The Excellent Mechanical Performance of Polymer-Coated Ceramsite Particles for Efficient Fracturing: An Explanation from a Surface, Tribological Perspective

Abstract

:1. Introduction

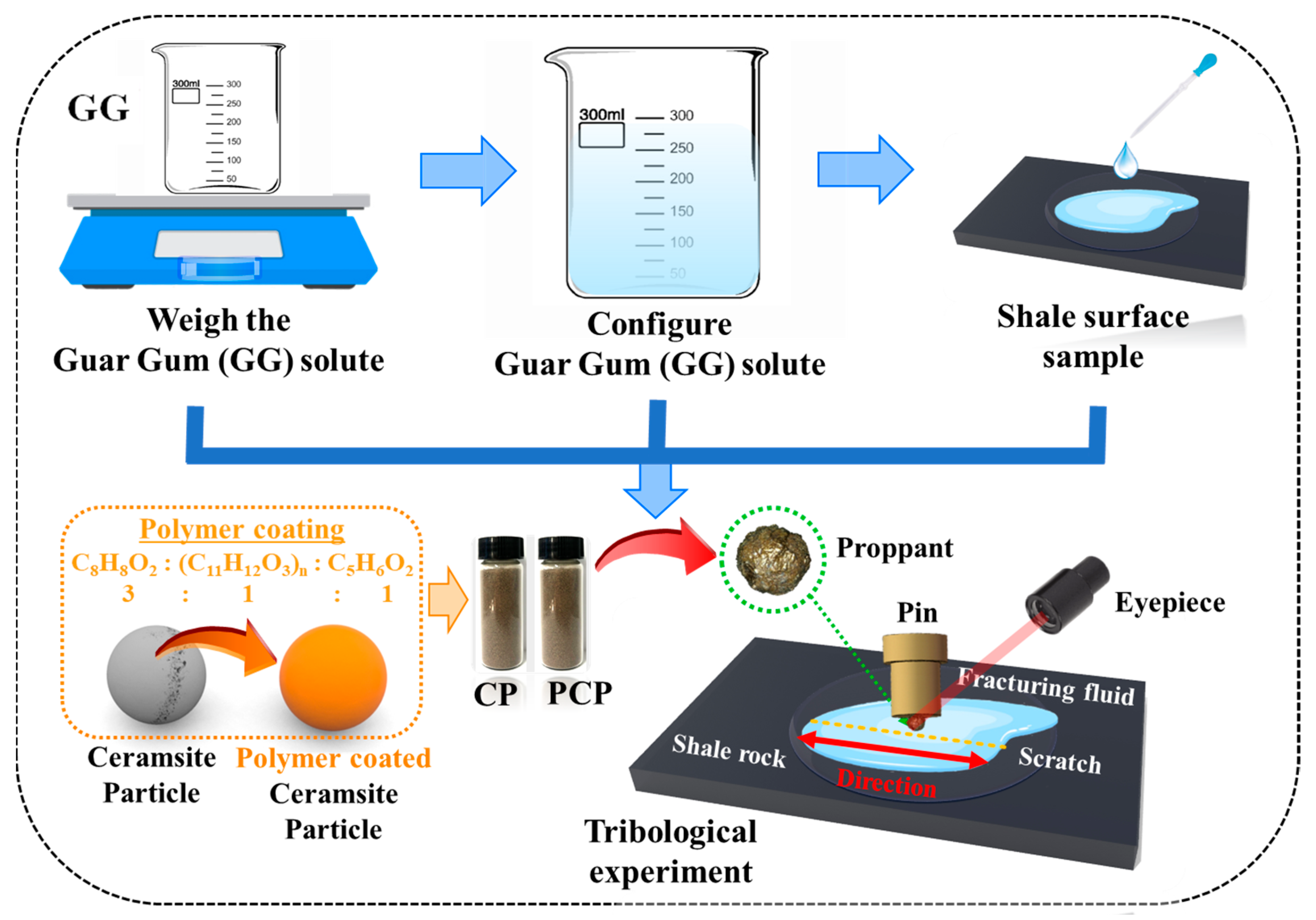

2. Material Methods and Characterization

2.1. Experimental Materials

2.2. Tribological Apparatus

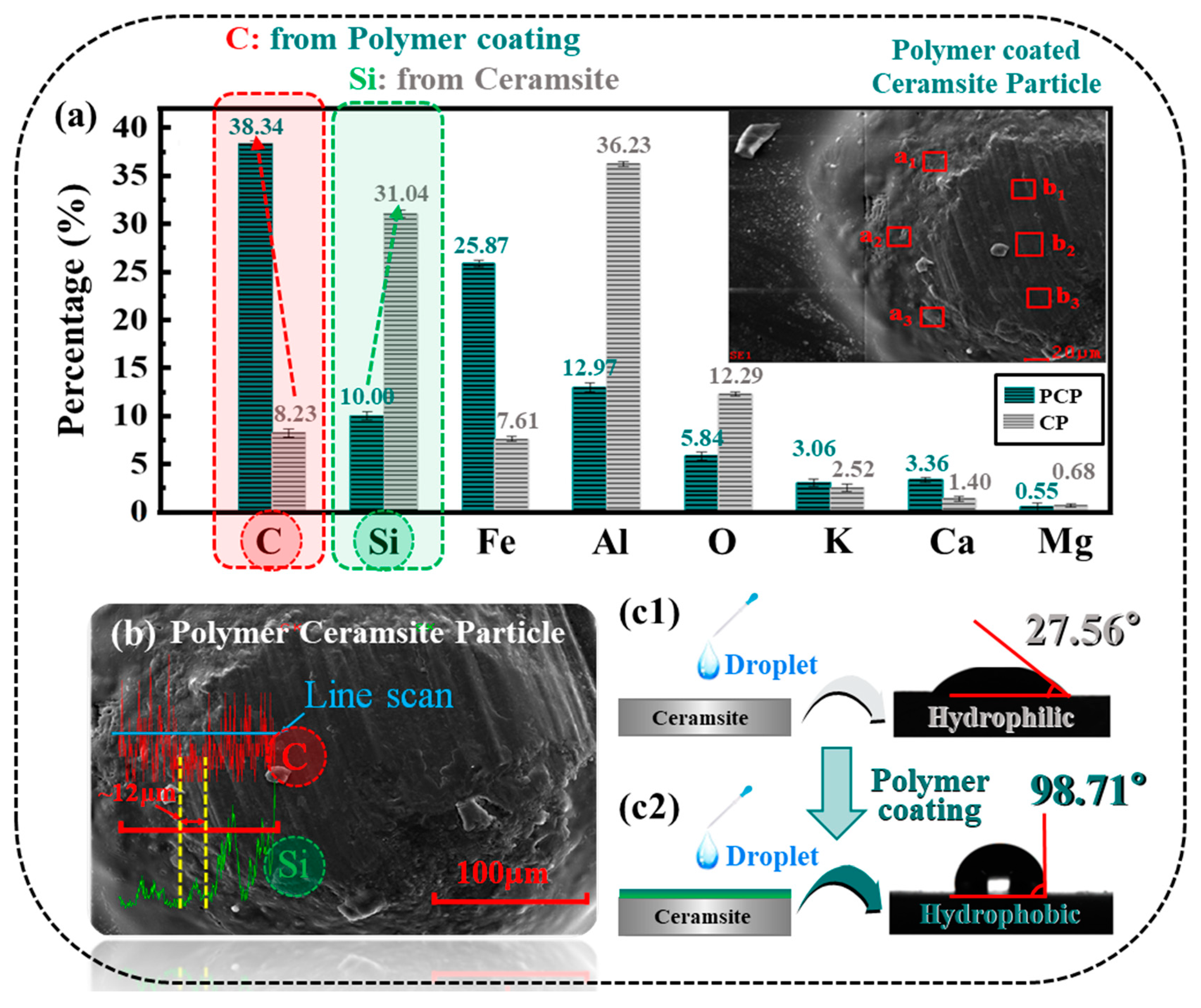

2.3. Material Characterization

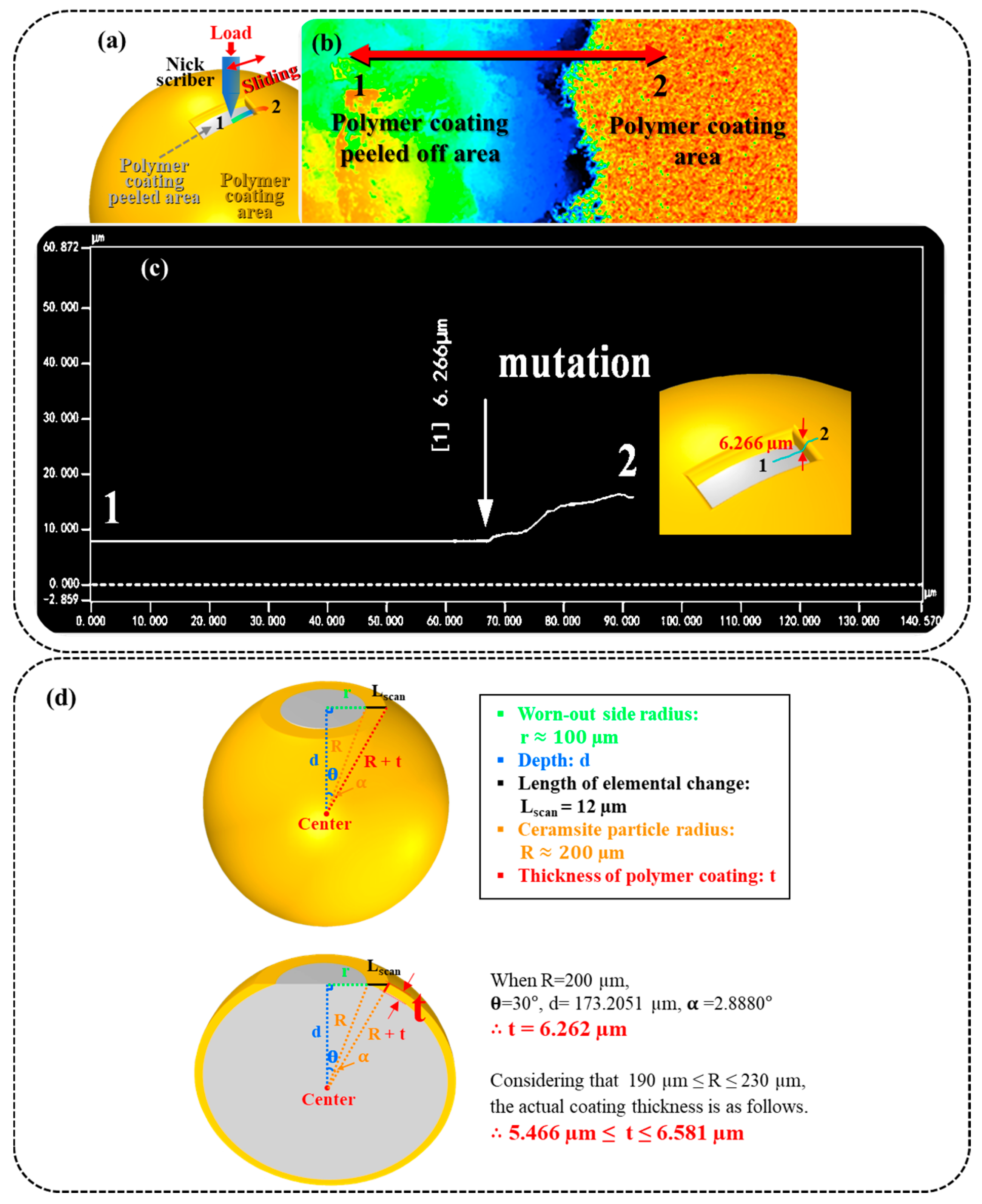

2.4. Polymer Coating Thickness Analysis

3. Results and Discussion

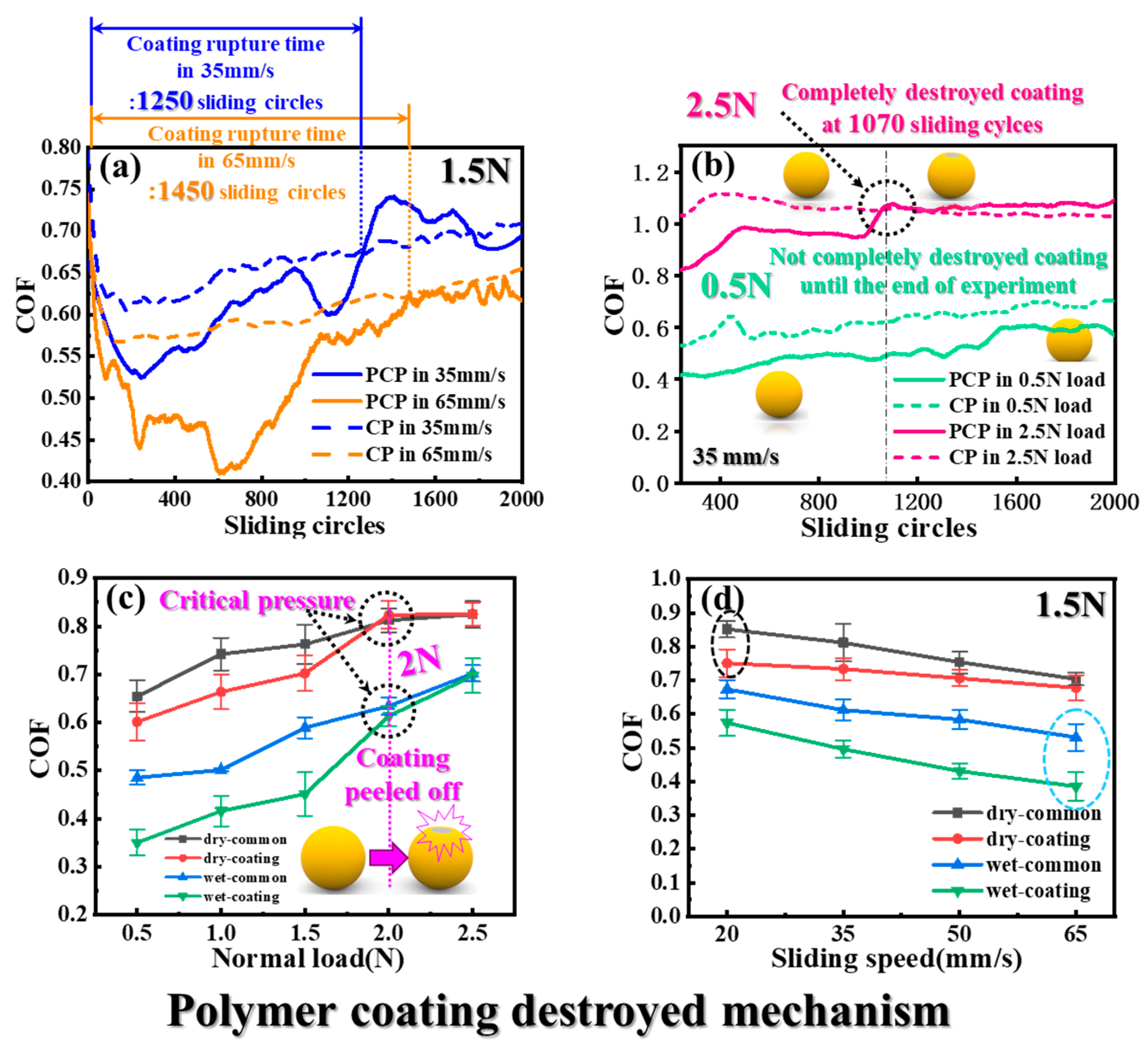

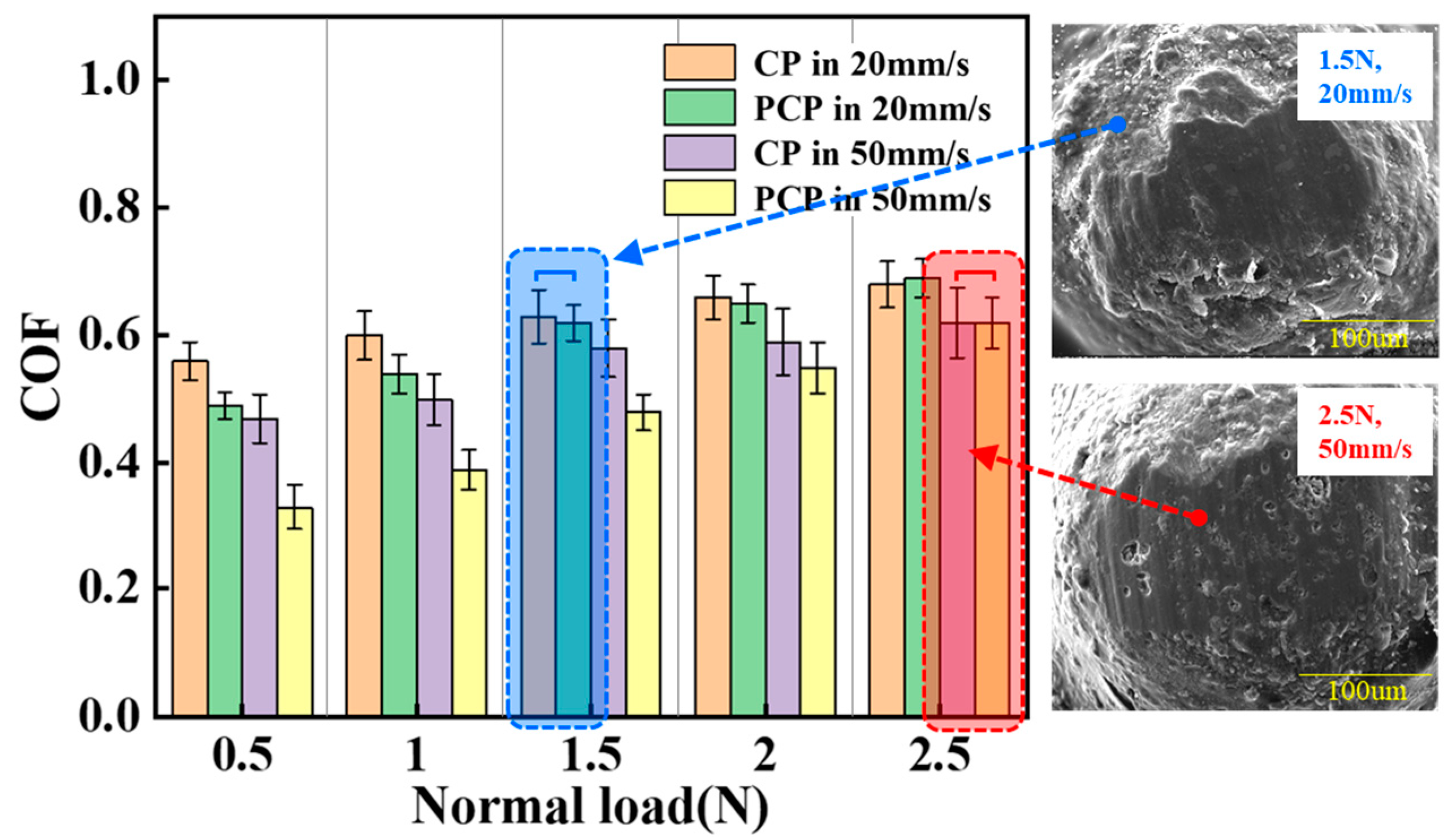

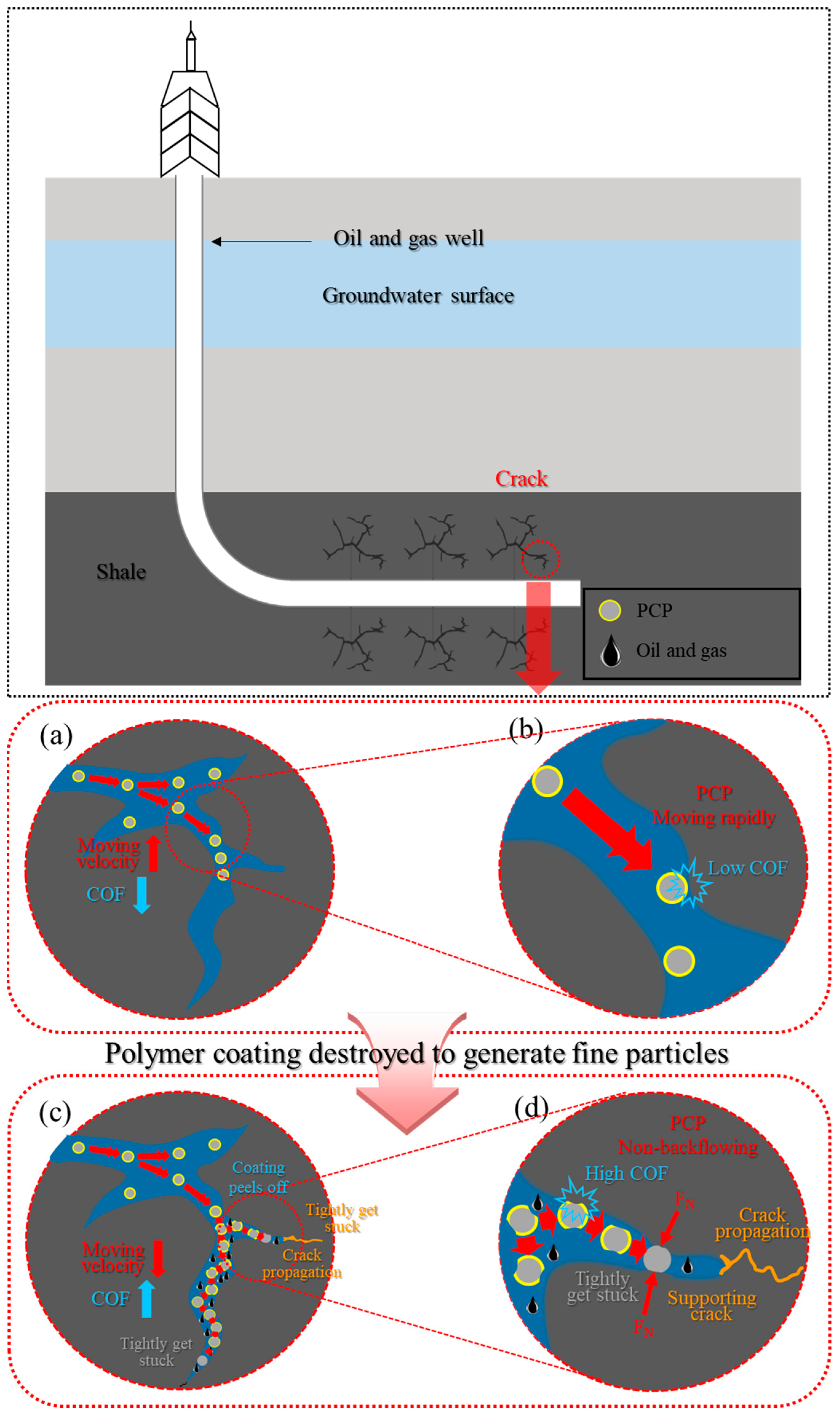

3.1. Tribological Behaviour of PCP

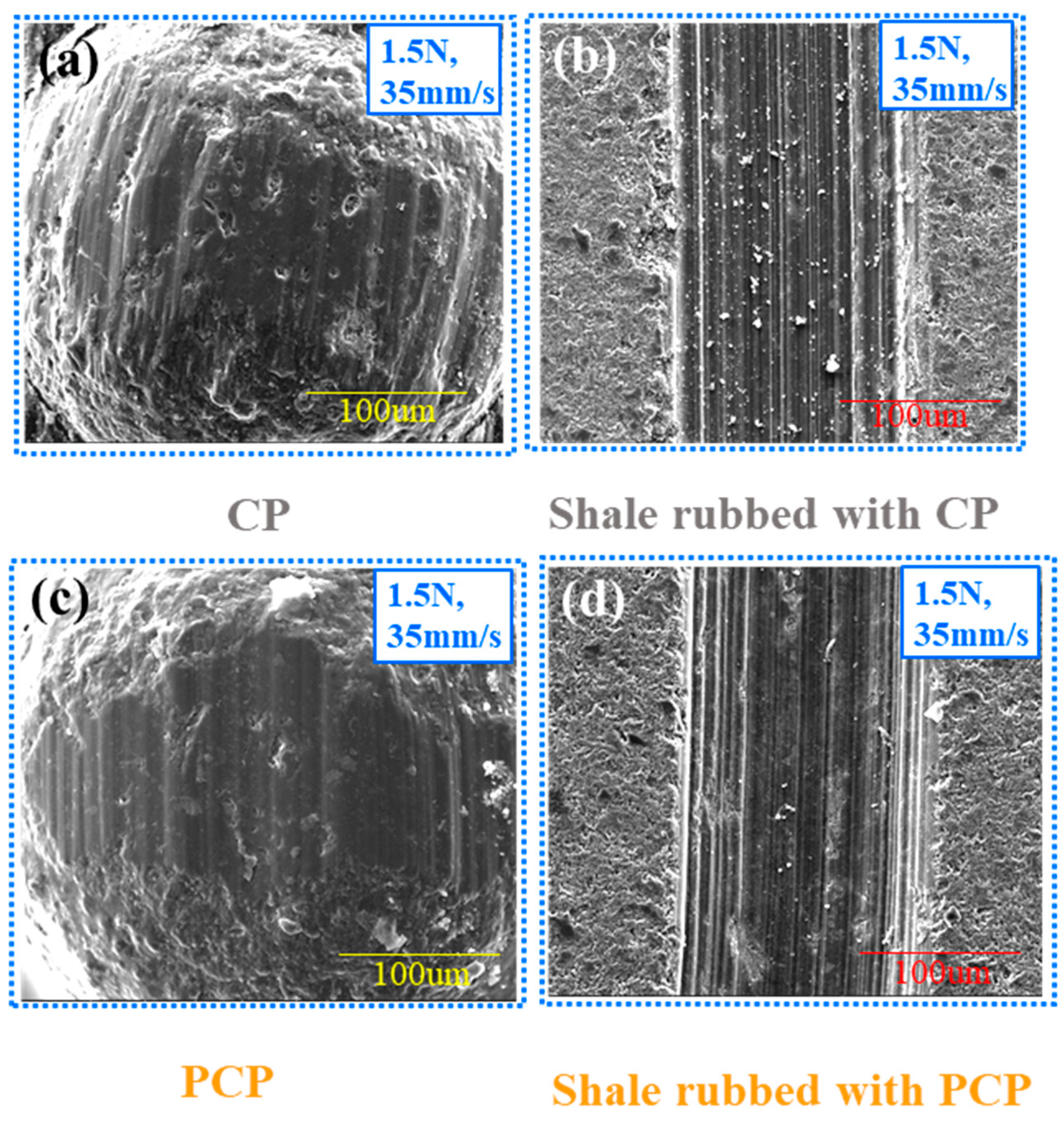

3.2. Wear Characterization of PCP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Muntasheri, G.A. A critical review of hydraulic fracturing fluids over the last decade. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 17 April 2014. [Google Scholar]

- Barati, R.; Liang, J.T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131, 40735. [Google Scholar] [CrossRef]

- Tan, P.; Jin, Y.; Han, K.; Hou, B.; Chen, M.; Guo, X.; Gao, J. Analysis of hydraulic fracture initiation and vertical propagation behavior in laminated shale formation. Fuel 2017, 206, 482–493. [Google Scholar] [CrossRef]

- Yang, L.; Wang, D.; Guo, Y.; Liu, S. Friction and wear behaviors of sand particle against casing steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 393–405. [Google Scholar] [CrossRef]

- Gallegos, T.J. Hydraulic fracturing (fracking). In Access Science; McGraw Hill: New York, NY, USA, 2018. [Google Scholar]

- Boudet, H.S.; Zanocco, C.M.; Howe, P.D. The effect of geographic proximity to unconventional oil and gas development on public support for hydraulic fracturing. Risk Anal. 2018, 38, 1871–1890. [Google Scholar] [CrossRef]

- Guo, T.; Nisbet, E.C.; Martin, J.F. Identifying mechanisms of environmental decision-making: How ideology and geographic proximity influence public support for managing agricultural runoff to curb harmful algal blooms. J. Environ. Manag. 2019, 241, 264–272. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Tan, J.; Wood, D.A.; Zhao, Z.; Becker, D.; Lyu, Q.; Shu, B.; Chen, H. A review of the current status of induced seismicity monitoring for hydraulic fracturing in unconventional tight oil and gas reservoirs. Fuel 2019, 242, 195–210. [Google Scholar] [CrossRef]

- Montgomery, C.T.; Smith, M.B. Hydraulic fracturing: History of an enduring technology. J. Pet. Technol. 2010, 62, 26–40. [Google Scholar] [CrossRef]

- Pangilinan, K.D.; Al, C.C.; Advincula, R.C. Polymers for proppants used in hydraulic fracturing. J. Pet. Sci. Eng. 2016, 145, 154–160. [Google Scholar] [CrossRef]

- Cannan, C.; Roper, T.; Savoy, S.; Mitchell, D.R. Electrically-Conductive Proppant and Methods for Making and Using Same. Google Patents 14/572,486, 28 May 2019. [Google Scholar]

- Parke, M.A.; Ramurthy, K.; Sanchez, P.W. New proppant for hydraulic fracturing improves well performance and decreases environmental impact of hydraulic fracturing operations. In Proceedings of the SPE Eastern Regional Meeting, Lexington, KY, USA, 3 October 2012. [Google Scholar]

- Alary, J.A.; Parias, T. Method of Manufacturing and Using Rod-Shaped Proppants and Anti-Flowback Additives. Google Patents 12/633,911, 23 September 2013. [Google Scholar]

- Zhang, C.; Zhao, L.; Yu, D.; Liu, G.; Pei, Y.; Huang, F.; Liu, B. The evaluation on physical property and fracture conductivity of a new self-generating solid proppant. J. Pet. Sci. Eng. 2019, 177, 841–848. [Google Scholar] [CrossRef]

- Hussain, H.; McDaniel, R.R.; Callanan, M.J. Proppants with Fiber Reinforced Resin Coatings. U.S. Patent 6,528,157, 3 April 2003. [Google Scholar]

- Burukhin, A.A.; Kalinin, S.; Abbott, J.; Bulova, M.; Wu, Y.K.; Crandall, M.; Kadoma, I.; Begich, M.; Papp, S. Novel interconnected bonded structure enhances proppant flowback control. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2012. [Google Scholar]

- Monastiriotis, S.; McCrary, A.L.; McDaniel, R.R.; Barthel, R.E. Proppant with Composite Coating. U.S. Patent 9,725,645, 8 August 2017. [Google Scholar]

- McCrary, A.L.; McDaniel, R.R.; Barthel, R.E.; Monastiriotis, S. Proppant with Polyurea-Type Coating. U.S. Patent 0,274,819. Available online: https://www.freepatentsonline.com/ (accessed on 18 September 2014).

- Guo, Z.; Li, X.-Y.; Liu, C.; Feng, X.; Shen, Y. A shale rock physics model for analysis of brittleness index, mineralogy and porosity in the Barnett Shale. J. Geophys. Eng. 2013, 10, 025006. [Google Scholar] [CrossRef]

- Yang, L.; Wang, D.; Guo, Y. Frictional behaviors of iron based tools-casing with sand deposition. Tribol. Int. 2018, 123, 180–190. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, Y.; Han, F.; Wang, D.; Zhang, S. Multilayer graphene for reducing friction and wear in water-based sand cleaning liquid. Wear 2021, 470–471, 203619. [Google Scholar] [CrossRef]

- He, H.; Luo, L.; Senetakis, K. Effect of normal load ans shearing velocity on the interface friciton of organic shale-Proppant simulant. Tribol. Int. 2020, 144, 106119. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Z.; Zhang, S.W. Advances in the application of biomimetic surface engineering in the oil and gas industry. Friction 2019, 7, 289–306. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Guar gum: Processing, properties and food applications-a review. J. Food Sci. Technol. 2014, 51, 409–418. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Senetakis, K. A micromechanical study of shale rock-proppant composite interface. J. Pet. Sci. Eng. 2020, 184, 106542. [Google Scholar] [CrossRef]

- He, B.; Lee, J.; Patankar, N.A. Contact angle hysteresis on rough hydrophobic surfaces. J. Colloids Surf. A Physicochem. Eng. Asp. 2004, 248, 101–104. [Google Scholar] [CrossRef]

- Karim, A.M.; Rothstein, J.P.; Kavehpour, H.P. Experimental study of dynamic contact angles on rough hydrophobic surfaces. J. Colloid Interface Sci. 2018, 513, 658–665. [Google Scholar] [CrossRef]

- An, T.; Deng, X.; Gao, Y.; Liu, S.; Dou, C.; Ju, J. Preparation of highly hydrophobic CeO2 films using glancing angle deposition. Mater. Lett. 2018, 216, 147–149. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, T.; Du, S.; Sepehrnoori, K. Numerical study of the effect of uneven proppant distribution between multiple fractures on shale gas well performance. Fuel 2015, 142, 189–198. [Google Scholar] [CrossRef]

- Sun, J.; Schechter, D. Investigating the effect of improved fracture conductivity on production performance of hydraulically fractured wells: Field-case studies and numerical simulations. J. Can. Pet. Technol. 2015, 54, 442–449. [Google Scholar] [CrossRef]

- Zheng, X.; Chen, M.; Hou, B.; Ye, Z.; Wang, W.; Yin, C.; Chen, X. Effect of proppant distribution pattern on fracture conductivity and permeability in channel fracturing. J. Pet. Sci. Eng. 2017, 149, 98–106. [Google Scholar] [CrossRef]

- Zhong, Y.; Kuru, E.; Zhang, H.; Kuang, J.; She, J. Effect of fracturing fluid/shale rock interaction on the rock physical and mechanical properties, the proppant embedment depth and the fracture conductivity. Rock Mech. Rock Eng. 2019, 52, 1011–1022. [Google Scholar] [CrossRef]

- Zoveidavianpoor, M.; Gharibi, A. Application of polymers for coating of proppant in hydraulic fracturing of subterraneous formations: A comprehensive review. J. Nat. Gas Sci. Eng. 2015, 24, 197–209. [Google Scholar] [CrossRef]

- Ueno, K.; Kunisad, K.; Yamada, A.K.; Tomita, T.; Mori, K.; Iwasa, T. Well Proppant and Method for Recovering Hydrocarbon from Hydrocarbon-Bearing Formation. U.S. Patent Application 14/638,315, 25 June 2015. [Google Scholar]

- Green, J.W.; Terracina, J.M.; Borges, J.F.; Spillars, S.E.; Mah, S.H. Proppant Materials and Methods of Tailoring Proppant Material Surface Wettability. U.S. Patent 9,879,515, 30 January 2018. [Google Scholar]

- Fu, L.; Zhang, G.; Ge, J.; Liao, K.; Jiang, P.; Pei, H.; Li, X. Surface modified proppants used for porppant flowback control in hydraulic fracturing. Colloids Surf. A Physicochem. Eng. Asp. 2016, 507, 18–25. [Google Scholar] [CrossRef]

- Fan, F.; Feng-Xia, L.; Shou-Ceng, T.; Mao, S.; Waleed, K.; Ai-Ping, S.; Yang, Z.; Quan, X. Hydrophobic epoxy resin coated proppants with ultra-high self-suspension ability and enhanced liquid conductivity. Pet. Sci. 2021, 18, 1753–1759. [Google Scholar] [CrossRef]

- Guo, T.; Wang, Y.; Du, Z.; Chen, M.; Liu, D.; Liu, X.; Rui, Z. Evaluation of coated proppant unconventional performance. Energy Fuels 2021, 35, 9268–9277. [Google Scholar] [CrossRef]

- Almond, S.W.; Penny, G.S.; Conway, M.W. Factors affecting proppant flowback with resin coated proppants. In Proceedings of the SPE European Formation Damage Conference and Exhibition, The Hague, The Netherlands, 15–16 May 1995; p. SPE-30096-MS. [Google Scholar]

- Haque, M.H.; Saini, R.K.; Sayed, M.A. Proceedings of the Nano-composite resin coated proppant for hydraulic fracturing//Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019; p. D021S021R005.

- Zhang, J.; Liu, K.; Cao, M. Experimental study on modified polyacrylamide coated self-suspending proppant. Fuel 2017, 199, 185–190. [Google Scholar] [CrossRef]

- Xie, X.; Niu, S.; Miao, Y.; Gao, X.; Cheng, L.; Gao, F. Preparation and properties of resin coated ceramic proppants with ultra light weight and high strength from coal-series kaolin. Appl. Clay Sci. 2019, 183, 105364. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, M.; Wang, J.; Wang, B.; Wu, Y.; Wang, L.; Guo, Y. The Excellent Mechanical Performance of Polymer-Coated Ceramsite Particles for Efficient Fracturing: An Explanation from a Surface, Tribological Perspective. Materials 2024, 17, 241. https://doi.org/10.3390/ma17010241

He M, Wang J, Wang B, Wu Y, Wang L, Guo Y. The Excellent Mechanical Performance of Polymer-Coated Ceramsite Particles for Efficient Fracturing: An Explanation from a Surface, Tribological Perspective. Materials. 2024; 17(1):241. https://doi.org/10.3390/ma17010241

Chicago/Turabian StyleHe, Mengqi, Jiangkuan Wang, Bin Wang, Yuxi Wu, Ling Wang, and Yanbao Guo. 2024. "The Excellent Mechanical Performance of Polymer-Coated Ceramsite Particles for Efficient Fracturing: An Explanation from a Surface, Tribological Perspective" Materials 17, no. 1: 241. https://doi.org/10.3390/ma17010241

APA StyleHe, M., Wang, J., Wang, B., Wu, Y., Wang, L., & Guo, Y. (2024). The Excellent Mechanical Performance of Polymer-Coated Ceramsite Particles for Efficient Fracturing: An Explanation from a Surface, Tribological Perspective. Materials, 17(1), 241. https://doi.org/10.3390/ma17010241