Initial Characteristics of Alkali–Silica Reaction Products in Mortar Containing Low-Purity Calcined Clay

Abstract

1. Introduction

2. Materials and Methods

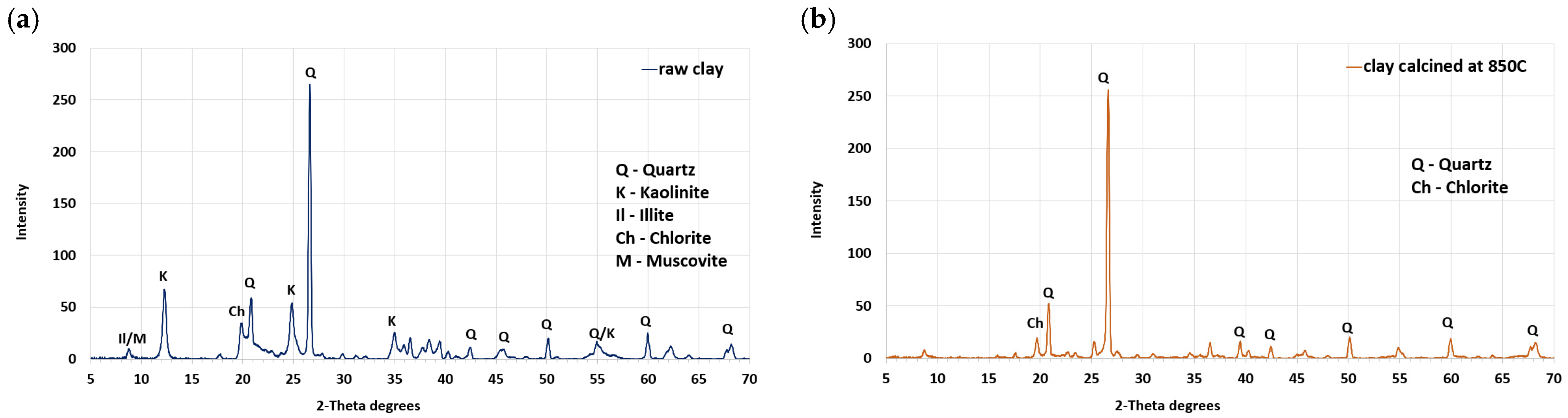

2.1. Raw Materials

| Oxide Composition | SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | (SO3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight percentage, % | 72.6 | 0.22 | 15.01 | 1.47 | 0.04 | 0.34 | 1.38 | 4.16 | 3.78 | 0.07 | <0.01 |

2.2. Specimens Preparation

2.3. Test Methods

2.3.1. Accelerated Mortar Bar Method

2.3.2. Scanning Electron Microscopy

2.3.3. Nanoindentation

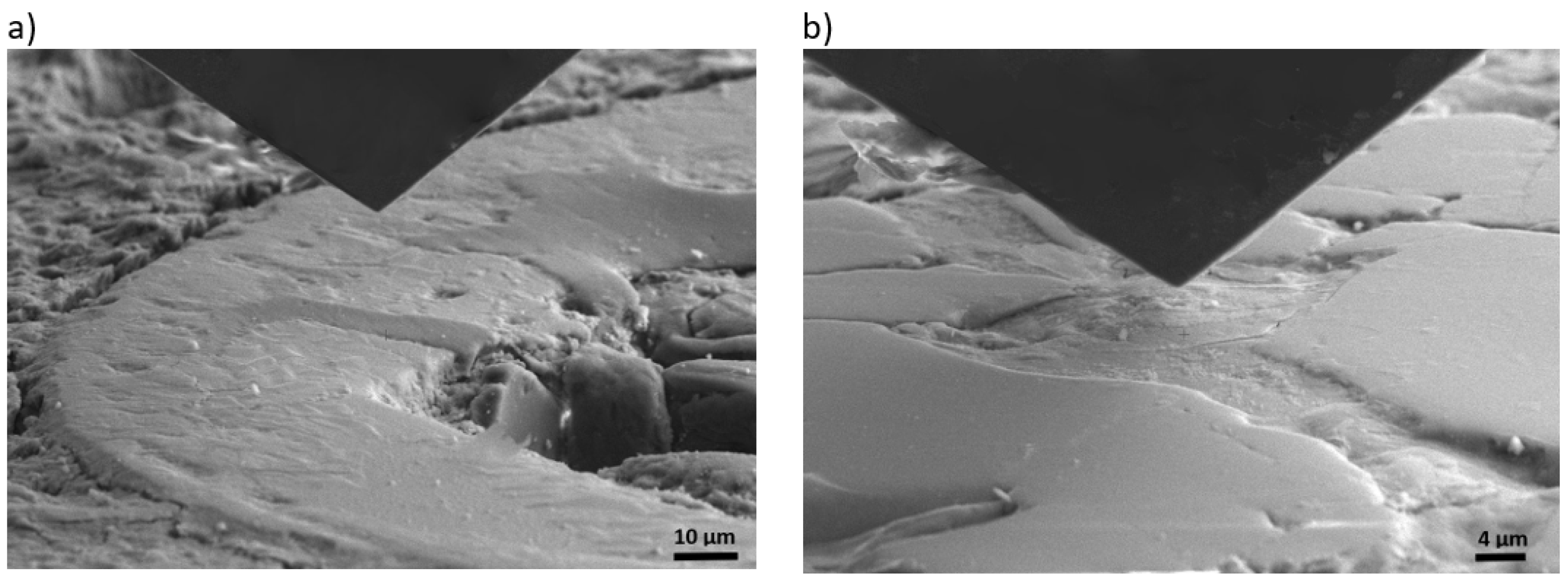

3. Results

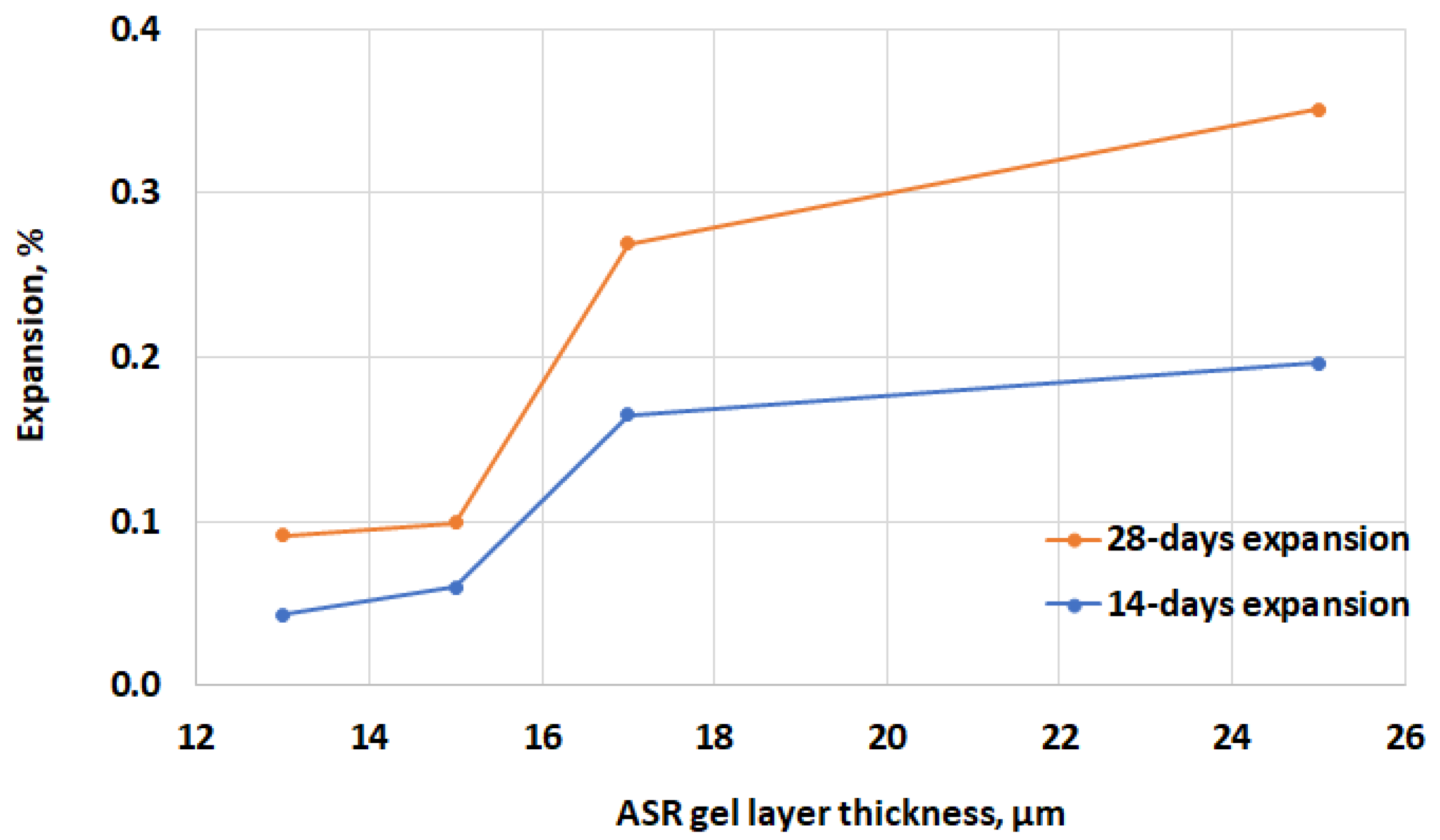

3.1. Accelerated Mortar Bar Method

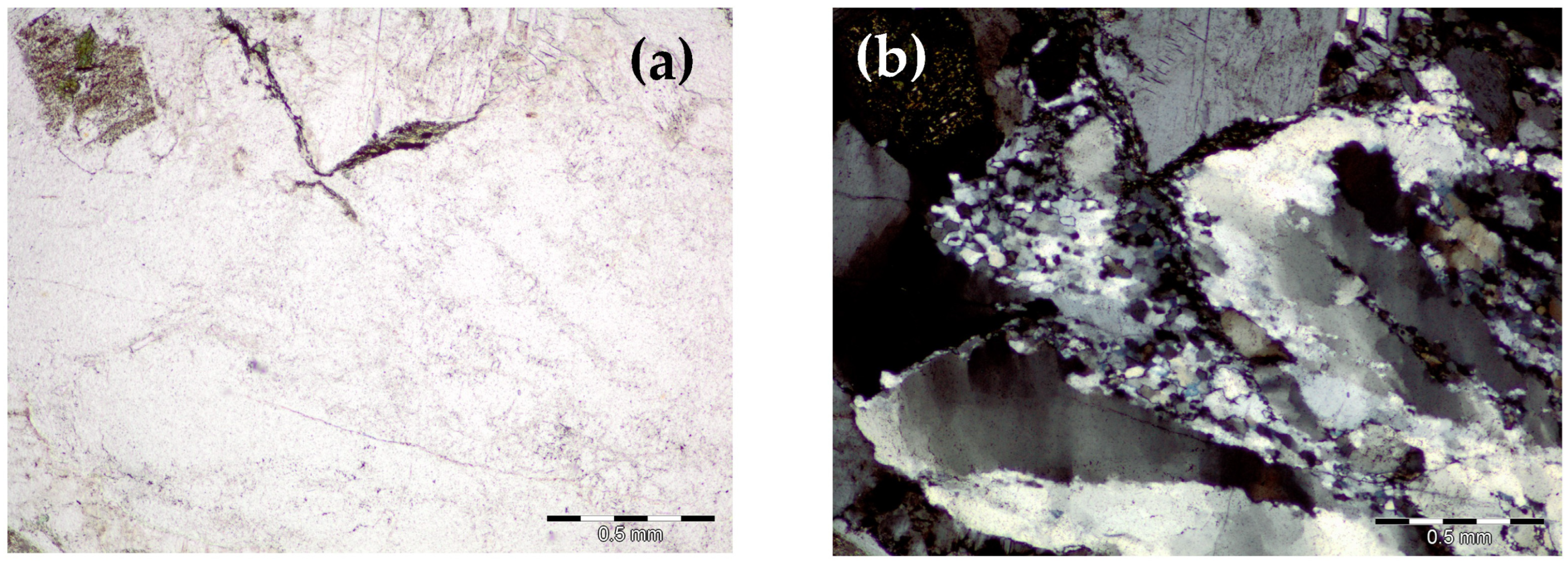

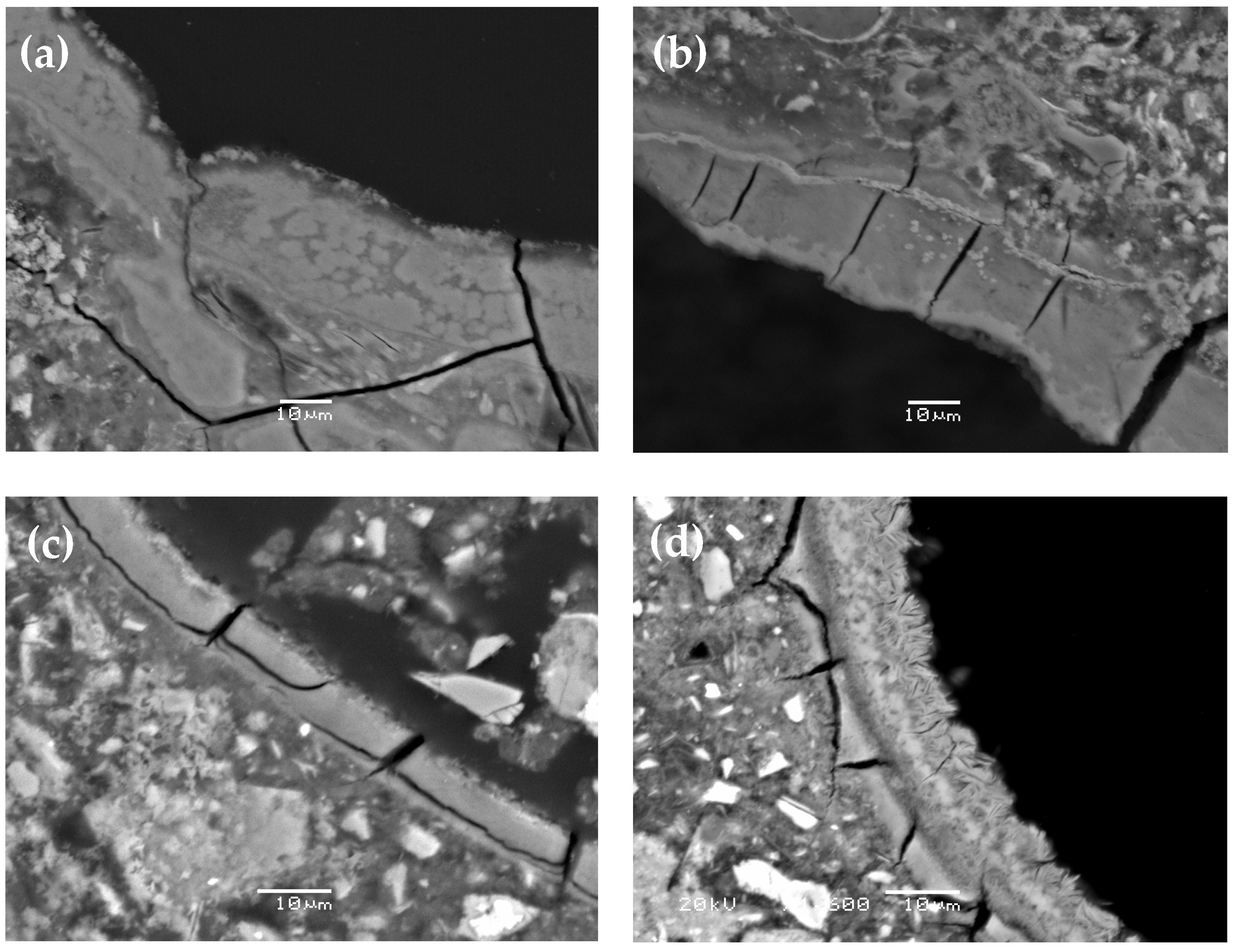

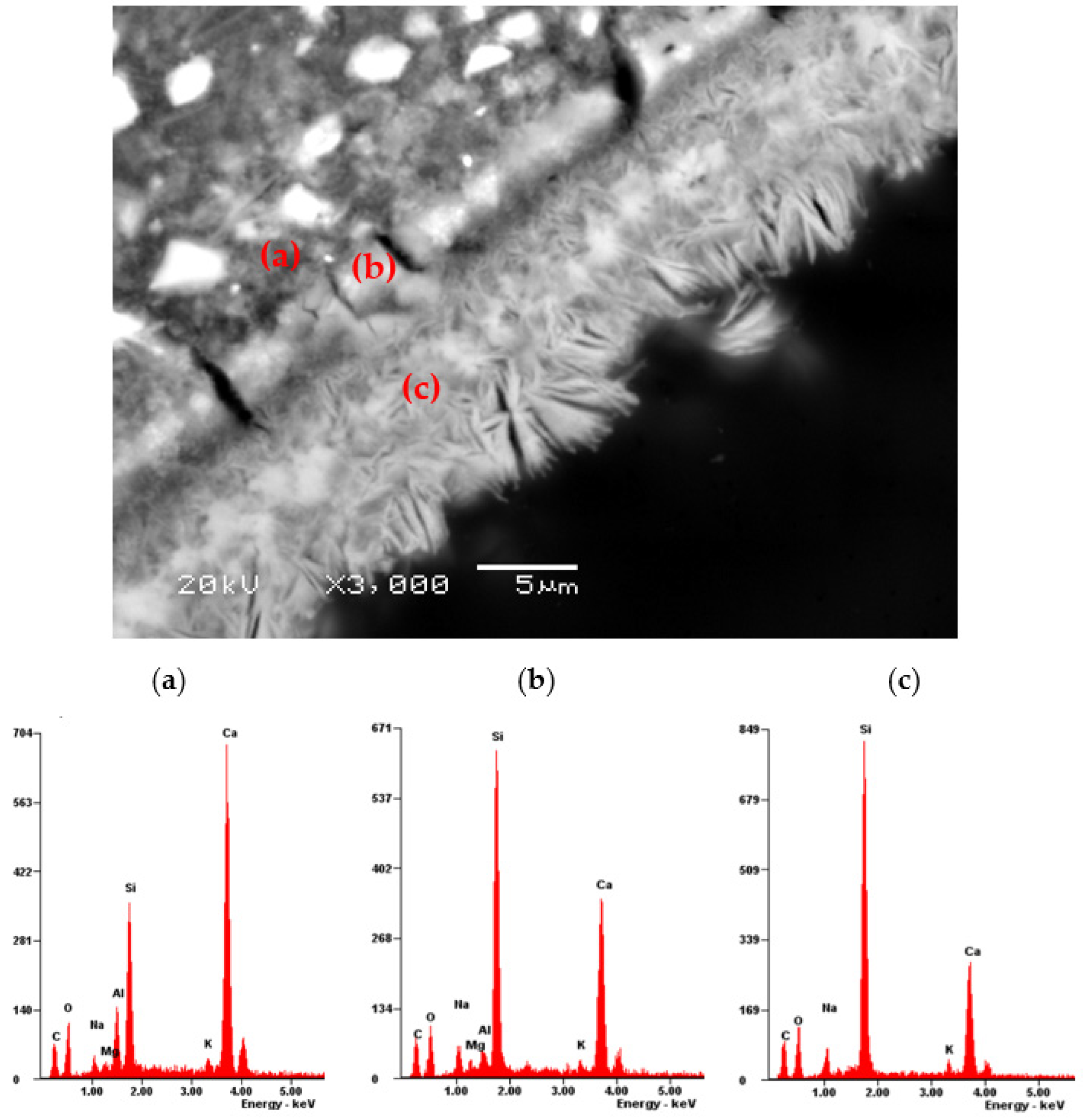

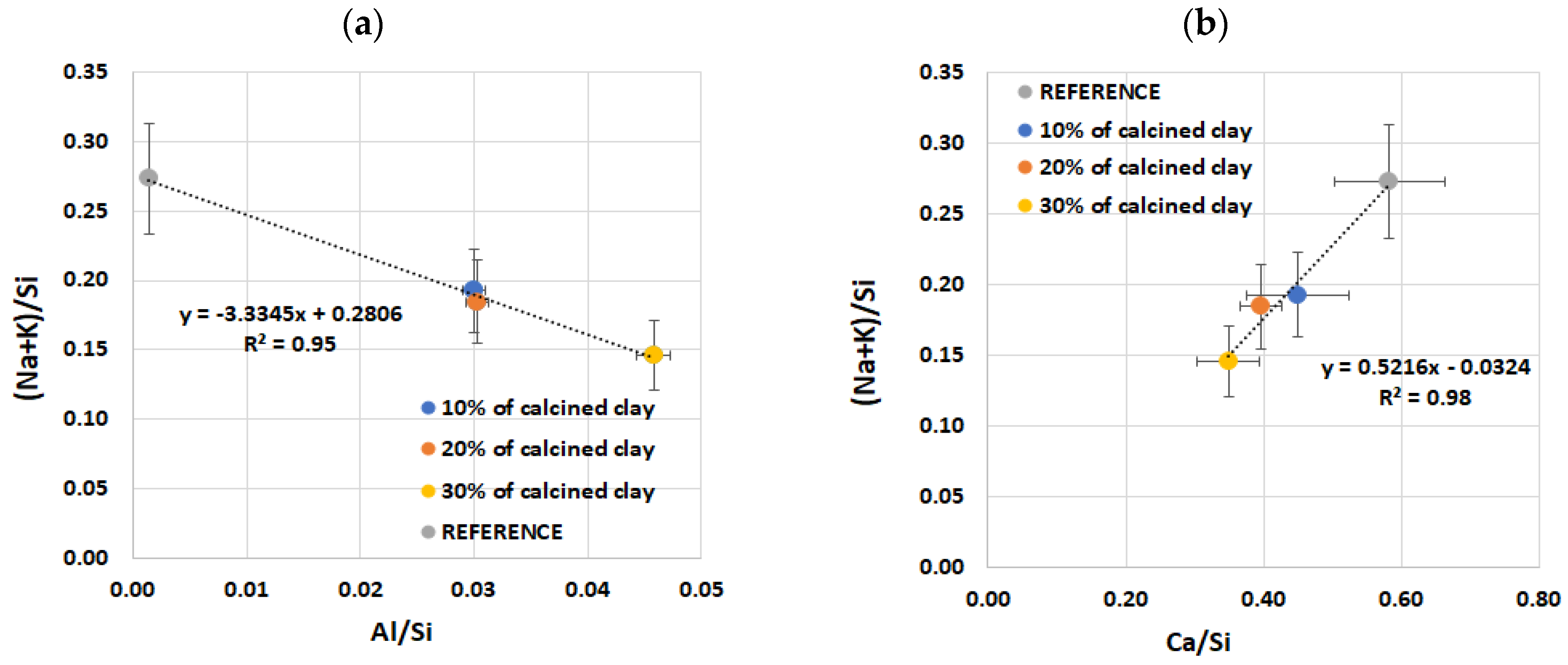

3.2. Microstructure Analysis

3.3. Nanoindentation Test Results

4. Discussion

5. Conclusions

- The influence of calcined clay on limiting the expansion of the mortar bars as a result of the alkali–silica reaction of the aggregate was demonstrated.

- The microscopic analysis and chemical evaluations showed clear differences in the ASR products depending on the amount of calcined clay used. As the calcined clay content increased, the crystalline form of the ASR gel decreased.

- The ASR gel located in the air voids showed an average Ca/Si ratio of 0.73 ± 0.18 and (Na+K)/Si of 0.26 ± 0.04 for the reference specimens, and 0.50 ± 0.11 and 0.17 ± 0.02, respectively, for the specimens with 30% calcined clay content. The effect of the calcined clay dosage on the Al/Si ratio was minimal; however, adding calcined clay had an effect.

- The nanohardness increased with an increasing calcined clay content. Under a load of 10 mN, Young’s modulus of the amorphous ASR products ranged from 5 to 12 GPa, with a standard deviation of about 1 GPa, while the nanohardness ranged from 0.41 to 0.67 GPa, with a standard deviation of about 0.04 GPa.

- The determined values of Young’s modulus and nanohardness can be used for comprehensive numerical modelling of the mechanical properties of alkali–silica reaction products in concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, T.; Alnahhal, M.F.; Nguyen, Q.D.; Panchmatia, P.; Hajimohammadi, A.; Castel, A. Initial sequence for alkali-silica reaction: Transport barrier and spatial distribution of reaction products. Cem. Concr. Compos. 2019, 104, 103378. [Google Scholar] [CrossRef]

- Kim, T.; Olek, J.; Jeong, H.G. Alkali-silica reaction: Kinetics of chemistry of pore solution and calcium hydroxide content in cementitious system. Cem. Concr. Res. 2015, 71, 36–45. [Google Scholar] [CrossRef]

- Leemann, A.; Shi, Z.; Lindgård, J. Characterization of amorphous and crystalline ASR products formed in concrete aggregates. Cem. Concr. Res. 2020, 137, 106190. [Google Scholar] [CrossRef]

- Katayama, T. ASR gels and their crystalline phases in concrete-universal products in alkali-silica, alkali-silicate and alkali-carbonate reactions. In Proceedings of the 14th International Conference of Alkali-Aggregate Reaction ICAAR, Austin, TX, USA, 20–25 May 2012; pp. 1–12. [Google Scholar]

- Rajabipour, F.; Giannini, E.; Dunant, C.; Ideker, J.H.; Thomas, M.D.A. Alkali–silica reaction: Current understanding of the reaction mechanisms and the knowledge gaps. Cem. Concr. Res. 2015, 76, 130–146. [Google Scholar] [CrossRef]

- Ma, P.; Li, J.; Bai, J.; Zhuo, Y.; Chi, L.; Zhu, Y.; Shi, Z.; Ma, H.; Chen, G. Effect of type and quantity of inherent alkali cations on alkali-silica reaction. Cem. Concr. Res. 2023, 173, 107293. [Google Scholar] [CrossRef]

- Hay, R.; Ostertag, C.P. New insights into the role of fly ash in mitigating alkali-silica reaction (ASR) in concrete. Cem. Concr. Res. 2021, 144, 106440. [Google Scholar] [CrossRef]

- Xu, G.J.Z.; Watt, D.F.; Hudec, P.P. Effectiveness of mineral admixtures in reducing ASR expansion. Cem. Concr. Res. 1995, 25, 1225–1236. [Google Scholar] [CrossRef]

- Tapas, M.J.; Sofia, L.; Vessalas, K.; Thomas, P.; Sirivivatnanon, V.; Scrivener, K. Efficacy of SCMs to mitigate ASR in systems with higher alkali contents assessed by pore solution method. Cem. Concr. Res. 2021, 142, 106353. [Google Scholar] [CrossRef]

- Cassiani, J.; Dugarte, M.; Martinez-Arguelles, G. Evaluation of the chemical index model for predicting supplementary cementitious material dosage to prevent the alkali-silica reaction in concrete. Constr. Build. Mater. 2021, 275, 122158. [Google Scholar] [CrossRef]

- Jones, T.R.; Walters, G.V.; Kostuch, J.A. Role of Metakaolin in suppressing ASR in concrete containing reactive aggregate and exposed to saturated NaCl solution. In Proceedings of the 9th International Conference on Alkali-Aggregate Reaction in Concrete ICAAR, London, UK, 27–31 July 1992; The Concrete Society: London, UK, 1992; pp. 485–496. [Google Scholar]

- Aquino, W.; Lange, D.A.; Olek, J. The influence of metakaolin and silica fume on the chemistry of alkali-silica reaction products. Cem. Concr. Compos. 2001, 23, 485–493. [Google Scholar] [CrossRef]

- Jaskulski, R.; Jóźwiak-Niedźwiedzka, D.; Yakymechko, Y. Calcined clay as supplementary cementitious material. Materials 2020, 13, 4734. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Favier, A.R. Calcined clays for sustainable concrete. In Proceedings of the 1st International Conference on Calcined Clays for Sustainable Concrete, Lausanne, Switzerland, 23–25 June 2015; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Hu, C.; Tao, Y.; Gautam, B.P.; Wang, F. Performance enhancement of sustainable cementitious material with ultrahigh content limestone and calcined clay. ACS Sustain. Chem. Eng. 2022, 10, 10733–10742. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Incorporation of calcined clays in mortars: Porous structure and compressive strength. Procedia Mater. Sci. 2012, 1, 366–373. [Google Scholar] [CrossRef]

- Yaraghi, A.H.Y.; Ramezanianpour, A.M.; Ramezanianpour, A.A.; Bahman-Zadeh, F.; Zolfagharnasab, A. Evaluation of test procedures for durability and permeability assessment of concretes containing calcined clay. J. Build. Eng. 2022, 58, 105016. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.F.; Wong, H.S.; Kamyab, H.; Scrivener, K.L. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Rossetti, A.; Ikumi, T.; Segura, I.; Irassar, E.F. Sulfate performance of blended cements (limestone and illite calcined clay) exposed to aggressive environment after casting. Cem. Concr. Res. 2021, 147, 106495. [Google Scholar] [CrossRef]

- Shi, Z.; Ferreiro, S.; Lothenbach, B.; Geiker, M.R.; Kunther, W.; Kaufmann, J.; Herfort, D.; Skibsted, J. Sulfate resistance of calcined clay—Limestone—Portland cements. Cem. Concr. Res. 2019, 116, 238–251. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Jaskulski, R.; Dziedzic, K.; Antolik, A.; Dąbrowski, M. Influence of calcination temperature and amount of low-grade clay replacement on mitigation of the alkali–silica reaction. Materials 2023, 16, 3210. [Google Scholar] [CrossRef]

- Li, C.; Ideker, J.H.; Drimalas, T. The efficacy of calcined clays on mitigating alkali-silica reaction (ASR) in mortar and its influence on microstructure. In Proceedings of the First International Conference on Calcined Clays for Sustainable Concrete, Lausanne, Switzerland, 23–25 June 2015; Rilem Bookseries. Springer: Berlin/Heidelberg, Germany, 2015; pp. 211–217. [Google Scholar] [CrossRef]

- Li, C.; Ideker, J.H.; Drimalas, T.; Adams, M.P. Review on using calcined clays to mitigate alkali-silica reaction. In Proceedings of the 15th ICAAR International Conference on Alkali-Aggregate Reaction in Concrete, São Paulo, Brazil, 3–7 July 2016; Bernardes, H.d.M., Hasparyk, N.P., Eds.; ICAAR: São Paulo, Brazil, 2016. [Google Scholar]

- Nguyen, Q.D.; Kim, T.; Castel, A. Mitigation of alkali-silica reaction by limestone calcined clay cement (LC3). Cem. Concr. Res. 2020, 137, 106176. [Google Scholar] [CrossRef]

- Luo, D.; Sinha, A.; Adhikari, M.; Wei, J. Mitigating alkali-silica reaction through metakaolin-based internal conditioning: New insights into property evolution and mitigation mechanism. Cem. Concr. Res. 2022, 159, 106888. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B.; Jain, A.; Hanifehzadeh, M. Mitigating alkali-silica reaction induced concrete degradation through cement substitution by metakaolin and bentonite. Appl. Clay Sci. 2019, 182, 105257. [Google Scholar] [CrossRef]

- Khatib, J.M.; Baalbaki, O.; El Kordi, A.A. Metakaolin. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 493–511. [Google Scholar] [CrossRef]

- Ilic, B.; Mitrovic, A.; Milicic, L. Thermal treatment of kaolin clay to obtain metakaolin. Hem. Ind. 2010, 64, 351–356. [Google Scholar] [CrossRef]

- Zhou, J.; Zheng, K.; Liu, Z.; Chen, L.; Lippiatt, N. Use of γ-Al2O3 to prevent alkali-silica reaction by altering solid and aqueous compositions of hydrated cement paste. Cem. Concr. Res. 2019, 124, 105817. [Google Scholar] [CrossRef]

- Prasad, M.S.; Reid, K.J.; Murray, H.H. Kaolin: Processing, properties and applications. Appl. Clay Sci. 1991, 6, 87–119. [Google Scholar] [CrossRef]

- Jepson, W.B. Kaolins: Their properties and uses. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1984, 311, 411–432. [Google Scholar] [CrossRef]

- Murray, H.H. Industrial applications of kaolin. Clay Clays Miner. 1961, 10, 291–298. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Jaskulski, R.; Dziedzic, K.; Antolik, A. Effect of low-quality calcined clay on the suppression of the alkali–silica reaction. Mater. Proc. 2023, 13, 15. [Google Scholar] [CrossRef]

- Habert, G.; Choupay, N.; Montel, J.M.; Guillaume, D.; Escadeillas, G. Effects of the secondary minerals of the natural pozzolans on their pozzolanic activity. Cem. Concr. Res. 2008, 38, 963–975. [Google Scholar] [CrossRef]

- Gholizadeh-Vayghan, A.; Rajabipour, F. Quantifying the swelling properties of alkali-silica reaction (ASR) gels as a function of their composition. J. Am. Ceram. Soc. 2017, 100, 3801–3818. [Google Scholar] [CrossRef]

- Gholizadeh-Vayghan, A.; Rajabipour, F.; Arndt, C. The influence of ASR gels composition on their swelling properties. In Proceedings of the 15th ICAAR International Conference on Concrete Alkali Aggregate Reactions, São Paulo, Brazil, 3–7 July 2016; pp. 1–10. [Google Scholar]

- Gholizadeh-Vayghan, A.; Rajabipour, F. The influence of alkali–silica reaction (ASR) gel composition on its hydrophilic properties and free swelling in contact with water vapor. Cem. Concr. Res. 2017, 94, 49–58. [Google Scholar] [CrossRef]

- Hou, X.; Struble, L.J.; Kirkpatrick, R.J. Kanemite as a model for ASR gel. In Proceedings of the 12th ICAAR International Conference on Concrete Alkali Aggregate Reactions, Beijing, China, 15–19 October 2004; pp. 11–14. [Google Scholar]

- Hou, X.; Kirkpatrick, R.J.; Struble, L.J.; Monteiro, P.J.M. Structural investigations of alkali silicate gels. J. Am. Ceram. Soc. 2005, 88, 943–949. [Google Scholar] [CrossRef]

- Bektas, F.; Wang, K. Performance of ground clay brick in ASR-affected concrete: Effects on expansion, mechanical properties and ASR gel chemistry. Cem. Concr. Compos. 2012, 34, 273–278. [Google Scholar] [CrossRef]

- ASTM C1567-21; Standard Test Method for Determination the Potential Alkali-Silica Reactivity of Combinations of Cementitious Materials and Aggregate (Accelerated Mortar-Bar Method). ATSM: West Conshohocken, PA, USA, 2021.

- Zheng, D.; Liang, X.; Cui, H.; Tang, W.; Liu, W.; Zhou, D. Study of performances and microstructures of mortar with calcined low-grade clay. Constr. Build. Mater. 2022, 327, 126963. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Antolik, A.; Dziedzic, K.; Glinicki, M.A.; Gibas, K. Resistance of selected aggregates from igneous rocks to alkali-silica reaction: Verification. Roads Bridges—Drogi Mosty 2019, 18, 67–83. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Glinicki, M.A. Petrographic identification of reactive minerals in domestic aggregates and their classification according to RILEM and ASTM recommendations. Roads Bridges—Drog. Mosty 2017, 16, 223–239. [Google Scholar] [CrossRef]

- Antolik, A.; Dąbrowski, M.; Jóźwiak-Niedźwiedzka, D. Petrographic Evaluation of Aggregate from Igneous Rocks: Alkali–Silica Reaction Potential. Minerals 2023, 13, 1004. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Zunino, F.; Boehm-Courjault, E.; Scrivener, K. The impact of calcite impurities in clays containing kaolinite on their reactivity in cement after calcination. Mater. Struct. 2020, 53, 44. [Google Scholar] [CrossRef]

- Ramlochan, T.; Thomas, M.; Gruber, K.A. The effect of metakaolin on alkali-silica reaction in concrete. Cem. Concr. Res. 2000, 30, 339–344. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Chang, L.; Hu, Y.; Xie, X.; Si, R.; Wang, J. Kinetic analysis and thermodynamic simulation of alkali-silica reaction in cementitious materials. J. Am. Ceram. Soc. 2019, 102, 1463–1478. [Google Scholar] [CrossRef]

- Leemann, A. Alkali-silica reaction—Sequence, products and possible mechanisms of expansion. In Proceedings of the 16th ICAAR International Conference on Concrete Alkali Aggregate Reactions, Lisbon, Portugal, 16–18 June 2022; p. 2. [Google Scholar]

- Leemann, A.; Le Saout, G.; Winnefeld, F.; Rentsch, D.; Lothenbach, B. Alkali-Silica reaction: The Influence of calcium on silica dissolution and the formation of reaction products. J. Am. Ceram. Soc. 2011, 94, 1243–1249. [Google Scholar] [CrossRef]

- Antolik, A.; Jóźwiak-Niedźwiedzka, D. ASR induced by chloride- and formate-based deicers in concrete with non-reactive aggregates. Constr. Build. Mater. 2023, 400, 132811. [Google Scholar] [CrossRef]

- Leemann, A.; Bernard, L.; Alahrache, S.; Winnefeld, F. ASR prevention—Effect of aluminum and lithium ions on the reaction products. Cem. Concr. Res. 2015, 76, 192–201. [Google Scholar] [CrossRef]

- Krüger, M.E.; Heisig, A.; Hilbig, H.; Eickhoff, H.; Heinz, D.; Machner, A. Effect of aluminum on the structure of synthetic alkali-silica gels. Cem. Concr. Res. 2023, 166, 107088. [Google Scholar] [CrossRef]

- De Souza, D.J.; Sanchez, L.F.M. Evaluating the efficiency of SCMs to avoid or mitigate ASR-induced expansion and deterioration through a multi-level assessment. Cem. Concr. Res. 2023, 173, 107262. [Google Scholar] [CrossRef]

- Leemann, A.; Lura, P. E-modulus of the alkali–silica-reaction product determined by micro-indentation. Constr. Build. Mater. 2013, 44, 221–227. [Google Scholar] [CrossRef]

- Wu, H.; Pan, J.; Wang, J. Nano-scale structure and mechanical properties of ASR products under saturated and dry conditions. Sci. Rep. 2020, 10, 9187. [Google Scholar] [CrossRef]

| Mortar | Number of Days | |||||||

|---|---|---|---|---|---|---|---|---|

| 4 | 7 | 11 | 14 | 18 | 21 | 25 | 28 | |

| Reference | 0.041 | 0.085 | 0.145 | 0.196 | 0.254 | 0.297 | 0.334 | 0.351 |

| 10% calcined clay | 0.033 | 0.081 | 0.138 | 0.165 | 0.207 | 0.243 | 0.263 | 0.269 |

| 20% calcined clay | 0.009 | 0.022 | 0.056 | 0.060 | 0.081 | 0.088 | 0.096 | 0.099 |

| 30% calcined clay | 0.007 | 0.020 | 0.034 | 0.043 | 0.062 | 0.065 | 0.078 | 0.080 |

| Mortar | Ca/Si | Al/Si | (Na+K)/Si | |||

|---|---|---|---|---|---|---|

| Air Void | Aggregate | Air Void | Aggregate | Air Void | Aggregate | |

| Reference | 0.73 ± 0.18 | 0.43 ± 0.11 | 0.00 ± 0.00 | 0.01 ± 0.00 | 0.26 ± 0.04 | 0.29 ± 0.09 |

| 10% calcined clay | 0.66 ± 0.15 | 0.24 ± 0.06 | 0.06 ± 0.00 | 0.00 ± 0.00 | 0.25 ± 0.02 | 0.14 ± 0.07 |

| 20% calcined clay | 0.55 ± 0.12 | 0.24 ± 0.04 | 0.06 ± 0.00 | 0.00 ± 0.00 | 0.23 ± 0.02 | 0.14 ± 0.05 |

| 30% calcined clay | 0.50 ± 0.11 | 0.20 ± 0.02 | 0.08 ± 0.00 | 0.01 ± 0.00 | 0.17 ± 0.02 | 0.13 ± 0.05 |

| Mortar | Ca/Si | Al/Si | (Na+K)/Si | |||

|---|---|---|---|---|---|---|

| Amorphous | Crystalline | Amorphous | Crystalline | Amorphous | Crystalline | |

| Reference | 0.73 ± 0.18 | — | 0.00 ± 0.00 | — | 0.26 ± 0.04 | — |

| 10% calcined clay | 0.80 ± 0.04 | 0.52 ± 0.17 | 0.08 ± 0.02 | 0.04 ± 0.01 | 0.24 ± 0.01 | 0.25 ± 0.02 |

| 20% calcined clay | 0.64 ± 0.13 | 0.46 ± 0.04 | 0.08 ± 0.02 | 0.04 ± 0.03 | 0.22 ± 0.04 | 0.24 ± 0.03 |

| 30% calcined clay | 0.59 ± 0.29 | 0.40 ± 0.01 | 0.12 ± 0.07 | 0.04 ± 0.00 | 0.14 ± 0.02 | 0.19 ± 0.01 |

| Mortar | Displacement, nm | Nanohardness, GPa | Young’s Modulus, GPa | |||

|---|---|---|---|---|---|---|

| Air Void | Aggregate | Air Void | Aggregate | Air Void | Aggregate | |

| Reference | 990 ± 30.0 | 304 ± 6.0 | 0.41 ± 0.03 | 2.0 ± 0.1 | 6 ± 2.0 | 88 ± 3.0 |

| 10% calcined clay | 980 ± 50.0 | - | 0.43 ± 0.05 | - | 5 ± 0.2 | - |

| 20% calcined clay | 840 ± 40.0 | - | 0.58 ± 0.04 | - | 10 ± 1.0 | - |

| 30% calcined clay | 780 ± 20.0 | - | 0.67 ± 0.04 | - | 12 ± 1.0 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jóźwiak-Niedźwiedzka, D.; Jaskulski, R.; Dziedzic, K.; Brachaczek, A.; Jarząbek, D.M. Initial Characteristics of Alkali–Silica Reaction Products in Mortar Containing Low-Purity Calcined Clay. Materials 2024, 17, 2207. https://doi.org/10.3390/ma17102207

Jóźwiak-Niedźwiedzka D, Jaskulski R, Dziedzic K, Brachaczek A, Jarząbek DM. Initial Characteristics of Alkali–Silica Reaction Products in Mortar Containing Low-Purity Calcined Clay. Materials. 2024; 17(10):2207. https://doi.org/10.3390/ma17102207

Chicago/Turabian StyleJóźwiak-Niedźwiedzka, Daria, Roman Jaskulski, Kinga Dziedzic, Aneta Brachaczek, and Dariusz M. Jarząbek. 2024. "Initial Characteristics of Alkali–Silica Reaction Products in Mortar Containing Low-Purity Calcined Clay" Materials 17, no. 10: 2207. https://doi.org/10.3390/ma17102207

APA StyleJóźwiak-Niedźwiedzka, D., Jaskulski, R., Dziedzic, K., Brachaczek, A., & Jarząbek, D. M. (2024). Initial Characteristics of Alkali–Silica Reaction Products in Mortar Containing Low-Purity Calcined Clay. Materials, 17(10), 2207. https://doi.org/10.3390/ma17102207