Microstructure and Texture Evolution in Cold-Rolled and Annealed Oxygen-Free Copper Sheets

Abstract

1. Introduction

2. Experimental Section

3. Results and Discussion

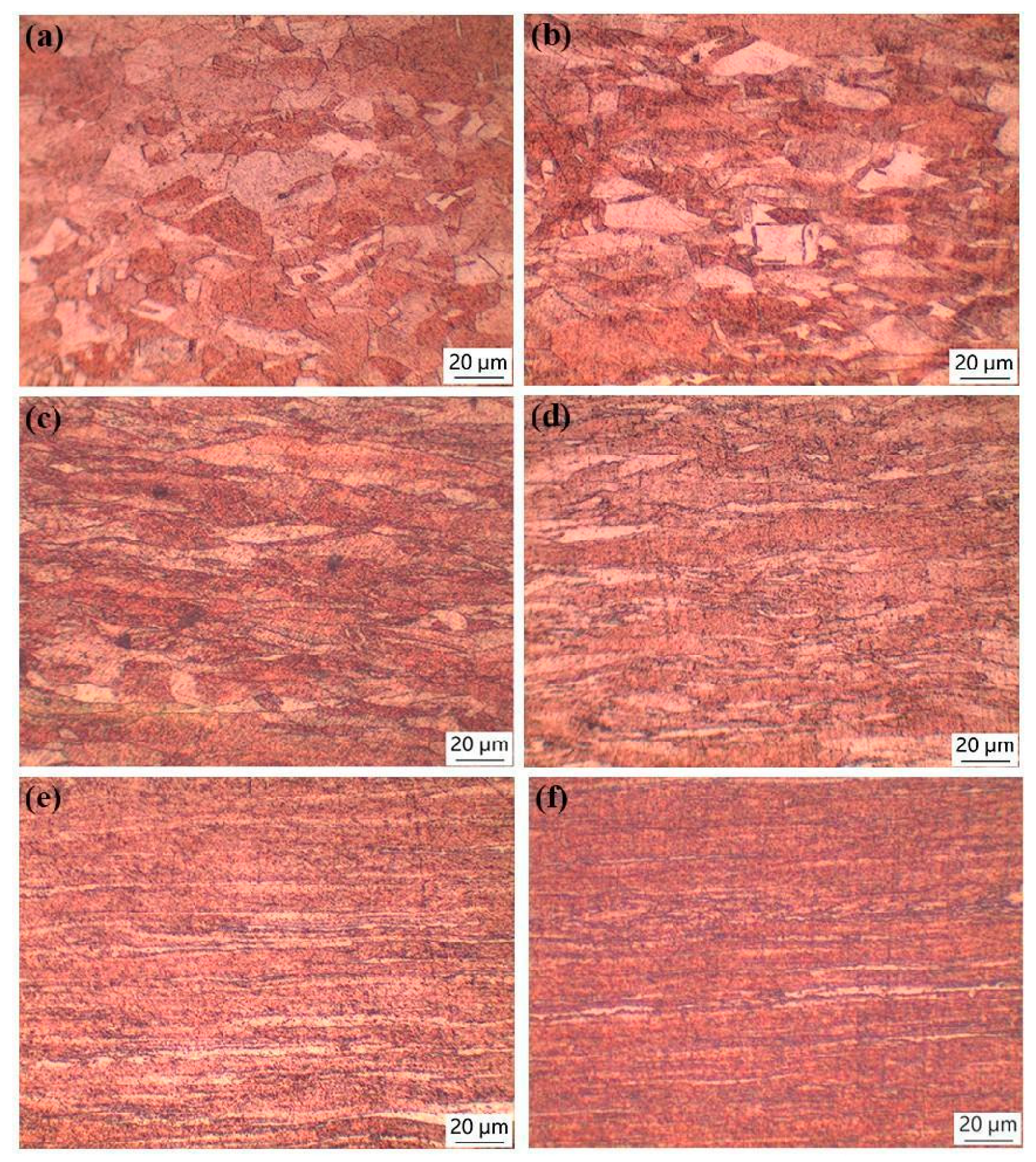

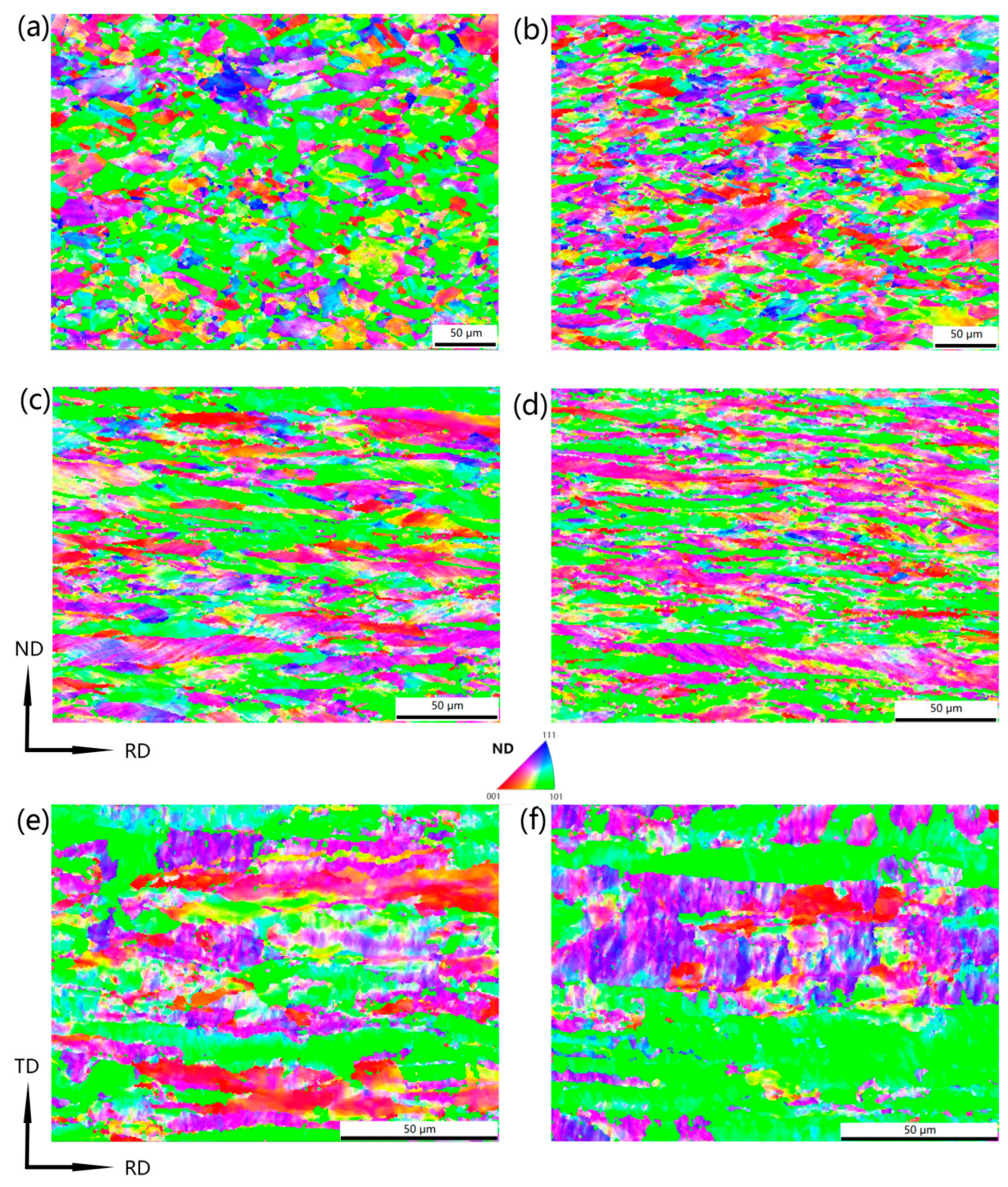

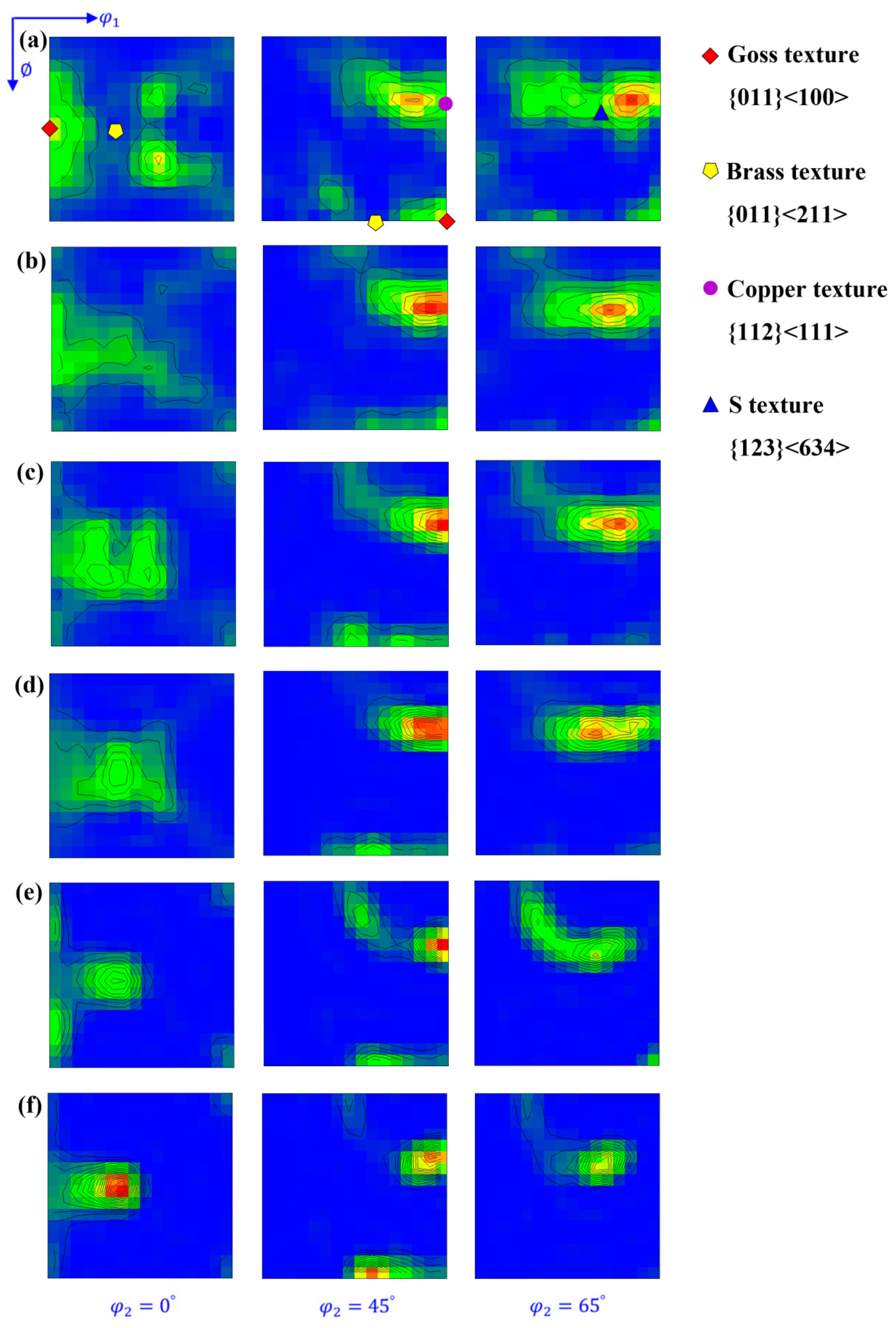

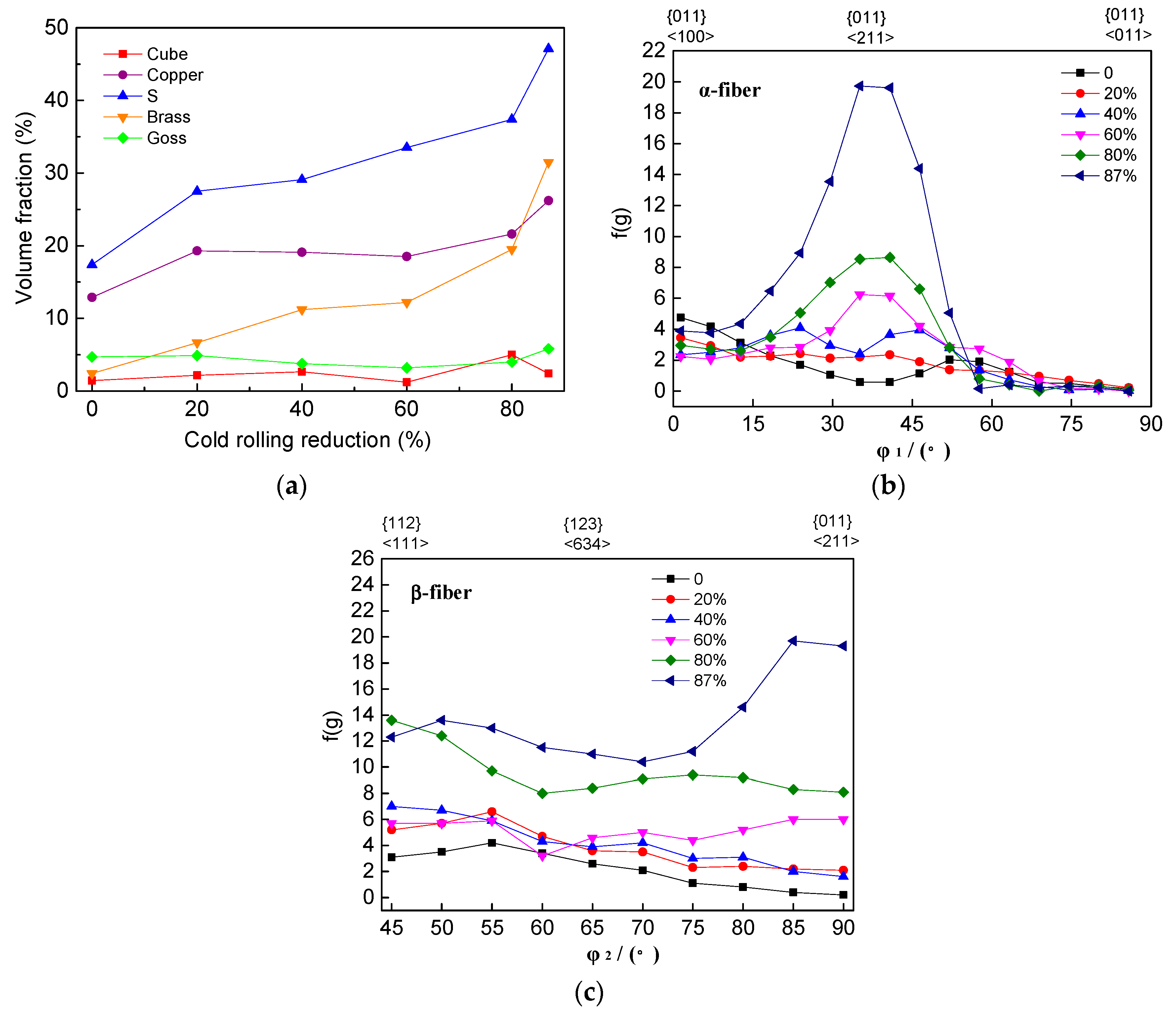

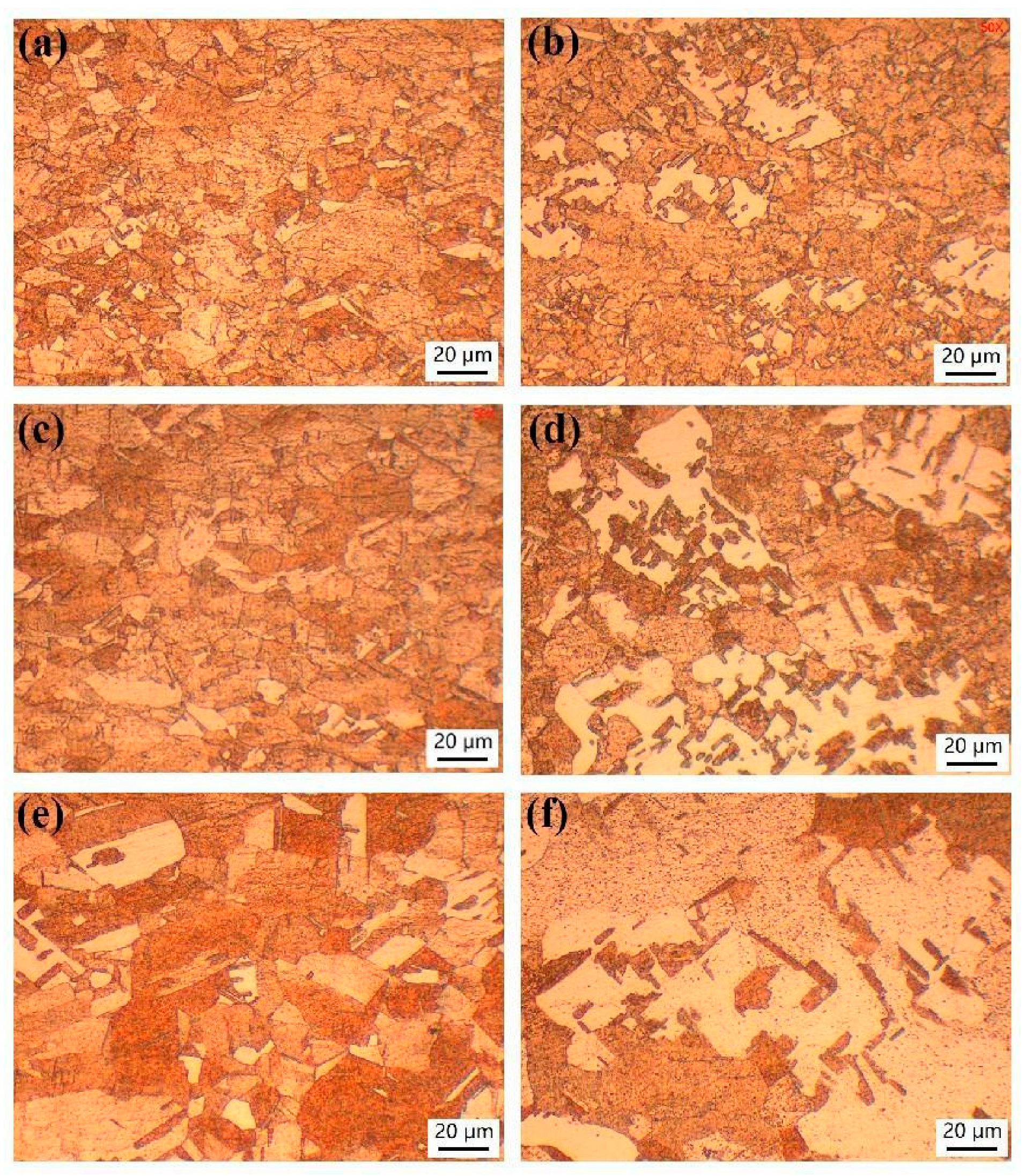

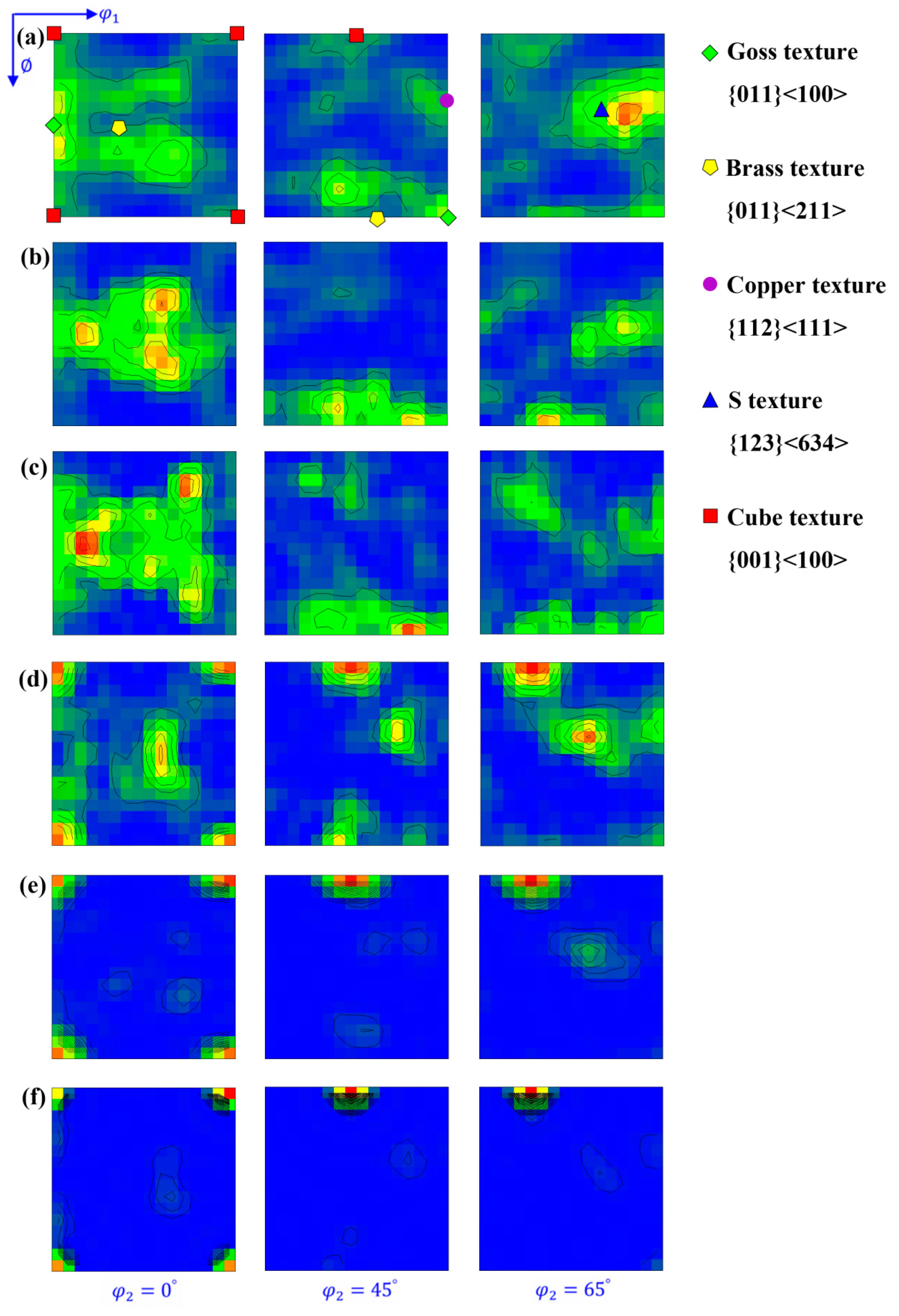

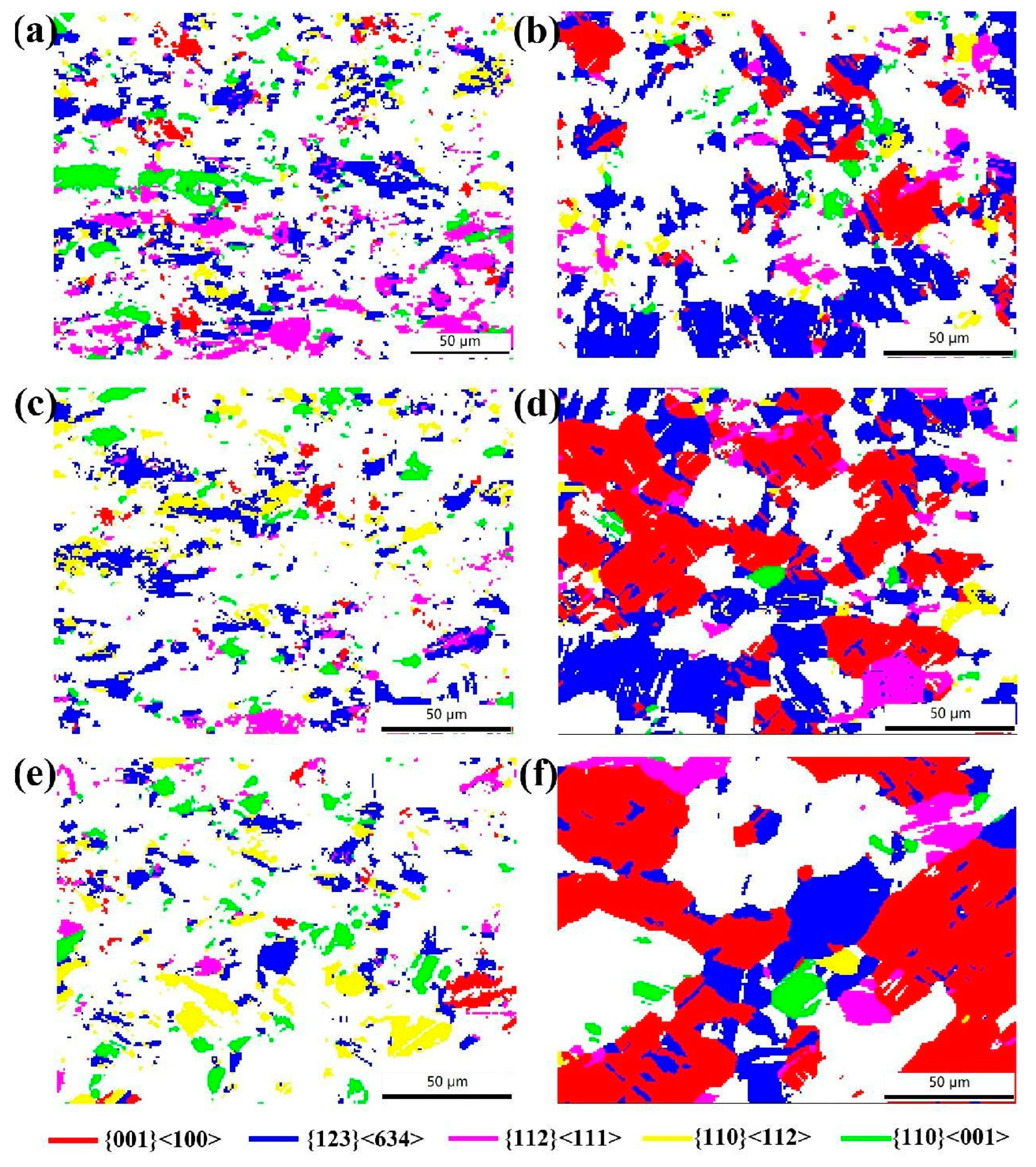

3.1. Microstructure and Texture of Rolled Copper Sheets

3.2. Microstructure and Texture of Annealed Copper Sheets

4. Conclusions

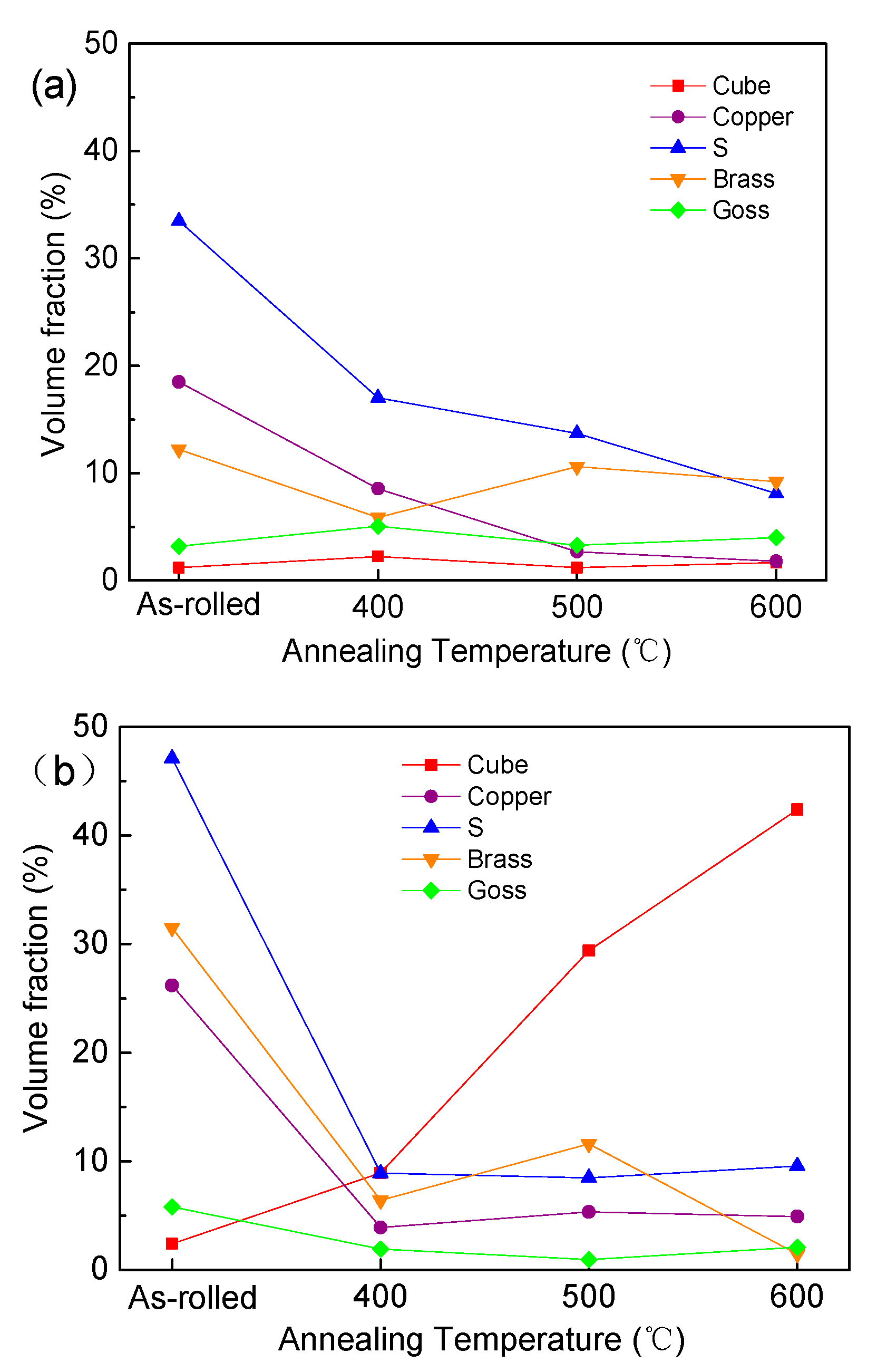

- The deformation textures of S, Copper and Brass were progressively enhanced with the increase in cold-rolling reduction. When the rolling reduction exceeded 60%, the orientations along the α-oriented fiber converged towards Brass, and the orientation density of the β fiber obviously increased.

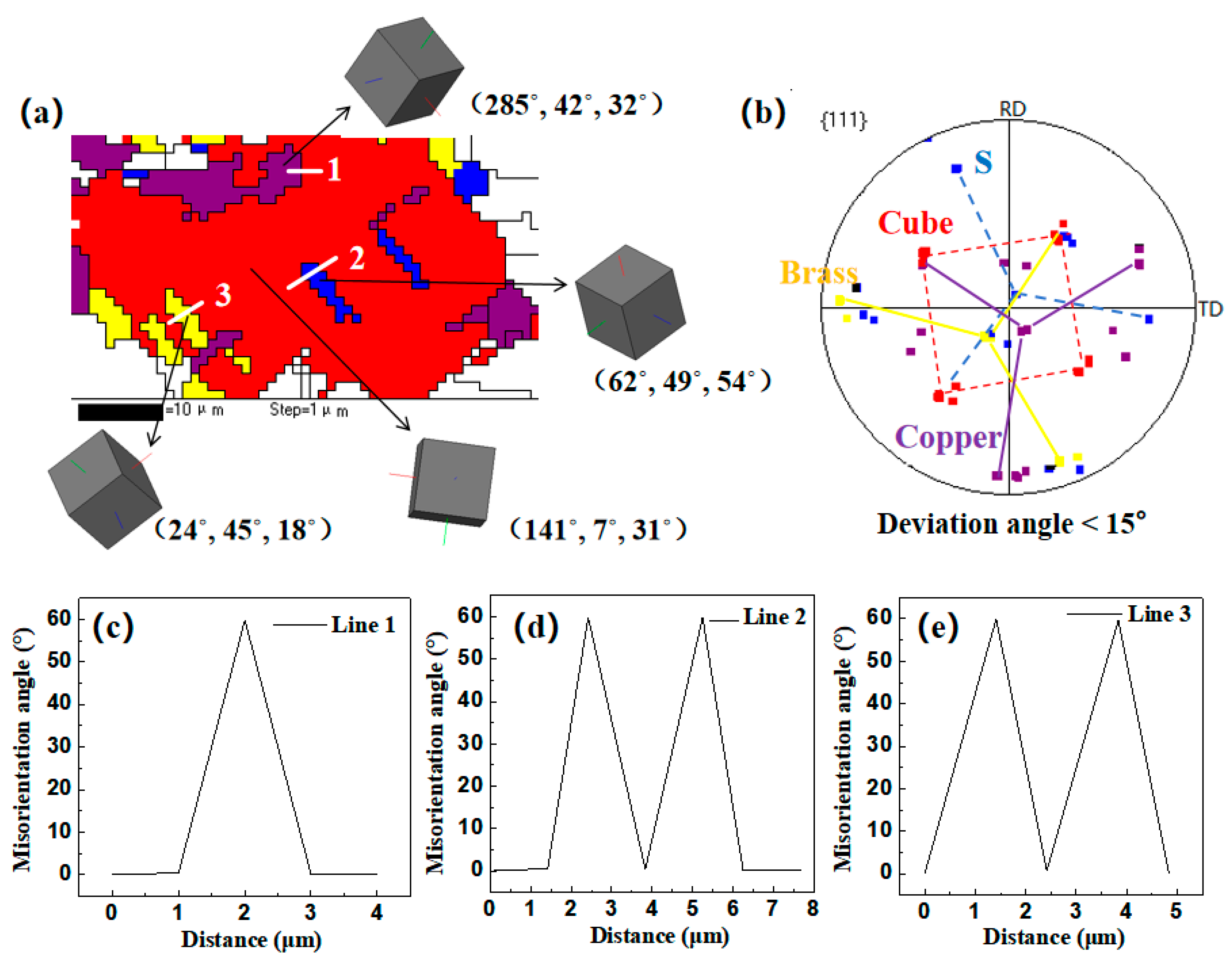

- The recrystallization texture was significantly influenced by the cold-rolling reduction. After a 60% cold-rolling reduction, Copper and S texture components gradually decreased, while the {011}<511> recrystallization texture component formed with an increase in annealing temperature. Following an 87% cold-rolling reduction, a strong Cube texture formed, and other textures were suppressed as annealing temperature increased. The strong Brass and S deformation texture favored the formation of a strong Cube annealing texture.

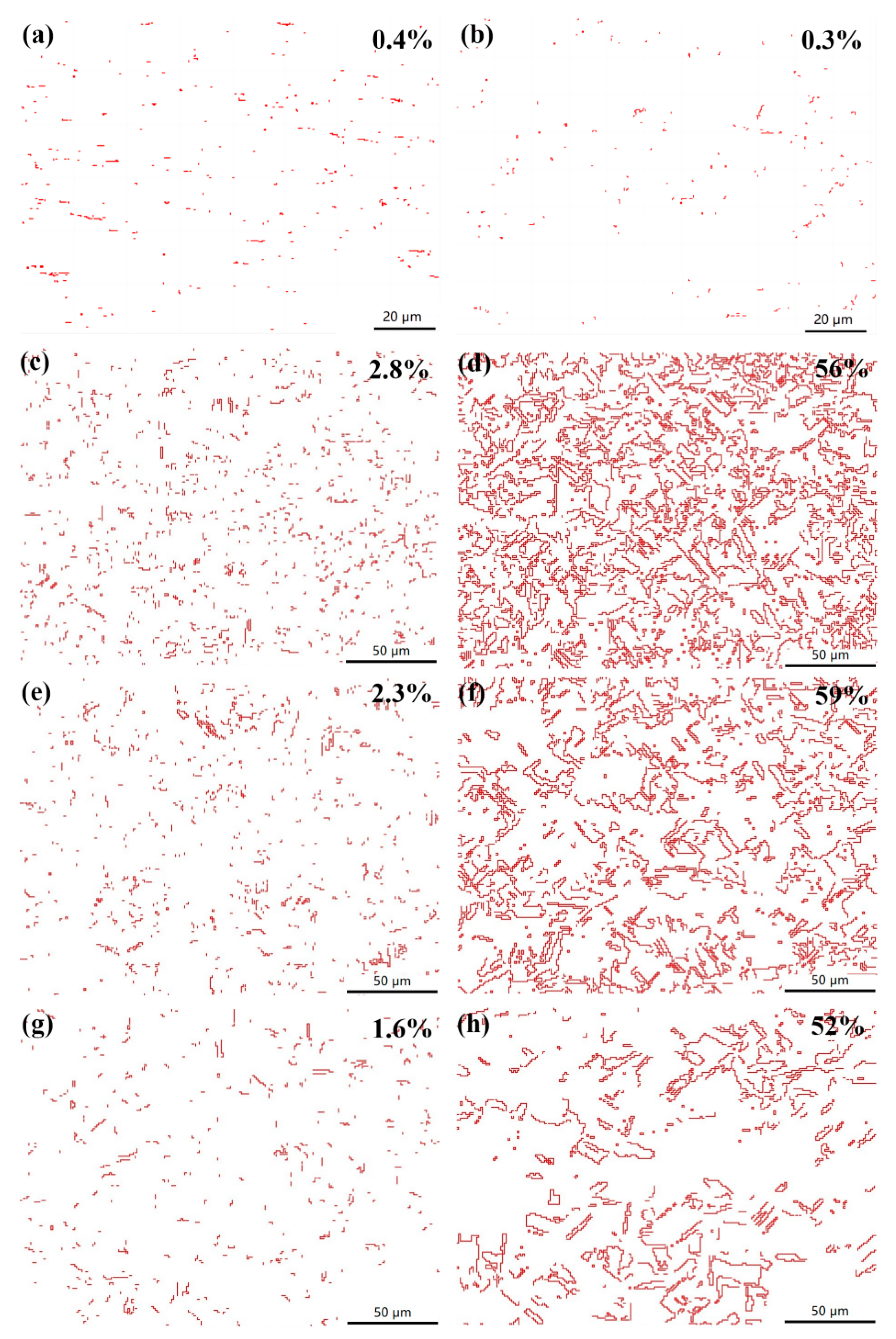

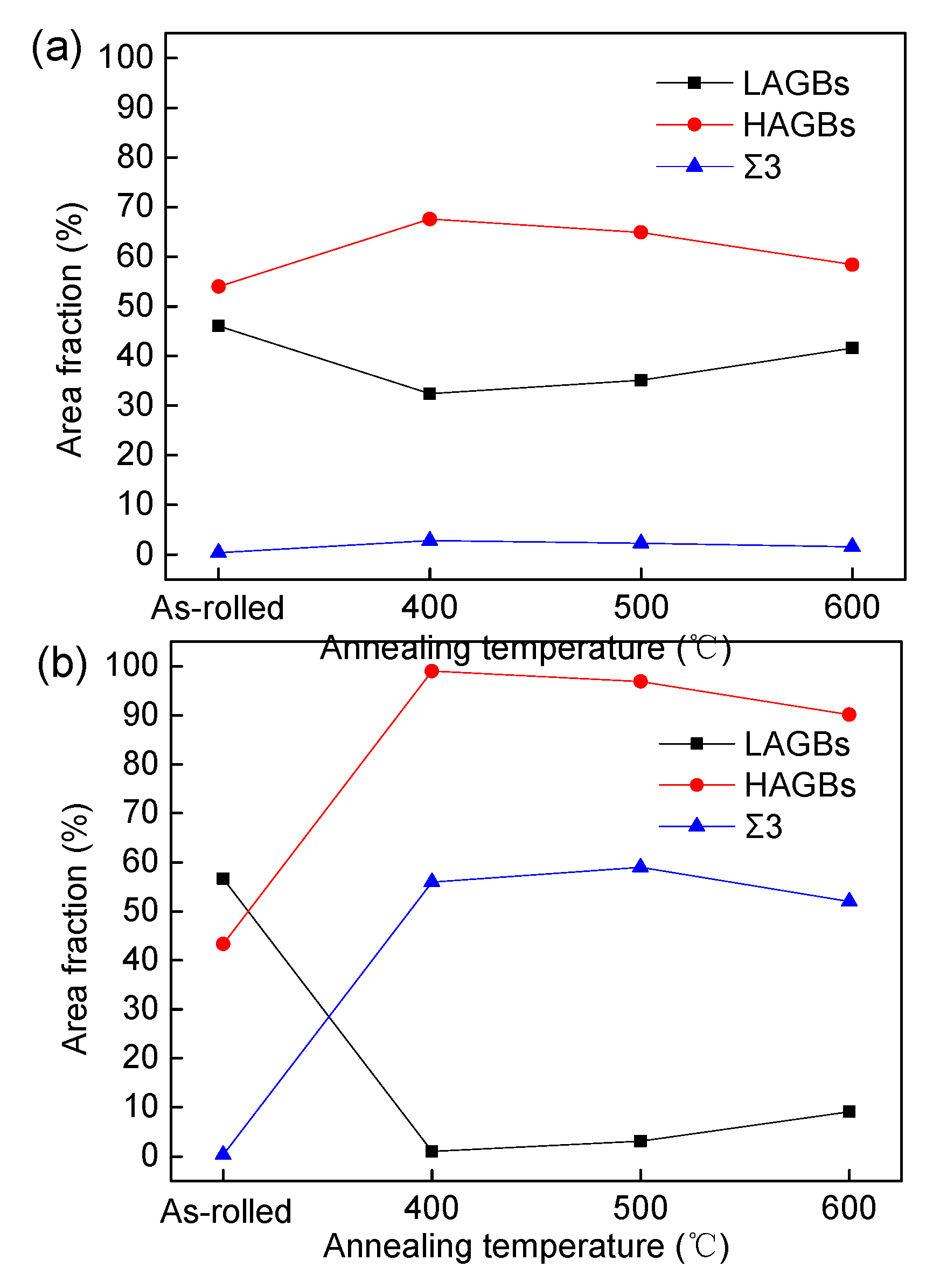

- The annealing twin density decreased with the increase in annealing temperature, and more annealing twin boundaries formed in oxygen-free copper sheets with the increase in cold-rolling reduction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.H.; Zhang, Y.; Tian, B.H.; Song, K.X.; Liu, P.; Jia, Y.L.; Chen, X.H.; An, J.C.; Zhao, Z.; Liu, Y.; et al. Review of nano-phase effects in high strength and conductivity copper alloys. Nanotechnol. Rev. 2019, 8, 383–395. [Google Scholar] [CrossRef]

- Geng, Y.F.; Ban, Y.J.; Wang, B.J.; Li, X.; Song, K.X.; Zhang, Y.; Jia, Y.L.; Tian, B.H.; Liu, Y.; Volinsky, A.A. A review of microstructure and texture evolution with nanoscale precipitates for copper alloys. J. Mater. Res. Technol. 2020, 9, 11918–11934. [Google Scholar] [CrossRef]

- Inoue, H. Simultaneous prediction of bendability and deep drawability based on orientation distribution function for polycrystalline cubic metal sheets. Mater. Sci. Forum. 2018, 941, 1468–1473. [Google Scholar] [CrossRef]

- Qin, J.; Zhou, C.; Wang, D.S.; Li, X.; Hu, T.S.; Wang, J.W.; Yang, Y.W. Effects of microstructure and texture on the deep drawability of C10200 copper sheets. J. Mater. Res. Technol. 2023, 25, 773–785. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.J.; Liu, Y.H.; Li, S.L.; Song, K.X.; Feng, C.L.; Wu, B.A.; Zhang, P.F.; Wu, H.J.; Gu, J.H.; et al. Texture evolution and its influence mechanism on properties of single crystal copper and polycrystalline copper during cumulative deformation. J. Mater. Res. Technol. 2023, 24, 6808–6819. [Google Scholar] [CrossRef]

- Hua, Y.X.; Liu, H.T.; Song, K.X.; Wang, J.W.; Guo, Y.G.; Tian, J.; Guo, H.W. Effect of cerium on microstructure, texture and properties of ultrahigh-purity copper. J. Rare Earths 2024, 42, 220–227. [Google Scholar] [CrossRef]

- Gong, L.K.; Huang, Y.Q.; Han, Z.; Song, S.X.; Feng, H.W.; Chen, Z.M.; Liu, X.B.; Huang, W. Texture evolution and strengthening mechanism of CuCrZr alloys during cold rolling. Vacuum 2024, 221, 112908. [Google Scholar] [CrossRef]

- Yang, J.Z.; Bu, K.; Song, K.X.; Zhou, Y.J.; Huang, T.; Niu, L.Y.; Guo, H.W.; Du, Y.B.; Kang, J.W. Influence of low-temperature annealing temperature on the evolution of the microstructure and mechanical properties of Cu-Cr-Ti-Si alloy strips. Mater. Sci. Eng. A 2020, 798, 140120. [Google Scholar] [CrossRef]

- Gu, C.F.; Hoffman, M.; Toth, L.S.; Zhang, Y.D. Grain size dependent texture evolution in severely rolled pure copper. Mater. Charact. 2015, 101, 180–188. [Google Scholar] [CrossRef]

- Wang, Z.G.; Feng, X.Y.; Yang, T.S.; Zhang, Y.H.; Xiao, X.P. Effects of precipitates and texture on the anisotropy of high-strength Cu-Ni-Si alloy sheets. Chin. J. Eng. 2017, 39, 867–874. [Google Scholar]

- Geng, Y.F.; Zhang, Y.; Song, K.X.; Jia, Y.L.; Li, X.; Stock, H.R.; Zhou, H.L.; Tian, B.H.; Liu, Y.; Volinsky, A.A.; et al. Effect of Ce addition on microstructure evolution and precipitation in Cu-Co-Si-Ti alloy during hot deformation. J. Alloys Compd. 2020, 842, 155666. [Google Scholar] [CrossRef]

- Liu, Z.S.; Chen, Y.L.; Wei, H.; Li, Z.C. Study on the distribution of texture and the second phase under different aging process of Cu-Ni-Si alloy. Mater. Lett. 2019, 236, 292–294. [Google Scholar] [CrossRef]

- Wei, H.; Chen, Y.L.; Su, L. Study on texture evolution and deformation mechanism of the Cu-Ni-Si alloy during cold-rolling treatment. Proc. Eng. 2017, 207, 1111–1116. [Google Scholar] [CrossRef]

- Uniwersał, A.; Wronski, M.; Wrobel, M.; Wierzbanowski, K.; Baczmanski, A. Texture effects due to asymmetric rolling of polycrystalline copper. Acta Mater. 2017, 139, 30–38. [Google Scholar] [CrossRef]

- Kikuchi, S.; Kimura, E.; Koiwa, M. Deformation and recrystallization textures of copper single crystals and bicrystals. J. Mater. Sci. Lett. 1992, 27, 4927–4964. [Google Scholar] [CrossRef]

- Hong, S.H.; Lee, D.N. The evolution of the cube recrystallization texture in cold rolled copper sheets. Mater. Sci. Eng. A 2003, 351, 133–147. [Google Scholar] [CrossRef]

- Mao, W.M. Modeling of rolling texture in aluminum. Mater. Sci. Eng. A 1988, 257, 171–177. [Google Scholar] [CrossRef]

- Wang, S.W.; Song, H.W.; Chen, Y.; Yu, Q.; Zhang, S.H. Evolution of Goss texture in thin-walled copper tube at different heat treatment temperatures. Trans. Nonferrous Met. Soc. China 2022, 32, 1205–1216. [Google Scholar] [CrossRef]

- Field, D.P.; Bradford, L.T.; Nowell, M.M.; Lillo, T.M. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Mahajan, S. Critique of mechanisms of formation of deformation, annealing and growth twins: Face centered cubic metals and alloys. Scr. Mater. 2013, 68, 95–99. [Google Scholar] [CrossRef]

| Cu | Zn | Ag | Fe | Sn | Pb | Bi | As | P | S | O |

|---|---|---|---|---|---|---|---|---|---|---|

| 99.995 | 0.0005 | 0.0005 | 0.0002 | 0.0004 | 0.0004 | 0.0003 | 0.0006 | 0.0003 | 0.0006 | 0.0003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, J.; Li, X.; Wang, D.; Zhou, C.; Hu, T.; Wang, J.; Yang, Y.; Hu, Y. Microstructure and Texture Evolution in Cold-Rolled and Annealed Oxygen-Free Copper Sheets. Materials 2024, 17, 2202. https://doi.org/10.3390/ma17102202

Qin J, Li X, Wang D, Zhou C, Hu T, Wang J, Yang Y, Hu Y. Microstructure and Texture Evolution in Cold-Rolled and Annealed Oxygen-Free Copper Sheets. Materials. 2024; 17(10):2202. https://doi.org/10.3390/ma17102202

Chicago/Turabian StyleQin, Jing, Xun Li, Dongsheng Wang, Chen Zhou, Tongsheng Hu, Jingwen Wang, Youwen Yang, and Yujun Hu. 2024. "Microstructure and Texture Evolution in Cold-Rolled and Annealed Oxygen-Free Copper Sheets" Materials 17, no. 10: 2202. https://doi.org/10.3390/ma17102202

APA StyleQin, J., Li, X., Wang, D., Zhou, C., Hu, T., Wang, J., Yang, Y., & Hu, Y. (2024). Microstructure and Texture Evolution in Cold-Rolled and Annealed Oxygen-Free Copper Sheets. Materials, 17(10), 2202. https://doi.org/10.3390/ma17102202