Use of Functionally Graded Material to Decrease Maximum Temperature of a Coating–Substrate System

Abstract

1. Introduction

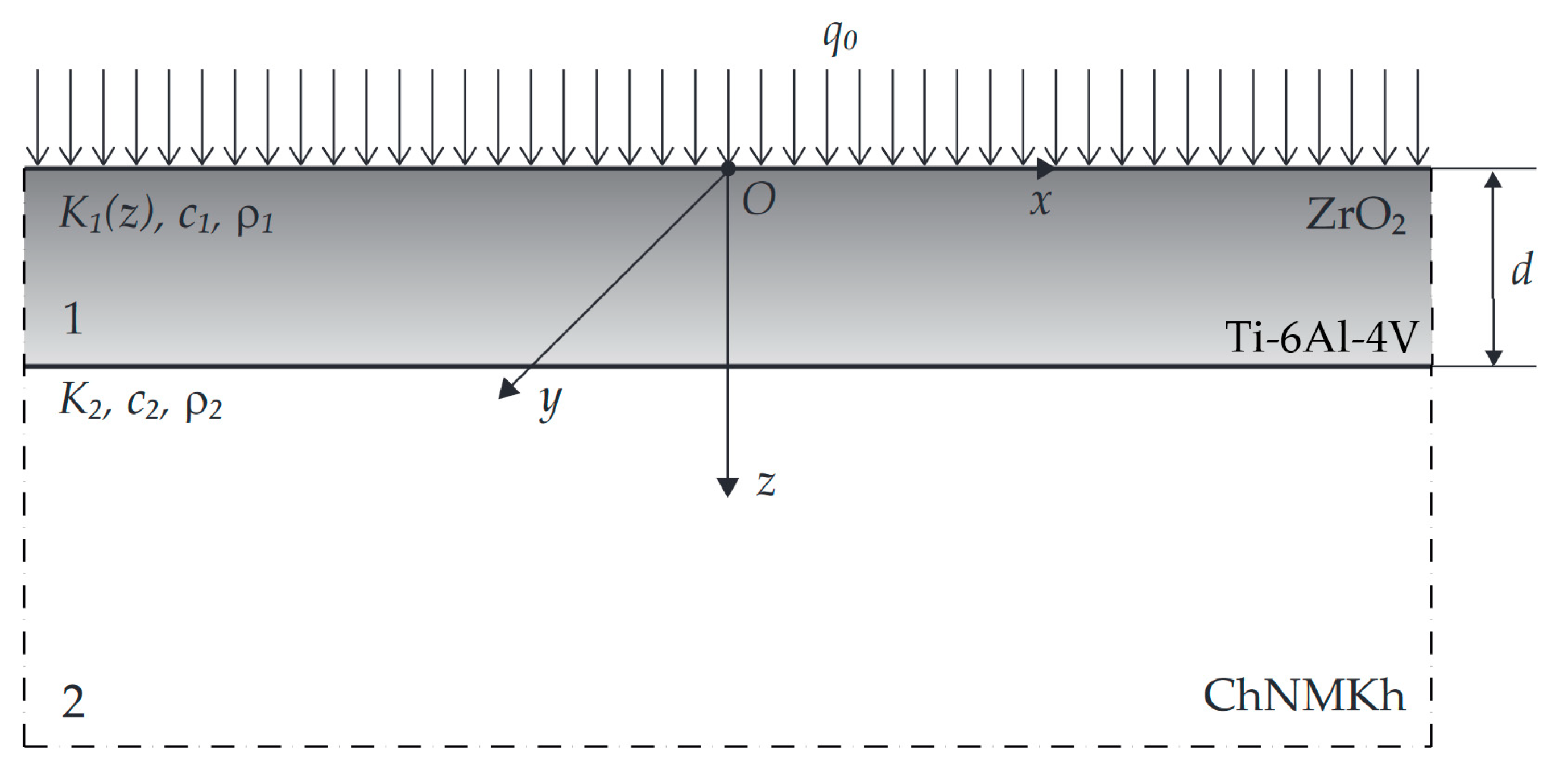

2. Statement to the Problem

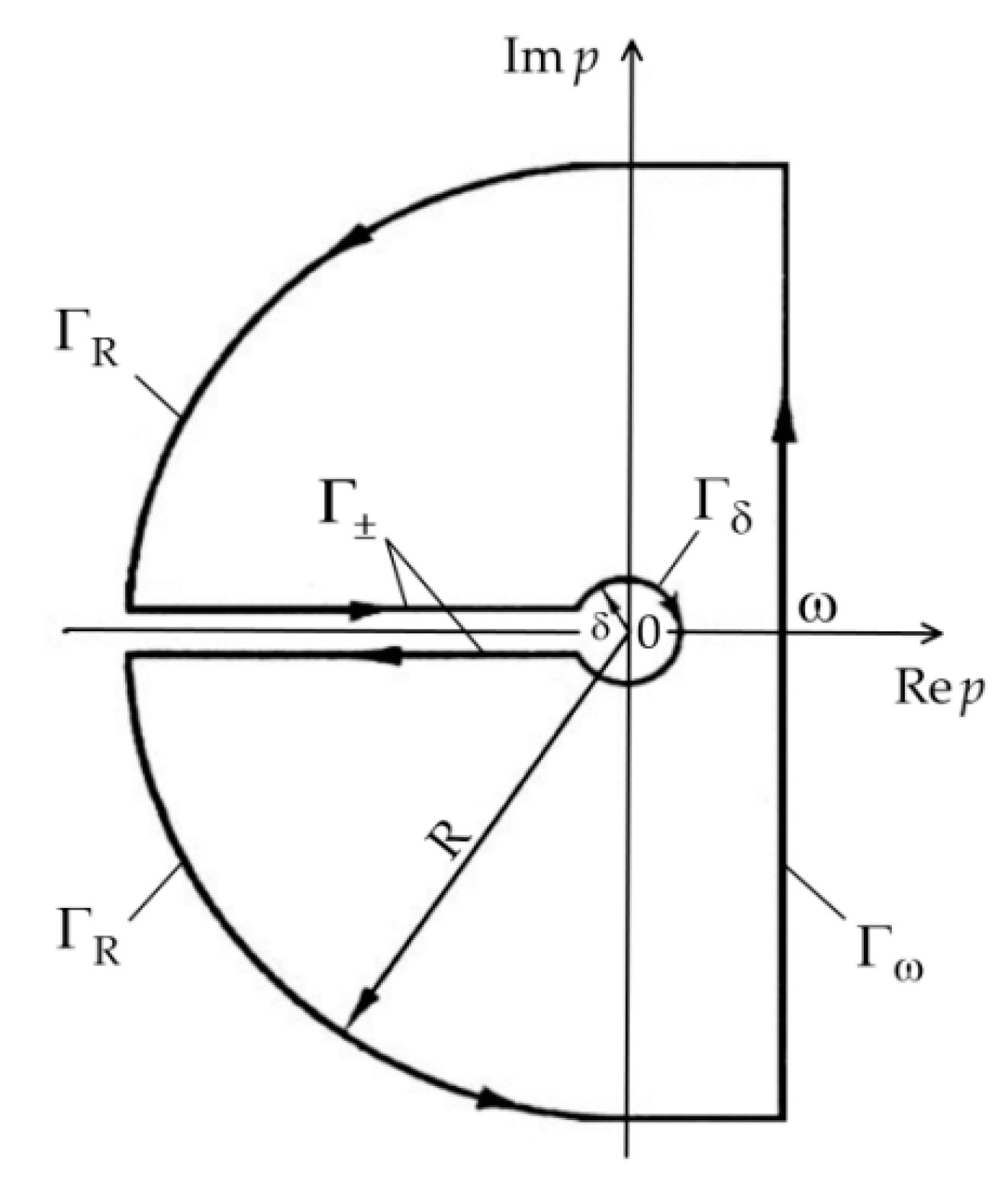

3. Solution to the Problem

4. Verification of the Solution

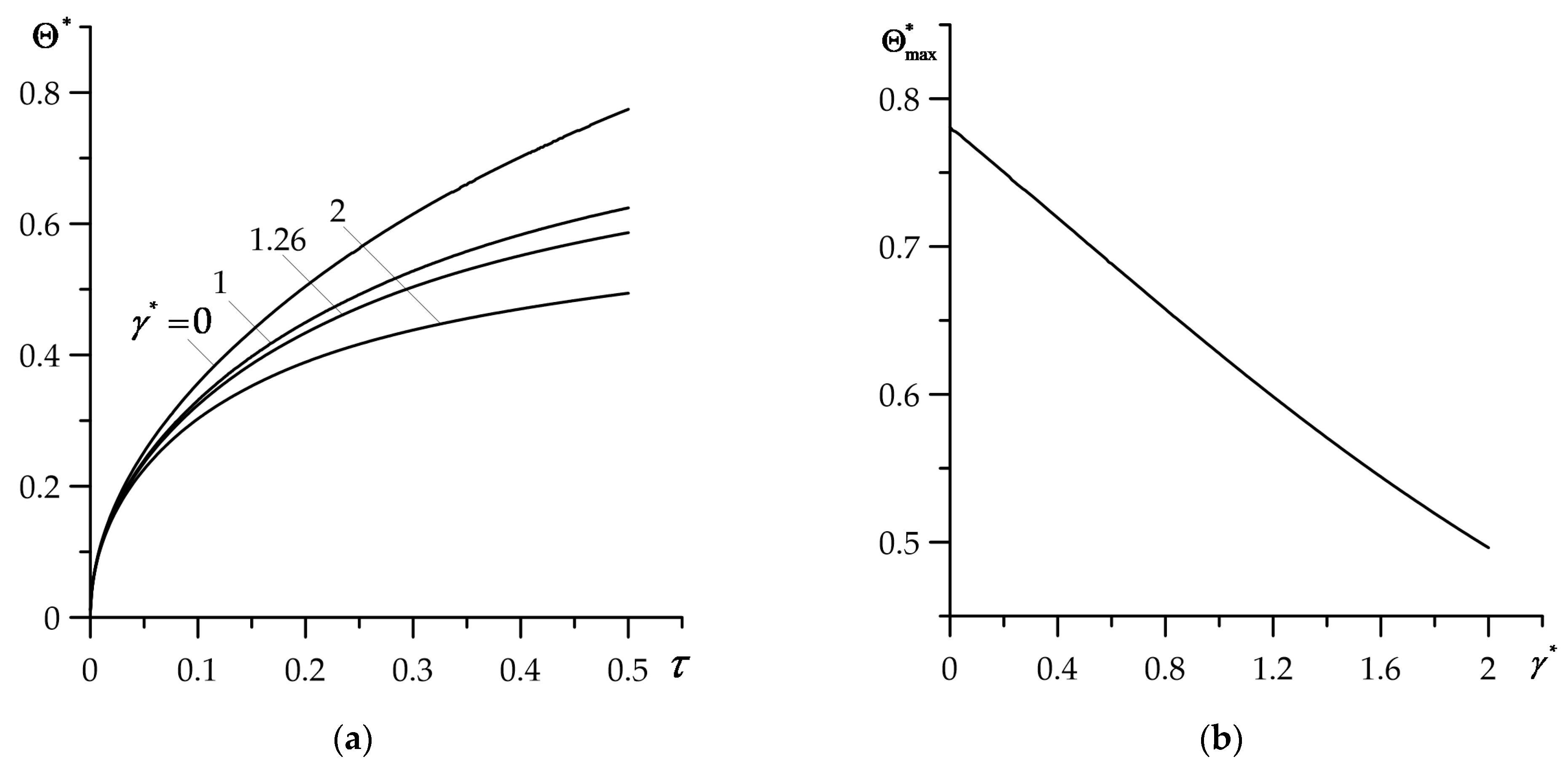

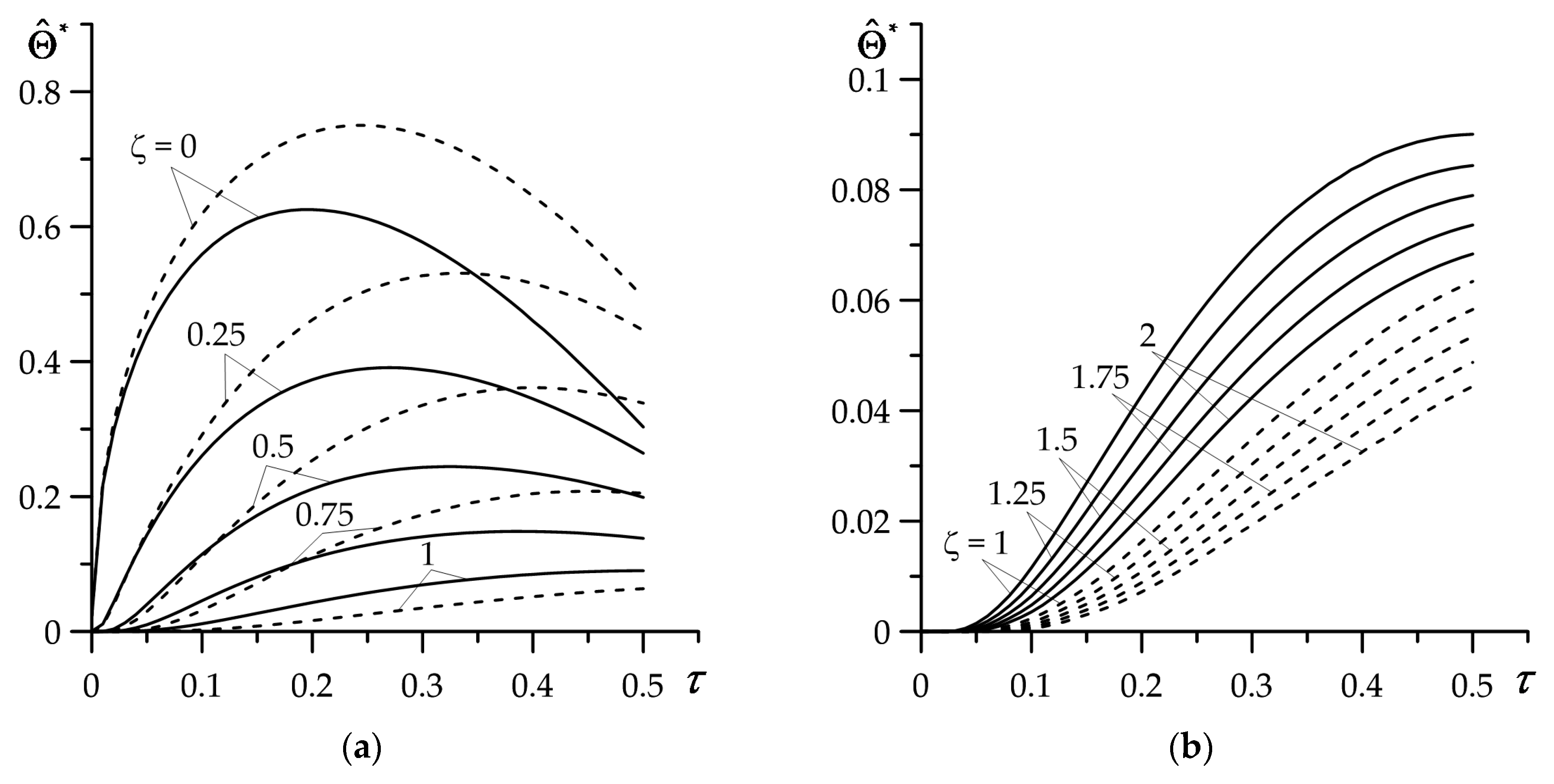

5. Heating the Coating Surface by a Heat Flux with Linearly Decreasing Intensity in Time

6. Numerical Analysis

7. Conclusions

- Deposition of functionally graded coating on the homogeneous substrate allow to effectively lower the temperature on the heated surface;

- FGC is the main adsorbent of frictional heat generated. As a result, values of temperature achieved in the substrate are much lower than that obtained in the coating temperature level;

- The temporal profile of the heat flux intensity has a noticeable impact on the spatial-temporal distribution of isotherms only in the coating;

- Gradient parameter of the FGC has a crucial influence on the maximum temperature for the selected coating–substrate system;

- Obtained asymptotic solutions are useful for the express estimation of the temperature of the FGC-substrate system at small and large values of the Fourier number;

- The proposed mathematical model can be utilized as an effective tool for simulating the temperature mode of homogeneous bodies with functionally graded coating.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Specific heat capacity () | |

| Thickness of FGC () | |

| Modified Bessel functions of the nth order of the first kind | |

| Bessel functions of the nth order of the first kind | |

| Modified Bessel functions of the nth order of the second kind | |

| Thermal diffusivity () | |

| Thermal conductivity () | |

| Intensity of heat flux () | |

| Nominal value of the heat flux intensity () | |

| Time () | |

| Final moment of the heating process () | |

| Temperature (°C) | |

| Initial temperature (°C) | |

| Volume fraction of the material phases (dimensionless) | |

| Bessel functions of the nth order of the second kind | |

| Spatial coordinate in axial direction () | |

| Parameter of FGM gradient () | |

| Dimensionless parameter of FGM gradient | |

| Temperature rise scaling factor (°C) | |

| Dimensionless coefficient of thermal activity of friction couple | |

| Temperature rise (°C) | |

| Dimensionless temperature rise | |

| Density () | |

| Dimensionless time | |

| Dimensionless final time of heating | |

| Dimensionless spatial coordinate in axial direction |

References

- Alinia, Y.; Beheshti, A.; Guler, M.A.; El-Borgi, S.; Polycarpou, A.A. Sliding contact analysis of functionally graded coating/substrate system. Mech. Mater. 2016, 94, 142–155. [Google Scholar] [CrossRef]

- Kulchytsky-Zhyhailo, R.; Bajkowski, A. Analytical and numerical methods of solution of three-dimensional problem of elasticity for functionally graded coated half-space. Int. J. Mech. Sci. 2012, 54, 105–112. [Google Scholar] [CrossRef]

- Bishnoi, D. Pressure exertion and heat dissipation analysis on uncoated and ceramic (Al2O3, TiO2 and ZrO2) coated braking pads. Mater. Today Proc. 2023, 74, 774–787. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Kuciej, M.; Och, E. Influence of thermal sensitivity of the materials on temperature and thermal stresses of the brake disc with thermal barrier coating. Int. Commun. Heat Mass Transf. 2017, 87, 288–294. [Google Scholar] [CrossRef]

- Varecha, D.; Bronček, J.; Kohar, R.; Nový, F.; Vicen, M.; Radek, N. Research of friction materials applicable to the multi-disc brake concept. J. Mater. Res. Technol. 2021, 14, 647–661. [Google Scholar] [CrossRef]

- Strojny-Nędza, A.; Pietrzak, K.; Gili, F.; Chmielewski, M. FGM based on copper–alumina composites for brake disc applications. Arch. Civ. Mech. Eng. 2020, 20, 83. [Google Scholar] [CrossRef]

- Govindaraju, M.; Megalingam, A.; Murugasan, J.; Vignesh, R.V.; Kota, P.K.; Ram, A.S.; Lakshana, P.; Kumar, V.N. Investigations on the tribological behavior of functionally gradient iron-based brake pad material. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 2474–2486. [Google Scholar] [CrossRef]

- Babu, K.V.; Marichamy, S.; Ganesan, P.; Madan, D.; Uthayakumar, M.; Rajan, T.P. Processing of functionally graded aluminum composite brake disc and machining parameters optimization. Mater. Today Proc. 2020, 21, 563–567. [Google Scholar] [CrossRef]

- Pakseresht, A.H.; Rahimipour, M.R.; Alizadeh, M.; Hadavi, S.M.M.; Shahbazkhan, A. Concept of advanced thermal barrier functional coatings in high temperature engineering components. In Research Perspectives on Functional Micro- and Nanoscale Coatings; Zuzuarregui, A., Morant-Minana, M.C., Eds.; IGI Global: Hershey, PA, USA, 2016; pp. 396–419. [Google Scholar] [CrossRef]

- Buyukkaya, E. Thermal analysis of functionally graded coating AlSi alloy and steel pistons. Surf. Coat. Technol. 2008, 202, 3856–3865. [Google Scholar] [CrossRef]

- Mondal, K.; Nuñez III, L.; Downey, C.M.; Van Rooyen, I.J. Recent advances in the thermal barrier coatings for extreme environments. Mater. Sci. Energy Technol. 2021, 4, 208–210. [Google Scholar] [CrossRef]

- Topczewska, K. Analytical model for investigation of the effect of friction power on the thermal stresses in friction elements of brakes. J. Theor. Appl. Mech. 2018, 56, 1017–1027. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Ai, X. Analysis of transient thermal stress in sandwich plate with functionally graded coatings. Thin Solid Film. 2008, 516, 7581–7587. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Saleh, B.A. critical review on functionally graded coatings: Methods, properties, and challenges. Compos. Part B Eng. 2021, 225, 109278. [Google Scholar] [CrossRef]

- Pasupuleti, K.T.; Dsouza, S.; Thejaraju, R.; Venkataraman, S.; Ramaswamy, P.; Murty, S.N. Performance and steady state heat transfer analysis of functionally graded thermal barrier coatings systems. Mater. Today Proc. 2018, 5, 27936–27945. [Google Scholar] [CrossRef]

- Suresh, S. Graded materials for resistance to contact deformation and damage. Science 2001, 292, 2447–2451. [Google Scholar] [CrossRef]

- Khor, K.A.; Gu, Y.W. Thermal properties of plasma-sprayed functionally graded thermal barrier coatings. Thin Solid Film. 2000, 372, 104–113. [Google Scholar] [CrossRef]

- Balci, M.N.; Dag, S.; Yildirim, B. Subsurface stresses in graded coatings subjected to frictional contact with heat generation. J. Therm. Stress. 2017, 40, 517–534. [Google Scholar] [CrossRef]

- Balci, M.N.; Dag, S. Solution of the dynamic frictional contact problem between a functionally graded coating and a moving cylindrical punch. Int. J. Solids Struct. 2019, 161, 267–281. [Google Scholar] [CrossRef]

- Fu, P.; Zhao, J.; Zhang, X.; Kang, G.; Wang, P.; Kan, Q. Thermo-mechanically coupled sliding contact shakedown analysis of functionally graded coating-substrate structures. Int. J. Mech. Sci. 2022, 222, 107241. [Google Scholar] [CrossRef]

- Jin, Z.H. An asymptotic solution of temperature field in a strip a functionally graded material. Int. Commun. Heat Mass Transf. 2002, 29, 887–895. [Google Scholar] [CrossRef]

- Jobin, K.J.; Abhilash, M.N.; Murthy, H. A simplified analysis of 2D sliding frictional contact between rigid indenters and FGM coated substrates. Tribol. Int. 2017, 108, 174–185. [Google Scholar] [CrossRef]

- Burlayenko, V.N.; Altenbach, H.; Sadowski, T.; Dimitrova, S.D.; Bhaskar, A. Modelling functionally graded materials in heat transfer and thermal stress analysis by means of graded finite elements. Appl. Math. Model. 2017, 45, 422–438. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Topczewska, K.; Zamojski, P. Temperature during Repetitive Short-Term Operation of a Brake with Functionally Graded Friction Element. Materials 2023, 16, 881. [Google Scholar] [CrossRef]

- Jojith, R.; Sam, M.; Radhika, N. Recent advances in tribological behavior of functionally graded composites: A review. Eng. Sci. Technol. Int. J. 2022, 25, 100999. [Google Scholar] [CrossRef]

- Bhandari, M.; Purohit, K. Dynamic fracture analysis of functionally graded material structures—A critical review. Compos. Part C Open Access 2022, 7, 100227. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Topczewska, K.; Zamojski, P. The Effect of Functionally Graded Materials on Temperature During Frictional Heating: Under Uniform Sliding. Materials 2021, 14, 4285. [Google Scholar] [CrossRef]

- Topczewska, K.; Gerlici, J.; Yevtushenko, A.; Kuciej, M.; Kravchenko, K. Analytical Model of the Frictional Heating in a Railway Brake Disc at Single Braking with Experimental Verification. Materials 2022, 15, 6821. [Google Scholar] [CrossRef] [PubMed]

- Rahmati Nezhad, Y.; Asemi, K.; Akhlaghi, M. Transient solution of temperature field in functionally graded hollow cylinder with finite length using multi layered approach. Int. J. Mech. Mater. Des. 2011, 7, 71–82. [Google Scholar] [CrossRef]

- Kulchytsky-Zhyhailo, R.; Bajkowski, A.S. Axisymmetrical problem of thermoelasticity for half-space with gradient coating. Int. J. Mech. Sci. 2016, 106, 62–71. [Google Scholar] [CrossRef]

- Kiani, Y.; Eslami, M.R. Geometrically non-linear rapid heating of temperature-dependent circular FGM plates. J. Therm. Stress. 2014, 37, 1495–1518. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Topczewska, K.; Zamojski, P. The Heat Partition Ratio during Braking in a Functionally Graded Friction Couple. Materials 2022, 15, 4623. [Google Scholar] [CrossRef]

- Yevtushenko, A.; Kuciej, M.; Topczewska, K.; Zamojski, P. Temperature in the Friction Couple Consisting of Functionally Graded and Homogeneous Materials. Materials 2022, 15, 3600. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.W.; Jang, Y.H. Frictionally excited thermoelastic instability in a thin layer of functionally graded material sliding between two half-planes. Wear 2009, 267, 1715–1722. [Google Scholar] [CrossRef]

- Liu, J.; Ke, L.L.; Wang, Y.S. Two-dimensional thermoelastic contact problem of functionally graded materials involving frictional heating. Int. J. Solids Struct. 2011, 48, 2536–2548. [Google Scholar] [CrossRef]

- Suresh, S.; Mortensen, A. Fundamentals of Functionally Graded Materials; The Institute of Materials, IOM Communications Ltd.: London, UK, 1998. [Google Scholar]

- Sneddon, I.N. The Use of Integral Transforms; McGraw-Hill: New York, NY, USA, 1972. [Google Scholar]

- Abramowitz, M.; Stegun, I. Handbook of Mathematical Functions with Formulas, Graphs, and Mathematical Tables; United States Department of Commerce, National Bureau of Standards (NBS): Washington, DC, USA, 1964.

- Bateman, H.; Erdelyi, A. Tables of Integrals Transforms; McGraw-Hill: New York, NY, USA, 1954; Volume 1. [Google Scholar]

- Luikov, A.V. Analitycal Heat Diffusion Theory; Academic Press: New York, NY, USA, 1968. [Google Scholar]

- Barber, J.R.; Martin-Moran, C.J. Green’s functions for transient thermoelastic contact problems for the half-plane. Wear 1982, 79, 11–19. [Google Scholar] [CrossRef]

- Yevtushenko, A.A.; Kuciej, M.; Topczewska, K. Analytical model for investigation of the effect of friction power on temperature in the disc brake. Adv. Mech. Eng. 2017, 9, 1–12. [Google Scholar] [CrossRef]

- Özis̨ik, N.M. Heat Conduction; John Wiley: New York, NY, USA, 1993. [Google Scholar]

- Chichinadze, A.V. Polymers in Friction Assembles of Machines and Devices: A Handbook; Allerton Press Inc.: New York, NY, USA, 1984. [Google Scholar]

- Mao, J.J.; Ke, L.L.; Yang, J.; Kitipornchai, S.; Wang, Y.S. The coupled thermoelastic instability of FGM coatings with arbitrarily varying properties: In-plane sliding. Acta Mech. 2018, 229, 2979–2995. [Google Scholar] [CrossRef]

- Piessens, R.; De Doneker-Kapenga, E.; Überhuber, C.W.; Kahaner, D.K. Quadpack: A Subroutine for Automatic Integration; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 1. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yevtushenko, A.; Topczewska, K.; Zamojski, P. Use of Functionally Graded Material to Decrease Maximum Temperature of a Coating–Substrate System. Materials 2023, 16, 2265. https://doi.org/10.3390/ma16062265

Yevtushenko A, Topczewska K, Zamojski P. Use of Functionally Graded Material to Decrease Maximum Temperature of a Coating–Substrate System. Materials. 2023; 16(6):2265. https://doi.org/10.3390/ma16062265

Chicago/Turabian StyleYevtushenko, Aleksander, Katarzyna Topczewska, and Przemysław Zamojski. 2023. "Use of Functionally Graded Material to Decrease Maximum Temperature of a Coating–Substrate System" Materials 16, no. 6: 2265. https://doi.org/10.3390/ma16062265

APA StyleYevtushenko, A., Topczewska, K., & Zamojski, P. (2023). Use of Functionally Graded Material to Decrease Maximum Temperature of a Coating–Substrate System. Materials, 16(6), 2265. https://doi.org/10.3390/ma16062265