Advances in Materials with Self-Healing Properties: A Brief Review

Abstract

1. Introduction

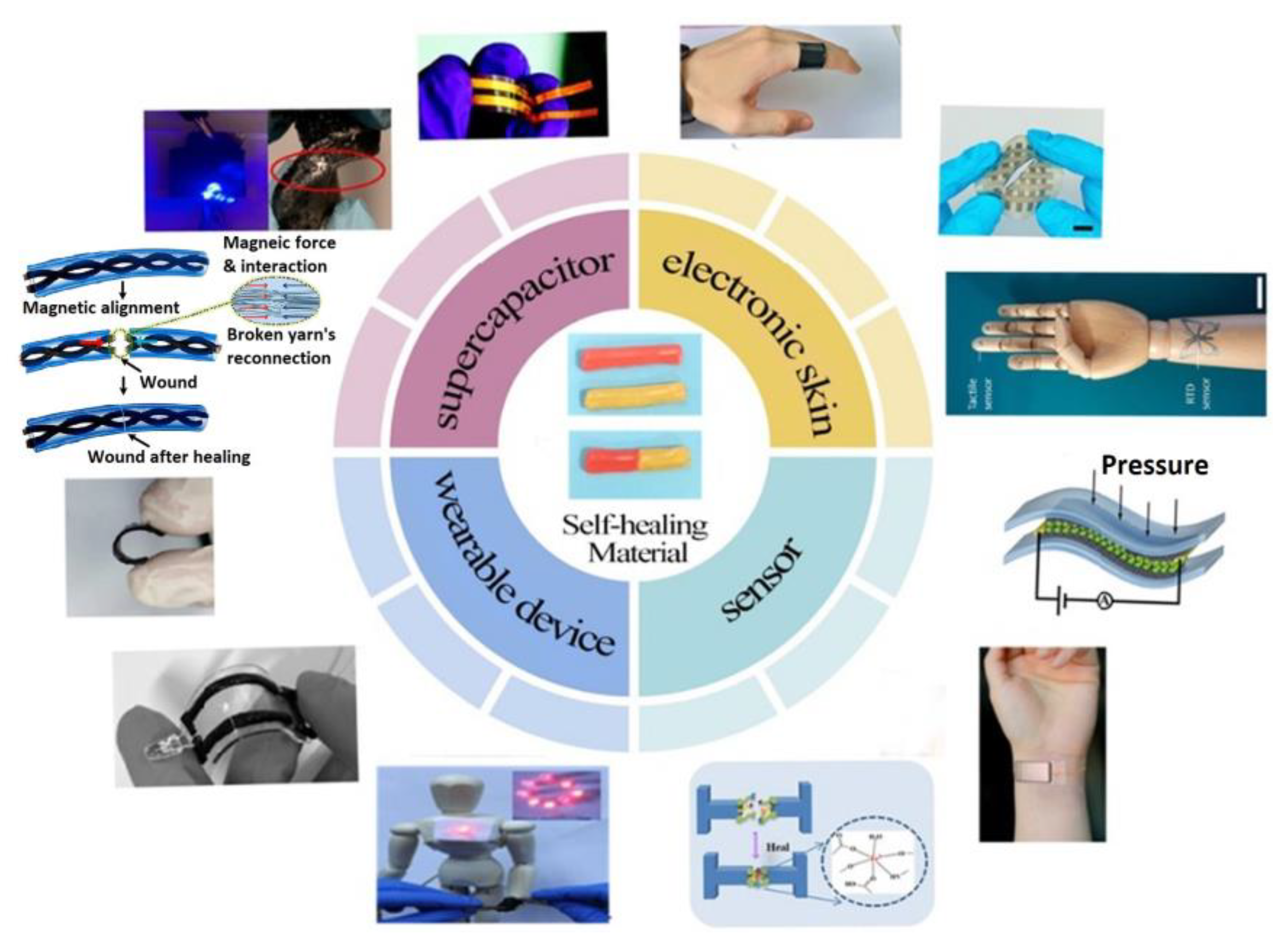

1.1. Applications of SHMs

1.2. Self-Healing Mechanisms

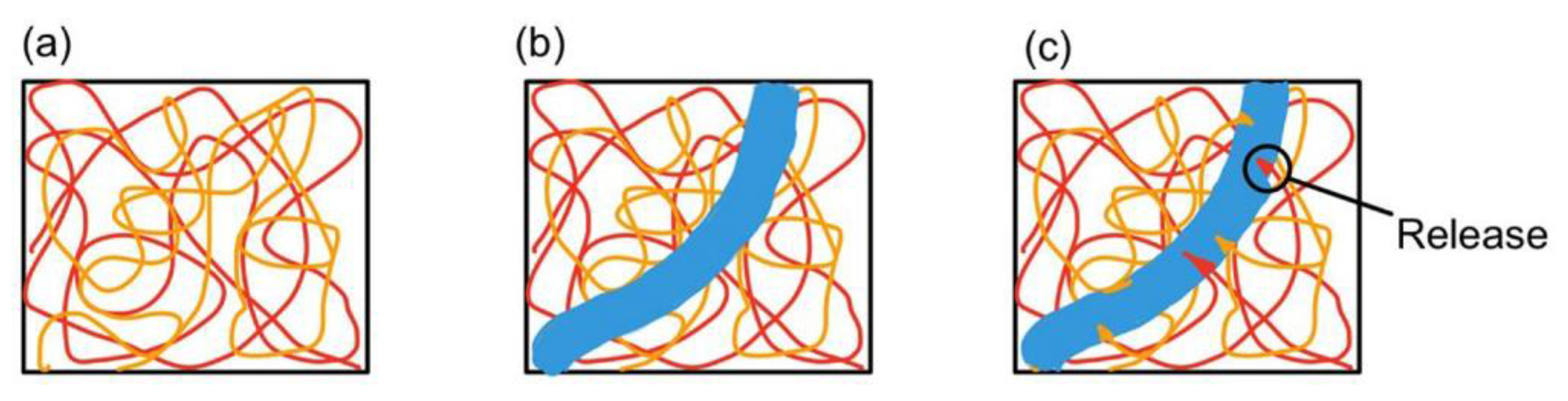

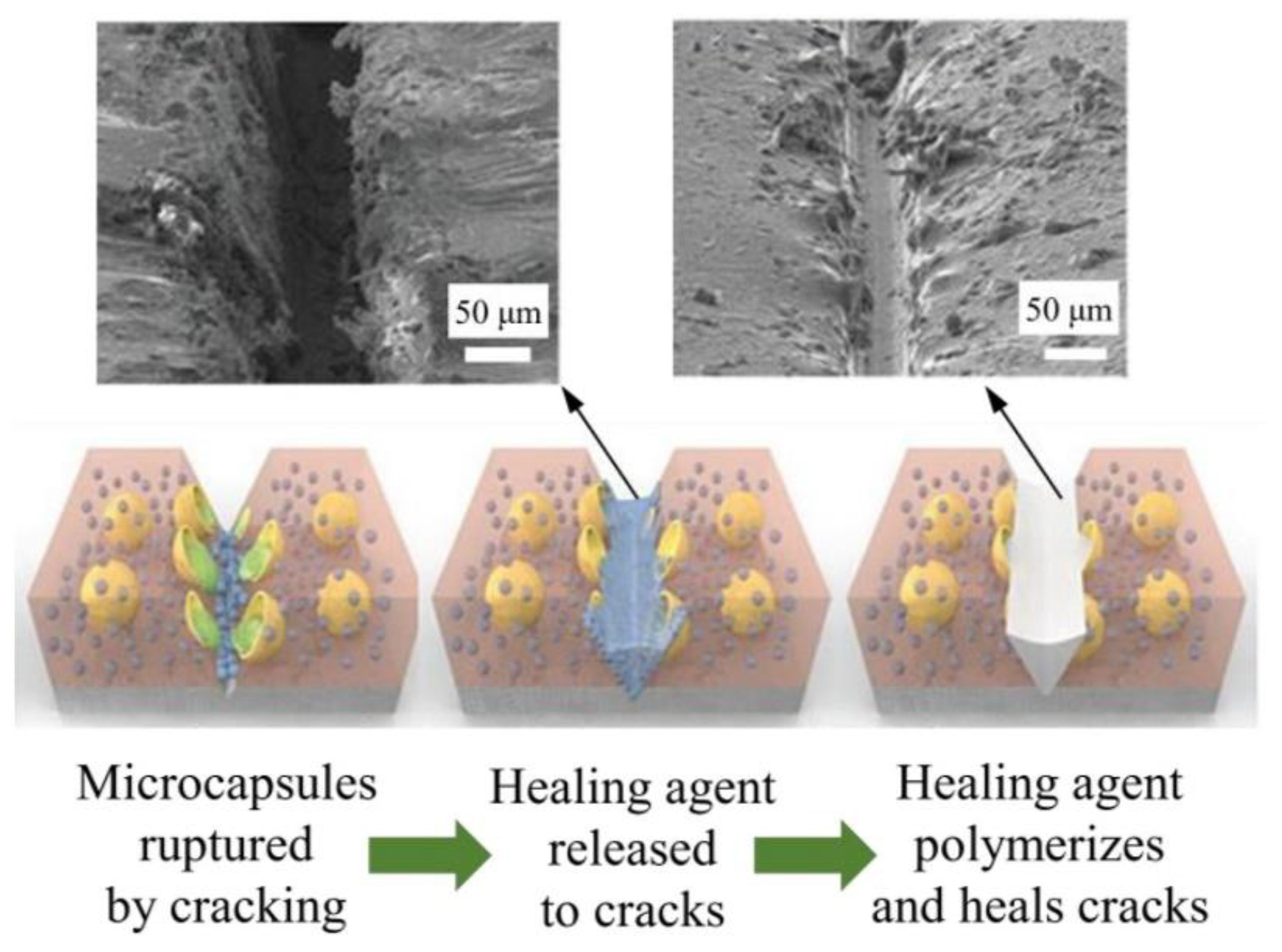

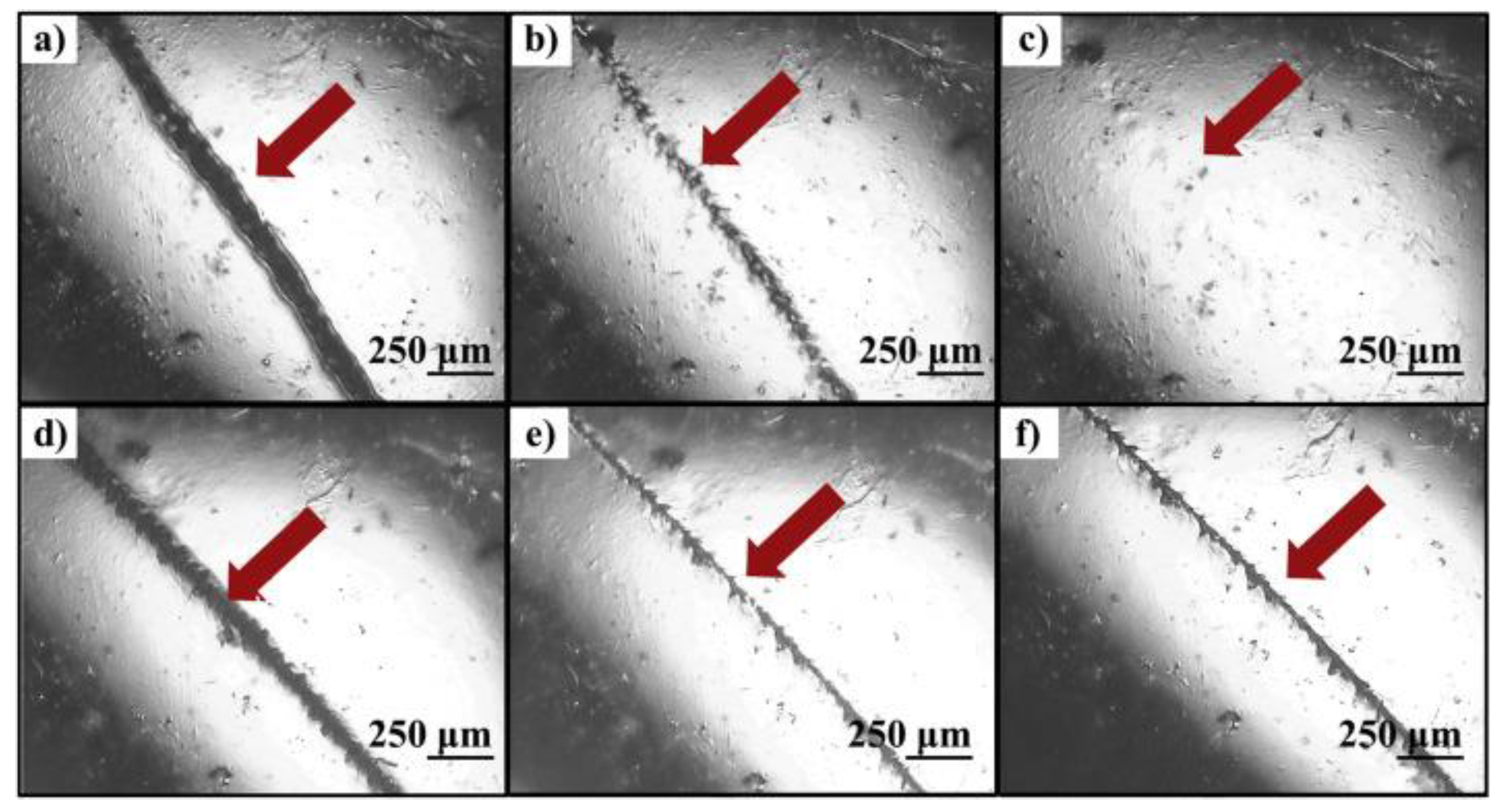

1.3. Composite SHMs and Microcapsules

1.4. SHMs in Biomedicine

1.5. SHMs in Implants and Prostheses

- Biocompatibility (ideally bioinert);

- Certain physical and mechanical properties;

- Resistance to infection;

- Ability/resistance to biodegradation;

- Minimum material consumption;

- Ease of use;

- Economic accessibility.

2. State-of-the-Art

3. Methodology and Relevance of the Review

3.1. Methodology

3.2. Relevance

4. Experimental Data on SHMs

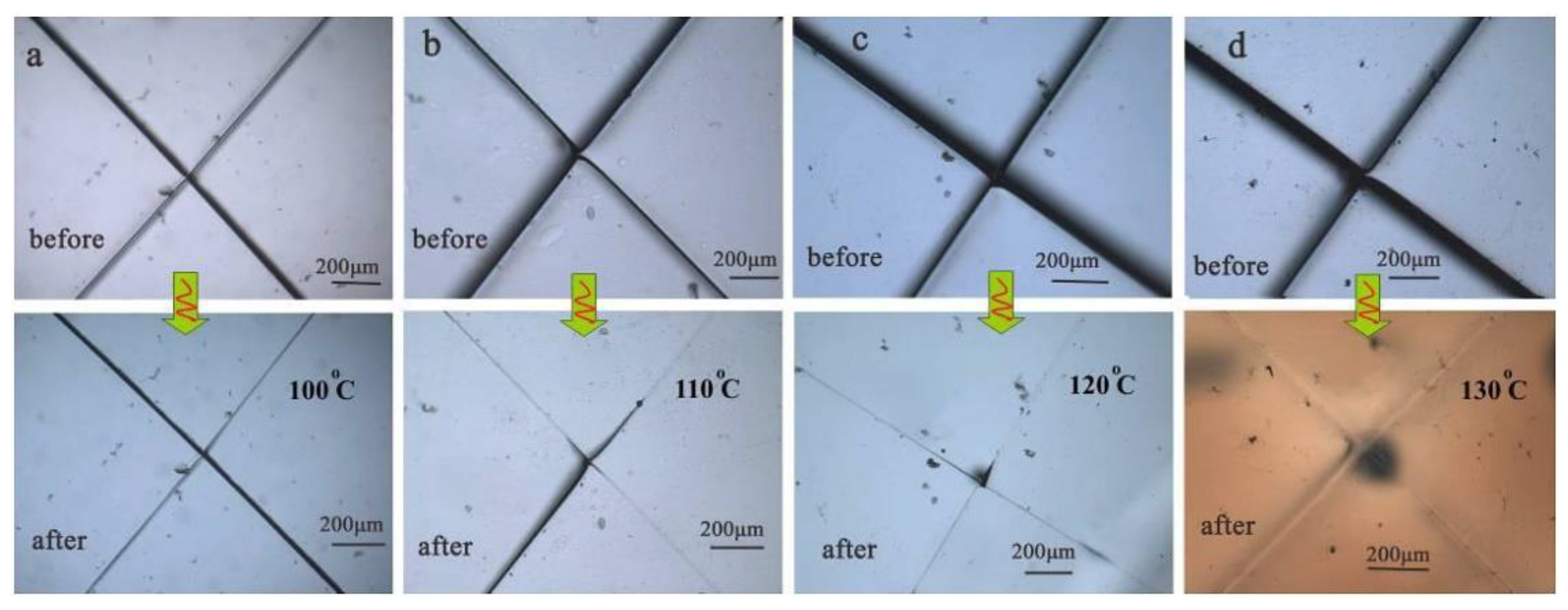

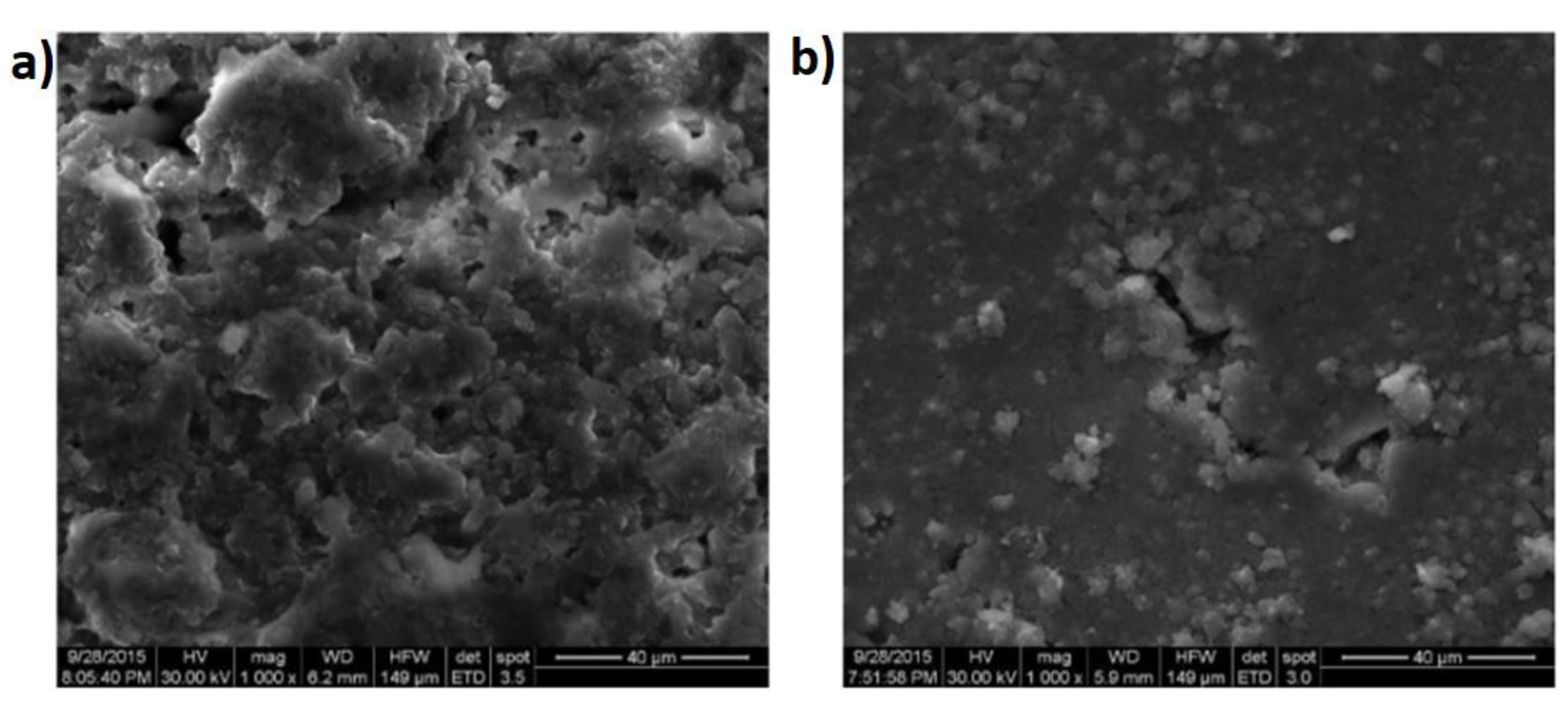

4.1. Self-Healing in Polymers

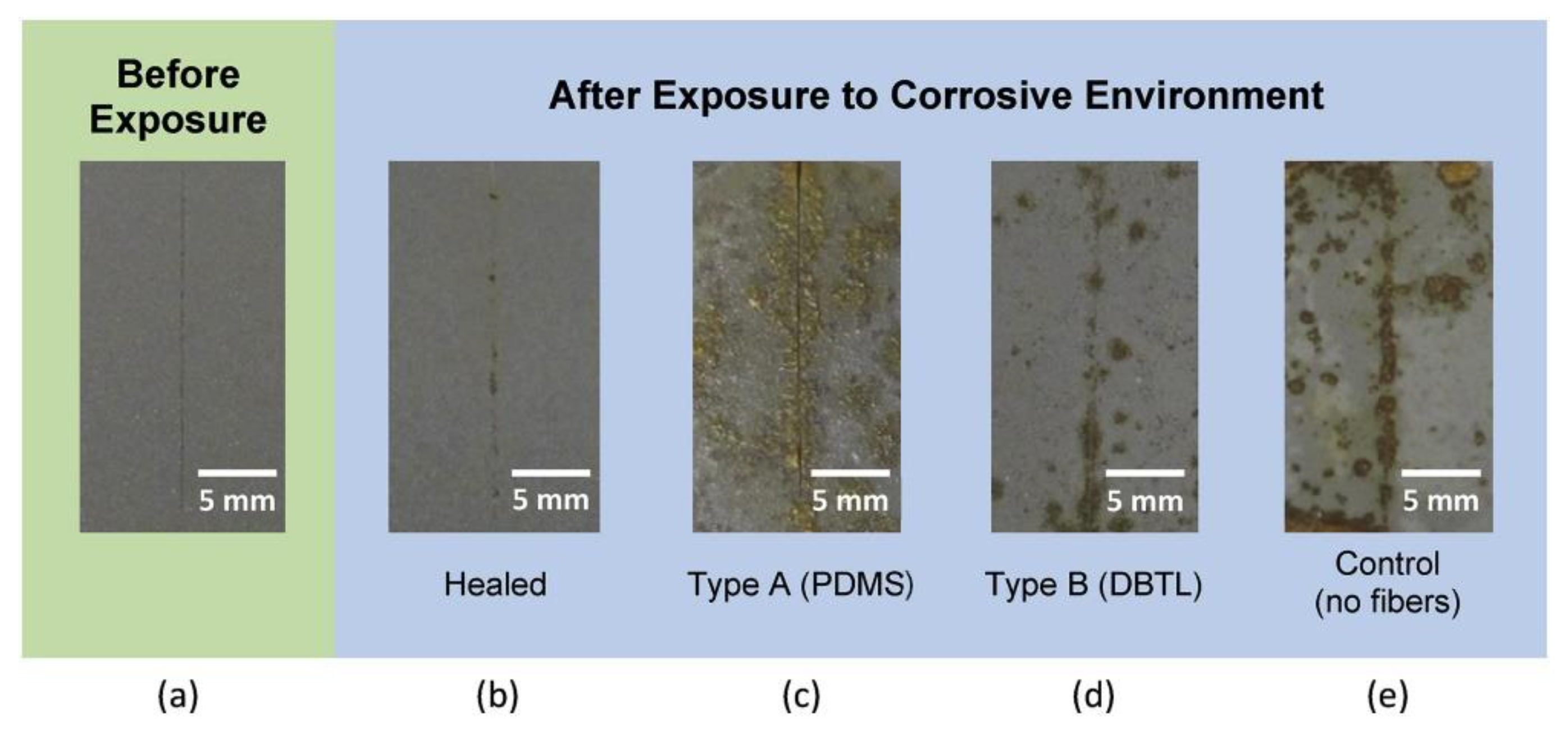

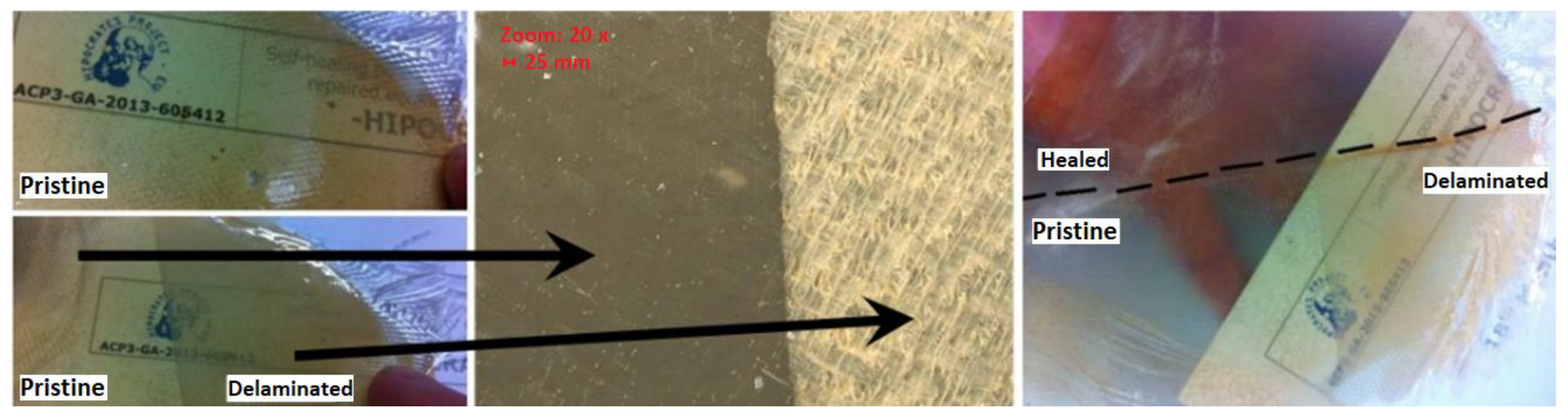

4.2. Self-Healing in Composites

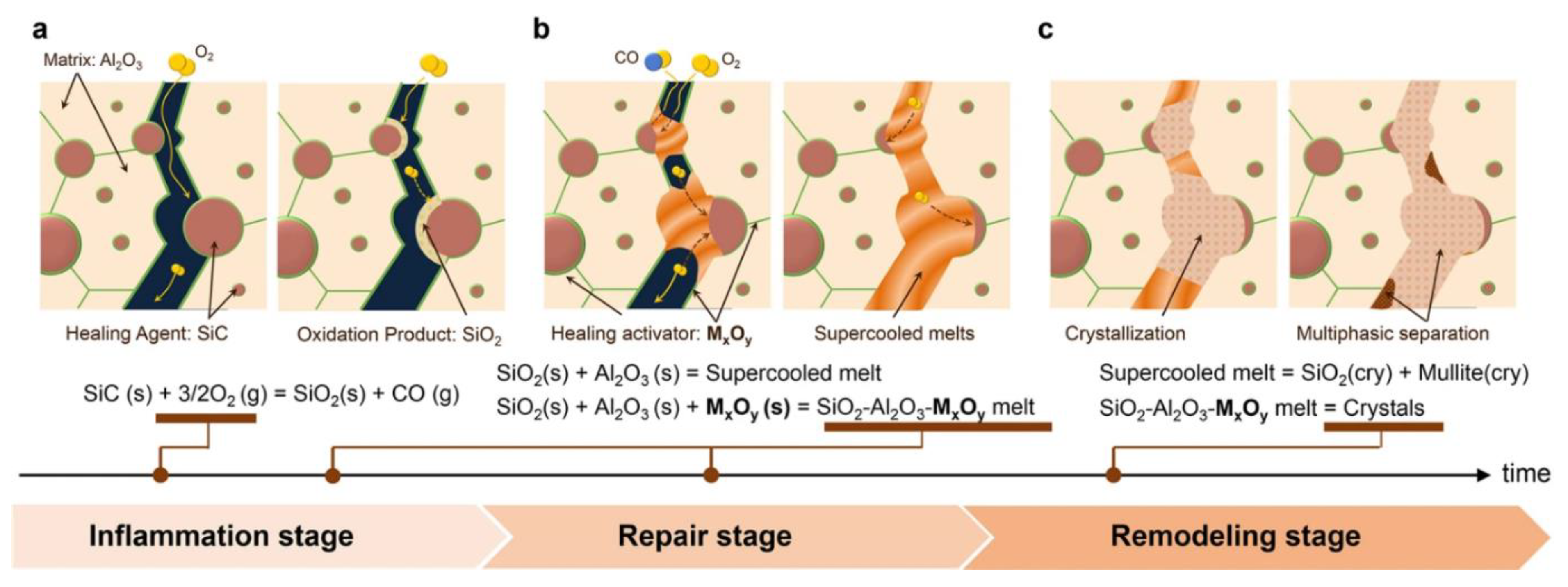

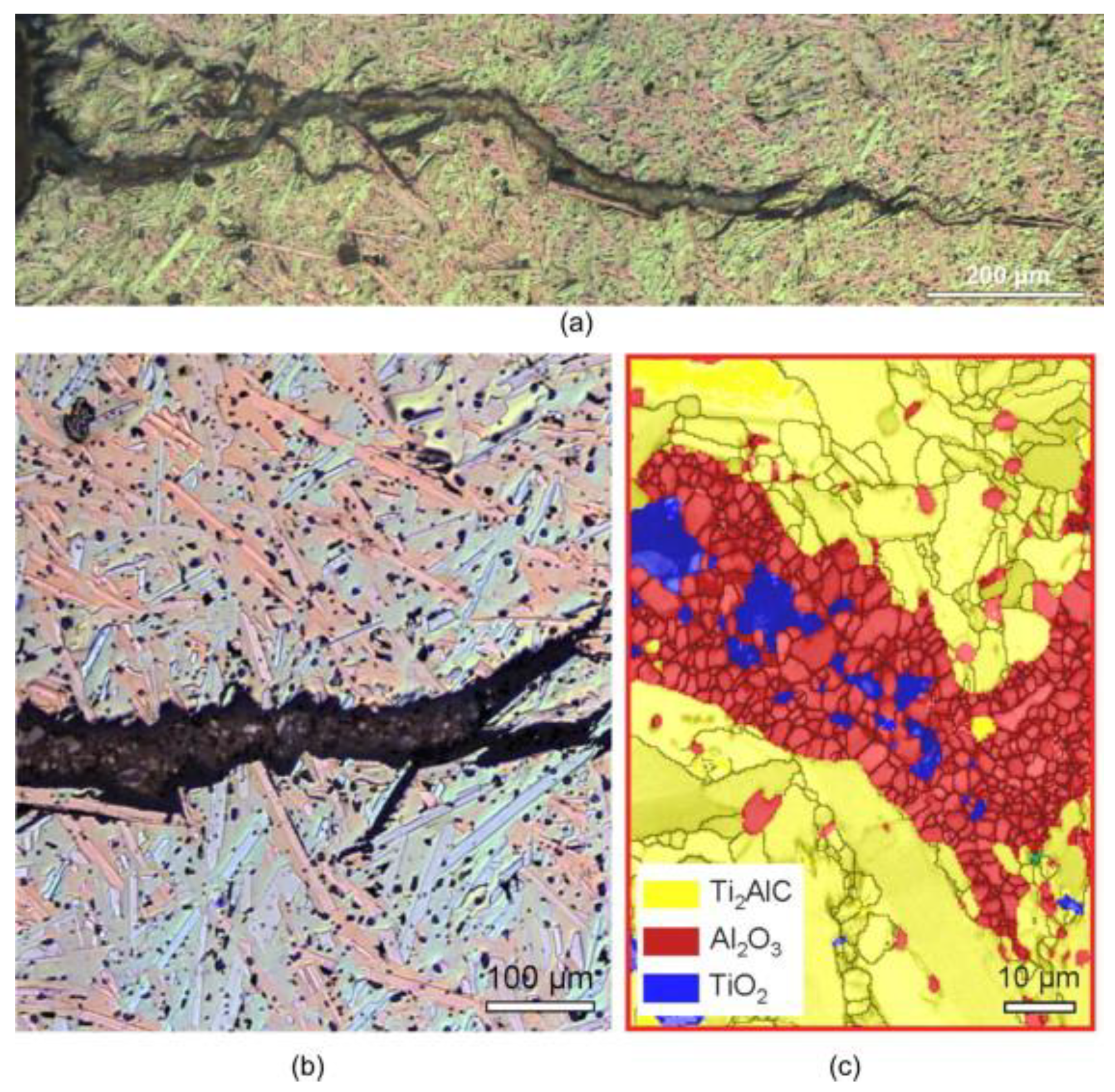

4.3. Self-Healing in Ceramics

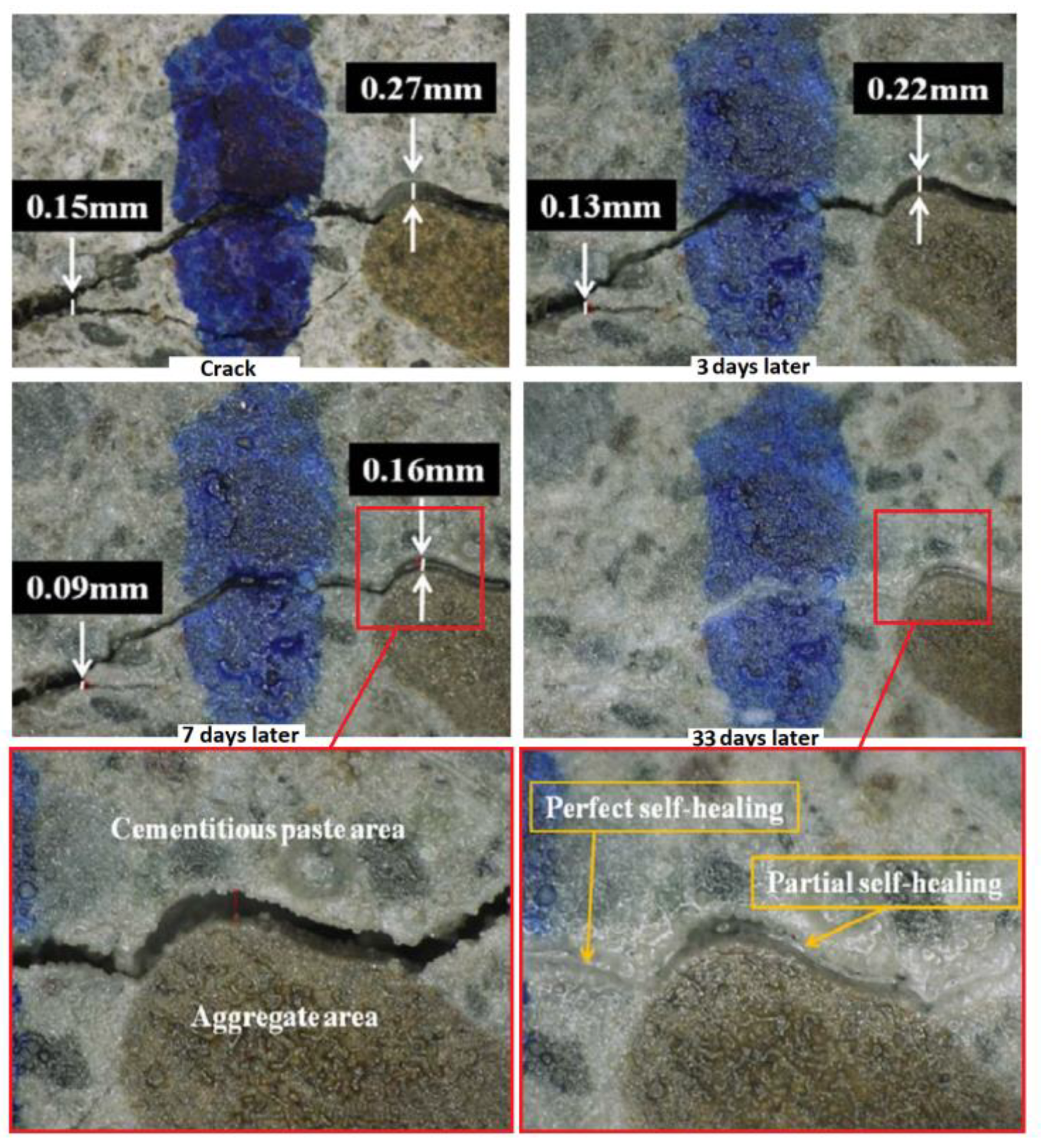

4.4. Self-Healing in Concrete and Cement

5. Key Findings and Future Implications

5.1. Key Findings

- Mechanisms of Self-Healing: This review elucidates various mechanisms underlying self-healing processes, spanning from microcapsules and intrinsic chemical reactions to external stimuli-triggered responses. Understanding these mechanisms is fundamental for the development of advanced SHMs.

- Applications Across Industries: SHMs hold immense potential for diverse applications across industries such as implants, prostheses, biomedicine, aerospace, and construction. These materials offer innovative solutions for enhancing durability, safety, and performance in various contexts.

- Material Diversity: This review explores the characteristics and applications of different types of SHMs, including hydrogels, self-healing gels, polymers, ceramics, concretes, and cements. Each material type presents unique advantages and opportunities for advancement.

- Importance of Crack Healing: Crack healing mechanisms play a crucial role in the performance of SHMs, influencing factors such as efficiency and reliability. Understanding and optimizing crack healing processes are essential for maximizing the effectiveness of these materials.

5.2. Future Implications

- Tailored Material Design: Future research should focus on developing SHMs tailored to specific applications, considering factors such as environmental conditions, mechanical properties, and biocompatibility requirements.

- Multifunctionality and Integration: There is potential for the integration of self-healing capabilities with other functionalities, such as sensing or antimicrobial properties, to create multifunctional materials with enhanced performance and versatility.

- Sustainable Solutions: Further efforts are needed to explore sustainable sources and manufacturing processes for SHMs, with an emphasis on reducing environmental impact and promoting circular economy principles.

- Translational Research: Continued collaboration between researchers, industry partners, and healthcare professionals is essential for translating advances in SHMs into practical applications, ultimately benefiting society and improving quality of life.

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McDonald, S.A.; Coban, S.B.; Sottos, N.R.; Withers, P.J. Tracking capsule activation and crack healing in a microcapsule-based self-healing polymer. Sci. Rep. 2019, 9, 17773. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, M.; Jayabalakrishnan, D. Influence of Pin offset and Weave Pattern on the Performance of Al-Cu Joints Reinforced with Graphene Particles. Int. J. Automot. Mech. Eng. 2020, 17, 8186–8196. [Google Scholar] [CrossRef]

- Ramesh, G.; Jayabalakrishnan, D.; Rameshkumar, C. Mechanical and thermal characterization of heat/surface treated egg shell filler diffused natural rubber green composite. J. Optoelectron. Biomed. Mater. 2018, 10, 21–28. [Google Scholar]

- Mashkoor, F.; Lee, S.J.; Yi, H.; Noh, S.M.; Jeong, C. Self-Healing Materials for Electronics Applications. Int. J. Mol. Sci. 2022, 23, 622. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Ding, X.; Urban, M.W. Urban Chemical and physical aspects of self-healing materials. Prog. Polym. Sci. 2015, 49–50, 34–59. [Google Scholar] [CrossRef]

- Meraz, M.M.; Mim, N.J.; Mehedi, M.T.; Bhattacharya, B.; Aftab, M.R.; Billah, M.M.; Meraz, M.M. Self-healing concrete: Fabrication, advancement, and effectiveness for long-term integrity of concrete infrastructures. Alexandria Eng. J. 2023, 73, 665–694. [Google Scholar] [CrossRef]

- Yue, H.; Wang, Z.; Zhen, Y. Recent Advances of Self-Healing Electronic Materials Applied in Organic Field-Effect Transistors. ACS Omega 2022, 7, 18197–18205. [Google Scholar] [CrossRef]

- Ding, Q.; Xu, X.; Yue, Y.; Mei, C.; Huang, C.; Jiang, S.; Wu, Q.; Han, J. Nanocellulose-mediated electroconductive self-healing hydrogels with high strength, plasticity, viscoelasticity, stretchability, and biocompatibility toward multifunctional applications. ACS Appl. Mater. Interfaces 2018, 10, 27987–28002. [Google Scholar] [CrossRef]

- Jayabalakrishnan, D.; Muruga, D.N.; Bhaskar, K.; Pavan, P.; Balaji, K.; Rajakumar, P.S.; Priya, C.; Deepa, R.A.B.; Sendilvelan, S.; Prabhahar, M. Self-Healing materials—A review. Mater. Today Proc. 2020, 45, 7195–7199. [Google Scholar] [CrossRef]

- Uguzzoni, A.M.P.; Fregonara, E.; Ferrando, D.G.; Anglani, G.; Antonaci, P.; Tulliani, J.-M. Concrete Self-Healing for Sustainable Buildings: A Focus on the Economic Evaluation from a Life-Cycle Perspective. Sustainability 2023, 15, 13637. [Google Scholar] [CrossRef]

- Reda, M.A.; Chidiac, S.E. Performance of Capsules in Self-Healing Cementitious Material. Materials 2022, 15, 7302. [Google Scholar] [CrossRef]

- Choi, K.; Noh, A.; Kim, J.; Hong, P.H.; Ko, M.J.; Hong, S.W. Properties and Applications of Self-Healing Polymeric Materials: A Review. Polymers 2023, 15, 4408. [Google Scholar] [CrossRef] [PubMed]

- Wen, N.; Song, T.; Ji, Z.; Jiang, D.; Wu, Z.; Wang, Y.; Guo, Z. Recent advancements in self-healing materials: Mechanicals, performances and features. React. Funct. Polym. 2021, 168, 105041. [Google Scholar] [CrossRef]

- Hardman, D.; Thuruthel, T.G.; Iida, F. Self-healing ionic gelatin/glycerol hydrogels for strain sensing applications. NPG Asia Mater. 2022, 14, 11. [Google Scholar] [CrossRef]

- Rehman, H.U.; Chen, Y.; Guo, Y.; Du, Q.; Zhou, J.; Guo, Y.; Duan, H.; Li, H.; Liu, H. Stretchable, strong and self-healing hydrogel by oxidized CNT-polymer composite, Self-healing nanocomposite materials: A review. Compos. Part A Appl. Sci. Manuf. 2016, 90, 250–260. [Google Scholar] [CrossRef]

- Cerdan, K.; Thys, M.; Cornellà, A.C.; Demir, F.; Norvez, S.; Vendamme, R.; Van Puyvelde, P.; Brancart, J. Progress in Polymer Science Sustainability of self-healing polymers: A holistic perspective towards circularity in polymer networks. Prog. Polym. Sci. 2024, 152, 101816. [Google Scholar] [CrossRef]

- Thakur, V.K.; Kessler, M.R. Self-healing polymer nanocomposite materials: A review. Polymer 2015, 69, 369–383. [Google Scholar] [CrossRef]

- Dry, C. Passive tuneable fibers and matrices. Int. J. Mod. Phys. B 1992, 6, 2763–2771. [Google Scholar] [CrossRef]

- Luo, J.; Wang, T.; Sim, C.; Li, Y. Mini-Review of Self-Healing Mechanism and Formulation Optimization of Polyurea Coating. Polymers 2022, 14, 2808. [Google Scholar] [CrossRef]

- Liu, Y.; Hsu, S.-H. Synthesis and Biomedical Applications of Self-healing Hydrogels. Front. Chem. 2018, 6, 449. [Google Scholar] [CrossRef]

- Liu, B.; Wu, M.; Du, W.; Jiang, L.; Li, H.; Wang, L.; Li, J.; Zuo, D.; Ding, Q. The Application of Self-Healing Microcapsule Technology in the Field of Cement-Based Materials: A Review and Prospect. Polymers 2023, 15, 2718. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.Y.; Rong, M.Z.; Zhang, M.Q. Self-healing polymeric materials based on microencapsulated healing agents: From design to preparation. Prog. Polym. Sci. 2015, 49–50, 175–220. [Google Scholar] [CrossRef]

- Jiang, S.; Lin, Z.; Tang, C.; Hao, W. Preparation and Mechanical Properties of Microcapsule-Based Self-Healing Cementitious Composites. Materials 2021, 14, 4866. [Google Scholar] [CrossRef] [PubMed]

- Urdl, K.; Kandelbauer, A.; Kern, W.; Müller, U.; Thebault, M.; Zikulnig-Rusch, E. Self-healing of densely crosslinked thermoset polymers—A critical review. Prog. Org. Coat. 2017, 104, 232–249. [Google Scholar] [CrossRef]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards self-healing polymers for composite structural applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Bekas, D.; Tsirka, K.; Baltzis, D.; Paipetis, A. Self-healing materials: A review of advances in materials, evaluation, characterization and monitoring techniques. Compos. Part B Eng. 2016, 87, 92–119. [Google Scholar] [CrossRef]

- Sitnikov, N.N.; Mostovaya, K.S.; Khabibullina, I.A.; Mashchenko, V.I. Self-healing materials: A review of self-healing mechanisms and their applications. Video Sci. 2018, 1, 2–30. Available online: https://cyberleninka.ru/article/n/samovosstanavlivayuschiesya-materialy-obzor-mehanizmov-samovosstanovleniya-i-ih-primeneniy (accessed on 4 January 2023).

- Guo, W.; Jia, Y.; Tian, K.; Xu, Z.; Jiao, J.; Li, R.; Wu, Y.; Cao, L.; Wang, H. UVtriggered Self-healing of a Single Robust SiO2 Microcapsule Based on Cationic Polymerization for Potential Application in Aerospace Coatings. ACS Appl. Mater. Interfaces 2016, 8, 21046–21054. [Google Scholar] [CrossRef]

- Yue, H.-B.; Fernández-Blázquez, J.P.; Beneitoac, D.F.; Vilatela, J.J. Real time monitoring of click chemistry self-healing in polymer composites. J. Mater. Chem. A 2014, 2, 3881–3887. [Google Scholar] [CrossRef]

- Pernigoni, L.; Lafont, U.; Grande, A.M. Self healing materials for space applications: Overview of present development and major limitations. CEAS Space J. 2021, 13, 341–352. [Google Scholar] [CrossRef]

- Aïssa, B.; Tagziria, K.; Haddad, E.; Jamroz, W.; Loiseau, J.; Higgins, A.; Asgar-Khan, M.; Hoa, S.V.; Merle, P.G.; Therriault, D.; et al. The Selfhealing capability of carbon fibre composite structures subjected to hypervelocity impacts simulating orbital space debris. Int. Sch. Res. Not. 2012, 2012, 351205. [Google Scholar]

- Ma, E.; Chen, X.; Lai, J.; Kong, X.; Guo, C. Self-healing of microcapsule-based materials for highway construction: A review. J. Traffic Transp. Eng. 2023, 10, 368–384. [Google Scholar] [CrossRef]

- Hu, K.; Li, Y.; Ke, Z.; Yang, H.; Lu, C.; Li, Y.; Guo, Y.; Wang, W. History, progress and future challenges of artificial blood vessels: A narrative review. Biomater Transl. 2022, 3, 81–98. [Google Scholar] [CrossRef] [PubMed]

- Los, D.M.; Shapovalov, V.M.; Zotov, S.V. Application of polymer materials for medical products. Probl. Health Ecol. 2020, 2, 5–12. Available online: https://cyberleninka.ru/article/n/primenenie-polimernyh-materialov-dlya-izdeliy-meditsinskogo-naznacheniya (accessed on 5 January 2023).

- Del Prado-Audelo, M.L.; Caballero-Florán, I.H.; Mendoza-Muñoz, N.; Giraldo-Gomez, D.; Sharifi-Rad, J.; Patra, J.K.; González-Torres, M.; Florán, B.; Cortes, H.; Leyva-Gómez, G. Current progress of self-healing polymers for medical applications in tissue engineering. Iran. Polym. J. 2021, 31, 7–29. [Google Scholar] [CrossRef]

- Muslov, S.A.; Yarema, I.V.; Danilevskaya, O.V. Nitinol—A new generation medical material. Mod. Sci. Intensive Technol. 2007, 11, 55–56. Available online: https://top-technologies.ru/ru/article/view?id=25600 (accessed on 10 April 2024).

- Lee, M.W.; An, S.; Yoon, S.S.; Yarin, A.L. Advances in self-healing materials based on vascular networks with mechanical self-repair characteristics. Adv. Colloid Interface Sci. 2017, 252, 21–37. [Google Scholar] [CrossRef]

- Hansen, C.J.; Wu, W.; Toohey, K.S.; Sottos, N.R.; White, S.R.; Lewis, J.A. Self-healing materials with interpenetrating microvascular networks. Adv. Mater. 2009, 21, 4143–4147. [Google Scholar] [CrossRef]

- Hamilton, A.R.; Sottos, N.R.; White, S.R. Self-healing of internal damage in synthetic vascular materials. Adv. Mater. 2010, 22, 5159–5163. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.; Hwang, S.Y.; Oh, D.X.; Park, J. Recent progress in self-healing polymers and hydrogels based on reversible dynamic B-O bonds: Boronic/boronate esters, borax, and benzoxaborole. J. Mater. Chem. 2021, 9, 14630–14655. [Google Scholar] [CrossRef]

- Rumon, M.H.; Akib, A.A.; Sultana, F.; Moniruzzaman; Niloy, M.S.; Shakil, S.; Roy, C.K. Self-Healing Hydrogels: Development, Biomedical Applications, and Challenges. Polymers 2022, 14, 4539. [Google Scholar] [CrossRef]

- Pathan, N.; Shende, P. Strategic conceptualization and potential of self-healing polymers in biomedical field. Mater. Sci. Eng. C 2021, 125, 112099. [Google Scholar] [CrossRef] [PubMed]

- Shirokova, E.S.; Vesnin, R.L.; Khusainov, A.D. Materials based on thermoplastic elastomers for use in medicine and the pharmaceutical industry. Bull. Kazan Technol. Univ. 2016, 11, 106–110. Available online: https://cyberleninka.ru/article/n/materialy-na-osnove-termoelastoplastov-dlya-primeneniya-v-meditsine-i-farmatsevticheskoy-promyshlennosti (accessed on 5 January 2023).

- Wolf, C.; Lederer, K.; Pfragner, R.; Schauenstein, K.; Ingolic, E.; Siegl, V. Biocompatibility of ultra-high molecular weight polyethylene (UHMW-PE) stabilized with α-tocopherol used for joint endoprostheses assessed in vitro. J. Mater. Sci. Mater. Med. 2007, 18, 1247–1252. [Google Scholar] [CrossRef] [PubMed]

- Paxton, N.C.; Allenby, M.C.; Lewis, P.M.; Woodruff, M.A. Biomedical applications of polyethylene. Eur. Polym. J. 2019, 118, 412–428. [Google Scholar] [CrossRef]

- Zhukovsky, V.A. Polymer Implants for Reconstructive Surgery. Innova. 2016. No. 2 (3). Available online: https://cyberleninka.ru/article/n/polimernye-implantaty-dlya-rekonstruktivnoy-hirurgii (accessed on 5 January 2023).

- Zhukovsky, V.A. Polymer Endoprostheses for Hernioplasty: Production, Properties, Possibilities for Improvement; Surgery Bulletin: Saint Petersburg, Russia, 2011; Volume 170, pp. 82–86. Available online: https://cyberleninka.ru/article/n/polimernye-endoprotezy-dlya-gernioplastiki-poluchenie-svoystva-vozmozhnosti-sovershenstvovaniya (accessed on 10 April 2024).

- Shi, Y.; Wang, M.; Ma, C.; Wang, Y.; Li, X.; Yu, G. A Conductive Self-Healing Hybrid Gel Enabled by Metal–Ligand Supramolecule and Nanostructured Conductive Polymer. Nano Lett. 2015, 15, 6276–6281. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Tan, Y.J.; Chen, G.; Wang, Z.; Susanto, G.J.; See, H.H.; Yang, Z.; Lim, Z.W.; Yang, L.; Tee, B.C.K. Artificially innervated self-healing foams as synthetic piezo-impedance sensor skins. Nat. Commun. 2020, 11, 5747. [Google Scholar] [CrossRef]

- Szarek, A.; Postawa, P.; Stachowiak, T.; Paszta, P.; Redutko, J.; Mordal, K.; Kalwik, A.; Łukomska-Szarek, J.; Gzik, M.; Joszko, K.; et al. The Analysis of Polyethylene Hip Joint Endoprostheses Strength Parameters Changes after Use inside the Human Body. Materials 2021, 14, 7091. [Google Scholar] [CrossRef] [PubMed]

- Kütting, M.; Roggenkamp, J.; Urban, U.; Schmitz-Rode, T.; Steinseifer, U. Polyurethane heart valves: Past, present and future. Expert Rev. Med. Devices 2011, 8, 227–233. [Google Scholar] [CrossRef]

- Zare, M.; Ghomi, E.R.; Venkatraman, P.D.; Ramakrishna, S. Silicone-based biomaterials for biomedical applications: Antimicrobial strategies and 3D printing technologies. J. Appl. Polym. Sci. 2021, 138, 50969. [Google Scholar] [CrossRef]

- On, S.-W.; Cho, S.-W.; Byun, S.-H.; Yang, B.-E. Bioabsorbable Osteofixation Materials for Maxillofacial Bone Surgery: A Review on Polymers and Magnesium-Based Materials. Biomedicines 2020, 8, 300. [Google Scholar] [CrossRef]

- Vasnetsova, O.A. Meditsinskoye i Farmatsevticheskoye Tovarovedeniye, 3rd ed.; pererab. i dop; Avtorskaya Akademiya: Moscow, Russia, 2016; 424p. (In Russian) [Google Scholar]

- Gazazjan, M.G.; Ponomarjova, S.V.; Lipatov, V.A.; Pugachjova, A.P. Heskij Vestnik “Chelovek i ego Zdorov’e”. 2012. No. 1. Available online: http://cyberleninka.ru/article/n/eksperimentalnoe-obosnovanie-primeneniya-implantata-mezogel-dlya-profilaktikivnutrimatochnoy-adgezii (accessed on 2 October 2016).

- Lipatov, V.A.; Indrkhov, M.A.; Yarmamedov, D.M.; Lysanskaya, K.V. Morphological and physical-mechanical properties of polymer film implants in in vitro experiments. Transbaikal Med. Bull. 2015, 2, 67–73. [Google Scholar]

- Rana, A.K.; Thakur, M.K.; Saini, A.K.; Mokhta, S.K.; Moradi, O.; Rydzkowski, T.; Alsanie, W.F.; Wang, Q.; Grammatikos, S.; Thakur, V.K. Recent developments in microbial degradation of polypropylene: Integrated approaches towards a sustainable environment. Sci. Total. Environ. 2022, 826, 154056. [Google Scholar] [CrossRef] [PubMed]

- Shim, D.; Yeon, J.; Yi, J.; Park, J.; Park, S.N.; Lee, N. A wide-angle camera module for disposable endoscopy. Opt. Rev. 2016, 23, 596–600. [Google Scholar] [CrossRef]

- Kim, S.J.; Choi, B.; Kim, K.S.; Bae, W.J.; Hong, S.H.; Lee, J.Y.; Hwang, T.K.; Kim, S.W. The potential role of polymethyl methacrylate as a new packaging material for the implantable medical device in the bladder. Biomed Res. Int. 2015, 2015, 852456. [Google Scholar] [CrossRef] [PubMed]

- Kantarci, Z.; Aksoy, S.; Hasirci, N. Estimation of Monomer Content in Polymethyl Methacrylate Contact Lens Materials by Raman Spectroscopy. Int. J. Artif. Organs 1997, 20, 407–411. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef]

- Özdemir, T.; Usanmaz, A. Use of poly(methyl methacrylate) in radioactive waste management: I. Radiation stability and degradation. Prog. Nucl. Energy 2009, 51, 240–245. [Google Scholar] [CrossRef]

- Vargas, K.F.; Borghetti, R.L.; Moure, S.P.; Salum, F.G.; Cherubini, K.; de Figueiredo, M.A.Z. Use of polymethylmethacrylate as permanent filling agent in the jaw, mouth and face regions—Implications for dental practice. Gerodontology 2011, 29, e16–e22. [Google Scholar] [CrossRef]

- Allègre, L.; Le Teuff, I.; Leprince, S.; Warembourg, S.; Taillades, H.; Garric, X.; Letouzey, V.; Huberlant, S. A new bioabsorbable polymer film to prevent peritoneal adhesions validated in a post-surgical animal model. PLoS ONE 2018, 13, e0202285. [Google Scholar] [CrossRef]

- Cai, J.; Guo, J.; Wang, S. Application of Polymer Hydrogels in the Prevention of Postoperative Adhesion: A Review. Gels 2023, 9, 98. [Google Scholar] [CrossRef]

- Taylor, D.L.; In Het Panhuis, M. Self-Healing Hydrogels. Adv Mater. 2016, 28, 9060–9093. [Google Scholar] [CrossRef] [PubMed]

- Sobczyk, M.; Wallmersperger, T. Modeling and simulation of the electro-chemical behavior of chemically stimulated polyelectrolyte hydrogel layer composites. J. Intell. Mater. Syst. Struct. 2016, 27, 1725–1737. [Google Scholar] [CrossRef]

- Nonoyama, T.; Gong, J.P. Double-network hydrogel and its potential biomedical application: A review. J. Eng. Med. 2015, 229, 853–863. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Di, F.; Zhu, Y.; Xiao, Y.; Che, J. Electroactive hybrid hydrogel: Toward a smart coating for neural electrodes. J. Bioact. Compat. Polym. 2015, 30, 600–616. [Google Scholar] [CrossRef]

- MJaiswal, V. Koul. Assessment of multicomponent hydrogel scaffolds of poly(acrylic acid-2-hydroxy ethyl methacrylate)/gelatin for tissue engineering applications. J. Biomater. Appl. 2013, 27, 848–861. [Google Scholar] [CrossRef] [PubMed]

- Nistor, M.T.; Vasile, C.; Chiriac, A.P.; Tarţău, L. Biocompatibility, biodegradability, and drug carrier ability of hybrid collagen-based hydrogel nanocomposites. J. Bioact. Compat. Polym. 2013, 28, 540–556. [Google Scholar] [CrossRef]

- Cometa, S.; Iatta, R.; Ricci, M.A.; Ferretti, C.; De Giglio, E. Analytical characterization and antimicrobial properties of novel copper nanoparticle–loaded electrosynthesized hydrogel coatings. J. Bioact. Compat. Polym. 2013, 28, 508–522. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, C.; Li, X.; Xu, C.; Zhang, Y.; Sun, Z.; Liu, Y.; Gao, J. Thermosensitive methyl cellulose-based injectable hydrogels for post-operation anti-adhesion. Carbohydr. Polym. 2014, 101, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Baek, S.; Kang, H.; Lee, D. Biomaterials to Prevent Post-Operative Adhesion. Materials 2020, 13, E3056. [Google Scholar] [CrossRef]

- Lazarenko, V.A.; Sukovatyh, B.S.; Bezhin, A.I.; Lipatov, V.A.; Dubonos, A.A.; Zhukovskij, V.A. Chelovek i Ego Zdorov’e”. 2011. No. 1. Available online: http://cyberleninka.ru/article/n/pervyy-opyt-primeneniya-protivospaechnogorassasyvayuschegosya-polimernogo-sredstva-mezogel-pri-ostrom-appenditsite (accessed on 26 September 2016).

- Huang, H.-J.; Tsai, Y.-L.; Lin, S.-H.; Hsu, S.-H. Smart polymers for cell therapy and precision medicine. J. Biomed. Sci. 2019, 26, 1–11. [Google Scholar] [CrossRef]

- Sheftel’, V.O.; Dyshinevich, N.E.; Sova, R.E. Toksikologiya Polimernykh Materialov; Izdaniye “Zdorov’ye”: Moscow, Russia, 1988; 216p. [Google Scholar]

- Mashchenko, V.I.; Shashkova, Y.O.; Solomatin, A.C.; Belyaev, V.V. Features of the formation of the microstructure of borosiloxane-based liquid crystal composites. Bull. MGOU. Ser. Phys. Math. 2017, 2, 34–45. [Google Scholar]

- Kuhl, N.; Bode, S.; Hager, M.D.; Schubert, U.S. Self-Healing Polymers Based on Reversible Covalent Bonds. In Self-healing Materials. Advances in Polymer Science; Hager, M., van der Zwaag, S., Schubert, U., Eds.; Springer: Cham, Switzerland, 2015; Volume 273. [Google Scholar] [CrossRef]

- Xie, Z.; Hu, B.-L.; Li, R.-W.; Zhang, Q. Hydrogen Bonding in Self-Healing Elastomers. ACS Omega 2021, 6, 9319–9333. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Han, Y.; Zhao, W.; Yang, J.; Zhang, L. Universally autonomous self-healing elastomer with high stretchability. Nat. Commun. 2020, 11, 2037. [Google Scholar] [CrossRef]

- Kar, A.K. Photofluidics—A New Platform for Biophotonics. In Proceedings of the 2012 International Conference on Fiber Optics and Photonics (PHOTONICS), Chennai, India, 9–12 December 2012. [Google Scholar]

- Yimyai, T.; Crespy, D.; Pena-Francesch, A. Self-Healing Photochromic Elastomer Composites for Wearable UV-Sensors. Adv. Funct. Mater. 2023, 33, 2213717. [Google Scholar] [CrossRef]

- Saito, M.; Sakiyama, K. Self-healable photochromic elastomer that transmits optical signals depending on the pulse frequency. J. Opt. 2013, 15, 105404. [Google Scholar] [CrossRef]

- Wang, S.; Lee, J.M.; Yeong, W.Y. Smart hydrogels for 3D bioprinting. Int. J. Bioprinting 2015, 1, 3–14. [Google Scholar] [CrossRef]

- El Choufi, N.; Mustapha, S.; Tehrani, B.A.; Grady, B.P. An Overview of Self-Healable Polymers and Recent Advances in the Field. Macromol. Rapid Commun. 2022, 43, e2200164. [Google Scholar] [CrossRef]

- Champagne, J.; Pang, S.; Li, G. Effect of Confinement Level and Local Heating on Healing Efficiency of Self-healing Particulate Composites. Compos. Part B 2016, 97, 344–352. [Google Scholar] [CrossRef]

- Lee, J.; Bhattacharyya, D.; Zhang, M.Q.; Yuan, Y.C. Mechanical properties of mendable composites containing self-healing thermoplastic agents. Compos. Part B 2014, 62, 10–18. [Google Scholar]

- Doan, T.Q.; Leslie, L.S.; Kim, S.Y.; Bhargava, R.; White, S.R.; Sottos, N.R. Characterization of core-shell microstructure and self-healing performance of electrospun fiber coatings. Polymer 2016, 107, 263–272. [Google Scholar] [CrossRef]

- Rong, Z.; Li, Y.; Lim, R.Z.; Wang, H.; Dong, Z.; Li, K.; Wang, X. Fire-retardant effect of titania-polyurea coating and additional enhancement via aromatic diamine and modified melamine polyphosphate. Npj Mater. Degrad. 2022, 6, 38. [Google Scholar] [CrossRef]

- Shen, X.; Dong, Z.; Sim, C.; Li, Y. A Comparative Study on the Self-Healing Characterizations and Formulation Optimization of Polyurea Coating. Polymers 2022, 14, 3520. [Google Scholar] [CrossRef]

- Ma, J.; Porath, L.E.; Haque, F.; Sett, S.; Rabbi, K.F.; Nam, S.; Miljkovic, N.; Evans, C.M. Ultra-thin self-healing vitrimer coatings for durable hydrophobicity. Nat. Commun. 2021, 12, 5210. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.Y.; Chen, F.; Rong, M.Z.; Zhang, M.Q. Chapter 5—Capsules-based self-healing polymers and polymer composites. In Recent Advances in Smart Self-Healing Polymers and Composites, 2nd ed.; Li, G., Feng, X., Eds.; Woodhead Publishing: Shaston, UK, 2022; pp. 113–140. [Google Scholar] [CrossRef]

- Kosarli, M.; Bekas, D.; Tsirka, K.; Paipetis, A.S. Capsule-Based Self-Healing Polymers and Composites; Thomas, S., Surendran, A., Eds.; Self-healing polymer-based systems; Elsevier: Amsterdam, The Netherlands, 2020; pp. 259–278. [Google Scholar] [CrossRef]

- Kötteritzsch, J.; Hager, M.D.; Schubert, U.S. Tuning the self-healing behavior of one-component intrinsic polymers. Polymer 2015, 69, 321–329. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Z.; Zhang, J.; Ding, L.; Pan, L.; Huang, C.; Zheng, X.; Zeng, C.; Lin, C. Novel polyurethane with high self-healing efficiency for functional energetic composites. Polym. Test. 2019, 76, 82–89. [Google Scholar] [CrossRef]

- Zavada, S.R.; McHardy, N.R.; Gordon, K.L.; Scott, T.F. Rapid, Puncture-Initiated Healing via Oxygen-Mediated Polymerization. ACS Macro Lett. 2015, 4, 819–824. [Google Scholar] [CrossRef]

- Hia, I.L.; Vahedi, V.; Pasbakhsh, P. Self-Healing Polymer Composites: Prospects, Challenges, and Applications. Polym. Rev. 2016, 56, 225–261. [Google Scholar] [CrossRef]

- Wang, J.; Xu, W.; Li, Z.; Zhou, Z. Damping and Self-Healing Properties of Polyborosiloxane Composites. Polym. Mater. Sci. Eng. 2018, 34, 84–90. [Google Scholar]

- Wu, T.; Chen, B. Synthesis of Multiwalled Carbon Nanotube-Reinforced Polyborosiloxane Nanocomposites with Mechanically Adaptive and Self-Healing Capabilities for Flexible Conductors. ACS Appl. Mater. Interfaces 2016, 8, 24071–24078. [Google Scholar] [CrossRef]

- Osada, T.; Kamoda, K.; Mitome, M.; Hara, T.; Abe, T.; Tamagawa, Y.; Nakao, W.; Ohmura, T. A Novel Design Approach for Self-Crack-Healing Structural Ceramics with 3D Networks of Healing Activator. Sci. Rep. 2017, 7, 17853. [Google Scholar] [CrossRef]

- Turkenburg, D.H.; Fischer, H.R. Reversible cross-linking in composite binders—In-situ repair options and recyclability. Adv. Mater. Lett. 2018, 9, 861–866. [Google Scholar] [CrossRef]

- Yoshioka, S.; Nakao, W. Methodology for evaluating self-healing agent of structural ceramics. J. Intell. Mater. Syst. Struct. 2015, 26, 1395–1403. [Google Scholar] [CrossRef]

- Nakao, W.; Abe, S. Enhancement of the self-healing ability in oxidation induced self-healing ceramic by modifying the healing agent. Smart Mater. Struct. 2012, 21, 025002. [Google Scholar] [CrossRef]

- Farle, A.S.; Kwakernaak, C.; van der Zwaag, S.; Sloof, W.G. A conceptual study into the potential of Mn+1AXn-phase ceramics for self-healing of crack damage. J. Eur. Ceram. Soc. 2015, 35, 37–45. [Google Scholar] [CrossRef]

- Li, S.; Song, G.; Kwakernaak, K.; van der Zwaag, S.; Sloof, W.G. Multiple crack healing of a Ti2AlC ceramic. J. Eur. Ceram. Soc. 2012, 32, 1813–1820. [Google Scholar] [CrossRef]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications Edited by Swapan Kumar Ghosh; WILEY-VCH Verlag GmbH & Co.: Weinheim, Germany, 2009; p. 306. [Google Scholar]

- Ono, M.; Nakao, W.; Takahashi, K.; Nakatani, M.; Ando, K. A new methodology to guarantee the structural integrity of Al2O3/SiC composite using crack healing and a proof test. Fatigue Fract. Eng. Mater. Struct 2007, 30, 599–607. [Google Scholar] [CrossRef]

- Zhang, S.; Kwakernaak, C.; Sloof, W.; Brück, E.; van der Zwaag, S.; van Dijk, N. Self healing of creep damage by gold precipitation in iron alloys. Adv. Eng. Mater. 2015, 17, 598–603. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Mahamood, M.A.A.; Al-Osta, M.A.; Ahmad, S. Performance and efficiency of self-healing geopolymer technologies: A review. Constr. Build. Mater. 2023, 386, 131571. [Google Scholar] [CrossRef]

- Laha, K.; Kyono, J.; Shinya, N. An advanced creep cavitation resistance Cu-containing 18Cr–12Ni–Nb austenitic stainless steel. Scr. Mater. 2007, 56, 915–918. [Google Scholar] [CrossRef]

- Kodzoev, M.-B.K.; Isachenko, S.L. Self-healing concrete [Electronic resource]. Sci. J. Bull. Sci. Pract. 2018, 4, 287–290. Available online: http://www.bulletennauki.com/kodzoev-isachenko-1 (accessed on 18 April 2024).

- Jonkers, H.M.; Schlangen, E. Development of a bacteria-based self healing concrete. Tailor Made Concr. Struct. 2008, 1, 425–430. [Google Scholar] [CrossRef]

- Stefanidou, M.; Tsardaka, E.-C.; Karozou, A. Nanoparticles controlling self-healing properties in cement pastes. Mater. Today Proc. 2021, 54, 22–27. [Google Scholar] [CrossRef]

- Ahn, T.H.; Kishi, T. Crack self-healing behavior of cementitious composites incorporating various miner admixtures. J. Adv. Concr. Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Solskiy, S.V.; Orlova, N.L.; Velichko, A.S. Crack self-healing in clay-cement concrete diaphragm of embankment dam. Mag. Civ. Eng. 2018, 77, 3–12. [Google Scholar]

- Tolstoy, A.; Gridchin, A.; Glagolev, E.; Lesovik, R.; Shapovalov, N. Efficient Construction Composites for Construction in the North and the Arctic. Lect. Notes Civ. Eng. 2021, 147, 15–22. [Google Scholar]

- Terzis, D.; Laloui, L. A decade of progress and turning points in the understanding of bio-improved soils: A review. Géoméch. Energy Environ. 2019, 19, 100116. [Google Scholar] [CrossRef]

- Bruyako, M.; Grigorieva, L.; Grigorieva, A.; Ivanova, I. Treatment of natural zeolites for increasing the sorption capacity. Solid State Phenom. 2016, 871, 70–75. [Google Scholar] [CrossRef]

- Bruyako, M.; Grigoryeva, L. Bioactive additives for self-healing of concretete microstructure. Mater. Sci. Forum 2018, 945, 36–41. [Google Scholar] [CrossRef]

- Bruyako, M.; Grigor’eva, A.; Stepina, I.; Golotenko, D.; Podsevalova, A. Biomodified building materials on the base of mineral binders. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 7th International Scientific Conference on Integration, Partnership and Innovation in Construction Science and Education, Tashkent, Uzbekistan, 11–14 November 2020; Volume 1030, p. 012005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dallaev, R. Advances in Materials with Self-Healing Properties: A Brief Review. Materials 2024, 17, 2464. https://doi.org/10.3390/ma17102464

Dallaev R. Advances in Materials with Self-Healing Properties: A Brief Review. Materials. 2024; 17(10):2464. https://doi.org/10.3390/ma17102464

Chicago/Turabian StyleDallaev, Rashid. 2024. "Advances in Materials with Self-Healing Properties: A Brief Review" Materials 17, no. 10: 2464. https://doi.org/10.3390/ma17102464

APA StyleDallaev, R. (2024). Advances in Materials with Self-Healing Properties: A Brief Review. Materials, 17(10), 2464. https://doi.org/10.3390/ma17102464