Study on the Effect of Calcium Alloy on Arsenic Removal from Scrap-Based Steel Production

Abstract

1. Introduction

2. Experiments

2.1. Experimental Materials

2.2. Add Arsenic Removal Agent for the Arsenic Removal Experiment

2.3. Composition Determination and Characterization of Non-Metallic Inclusions

3. Results and Discussion

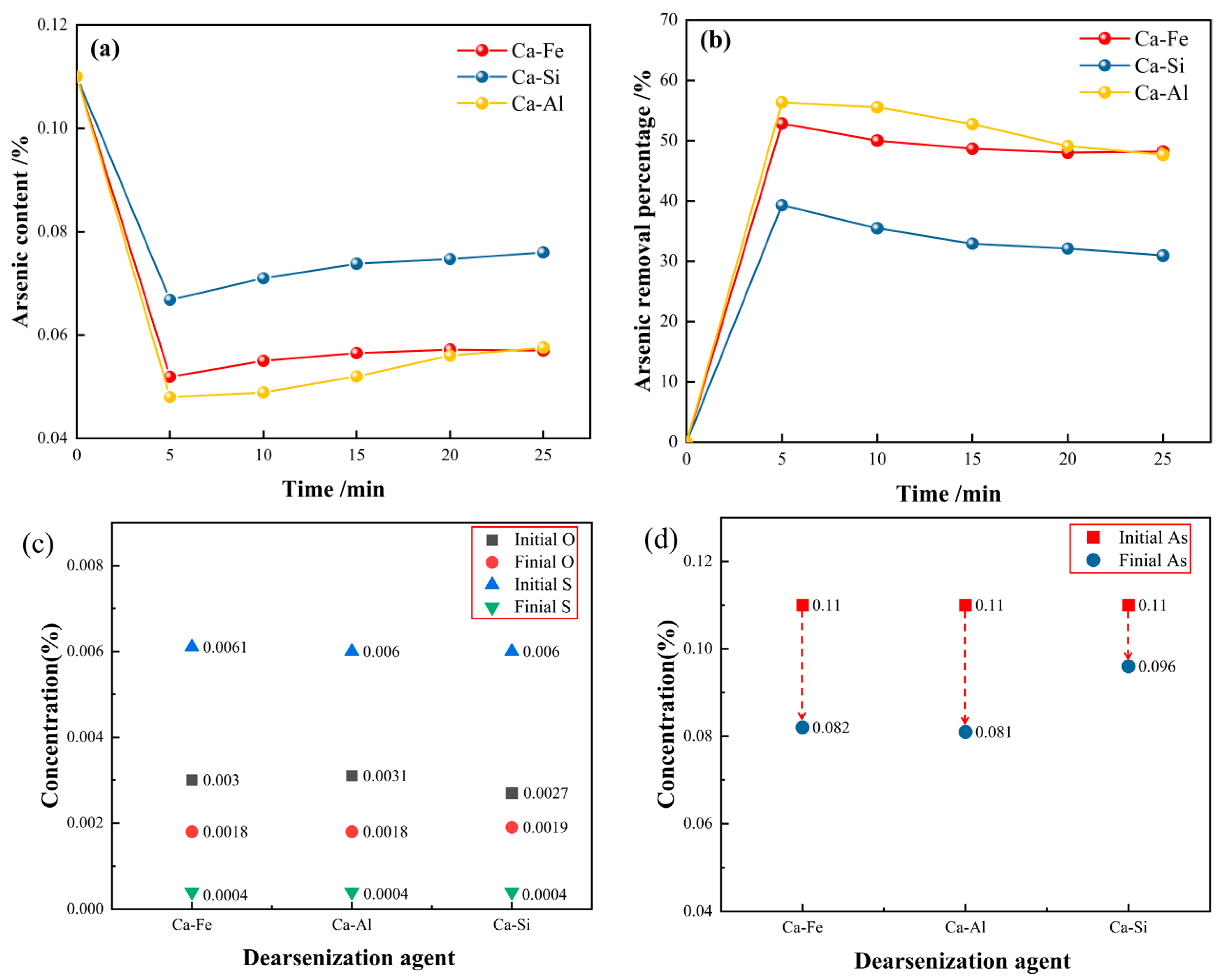

3.1. Experimental Results of Different Arsenic Removal Agents

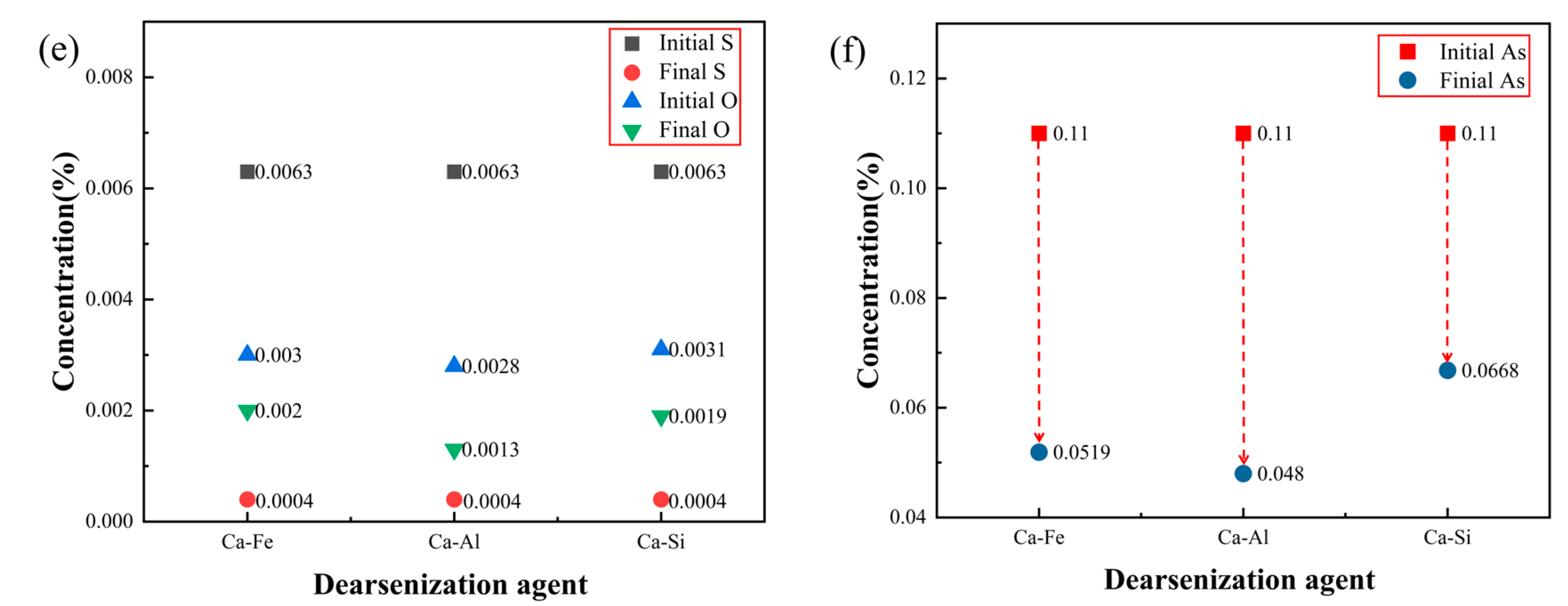

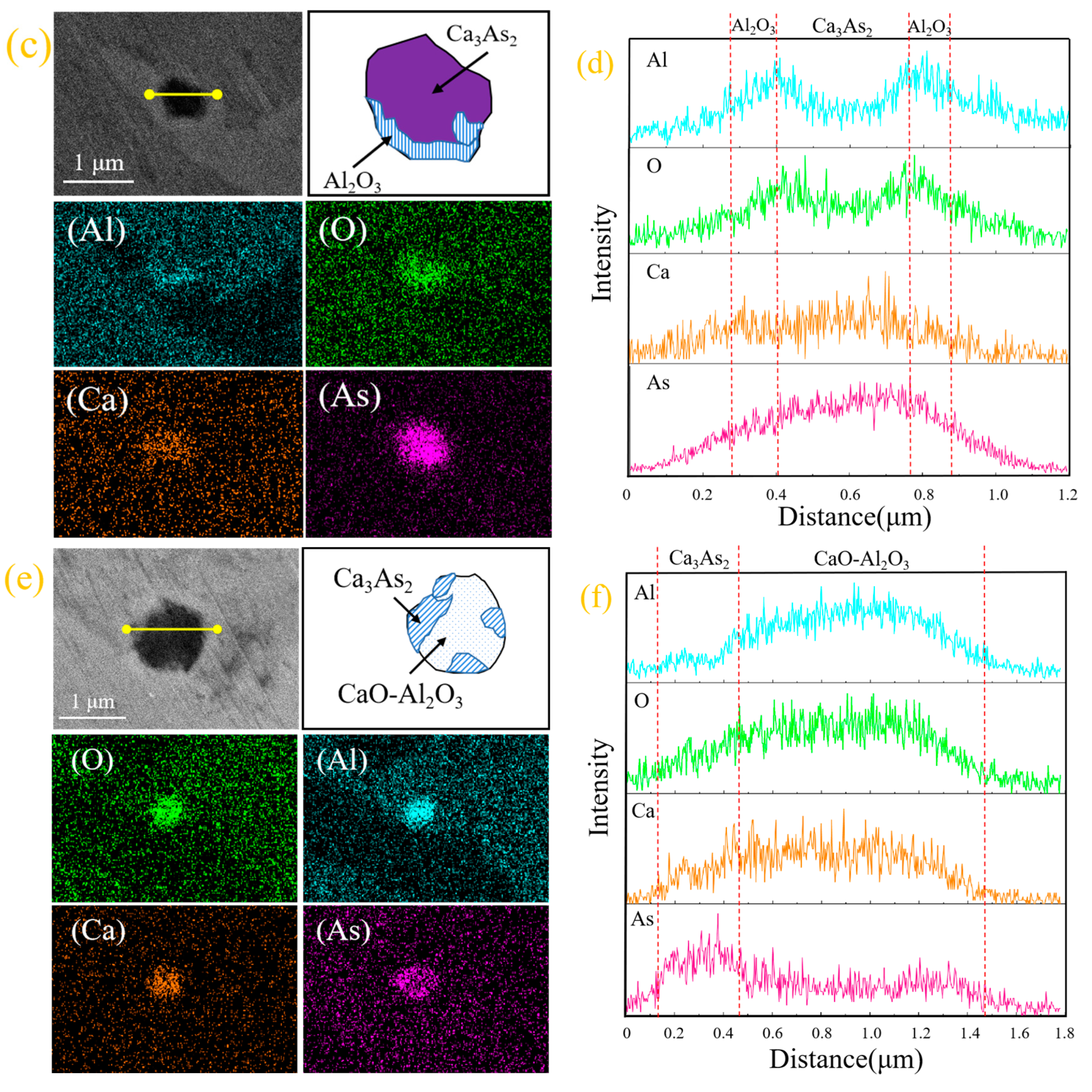

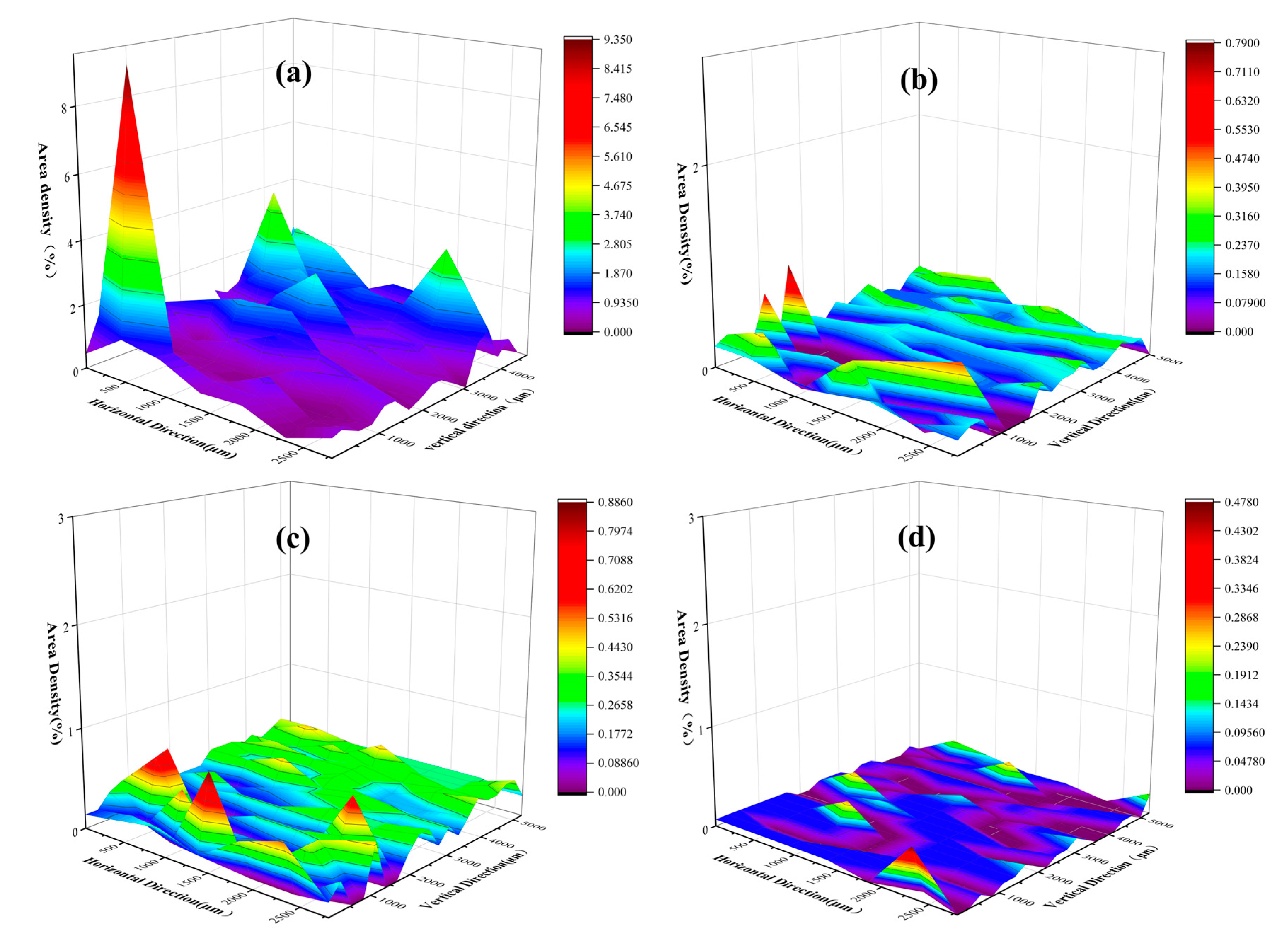

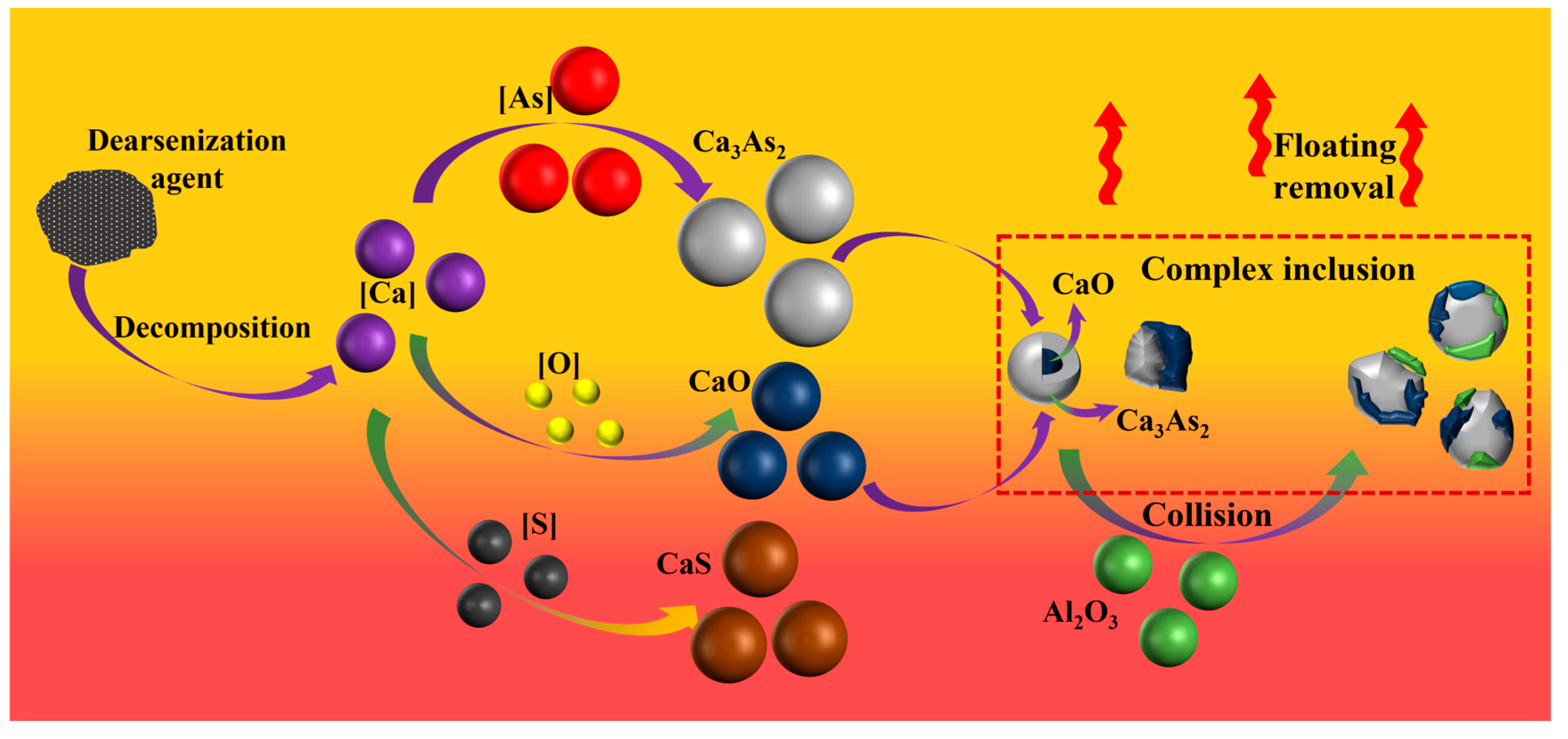

3.2. Dearsenication Products

4. Analysis and Discussion

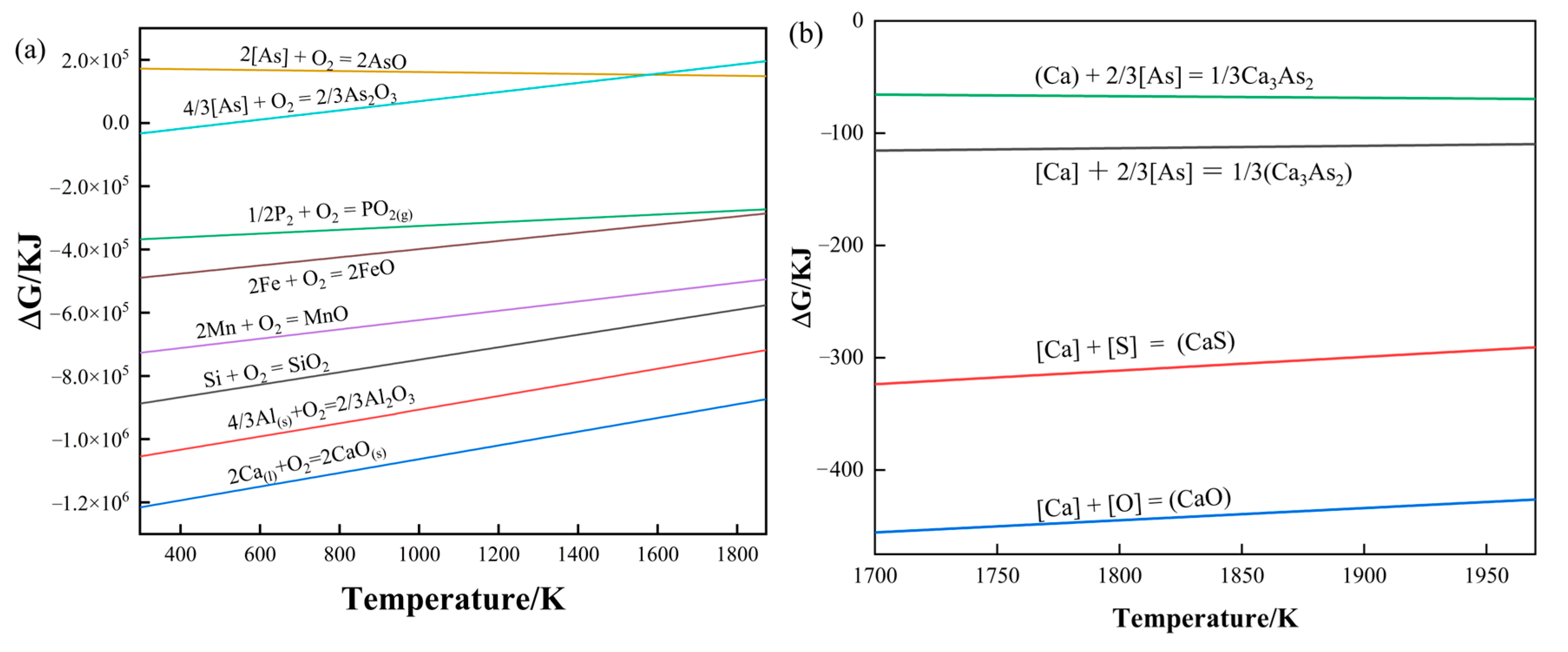

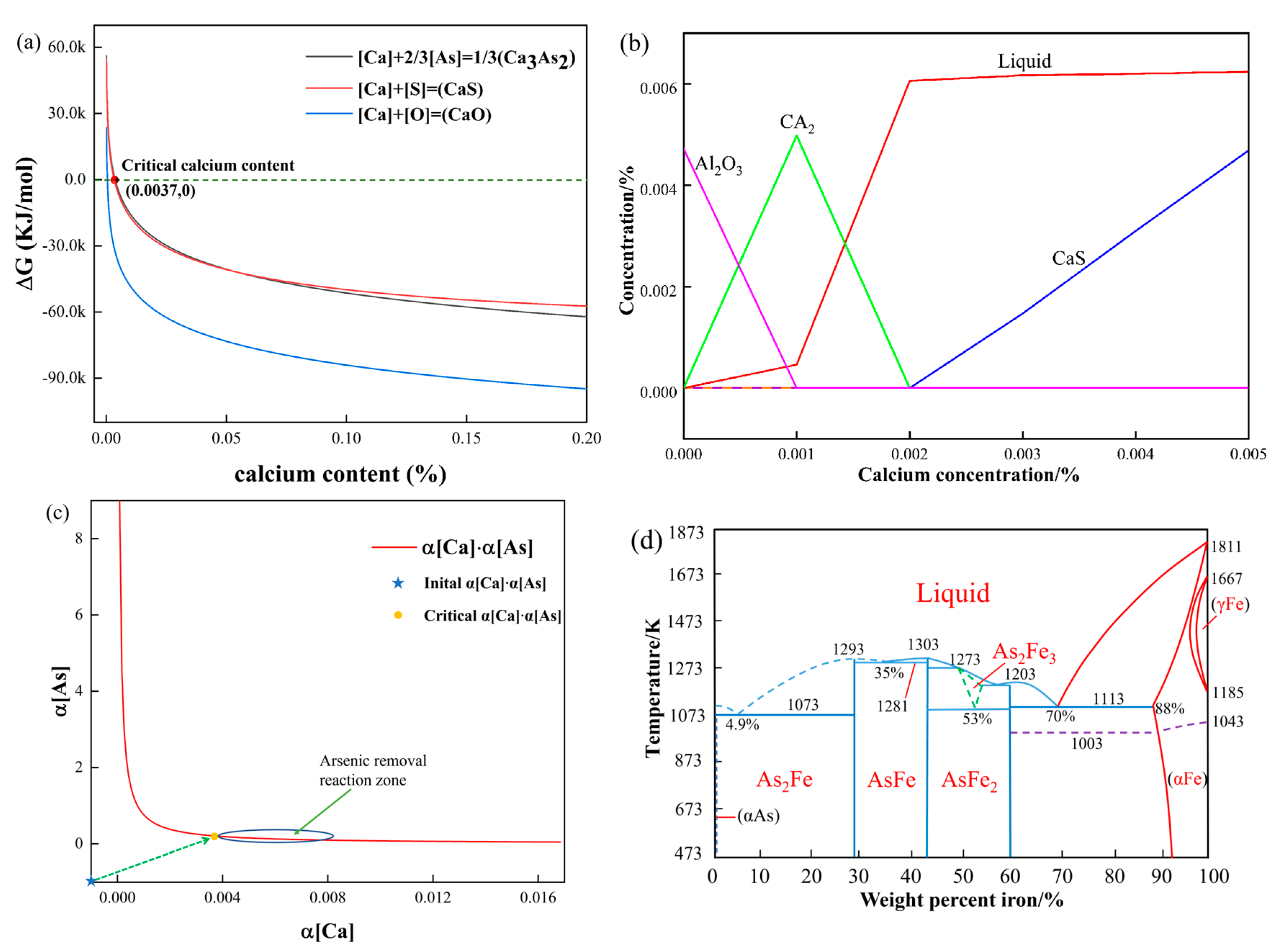

Thermodynamic Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

- Andonovski, G.; Tomažič, S. Comparison of data-based models for prediction and optimization of energy consumption in electric arc furnace (EAF). IFAC-PapersOnLine 2022, 55, 373–378. [Google Scholar] [CrossRef]

- Zhang, X.; He, Y.; Li, M.; Hu, X. The study of heat-mass transfer characteristics and multi-objective optimization on electric arc furnace. Appl. Energy 2022, 317, 119147. [Google Scholar] [CrossRef]

- Marulanda-Durango, J.; Escobar-Mejía, A.; Alzate-Gómez, A.; Álvarez-López, M. A Support Vector machine-Based method for parameter estimation of an electric arc furnace model. Electr. Power Syst. Res. 2021, 196, 107228. [Google Scholar] [CrossRef]

- Kumar, B.; Roy, G.G.; Sen, P.K. Comparative exergy analysis between rotary hearth furnace-electric arc furnace and blast furnace-basic oxygen furnace steelmaking routes. Energy Clim. Chang. 2020, 1, 100016. [Google Scholar] [CrossRef]

- Brandner, U.; Antrekowitsch, J.; Leuchtenmueller, M. A review on the fundamentals of hydrogen-based reduction and recycling concepts for electric arc furnace dust extended by a novel conceptualization. Int. J. Hydrogen Energy 2021, 46, 31894–31902. [Google Scholar] [CrossRef]

- Kim, J.; Son, M.; Park, J.; Kim, J. Optimized rotary hearth furnace utilization with blast furnace and electric arc furnace: Techno-economics, CO2 reduction. Fuel Process Technol. 2022, 237, 107450. [Google Scholar] [CrossRef]

- Tian, B.; Wei, G.; Li, X.; Zhu, R.; Bai, H.; Tian, W. Effect of hot metal charging on economic and environmental indices of electric arc furnace steelmaking in China. J. Clean. Prod. 2022, 379, 134597. [Google Scholar] [CrossRef]

- Cheng, R.J.; Ni, H.W.; Zhang, H.; Zhang, X.K.; Bai, S.C. Mechanism research on arsenic removal from arsenopyrite ore during a sintering process. Int. J. Miner. Metall. Mater. 2017, 24, 7. [Google Scholar] [CrossRef]

- Su, Y.; Huang, W.; Liu, Y.; Chang, C.; Kuo, Y. Utilization of electric arc furnace dust as regenerable sorbents for the removal of hydrogen sulfide. Ceram. Int. 2017, 43, S694–S699. [Google Scholar] [CrossRef]

- Kicińska, A. Environmental risk related to presence and mobility of As, Cd and Tl in soils in the vicinity of a metallurgical plant—Long-term observations. Chemosphere 2019, 236, 124308. [Google Scholar] [CrossRef] [PubMed]

- Potysz, A. Microbial influence and dynamics of metallurgical waste dissolution in a landfill and recovery context: A multi-phase experimental approach and geochemical model. Chemosphere 2023, 311, 136964. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Ma, G.; Zhang, X.; Liu, J.; Wang, Q. Preparation of Black Ceramic Tiles Using Waste Copper Slag and Stainless Steel Slag of Electric Arc Furnace. Materials 2020, 13, 776. [Google Scholar] [CrossRef] [PubMed]

- Maecki, S.; Gargul, K.; Warzecha, M.; Stradomski, G.; Hutny, A.; Madej, M.; Dobrzyński, M.; Prajsnar, R.; Krawiec, G. High-Performance Method of Recovery of Metals from EAF Dust—Processing without Solid Waste. Materials 2021, 14, 6061. [Google Scholar] [CrossRef]

- Moskal, M.; Migas, P.; Karbowniczek, M. Multi-Parameter Characteristics of Electric Arc Furnace Melting. Materials 2022, 15, 1601. [Google Scholar] [CrossRef]

- Cao, R.; Ma, H.; Yi, L.; Zhang, J.; Cui, R.J. Effect of Arsenic, Tin and Antimony on Hot Plasticity of Steel 35Mn. Spec. Steel 1998, 19, 3. [Google Scholar]

- Liu, S.; Sun, S. A study on dearsenication of molten iron and liquid steel with Ca-Si alloy. Spec. Steel 2001, 22, 12–15. [Google Scholar]

- Xu, X. The physico-chemical characteristics of arsenic in metallurgical process and their influence on the steel during the hot rolling. Shonghai Steel Iron Res. 2005, 4, 4. [Google Scholar]

- Wang, H.; Kang, J.; Wang, Y. Discovery and identification of arsenic removal products from molten steel by adding rare earth. J. Mater. Res. Technol. 2022, 18, 2922–2931. [Google Scholar] [CrossRef]

- Wang, H.; Bai, B.; Jiang, S.; Sun, L.; Wang, Y. An in situ Study of the Formation of Rare Earth Inclusions in Arsenic High Carbon Steels. ISIJ Int. 2019, 59, 1259–1265. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Xu, J.P. A method to study interface diffusion of arsenic into a Nb-Ti microalloyed low carbon steel. Int. J. Miner. Metall. Mater. 2012, 19, 821–826. [Google Scholar] [CrossRef]

- Cheng, R.; Zhang, H.; Ni, H. Arsenic Removal from Arsenopyrite-Bearing Iron Ore and Arsenic Recovery from Dust Ash by Roasting Method. Processes 2019, 7, 754. [Google Scholar] [CrossRef]

- Paz-Gómez, D.C.; Pérez-Moreno, S.M.; Gázquez, M.J.; Guerrero, J.L.; Ruiz-Oria, I.; Ríos, G. Arsenic removal procedure for the electrolyte from a hydro-pyrometallurgical complex. Chemosphere 2021, 281, 130651. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qi, X.; Li, G.; Duan, X.; Yang, N. Removal of arsenic in acidic wastewater using Lead-Zinc smelting slag: From waste solid to As-stabilized mineral. Chemosphere 2022, 301, 134736. [Google Scholar] [CrossRef]

- Marcińczyk, M.; Ok, Y.S.; Oleszczuk, P. From waste to fertilizer: Nutrient recovery from wastewater by pristine and engineered biochars. Chemosphere 2022, 306, 135310. [Google Scholar] [CrossRef] [PubMed]

- Khanam, T.; Liang, S.; Xu, S.; Musstjab Akber Shah Eqani, S.A.; Shafqat, M.N.; Rasheed, H.; Bibi, N.; Shen, H.; Zhang, J. Arsenic exposure induces urinary metabolome disruption in Pakistani male population. Chemosphere 2023, 312, 137228. [Google Scholar] [CrossRef]

- Lin, L.; Zeng, J.Q. Consideration of green intelligent steel processes and narrow window stability control technology on steel quality. Int. J. Miner. Metall. Mater. 2021, 28, 1264–1273. [Google Scholar] [CrossRef]

- Tshilombo, K. Determination of inclusions in liquid steel after calcium treatment. Int. J. Min. Met. Mater. 2010, 17, 28–31. [Google Scholar] [CrossRef]

- Li, C.X. Effect of La on the Precipitation of Inclusions in As-Bearing High Carbon Steel. Master’s Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Xiong, L. Study of Effect of Arsenic and Lanthanum on Properties of High Carbon Steel. Master’s Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Xin, W. Effect of Arsenic on the Properties of Steel and Improvement by Adding Rare Earth. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Li, W. The Applied Fundamental Research on the Removal of Residual Element Arsenic during Steelmaking Process. Ph.D. Thesis, University of Science and Technology Beijing, Beijing, China, 2016. [Google Scholar]

- Zhang, T.; Li, Z.; Young, F.; Kim, H.J.; Tillmann, W. Global Progress on Welding Consumables for HSLA Steel. ISIJ Int. 2014, 54, 1472–1484. [Google Scholar] [CrossRef]

- Lan, F.; Zhuang, C.; Li, C.; Yang, G.; Yao, H. Effect of Calcium Treatment on Inclusions in H08A Welding Rod Steel. Met. Open Access Metall. J. 2021, 11, 1227. [Google Scholar] [CrossRef]

- Nakamura, Y.; Tokumitsu, N.; Harashima, K.; Segawa, K. Refining of 18%Cr–8%Ni Steel with Ca-CaF2 Solution. Trans. Iron Steel Inst. Jpn. 1976, 16, 623–627. [Google Scholar] [CrossRef]

- Katayama, H.; Kajioka, H.; Harashima, K.U.; Inatomi, M. Dephosphorization of High Chromium Molten Steel with CaC2-CaF2 Flux. Trans. Iron Steel Inst. Jpn. 1979, 19, 635–643. [Google Scholar] [CrossRef]

- Zhu, Y.K. Dearsenification of Hot Metal with CaC2-CaF2 Slag. J. Beijing Iron Steel Technol. 1986, 2, 103–112. [Google Scholar]

- Zhu, Y.K.; Dong, Y.C.; Peng, Y.Q.; Wei, S.K. A Study of the Chemical Equilibrium between Arsenic and Calcium in Steel Melt. Iron Steel 1985, 10, 38–44. [Google Scholar]

- Dong, Y.; Shi, Z.; Zhang, L.; Peng, Y.; Hong, Y. Study on dearsenization of molten iron. Gangtie 1984, 9, 4–10. [Google Scholar]

- Li, W.B.; Bao, Y.P.; Wang, M.; Lin, L. Analysis of factors for Si-Ca-Ba alloy+CaF2 dearsenication of molten steel. Iron Steel 2015, 50, 6. [Google Scholar]

- Wang, H.; Yu, P.; Jiang, S.; Wang, Y. Effect of Heterogeneous Nucleation on Removal of Arsenic from Molten Steel by Rare Earth Addition. Met. Open Access Metall. J. 2020, 10, 664. [Google Scholar] [CrossRef]

- Lan, F.; Zhuang, C.; Li, C.; Yang, H.; Yang, G.; Yao, H.; Zhang, Z. Effect of Rare-Earth Cerium on Nonmetallic Inclusions in Fe–Mn–C–Al Twinning-Induced Plasticity Steel. Steel Res. Int. 2023, 94, 2200421. [Google Scholar] [CrossRef]

- Wang, J.; Luo, L.; Kong, H.; Zhou, L. The Arsenic Removal from Molten Steel. High Temp. Mater. Process. 2011, 30, 171. [Google Scholar] [CrossRef]

- Liang, Y. The influence of arsenic (as) on the physical properties of carbon steel. Gangtie 1983, 7, 57–62. [Google Scholar]

- Xian, A. Impurities in steel and their influence on steel properties. Iron Steel 1999, 34, 64–68. [Google Scholar]

- Lan, Y.; Sridhar, S. Effects of Residual Elements Arsenic, Antimony, and Tin on Surface Hot Shortness. Metall. Mater. Trans. B 2011, 42, 1031–1043. [Google Scholar]

- Wang, X.; Tang, X.P.; Yang, J.M.; Lei, Y. Characteristics and Effect of Impurity Elements in Steel. Spec. Steel Technol. 2011, 17, 13–15. [Google Scholar]

- Wang, H.; Xiong, L.; Zhang, L.; Wang, Y.; Shu, Y.; Zhou, Y. Investigation of RE-O-S-As Inclusions in High Carbon Steels. Metall. Mater. Trans. B. 2017, 48, 2849–2858. [Google Scholar] [CrossRef]

- Verma, N.; Pistorius, P.C.; Fruehan, R.J.; Potter, M.; Story, S.R. Transient Inclusion Evolution During Modification of Alumina Inclusions by Calcium in Liquid Steel: Part II. Results and Discussion. Metall. Mater. Trans. B. 2011, 42, 720–729. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, S.; Yu, P.; Bai, B.; Wang, Y. Distribution of Arsenic Inclusions in Rare Earth Steel Ingots. Met. Open Access Metall. J. 2020, 10, 146. [Google Scholar] [CrossRef]

- Xin, W.; Song, B.; Song, M.; Song, G. Effect of Cerium on Characteristic of Inclusions and Grain Boundary Segregation of Arsenic in Iron Melts. Steel Res. Int. 2015, 86, 1430–1438. [Google Scholar] [CrossRef]

- Dong, Y.; Wei, S.K.; Peng, Y.Q.; Zhu, Y.K. Activity of as in Fe-As-C-j Melts. Acta Metall. Sin. 1986, 6, 90–92. [Google Scholar]

- Zhuang, C.; Liu, J.; Mi, Z.; Jiang, H.; Tang, D.; Wang, G. Non-Metallic Inclusions in TWIP Steel. Steel Res. Int. 2014, 85, 1432. [Google Scholar] [CrossRef]

- Shi, C.B.; Chen, X.C.; Guo, H.J. Characteristics of inclusions in high-Al steel during electroslag remelting process. Int. J. Miner. Metall. Mater. 2012, 19, 8. [Google Scholar] [CrossRef]

- Liu, S.P. Study on Thermodynamic Properties of Iron-Arsenic Melt and Arsenic Removal from Molten Iron and Molten Steel. Ph.D. Thesis, Chongqing University, Chongqing, China, 2000. [Google Scholar]

- Janke, D.; Zhongting, M.A.; Valentin, P. Improvement of Castability and Quality of Continuously Cast Steel. ISIJ Int. 2000, 40, 31–39. [Google Scholar] [CrossRef]

| Brand | C | Si | Mn | P | S | As |

|---|---|---|---|---|---|---|

| H08-3 | ≤0.10 | ≤0.08 | 0.30–0.55 | ≤0.008 | ≤0.003 | ≤0.007 |

| Experimental base metal | 0.092 | 0.077 | 0.36 | 0.007 | 0.0061 | 0.11 |

| Ca-Fe Alloy | Ca-Si Alloy | Ca-Al Alloy | ||||

|---|---|---|---|---|---|---|

| Time/min | Content/% | Arsenic Removal Percentage/% | Content/% | Arsenic Removal Percentage/% | Content/% | Arsenic Removal Percentage/% |

| 0 | 0.11 | - | 0.11 | - | 0.11 | - |

| 5 | 0.0519 | 52.82 | 0.0668 | 39.27 | 0.048 | 56.36 |

| 10 | 0.055 | 50.00 | 0.071 | 35.45 | 0.0489 | 55.55 |

| 15 | 0.0565 | 48.64 | 0.0738 | 32.91 | 0.052 | 52.73 |

| 20 | 0.0572 | 48.00 | 0.0747 | 32.09 | 0.056 | 49.09 |

| 25 | 0.057 | 48.18 | 0.076 | 30.91 | 0.0576 | 47.64 |

| No Deoxidation Experiment | Conduct Aluminum Powder Deoxidation Experiment | |||||

|---|---|---|---|---|---|---|

| Ca-Fe | Ca-Al | Ca-Si | Ca-Fe | Ca-Al | Ca-Si | |

| Initial O | 0.0042 | 0.005 | 0.0079 | 0.003 | 0.00385 | 0.0053 |

| Terminal O | 0.0018 | 0.0018 | 0.0019 | 0.002 | 0.0013 | 0.0019 |

| Initial S | 0.0061 | 0.006 | 0.006 | 0.0063 | 0.0063 | 0.0063 |

| Terminal S | 0.0004 | 0.0004 | 0.0004 | 0.0004 | 0.0004 | 0.0004 |

| Initial As | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 | 0.11 |

| Terminal As | 0.082 | 0.081 | 0.096 | 0.0519 | 0.048 | 0.0668 |

| Arsenic removal percentage | 25.45 | 26.36 | 12.73 | 52.82 | 56.36 | 39.27 |

| i | j | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | O | S | P | Si | As | Ca | |

| O | −0.45 | −0.021 | −0.2 | −0.127 | 0.07 | −0.131 | - | - |

| S | 0.11 | −0.012 | −0.27 | −0.028 | - | 0.08 | 0.0041 | −0.931 |

| Ca | −0.34 | −0.1 | - | 0 | - | −0.097 | - | −0.002 |

| As | 0.25 | −0.029 | - | 0 | 0.1124 | 0.224 | 0.11 | - |

| 0.8421 | 0.8712 | 1.0045 | 0.0037 | 316,225 | 58,530 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, H.; Zhuang, C.; Li, C.; Xiang, S.; Li, X.; Yang, G.; Zhang, Z. Study on the Effect of Calcium Alloy on Arsenic Removal from Scrap-Based Steel Production. Materials 2023, 16, 3113. https://doi.org/10.3390/ma16083113

Yao H, Zhuang C, Li C, Xiang S, Li X, Yang G, Zhang Z. Study on the Effect of Calcium Alloy on Arsenic Removal from Scrap-Based Steel Production. Materials. 2023; 16(8):3113. https://doi.org/10.3390/ma16083113

Chicago/Turabian StyleYao, Hanjie, Changling Zhuang, Changrong Li, Song Xiang, Xiang Li, Guangkai Yang, and Zezhong Zhang. 2023. "Study on the Effect of Calcium Alloy on Arsenic Removal from Scrap-Based Steel Production" Materials 16, no. 8: 3113. https://doi.org/10.3390/ma16083113

APA StyleYao, H., Zhuang, C., Li, C., Xiang, S., Li, X., Yang, G., & Zhang, Z. (2023). Study on the Effect of Calcium Alloy on Arsenic Removal from Scrap-Based Steel Production. Materials, 16(8), 3113. https://doi.org/10.3390/ma16083113