Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Mg–2.2Gd–2.2Zn–0.2Ca (wt%) Alloy by Extrusion at Various Temperatures

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

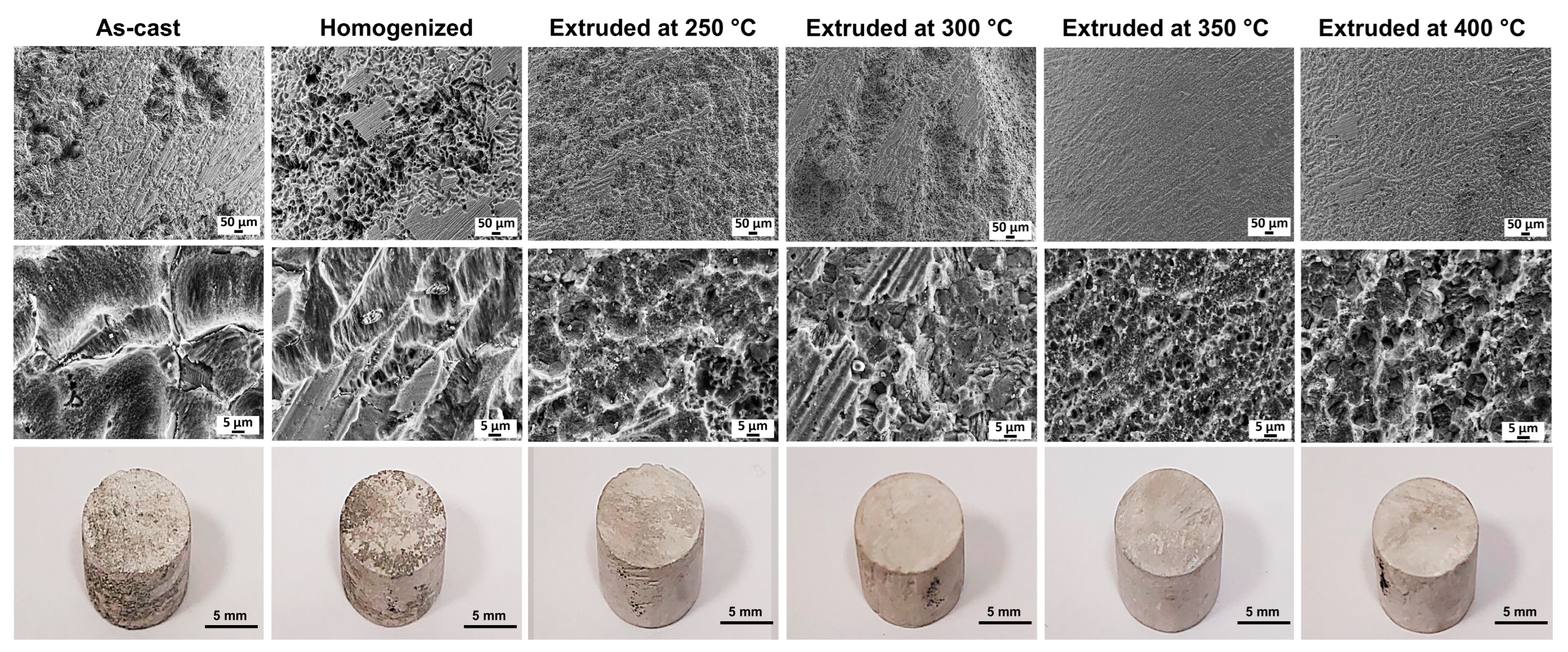

3.1. Microstructural Characterizations

3.1.1. Microstructure of the As-Cast and Homogenized Alloys

3.1.2. Microstructure of the Extruded Alloys

3.2. Mechanical Properties

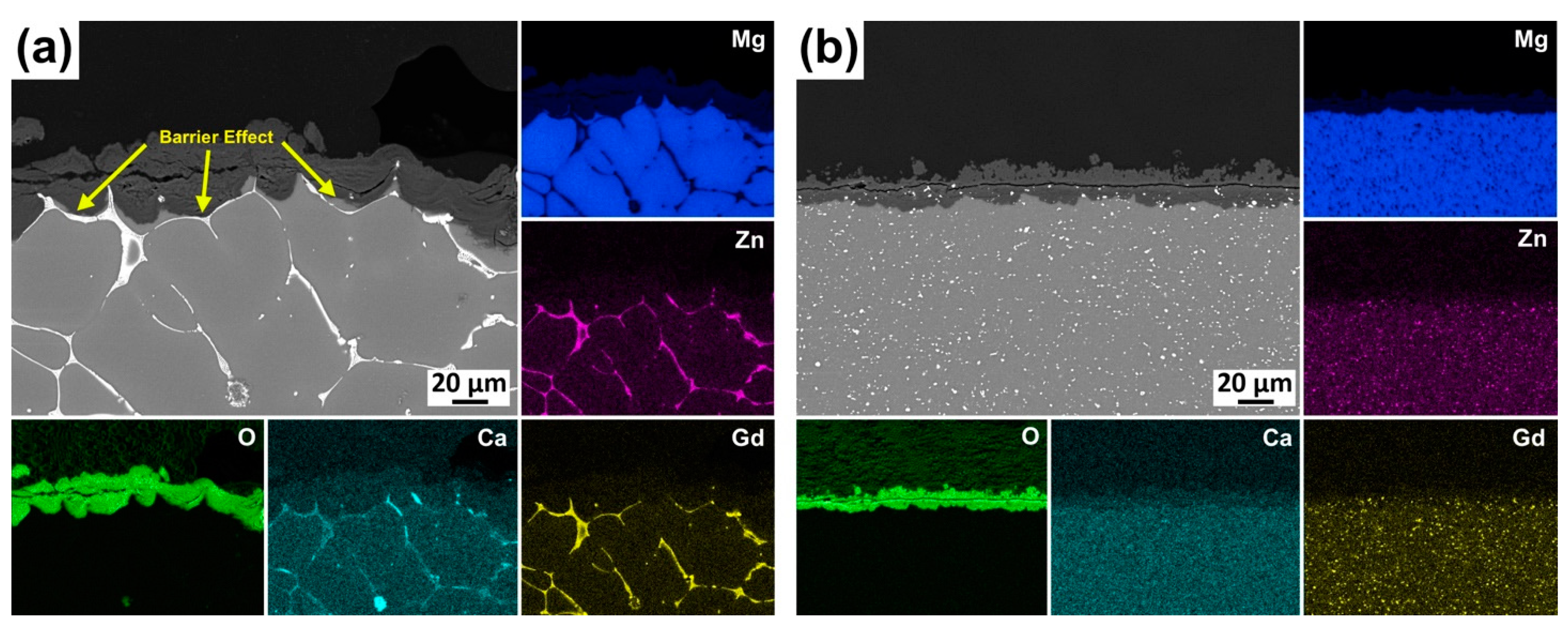

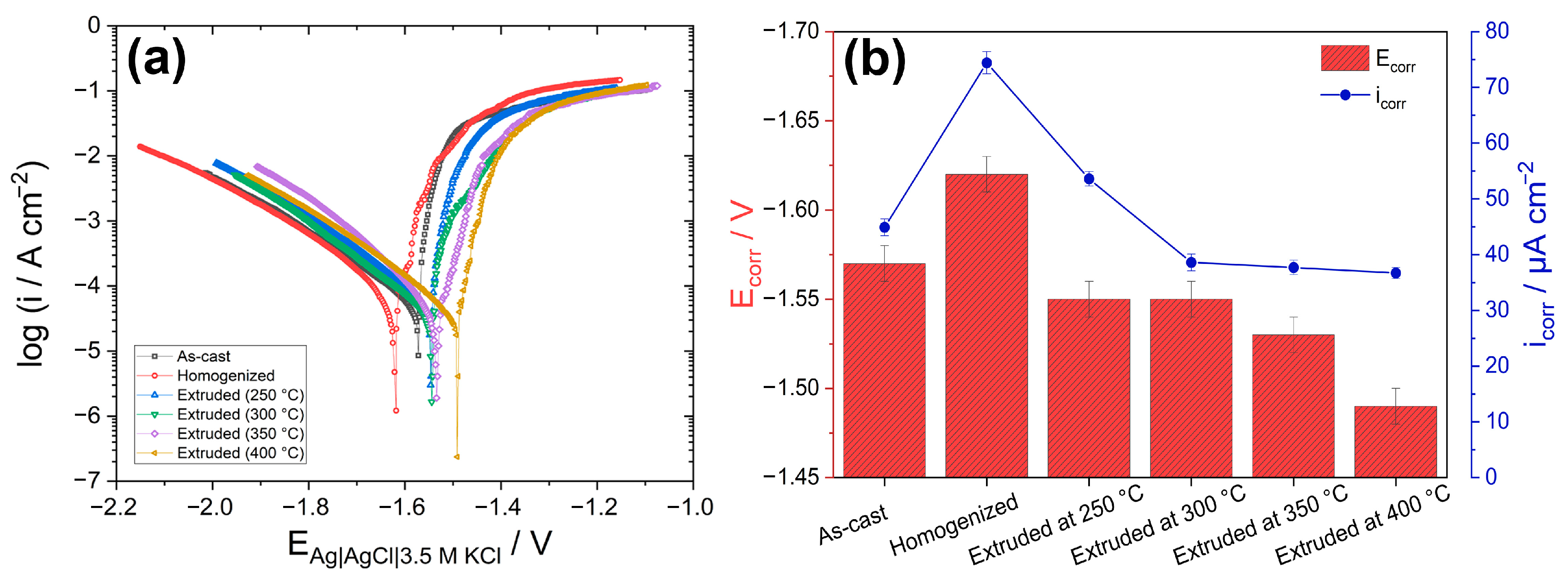

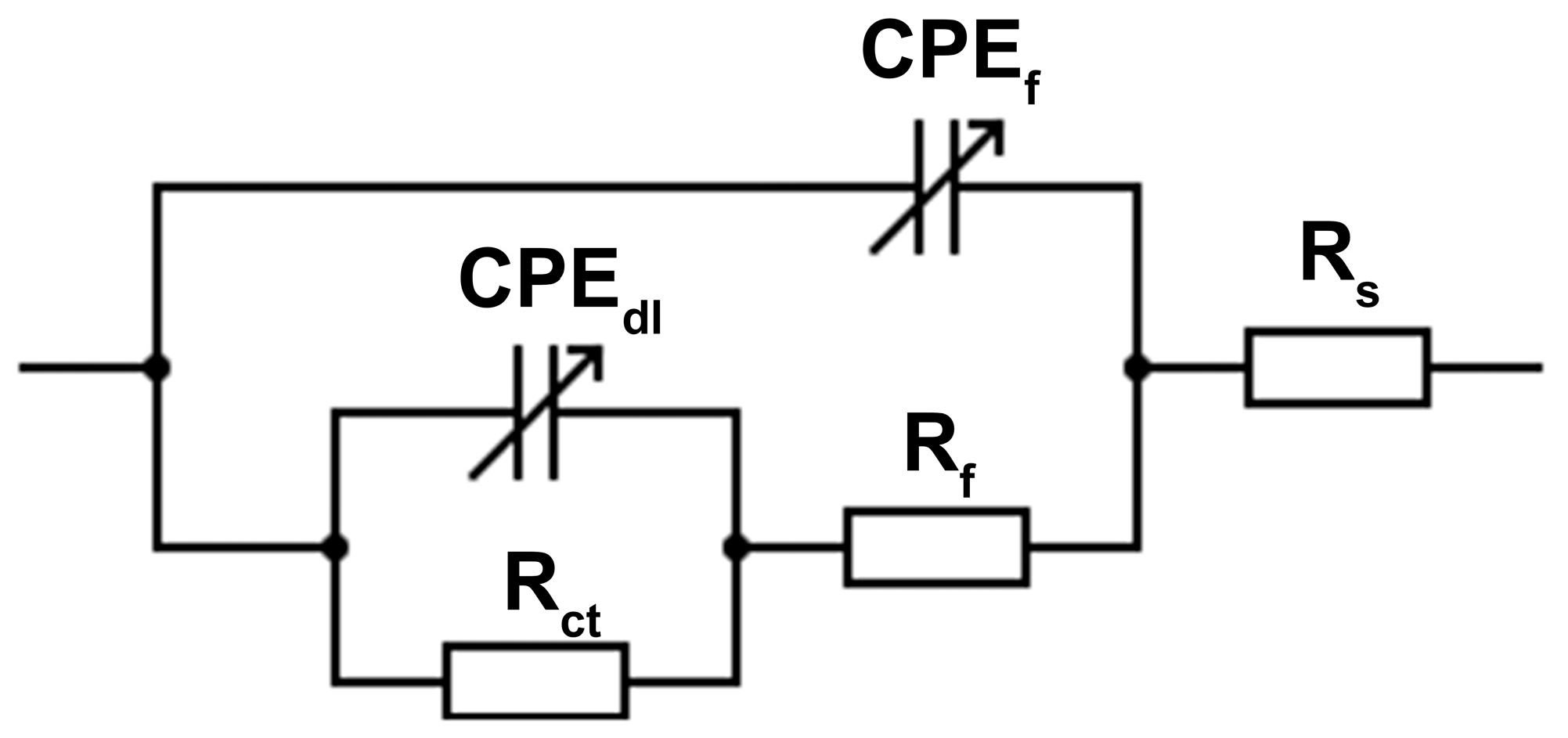

3.3. Corrosion

4. Conclusions

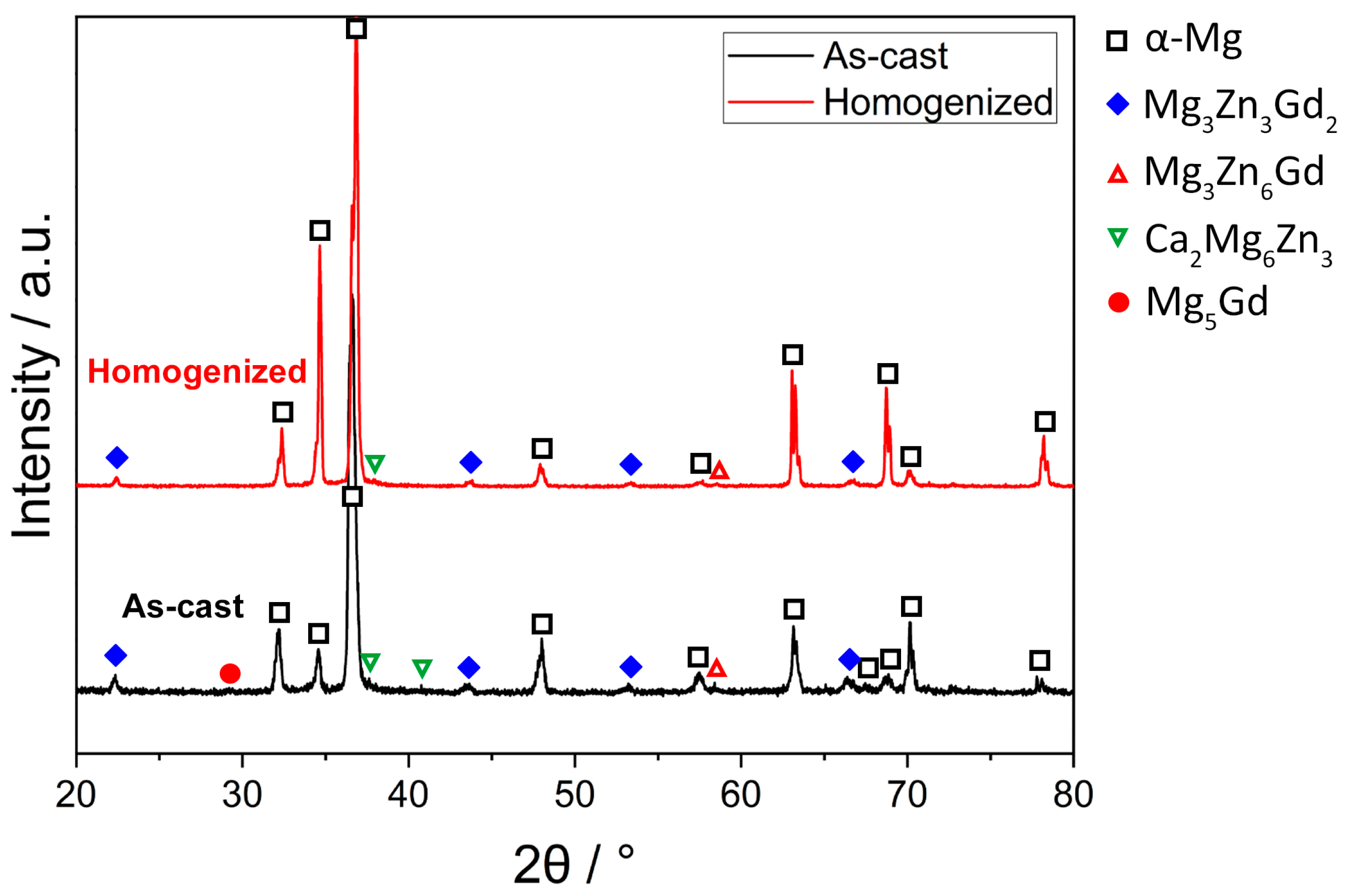

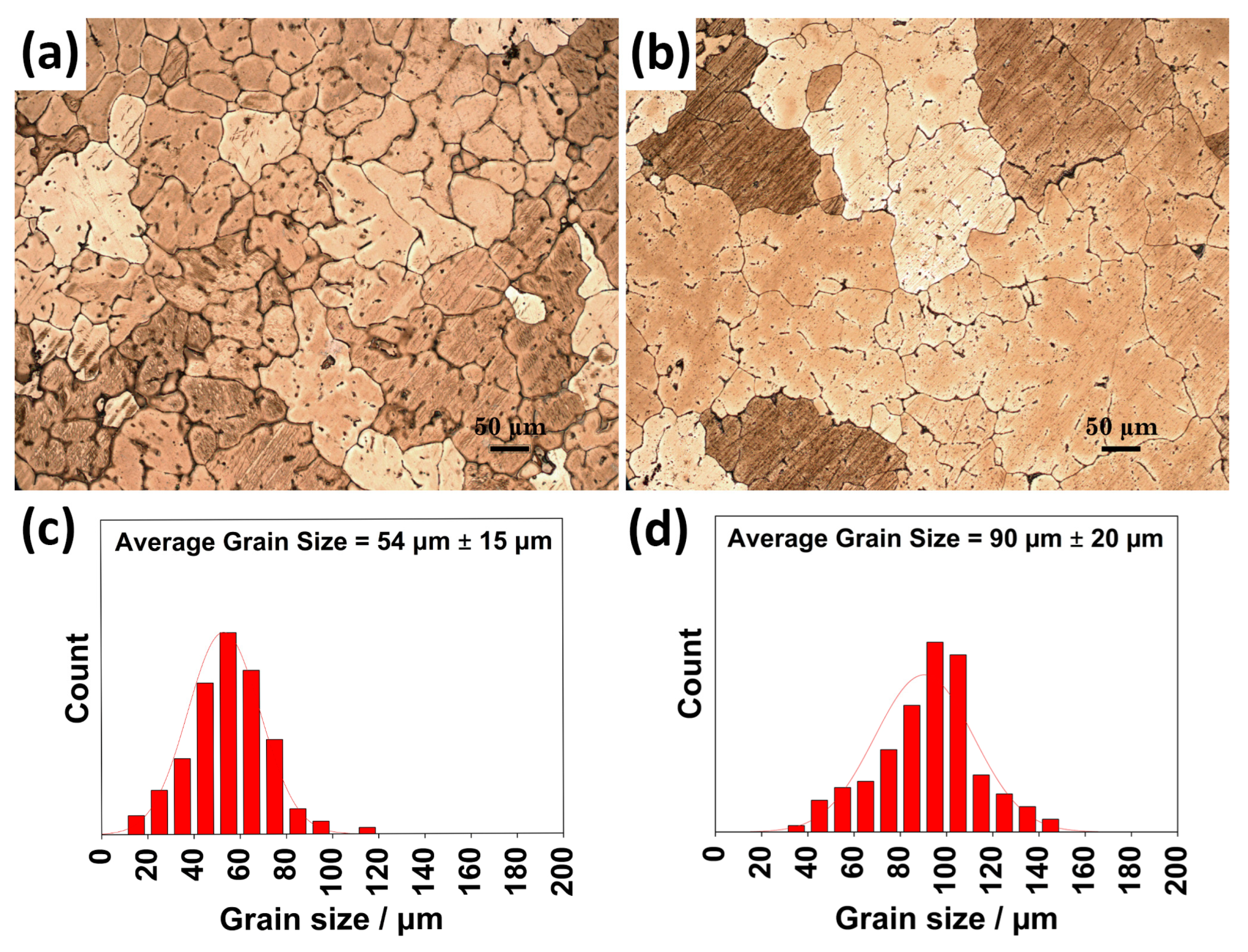

- The as-cast alloy consisted mainly of α-Mg, Mg3Gd2Zn3 (also denoted as W-phase), and Ca2Mg6Zn3 phases. After the homogenization treatment, the α-Mg grain size increased, and the second-phase particles underwent partial dissolution.

- A substantial grain refinement was obtained by the extrusion process. Increasing the extrusion temperature led to a rise in the proportion of DRXed grains and a decline in their size. At low extrusion temperatures, higher basal texture intensities were observed.

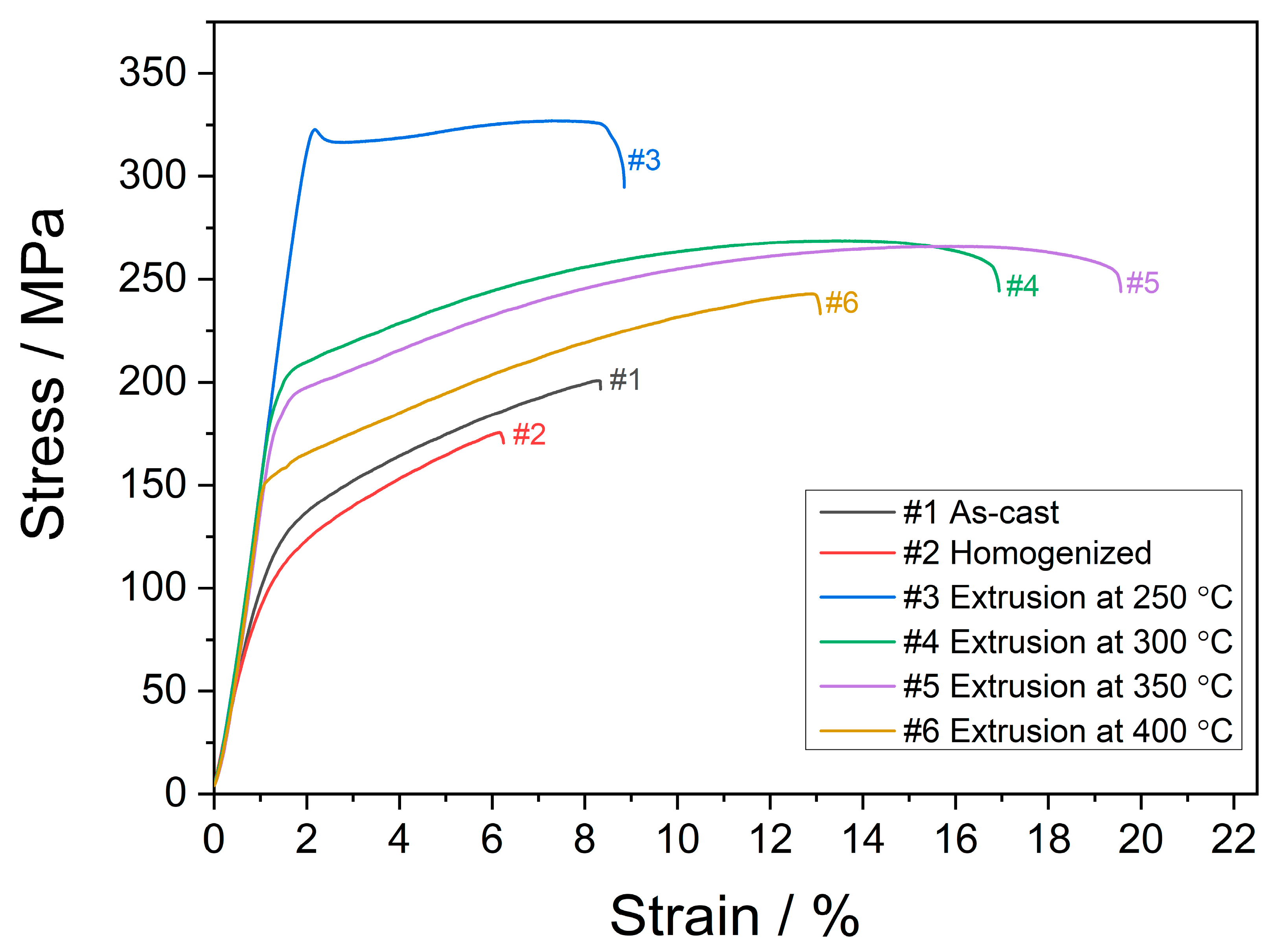

- The mechanical properties exhibited a significant enhancement after the extrusion procedure. The alloy extruded at 250 °C showed the highest strength but low ductility, which improved up to the extrusion at 350 °C above which it decreased.

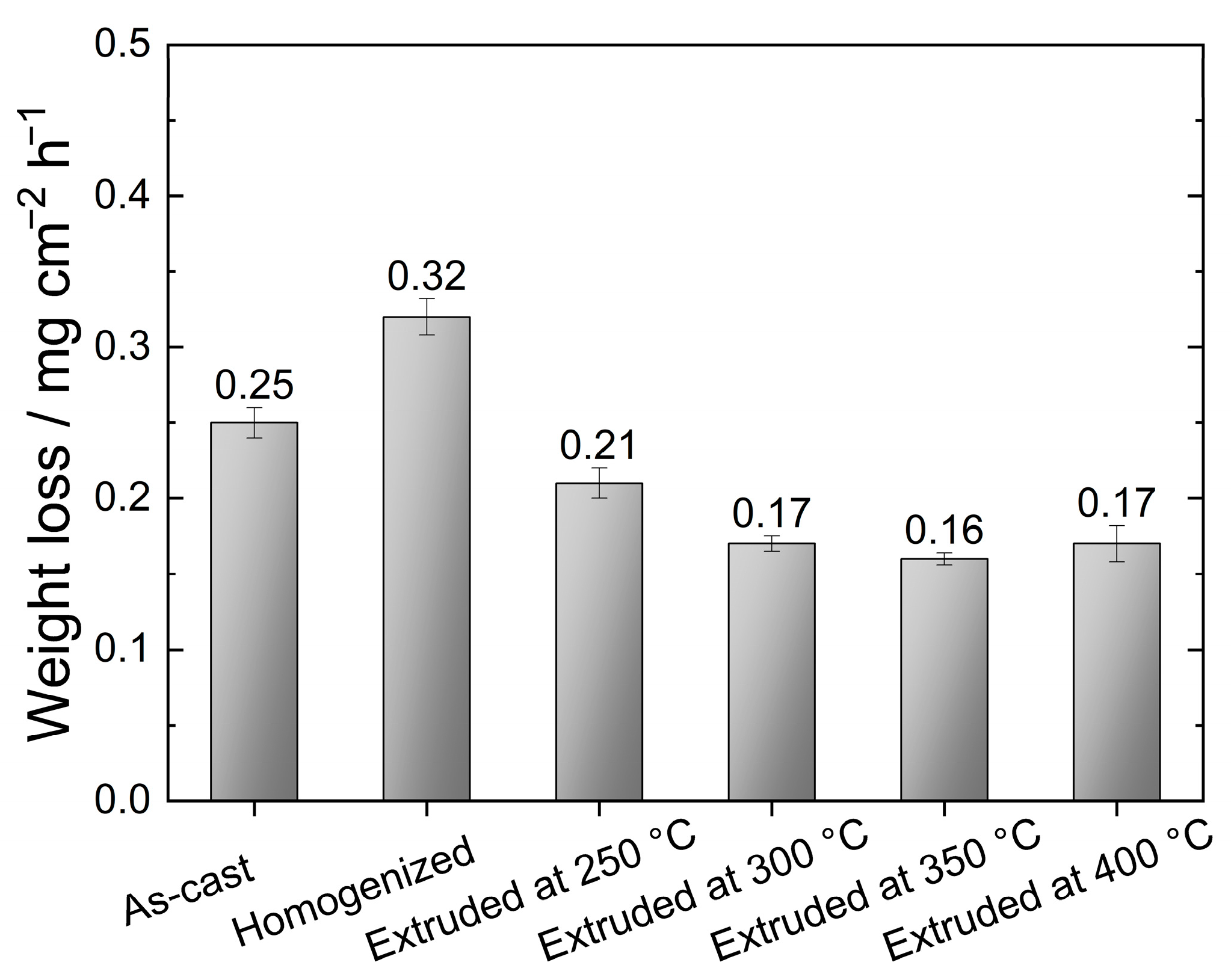

- The as-cast alloy displayed a moderate corrosion resistance having a barrier effect of secondary particles. However, after the homogenization treatment, the corrosion resistance deteriorated by the increased micro-galvanic coupling effect. The extrusion process with an increasing initial temperature of up to 350 °C resulted in a gradual improvement of the corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Avedesian, M.M.; Baker, H. ASM Specialty Handbook: Magnesium and Magnesium Alloys; ASM International: Materials Park, OH, USA, 1999; ISBN 978-0-87170-657-7. [Google Scholar]

- Kulekci, M.K. Magnesium and Its Alloys Applications in Automotive Industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Aghion, E.; Bronfín, B.; Buch, F.V.; Schumann, S.; Friedrich, H. Newly Developed Magnesium Alloys for Powertrain Applications. JOM 2003, 55, 30–33. [Google Scholar] [CrossRef]

- Kiani, M.; Gandikota, I.; Rais-Rohani, M.; Motoyama, K. Design of Lightweight Magnesium Car Body Structure under Crash and Vibration Constraints. J. Magnes. Alloys 2014, 2, 99–108. [Google Scholar] [CrossRef]

- Pan, H.; Ren, Y.; Fu, H.; Zhao, H.; Wang, L.; Meng, X.; Qin, G. Recent Developments in Rare-Earth Free Wrought Magnesium Alloys Having High Strength: A Review. J. Alloys Compd. 2016, 663, 321–331. [Google Scholar] [CrossRef]

- Bettles, C.; Barnett, M. Advances in Wrought Magnesium Alloys: Fundamentals of Processing, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 978-0-85709-384-4. [Google Scholar]

- Bettles, C.; Gibson, M. Current Wrought Magnesium Alloys: Strengths and Weaknesses. JOM 2005, 57, 46–49. [Google Scholar] [CrossRef]

- Park, S.H.; You, B.S.; Mishra, R.K.; Sachdev, A.K. Effects of Extrusion Parameters on the Microstructure and Mechanical Properties of Mg–Zn–(Mn)–Ce/Gd Alloys. Mater. Sci. Eng. A 2014, 598, 396–406. [Google Scholar] [CrossRef]

- Caceres, C.H.; Mann, G.E.; Griffiths, J.R. Grain Size Hardening in Mg and Mg-Zn Solid Solutions. Metall. Mater. Trans. A 2011, 42, 1950–1959. [Google Scholar] [CrossRef]

- Subasi, Y.; Turen, Y.; Zengin, H.; Ahlatci, H.; Sun, Y. Effect of Zn Addition on Mechanical and Corrosion Properties of As-Cast and as-Extruded WE43 Magnesium Alloys. Mater. Res. Express 2019, 6, 1165f9. [Google Scholar] [CrossRef]

- Cai, S.; Lei, T.; Li, N.; Feng, F. Effects of Zn on Microstructure, Mechanical Properties and Corrosion Behavior of Mg–Zn Alloys. Mater. Sci. Eng. C 2012, 32, 2570–2577. [Google Scholar] [CrossRef]

- Bai, J.; Sun, Y.; Xue, F.; Qiang, J. Microstructures and Creep Properties of Mg–4Al–(1–4) La Alloys Produced by Different Casting Techniques. Mater. Sci. Eng. A 2012, 552, 472–480. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Elen, L. A Comparative Study on Microstructure, Mechanical and Tribological Properties of A4, AE41, AS41 and AJ41 Magnesium Alloys. J. Mater. Eng. Perform. 2019, 28, 4647–4657. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Ahlatci, H.; Sun, Y. Mechanical Properties and Corrosion Behavior of As-Cast Mg-Zn-Zr-(La) Magnesium Alloys. J. Mater. Eng. Perform. 2018, 27, 389–397. [Google Scholar] [CrossRef]

- Stanford, N.; Atwell, D.; Barnett, M.R. The Effect of Gd on the Recrystallisation, Texture and Deformation Behaviour of Magnesium-Based Alloys. Acta Mater. 2010, 58, 6773–6783. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Liu, J.; Yu, Y.; Wang, S. The Effect of Gd Element and Solution Treatment on the Microstructure of AZ31 Magnesium Alloy and Its Kinetic Model. J. Alloys Compd. 2016, 663, 610–616. [Google Scholar] [CrossRef]

- Pourbahari, B.; Emamy, M.; Mirzadeh, H. Synergistic Effect of Al and Gd on Enhancement of Mechanical Properties of Magnesium Alloys. Prog. Nat. Sci. Mater. Int. 2017, 27, 228–235. [Google Scholar] [CrossRef]

- Shi, F.; Wang, C.; Zhang, Z. Microstructures, Corrosion and Mechanical Properties of as-Cast Mg–Zn–Y–(Gd) Alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2172–2180. [Google Scholar] [CrossRef]

- Yang, M.; Zhu, Y.; Liang, X.; Pan, F. Effects of Gd Addition on As-Cast Microstructure and Mechanical Properties of Mg–3Sn–2Ca Magnesium Alloy. Mater. Sci. Eng. A 2011, 528, 1721–1726. [Google Scholar] [CrossRef]

- Gu, D.; Peng, J.; Sun, S.; Pan, F. On the Solid Solution Substitutional Position and Properties of Mg–Gd Alloy. J. Mater. Res. Technol. 2022, 20, 2859–2871. [Google Scholar] [CrossRef]

- Mahjoub, R.; Stanford, N. The Electronic Origins of the “Rare Earth” Texture Effect in Magnesium Alloys. Sci. Rep. 2021, 11, 14159. [Google Scholar] [CrossRef]

- Liu, Z.R.; Li, D.Y. The Electronic Origin of Strengthening and Ductilizing Magnesium by Solid Solutes. Acta Mater. 2015, 89, 225–233. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, Y.; Geng, L.; Lu, C. Effects of Calcium on Texture and Mechanical Properties of Hot-Extruded Mg–Zn–Ca Alloys. Mater. Sci. Eng. A 2012, 539, 56–60. [Google Scholar] [CrossRef]

- Kamrani, S.; Fleck, C. Effects of Calcium and Rare-Earth Elements on the Microstructure and Tension–Compression Yield Asymmetry of ZEK100 Alloy. Mater. Sci. Eng. A 2014, 618, 238–243. [Google Scholar] [CrossRef]

- Hoseini-Athar, M.M.; Mahmudi, R.; Prasath Babu, R.; Hedström, P. Effect of Zn Addition on Dynamic Recrystallization Behavior of Mg-2Gd Alloy during High-Temperature Deformation. J. Alloys Compd. 2019, 806, 1200–1206. [Google Scholar] [CrossRef]

- Chen, J.; Tan, L.; Yu, X.; Yang, K. Effect of Minor Content of Gd on the Mechanical and Degradable Properties of As-Cast Mg-2Zn-XGd-0.5Zr Alloys. J. Mater. Sci. Technol. 2019, 35, 503–511. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, Z.; Liu, X.; Le, Q.; Lan, Q.; Bao, L.; Cui, J. Effects of Zn/Gd Ratio on the Microstructures and Mechanical Properties of Mg-Zn-Gd-Zr Alloys. Mater. Sci. Eng. A 2017, 695, 135–143. [Google Scholar] [CrossRef]

- Luo, L.; Liu, Y.; Duan, M. Phase Formation of Mg-Zn-Gd Alloys on the Mg-Rich Corner. Materials 2018, 11, 1351. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, G.; Zhang, S.; Zhang, X.; Lu, C.; Ding, W. Effects of Zn/Gd Ratio and Content of Zn, Gd on Phase Constitutions of Mg Alloys. Mater. Trans. 2008, 49, 941–944. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Li, J. Effects of Microstructure Transformation on Mechanical Properties, Corrosion Behaviors of Mg-Zn-Mn-Ca Alloys in Simulated Body Fluid. J. Mech. Behav. Biomed. Mater. 2018, 80, 246–257. [Google Scholar] [CrossRef]

- Chen, J.-X.; Gao, M.; Tan, L.-L.; Yang, K. Microstructure, Mechanical and Biodegradable Properties of a Mg–2Zn–1Gd–0.5Zr Alloy with Different Solution Treatments. Rare Met. 2019, 38, 532–542. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, G.; Chu, Z.; Ding, W. Microstructure and Mechanical Properties of Double Continuously Extruded Mg–Zn–Gd-Based Magnesium Alloys. Mater. Sci. Eng. A 2013, 560, 241–248. [Google Scholar] [CrossRef]

- Miao, H.; Huang, H.; Shi, Y.; Zhang, H.; Pei, J.; Yuan, G. Effects of Solution Treatment before Extrusion on the Microstructure, Mechanical Properties and Corrosion of Mg-Zn-Gd Alloy in Vitro. Corros. Sci. 2017, 122, 90–99. [Google Scholar] [CrossRef]

- Shahzad, M.; Wagner, L. Influence of Extrusion Parameters on Microstructure and Texture Developments, and Their Effects on Mechanical Properties of the Magnesium Alloy AZ80. Mater. Sci. Eng. A 2009, 506, 141–147. [Google Scholar] [CrossRef]

- Ross, N.G.; Barnett, M.R.; Beer, A.G. Effect of Alloying and Extrusion Temperature on the Microstructure and Mechanical Properties of Mg–Zn and Mg–Zn–RE Alloys. Mater. Sci. Eng. A 2014, 619, 238–246. [Google Scholar] [CrossRef]

- Kim, H.J.; Jin, S.-C.; Jung, J.-G.; Park, S.H. Influence of Undissolved Second-Phase Particles on Dynamic Recrystallization Behavior of Mg–7Sn–1Al–1Zn Alloy during Low- and High-Temperature Extrusions. J. Mater. Sci. Technol. 2021, 71, 87–97. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y. Effect of La Content and Extrusion Temperature on Microstructure, Texture and Mechanical Properties of Mg-Zn-Zr Magnesium Alloy. Mater. Chem. Phys. 2018, 214, 421–430. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 978-0-08-098388-2. [Google Scholar]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle Effects on Recrystallization in Magnesium–Manganese Alloys: Particle-Stimulated Nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Turan, M.E.; Aydın, F. Evolution of Microstructure, Residual Stress, and Tensile Properties of Mg–Zn–Y–La–Zr Magnesium Alloy Processed by Extrusion. Acta Metall. Sin. Engl. Lett. 2019, 32, 1309–1319. [Google Scholar] [CrossRef]

- Huang, X.; Chino, Y.; Yuasa, M.; Ueda, H.; Inoue, M.; Kido, F.; Matsumoto, T. Microstructure and Mechanical Properties of AZX912 Magnesium Alloy Extruded at Different Temperatures. Mater. Sci. Eng. A 2017, 679, 162–171. [Google Scholar] [CrossRef]

- Stanford, N.; Barnett, M.R. The Origin of “Rare Earth” Texture Development in Extruded Mg-Based Alloys and Its Effect on Tensile Ductility. Mater. Sci. Eng. A 2008, 496, 399–408. [Google Scholar] [CrossRef]

- Yu, H.; Kim, Y.M.; You, B.S.; Yu, H.S.; Park, S.H. Effects of Cerium Addition on the Microstructure, Mechanical Properties and Hot Workability of ZK60 Alloy. Mater. Sci. Eng. A 2013, 559, 798–807. [Google Scholar] [CrossRef]

- Petch, N.J. The Cleavage Strength of Polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Xu, C.; Nakata, T.; Qiao, X.G.; Jiang, H.S.; Sun, W.T.; Chi, Y.C.; Zheng, M.Y.; Kamado, S. Effect of Extrusion Parameters on Microstructure and Mechanical Properties of Mg-7.5Gd-2.5Y-3.5Zn-0.9Ca-0.4Zr (Wt%) Alloy. Mater. Sci. Eng. A 2017, 685, 159–167. [Google Scholar] [CrossRef]

- Yu, H.; Hyuk Park, S.; Sun You, B.; Min Kim, Y.; Shun Yu, H.; Soo Park, S. Effects of Extrusion Speed on the Microstructure and Mechanical Properties of ZK60 Alloys with and without 1 Wt% Cerium Addition. Mater. Sci. Eng. A 2013, 583, 25–35. [Google Scholar] [CrossRef]

- Barnett, M.R. Twinning and the Ductility of Magnesium Alloys: Part II. “Contraction” Twins. Mater. Sci. Eng. A 2007, 464, 8–16. [Google Scholar] [CrossRef]

- Park, S.H.; Yu, H.; Bae, J.H.; Yim, C.D.; You, B.S. Microstructural Evolution of Indirect-Extruded ZK60 Alloy by Adding Ce. J. Alloys Compd. 2012, 545, 139–143. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Qi, M.; Gu, J.; Zhang, Y. Effect of Extrusion on the Microstructure and Corrosion Behaviors of Biodegradable Mg–Zn–Y–Gd–Zr Alloy. J. Mater. Sci. 2020, 55, 1231–1245. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Ahlatci, H.; Sun, Y.; Kara, I.H. Microstructure and Corrosion Properties of Homogenized Mg-4Zn-1La Magnesium Alloy. Key Eng. Mater. 2017, 750, 118–123. [Google Scholar] [CrossRef]

- Argade, G.R.; Panigrahi, S.K.; Mishra, R.S. Effects of Grain Size on the Corrosion Resistance of Wrought Magnesium Alloys Containing Neodymium. Corros. Sci. 2012, 58, 145–151. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, X.; Zhang, K.; Shi, Y.; Ren, J. Effect of Extrusion on Corrosion Behavior and Corrosion Mechanism of Mg-Y Alloy. J. Rare Earths 2016, 34, 315–327. [Google Scholar] [CrossRef]

- Zengin, H.; Turen, Y.; Ahlatci, H.; Sun, Y. Microstructure, Mechanical Properties and Corrosion Resistance of as-Cast and as-Extruded Mg–4Zn–1La Magnesium Alloy. Rare Met. 2018, 39, 909–917. [Google Scholar] [CrossRef]

- Neil, W.C.; Forsyth, M.; Howlett, P.C.; Hutchinson, C.R.; Hinton, B.R.W. Corrosion of Magnesium Alloy ZE41—The Role of Microstructural Features. Corros. Sci. 2009, 51, 387–394. [Google Scholar] [CrossRef]

- Zhao, M.-C.; Liu, M.; Song, G.L.; Atrens, A. Influence of Microstructure on Corrosion of As-Cast ZE41. Adv. Eng. Mater. 2008, 10, 104–111. [Google Scholar] [CrossRef]

- Yin, S.; Duan, W.; Liu, W.; Wu, L.; Yu, J.; Zhao, Z.; Liu, M.; Wang, P.; Cui, J.; Zhang, Z. Influence of Specific Second Phases on Corrosion Behaviors of Mg-Zn-Gd-Zr Alloys. Corros. Sci. 2020, 166, 108419. [Google Scholar] [CrossRef]

- Song, G.; Atrens, A.; Dargusch, M. Influence of Microstructure on the Corrosion of Diecast AZ91D. Corros. Sci. 1998, 41, 249–273. [Google Scholar] [CrossRef]

- Cheng, W.; Ma, S.; Bai, Y.; Cui, Z.; Wang, H. Corrosion Behavior of Mg-6Bi-2Sn Alloy in the Simulated Body Fluid Solution: The Influence of Microstructural Characteristics. J. Alloys Compd. 2018, 731, 945–954. [Google Scholar] [CrossRef]

- Chang, J.W.; Peng, L.M.; Guo, X.W.; Atrens, A.; Fu, P.H.; Ding, W.J.; Wang, X.S. Comparison of the Corrosion Behaviour in 5% NaCl Solution of Mg Alloys NZ30K and AZ91D. J. Appl. Electrochem. 2008, 38, 207–214. [Google Scholar] [CrossRef]

- Prince, L.; Noirfalise, X.; Paint, Y.; Olivier, M. Corrosion Mechanisms of AZ31 Magnesium Alloy: Importance of Starting PH and Its Evolution. Mater. Corros. 2022, 73, 1615–1630. [Google Scholar] [CrossRef]

- Jiang, P.; Blawert, C.; Hou, R.; Scharnagl, N.; Bohlen, J.; Zheludkevich, M.L. Microstructural Influence on Corrosion Behavior of MgZnGe Alloy in NaCl Solution. J. Alloys Compd. 2019, 783, 179–192. [Google Scholar] [CrossRef]

- Wang, L.; Snihirova, D.; Deng, M.; Wang, C.; Vaghefinazari, B.; Wiese, G.; Langridge, M.; Höche, D.; Lamaka, S.V.; Zheludkevich, M.L. Insight into Physical Interpretation of High Frequency Time Constant in Electrochemical Impedance Spectra of Mg. Corros. Sci. 2021, 187, 109501. [Google Scholar] [CrossRef]

- Wang, L.; Snihirova, D.; Deng, M.; Vaghefinazari, B.; Höche, D.; Lamaka, S.V.; Zheludkevich, M.L. Revealing Physical Interpretation of Time Constants in Electrochemical Impedance Spectra of Mg via Tribo-EIS Measurements. Electrochim. Acta 2022, 404, 139582. [Google Scholar] [CrossRef]

- Stern, M.; Geary, A.L. Electrochemical Polarization: I. A Theoretical Analysis of the Shape of Polarization Curves. J. Electrochem. Soc. 1957, 104, 56. [Google Scholar] [CrossRef]

- Wang, B.J.; Xu, D.K.; Dong, J.H.; Ke, W. Effect of the Crystallographic Orientation and Twinning on the Corrosion Resistance of an As-Extruded Mg–3Al–1Zn (Wt.%) Bar. Scr. Mater. 2014, 88, 5–8. [Google Scholar] [CrossRef]

- Gerashi, E.; Alizadeh, R.; Langdon, T.G. Effect of Crystallographic Texture and Twinning on the Corrosion Behavior of Mg Alloys: A Review. J. Magnes. Alloys 2022, 10, 313–325. [Google Scholar] [CrossRef]

| Alloy | Compositions/wt% | |||

|---|---|---|---|---|

| Zn | Gd | Ca | Mg | |

| GZX220 | 2.23 | 2.21 | 0.19 | Bal. |

| Condition | Spectrum | Elements | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mg | Zn | Gd | Ca | ||||||

| /wt% | /at% | /wt% | /at% | /wt% | /at% | /wt% | /at% | ||

| As-cast | 1 | 15.5 | 36.6 | 55.6 | 48.7 | 24.6 | 8.9 | 4.2 | 5.7 |

| 2 | 22.6 | 46.5 | 50.0 | 38.3 | 20.4 | 6.5 | 7.0 | 8.7 | |

| 3 | 30.6 | 51.8 | 50.1 | 31.6 | 4.2 | 1.1 | 15.1 | 15.5 | |

| 4 | 42.8 | 69.5 | 39.7 | 24.1 | 14.3 | 3.6 | 2.9 | 2.6 | |

| 5 | 96.2 | 98.6 | 2.4 | 0.9 | 0.8 | 0.1 | 0.5 | 0.3 | |

| Homogenized | 1 | 20.1 | 44.5 | 56.6 | 46.6 | 22.3 | 7.7 | 0.8 | 1.1 |

| 2 | 32.7 | 69.7 | 6.3 | 5 | 53.2 | 17.5 | 4.6 | 6.1 | |

| 3 | 14.2 | 35.6 | 57.7 | 53.4 | 27.8 | 10.6 | 0.3 | 0.5 | |

| 4 | 11.3 | 29.2 | 62.3 | 59.9 | 26.1 | 10.4 | 0.3 | 0.5 | |

| 5 | 94.9 | 98.2 | 3.1 | 1.2 | 1.3 | 0.2 | 0.4 | 0.3 | |

| Alloy | 0.2% YS/MPa | UTS/MPa | Strain at Failure/% |

|---|---|---|---|

| As-cast | 114 ± 6 | 200 ± 7 | 8.3 ± 1.4 |

| Homogenized | 95 ± 5 | 176 ± 6 | 6.2 ± 1.8 |

| Extruded (250 °C) | 321 ± 4 | 326 ± 4 | 8.8 ± 1.1 |

| Extruded (300 °C) | 197 ± 4 | 269 ± 7 | 16.9 ± 1.8 |

| Extruded (350 °C) | 176 ± 5 | 266 ± 7 | 19.5 ± 2.1 |

| Extruded (400 °C) | 155 ± 6 | 242 ± 8 | 13.1 ± 1.4 |

| Specimen | Rs /Ω cm2 | Rf /Ω cm2 | Rct /Ω cm2 | CPEf 10−5 /Ω−1 sn cm−2 | n1 | CPEdl 10−3 /Ω−1 sn cm−2 | n2 | Rp /Ω cm2 |

|---|---|---|---|---|---|---|---|---|

| As-cast | 15.2 | 470.7 | 372.7 | 1.59 | 0.94 | 5.35 | 0.58 | 843.4 |

| Homogenized | 15.3 | 397.9 | 321.7 | 1.62 | 0.94 | 6.17 | 0.57 | 719.5 |

| Ext. (250°) | 15.1 | 419.7 | 360.9 | 1.69 | 0.94 | 5.83 | 0.61 | 780.6 |

| Ext. (300°) | 14.5 | 545.5 | 285.4 | 1.55 | 0.94 | 4.10 | 0.67 | 830.9 |

| Ext. (350°) | 14.9 | 654.5 | 430.2 | 1.69 | 0.93 | 3.63 | 0.54 | 1084.7 |

| Ext. (400°) | 14.6 | 542.0 | 447.9 | 1.53 | 0.94 | 4.82 | 0.57 | 989.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zengin, H.; Ari, S.; Turan, M.E.; Hassel, A.W. Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Mg–2.2Gd–2.2Zn–0.2Ca (wt%) Alloy by Extrusion at Various Temperatures. Materials 2023, 16, 3075. https://doi.org/10.3390/ma16083075

Zengin H, Ari S, Turan ME, Hassel AW. Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Mg–2.2Gd–2.2Zn–0.2Ca (wt%) Alloy by Extrusion at Various Temperatures. Materials. 2023; 16(8):3075. https://doi.org/10.3390/ma16083075

Chicago/Turabian StyleZengin, Hüseyin, Soner Ari, Muhammet Emre Turan, and Achim Walter Hassel. 2023. "Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Mg–2.2Gd–2.2Zn–0.2Ca (wt%) Alloy by Extrusion at Various Temperatures" Materials 16, no. 8: 3075. https://doi.org/10.3390/ma16083075

APA StyleZengin, H., Ari, S., Turan, M. E., & Hassel, A. W. (2023). Evolution of Microstructure, Mechanical Properties, and Corrosion Resistance of Mg–2.2Gd–2.2Zn–0.2Ca (wt%) Alloy by Extrusion at Various Temperatures. Materials, 16(8), 3075. https://doi.org/10.3390/ma16083075