A Simple Method for Estimation of the Scattering Exponent of Nanostructured Glasses

Abstract

1. Introduction

2. A Simple Method for Estimation of the Scattering Exponent and Its Testing

2.1. The Method

2.2. Application of the Novel Method and Comparison to the Results with Those Obtained Using the First Method

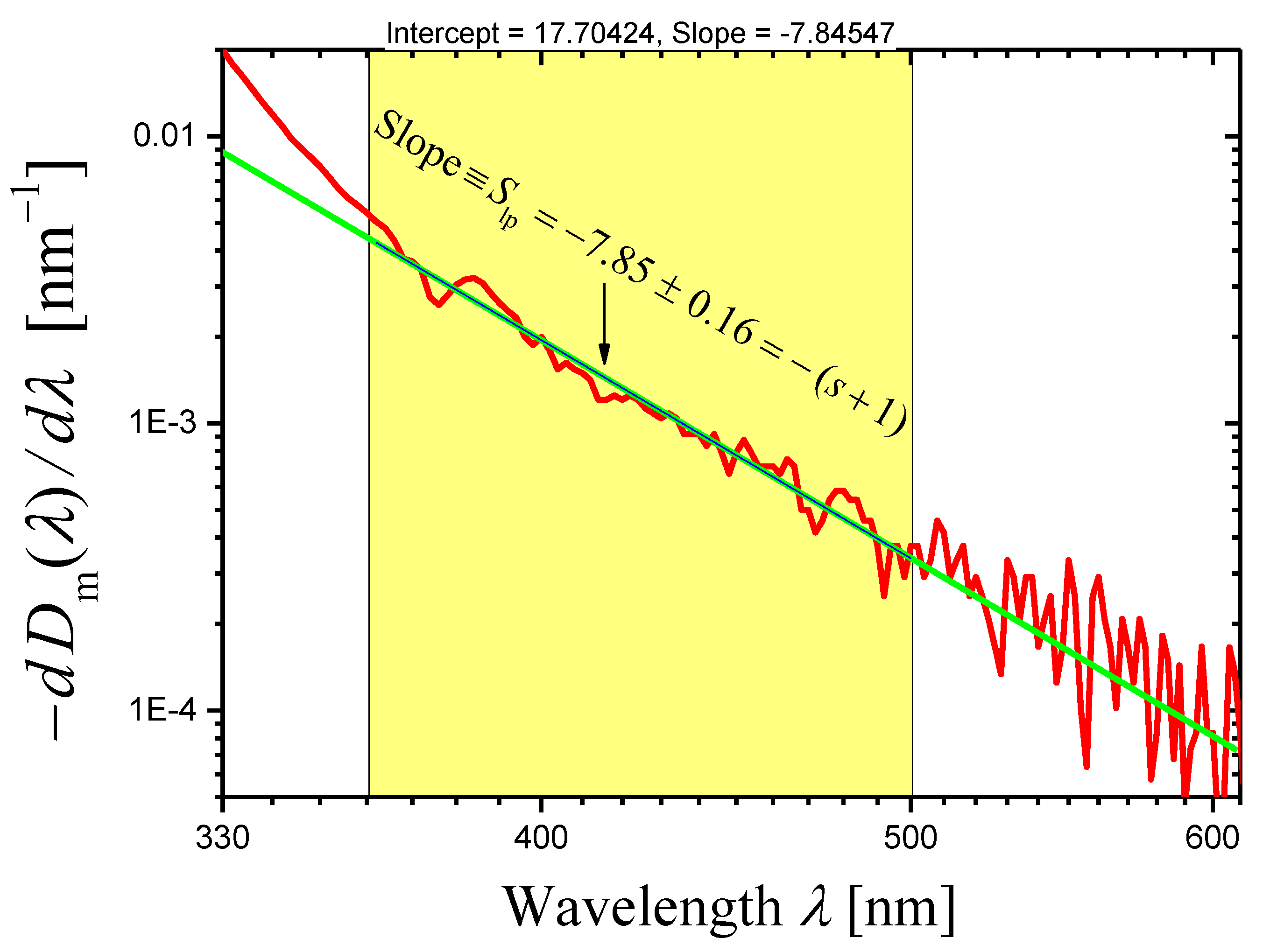

2.2.1. Phase-Separated Sodium Borosilicate Glass

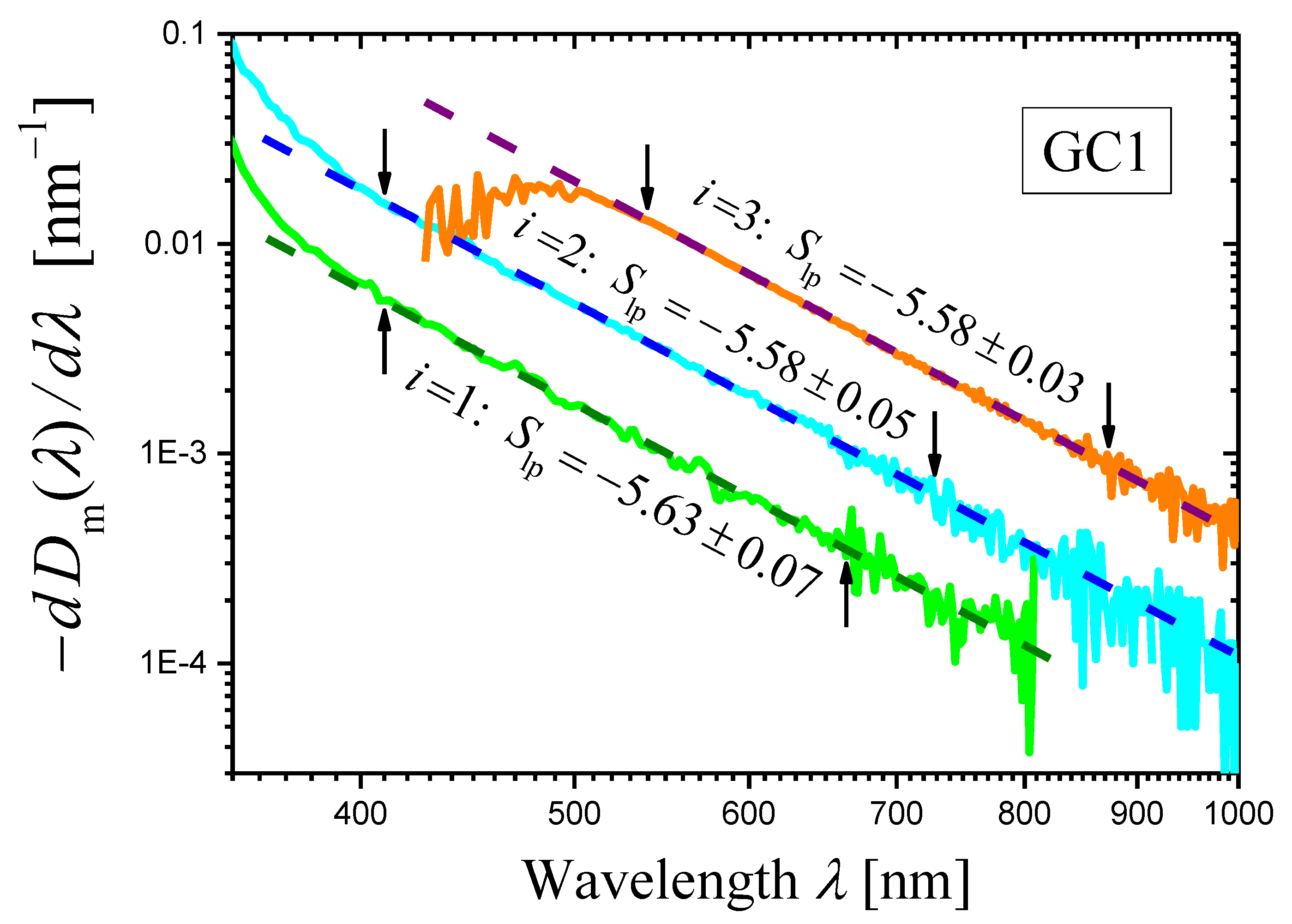

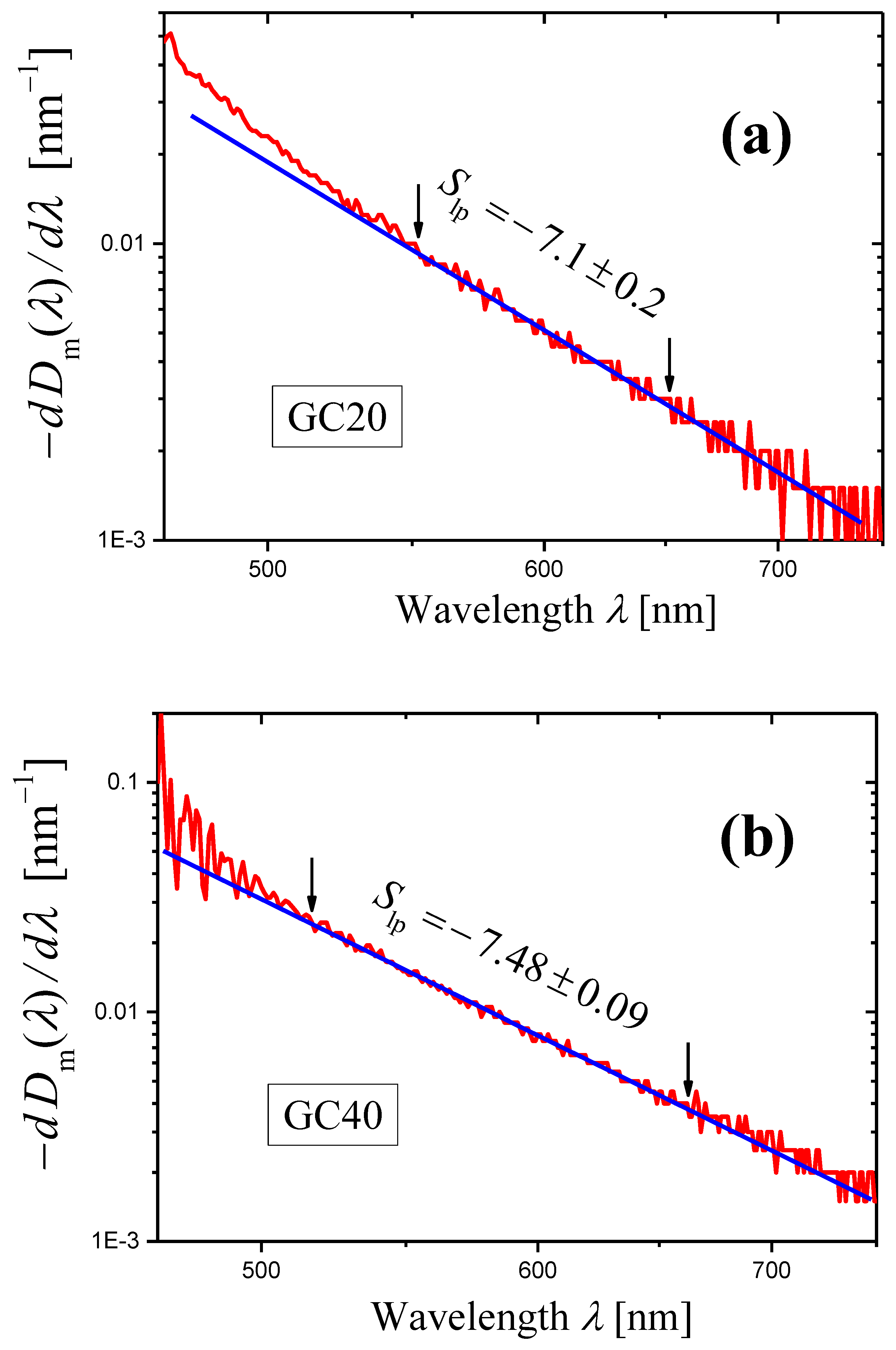

2.2.2. Gahnite-Based Zinc Aluminosilicate Glass-Ceramic Studied in Reference [34] and Denoted as GC1

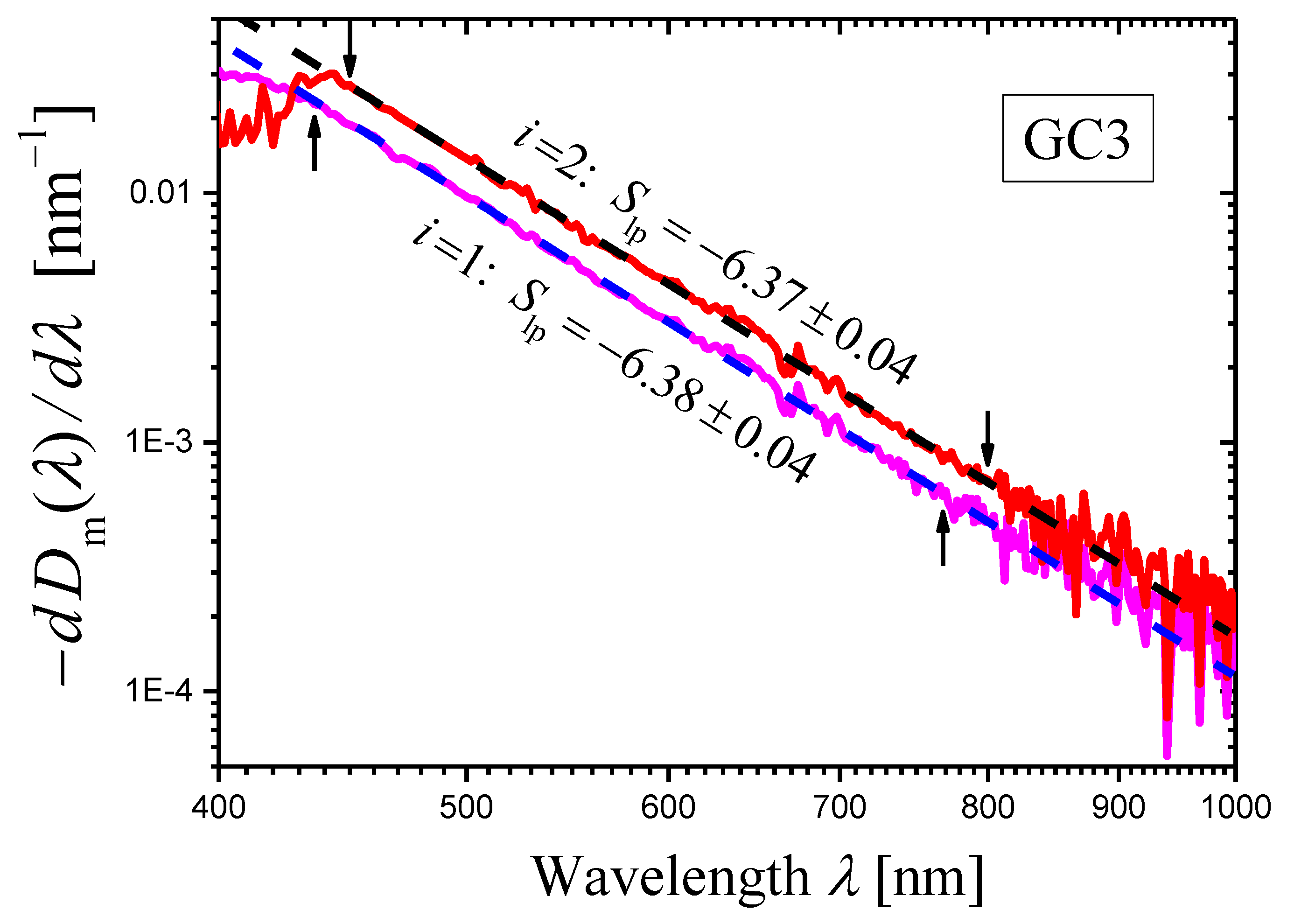

2.2.3. Gahnite-Based Zinc Aluminosilicate Glass-Ceramic Studied in Ref. [34] and Denoted as GC3

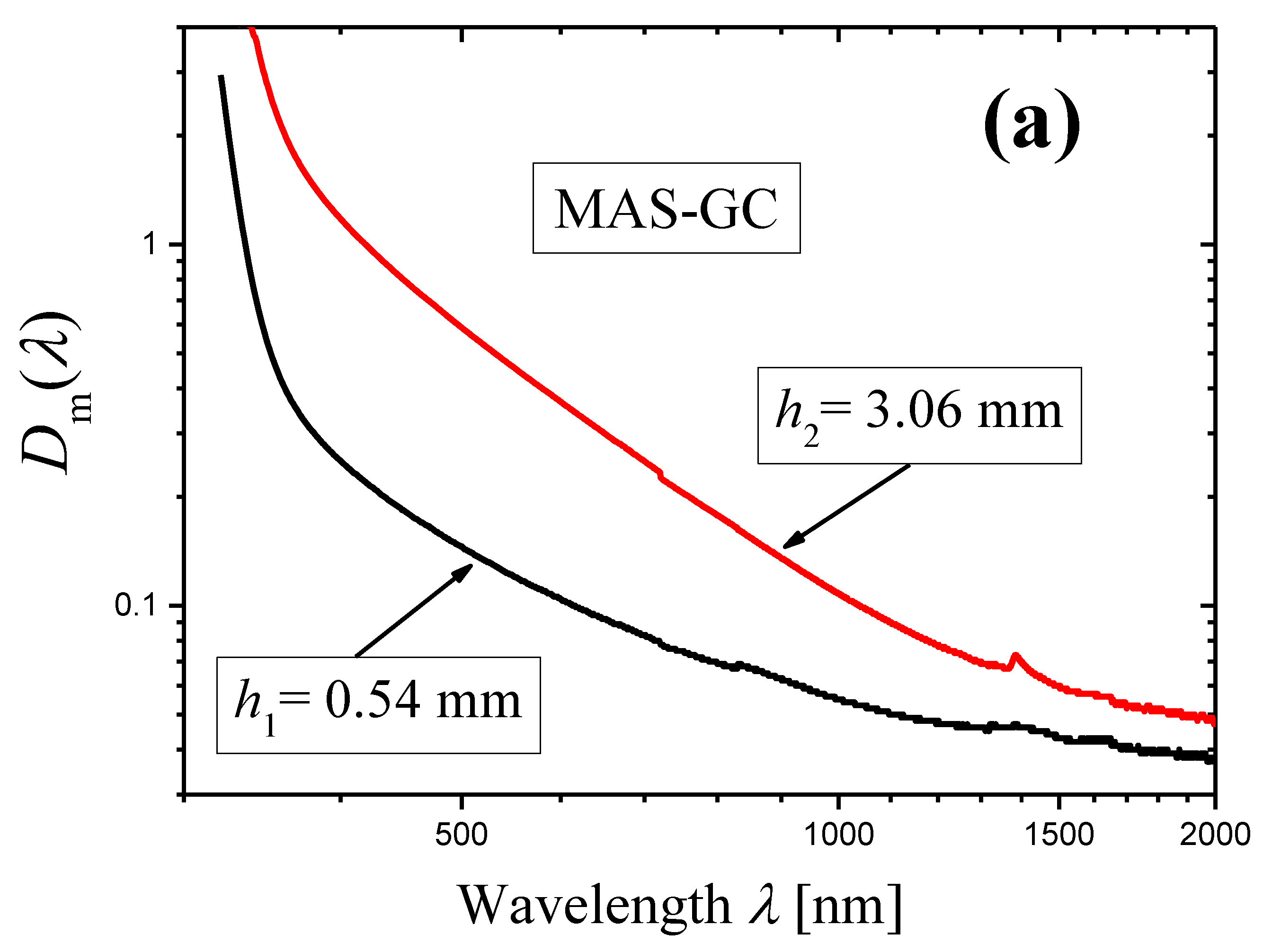

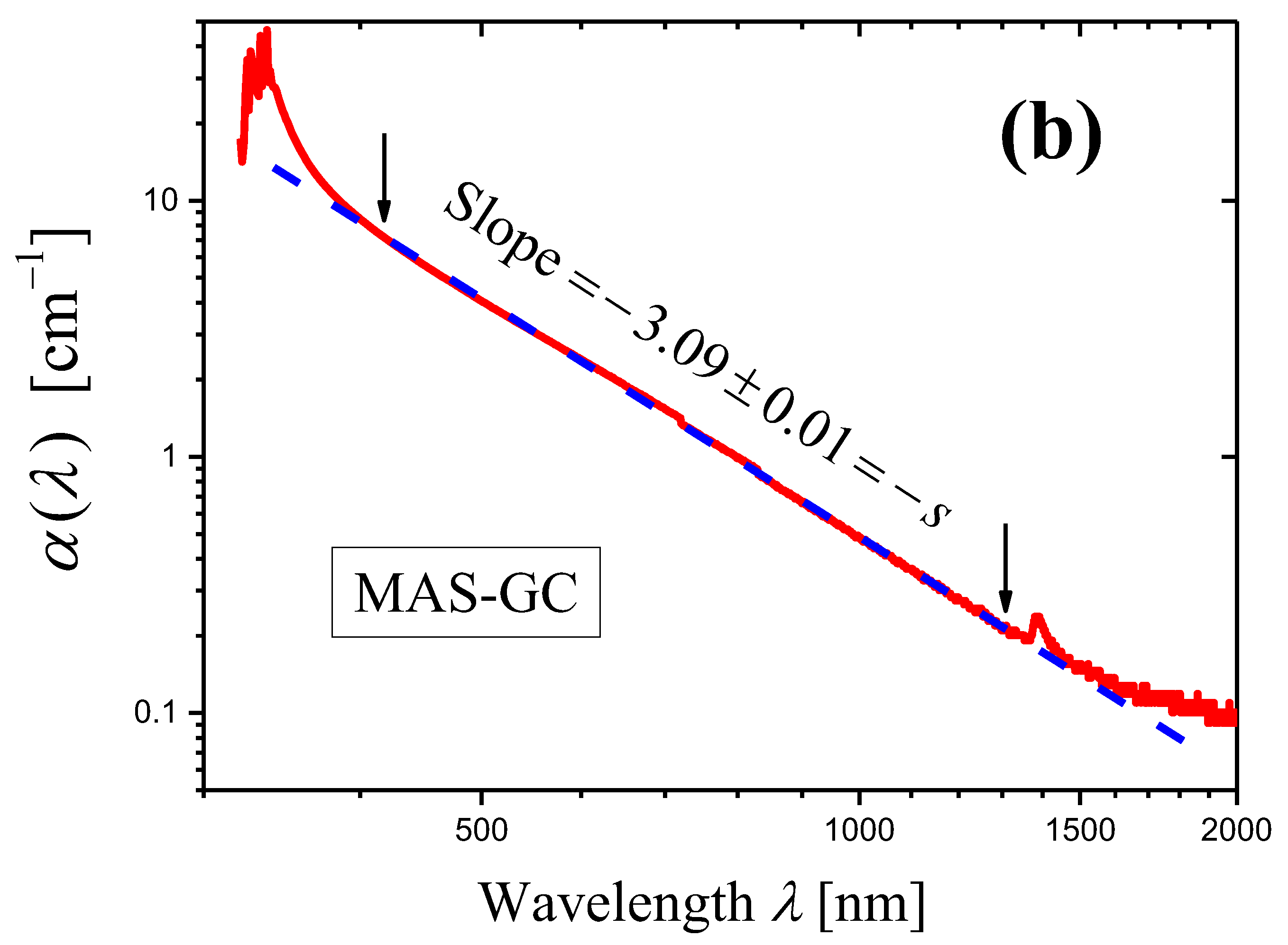

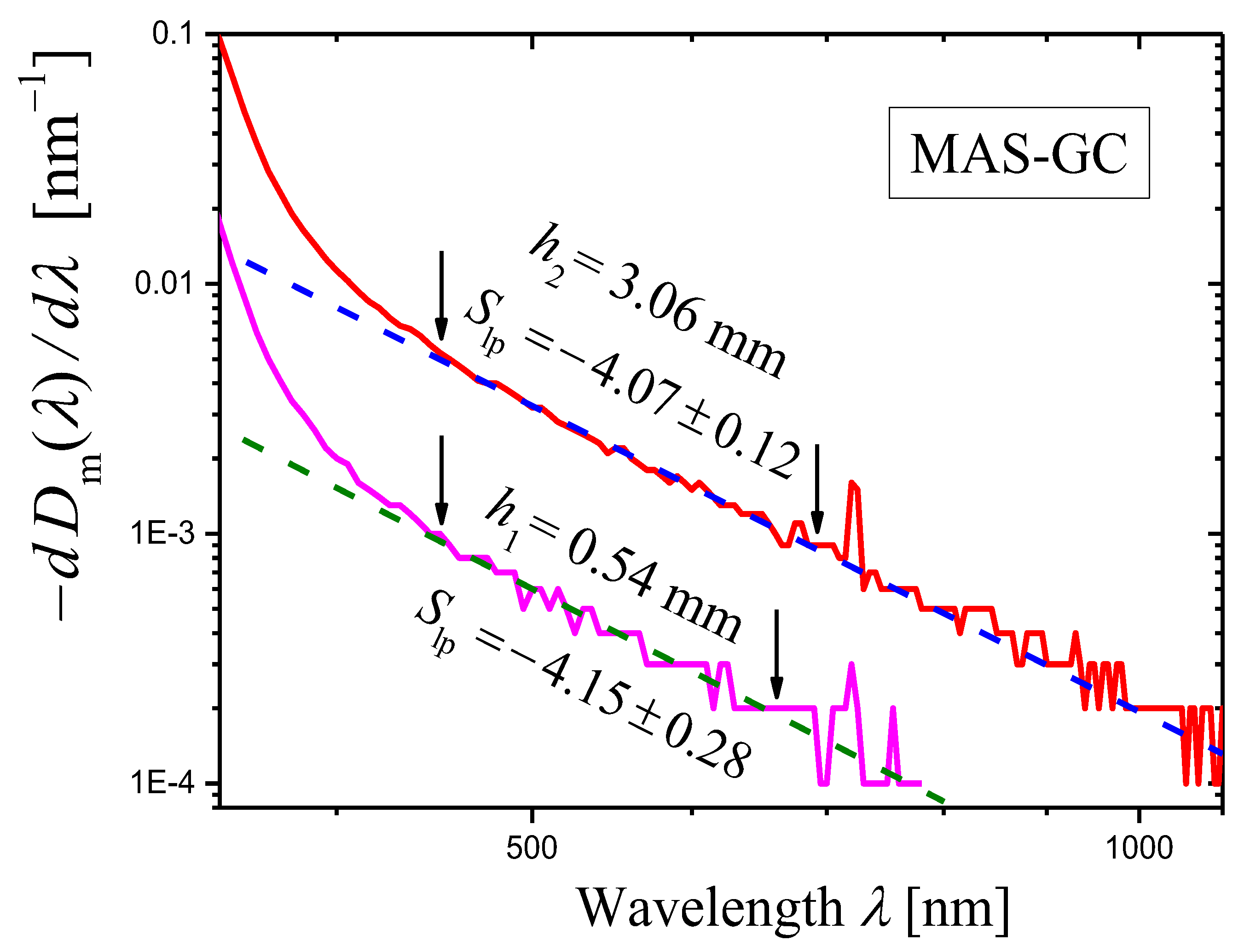

2.2.4. Spinel-Based Magnesium Aluminosilicate Glass-Ceramic

2.3. Application of the Novel Method and Comparison of the Results with Those Obtained in Ref. [35] for Glass-Ceramics Based on SrIINbIVO3 Crystals Using the Second Method

2.4. Application of the Novel Method and Comparison of the Results with Those Obtained Using the Third Method

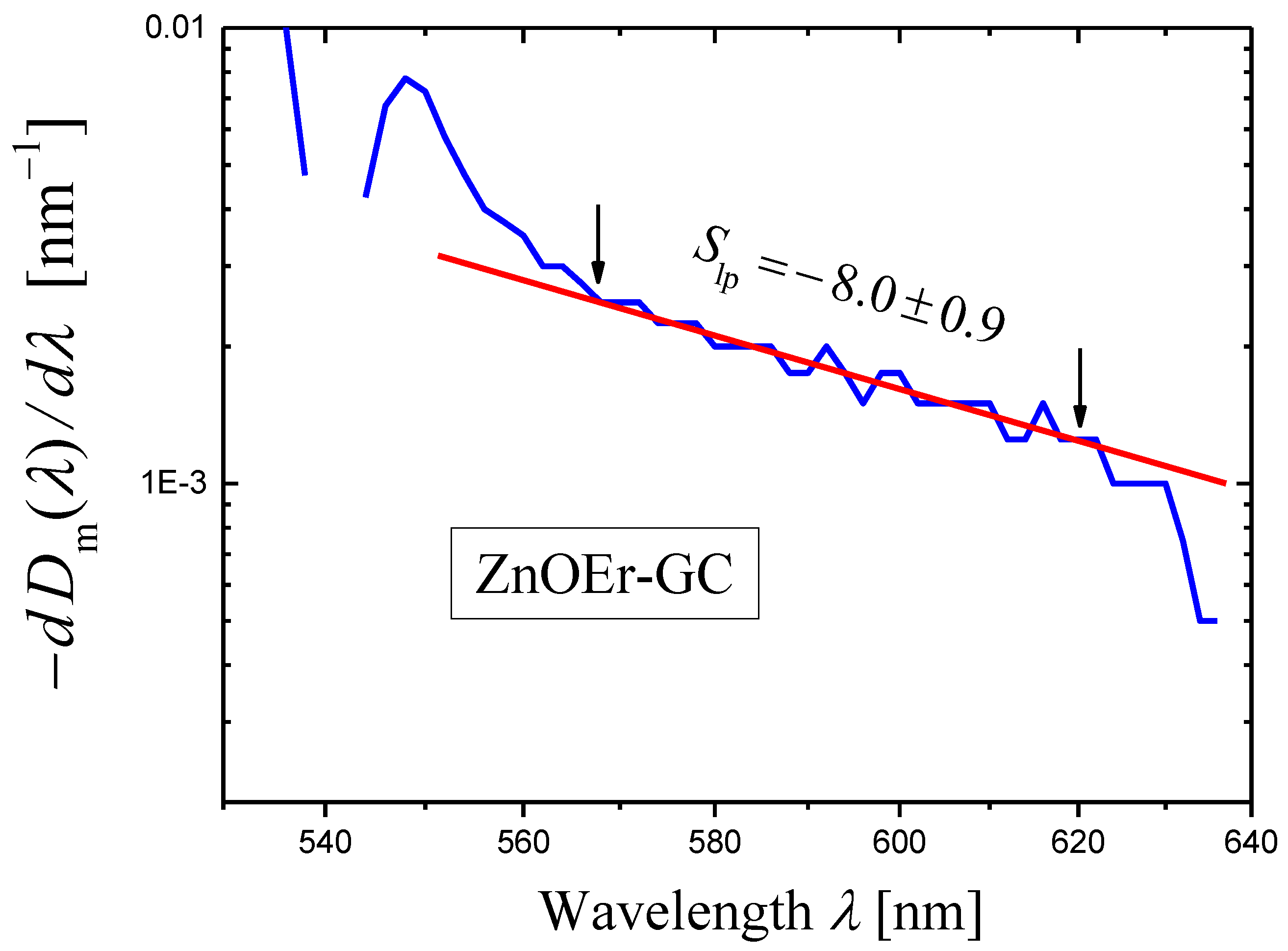

2.4.1. Er-Doped Potassium Zinc Aluminosilicate Glass-Ceramic Containing ZnO Nanocrystals

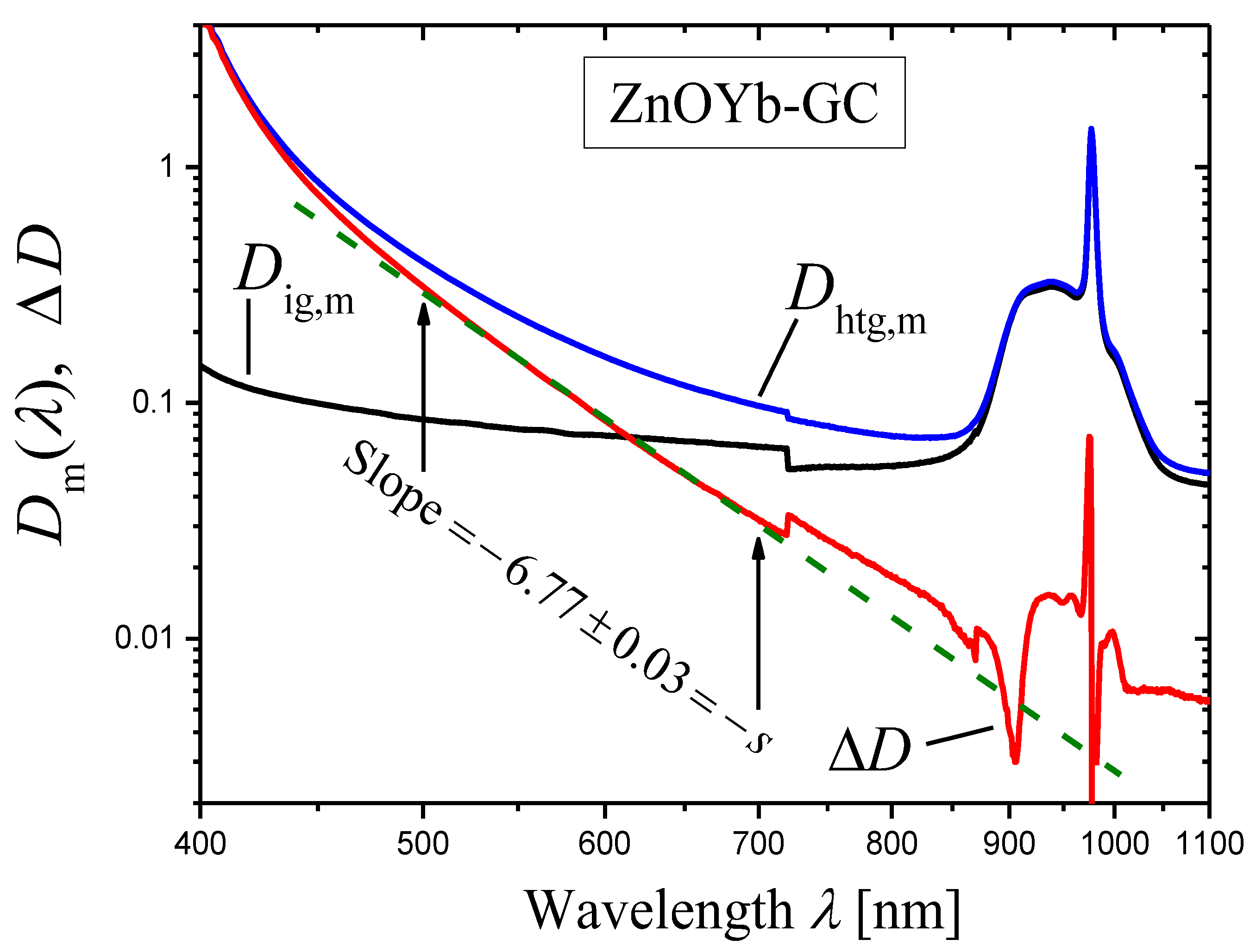

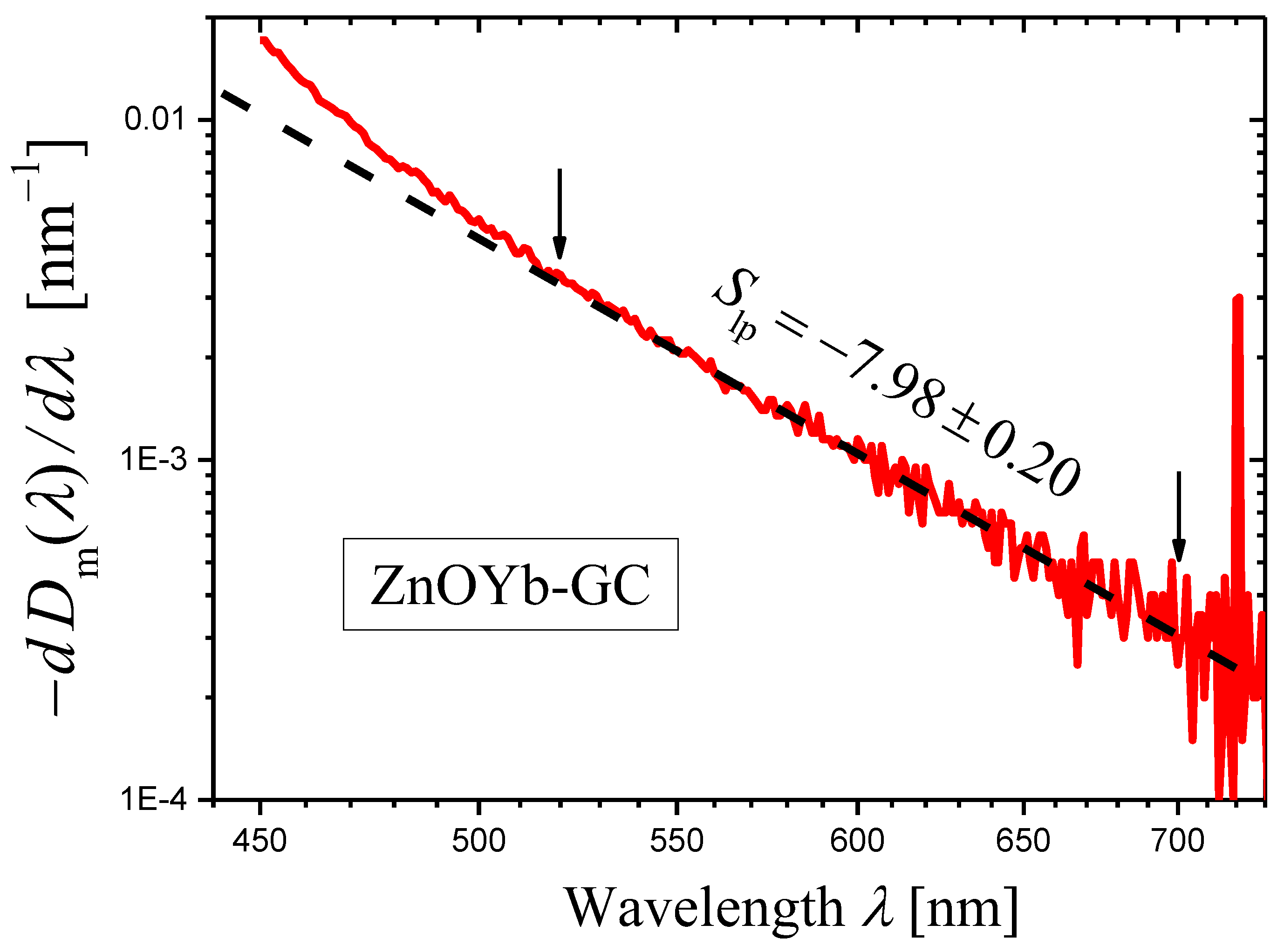

2.4.2. Yb-Doped Potassium Zinc Aluminosilicate Glass-Ceramic Containing ZnO Nanocrystals

3. Discussion

3.1. Comparison of the Scattering Exponent Values Obtained by the New and Traditional Methods

3.2. On the Choice of the Wavelength Step in the Spectrum of the Measured Optical Density

3.3. On the Choice of the Sample Thickness

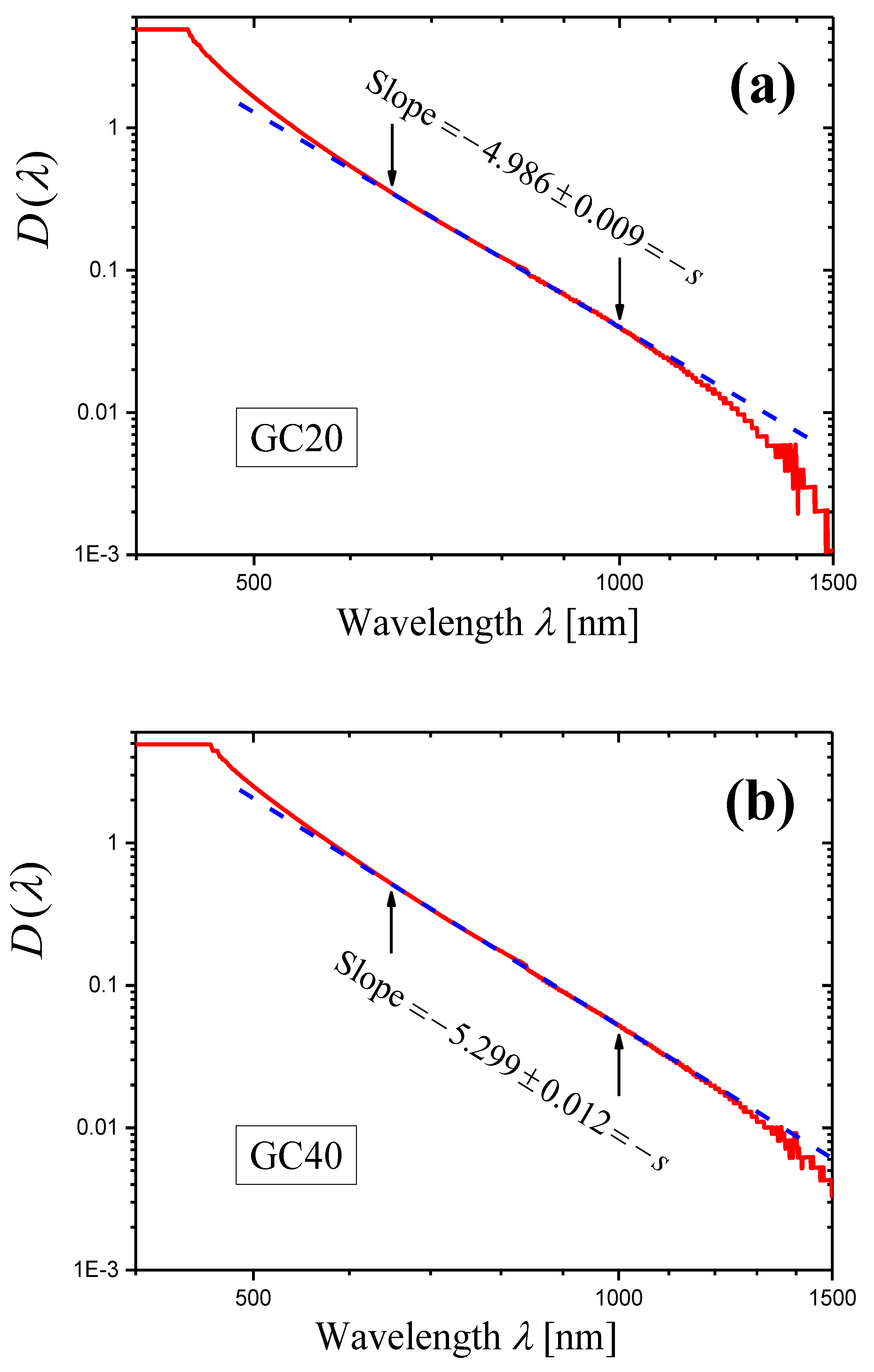

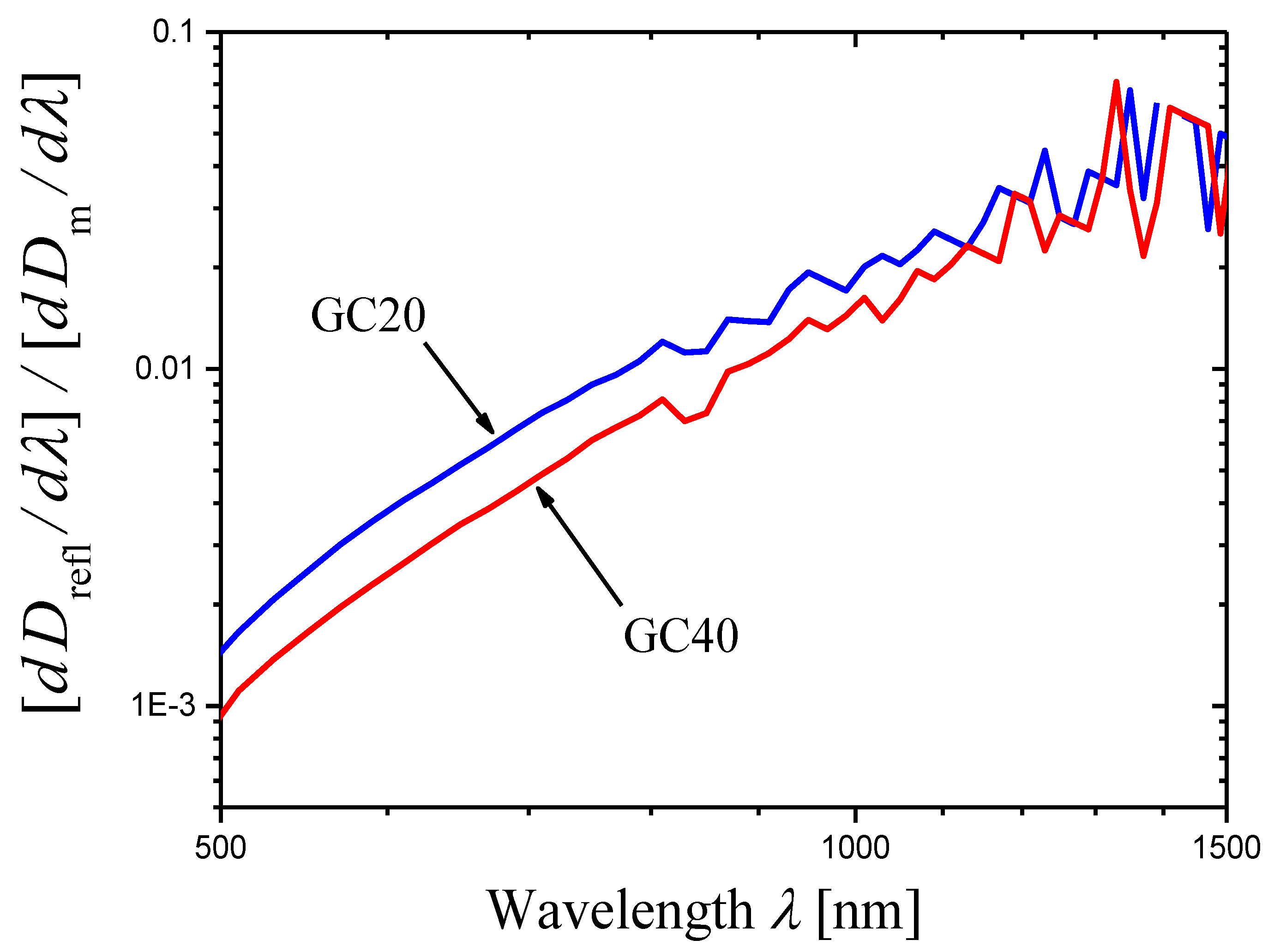

3.4. Applicability of the New Method to the Cases of Wavelength-Dependent Reflection Losses

- The internal optical densities of the thick and thin samples calculated by Equation (36) differ only by a constant factor: . The similar equation also applies to derivatives: . Thus, in the logarithmic representation (Figure 15), the curve of (curve 1′) can be obtained by shifting the curve of (curve 2′) along the y-axis. Figure 15 confirms this conclusion. A slight difference in slopes of curves 1′ and 2′ (see the text preceding Equation (37)) is due to different wavelength ranges of the linear approximation, shown by arrows in Figure 15.

- If the thicknesses of the thin and thick samples are significantly different (as in the case shown in Figure 15), the internal optical densities and of both samples (see Equation (36)) are determined to a greater extent by the measured optical density of the thick sample, the relative measurement error for which is smaller than for the thin one. Therefore, the curve 1′ is smoother than the curve 1, obtained from measurements made for the thin sample.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andreev, N.S. Scattering of visible light by glasses undergoing phase separation and homogenization. J. Non-Cryst. Solids 1978, 30, 99–126. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Dymshits, O.S.; Zhilin, A.A. Light scattering in glass-ceramics: Revision of the concept. J. Opt. Soc. Am. B 2018, 35, 1717–1724. [Google Scholar] [CrossRef]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles; Wiley: New York, NY, USA, 2004; pp. 36–41;+130–136. [Google Scholar]

- Shepilov, M.P. Angular distribution of light scattered by nanostructured glass predicted from experimental wavelength dependence of turbidity. OSA Contin. 2018, 1, 939–952. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Dymshits, O.S.; Zhilin, A.A.; Golubkov, V.V.; Kalmykov, A.E.; Myasoedov, A.V.; Hubetsov, A.A.; Zapalova, S.S. Effect of low NiO doping on anomalous light scattering in zinc aluminosilicate glass-ceramics. J. Non-Cryst. Solids 2017, 473, 152–169. [Google Scholar] [CrossRef]

- Levin, D.I. Rayleigh scattering in glasses and the structure of glass. In Collection: The Structure of Glass, Proceedings of the Conference on the Structure of Glass; Izd. Akad. Nauk SSSR: Moscow, Russia, 1955; pp. 198–201. (In Russian) [Google Scholar]

- Gurevich, M.M. Spectral dependence of light scattering in sodium borosilicate glasses. In Stroenie Stekla, Structure of Glass, Proceedings of the Conference on the Structure of Glass; Izd. Akad. Nauk SSSR: Moscow, Russia, 1955; pp. 202–206. (In Russian) [Google Scholar]

- Kolyadin, A.I. Anomalous light scattering in glass. Dokl. Akad. Nauk SSSR 1956, 109, 64–67. [Soviet Phys.-Doklady 1956, 1, 406–408] (In Russian) [Google Scholar]

- Kolyadin, A.I. Anomalous scattering of light in glass. Opt. Spektrosk. 1956, 1, 907–916. (In Russian) [Google Scholar]

- Beall, G.H.; Duke, D.A. Transparent glass-ceramics. J. Mater. Sci. 1969, 4, 340–352. [Google Scholar] [CrossRef]

- Beall, G.H.; Pinckney, L.R. Nanophase glass-ceramics. J. Am. Ceram. Soc. 1999, 82, 5–16. [Google Scholar] [CrossRef]

- Höland, W.; Beall, G.H. Glass-Ceramic Technology, 2nd ed.; Wiley: Hoboken, NJ, USA, 2012; pp. 271–272. [Google Scholar]

- Marghussian, V. Nano-Glass Ceramics: Processing, Properties and Applications; Elsevier: Amsterdam, The Netherlands, 2015; pp. 63–64. [Google Scholar] [CrossRef]

- Maeda, K.; Hirose, M.; Kobayashi, T. High performance transparent glass-ceramics for optical components. J. Ceram. Soc. Jpn. 2015, 123, 949–954. [Google Scholar] [CrossRef]

- Borrelli, N.F.; Mitchell, A.L.; Smith, C.M. Relationship between morphology and transparency in glass-ceramic materials. J. Opt. Soc. Am. B 2018, 35, 1725–1732. [Google Scholar] [CrossRef]

- Debye, P.; Bueche, A.M. Scattering by an inhomogeneous solid. J. Appl. Phys. 1949, 20, 518–525. [Google Scholar] [CrossRef]

- Shepilov, M.P. Relationship between morphology and transparency in glass-ceramic materials: Comment. J. Opt. Soc. Am. B 2019, 36, 1765–1768. [Google Scholar] [CrossRef]

- Hopper, R.W. Stochastic theory of scattering from idealized spinodal structures: II. Scattering in general and for the basic late stage model. J. Non-Cryst. Solids 1985, 70, 111–142. [Google Scholar] [CrossRef]

- Goldstein, M. Theory of scattering for diffusion-controlled phase separation. J. Appl. Phys. 1963, 34, 1928–1934. [Google Scholar] [CrossRef]

- Edgar, A. Core-shell particle model for optical transparency in glass ceramics. Appl. Phys. Lett. 2006, 89, 041909. [Google Scholar] [CrossRef]

- Hendy, S. Light scattering in transparent glass ceramics. Appl. Phys. Lett. 2002, 81, 1171–1173. [Google Scholar] [CrossRef]

- Mattarelli, M.; Gasperi, G.; Montagna, M.; Verrocchio, P. Transparency and longranged fluctuations: The case of glass ceramics. Phys. Rev. B 2010, 82, 094204. [Google Scholar] [CrossRef]

- Shepilov, M.P. Extremely low light scattering in nanostructured glasses formed by simultaneous nucleation and diffusion-limited growth of particles: Modeling. Opt. Lett. 2020, 45, 3645–3648. [Google Scholar] [CrossRef] [PubMed]

- Shepilov, M.P. Anomalous light scattering in nanostructured glasses formed by simultaneous nucleation and diffusion-limited growth of particles: Modelling. J. Non-Cryst. Solids 2023, 600, 121958. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Kalmykov, A.E.; Sycheva, G.A. Liquid–liquid phase separation in sodium borosilicate glass: Ordering phenomena in particle arrangement. J. Non-Cryst. Solids 2007, 353, 2415–2430. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Dymshits, O.S.; Zhilin, A.A.; Kalmykov, A.E.; Sycheva, G.A. Features of the anomalous scattering of light in two-phase sodium borosilicate glass. J. Opt. Technol. 2013, 80, 706–713. [Google Scholar] [CrossRef]

- Shepilov, M.P. Asymmetry parameter for anomalous scattering of light in nanostructured glasses. Opt. Lett. 2017, 42, 4513–4516. [Google Scholar] [CrossRef] [PubMed]

- Dunch, T.; Jackson, S. Rayleigh scattering with material dispersion for low volume fraction transparent glass ceramics. Opt. Mater. Express 2022, 12, 2595–2608. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Dymshits, O.S.; Alekseeva, I.P.; Zhilin, A.A.; Zapalova, S.S.; Verbo, V.A. Inconsistency between light scattering in magnesium aluminosilicate glass-ceramics and their nanostructure. J. Opt. Technol. 2018, 85, 738–741. [Google Scholar] [CrossRef]

- Berthier, T.; Fokin, V.M.; Zanotto, E.D. New large grain, highly crystalline, transparent glass-ceramics. J. Non-Cryst. Solids 2008, 354, 1721–1730. [Google Scholar] [CrossRef]

- Apetz, R.; van Bruggen, M.P.B. Transparent alumina: A light-scattering model. J. Am. Ceram. Soc. 2003, 86, 480–486. [Google Scholar] [CrossRef]

- Milisavljevic, I.; Pitcher, M.J.; Li, J.; Chenu, S.; Allix, M.; Wu, Y. Crystallization of glass materials into transparent optical ceramics. Int. Mater. Rev. 2022. [Google Scholar] [CrossRef]

- Hříbalová, S.; Pabst, W. Transmittance predictions for transparent alumina ceramics based on the complete grain size distribution or a single mean grain size replacing the whole distribution. J. Eur. Ceram. Soc. 2022, 42, 5093–5107. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Dymshits, O.S.; Zhilin, A.A.; Zapalova, S.S. On the measurements of scattering coefficient of nanostructured glass-ceramics by a serial spectrophotometer. Measurement 2017, 95, 306–316. [Google Scholar] [CrossRef]

- Shepilov, M.P.; Upender, G.; Dymshits, O.S.; Zhilin, A.A. Light scattering in Eu3+-doped glass-ceramics containing SrIINbIVO3 nanocrystals. J. Opt. Soc. Am. B 2018, 35, 3116–3121. [Google Scholar] [CrossRef]

- Shepilov, M.; Dymshits, O.; Alekseeva, I.; Hubetsov, A.; Shemchuk, D.; Zhilin, A. Structure and anomalous light scattering of Er-doped transparent glass-ceramics containing ZnO nanocrystals. J. Non-Cryst. Solids 2021, 571, 121067. [Google Scholar] [CrossRef]

- Alekseeva, I.P.; Dymshits, O.S.; Golubkov, V.V.; Loiko, P.A.; Tsenter, M.Y.; Yumashev, K.V.; Zapalova, S.S.; Zhilin, A.A. Influence of NiO on phase transformations and optical properties of ZnO–Al2O3–SiO2 glass-ceramics nucleated by TiO2 and ZrO2. Part, I. Influence of NiO on phase transformations of ZnO–Al2O3–SiO2 glass-ceramics nucleated by TiO2 and ZrO2. J. Non-Cryst. Solids 2014, 384, 73–82. [Google Scholar] [CrossRef]

- Alekseeva, I.P.; Dymshits, O.S.; Zhilin, A.A.; Zapalova, S.S.; Shepilov, M.P.; Golubkov, V.V.; Kalmykov, A.E.; Myacoedov, A.V. Anomalies in light scattering by glass-ceramics of the zinc aluminum silicate system, caused by low nickel oxide doping. J. Opt. Technol. 2014, 81, 729–734. [Google Scholar] [CrossRef]

- Dymshits, O.S.; Zhilin, A.A.; Petrov, V.I.; Tsenter, M.Y.; Chuvaeva, T.I.; Shashkin, A.V.; Golubkov, V.V.; Kang, U.; Lee, K.H. Raman spectroscopic study of phase transformations in titanium-containing magnesium aluminosilicate glasses. Glass Phys. Chem. 2002, 28, 66–78. [Google Scholar] [CrossRef]

- Golubkov, V.V.; Dymshits, O.S.; Zhilin, A.A.; Chuvaeva, T.I.; Shashkin, A.V. On the phase separation and crystallization of glasses in the MgO-Al2O3-SiO2-TiO2 system. Glass Phys. Chem. 2003, 29, 254–266. [Google Scholar] [CrossRef]

- Gangadharini, U.; Molla, A.R.; Tarafder, A.; Karmakar, B. Synthesis and characterization of Eu3+-doped transparent glass-ceramics containing nanocrystalline SrIINbIVO3. J. Am. Ceram. Soc. 2013, 96, 2155–2162. [Google Scholar] [CrossRef]

- Shemchuk, D.V.; Alekseeva, I.P.; Zhilin, A.A.; Tsenter, M.Y.; Loiko, P.A.; Volokitina, A.A.; Khubetsov, A.A.; Dymshits, O.S. The influence of ytterbium oxide on the phase composition, structure and spectral properties of transparent glass-ceramics based on ZnO. In Proceedings of the XIX All-Russian Conference of Young Scientists “Functional materials: Synthesis, Properties, Applications”, Saint-Petersburg, Russia, 1–3 December 2020; LEMA: Saint-Petersburg, Russia, 2020; pp. 106–108, 241p. (In Russian). [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shepilov, M.; Dymshits, O.; Zhilin, A. A Simple Method for Estimation of the Scattering Exponent of Nanostructured Glasses. Materials 2023, 16, 2630. https://doi.org/10.3390/ma16072630

Shepilov M, Dymshits O, Zhilin A. A Simple Method for Estimation of the Scattering Exponent of Nanostructured Glasses. Materials. 2023; 16(7):2630. https://doi.org/10.3390/ma16072630

Chicago/Turabian StyleShepilov, Michael, Olga Dymshits, and Aleksandr Zhilin. 2023. "A Simple Method for Estimation of the Scattering Exponent of Nanostructured Glasses" Materials 16, no. 7: 2630. https://doi.org/10.3390/ma16072630

APA StyleShepilov, M., Dymshits, O., & Zhilin, A. (2023). A Simple Method for Estimation of the Scattering Exponent of Nanostructured Glasses. Materials, 16(7), 2630. https://doi.org/10.3390/ma16072630