Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements

Abstract

1. Introduction

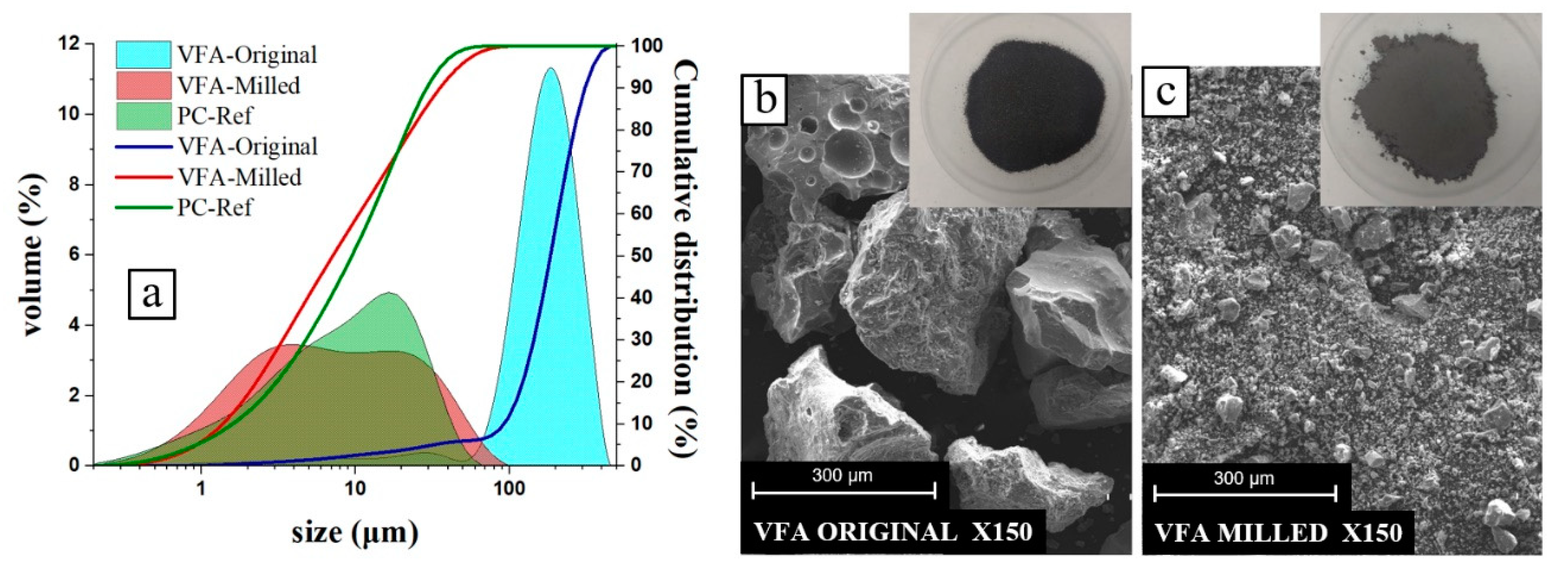

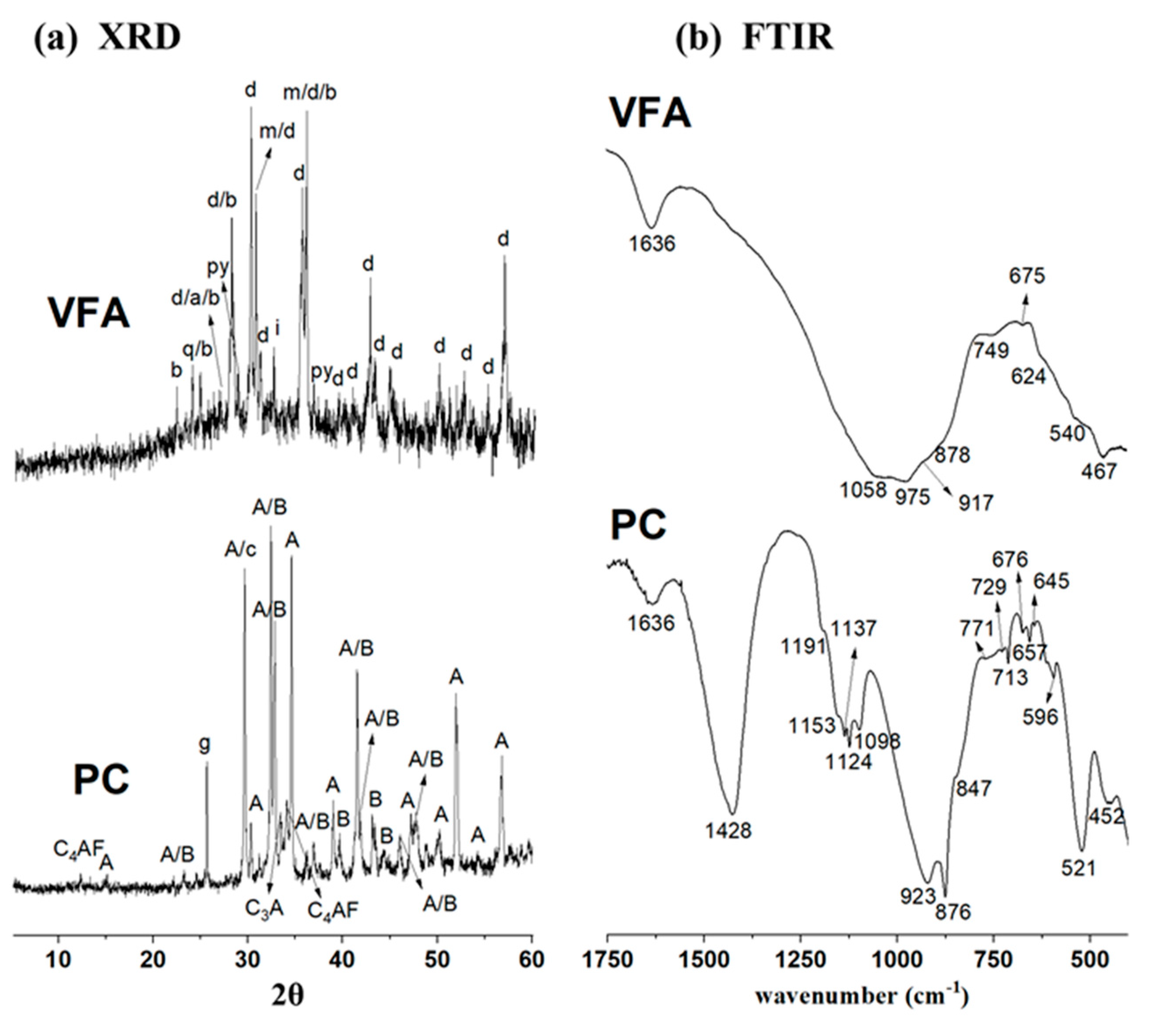

2. Material Characterisation and Methodologies

2.1. Chemical, Mineralogical and Physical Characterisation of the Raw Materials

2.2. Preparation of the Pastes

2.3. Mechanical, Mineralogical and Microstructural Characterisation of Pastes

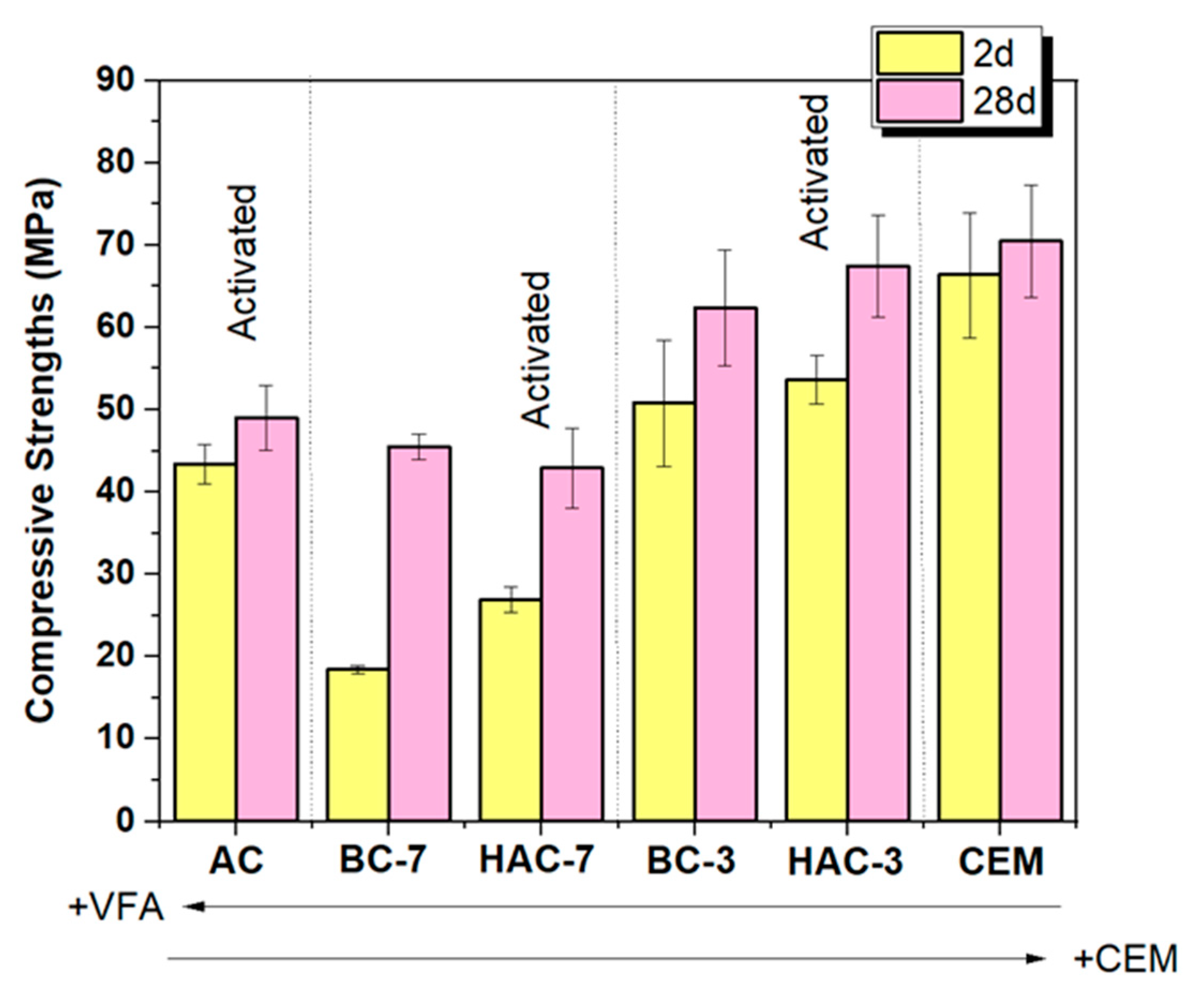

3. Results and Discussion

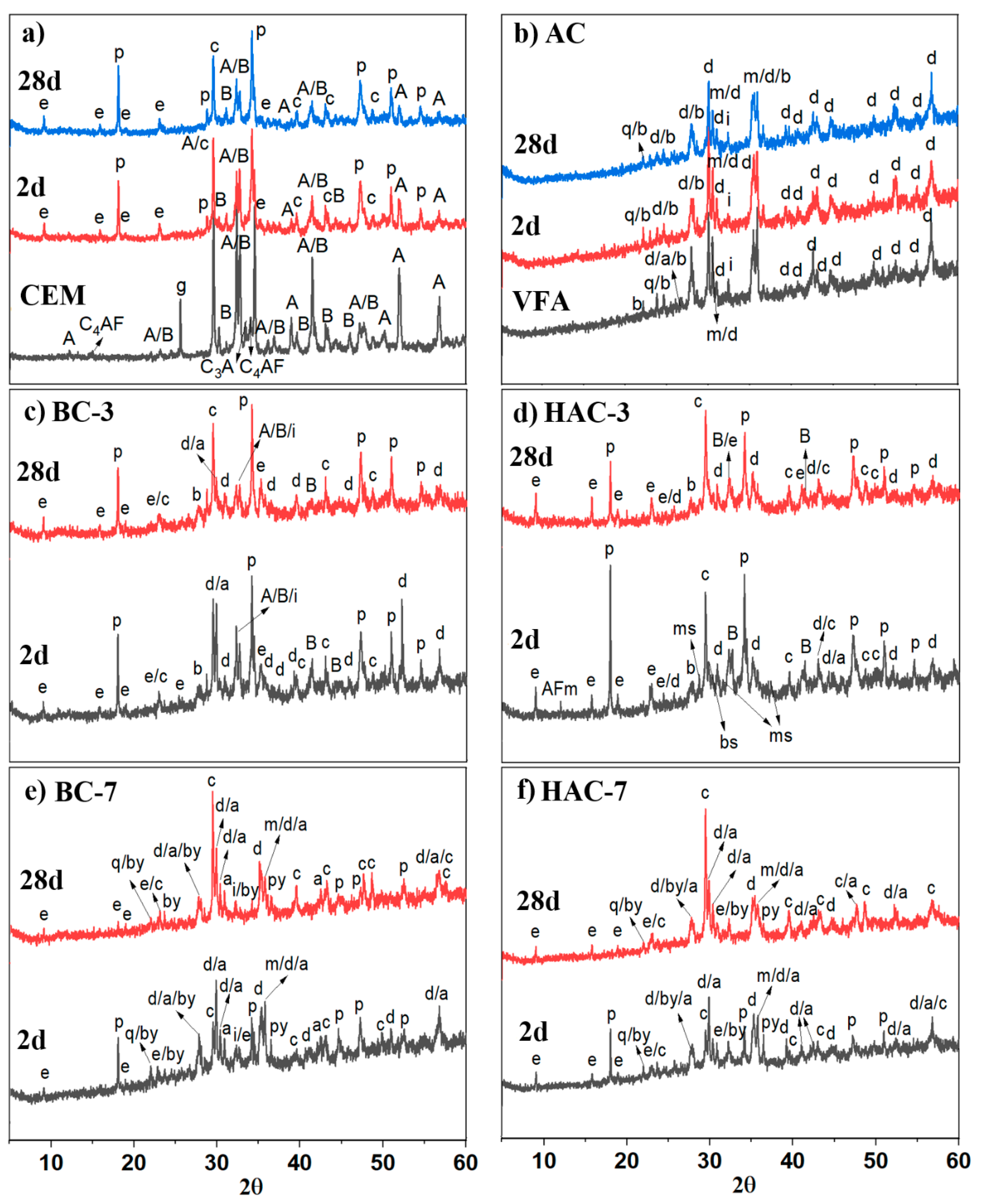

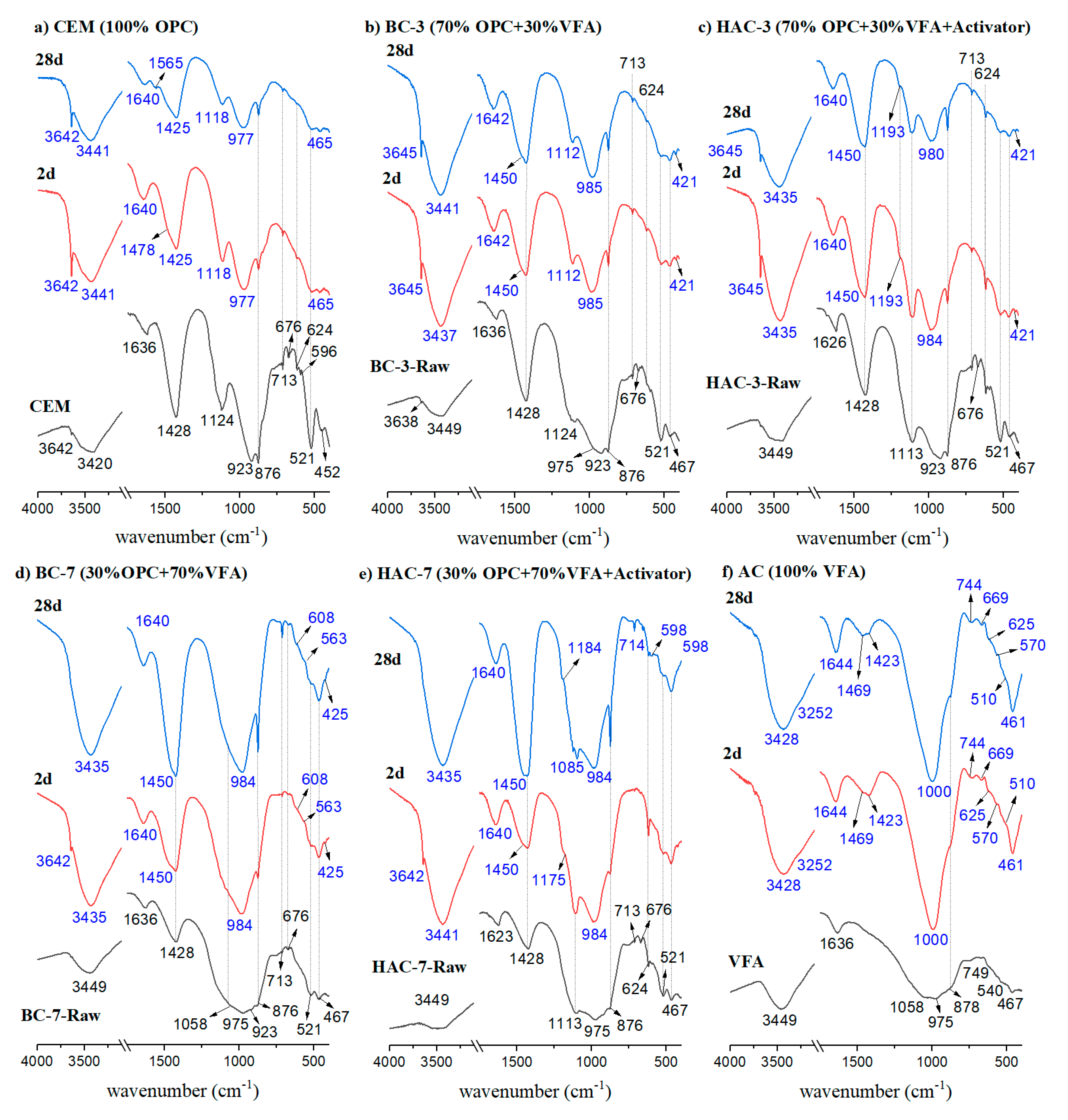

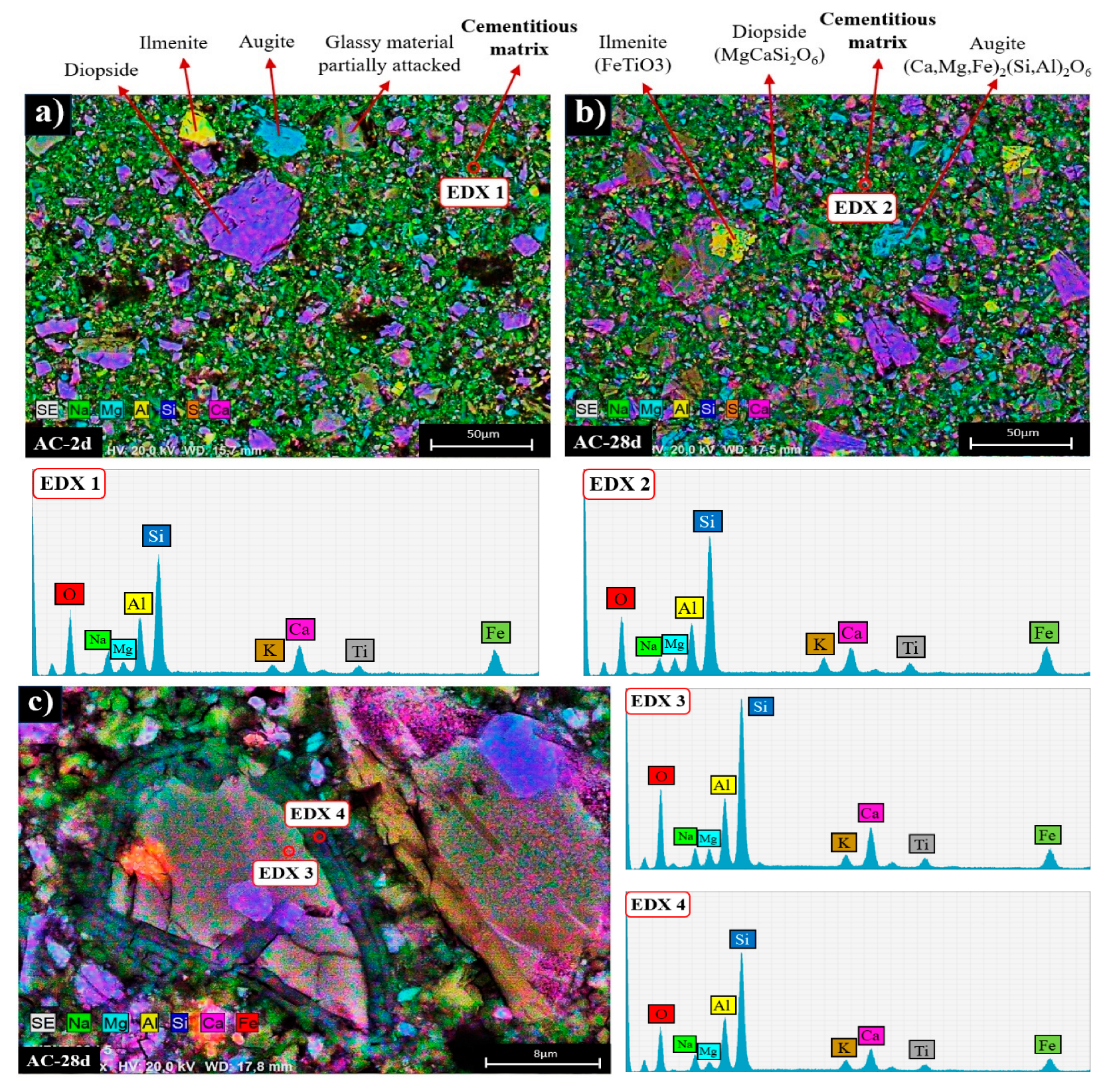

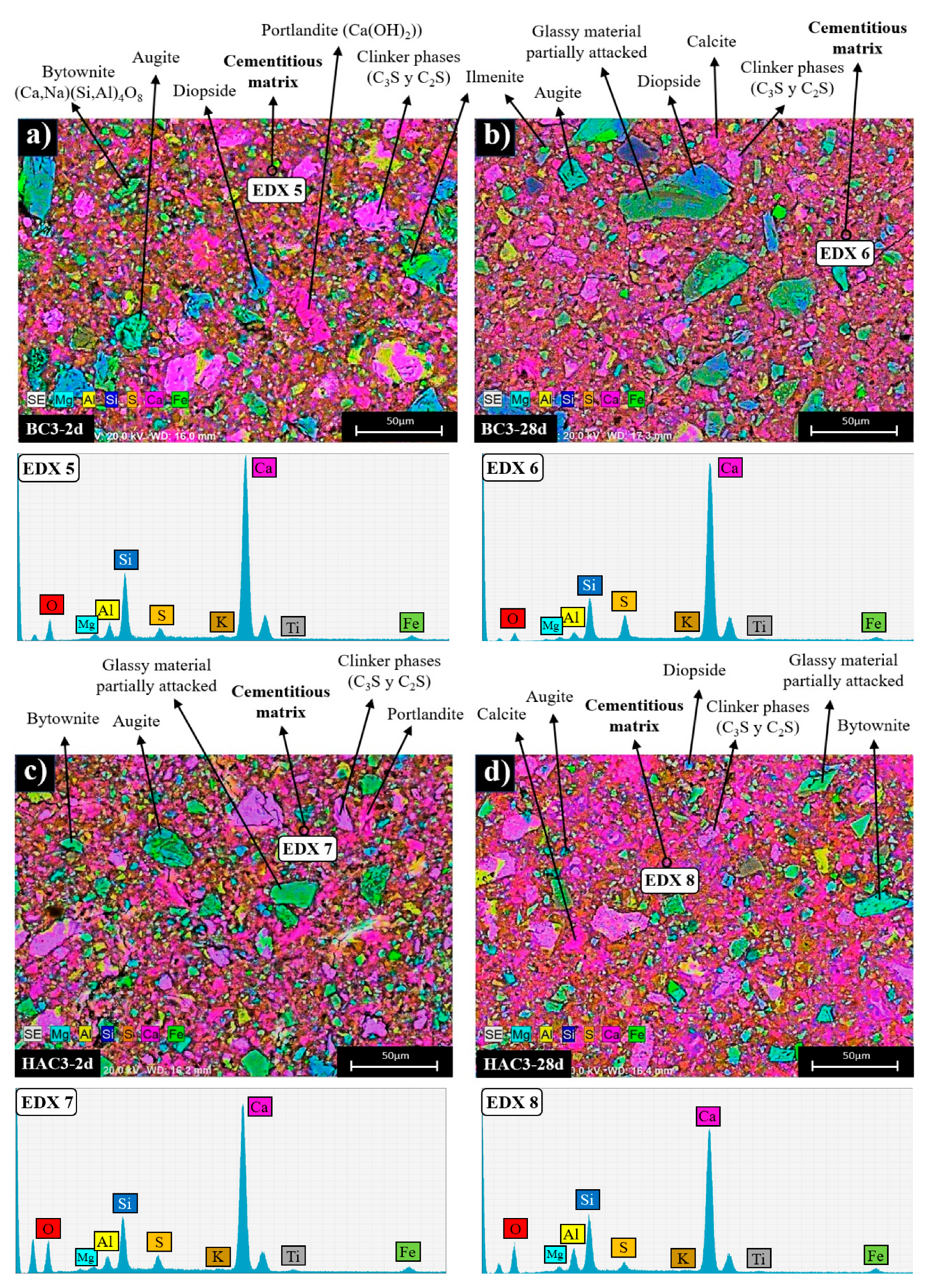

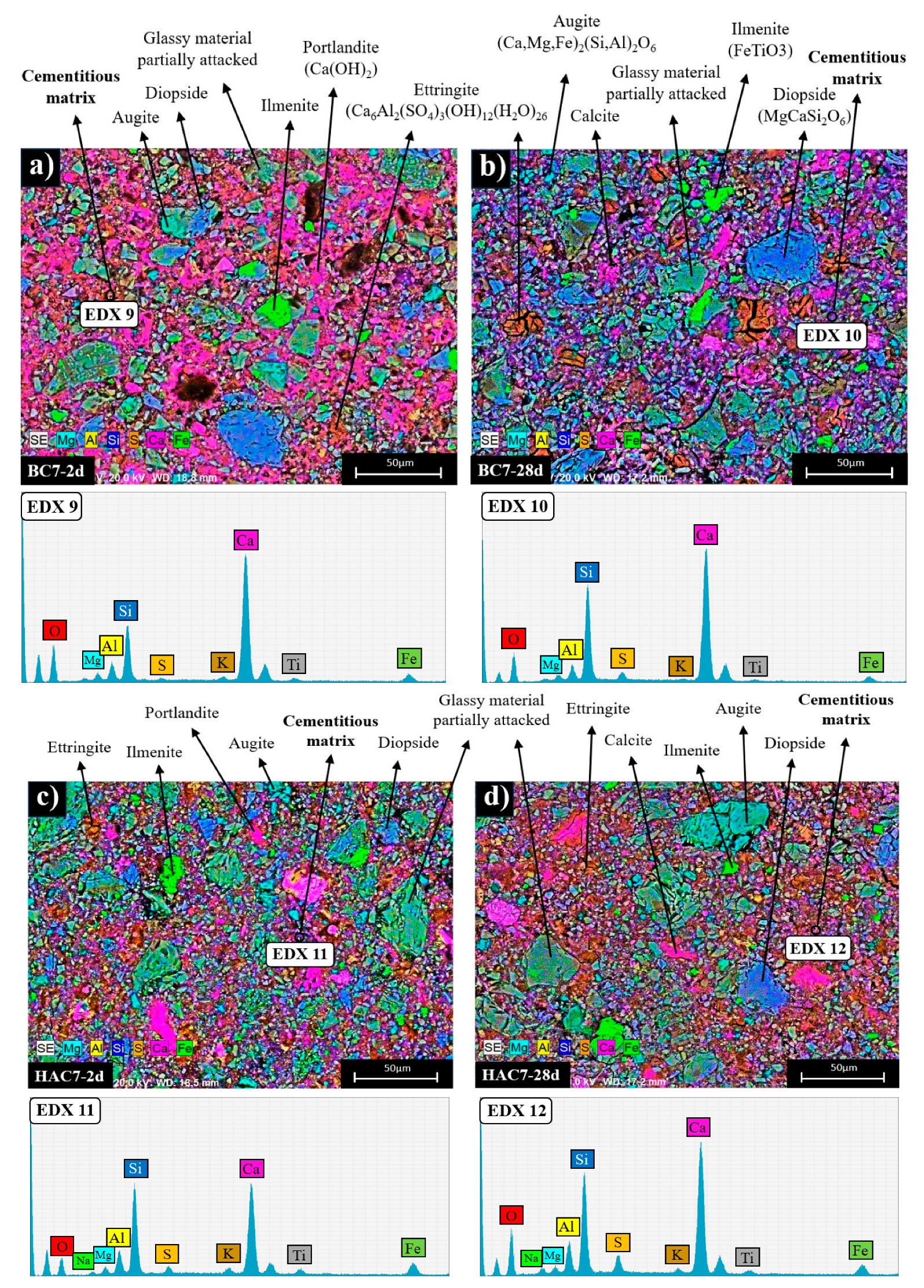

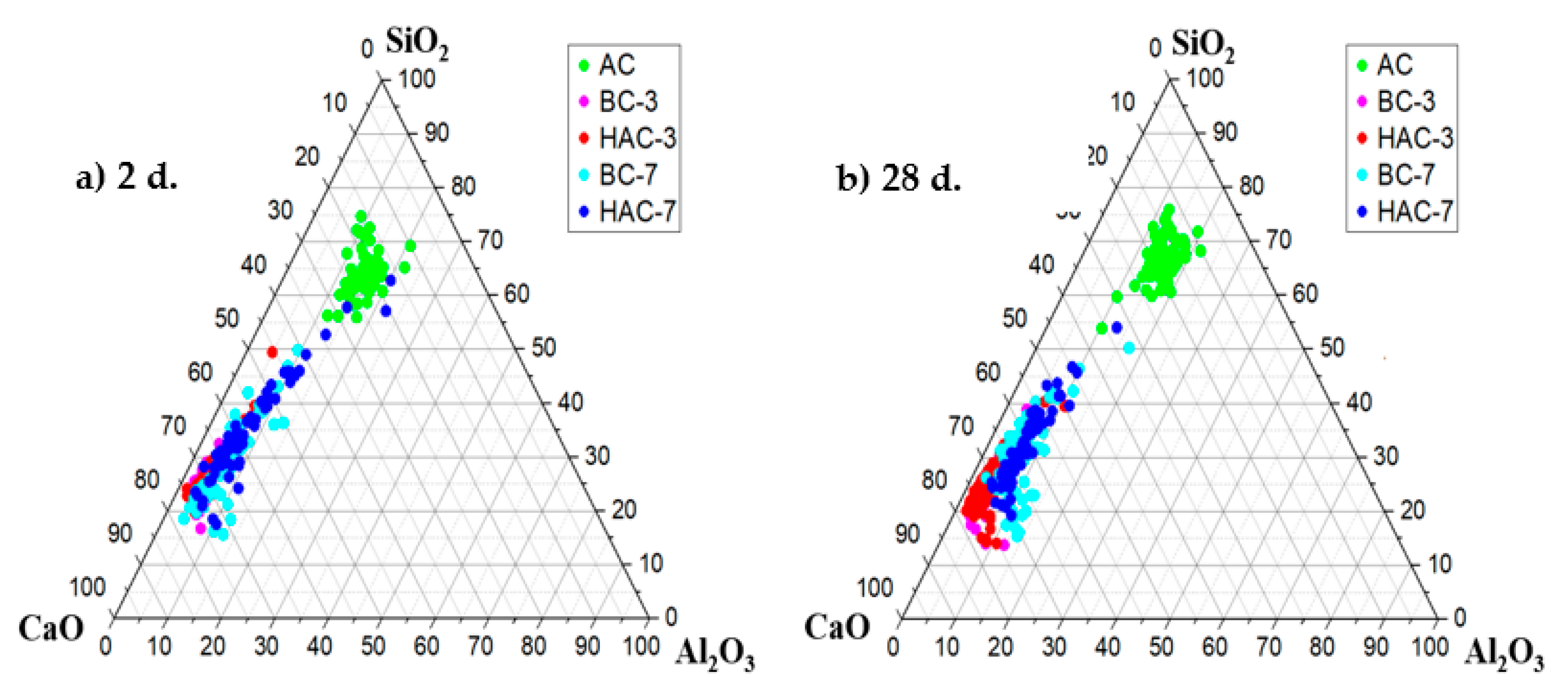

3.1. Reaction Products Characterisation

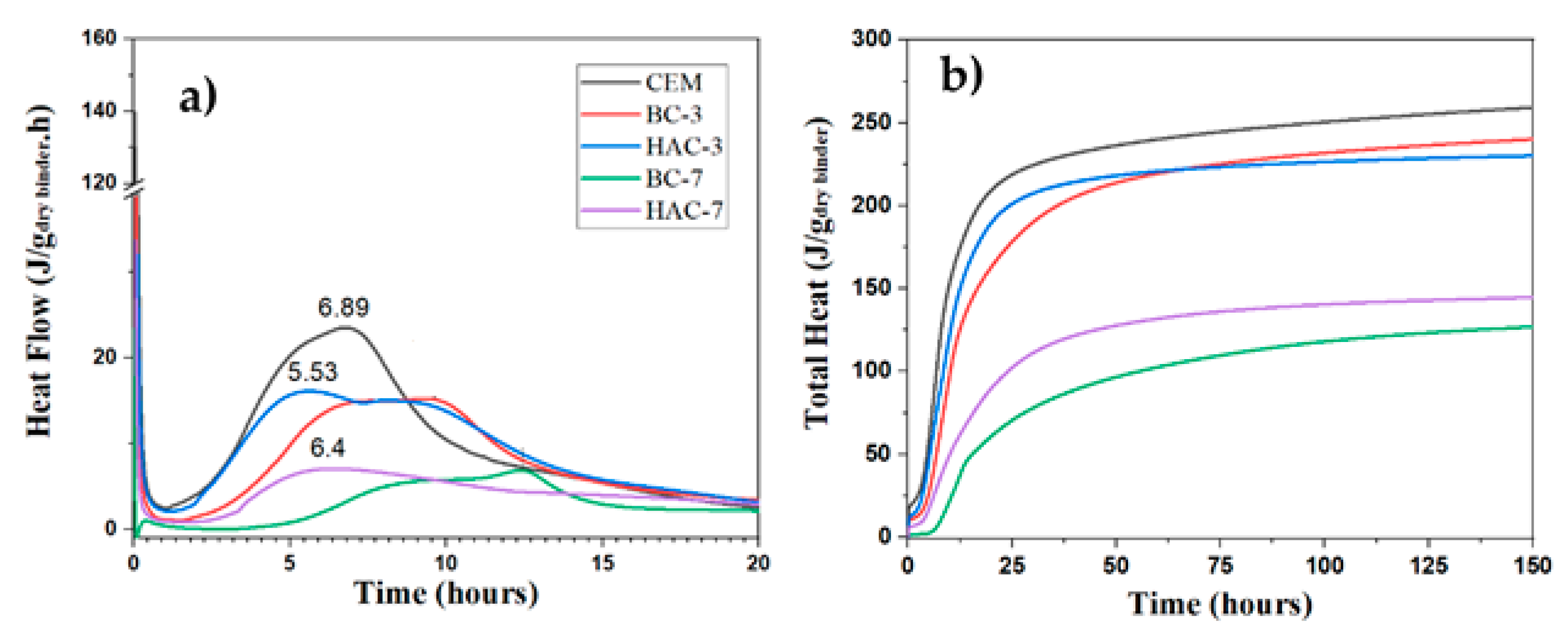

3.2. Hydration Kinetics

4. Conclusions

- In the blended cements (BC-3 and BC-7), volcanic fly ash (VFA) shows pozzolanic behaviour. This effect is more pronounced at higher VFA contents. The incorporation of VFA leads to a reduction in mechanical strength, hydration product formed is a C-(A)-S-H gel, with secondary materials such as AFt and Ca(OH)2 detected. The Ca(OH)2 content decreases with time due to pozzolanic reaction and carbonation.

- In hybrid alkaline cements (HAC-3 and HAC-7), the use of the alkaline activator accelerates the hydration kinetics and generates a higher degree of heat release, increasing the total heat compared to the same mixtures without the activator (BC-3 and BC-7). This phenomenon can be correlated with a greater precipitation of reaction products. Reaction products include the formation of a C-(A)-S-H gel with higher aluminium contents when higher amounts of VFA are used. The disappearance of Ca(OH)2 is related to several factors: (i) less cement leads to less Ca(OH)2 formation; (ii) pozzolanic reaction where Ca(OH)2 reacts with VFA to form hydration products; (iii) chemical reaction with the activator (see Equation (1)) to produce in situ alkalinity which accelerates the VFA reaction; and eventually (iv) carbonation.

- Alkali-activated cements (100% VFA, AC): The activation of these volcanic fly ashes results in a binder with excellent mechanical properties. The primary reaction product, in this case is a gel of the type (N,C)-A-S-H, similar to that obtained when other types of fly ash are activated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gobierno de Canarias, Informe Comite Científico, Islas Canarias, 2021. Available online: https://www3.gobiernodecanarias.org/noticias/la-erupcion-de-la-palma-se-declara-finalizada-tras-85-dias-y-8-horas-de-duracion-y-1-219-hectareas-de-coladas/ (accessed on 9 September 2023).

- Tashima, M.M.; Soriano, L.; Borrachero, M.V.; Monzó, J.; Payá, J. Towards the valorization of Cumbre Vieja volcanic ash–Production of alternative cements. Constr. Build. Mater. 2023, 370, 130635. [Google Scholar] [CrossRef]

- Játiva, A.; Ruales, E.; Etxeberria, M. Volcanic Ash as a Sustainable Binder Material: An Extensive Review. Materials 2021, 14, 1302. [Google Scholar] [CrossRef] [PubMed]

- Olawuyi, B.J.; Olusola, K.O. Compressive Strength of Volcanic Ash/Ordinary Portland Cement Laterized Concrete. Civ. Eng. Dimens. 2013, 12, 23–28. [Google Scholar] [CrossRef][Green Version]

- Siddique, R. Properties of concrete made with volcanic ash. Resour. Conserv. Recycl. 2012, 66, 40–44. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Wang, K.-T.; Tang, Q.; Nzeukou, A.; Billong, N.; Melo, U.C.; Cui, X.-M. Review on the use of volcanic ashes for engineering applications. Resour. Conserv. Recycl. 2018, 137, 177–190. [Google Scholar] [CrossRef]

- Jackson, M.D.; Deocampo, D.; Marra, F.; Scheetz, B. Mid-Pleistocene pozzolanic volcanic ash in ancient Roman concretes. Geoarchaeology 2010, 25, 36–74. [Google Scholar] [CrossRef]

- Palomo, A.; Monteiro, P.; Martauz, P.; Bilek, V.; Fernandez-Jimenez, A. Hybrid binders: A journey from the past to a sustainable future (opus caementicium futurum). Cem. Concr. Res. 2019, 124, 105829. [Google Scholar] [CrossRef]

- ASTM C618; Standard Specification for Coal Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. 2023 Edition. ASTM International: West Conshohocken, PA, USA, 2023.

- Al-Swaidani, A.M.; Aliyan, S.D.; Adarnaly, N. Mechanical strength development of mortars containing volcanic scoria-based binders with different fineness. Eng. Sci. Technol. Int. J. 2016, 19, 970–979. [Google Scholar] [CrossRef]

- Celik, K.; Jackson, M.D.; Mancio, M.; Meral, C.; Emwas, A.-H.; Mehta, P.K.; Monteiro, P.J.M. High-volume natural volcanic pozzolan and limestone powder as partial replacements for portland cement in self-compacting and sustainable concrete. Cem. Concr. Comps. 2014, 45, 136–147. [Google Scholar] [CrossRef]

- Al-Fadala, S.; Chakkamalayath, J.; Al-Bahar, S.; Al-Aibani, A.; Ahmed, S. Significance of performance based specifications in the qualification and characterization of blended cement using volcanic ash. Constr. Build. Mater. 2017, 144, 532–540. [Google Scholar] [CrossRef]

- Khandaker, M.A.H. Blended cement using volcanic ash and pumice. Cem. Concr. Res. 2003, 33, 1601–1605. [Google Scholar] [CrossRef]

- Contrafatto, L. Recycled Etna volcanic ash for cement, mortar and concrete manufacturing. Constr. Build. Mater. 2017, 151, 704–713. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Rahhal, V.F.; Locati, F.; Irassar, E.F.; Marfil, S.; Maiza, P. Pozzolanic activity of argentine vitreous breccia containing mordenite. Mater. Constr. 2020, 70, e208. [Google Scholar] [CrossRef]

- Medeiros, S.; Fernandes, I.; Fournier, B.; Nunes, J.; Santos-Silva, A.; Ramos, V.; Soares, D. Alkali-silica reaction in volcanic rocks: A worldwide comparative approach. Mater. Constr. 2022, 72, e278. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; De Wolf, C.; Chin, S.; Ochsendorf, J.; Hajiah, A.E.; Al-Mumin, A.; Büyüköztürk, O. Impact of Embodied Energy on materials/buildings with partial replacement of ordinary Portland Cement (OPC) by natural Pozzolanic Volcanic Ash. J. Clean. Prod. 2018, 177, 547–554. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Palkovic, S.D.; Bumajdad, A.; Soriano, C.; Büyüköztürk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 2018, 158, 574–590. [Google Scholar] [CrossRef]

- Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Effect of Processed Volcanic Ash as Active Mineral Addition for Cement Manufacture. Materials 2022, 15, 6305. [Google Scholar] [CrossRef]

- Rosales, J.; Rosales, M.; Díaz-López, J.L.; Agrela, F.; Cabrera, M. Rational utilization of volcanic ashes based on factors affecting their alkaline activation. J. Non-Cryst. Solids 2017, 463, 31–39. [Google Scholar] [CrossRef]

- Tchakoute, H.K.; Elimbi, A.; Yanne, E.; Djangang, C.N. Utilization of volcanic ashes for the production of geopolymers cured at ambient temperature. Cem. Concr. Compos. 2013, 38, 75–81. [Google Scholar] [CrossRef]

- Kouamo Tchakoute, H.; Elimbi, A.; Diffo Kenne, B.B.; Mbey, J.A.; Njopwouo, D. Synthesis of geopolymers from volcanic ash via the alkaline fusion method: Effect of Al2O3/Na2O molar ratio of soda-volcanic ash. Ceram. Int. 2013, 39, 269–276. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Chinje Melo, U.F.; Delplancke, M.P.; Rahier, H. Influence of the chemical and mineralogical composition on the reactivity of volcanic ashes during alkali activation. Ceram. Int. 2014, 40, 811–820. [Google Scholar] [CrossRef]

- Tchakoute, H.K.; Elimbi, A.; Kenne, B.D.; Mbey, J.; Njopwouo, D. Volcanic ash-based geopolymer cements/concretes: The current state of the art and perspectives. Environ. Sci. Pollut. Res. 2017, 24, 4433–4446. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Melo, U.C.; Delplancke, M.-P.; Rahier, H. Influence of the activating solution composition on the stability and thermo-mechanical properties of inorganic polymers (geopolymers) from volcanic ash. Constr. Build. Mater. 2013, 48, 278–286. [Google Scholar] [CrossRef]

- Yankwa Djobo, J.N.; Elimbi, A.; Tchakouté, H.K.; Kumar, S. Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr. Build. Mater. 2016, 124, 606–614. [Google Scholar] [CrossRef]

- Çetintaş, R.; Soyer-Uzun, S. Relations between structural characteristics and compressive strength in volcanic ash based one–part geopolymer systems. J. Build. Eng. 2018, 20, 130–136. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernández-Jiménez, A. A review on alkaline activation: New analytical perspective. Mater. Constr. 2014, 64, e022. [Google Scholar] [CrossRef]

- Azenha, M.; Schlicke, D.; Benboudjema, F.; Jędrzejewska, A. SynerCrete’18: Interdisciplinary Approaches for Cement-based Materials and Structural Concrete: Synergizing Expertise and Bridging Scales of Space and Time. In Proceedings of the SynerCrete’18: Interdisciplinary Approaches for Cement-based Materials and Structural Concrete: Synergizing Expertise and Bridging Scales of Space and Time, Funchal, Portugal, 24–26 October 2018. [Google Scholar] [CrossRef]

- Qu, B.; Fernández Jiménez, A.; Palomo, A.; Martin, A.; Pastor, J.Y. Effect of high temperatures on the mechanical behaviour of hybrid cement. Mater. Constr. 2020, 70, e213. [Google Scholar] [CrossRef]

- Diamond, S. Particle morphologies in fly ash. Cem. Concr. Res. 1986, 16, 569–579. [Google Scholar] [CrossRef]

- Tusheng, H.; Zaibo, L.; Sanyin, Z.; Xuguang, Z.; Xiaoling, Q. Study on the particle morphology, powder characteristics and hydration activity of blast furnace slag prepared by different grinding methods. Constr. Build. Mater. 2021, 270, 121445. [Google Scholar] [CrossRef]

- Alraddadi, S.; Assaedi, H. Characterization and potential applications of different powder volcanic ash. J. King Saud Univ.-Sci. 2020, 32, 2969–2975. [Google Scholar] [CrossRef]

- Farmer, V.C. The Infrared Spectra of Minerals. In Mineralogical Society; Farmer, V.C., Ed.; Monograph 4; University of Aberdeen: Aberdeen, UK, 1974. [Google Scholar]

- Hamidi, M.; Kacimi, L.; Cyr, M.; Clastres, P. Evaluation and improvement of pozzolanic activity of andesite for its use in ecoefficient cement. Constr. Build. Mater. 2013, 47, 1268–1277. [Google Scholar] [CrossRef]

- Sánchez de Rojas, M.I.; Frías, M.; Rivera Lozano, J.; Escorihuela, M.J.; Marín, F.P. Research about the pozzolanic activity of waste materials from calcined clay. Mater. Constr. 2001, 51, 45–52. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Fernández-Jimenez, A.; Pena, P.; Palomo, A. Alkaline activation of synthetic aluminosilicate glass. Ceram. Int. 2014, 40, 5547–5558. [Google Scholar] [CrossRef]

- Mejía, M.J.; Rodríguez, E.; Mejía de Gutiérrez, R.; Gallego, N. Preparation and characterization of a hybrid alkaline binder based on a fly ash with no commercial value. J. Clean. Prod. 2015, 104, 346–352. [Google Scholar] [CrossRef]

- Cristelo, N.; Garcia-Lodeiro, I.; Fernando Rivera, J.; Miranda, T.; Palomo, A.; Coelho, J.; Fernández-Jiménez, A. One-part hybrid cements from fly ash and electric arc furnace slag activated by sodium sulphate or sodium chloride. J. Build. Eng. 2021, 44, 103298. [Google Scholar] [CrossRef]

- Djobo, N.; Elimbi, A.; Tchakouté Kouamo, H.; Kumar, S. Reactivity of volcanic ash in alkaline medium, microstructural and strength characteristics of resulting geopolymers under different synthesis conditions. J. Mater. Sci. 2016, 51, 10301–10317. [Google Scholar] [CrossRef]

- Churata, R.; Almirón, J.; Vargas, M.; Tupayachy-Quispe, D.; Torres-Almirón, J.; Ortiz-Valdivia, Y.; Velasco, F. Study of Geopolymer Composites Based on Volcanic Ash, Fly Ash, Pozzolan, Metakaolin and Mining Tailing. Buildings 2022, 12, 1118. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; Macphee, D.E. Compatibility studies between N-A-S-H and C-A-S-H gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Pajares, I.; Martínez-Ramírez, S.; Blanco-Varela, M.T. Evolution of ettringite in presence of carbonate, and silicate ions. Cem. Concr. Compos. 2003, 25, 861–865. [Google Scholar] [CrossRef]

- Lothenbach, B.; Durdzinski, P.; De Weerdt, K. Thermogravimetric Analysys. In A practical Guide to Microestructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; pp. 178–206. ISBN 978-4987-3867-5. [Google Scholar]

- Wongkeo, W.; Thongsanitgarn, P.; Chindaprasirt, P.; Chaipanic, A. Thermogravimetry of ternary cement blends. J. Therm. Anal. Calorim. 2013, 113, 1079–1090. [Google Scholar] [CrossRef]

- Chinh Chu, D.; Kleib, J.; Amar, M.; Benzerzour, M.; Abriak, N. Determination of the degree of hydration of Portland cement using three different approaches: Scanning electron microscopy (SEM-BSE) and Thermogravimetric analysis (TGA). Case Stud. Constr. Mater. 2021, 15, e00754. [Google Scholar] [CrossRef]

- Celik, K.; Hay, R.; Hargis, C.W.; Moon, J. Effect of volcanic ash pozzolan or limestone replacement on hydration of Portland cement. Constr. Build. Mater. 2019, 197, 803–812. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Tayeh, B.A.; Rangel Garcez de Azevedo, A.; Abutaleb, A.; Hussain, Q. Production of geopolymer concrete by utilizing volcanic pumice dust. Case Stud. Constr. Mater. 2022, 16, e00802. [Google Scholar] [CrossRef]

- Ruiz-Agudo, E.; Kudłacz, K.; Putnis, C.V.; Putnis, A.; Rodriguez-Navarro, C. Dissolution and Carbonation of Portlandite [Ca(OH)2] Single Crystals. Environ. Sci. Technol. 2013, 47, 11342–11349. [Google Scholar] [CrossRef]

- Park, S.M.; Seo, J.H.; Lee, H.K. Thermal evolution of hydrates in carbonation-cured Portland cement. Mater. Struct. 2018, 51, 7. [Google Scholar] [CrossRef]

- Garcia-Lodeiro, I.; Donatello, S.; Fernández-Jiménez, A.; Palomo, A. Hydration of Hybrid Alkaline Cement Containing a Very Large Proportion of Fly Ash: A Descriptive Model. Materials 2016, 9, 605. [Google Scholar] [CrossRef]

- Gutteridge, W.A.; Dalziel, J.A. Filler cement: The effect of the secondary component on the hydration of Portland cement: Part, I. A fine non-hydraulic filler. Cem. Concr. Res. 1990, 20, 778–782. [Google Scholar] [CrossRef]

- Bullard, J.W.; Jennings, H.M.; Livingston, R.A.; Nonat, A.; Scherer, G.W.; Schweitzer, J.S.; Scrivener, K.L.; Thomas, J.J. Mechanisms of cement hydration. Cem. Concr. Res. 2011, 41, 1208–1223. [Google Scholar] [CrossRef]

- Andrade Neto, J.S.; De la Torre, A.G.; Kirchheim, A.P. Effects of sulfates on the hydration of Portland cement–A review. Constr. Build. Mater. 2021, 279, 122428. [Google Scholar] [CrossRef]

- Palomo, A.; Maltseva, O.; Garcia-Lodeiro, I.; Fernández-Jiménez, A. Portland Versus Alkaline Cement: Continuity or Clean Break: “A Key Decision for Global Sustainability”. Front. Chem. 2021, 9, 705475. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | K2O | P2O5 | SO3 | Others | LoI * | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VFA | 41.56 | 14.49 | 14.73 | 11.92 | 5.57 | 4.03 | 4.21 | 1.75 | 0.81 | 0.19 | 0.74 | - |

| PC | 18.13 | 4.29 | 3.00 | 61.47 | 3.33 | 0.26 | 0.50 | 0.56 | 0.10 | 3.00 | 5.36 | 4.36 |

| CaO Saturated Solution Test Results | |||||

| Age | pH | % CaO Fixed | |||

| 2 | 12.51 ± 0.01 | 13.46 ± 0.05 | |||

| 28 | 12.32 ± 0.01 | 55.48 ± 3.16 | |||

| HF Attack Analysis Results | |||||

| %SiO2 | %Al2O3 | SiO2 + Al2O3 %Reactive | Ratio SiO2/Al2O3 | ||

| Initial | Reactive | Initial | Reactive | ||

| 41.56 | 35.73 | 14.49 | 10.70 | 46.43 | 3.34 |

| Name | BINDERS (B) | Activator | Liquid Hydration (L) | L/B | Curing Conditions | |

|---|---|---|---|---|---|---|

| VFA | PC | |||||

| CEM | -- | 100 | -- | Water | 0.3 | 20 h. 25 °C |

| BC-3 | 30 | 70 | -- | Water | 0.3 | 20 h. 25 °C |

| HAC-3 | 30 | 70 | SAc * | Water | 0.3 | 20 h. 25 °C |

| BC-7 | 70 | 30 | -- | Water | 0.3 | 20 h. 25 °C |

| HAC-7 | 70 | 30 | SAc * | Water | 0.3 | 20 h. 25 °C |

| AC | 100 | -- | LAc * | NaOH 8 M | 0.4 | 20 h. 85 °C |

| Sample | % Portlandite | % Carbonates | ||

|---|---|---|---|---|

| 2 d | 28 d | 2 d | 28 d | |

| CEM | 10.27 | 9.86 | 16.36 | 16.36 |

| BC-3 | 7.81 | 8.22 | 12.04 | 14.77 |

| HAC-3 | 5.34 | 4.93 | 15.00 | 21.36 |

| BC-7 | 4.11 | 1.64 | 7.27 | 15.22 |

| HAC-7 | 3.28 | 2.46 | 8.18 | 16.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Rodríguez, P.; Fernández-Jiménez, A.; Alonso, M.d.M.; Palomo, A.; García-Lodeiro, I. Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements. Materials 2024, 17, 242. https://doi.org/10.3390/ma17010242

Martín-Rodríguez P, Fernández-Jiménez A, Alonso MdM, Palomo A, García-Lodeiro I. Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements. Materials. 2024; 17(1):242. https://doi.org/10.3390/ma17010242

Chicago/Turabian StyleMartín-Rodríguez, Pablo, Ana Fernández-Jiménez, María del Mar Alonso, Angel Palomo, and Inés García-Lodeiro. 2024. "Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements" Materials 17, no. 1: 242. https://doi.org/10.3390/ma17010242

APA StyleMartín-Rodríguez, P., Fernández-Jiménez, A., Alonso, M. d. M., Palomo, A., & García-Lodeiro, I. (2024). Valorisation of “La Palma” Volcanic Ash for Making Portland-Blended, Alkaline and Hybrid Portland–Alkaline Cements. Materials, 17(1), 242. https://doi.org/10.3390/ma17010242