Influence of Fines Content and Pile Surface Characteristics on the Pullout Resistance Performance of Piles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pullout Resistance of Pile

2.2. Laboratory Experiment

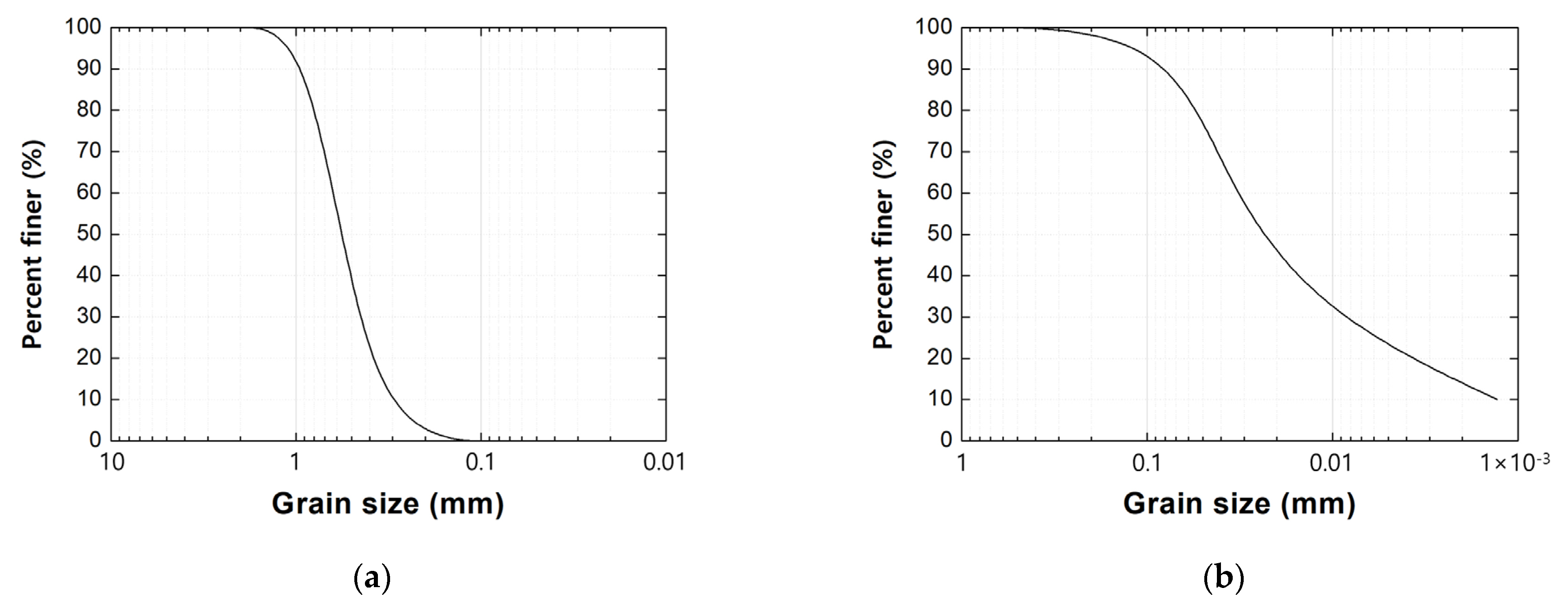

2.2.1. Engineering Properties of Soils

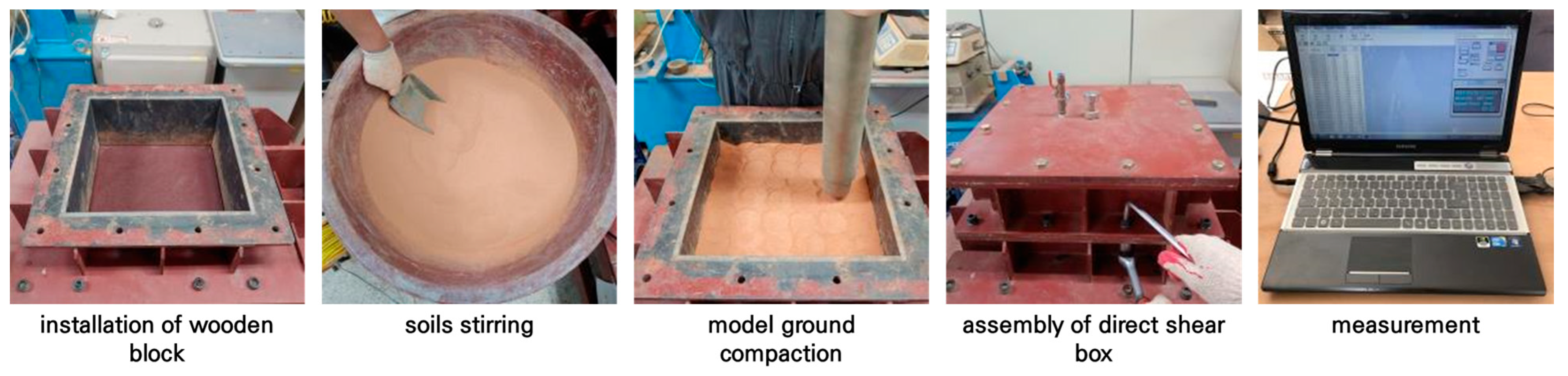

2.2.2. Direct Shear Tests

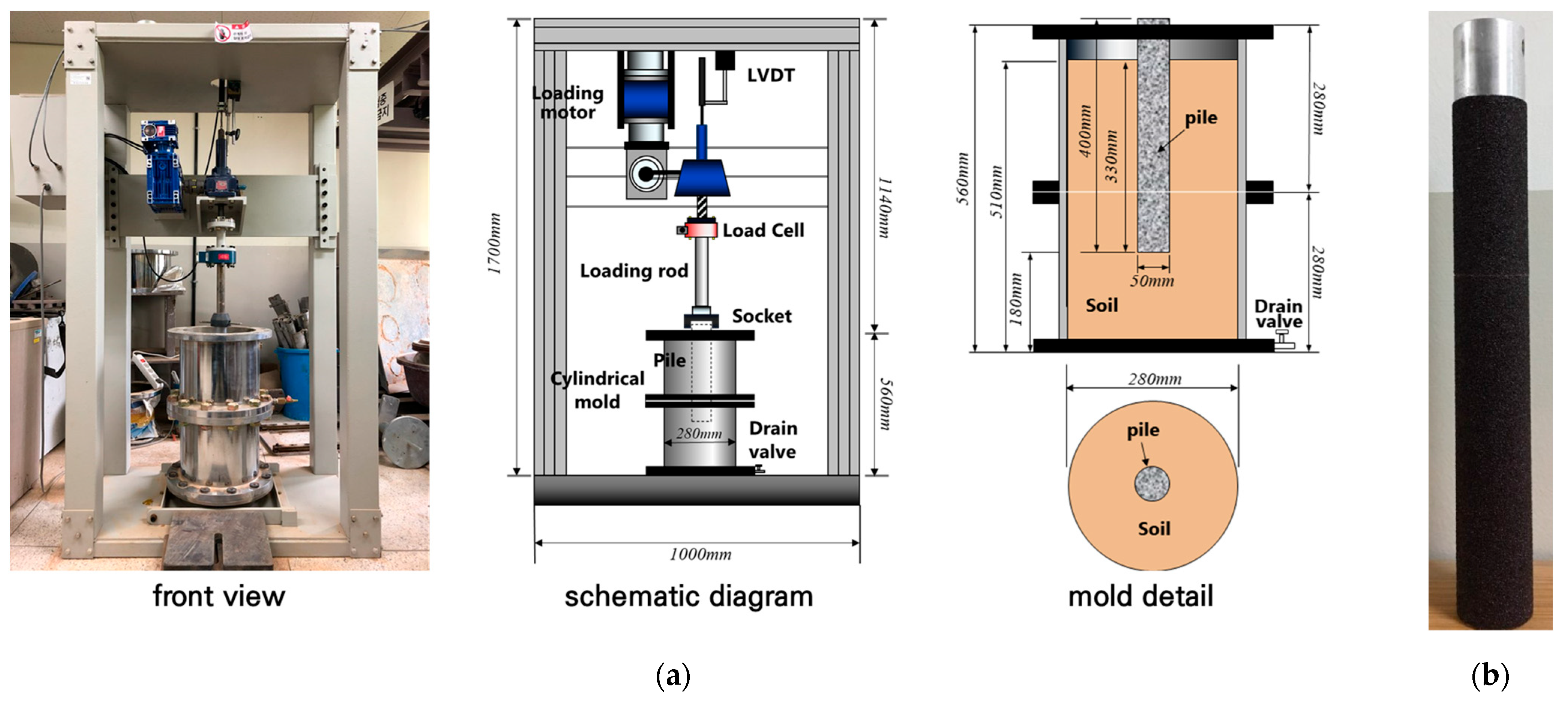

2.2.3. Pullout Tests of Model Pile Wrapped in Sandpaper

3. Results and Discussion

3.1. Shear Resistance of Soils and Pile–Soil Interface

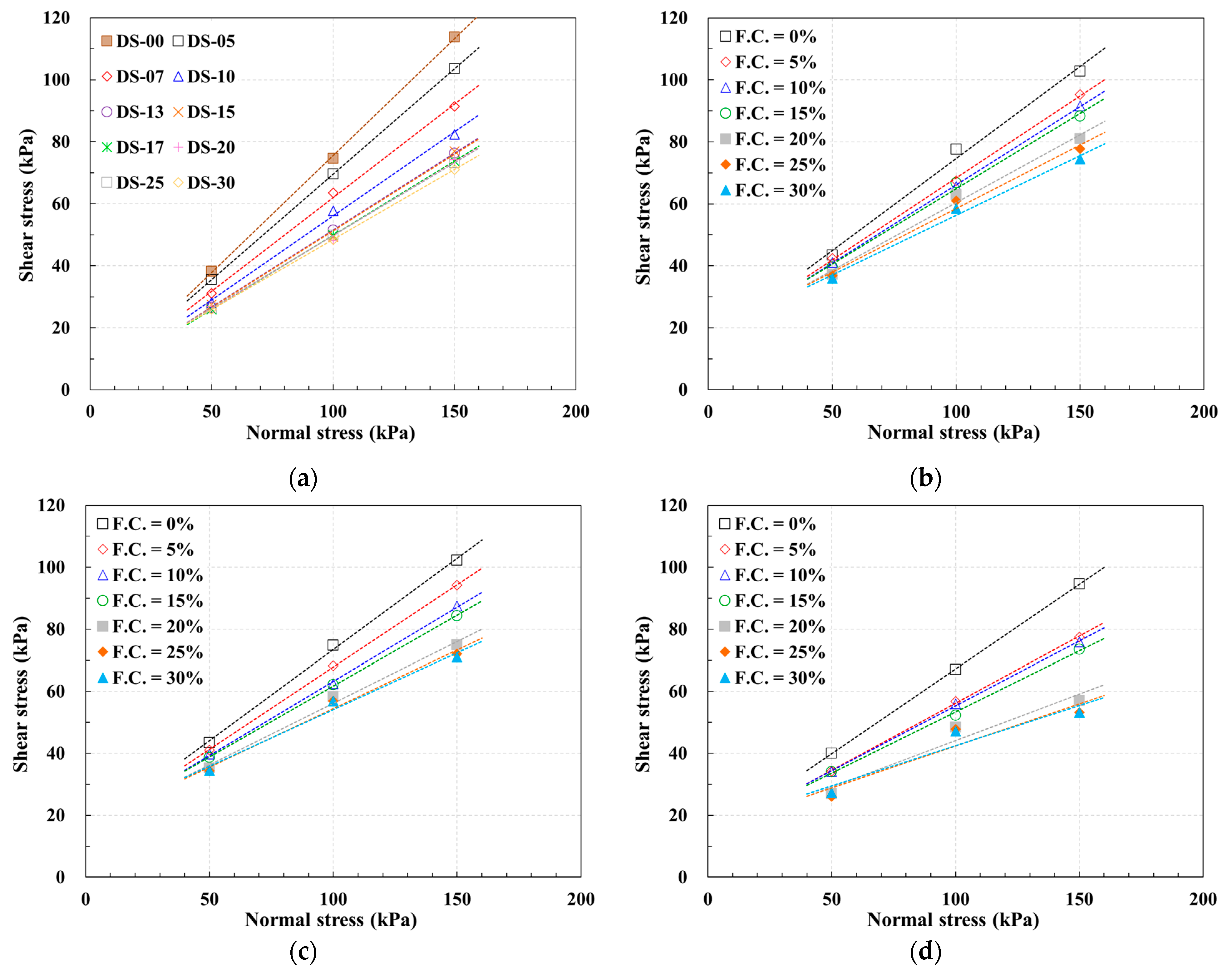

3.1.1. Test Results

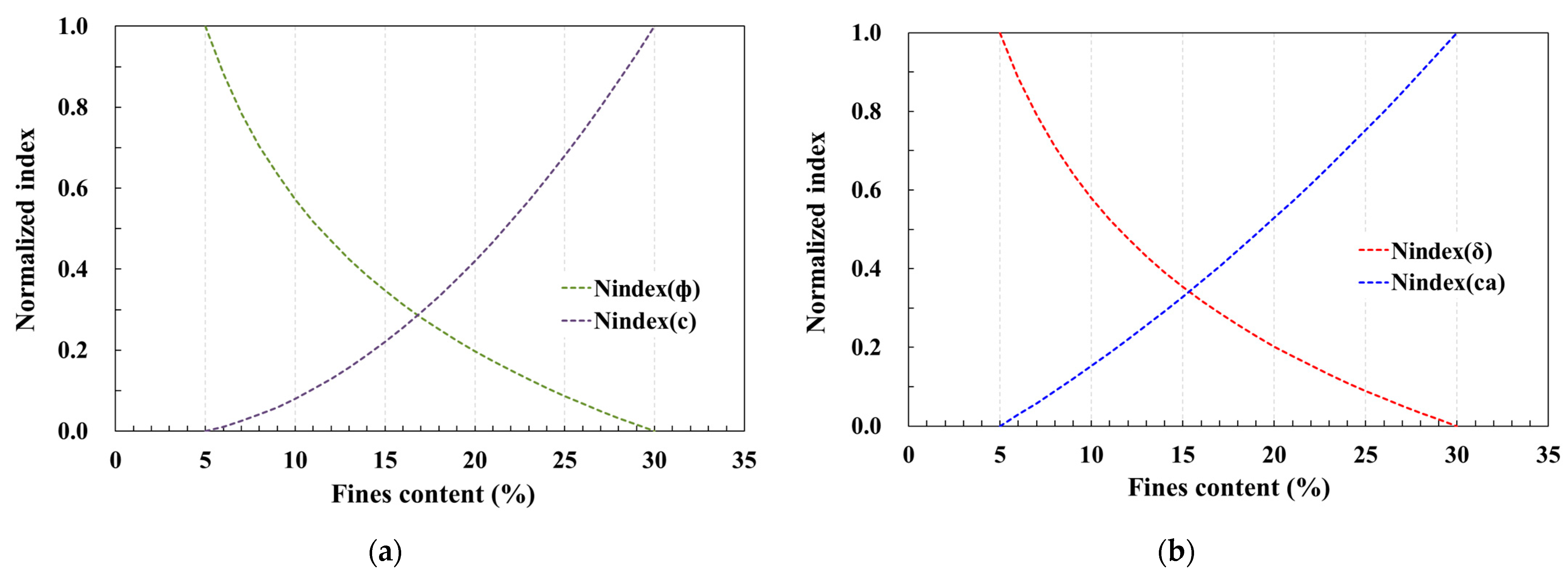

3.1.2. Shear Resistance Characteristics of Soil–Pile Surface Interface with Fines Content

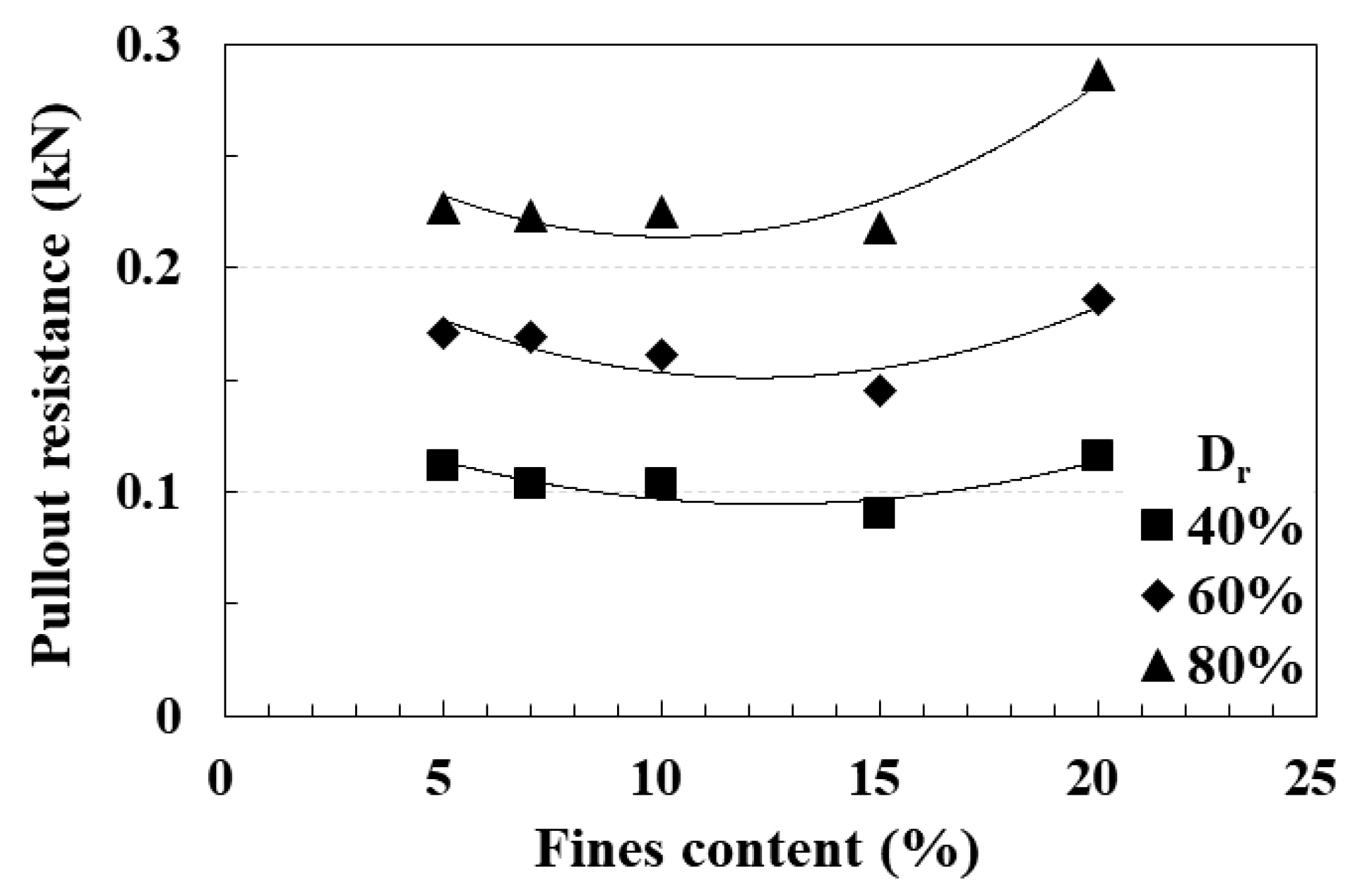

3.2. Influence of Fines Content on the Pullout Resistance Performance of Pile

4. Conclusions

- (1)

- The direct shear test outcomes revealed that, irrespective of the material characteristics of the shear surface, the internal friction angle of soil and the soil–sandpaper interface friction angle decreased with increasing fines content. Conversely, the cohesion of soil and the adhesion at the soil–sandpaper interface exhibited an upward trend as the fines content increased. Remarkably, the increase in the rate of adhesion at the soil–sandpaper interface was approximately ten times higher than that of cohesion. It was further emphasized that both the interface friction angle and adhesion are crucial considerations in assessing the shear resistance characteristics at the soil–sandpaper interface, as compared to the shear resistance of soil.

- (2)

- The shear strength parameters, normalized based on the fines content using the direct shear test results, revealed an intersection between the normalized curves of the friction angle and cohesion (or adhesion) within a specific fines content range, irrespective of the shear surface characteristics of the material. This implies that shear strength parameters serve as influential factors dependent on fines content.

- (3)

- Analysis of the normalized index results from the model pullout test indicated a substantial contribution of the soil fines content to the pullout resistance of the pile. Consequently, predicting the pullout resistance of piles necessitates an evaluation of the contribution of the friction angle and cohesion (or adhesion) in consideration of the fines content of the soil, aligning with the methodology employed in this study.

- (4)

- Piles are mostly installed in saturated soil at the bottom of the ground surface. This research could not consider the conditions of saturated soil because it is difficult to simulate the conditions of model ground with saturated soil using the direct shear test device applied in this research. In other words, this research includes test results due to the limitations of the testing device. Therefore, the research considering the conditions of saturated soil must continue to be conducted in order to ensure the reliability of the shear resistance evaluation results of the soil–pile interface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Meyerhof, G.G.; Adams, J.I. The Ultimate Uplift Capacity of Foundations. Can. Geotech. J. 1968, 5, 225–244. [Google Scholar] [CrossRef]

- Meyerhof, G.G. Bearing capacity and settlement of pile foundations. J. Geotech. Eng. Div. 1976, 102, 197–228. [Google Scholar] [CrossRef]

- Das, B.M.; Seeley, G.R. Uplift capacity of buried model piles in sand. J. Geotech. Eng. Div. ASCE 1975, 101, 1091–1094. [Google Scholar] [CrossRef]

- O’Neill, M.W.; Reese, L.C. Drilled Shafts: Construction Procedures and Design Methods; Publication No. FHWA-IF-99-025; Federal Highway Administration: Washington, DC, USA, 1999. [Google Scholar]

- Pu, S.; Zhu, Z.; Song, W. A method for calculating the ultimate bearing capacity of uplift piles in combined soil and rock mass. Eur. J. Environ. Civ. Eng. 2022, 26, 2158–2183. [Google Scholar] [CrossRef]

- Kumara, J.J.; Kikuchi, Y.; Kurashina, T. Effects of the lateral stress on the inner frictional resistance of pipe piles driven into sand. Int. J. Geo-Eng. 2016, 7, 1. [Google Scholar] [CrossRef]

- Ha, I.S.; Han, J.T. Evaluation of the allowable axial bearing capacity of a single pile subjected to machine vibration by numerical analysis. Int. J. Geo-Eng. 2016, 7, 22. [Google Scholar] [CrossRef]

- Hosseini, M.A.; Rayhani, M. Evolution of pile shaft capacity over time in marine soils. Int. J. Geo-Eng. 2017, 8, 12. [Google Scholar] [CrossRef]

- Dai, G.L.; Wan, Z.H. Full-Scale Field Study on Large-Diameter Post-grouting Drilled Shafts. In Proceedings of the 4th GeoShanghai International Conference on Advances in Soil Dynamics and Foundation Engineering, Shanghai, China, 27–30 May 2018; pp. 662–674. [Google Scholar]

- Wang, G.; Hong, B.; Liu, X.; Sun, D.; Shao, Z.; Yao, Y. Experimental Study on the Shear Properties of Soil around Piles with Permeation Grouting. Appl. Sci. 2023, 13, 621. [Google Scholar] [CrossRef]

- Mullins, G.; Winters, D.; Dapp, S. Predicting End Bearing Capacity of Post-Grouted Drilled Shaft in Cohesionless Soils. J. Geotech. Geoenviron. 2006, 132, 478–487. [Google Scholar] [CrossRef]

- Yoo, B.-S.; Tran, N.X.; Kim, S.-R. Numerical Simulation of Piles in a Liquefied Slope Using a Modified Soil–Pile Interface Model. Appl. Sci. 2023, 13, 6626. [Google Scholar] [CrossRef]

- Ma, H.; Ma, Y.; Zhu, L.; Zhang, H. Experimental Study on the Difference Mechanism of Shaft Resistance between Uplift Piles and Compressive Piles. Appl. Sci. 2023, 13, 3158. [Google Scholar] [CrossRef]

- Basha, A.; Azzam, W.R. Uplift capacity of single pile embedded in partially submerged sand. KSCE J. Civil. Eng. 2018, 22, 4882–4890. [Google Scholar] [CrossRef]

- Emirler, B.; Tolun, M.; Yildiz, A. An experimental study of rough single pile and pile group under uplift loading in sand. Eur. J. Environ. Civ. Eng. 2019, 25, 557–574. [Google Scholar] [CrossRef]

- Ashour, M.; Abbas, A. Response of piles in multilayers of soil under uplift forces. Int. J. Geom. 2020, 20, 4020056. [Google Scholar] [CrossRef]

- Das, B.M. A procedure for estimation of uplift capacity of rough piles. Soils Found. 1983, 23, 122–126. [Google Scholar] [CrossRef] [PubMed]

- Tovar-Valencia, R.D.; Galvis-Castro, A.; Salgado, R.; Prezzi, M. Effect of surface roughness on the shaft resistance of displacement model piles in sand. J. Geotech. Geoenviron. 2018, 144, 1943–5606. [Google Scholar] [CrossRef]

- Ma, J.; Luo, L.; Mu, T.; Guo, H.; Tang, Y. Experimental Study on Characteristics of Pile-Soil Interaction in Screw Piles. Buildings 2022, 12, 2091. [Google Scholar] [CrossRef]

- Ma, H.W.; Liu, L.; Wang, P.; Yuan, S.; He, Q.R.; Yang, X.L. Calculation method and mechanism of ultimate side resistance of screw pile. Mar. Georesour. Geotech. 2021, 41, 99–113. [Google Scholar] [CrossRef]

- Chen, Y.D.; Deng, A.; Wang, A.T.; Sun, H.S. Performance of screw-shaft pile in sand: Model test and DEM simulation. Comput. Geotech. 2018, 104, 118–130. [Google Scholar] [CrossRef]

- Abi, E.; Shen, L.; Liu, M.; Du, H.; Shu, D.; Han, Y. Calculation Model of Vertical Bearing Capacity of Rock-Embedded Piles Based on the Softening of Pile Side Friction Resistance. J. Mar. Sci. Eng. 2023, 11, 939. [Google Scholar] [CrossRef]

- Yamin, M.; Khan, Z.; Hesham, E.N.; El Naggar, H.; Al Hai, N. Nonlinear Regression Analysis for Side Resistance of Socketed Piles in Rock Formations of Dubai Area. Geotech. Geol. Eng. 2018, 36, 3857–3869. [Google Scholar] [CrossRef]

- Wang, L.; Chen, H.; Tian, Y. The Influence of the Shaft on the Uplift Capacity of Single-Plate Helical Pile in Clay. J. Mar. Sci. Eng. 2023, 11, 955. [Google Scholar] [CrossRef]

- Khatri, V.N.; Kumar, J. Uplift Capacity of Axially Loaded Piles in Clays. Int. J. Geomech. 2011, 11, 23–28. [Google Scholar] [CrossRef]

- Tien Bui, D.; Moayedi, H.; Abdullahi, M.M.; Safuan, A.; Rashid, A.; Nguyen, H. Prediction of Pullout Behavior of Belled Piles through Various Machine Learning Modelling Techniques. Sensors 2019, 19, 3678. [Google Scholar] [CrossRef] [PubMed]

- Park, K.; Kim, D.; Kim, G.; Lee, W. Evaluation of the Pullout Behavior of Pre-Bored Piles Embedded in Rock. Materials 2021, 14, 5593. [Google Scholar] [CrossRef] [PubMed]

- Potyondy, J.G. Skin Friction between Various Soils and Construction Materials. Géotechnique 1961, 11, 339–353. [Google Scholar] [CrossRef]

- Uesugi, M.; Engineering, H.K.O.G. Frictional Resistance at Yield between Dry Sand and Mild Steel. Soils Found. 1986, 26, 139–149. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.Z.; Zhu, H.; Xu, G.H. A Study of Deformation in the Interface between Soil and Concrete. Comput. Geotech. 1995, 17, 75–92. [Google Scholar]

- Reddy, E.S.; Chapman, D.N.; Sastry, V.V. Direct Shear Interface Test for Shaft Capacity of Piles in Sand. Geotech. Test. J. 2000, 23, 199–205. [Google Scholar]

- Hu, L.; Pu, J. Testing and modeling of soil-structure interface. J. Geotech. Geoenviron. Eng. 2004, 130, 851–860. [Google Scholar] [CrossRef]

- Lings, M.L.; Dietz, M.S. The peak strength of sand–steel interfaces and the role of dilation. Soils Found. 2005, 45, 1–14. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.M. State of the art: Mechanical behavior of soil-structure interface. Prog. Nat. Sci. Mater. Int. 2009, 19, 1187–1196. [Google Scholar] [CrossRef]

- Tehrani, F.S.; Han, F.; Salgado, R.; Prezzi, M.; Tovar, R.D.; Castro, A.G. Effect of surface roughness on the shaft resistance of non-displacement piles embedded in sand. Geotechnique 2016, 66, 386–400. [Google Scholar] [CrossRef]

- Wang, Y.-B.; Zhao, C.; Wu, Y. Study on the Effects of Grouting and Roughness on the Shear Behavior of Cohesive Soil–Concrete Interfaces. Materials 2020, 13, 3043. [Google Scholar] [CrossRef] [PubMed]

- Konkol, J.; Mikina, K. Some Aspects of Shear Behavior of Soft Soil-Concrete Interfaces and Its Consequences in Pile Shaft Friction Modeling. Materials 2021, 14, 2578. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Yang, Q.; Leng, W.; Dong, J.; Xu, F.; Wei, L.; Ruan, B. Experimental Investigation of the Mechanical Properties of the Sand-Concrete Pile Interface Considering Roughness and Relative Density. Materials 2022, 15, 4480. [Google Scholar] [CrossRef] [PubMed]

- Ni, Q.; Tan, T.S.; Dasari, G.R.; Hight, D.W. Contribution of fines to the compressive strength of mixed soils. Géotechnique 2004, 54, 561–569. [Google Scholar] [CrossRef]

- Ruggeri, P.; Segato, D.; Fruzzetti, V.M.E.; Scarpelli, G. Evaluating the shear strength of a natural heterogeneous soil using reconstituted mixtures. Géotechnique 2016, 66, 941–946. [Google Scholar] [CrossRef]

- You, S.-K.; Hong, G.; Jeong, M.; Shin, H.; Lee, K.-W.; Rtu, J. Effect of Relative Density and Fines Content on Pullout Resistance Performance of Drilled Shafts. J. Korean Geotech. Soc. 2018, 34, 37–47. [Google Scholar]

- You, S.K.; Hong, G.; Gong, Y.R.; Ahn, H.C.; Lee, K.W.; Choi, C.L. A study on Numerical Analysis Application for Pullout Resistance Evaluation of Mid-Sized Drilled Shaft. In Proceedings of the 2017 KSCE Convention, Busan, Republic of Korea, 18–20 October 2017; pp. 29–30. [Google Scholar]

| Soil Classification | Properties | |

|---|---|---|

| Jumunjin standard sand | Gs | 2.63 |

| Cu | 2.1 | |

| Cg | 1.1 | |

| U.S.C.S. | SP | |

| Fine-grained soil | LL (%) | 39.4 |

| PL (%) | 31.3 | |

| PI (%) | 8.1 | |

| U.S.C.S. | ML | |

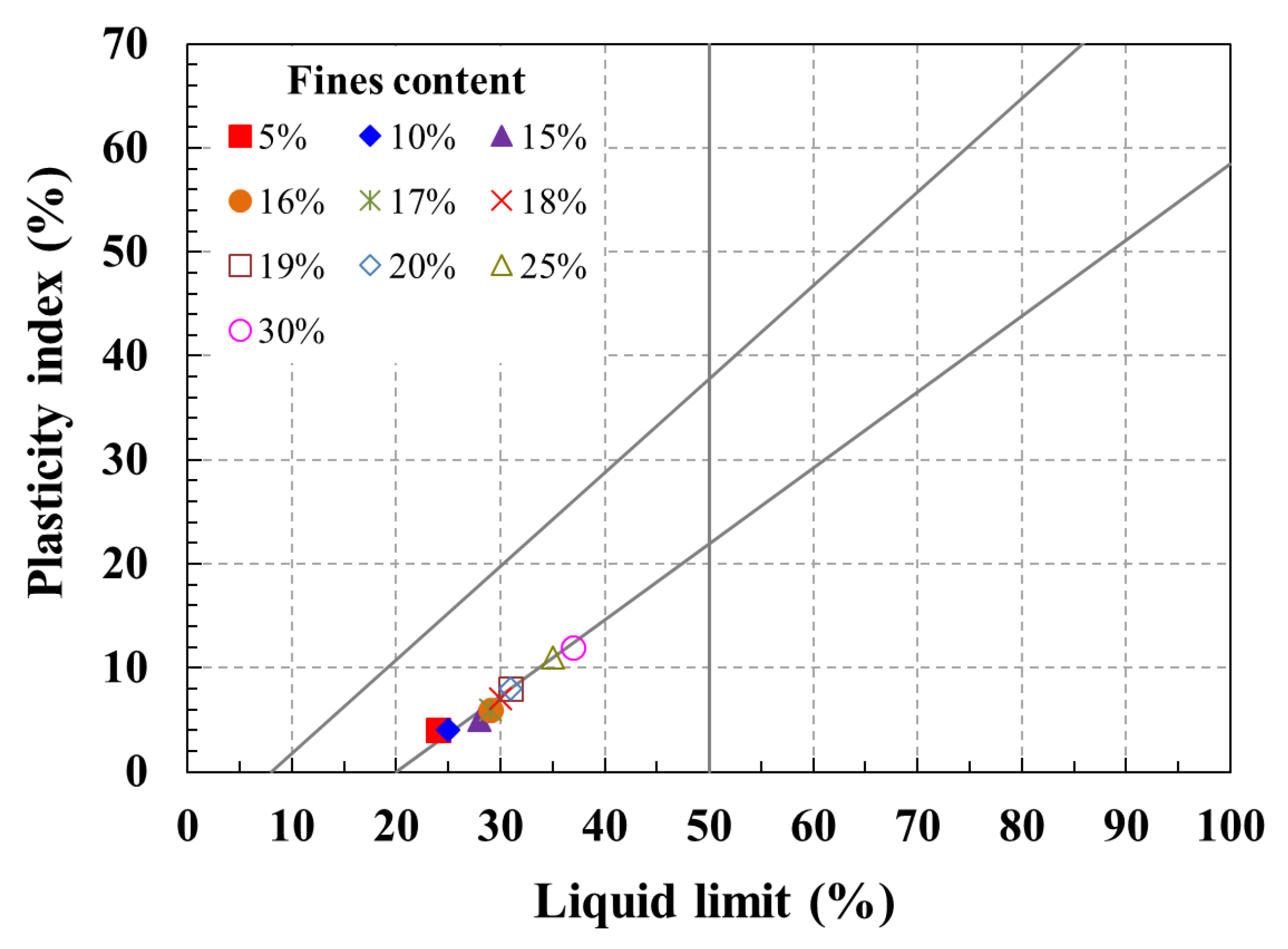

| Fines Content (%) | PI (%) | LL (%) | PL (%) | Soil Classification |

|---|---|---|---|---|

| 5 | 4 | 24 | 20 | SP |

| 10 | 4 | 25 | 21 | SP-SM |

| 15 | 5 | 28 | 23 | SC-SM |

| 16 | 6 | 29 | 23 | SC-SM |

| 17 | 6 | 29 | 23 | SC-SM |

| 18 | 7 | 30 | 23 | SC-SM |

| 19 | 8 | 31 | 23 | SC |

| 20 | 8 | 31 | 23 | SC |

| 25 | 11 | 35 | 24 | SC |

| 30 | 12 | 37 | 25 | SC |

| Test Classification | Test Condition | |||

|---|---|---|---|---|

| Soils | Soil–Sandpaper | Fines Content (%) | Normal Stress (kPa) | |

| DS-00 | Sandpaper type #24, #40, #400 | DSSP-00 | 0 | 50 100 150 |

| DS-05 | DSSP-05 | 5 | ||

| DS-07 | 7 | |||

| DS-10 | DSSP-10 | 10 | ||

| DS-13 | 13 | |||

| DS-15 | DSSP-15 | 15 | ||

| DS-17 | 17 | |||

| DS-20 | DSSP-20 | 20 | ||

| DS-25 | DSSP-25 | 25 | ||

| DS-30 | DSSP-30 | 30 | ||

| Cases | Fines Content (%) | Relative Density (%) | Buried Depth of Pile (m) |

|---|---|---|---|

| P-05-40 | 5 | 40 | 0.33 |

| P-05-60 | 60 | ||

| P-05-80 | 80 | ||

| P-07-40 | 7 | 40 | |

| P-07-60 | 60 | ||

| P-07-80 | 80 | ||

| P-10-40 | 10 | 40 | |

| P-10-60 | 60 | ||

| P-10-80 | 80 | ||

| P-15-40 | 15 | 40 | |

| P-15-60 | 60 | ||

| P-15-80 | 80 | ||

| P-20-40 | 20 | 40 | |

| P-20-60 | 60 | ||

| P-20-80 | 80 |

| Fines Content (%) | Cases DS (Soils) | Case DSSP (Soil–Sandpaper) | ||||||

|---|---|---|---|---|---|---|---|---|

| Internal Friction Angle (ϕ, °) | Cohesion (c, kPa) | Interface Friction Angle (δ, °) | Adhesion (Ca, kPa) | |||||

| #24 | #40 | #400 | #24 | #40 | #400 | |||

| 0 | 37.1 | 0.0 | 30.7 | 30.5 | 28.6 | 15.3 | 14.7 | 12.6 |

| 5 | 34.2 | 1.6 | 27.9 | 27.9 | 23.4 | 15.5 | 14.8 | 12.8 |

| 7 | 31.1 | 1.7 | ||||||

| 10 | 28.5 | 1.8 | 26.8 | 25.5 | 22.7 | 15.6 | 15.5 | 13.4 |

| 13 | 26.4 | 1.9 | ||||||

| 15 | 26.3 | 1.9 | 25.9 | 24.5 | 21.6 | 16.3 | 16.1 | 13.8 |

| 17 | 25.6 | 2.0 | ||||||

| 20 | 25.3 | 2.5 | 23.7 | 21.7 | 16.7 | 16.6 | 16.4 | 14.1 |

| 25 | 25.1 | 3.0 | 22.3 | 20.7 | 15.2 | 17.6 | 16.6 | 15.2 |

| 30 | 24.3 | 3.4 | 21.0 | 20.1 | 14.6 | 17.8 | 17.6 | 16.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, S.; Lee, K.; Hong, G. Influence of Fines Content and Pile Surface Characteristics on the Pullout Resistance Performance of Piles. Materials 2024, 17, 124. https://doi.org/10.3390/ma17010124

You S, Lee K, Hong G. Influence of Fines Content and Pile Surface Characteristics on the Pullout Resistance Performance of Piles. Materials. 2024; 17(1):124. https://doi.org/10.3390/ma17010124

Chicago/Turabian StyleYou, Seungkyong, Kwangwu Lee, and Gigwon Hong. 2024. "Influence of Fines Content and Pile Surface Characteristics on the Pullout Resistance Performance of Piles" Materials 17, no. 1: 124. https://doi.org/10.3390/ma17010124

APA StyleYou, S., Lee, K., & Hong, G. (2024). Influence of Fines Content and Pile Surface Characteristics on the Pullout Resistance Performance of Piles. Materials, 17(1), 124. https://doi.org/10.3390/ma17010124