Model-Based Sensitivity Analysis of the Temperature in Laser Powder Bed Fusion

Abstract

1. Introduction

2. Methods

2.1. Physical Phenomena of Laser Powder Bed Fusion

2.2. Analytical Modeling of LPBF

2.2.1. Heat Transfer Analysis

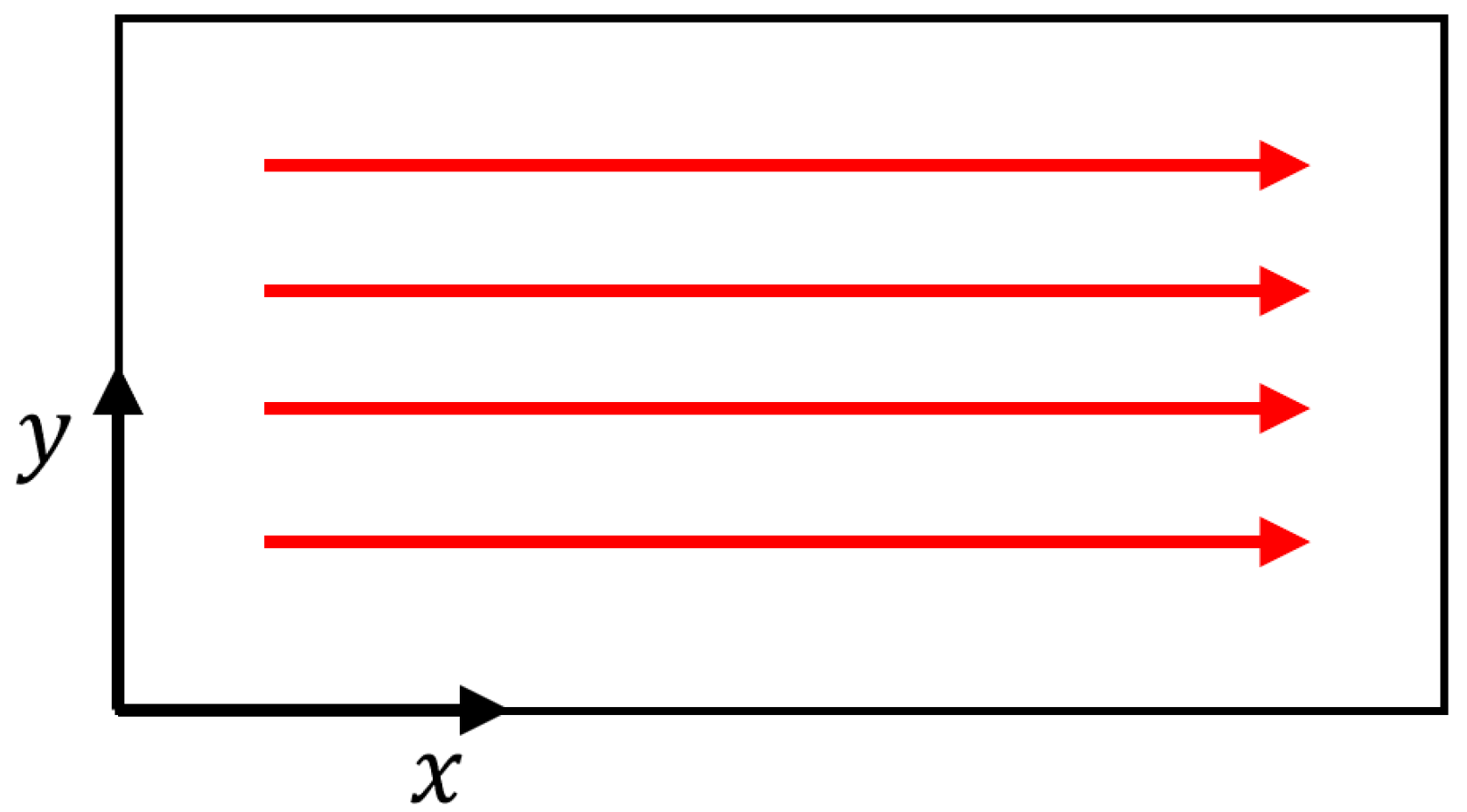

2.2.2. Boundary Condition Setting

2.2.3. Thermophysical Parameters of Materials

3. Results and Discussion

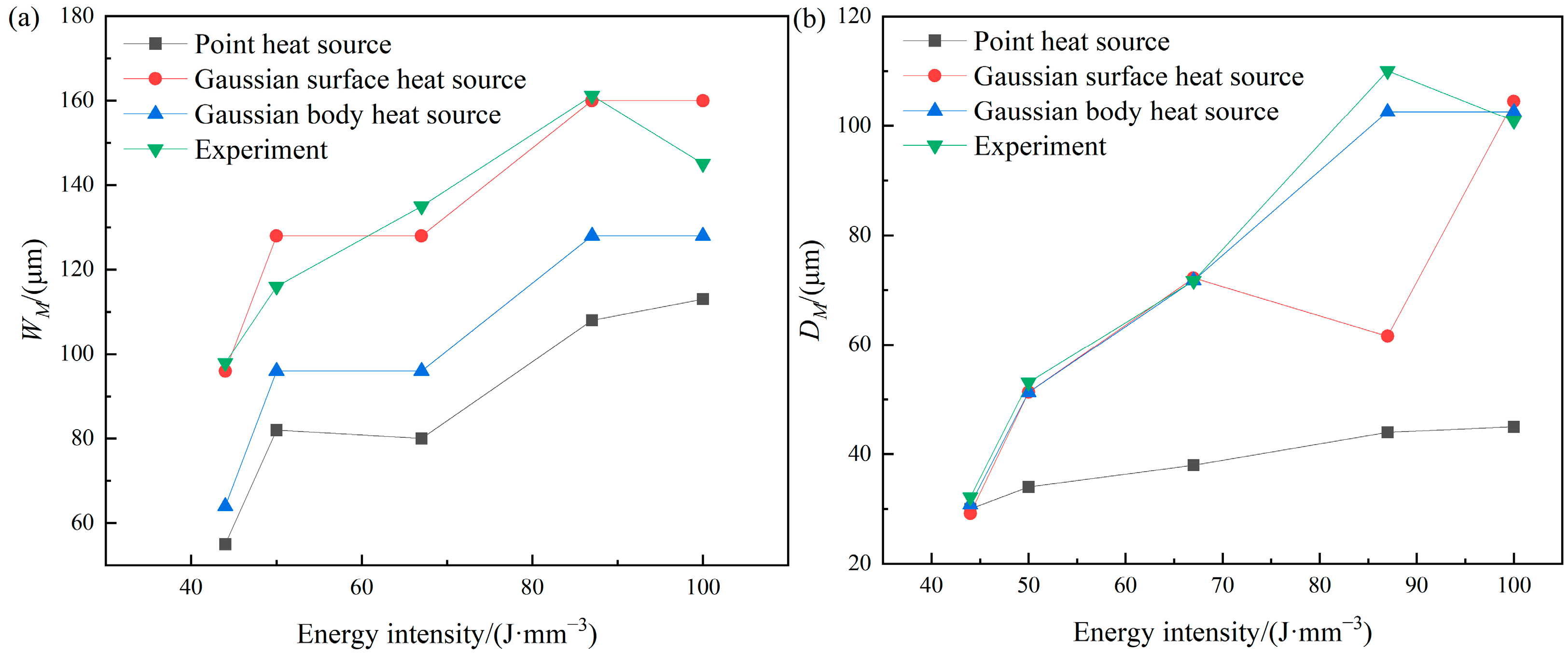

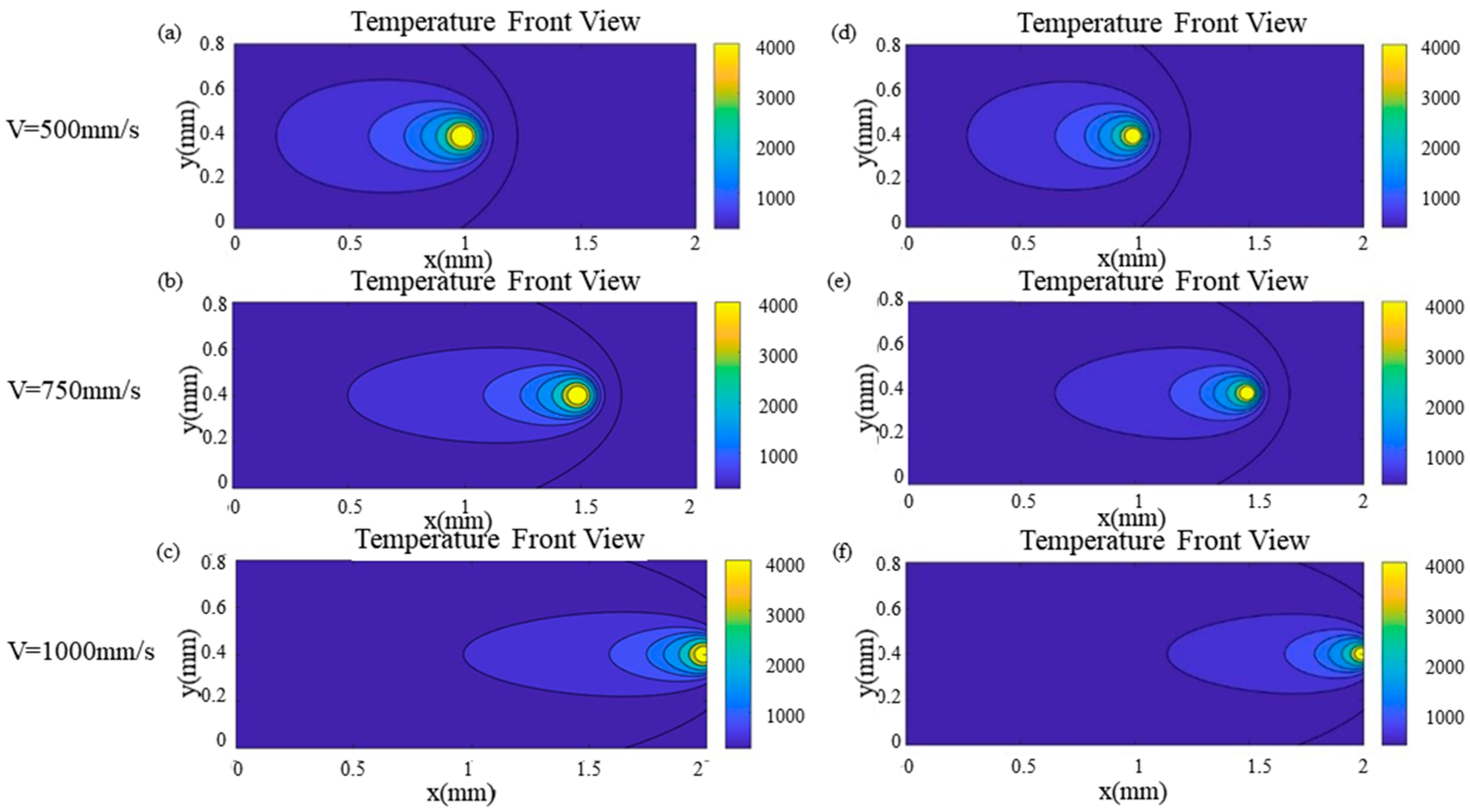

3.1. Comparison of Heat Source Models

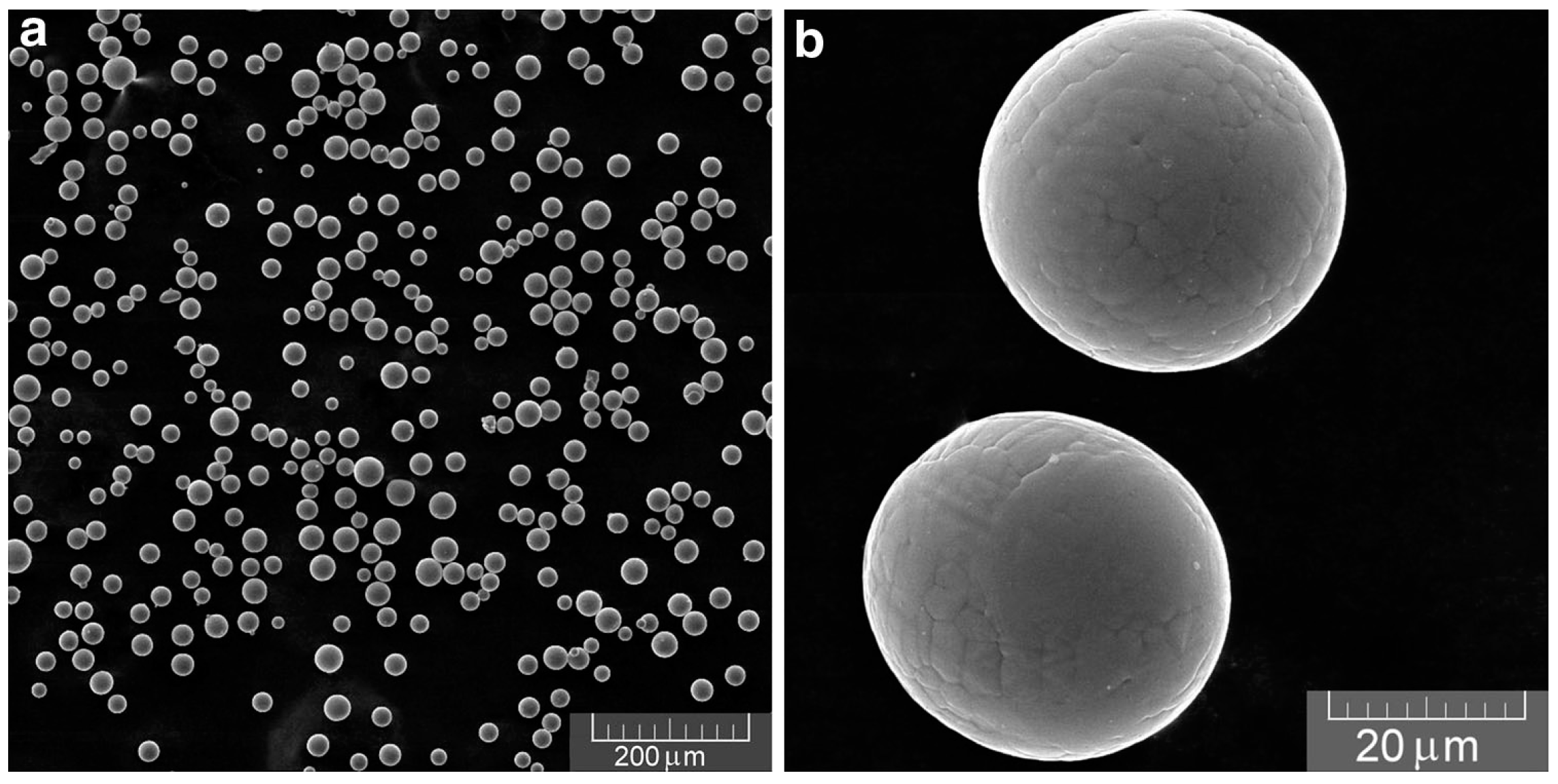

3.1.1. Experimental Condition

3.1.2. Results and Discussion of Molten Pool Size

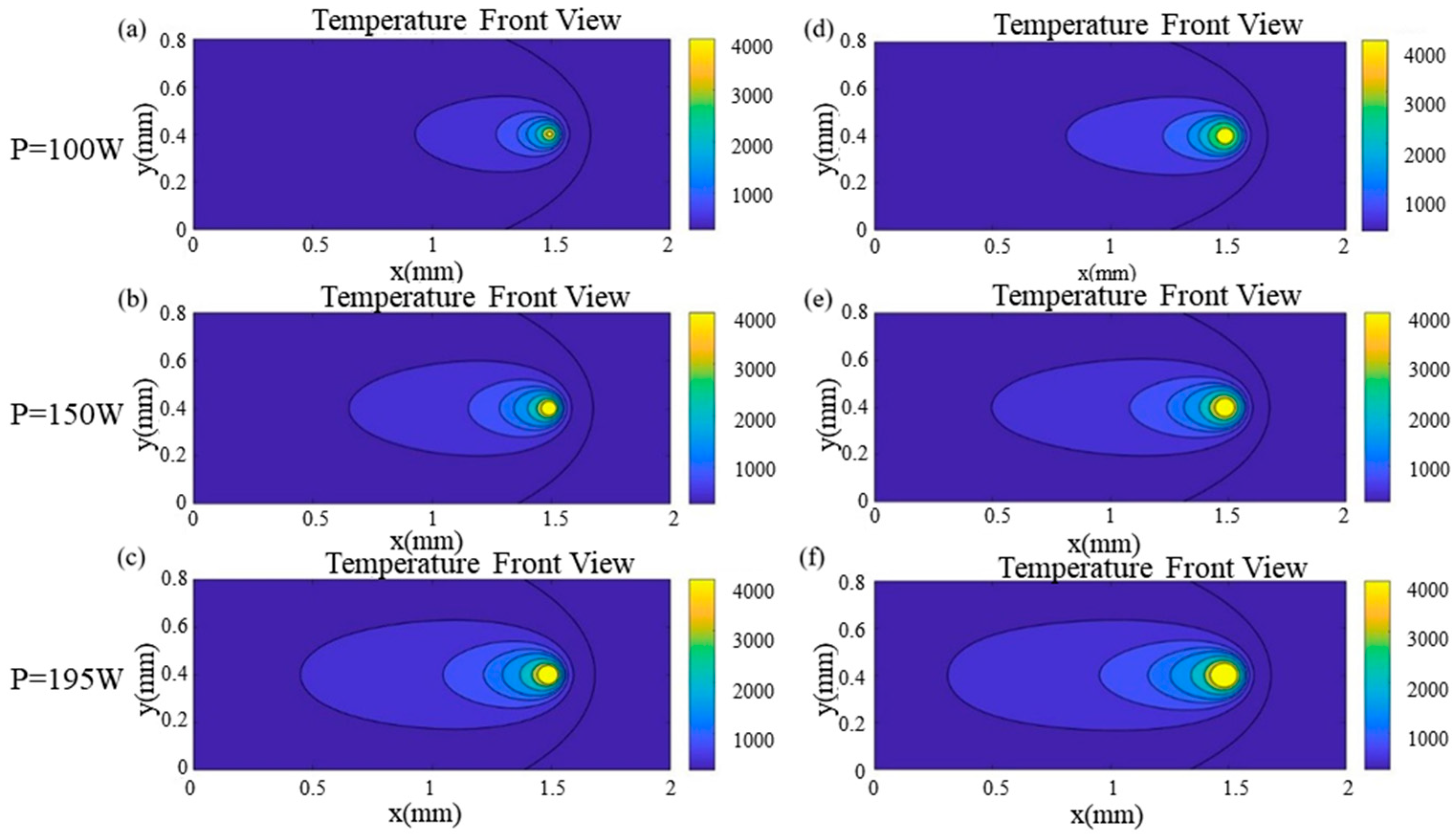

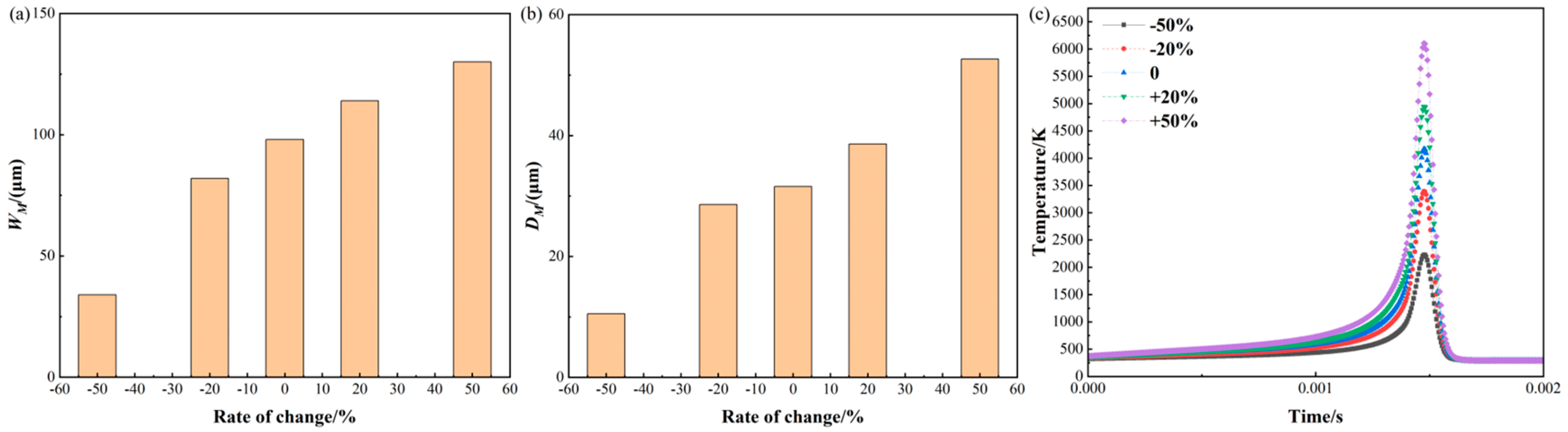

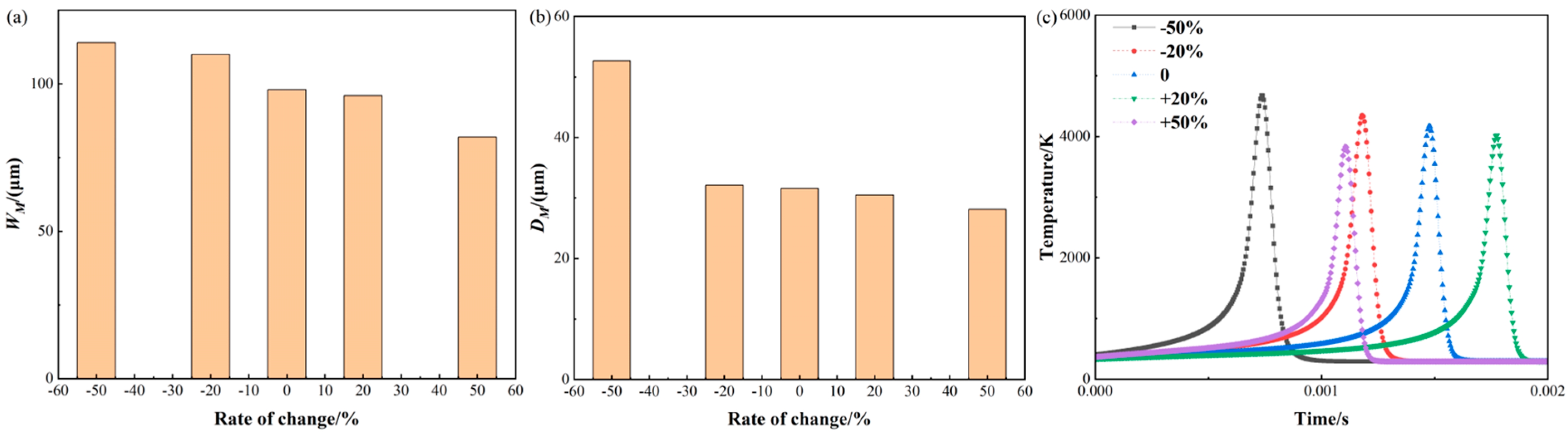

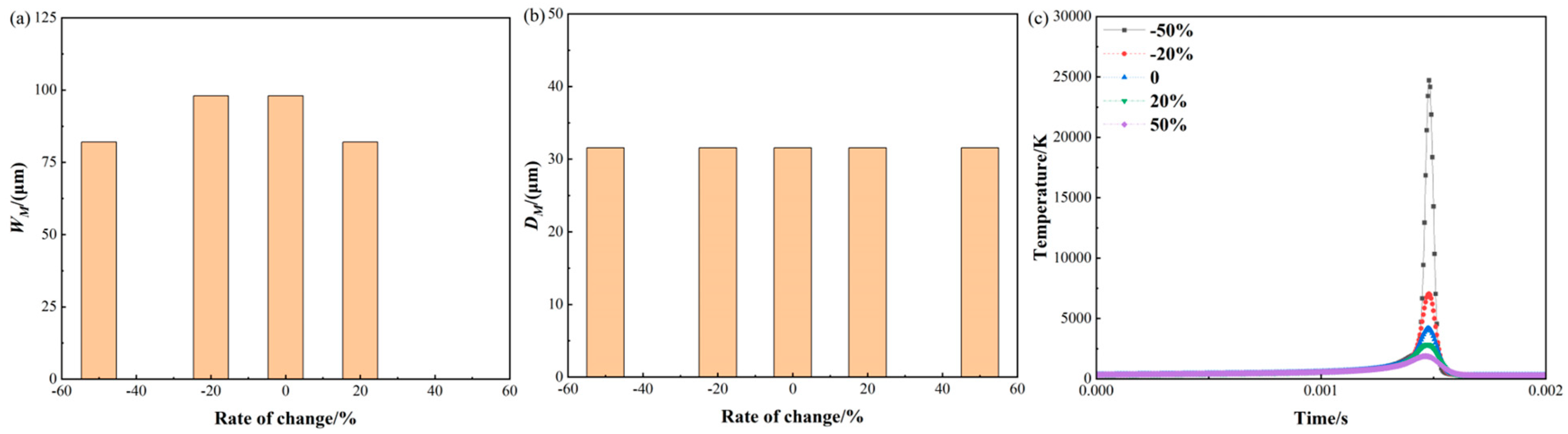

3.2. Sensitivity Analysis of Temperature for Gaussian Surface Heat Source

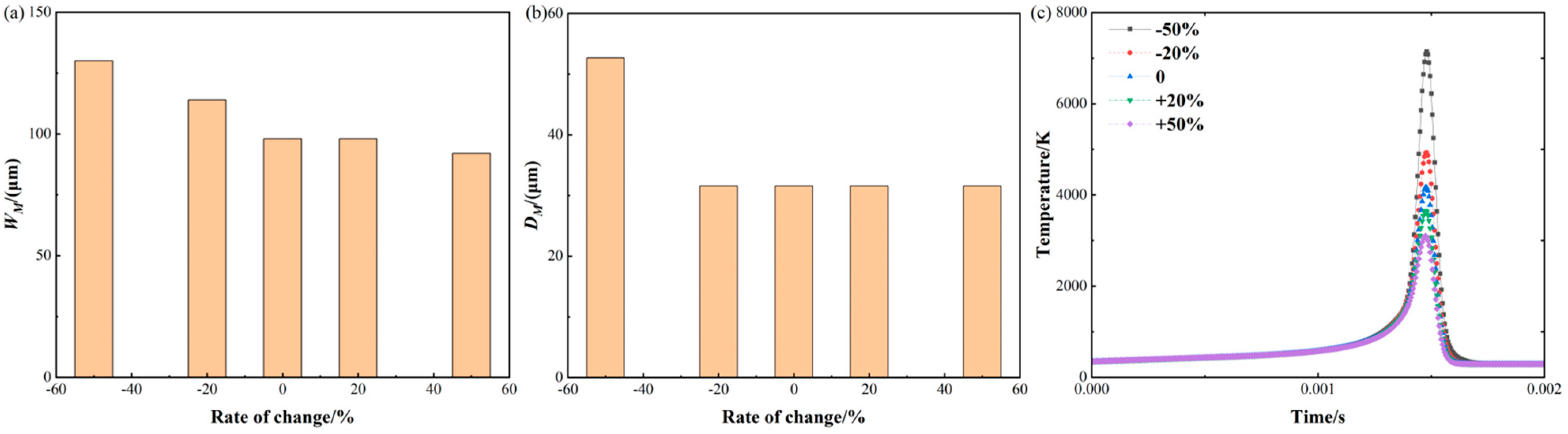

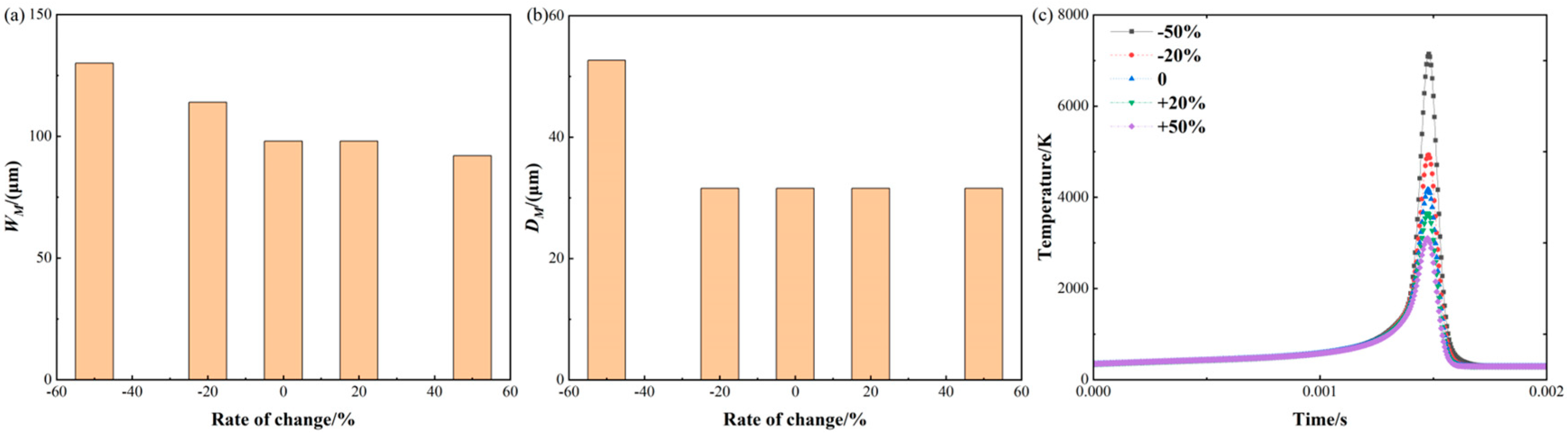

3.2.1. Effects of Process Parameters

3.2.2. Effects of the Material Properties

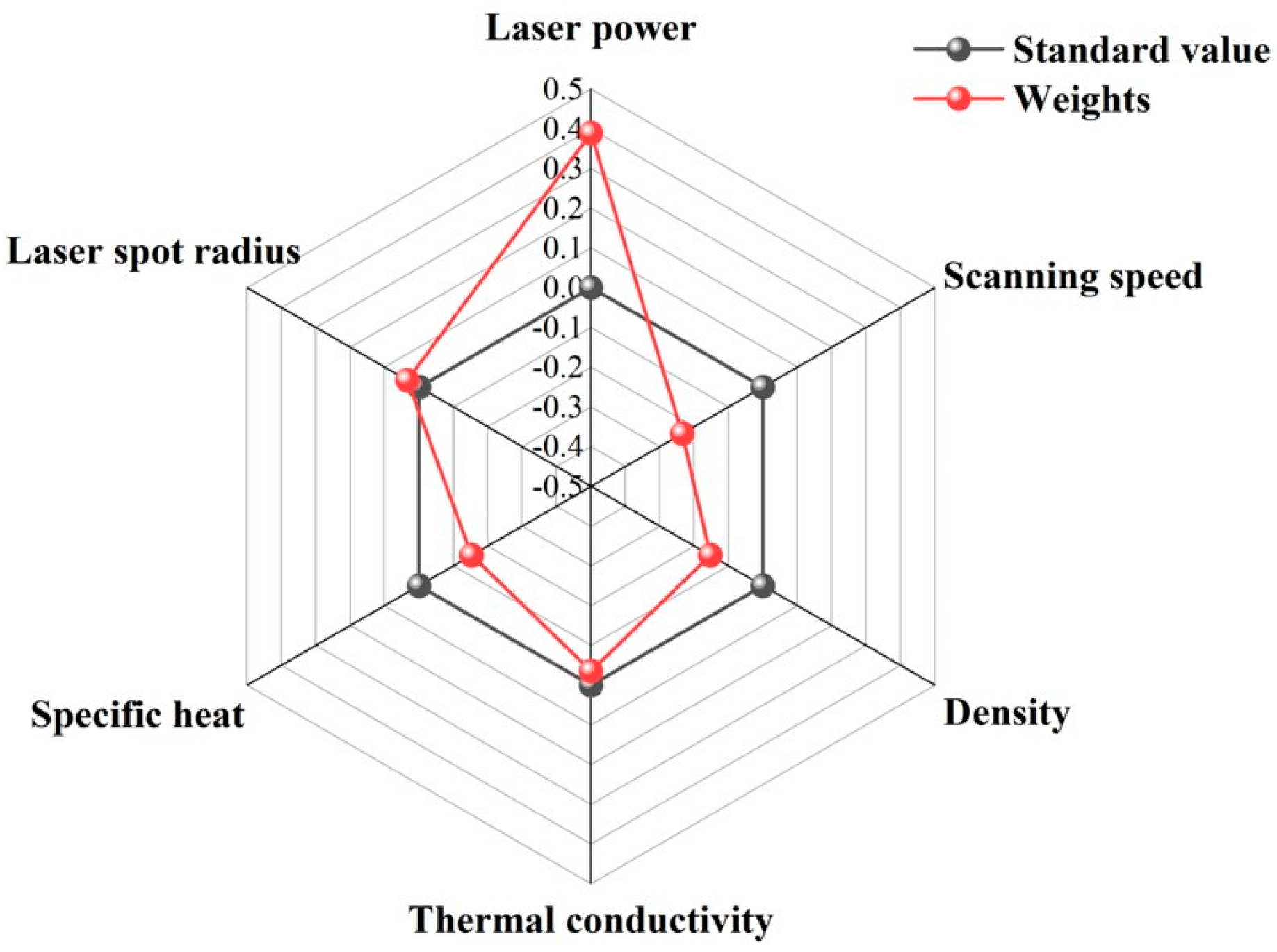

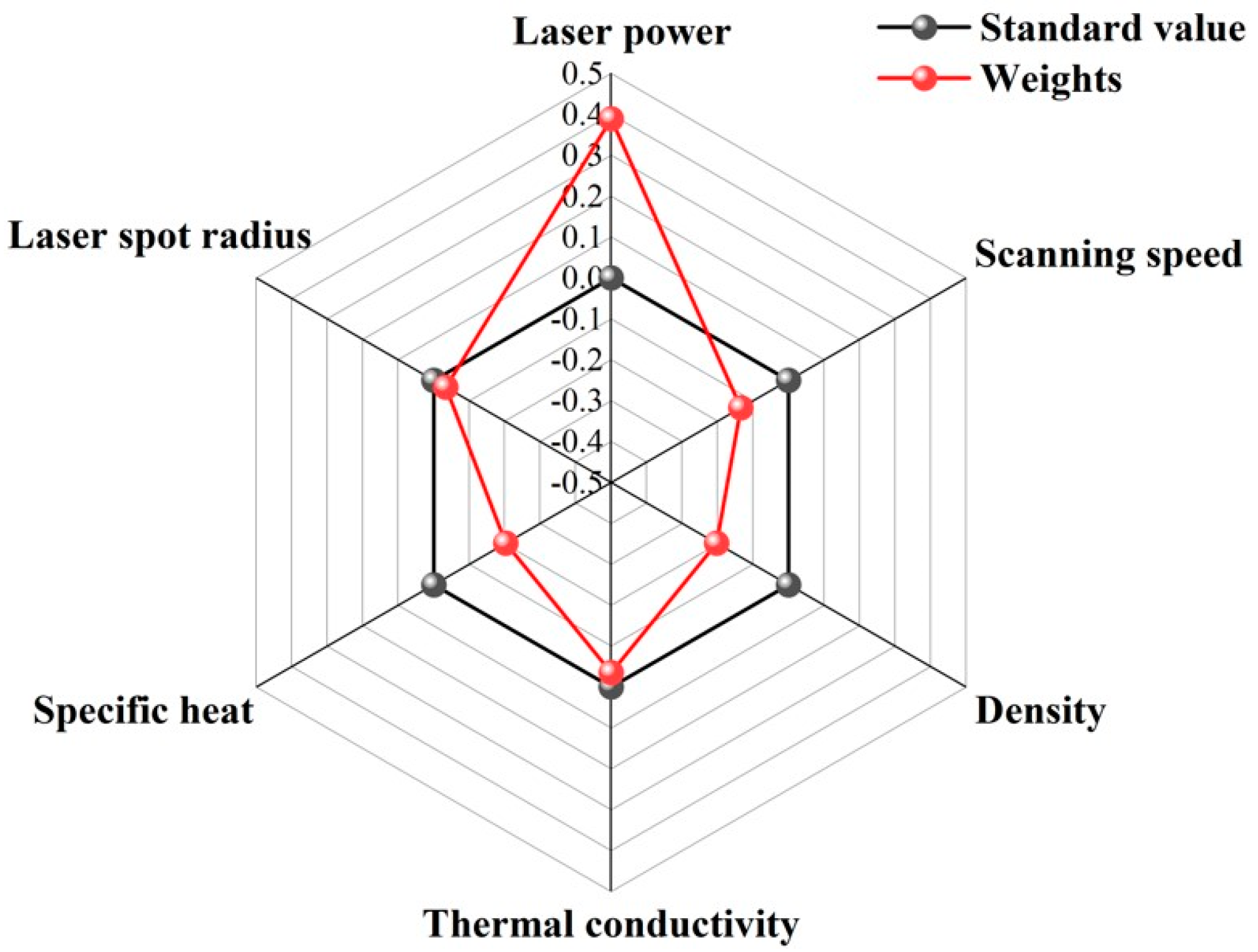

3.2.3. Combination Effects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, Z.; Yu, W.; Fu, H.; Deng, Y.; Wu, Y.; Zheng, H. Recent Progress on Microstructure Manipulation of Aluminium Alloys Manufactured Via Laser Powder Bed Fusion. Virtual Phys. Prototyp. 2023, 18, e2125880. [Google Scholar] [CrossRef]

- Hasanabadi, M.; Shahabad, S.I.; Keshavarzkermani, A.; Eybel, R.; Gerlich, A.; Toyserkani, E. A Numerical Modelling for Laser Powder-Bed Fusion of Ti-Alloy with a Hybrid Heat Source: An Investigation on Solidification and Microstructure Formation. Opt. Laser Technol. 2024, 174, 110647. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Fang, J.X.; Ma, G.Z.; Tian, H.L.; Li, S.B.; Huang, H.S.; Liu, Y.; Jiang, Y.L.; Liu, B. Transformation-Induced Strain of a Low Transformation Temperature Alloy with High Hardness During Laser Metal Deposition. J. Manuf. Process. 2021, 68, 1585–1595. [Google Scholar] [CrossRef]

- Jiang, Y.L.; Fang, J.X.; Ma, G.Z.; Tian, H.L.; Zhang, D.B.; Cao, Y. Microstructure and Properties of an as-Deposited and Post Treated High Strength Carbide-Free Bainite Steel Fabricated Via Laser Powder Deposition. Mater. Sci. Eng. A 2021, 824, 141791. [Google Scholar] [CrossRef]

- Jiang, X.J.; Bao, S.J.; Zhang, L.W.; Zhang, X.Y.; Jiao, L.S.; Qi, H.B.; Wang, F. Effect of Zr on Microstructure and Properties of Tc4 Alloy Fabricated by Laser Additive Manufacturing. J. Mater. Res. Technol. 2023, 24, 8782–8792. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A Study of the Microstructural Evolution During Selective Laser Melting of Ti–6al–4v. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Chen, Z. Effects Ofprocess Parameterson Temperature and Stress Distributions During Selectivelaser Meltingofti-6al-4v. Trans. Indian. Inst. Met. 2019, 72, 3201–3214. [Google Scholar] [CrossRef]

- Ding, L.; Sun, Z.; Liang, Z.; Li, F.; Xu, G.; Chang, H. Investigation on Ti-6al-4v Microstructure Evolution in Selective Laser Melting. Metals 2019, 9, 1270. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite Element Simulation of the Temperature and Stress Fields in Single Layers Built without-Support in Selective Laser Melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, J.; Du, W.; Bai, P.; Wu, X. Numerical Simulation and Experimental Study of the 7075 Aluminum Alloy During Selective Laser Melting. Opt. Laser Technol. 2023, 167, 109814. [Google Scholar] [CrossRef]

- Anand, N.; Chang, K.-C.; Yeh, A.-C.; Chen, Y.-B.; Lee, M.-T. Development of a Comprehensive Model for Predicting Melt Pool Characteristics with Dissimilar Materials in Selective Laser Melting Processes. J. Mater. Process. Technol. 2023, 319, 118069. [Google Scholar] [CrossRef]

- Wang, Q.; Shao, H.; Zhang, X.; Wang, K.; Liu, S.; Yang, C.; Wang, W. Study of Thermal Behavior and Microstructure Formation Mechanism of Cucrzr Alloy Melted by Laser Powder Bed Fusion. Mater. Charact. 2023, 198, 112721. [Google Scholar] [CrossRef]

- Yang, Y.; Ayas, C. Point, Surface and Volumetric Heat Sources in the Thermal Modelling of Selective Laser Melting. AIP Conf. Proc. 2017, 1896, 040006. [Google Scholar]

- Liu, B.; Fang, G.; Lei, L. An Analytical Model for Rapid Predicting Molten Pool Geometry of Selective Laser Melting (Slm). Appl. Math. Model. 2021, 92, 505–524. [Google Scholar] [CrossRef]

- Liu, B.; Fang, G.; Lei, L.; Yan, X. Predicting the Porosity Defects in Selective Laser Melting (Slm) by Molten Pool Geometry. Int. J. Mech. Sci. 2022, 228, 107478. [Google Scholar] [CrossRef]

- Ökten, K.; Biyikoğlu, A. Development of Thermal Model for the Determination of Slm Process Parameters. Opt. Laser Technol. 2021, 137, 106825. [Google Scholar] [CrossRef]

- Ji, X.; Wang, Y.; Liang, S.Y. Analytical Modeling of Temperature Evolution in Laser Powder Bed Fusion Considering the Size and Shape of the Build Part. J. Mater. Process. Technol. 2022, 301, 117452. [Google Scholar] [CrossRef]

- Wang, Y.; Ji, X.; Liang, S.Y. Analytical Modeling of Temperature Distribution in Laser Powder Bed Fusion with Different Scan Strategies. Opt. Laser Technol. 2023, 157, 108708. [Google Scholar] [CrossRef]

- Li, Y.; Gu, D. Thermal Behavior During Selective Laser Melting of Commercially Pure Titanium Powder: Numerical Simulation and Experimental Study. Addit. Manuf. 2014, 1–4, 99–109. [Google Scholar] [CrossRef]

- Fu, C.; Guo, Y. Three-Dimensional Temperature Gradient Mechanism in Selective Laser Melting of Ti-6al-4v. J. Manuf. Sci. Eng. 2014, 136, 061004. [Google Scholar] [CrossRef]

- Ji, X.; Zhang, S.; Wang, Y.; Liang, S.Y. Effect of Thermal-Fluidic Transport on the Temperature Distribution and the Melt Pool in Laser Powder Bed Fusion of Ti6al4v. Opt. Laser Technol. 2022, 156, 108587. [Google Scholar] [CrossRef]

- Ning, J.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical Modeling of in-Process Temperature in Powder Bed Additive Manufacturing Considering Laser Power Absorption, Latent Heat, Scanning Strategy, and Powder Packing. Materials 2019, 12, 808. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Peng, Y.; Shen, Y.; Shen, S.; Wei, G.; Yin, J.; Zhang, J. The Use of Phase-Change Cooling Strategy in Proton Exchange Membrane Fuel Cells: A Numerical Study. Sci. China Technol. Sci. 2021, 64, 2762–2770. [Google Scholar] [CrossRef]

- Li, C.; Han, X.; Zhang, D.; Gao, X.; Jia, T. Quantitative Analysis and Experimental Study of the Influence of Process Parameters on the Evolution of Laser Cladding. J. Adhes. Sci. Technol. 2022, 36, 1894–1920. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Seivers, D.E.; Garmestani, H.; Liang, S.Y. Heat Source Modeling in Selective Laser Melting. Materials 2019, 12, 2052. [Google Scholar] [CrossRef]

- Wang, W.; Garmestani, H.; Liang, S.Y. Prediction of Molten Pool Size and Vapor Depression Depth in Keyhole Melting Mode of Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2022, 119, 6215–6223. [Google Scholar] [CrossRef]

- Jia, L.; Zou, Y.; Zou, Z.D.; Zhao, Y.S.; Yao, Q.S. Research and Application Status of Arc Welding Heat Source Model for T-Joint Numerical Simulation. Adv. Mater. Res. 2011, 154, 1423–1426. [Google Scholar] [CrossRef]

- Carslaw, H.S. Introduction to the Mathematical Theory of the Conduction of Heat in Solids; Macmillan and Company, Limited: London, UK, 1947. [Google Scholar]

- Zhang, D.; Cai, Q.; Liu, J.; Zhang, L.; Li, R. Select Laser Melting of W–Ni–Fe Powders: Simulation and Experimental Study. Int. J. Adv. Manuf. Technol. 2010, 51, 649–658. [Google Scholar] [CrossRef]

- Mishra, A.K.; Kumar, A. Numerical and Experimental Analysis of the Effect of Volumetric Energy Absorption in Powder Layer on Thermal-Fluidic Transport in Selective Laser Melting of Ti6al4v. Opt. Laser Technol. 2019, 111, 227–239. [Google Scholar] [CrossRef]

- Li, Z.-J.; Dai, H.-L.; Xu, J.; Huang, Z.-W. A Semi-Analytical Approach for Analysis of Thermal Behaviors Coupling Heat Loss in Powder Bed Fusion. Int. J. Heat Mass Transf. 2023, 201, 123621. [Google Scholar] [CrossRef]

- Liu, B.; Li, S.; Li, Y. Bending of Fgm Sandwich Plates with Tunable Auxetic Core Using Dqm. Eur. J. Mech. A Solids 2023, 97, 104838. [Google Scholar] [CrossRef]

- Dilip, J.; Zhang, S.; Teng, C.; Zeng, K.; Robinson, C.; Pal, D.; Stucker, B. Influence of Processing Parameters on the Evolution of Melt Pool, Porosity, and Microstructures in Ti-6al-4v Alloy Parts Fabricated by Selective Laser Melting. Prog. Addit. Manuf. 2017, 2, 157–167. [Google Scholar] [CrossRef]

- Hu, K.; Wang, Y.; Li, W.; Wang, L. Cnn-Bilstm Enabled Prediction on Molten Pool Width for Thin-Walled Part Fabrication Using Laser Directed Energy Deposition. J. Manuf. Process. 2022, 78, 32–45. [Google Scholar] [CrossRef]

- Shi, Q.; Gu, D.; Xia, M.; Cao, S.; Rong, T. Effects of Laser Processing Parameters on Thermal Behavior and Melting/Solidification Mechanism During Selective Laser Melting of Tic/Inconel 718 Composites. Opt. Laser Technol. 2016, 84, 9–22. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Vora, H.D.; Rajamure, R.S.; Soundarapandian, S.; Srinivasan, S.G.; Dahotre, N.B. Dilution of Molybdenum on Aluminum During Laser Surface Alloying. J. Alloys Compd. 2013, 570, 133–143. [Google Scholar] [CrossRef]

- Lee, Y.; Zhang, W. Modeling of Heat Transfer, Fluid Flow and Solidification Microstructure of Nickel-Base Superalloy Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef]

| C | O | Ni | H | Fe | Al | V | Ti | Other |

|---|---|---|---|---|---|---|---|---|

| 0.02 | 0.11 | 0.02 | 0.0034 | 0.19 | 6.5 | 3.9 | surplus | <0.1 |

| Material Properties | Ti6Al4V |

|---|---|

| Liquidus temperature TL (K) | 1923 |

| Solidus temperature TS (K) | 1877 |

| Thermal conductivity k (W m−2 K−1) | 31.4 |

| Specific heat c (J kg−1 K−1) | 830 |

| Density (kg m−3) | 4200 |

| Laser Power P (W) | Scan Speed V (mm s−1) | Powder Layer Thickness (μm) | Energy Density E (J mm−3) |

|---|---|---|---|

| 100 | 500,750 | 30 | 67,44 |

| 150 | 500,750,1000,1200 | 30 | 100,67,50,42 |

| 195 | 500,750,1000,1200 | 30 | 130,87,65,54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Zhang, S.; Ji, X.; Liang, S.Y. Model-Based Sensitivity Analysis of the Temperature in Laser Powder Bed Fusion. Materials 2024, 17, 2565. https://doi.org/10.3390/ma17112565

Yang Z, Zhang S, Ji X, Liang SY. Model-Based Sensitivity Analysis of the Temperature in Laser Powder Bed Fusion. Materials. 2024; 17(11):2565. https://doi.org/10.3390/ma17112565

Chicago/Turabian StyleYang, Zhihao, Shiting Zhang, Xia Ji, and Steven Y. Liang. 2024. "Model-Based Sensitivity Analysis of the Temperature in Laser Powder Bed Fusion" Materials 17, no. 11: 2565. https://doi.org/10.3390/ma17112565

APA StyleYang, Z., Zhang, S., Ji, X., & Liang, S. Y. (2024). Model-Based Sensitivity Analysis of the Temperature in Laser Powder Bed Fusion. Materials, 17(11), 2565. https://doi.org/10.3390/ma17112565