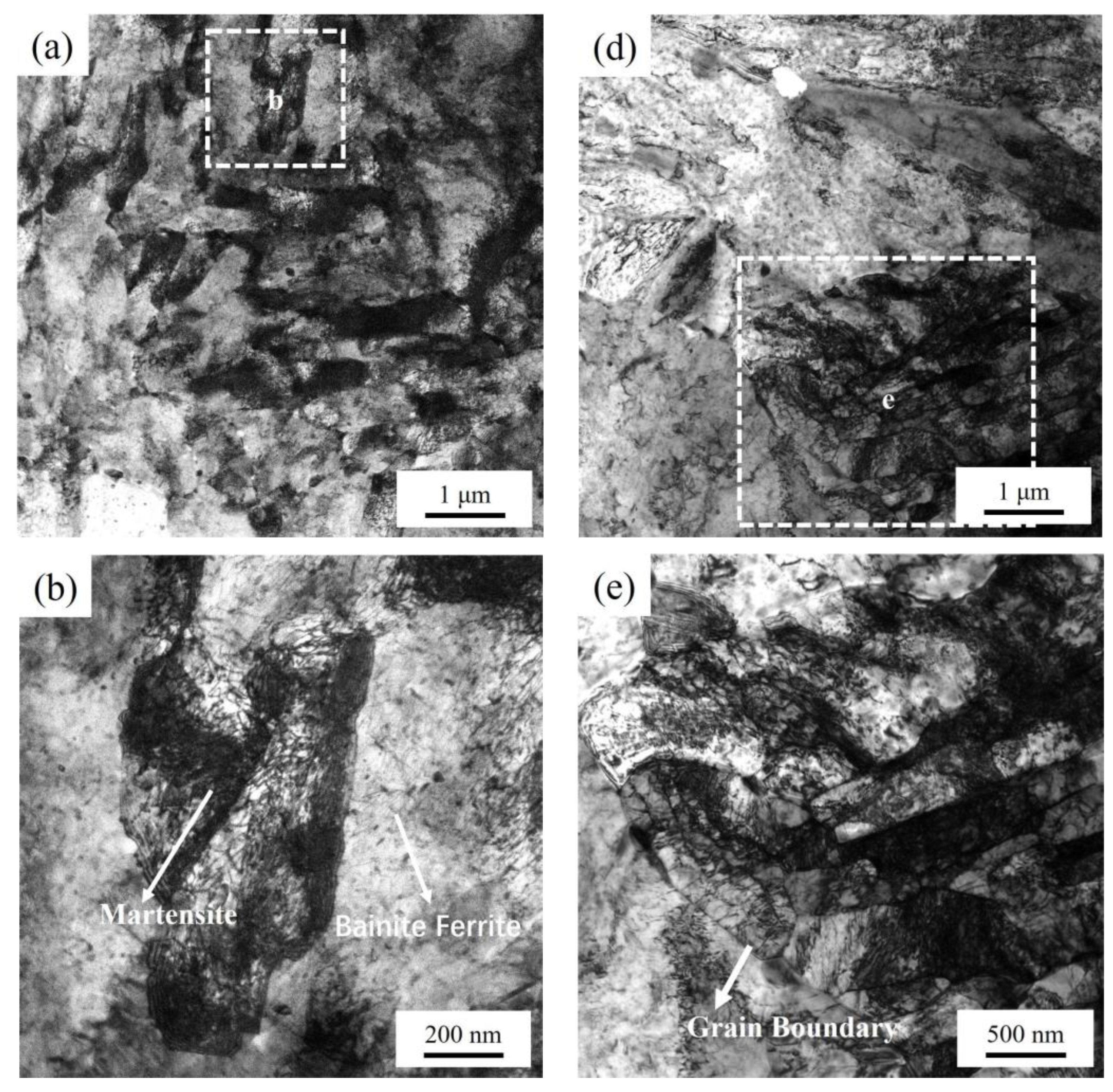

3.2.2. Microstructure Examinations via SEM and TEM

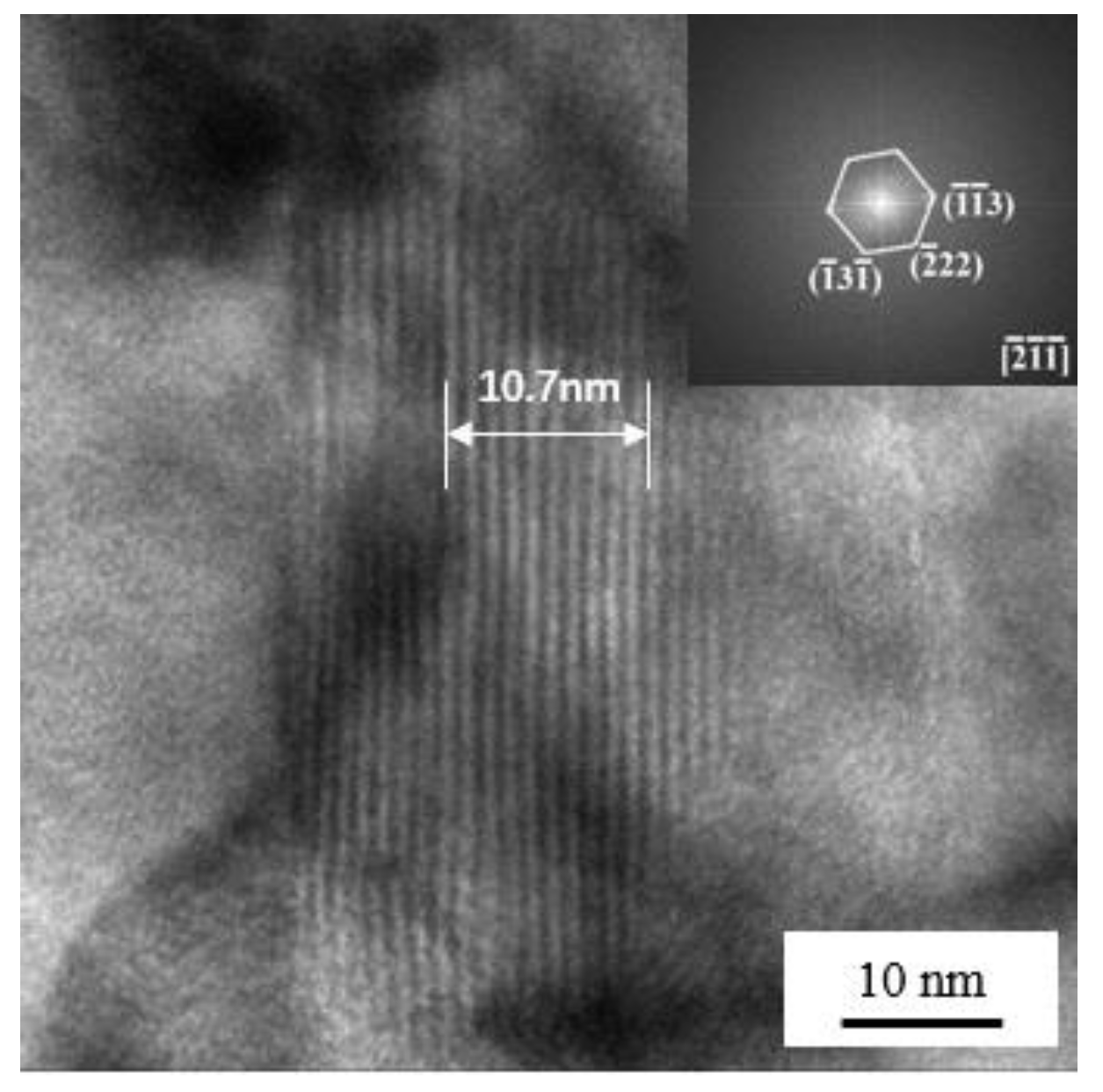

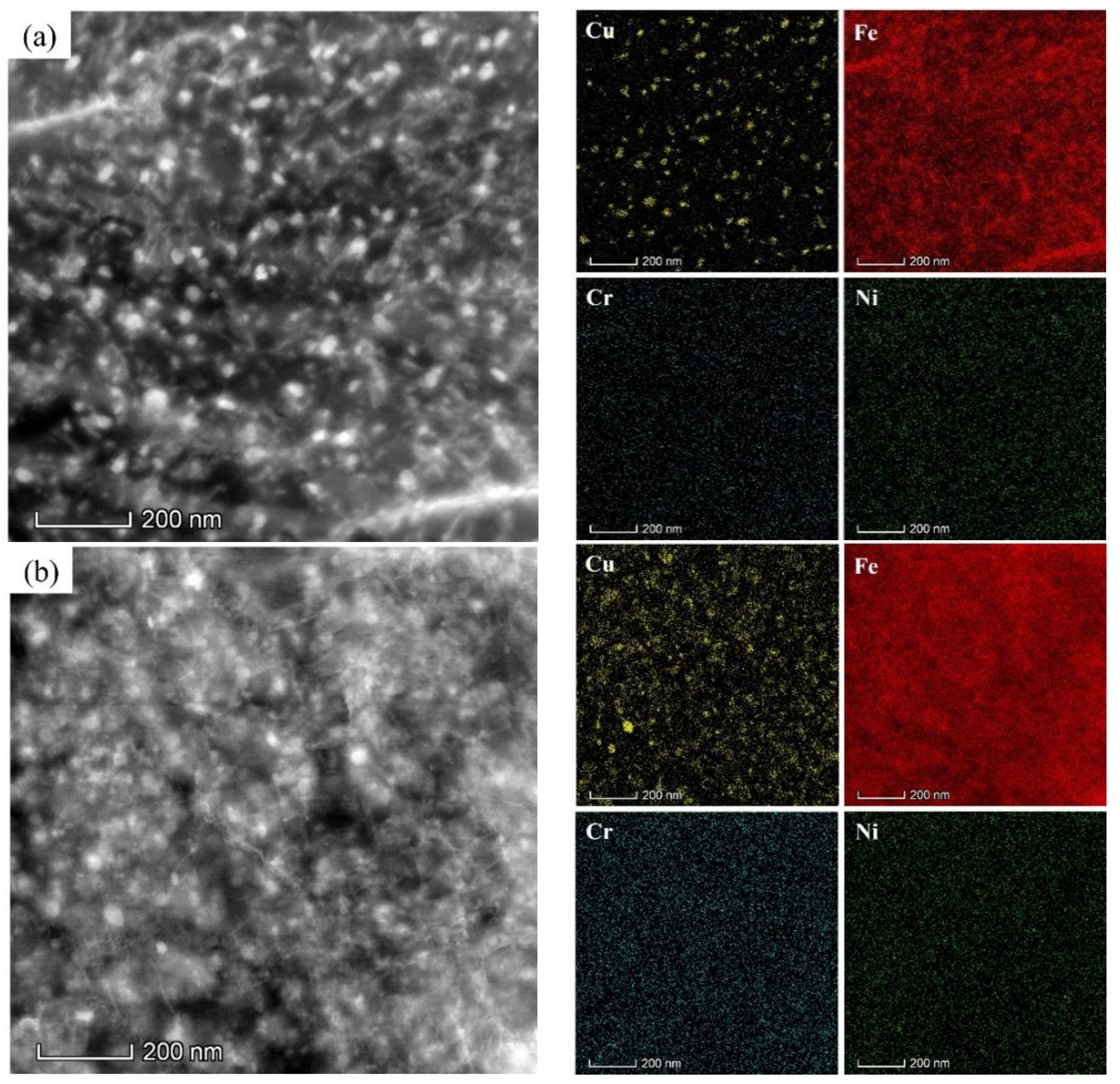

3.2.3. Precipitates and Their Distribution in As-Tempered Specimens

4. Conclusions

- (1)

- Reducing the roller speed leads to an increase in the prior austenite grain size, while enhancing the hardenability depth along the thickness direction of the rolled sheet forms a larger volume fraction of martensite. The rolled sheet prepared at lower quenching roller speed has a higher hardness value and excellent toughness at low temperature.

- (2)

- The tempered martensite is the dominant characteristic of the microstructure of as-tempered steels. Significant quantities of Cu-rich particles are observed to precipitate during the tempering treatment, regardless of the quenching roller speed. TEM analysis confirms that the particles rich in Cu have a typical 9R structure.

- (3)

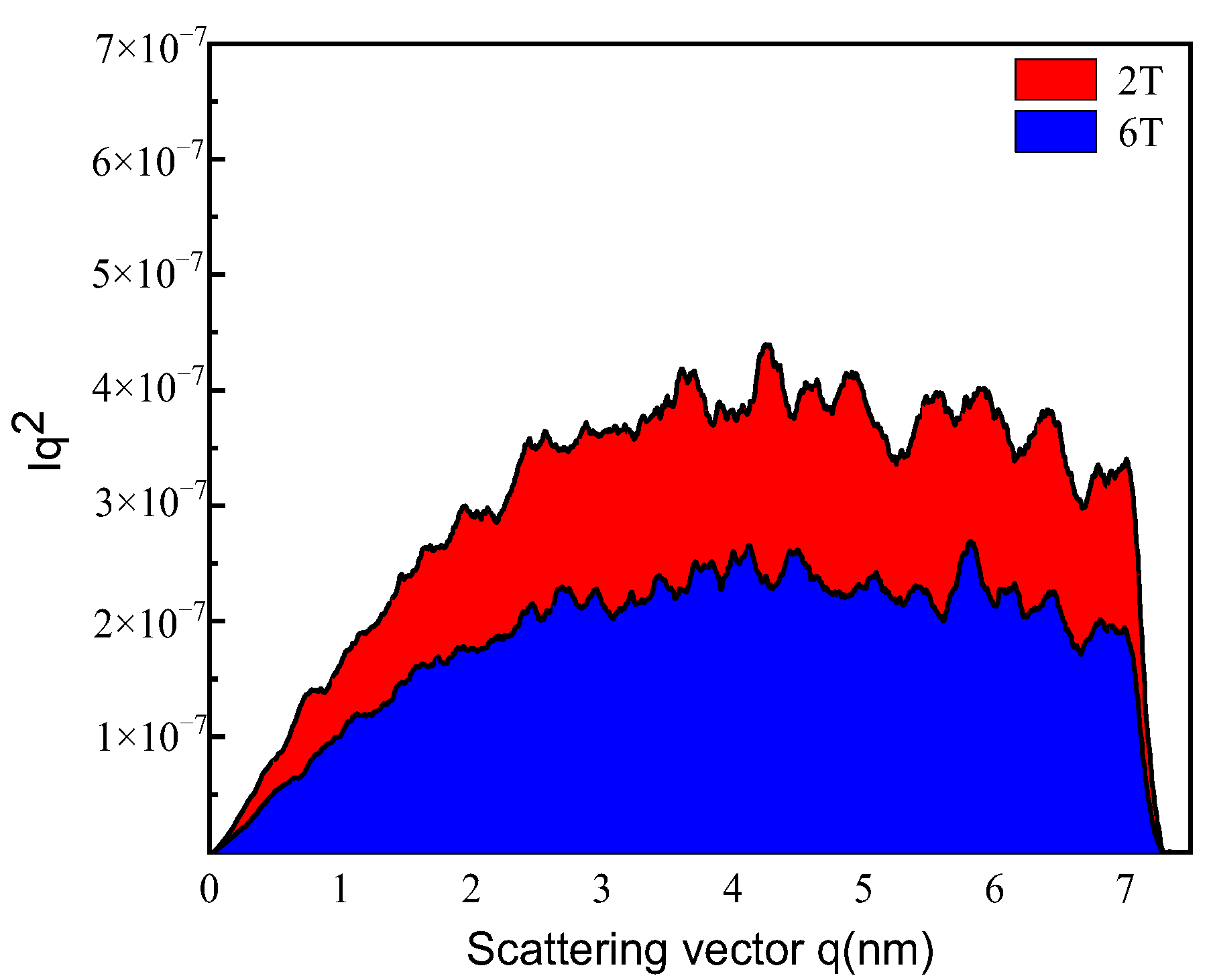

- In comparison to the steel produced under a quenching roller speed of 6 m/min, the steel prepared at 2 m/min exhibits a higher density of dislocations and Cu-rich particles. The estimated volume fraction of Cu-rich particles based on SAXS data is approximately 0.63% for sample 2T and 0.38% for sample 6T. The primary factor contributing to the achievement of excellent low-temperature toughness is the precipitation of a higher volume fraction of Cu-rich particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.; Ke, J.; Xu, Y.; Pang, H.; Jin, X. Study of the impact properties and microstructure evolution in a high-strength low-alloy heavy steel. Mater. Sci. Eng. A 2021, 819, 141404. [Google Scholar] [CrossRef]

- Sun, X.J.; Yuan, S.F.; Xie, Z.J.; Dong, L.L.; Shang, C.J.; Misra, R.D.K. Microstructure-property relationship in a high strength-high toughness combination ultra-heavy gauge offshore plate steel: The significance of multiphase microstructure. Mater. Sci. Eng. A 2017, 689, 212–219. [Google Scholar] [CrossRef]

- Hu, J.; Du, L.X.; Xie, H.; Gao, X.H.; Misra, R.D.K. Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater. Sci. Eng. A 2014, 607, 122–131. [Google Scholar] [CrossRef]

- Zhang, D.; Chai, F.; Luo, X.; Shi, Z. Effect of Reheating Temperature on the Microstructure and Properties of Cu-Containing 440 MPa Grade Non-Tempered Ship Plate Steel. Materials 2024, 17, 1630. [Google Scholar] [CrossRef] [PubMed]

- Pallaspuro, S.; Kaijalainen, A.; Mehtonen, S.; Kömi, J.; Zhang, Z.; Porter, D. Effect of microstructure on the impact toughness transition temperature of direct-quenched steels. Mater. Sci. Eng. A. 2018, 712, 671–680. [Google Scholar] [CrossRef]

- Liu, D.S.; Cheng, B.G.; Chen, Y.Y. Strengthening and toughening of a heavy plate steel for shipbuilding with yield strength of approximately 690 MPa. Metall. Mater. Trans. A 2013, 44A, 440–455. [Google Scholar] [CrossRef]

- Wang, Q.; Ye, Q.; Wang, Z.; Kan, L.; Wang, H. Thickness effect on microstructure, strength, and toughness of a quenched and tempered 178 mm thickness steel plate. Metals 2020, 10, 572. [Google Scholar] [CrossRef]

- Zhou, T.; Yu, H.; Wang, S.Y. Effect of microstructural types on toughness and microstructural optimization of ultra-heavy steel plate: EBSD analysis and microscopic fracture mechanism. Mater. Sci. Eng. A 2016, 658, 150–158. [Google Scholar] [CrossRef]

- Vaikar, S.J.; Narayanan, V.; George, J.C.; Kanish, T.C.; Ramkumar, K.D. Effect of weld microstructure on the tensile properties and impact toughness of the naval, marine-grade steel weld joints. Mater. Res. Technol. 2022, 19, 3724–3737. [Google Scholar] [CrossRef]

- Fu, T.L.; Wang, Z.D.; Li, Y.; Li, J.D.; Wang, G.D. The influential factor studies on the cooling rate of roller quenching for ultra heavy plate. Appl. Therm. Eng. 2014, 70, 800–807. [Google Scholar] [CrossRef][Green Version]

- Bian, S.-Y.; Zhang, X.; Li, S.-L.; Zhang, L.; Li, W.-J.; Yan, L. Numerical simulation, microstructure, properties of EH40 ultra-heavy plate under gradient temperature rolling. Mater. Sci. Eng. A 2020, 791, 139778. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Zhang, Z.W.; Miller, M.K.; Ma, W.B.; Liu, C.T. Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels. Acta Mater. 2013, 61, 5996–6005. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Liu, C.T. Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles. Acta Mater. 2015, 97, 58–67. [Google Scholar] [CrossRef]

- Kong, H.J.; Xu, C.; Bu, C.C.; Da, C.; Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions. Acta Mater. 2019, 172, 150–160. [Google Scholar] [CrossRef]

- Xie, B.S.; Cai, Q.W.; Yun, Y.; Li, G.S.; Ning, Z. Development of high strength ultra-heavy plate processed with gradient temperature rolling, intercritical quenching and tempering. Mater. Sci. Eng. A 2017, 680, 454–468. [Google Scholar] [CrossRef]

- Lesoult, G. Macrosegregation in steel strands and ingots: Characterisation, formation and consequences. Mater. Sci. Eng. A 2005, 413–414, 19–29. [Google Scholar] [CrossRef]

- Pickering, E.J.; Bhadeshia, H.K.D.H. Macrosegregation and microstructural evolution in a pressure-vessel steel. Metall. Mater. Trans. A 2014, 45A, 2983–2997. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S.; Xi, X.; Wang, G.; Chen, L. The role of copper in microstructure and toughness of intercritically reheated coarse grained heat affected zone in a high strength low alloy steel. Mater. Charact. 2021, 181, 111511. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Bandyopadhyay, P.S.; Kundu, S.; Chatterjee, S. Copper bearing microalloyed ultrahigh strength steel on a pilot scale: Microstructure and properties. Mater. Sci. Eng. A 2011, 528, 7887–7894. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, X.H.; Wu, X.X.; Liu, S.C.; Zhang, Y.; Chen, L.; Xu, S.S.; Liang, X.; Li, X.Z.; Zhang, Z.W. Microstructure and mechanical properties of a Cu/NiAl nanoprecipitate strengthened dual-phase steel. Mater. Charact. 2023, 196, 112594. [Google Scholar] [CrossRef]

- Far, A.R.H.; Anijdana, S.H.M.; Abbasi, S.M. The effect of increasing Cu and Ni on a significant enhancement of mechanical properties of high strength low alloy, low carbon steels of HSLA-100 type. Mater. Sci. Eng. A 2019, 746, 384–393. [Google Scholar] [CrossRef]

- Thompson, S.W. Interrelationships between yield strength, low-temperature impact toughness, and microstructure in low-carbon, copper-precipitation strengthened, high-strength low-alloy plate steels. Mater. Sci. Eng. A 2018, 711, 424–433. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, W.; Yang, Y.; Xing, J.; Dong, B.; Zhao, Y.; Fan, Y.; Li, X. Heat treatment simulation investigation on the mechanical performance of the inter-critical heated affected zone (ICHAZ) in ship plate steel weld joint. Appl. Ocean Res. 2020, 101, 102237. [Google Scholar] [CrossRef]

- Li, H.; Ma, T.; He, Y.; Li, Y. Research on the diffusion behavior of Cu in low-carbon steel under high temperatures. Crystals 2022, 12, 207. [Google Scholar] [CrossRef]

- Li, H.; Gong, M.; Li, T.; Wang, Z.; Wang, G. Effects of hot-inner heavy reduction rolling during continuous casting on microstructures and mechanical properties of hot-rolled plates. Mater. Process. Tech. 2020, 283, 116708. [Google Scholar] [CrossRef]

- Tsuyama, S.S. Thick plate technology for the last 100 years: A world leader in thermo mechanical control process. ISIJ Int. 2015, 55, 67–78. [Google Scholar] [CrossRef]

- Mandal, S.; Tewary, N.K.; Ghosh, S.K.; Chakrabarti, D.; Chatterjee, S. Thermo-mechanically controlled processed ultra high strength steel: Microstructure, texture and mechanical properties. Mater. Sci. Eng. A 2016, 663, 126–140. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, W.; Liu, Z.; Wang, G. Direct observations on the crystal structure evolution of nano Cu precipitates in an extremely low carbon steel. Mater. Lett. 2017, 187, 49–52. [Google Scholar] [CrossRef]

- Kan, L.Y.; Ye, Q.B.; Shen, Y.F.; Wang, Z.D.; Zhao, T. Co-precipitation of nanosized Cu and carbides improving mechanical properties of 1 GPa grade HSLA steel. Mater. Sci. Eng. A 2022, 859, 144211. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Jia, Z.; O’Malley, R.; Jansto, S.J. Precipitation behavior during thin slab thermomechanical processing and isothermal aging of copper-bearing niobium-microalloyed high strength structural steels: The effect on mechanical properties. Mater. Sci. Eng. A 2011, 528, 8772–8780. [Google Scholar] [CrossRef]

- Antion, C.; Donnadieu, P.; Perrard, F.; Deschamps, A.; Tassin, C.; Pisch, A. Hardening precipitation in a Mg-4Y-3RE alloy. Acta Mater. 2003, 51, 5335–5348. [Google Scholar] [CrossRef]

- Stubbera, A.; Balk, T. Quantitative SAXS analysis of precipitate characteristics limiting hot ductility in HSLA steels containing V, Nb & Nb Ti. ISIJ Int. 2023, 63, 1044–1053. [Google Scholar] [CrossRef]

- Blankenburg, M.; Bäcke, L.; Claesson, E.; Moberg, R.; Jaladurgam, N.R.; Lindberg, F.; Gladh, M.; Edwards, M.; Lind, M.; Hall, S.A. Revealing precipitate development during hot rolling and cooling of a Ti-Nb micro-alloyed high strength low-alloy steel through X-ray scattering. Adv. Eng. Mater. 2023, 25, 2201356. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Cu | Mo | Ti | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.033 | 0.22 | 0.57 | 0.66 | 1.3~1.6 | 1.1~1.4 | 0.15~0.35 | 0.016 | 0.030 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Chen, R.; Luo, X.; Wang, Z.; Ding, H.; Chai, F. Improving the Mechanical Properties of Hot Rolled Low-Carbon Copper-Containing Steel by Adjusting Quenching Roll Speed. Materials 2024, 17, 2953. https://doi.org/10.3390/ma17122953

Wang H, Chen R, Luo X, Wang Z, Ding H, Chai F. Improving the Mechanical Properties of Hot Rolled Low-Carbon Copper-Containing Steel by Adjusting Quenching Roll Speed. Materials. 2024; 17(12):2953. https://doi.org/10.3390/ma17122953

Chicago/Turabian StyleWang, Henglin, Ruiyang Chen, Xiaobing Luo, Zijian Wang, Hanlin Ding, and Feng Chai. 2024. "Improving the Mechanical Properties of Hot Rolled Low-Carbon Copper-Containing Steel by Adjusting Quenching Roll Speed" Materials 17, no. 12: 2953. https://doi.org/10.3390/ma17122953

APA StyleWang, H., Chen, R., Luo, X., Wang, Z., Ding, H., & Chai, F. (2024). Improving the Mechanical Properties of Hot Rolled Low-Carbon Copper-Containing Steel by Adjusting Quenching Roll Speed. Materials, 17(12), 2953. https://doi.org/10.3390/ma17122953