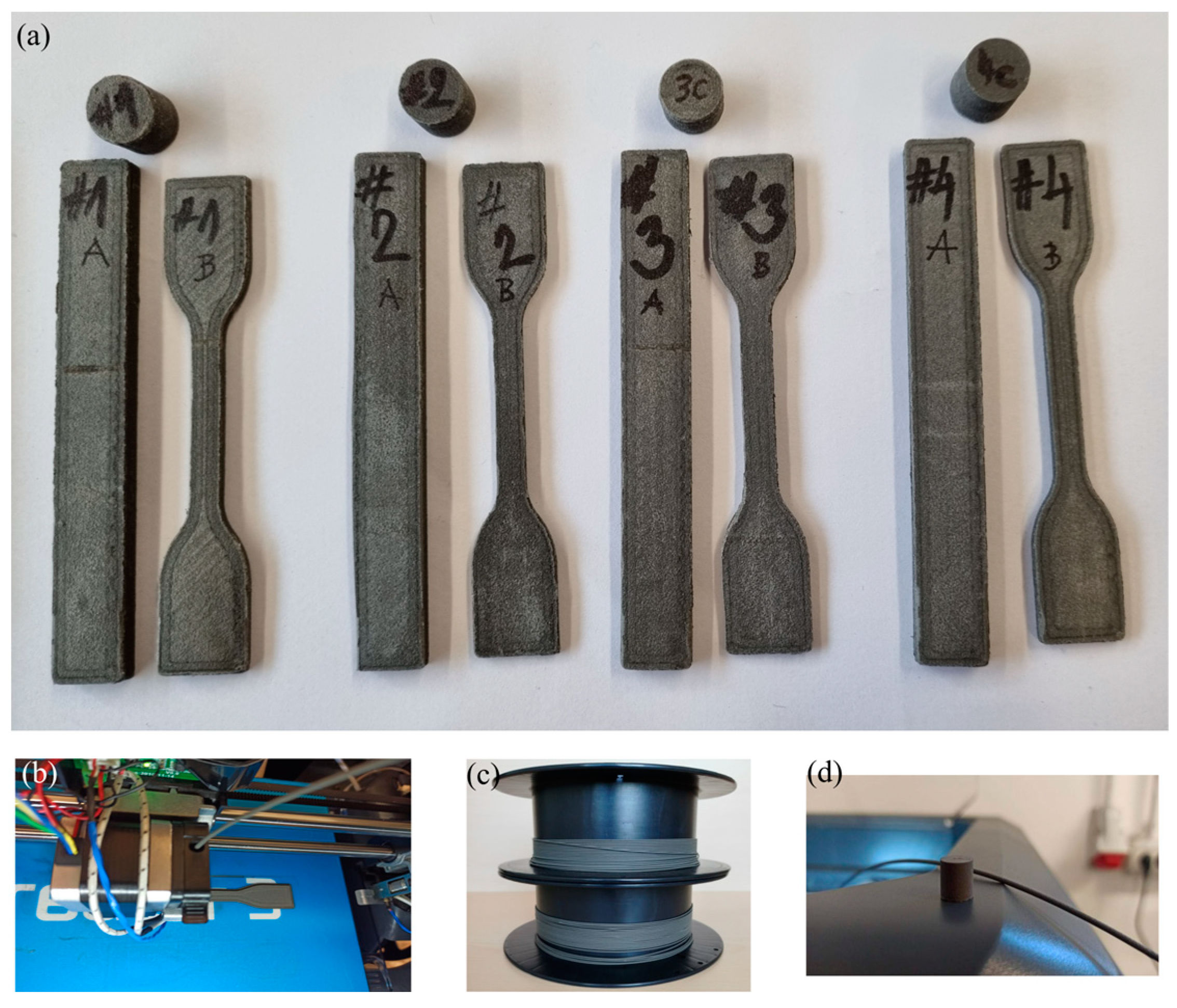

3.1. Characterisation of the Filaments

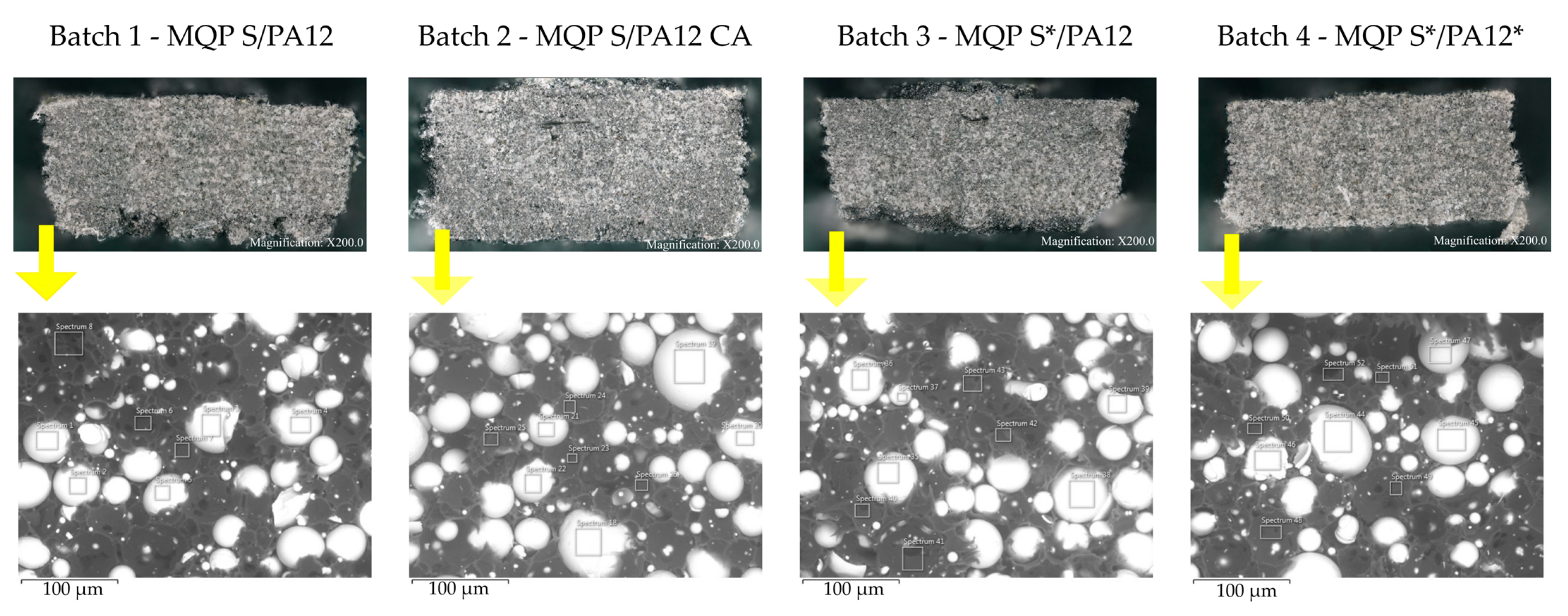

SEM micrographs of fractured surfaces of filaments for all four batches are shown in

Figure 4.

Table 3,

Table 4,

Table 5 and

Table 6 present the elemental compositions (wt.%) of major elements detected on the cross-sectional areas of the filament surfaces by EDX, including both the magnetic powders and the polymer matrix within the filament. Examination of the SEM images revealed no noticeable contrast variation among batches. The homogeneity and distribution of the magnetic particles within the polymer matrix were consistent across all batches. The voids observed in the images suggest a debonding mechanism in which the MQP S particles are pulled from the matrix. The elemental compositions of all filament batches were comparable, with a rather high concentration of carbon (C) observed in the spectra MQP S. This high C concentration is likely attributed to the examination of cross-sections involving filament breakage by pulling. It appears that when the filament was torn apart, the MQP S particles retained some polymer on their surfaces, contributing to the high concentration of C observed in the spectra of MQP S.

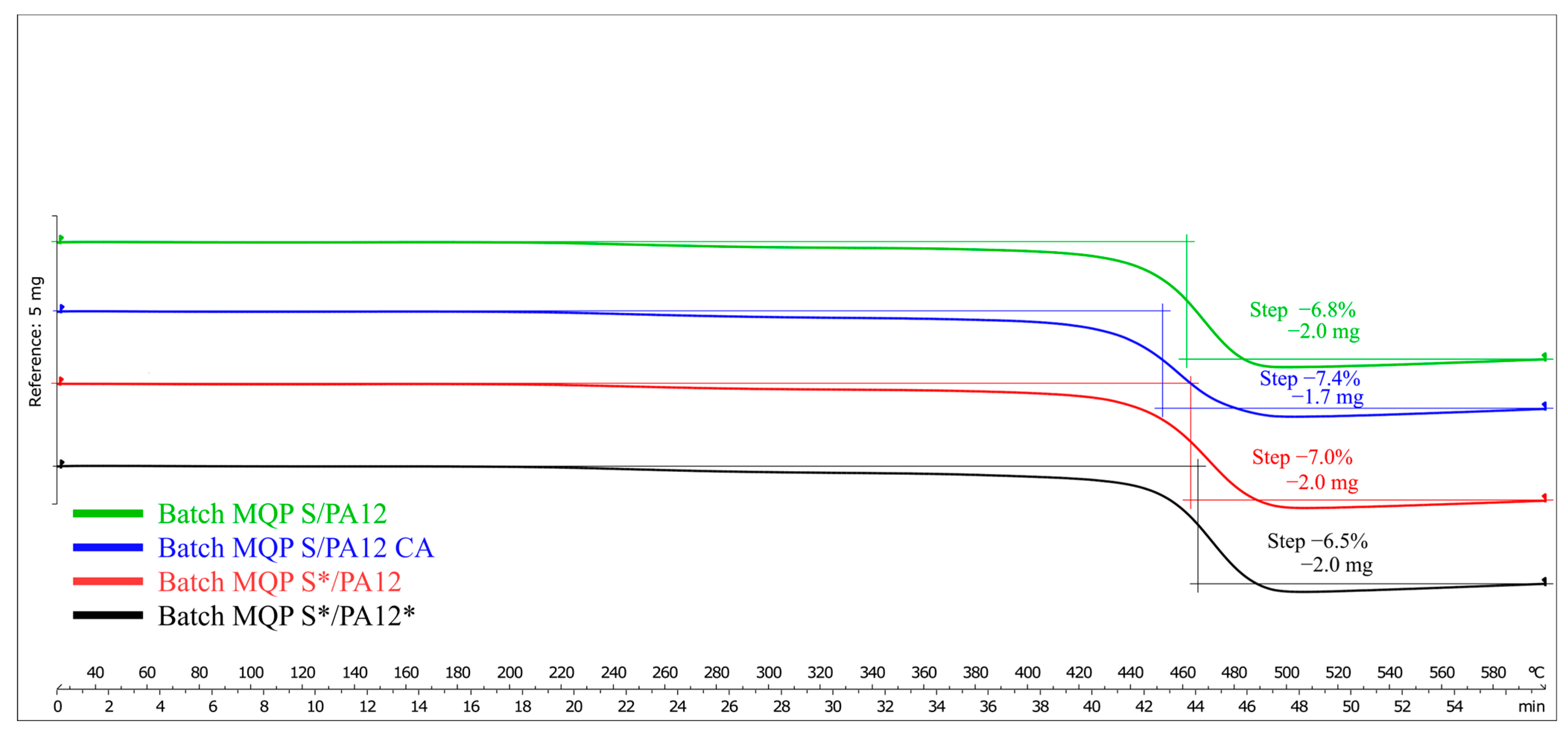

The results obtained from the TGA analysis are shown in

Figure 5. TGA offers a useful means of estimating polymer content, as the percentage of mass loss corresponds to the extent of polymer degradation. As expected, across all four batches, each containing 7 wt.% polymer, the mass loss remained close to 7%, as demonstrated in

Figure 5. Although there were minor variations among the batches, these fluctuations suggest that the feedstock materials may not have been perfectly homogenized during filament production. Notably, the second batch (blue curve in

Figure 5), which incorporated organo-titanate as a coupling agent, exhibited the highest mass loss due to the partial degradation of the coupling agent itself.

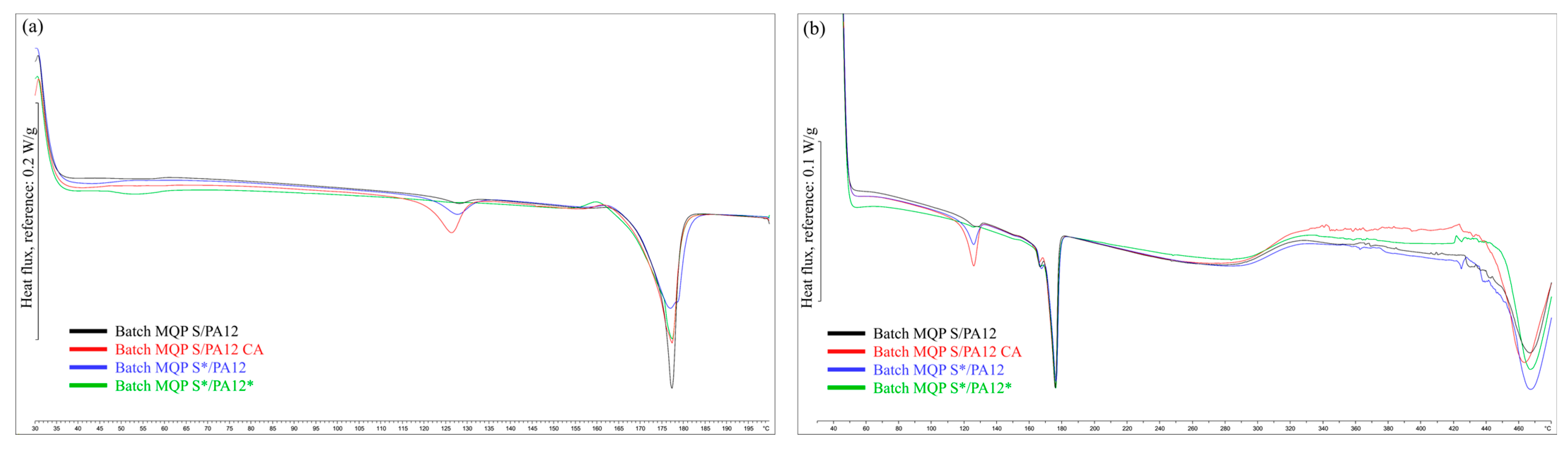

Results of the DSC analysis, presented in

Figure 6 and

Table 7, revealed that the melting temperatures (T

m1 and T

m2) after the first and second heating cycles for all four batches were consistently close, with T

m1 at approximately 176 °C and T

m2 at approximately 175 °C. This uniformity suggests similar thermal stability and composition among batches in terms of the factors influencing the melting points. The enthalpy changes (ΔH

m1 and ΔH

m2) after the first and second heating cycles showed minor variations among batches, with values in the second heating cycle (ΔH

m2) being slightly lower, possibly owing to decreased crystallinity or structural changes [

44]. The calculated degree of crystallinity ranged from 19.5% to 21.7%. Notably, the batch MQP S/PA12 CA exhibited slightly higher crystallinity, suggesting that the presence of organo-titanate as a coupling agent contributed to the increased crystalline structure formation. Similarly, in the case of MQP S*/PA12*, where both the filler and binder underwent plasma surface modification, the higher degree of crystallinity can be attributed to these modifications.

The MFI data for all batches of filament are presented in

Table 8. The batch labeled MQP S/PA12 CA exhibited the highest MFI among all the batches. A higher MFI can be attributed to the presence of a coupling agent in the form of organo-titanate, which enhances the dispersion between the inorganic filler phase and organic polymer phase. Consequently, it promotes effective deagglomeration and the subsequent removal of air and water from the interface [

45]. Conversely, the batch in which only the polymer underwent treatment in a low-pressure microwave plasma reactor displayed the lowest MFI. Similar plasma treatment resulted in suboptimal polymer melting behavior, particularly when prolonged low-pressure microwave plasma treatment was applied to achieve target morphological changes [

33]. These changes proved to be more advantageous when the magnetic filler was also subjected to radio-frequency plasma treatment, as observed in the case of batch MQP S*/PA12*. Importantly, suboptimal MFI values can lead to challenges in the extrusion process, such as over-extrusion or inconsistent filament extrusion, impacting the quality and consistency of FDM-printed samples.

3.2. Properties of the FDM-Printed Polymer-Bonded Magnets

Table 9 provides an overview of the measured and calculated densities of FDM-printed cylinders, along with the corresponding calculated porosity. It is noteworthy that in a prior study, injection-molded cylinders produced from the same feedstock materials as batch MQP S/PA12 CA achieved a measured density exceeding 4.5 g/cm

3 and exhibited a calculated porosity of less than 2%. In the context of this study, the achieved FDM densities ranged from 92% to 94% of the theoretical density, indicating a reasonably high level of material consolidation. Nevertheless, it is important to acknowledge that FDM-printed cylinders inherently possess higher porosity compared to injection-molded ones, due to the nature of the printing process itself. FDM technology is known to yield parts with increased porosity when compared to those produced through alternative manufacturing methods [

46]. Given that identical printing parameters were applied across all batches, the observed higher porosity in the FDM cylinders can be attributed to potential challenges in achieving optimal layer-to-layer adhesion during the printing process.

The CT scan analysis across all batches, including tensile test tubes, flexural test tubes, and cylinders, showed that the cylinders exhibited the least detectable voids. This suggests a correlation between the smaller dimensional scale of the cylinders and a reduction in observable porosity, potentially due to the layer resolution and deposition characteristics inherent to FDM. In contrast, mechanical test tubes manifested a greater frequency of air voids, indicating a variance in the filament-to-filament adhesion during the printing process. In the reference batch (MQP S/PA12), voids are present sporadically, which could be indicative of a uniform filler distribution that is not influenced by a coupling agent. Contrastingly, introducing an organo-titanate coupling agent in batch MQP S/PA12 CA is associated with the most detectable voids and air gaps. This observation is particularly interesting when considering the batch’s highest MFI value. The elevated MFI could imply a reduced viscosity, potentially facilitating the printing process but also allowing for increased void formation, likely due to the material flowing too readily, leading to inconsistent layer adhesion and increased porosity. Similarly, batch MQP S/PA12* also exhibited a significant presence of voids. The lowest MFI value of this batch suggests that the increased viscosity could have adversely affected the printing process, possibly hindering the material’s ability to flow and merge between layers, thus contributing to the formation of voids [

47]. The batch MQP S*/PA12* voids may signal an altered interaction between the modified surfaces of the filler and the polymer, potentially influenced by the interaction between the altered surface-free energies of plasma-treated filler and polymer [

33]. Detailed visualisation of these characteristics can be seen in the CT scan depicted in

Figure 7.

When it comes to magnetic properties and residual remanence (B

r) in PBMs, they are significantly influenced by the volume fraction of the magnetic filler within the magnet. Generally, higher volume percentages of filler lead to increased B

r values. However, the presence of pores can have a counteractive effect, diminishing the achieved B

r [

48]. In

Table 10, both measured and theoretical B

r values for FDM-printed cylinders are presented. Across all batches, the achieved Br values ranged from 85% to 89% of their theoretical counterparts. Notably, a correlation can be observed between measured porosity values from

Table 9 and the achieved B

r values; samples with higher porosity tend to exhibit lower B

r values. Specifically, batches MQP S/PA12 CA and MQP S/PA12* had porosity levels of 8.4% and 8%, respectively, achieving B

r values of 85% and 86% of their theoretical B

r. Conversely, batches MQP S/PA12 and MQP S*/PA12*, which had lower porosity at approximately 6%, achieved nearly 89% of their theoretical B

r values.

In

Table 10, measured values for intrinsic coercivity (H

ci) can be observed. Considering that the as-received MQP S powder exhibits an H

ci range of 670–750 kA/m [

35], it becomes evident that certain FDM batches displayed H

ci lower than that of the as-received MQP S powder. This decrease in H

ci can be attributed to inappropriate processing conditions that may have altered the microstructure of the materials. Poor adhesion between the polymer matrix and the magnetic particles results in a reduction in coercivity. It is worth mentioning that during filament extrusion, the feedstock material, including MQP S powder, was exposed to a temperature range of 180 °C to 200 °C for a 30-min duration. This thermal exposure likely contributed to the oxidation of MQP S particles. Furthermore, any occurrence of larger grain sizes or misaligned grains during the printing process could lead to a decrease in H

ci values. Interestingly, the batch containing a coupling agent stands out as the exception, maintaining the same H

ci values as the as-received MQP S powder. This further confirms that the coupling agent could effectively shield the magnetic powder during filament manufacturing and extrusion processes.

Tensile test results of batches of FDM-produced composites, presented in

Table 11, provide an overview of how different treatments and the inherent characteristics of FDM, such as increased porosity and layer adhesion variability, impact the mechanical properties of these materials. All batches exhibited variations in elastic modulus as well as relatively large standard deviations, indicating potential inconsistencies in material properties. This variability could stem from the FDM process itself, where issues in layer consolidation can lead to poor interlayer adhesion, reducing the structural integrity of the printed parts. Additionally, the presence of porosity within the layers is a common concern in FDM printing, further contributing to potential weaknesses in the mechanical structure and impacting the elastic modulus measurements [

49]. The addition of 0.5 wt.% of organo-titanate in MQP S/PA12 CA led to a reduced modulus of 141 ± 40 MPa when compared to MQP S/PA12, indicating enhanced flexibility but at the cost of increased brittleness, as evidenced by its significantly lower ductility (5 ± 2%). In the third batch, MQP S/PA12*, where PA12 was treated with low-pressure microwave plasma, a considerable increase in stiffness was observed, with an elastic modulus of 974 ± 161 MPa. This suggests that plasma treatment improves material properties, likely due to enhanced adhesion at the molecular level. The final batch, MQP S*/PA12*, which underwent dual plasma treatment, presented a balanced profile of moderate stiffness (578 ± 389 MPa) and the highest ductility (21 ± 2%), indicating an optimal combination of treatments for improved flexibility and consistency. Across all batches, tensile strength values were relatively similar, ranging from 5.5 to 6.9 MPa. Despite the different treatments, this uniformity suggests that while FDM-produced materials can withstand some tension, their strength in resisting a pulling force is not exceptionally high, which is a characteristic to be considered in their application. Overall, the results show that the tensile properties of FDM-produced materials, particularly elastic modulus and elongation at break, vary significantly across different batches, emphasizing the crucial role of specific treatments in material optimization. Evidently, microwave and radiofrequency plasma treatments have been shown to enhance these properties markedly. Despite these variations, the tensile strength across all batches remains consistently limited, underscoring a characteristic trait of FDM materials in their response to tensile stress.

When it comes to flexural properties, presented in

Table 12, the first batch, MQP S/PA12, which combined MQP S filler with PA12 without coupling agents, demonstrated a flexural strength of 14 ± 2 MPa and a strain of 6 ± 2%. This serves as a reference for the untreated material’s performance. In contrast, the second batch, MQP S/PA12 CA, which included an organo-titanate coupling agent, showed a lower flexural strength of 10 ± 1 MPa but a slightly higher strain of 7 ± 1%, suggesting that the addition of the coupling agent may lead to a decrease in strength but a marginal increase in flexibility. The third batch, MQP S/PA12*, where PA12 underwent microwave plasma treatment, exhibited a flexural strength of 10 ± 1 MPa and an increased strain of 8.6 ± 0.3%, indicating that plasma treatment of the polymer powder can enhance the material’s flexibility. This is evident in the higher strain value compared to the untreated and coupling agent-treated batches. The final batch, MQP S*/PA12*, where both MQP S and PA12 underwent radiofrequency and microwave plasma treatment, respectively, showed the highest flexural strength of 15.4 ± 0.4 MPa and a strain of 5 ± 1%. This suggests that the dual plasma treatment significantly enhances the material’s strength while maintaining a comparable level of flexibility to the untreated batch. These results highlight the influence of material treatments on the flexural properties of FDM-printed composites. The inclusion of a coupling agent and plasma treatments, particularly dual plasma treatment, has been found to significantly alter the flexural strength and strain, demonstrating the potential for tailoring material properties through specific processing techniques in FDM applications.

Figure 8 displays SEM micrographs of the fractured surfaces from each batch after the tensile test. It is evident from the images that the breakage occurs directly along the magnet/polymer interface, suggesting that delamination is more likely to occur in regions with smooth uniform surfaces compared to areas with irregularly shaped particles [

50]. This observation underscores the importance of particle morphology in influencing the adhesive bonding within the composite, potentially affecting the overall mechanical integrity of the printed structures.