Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel–Titanium Rotary Files

Abstract

1. Introduction

2. Materials and Methods

2.1. Simulated Canal Preparation

2.2. Cyclic Fatigue Resistance Test

2.3. Experimental Test of Torsional Resistance

2.4. Statistical Analysis

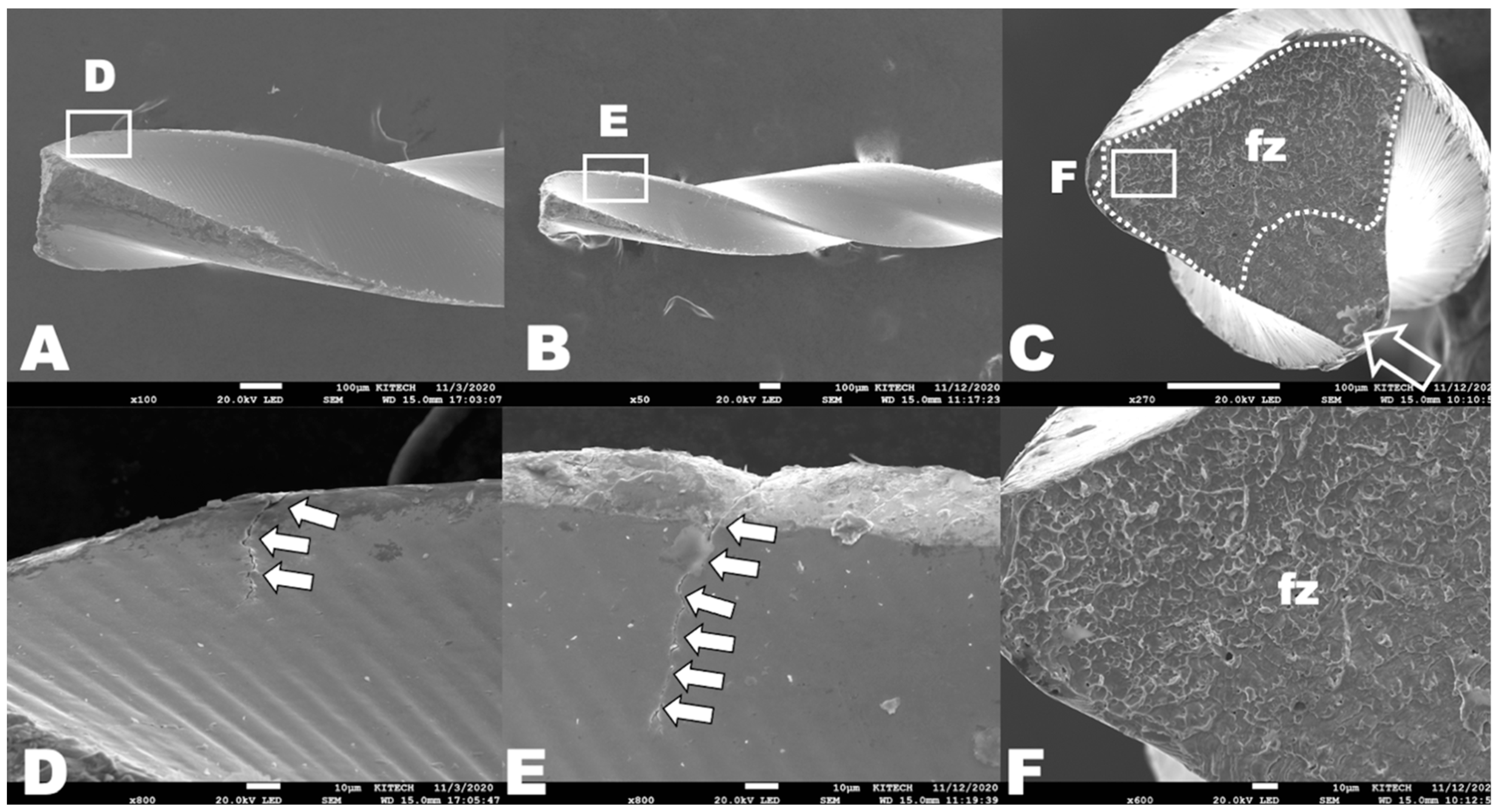

2.5. Scanning Electron Microscopy (SEM) Evaluation

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gavini, G.; Santos, M.D.; Caldeira, C.L.; Machado, M.E.L.; Freire, L.G.; Iglecias, E.F.; Peters, O.A.; Candeiro, G.T.M. Nickel-titanium instruments in endodontics: A concise review of the state of the art. Braz. Oral. Res. 2018, 32 (Suppl. S1), e67. [Google Scholar] [CrossRef] [PubMed]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New thermomechanically treated NiTi alloys—A review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef] [PubMed]

- Parashos, P.; Messer, H.H. Rotary NiTi instrument fracture and its consequences. J. Endod. 2006, 32, 1031–1043. [Google Scholar] [CrossRef]

- Zelada, G.; Varela, P.; Martín, B.; Bahíllo, J.G.; Magán, F.; Ahn, S. The effect of rotational speed and the curvature of root canals on the breakage of rotary endodontic instruments. J. Endod. 2002, 28, 540–542. [Google Scholar] [CrossRef]

- Cheung, G.S.; Oh, S.H.; Ha, J.H.; Kim, S.K.; Park, S.H.; Kim, H.C. Effect of torsional loading of nickel-titanium instruments on cyclic fatigue resistance. J. Endod. 2013, 39, 1593–1597. [Google Scholar] [CrossRef] [PubMed]

- Ashok, L.; Krishnan, V.; Nair, R.S.; Angelo, M.C. An Overview of Thermomechanically Heat-treated Nickel–Titanium Alloy Used in Endodontics. Cons. Dent. Endod. J. 2019, 4, 34–38. [Google Scholar]

- Kwak, S.W.; Shen, Y.; Liu, H.; Wang, Z.; Kim, H.C.; Haapasalo, M. Heat Treatment and Surface Treatment of Nickel–Titanium Endodontic Instruments. Front. Dent. Med. 2021, 2, 769977. [Google Scholar] [CrossRef]

- Kuhn, G.; Jordan, L. Fatigue and mechanical properties of nickel-titanium endodontic instruments. J. Endod. 2002, 28, 716–720. [Google Scholar] [CrossRef] [PubMed]

- Yahata, Y.; Yoneyama, T.; Hayashi, Y.; Ebihara, A.; Doi, H.; Hanawa, T.; Suda, H. Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 2009, 42, 621–626. [Google Scholar] [CrossRef]

- Kim, J.Y.; Cheung, G.S.; Park, S.H.; Ko, D.C.; Kim, J.W.; Kim, H.C. Effect from cyclic fatigue of nickel-titanium rotary files on torsional resistance. J. Endod. 2012, 38, 527–530. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Kim, S.K.; Cheung, G.S.; Jeong, S.H.; Bae, Y.C.; Kim, H.C. Effect of alloy type on the life-time of torsion-preloaded nickel-titanium endodontic instruments. Scanning 2015, 37, 172–178. [Google Scholar] [CrossRef]

- Spagnuolo, G.; Ametrano, G.; D’Antò, V.; Rengo, C.; Simeone, M.; Riccitiello, F.; Amato, M. Effect of autoclaving on the surfaces of TiN -coated and conventional nickel-titanium rotary instruments. Int. Endod. J. 2012, 45, 1148–1155. [Google Scholar] [CrossRef]

- Zhao, D.; Shen, Y.; Peng, B.; Haapasalo, M. Effect of autoclave sterilization on the cyclic fatigue resistance of thermally treated Nickel-Titanium instruments. Int. Endod. J. 2016, 49, 990–995. [Google Scholar] [CrossRef]

- Pun, D.K.; Berzins, D.W. Corrosion behavior of shape memory, superelastic, and nonsuperelastic nickel-titanium-based orthodontic wires at various temperatures. Dent. Mater. 2008, 24, 221–227. [Google Scholar] [CrossRef] [PubMed]

- Silvaggio, J.; Hicks, M.L. Effect of heat sterilization on the torsional properties of rotary nickel-titanium endodontic files. J. Endod. 1997, 23, 731–734. [Google Scholar] [CrossRef] [PubMed]

- Viana, A.C.; Gonzalez, B.M.; Buono, V.T.; Bahia, M.G. Influence of sterilization on mechanical properties and fatigue resistance of nickel-titanium rotary endodontic instruments. Int. Endod. J. 2006, 39, 709–715. [Google Scholar] [CrossRef] [PubMed]

- Canalda-Sahli, C.; Brau-Aguadé, E.; Sentís-Vilalta, J. The effect of sterilization on bending and torsional properties of K-files manufactured with different metallic alloys. Int. Endod. J. 1998, 31, 48–52. [Google Scholar] [CrossRef] [PubMed]

- King, J.B.; Roberts, H.W.; Bergeron, B.E.; Mayerchak, M.J. The effect of autoclaving on torsional moment of two nickel-titanium endodontic files. Int. Endod. J. 2012, 45, 156–161. [Google Scholar] [CrossRef]

- Mize, S.B.; Clement, D.J.; Pruett, J.P.; Carnes, D.L., Jr. Effect of sterilization on cyclic fatigue of rotary nickel-titanium endodontic instruments. J. Endod. 1998, 24, 843–847. [Google Scholar] [CrossRef]

- The One Curve Brochure. Micro-Mega. Available online: http://micro-mega.com/wp-content/uploads/2018/03/Brochure-One-Curve-EN-1.pdf (accessed on 4 January 2018).

- Micoogullari Kurt, S.; Kaval, M.E.; Serefoglu, B.; Kandemir Demirci, G.; Çalışkan, M.K. Cyclic fatigue resistance and energy dispersive X-ray spectroscopy analysis of novel heat-treated nickel-titanium instruments at body temperature. Microsc. Res. Tech. 2020, 83, 790–794. [Google Scholar] [CrossRef]

- Serafin, M.; De Biasi, M.; Franco, V.; Angerame, D. In vitro comparison of cyclic fatigue resistance of two rotary single-file endodontic systems: OneCurve versus OneShape. Odontology. 2019, 107, 196–201. [Google Scholar] [CrossRef] [PubMed]

- El Abed, R.; Alshehhi, A.; Kang, Y.J.; Al Raeesi, D.; Khamis, A.H.; Jamal, M.; Kim, H.C. Fracture Resistance of Heat-Treated Nickel-Titanium Rotary Files After Usage and Autoclave Sterilization: An In Vitro Study. J. Endod. 2022, 48, 1428–1433. [Google Scholar] [CrossRef] [PubMed]

- Ha, J.H.; Kim, S.K.; Cohenca, N.; Kim, H.C. Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J. Endod. 2013, 39, 389–393. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.N.R.; Martins, R.F.; Braz Fernandes, F.M.; Silva, E.J.N.L. What Meaningful Information Are the Instruments Mechanical Testing Giving Us? A Comprehensive Review. J. Endod. 2022, 48, 985–1004. [Google Scholar] [CrossRef] [PubMed]

- Topçuoğlu, H.S.; Topçuoğlu, G.; Kafdağ, Ö.; Balkaya, H. Effect of two different temperatures on resistance to cyclic fatigue of one Curve, EdgeFile, HyFlex CM and ProTaper next files. Aust. Endod. J. 2020, 46, 68–72. [Google Scholar] [CrossRef]

- Elnaghy Amr, M.; Elsaka Shaymaa, E. Cyclic fatigue and torsional resistance of heat-treated One Curve compared with different nickel-titanium rotary instruments. Endo. Ept. 2019, 13, 247–253. [Google Scholar]

- Lausmaa, J. Mechanical, thermal, chemical and electrochemical surface treatment of titanium. In Titanium in Medicine: Materials Science, Surface Science, Engineering, Biological Responses and Medical Applications, 1st ed.; Brunette, D.M., Tengvall, P., Textor, M., Thomsen, P., Eds.; Springer: Berlin, Germany, 2001; pp. 247–248. [Google Scholar]

- Anderson, M.E.; Price, J.W.; Parashos, P. Fracture resistance of electropolished rotary nickel-titanium endodontic instruments. J. Endod. 2007, 33, 1212–1216. [Google Scholar] [CrossRef] [PubMed]

- Bui, T.B.; Mitchell, J.C.; Baumgartner, J.C. Effect of electropolishing ProFile nickel-titanium rotary instruments on cyclic fatigue resistance, torsional resistance, and cutting efficiency. J. Endod. 2008, 34, 190–193. [Google Scholar] [CrossRef] [PubMed]

- ISO3630–3631; Dentistry—Root Canal Instruments—Part 1: General Requirements and Test Methods. ISO: Geneva, Switzerland, 2019.

- Xu, X.; Eng, M.; Zheng, Y.; Eng, D. Comparative study of torsional and bending properties for six models of nickel-titanium root canal instruments with different cross-sections. J. Endod. 2006, 32, 372–375. [Google Scholar] [CrossRef]

- Shabalovskaya, S.A.; Anderegg, J.W. Surface spectroscopic characterization of TiNi nearly equitamic shape memory alloys for implant. J. Vac. Sci. Technol. 1995, 13, 2624–2632. [Google Scholar] [CrossRef]

- Rapisarda, E.; Bonaccorso, A.; Tripi, T.R. Condorelli GG. Effect of sterilization on the cutting efficiency of rotary nickel-titanium endodontic files. Oral. Surg. Oral. Med. Oral. Pathol. Oral. Radiol. Endod. 1999, 88, 343–347. [Google Scholar] [CrossRef] [PubMed]

| Torsional Resistance | Cyclic Fatigue Resistance | ||||

|---|---|---|---|---|---|

| Ultimate Strength (Ncm) | Distortion Angle (°) | Toughness (°•Ncm) | NCF | Fragment Length (mm) | |

| Group-N | 0.70 ± 0.10 a | 548 ± 40 a | 301.82 ± 56.36 a | 1382 ± 129 ab | 2.74 ± 0.31 |

| Group-U | 0.64 ± 0.05 a | 465 ± 48 b | 216.13 ± 37.99 b | 1527 ± 136 a | 2.68 ± 0.23 |

| Group-S | 0.66 ± 0.05 a | 459 ± 47 b | 216.61 ± 35.11 b | 1286 ± 219 b | 2.97 ± 0.41 |

| p-value | 0.488 | <0.001 | <0.001 | 0.012 | 0.130 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Abed, R.; Al Raeesi, D.; Alshehhi, A.; Alkhatib, Z.; Khamis, A.H.; Jamal, M.; Kim, H.-C. Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel–Titanium Rotary Files. Materials 2023, 16, 2261. https://doi.org/10.3390/ma16062261

El Abed R, Al Raeesi D, Alshehhi A, Alkhatib Z, Khamis AH, Jamal M, Kim H-C. Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel–Titanium Rotary Files. Materials. 2023; 16(6):2261. https://doi.org/10.3390/ma16062261

Chicago/Turabian StyleEl Abed, Rashid, Dana Al Raeesi, Aisha Alshehhi, Zuhair Alkhatib, Amar H. Khamis, Mohamed Jamal, and Hyeon-Cheol Kim. 2023. "Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel–Titanium Rotary Files" Materials 16, no. 6: 2261. https://doi.org/10.3390/ma16062261

APA StyleEl Abed, R., Al Raeesi, D., Alshehhi, A., Alkhatib, Z., Khamis, A. H., Jamal, M., & Kim, H.-C. (2023). Effect from Autoclave Sterilization and Usage on the Fracture Resistance of Heat-Treated Nickel–Titanium Rotary Files. Materials, 16(6), 2261. https://doi.org/10.3390/ma16062261