Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers

Abstract

1. Introduction

2. Materials and Methods

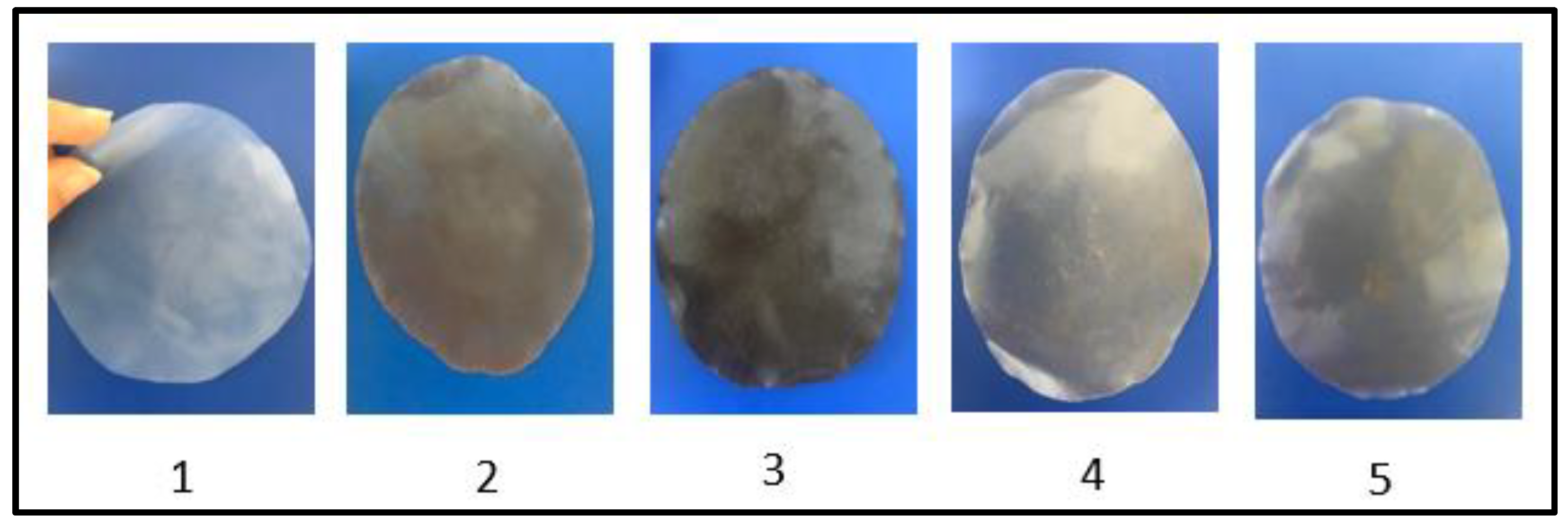

2.1. Raw Materials

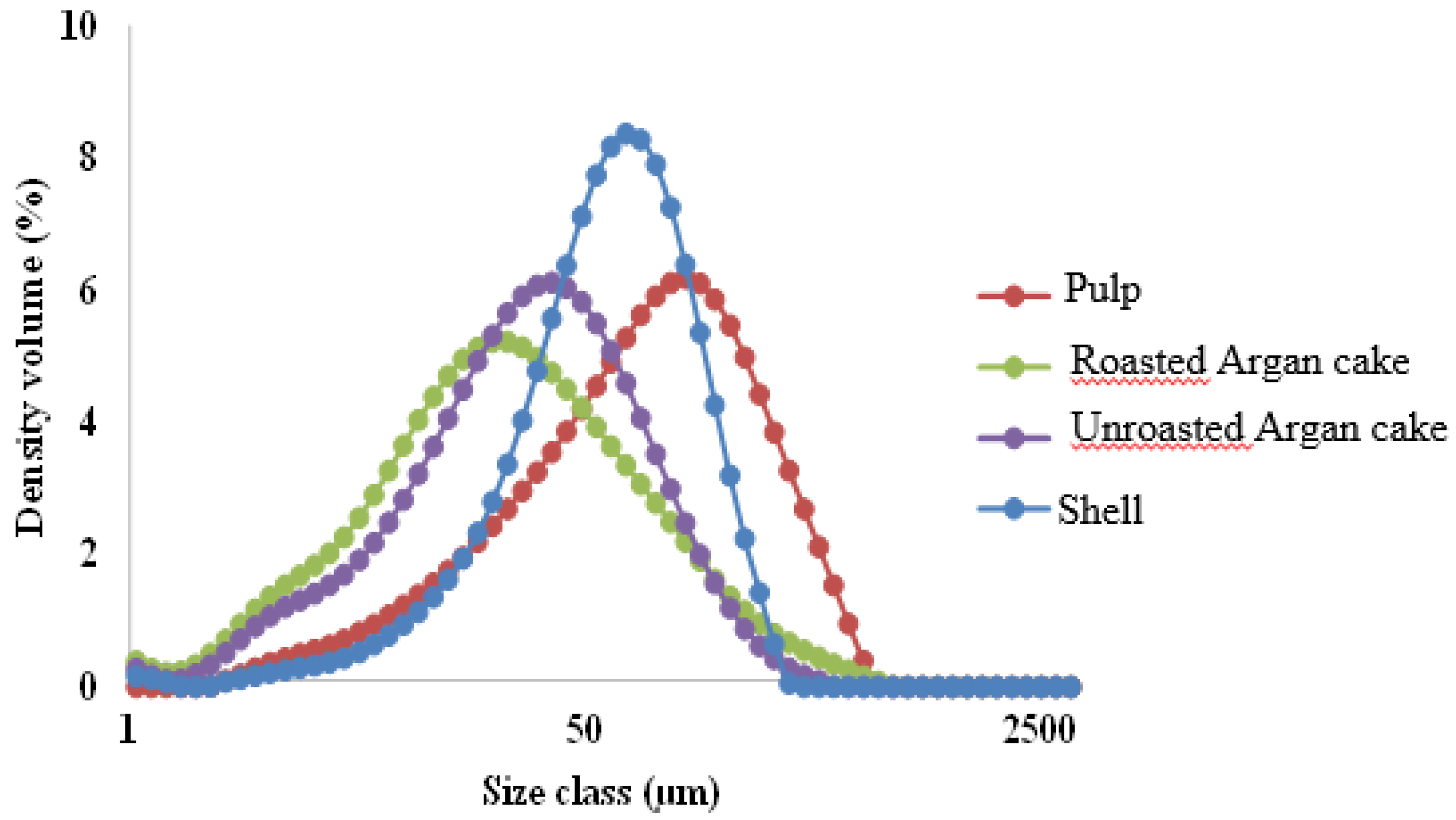

2.2. Laser Granulometry Measurement

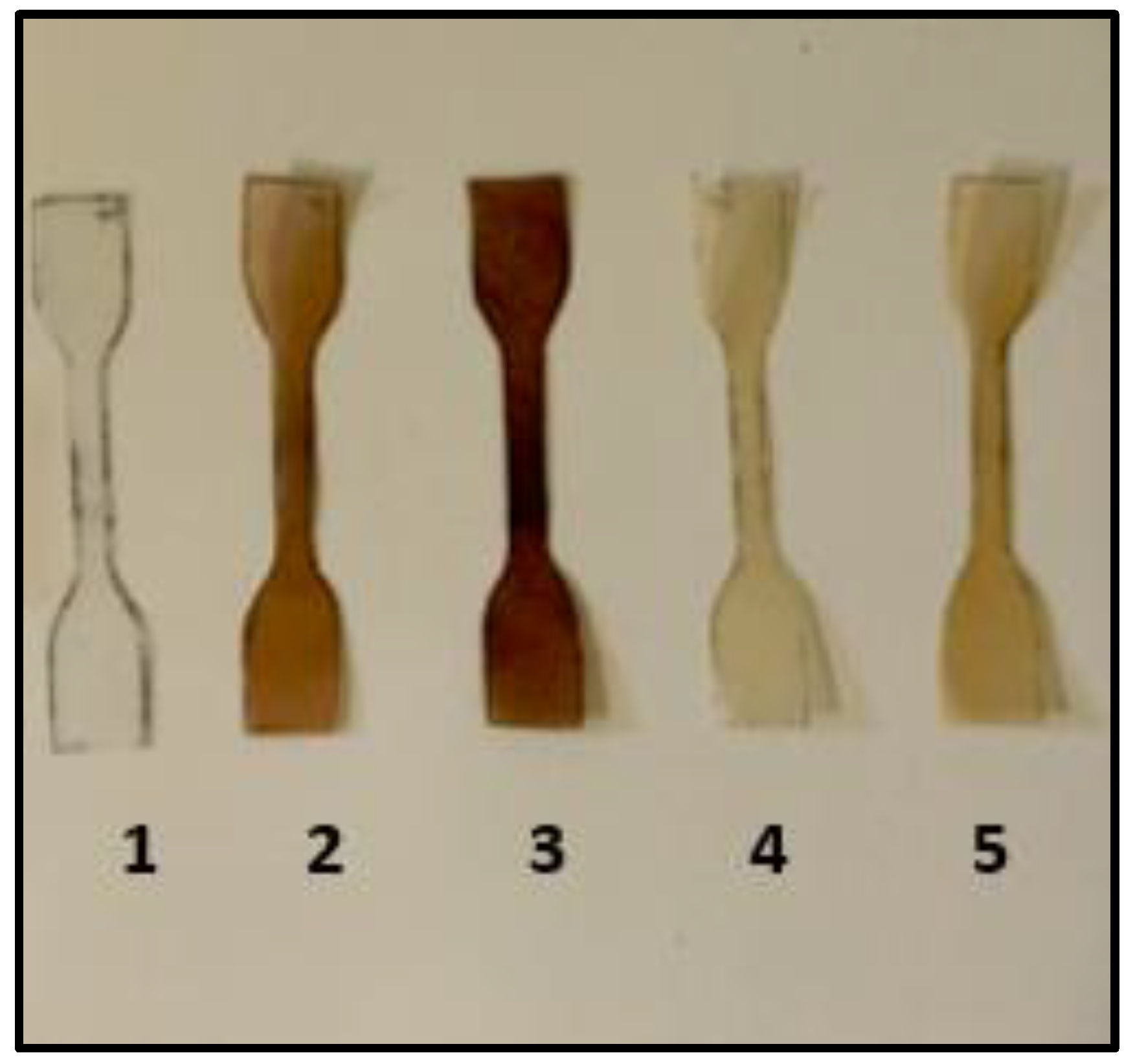

2.3. Composite Film and Filament Preparation for 3D Printing

2.4. Rheological Testing

2.5. Thermal Characterization

2.5.1. Thermogravimetric Analyses (TGA)

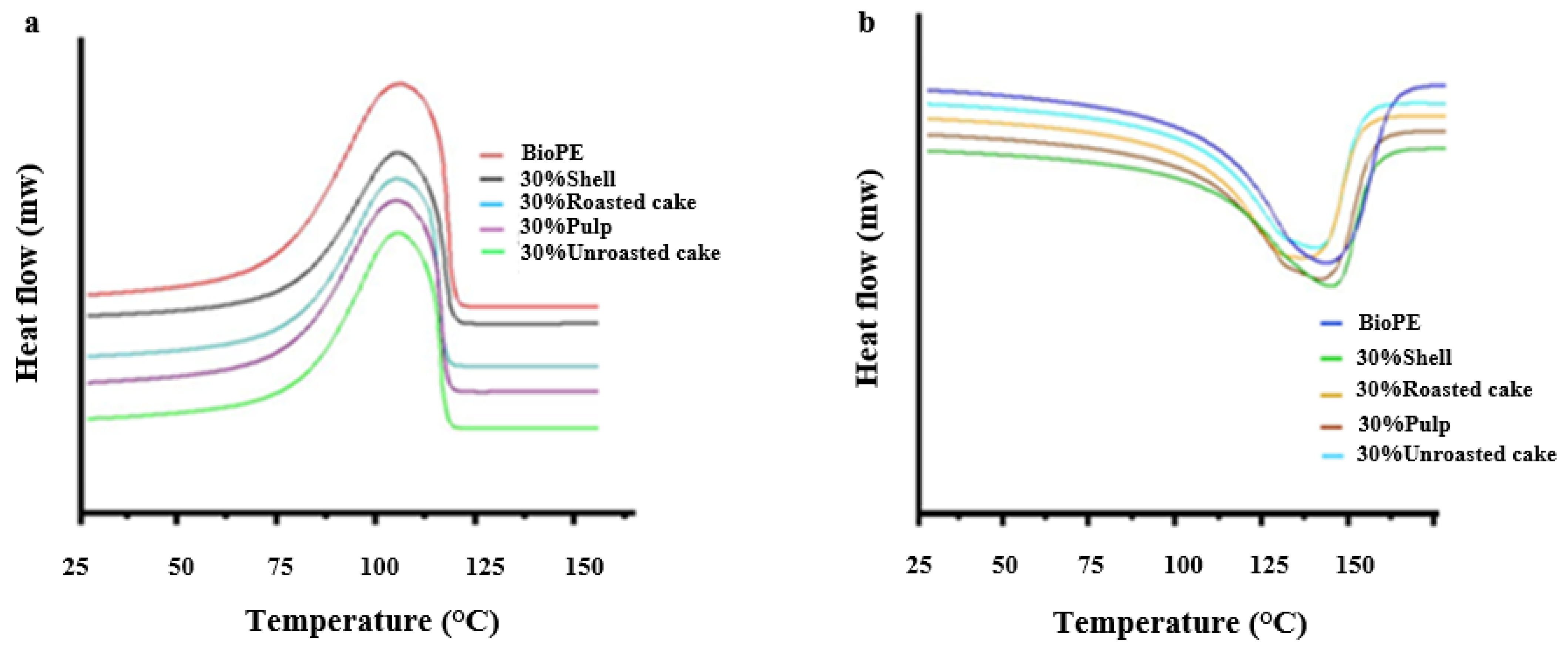

2.5.2. Differential Scanning Calorimetry (DSC) Analysis

2.6. Mechanical Characterization

3. Results and Discussion

3.1. Granulometry Distribution

3.2. Composite Thermal and Rheological Properties

3.2.1. Analysis of Differential Scanning Calorimetry (DSC)

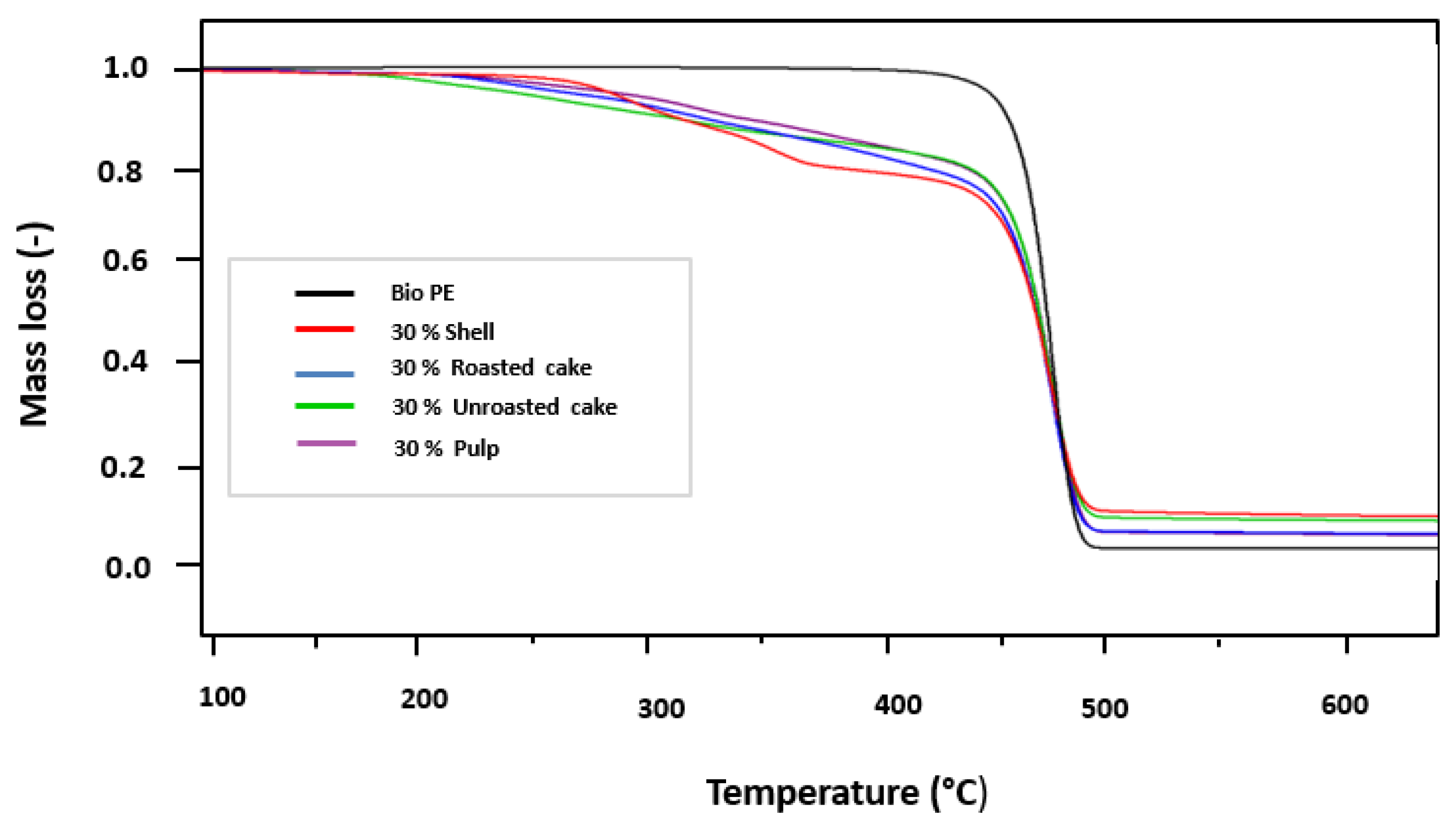

3.2.2. Thermogravimetric Analysis (TGA)

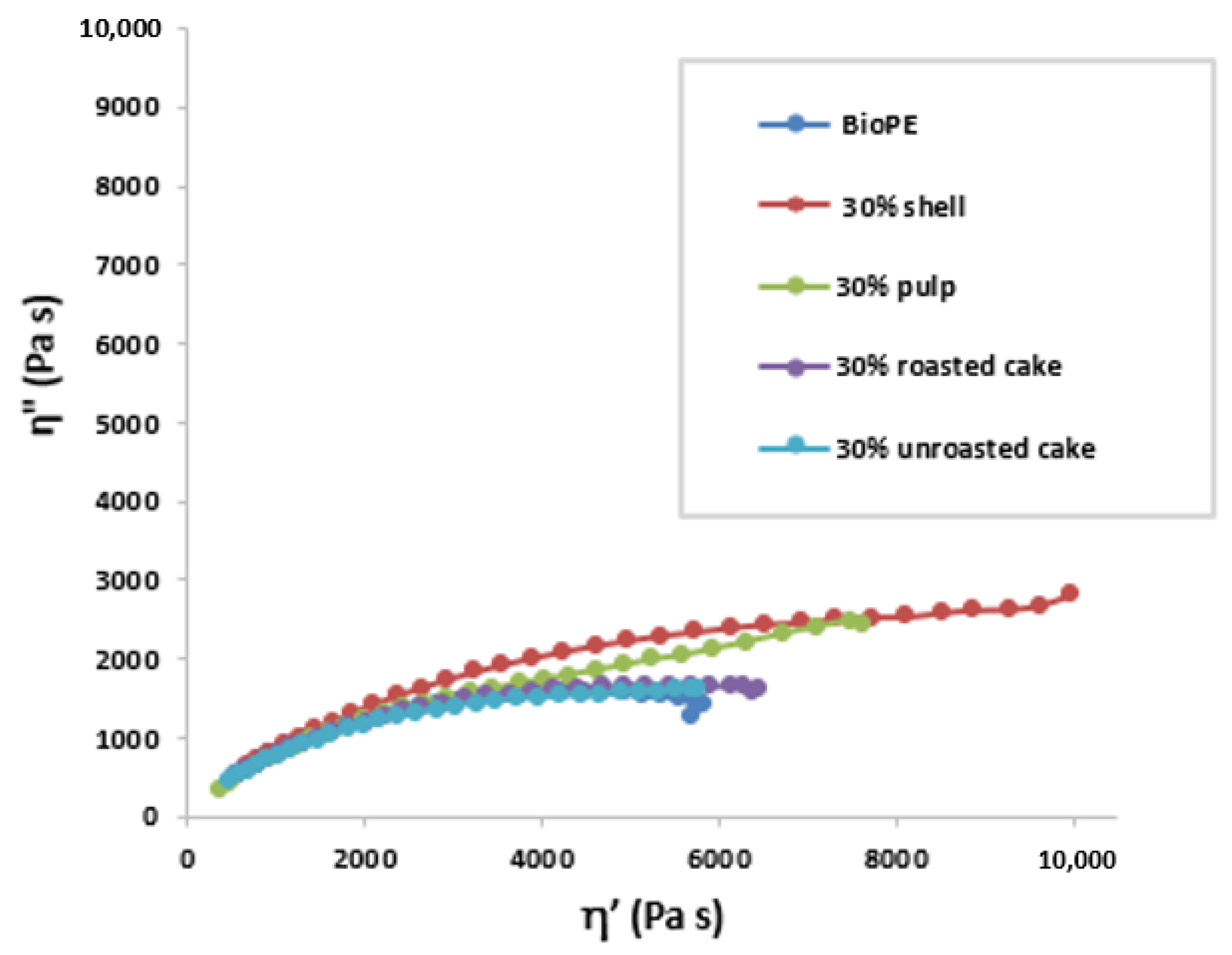

3.2.3. Rheology

3.3. Mechanical Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agustin-Salazar, S.; Ricciulli, M.; Ambrogi, V.; Cerruti, P.; Scarinzi, G. Effect of thermal annealing and filler ball-milling on the properties of highly filled polylactic acid/pecan (Carya illinoinensis) nutshell biocomposites. Int. J. Biol. Macromol. 2022, 200, 350–361. [Google Scholar] [CrossRef] [PubMed]

- Hazrati, K.Z.; Sapuan, S.M.; Zuhri, M.Y.M.; Jumaidin, R. Preparation and characterization of starch-based biocomposite films reinforced by Dioscorea hispida fibers. J. Mater. Res. Technol. 2021, 15, 1342–1355. [Google Scholar] [CrossRef]

- Izwan, S.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Mohamed, A.R. Effects of benzoyl treatment on NaOH treated sugar palm fiber: Tensile, thermal, and morphological properties. J. Mater. Res. Technol. 2020, 9, 5805–5814. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Khalina, A. Effect of glycerol plasticizer loading on the physical, mechanical, thermal, and barrier properties of arrowroot (Maranta arundinacea) starch biopolymers. Sci. Rep. 2021, 11, 13900. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Song, B.; Zeng, G.; Zhang, Y.; Huang, W.; Wen, X.; Tang, W. Are biodegradable plastics a promising solution to solve the global plastic pollution? Environ. Pollut. 2020, 263, 114469. [Google Scholar] [CrossRef]

- Yu, J.; Chen, L.X.L. The greenhouse gas emissions and fossil energy requirement of bioplastics from cradle to gate of a biomass refinery. Environ. Sci. Technol. 2008, 42, 6961–6966. [Google Scholar] [CrossRef]

- Khodaei, D.; Oltrogge, K.; Hamidi-Esfahani, Z. Preparation and characterization of blended edible films manufactured using gelatin, tragacanth gum and, Persian gum. LWT 2020, 117, 108617. [Google Scholar] [CrossRef]

- Ren, L.; Yan, X.; Zhou, J.; Tong, J.; Su, X. Influence of chitosan concentration on mechanical and barrier properties of corn starch/chitosan films. Int. J. Biol. Macromol. 2017, 105, 1636–1643. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Ibrahim, R.; Hazrol, M.D.; Sherwani, S.F.K.; Harussani, M.M.; Jamal, T.; Nazrin, A.; Syafiq, R. Natural fibre: A promising source for the production of nanocellulose. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites; Institute of Tropical Forest and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Malaysia, 2020. [Google Scholar]

- Tarique, J.; Sapuan, S.M.; Khalina, A.; Sherwani, S.F.K.; Yusuf, J.; Ilyas, R.A. Recent developments in sustainable Arrowroot (Maranta arundinacea Linn) starch biopolymers, fibres, biopolymer composites and their potential industrial applications: A review. J. Mater. Res. Technol. 2021, 13, 1191–1219. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, F.; Zhu, P. Structure and properties of urea-plasticized starch films with different urea contents. Carbohydr. Polym. 2014, 101, 1109–1115. [Google Scholar] [CrossRef]

- Perdana, M.I.; Ruamcharoen, J.; Panphon, S.; Leelakriangsak, M. Antimicrobial activity and physical properties of starch/chitosan film incorporated with lemongrass essential oil and its application. LWT 2021, 141, 110934. [Google Scholar] [CrossRef]

- Yusoff, N.H.; Pal, K.; Narayanan, T.; de Souza, F.G. Recent trends on bioplastics synthesis and characterizations: Polylactic acid (PLA) incorporated with tapioca starch for packaging applications. J. Mol. Struct. 2021, 1232, 129954. [Google Scholar] [CrossRef]

- Aydoğmuş, E.; Dağ, M.; Yalçin, Z.G.; Arslanoğlu, H. Synthesis and characterization of EPS reinforced modified castor oil-based epoxy biocomposite. J. Build. Eng. 2021, 47, 103897. [Google Scholar] [CrossRef]

- Chen, S.; Wu, M.; Wang, C.; Yan, S.; Lu, P.; Wang, S. Developed chitosan/oregano essential oil biocomposite packaging film enhanced by cellulose nanofibril. Polymers 2020, 12, 1780. [Google Scholar] [CrossRef]

- Sherwani, S.F.K.; Sapuan, S.M.; Leman, Z.; Zainuddin, E.S.; Ilyas, R.A. Application of polymer composite materials in motorcycles: A Comprehensive review. Biocompos. Synth. Compos. Automot. Appl. 2021, 401–426. [Google Scholar] [CrossRef]

- Aly, N.M.; ElNashar, D.E. Polyester/flax biocomposites reinforced using date palm leaves and wood flour as fillers. Int. J. Eng. Technol. 2016, 8. Available online: https://www.enggjournals.com/ijet/docs/IJET16-08-03-150.pdf (accessed on 20 November 2022).

- Rafeeq, S.N.; Abdulmajeed, I.M.; Saeed, A.R. Mechanical and thermal properties of Date Palm Fiber and Coconut shell particulate filler reinforced Epoxy composite. Indian J. Appl. Res. 2013, 3, 89–92. [Google Scholar] [CrossRef]

- Nguong, C.W.; Lee, S.N.B.; Sujan, D. A review on natural fibre reinforced polymer composites. Int. J. Mater. Metall. Eng. 2013, 7, 52–59. [Google Scholar]

- Setswalo, K.; Molaletsa, N.; Oladijo, O.P.; Akinlabi, E.T.; Rangappa, S.M.; Siengchin, S. The Influence of Fiber Processing and Alkaline Treatment on the Properties of Natural Fiber-reinforced Composites: A Review. Appl. Sci. Eng. Prog. 2021, 14, 632–650. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Alothman, O.Y.; Jawaid, M.; Sapuan, S.M.; Es-Saheb, M.H. Processing and properties of date palm fibers and its composites. In Biomass and Bioenergy; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–25. [Google Scholar]

- Petchwattana, N.; Covavisaruch, S. Mechanical and morphological properties of wood plastic biocomposites prepared from toughened poly (lactic acid) and rubber wood sawdust (Hevea brasiliensis). J. Bionic Eng. 2014, 11, 630–637. [Google Scholar] [CrossRef]

- Pérez, E.; Famá, L.; Pardo, S.G.; Abad, M.J.; Bernal, C. Tensile and fracture behaviour of PP/wood flour composites. Compos. Part B Eng. 2012, 43, 2795–2800. [Google Scholar] [CrossRef]

- Josefsson, G.; Berthold, F.; Gamstedt, E.K. Stiffness contribution of cellulose nanofibrils to composite materials. Int. J. Solids Struct. 2014, 51, 945–953. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Julián, F.; Tarrés, Q.; Méndez, J.A.; Mutjé, P.; Espinach, F.X. Bio composite from bleached pine fibers reinforced polylactic acid as a replacement of glass fiber reinforced polypropylene, macro and micro-mechanics of the Young’s modulus. Compos. Part B Eng. 2017, 125, 203–210. [Google Scholar] [CrossRef]

- Brodin, M.; Vallejos, M.; Opedal, M.T.; Area, M.C.; Chinga-Carrasco, G. Lignocellulosics as sustainable resources for production of bioplastics—A review. J. Clean. Prod. 2017, 162, 646–664. [Google Scholar] [CrossRef]

- Bari, E.; Sistani, A.; Morrell, J.J.; Pizzi, A.; Akbari, M.R.; Ribera, J. Current strategies for the production of sustainable biopolymer composites. Polymers 2021, 13, 2878. [Google Scholar] [CrossRef] [PubMed]

- Sreenivas, H.T.; Krishnamurthy, N.; Arpitha, G.R. A comprehensive review on light weight kenaf fiber for automobiles. Int. J. Lightweight Mater. Manuf. 2020, 3, 328–337. [Google Scholar] [CrossRef]

- Charlet, K. Natural fibres as composite reinforcement materials: Description and new sources. Nat. Polym. 2012, 1, 37–62. [Google Scholar]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Vannini, M.; Marchese, P.; Tassoni, A.; Lenucci, M.S.; Lamborghini, M.; Kalia, S.; Celli, A. A new route of valorization of rice endosperm by-product: Production of polymeric biocomposites. Compos. Part B Eng. 2018, 139, 195–202. [Google Scholar] [CrossRef]

- Yap, S.Y.; Sreekantan, S.; Hassan, M.; Sudesh, K.; Ong, M.T. Characterization and Biodegradability of Rice Husk-Filled Polymer Composites. Polymers 2021, 13, 104. [Google Scholar] [CrossRef] [PubMed]

- Hongsriphan, N.; Kamsantia, P.; Sillapasangloed, P.; Loychuen, S. Bio-based composite from poly (butylene succinate) and peanut shell waste adding maleinized linseed oil. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 773, p. 12046. [Google Scholar]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Optimization of maleinized linseed oil loading as a biobased compatibilizer in poly (butylene succinate) composites with almond shell flour. Materials 2019, 12, 685. [Google Scholar] [CrossRef] [PubMed]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Rojas-Lema, S.; Arevalo, J.; Gomez-Caturla, J.; Garcia-Garcia, D.; Torres-Giner, S. Peroxide-Induced Synthesis of Maleic Anhydride-Grafted Poly (butylene succinate) and Its Compatibilizing Effect on Poly (butylene succinate)/Pistachio Shell Flour Composites. Molecules 2021, 26, 5927. [Google Scholar] [CrossRef]

- Heller, D.; Einfalt, D. Wildflower mixtures for bioethanol production—Pretreatment and enzymatic hydrolysis. Biomass Bioenergy 2020, 141, 105727. [Google Scholar] [CrossRef]

- Perry, W. Social sustainability and the argan boom as green development in Morocco. World Dev. Perspect. 2020, 20, 100238. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Christophe, G.; Guendouz, A.; El Modafar, C.; Belkamel, A.; Michaud, P.; Delattre, C. Optimization of Bioethanol Production from Enzymatic Treatment of Argan Pulp Feedstock. Molecules 2021, 26, 2516. [Google Scholar] [CrossRef]

- Essabir, H.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R. Biocomposites based on Argan nut shell and a polymer matrix: Effect of filler content and coupling agent. Carbohydr. Polym. 2016, 143, 70–83. [Google Scholar] [CrossRef]

- El Moumen, A.; N’Guyen, F.; Kanit, T.; Imad, A. Mechanical properties of poly–propylene reinforced with Argan nut shell aggregates: Computational strategy based microstructures. Mech. Mater. 2020, 145, 103348. [Google Scholar] [CrossRef]

- Laaziz, S.A.; Raji, M.; Hilali, E.; Essabir, H.; Rodrigue, D.; Bouhfid, R. Bio-composites based on polylactic acid and argan nut shell: Production and properties. Int. J. Biol. Macromol. 2017, 104, 30–42. [Google Scholar] [CrossRef]

- Akhzouz, H.; El Minor, H.; Tatane, M.; Bendarma, A. Physical characterization of bio-composite CEB stabilized with Argan nut shell and cement. Mater. Today Proc. 2021, 36, 107–114. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Christophe, G.; Ogura, K.; Sawamura, N.; Guendouz, A.; El Modafar, C.; Michaud, P.; Delattre, C. High-Pressure Water Jet System Treatment of Argan Nut Shell and Enzymatic Hydrolysis for Bioethanol Production. Fermentation 2022, 8, 627. [Google Scholar] [CrossRef]

- Marek, A.A.; Verney, V. Rheological behavior of polyolefins during UV irradiation at high temperature as a coupled degradative process. Eur. Polym. J. 2015, 72, 1–11. [Google Scholar] [CrossRef]

- Schiavone, N.; Verney, V.; Askanian, H. High-Density Bio-PE and Pozzolan Based Composites: Formulation and Prototype Design for Control of Low Water Flow. Polymers 2021, 13, 1908. [Google Scholar] [CrossRef]

- Schiavone, N.; Verney, V.; Askanian, H. Pozzolan Based 3D Printing Composites: From the Formulation Till the Final Application in the Precision Irrigation Field. Materials 2020, 14, 43. [Google Scholar] [CrossRef] [PubMed]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Ravi, A.K.; Deshpande, A.; Hsu, K.H. An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. J. Manuf. Process. 2016, 24, 179–185. [Google Scholar] [CrossRef]

- Das Lala, S.; Deoghare, A.B.; Chatterjee, S. Effect of reinforcements on polymer matrix bio-composites—An overview. Sci. Eng. Compos. Mater. 2018, 25, 1039–1058. [Google Scholar] [CrossRef]

- Jorda-Reolid, M.; Gomez-Caturla, J.; Ivorra-Martinez, J.; Stefani, P.M.; Rojas-Lema, S.; Quiles-Carrillo, L. Upgrading Argan Shell Wastes in Wood Plastic Composites with Biobased Polyethylene Matrix and Different Compatibilizers. Polymers 2021, 13, 922. [Google Scholar] [CrossRef] [PubMed]

- Montanes, N.; Garcia-Sanoguera, D.; Segui, V.J.; Fenollar, O.; Boronat, T. Processing and characterization of environmentally friendly composites from biobased polyethylene and natural fillers from thyme herbs. J. Polym. Environ. 2018, 26, 1218–1230. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R.A. Composition, structure and thermal degradation of hemp cellulose after chemical treatments. Polym. Degrad. Stab. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- Albano, C.; Gonzalez, J.; Ichazo, M.; Kaiser, D. Thermal stability of blends of polyolefins and sisal fiber. Polym. Degrad. Stab. 1999, 66, 179–190. [Google Scholar] [CrossRef]

- Kumar, A.; Commereuc, S.; Verney, V. Ageing of elastomers: A molecular approach based on rheological characterization. Polym. Degrad. Stab. 2004, 85, 751–757. [Google Scholar] [CrossRef]

- Dealy, J.M.; Wang, J. Melt Rheology and Its Applications in the Plastics Industry; Springer Science & Business Media: Berlin, Germany, 2013; ISBN 9400763956. [Google Scholar]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Impact of interfacial adhesion on the microstructure and property variations of biocarbons reinforced nylon 6 biocomposites. Compos. Part A Appl. Sci. Manuf. 2017, 98, 32–44. [Google Scholar] [CrossRef]

- Shenoy, A.V. Rheology of Filled Polymer Systems; Springer Science & Business Media: Berlin, Germany, 2013; ISBN 9401592136. [Google Scholar]

- Essabir, H.; El Achaby, M.; Bouhfid, R.; Qaiss, A. Morphological, structural, thermal and tensile properties of high density polyethylene composites reinforced with treated argan nut shell particles. J. Bionic Eng. 2015, 12, 129–141. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Méndez, J.A.; Vilaseca, F.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene composites: Flexural characterisation, impact behaviour and water uptake properties. Compos. Part B Eng. 2016, 97, 176–182. [Google Scholar] [CrossRef]

- Askanian, H.; Verney, V.; Commereuc, S.; Guyonnet, R.; Massardier, V. Wood polypropylene composites prepared by thermally modified fibers at two extrusion speeds: Mechanical and viscoelastic properties. Holzforschung 2015, 69, 313–319. [Google Scholar] [CrossRef]

- Kiran, M.D.; Govindaraju, H.K.; Jayaraju, T.; Kumar, N. Effect of fillers on mechanical properties of polymer matrix composites. Mater. Today Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

| Composition %w/w | Pulp | Roasted Cake | Unroasted Cake | Shell |

|---|---|---|---|---|

| Dry matter | 5.02 ± 0.16 | 3.48 ± 0.11 | 3.42 ± 0.10 | 5.02 ± 0.13 |

| Ash | 0.29 ± 0.01 | 0.20 ± 0.01 | 0.21 ± 0.01 | 3.20 ± 0.01 |

| Fat | 5.46 ± 0.26 | 7.8 ± 0.22 | 7.01 ± 0.20 | 1.02 ± 0.16 |

| Protein | 5.02 ± 0.16 | 38.1 ± 0.1 | 36.7 ± 0.6 | 3.46 ± 0.12 |

| Cellulose | 19.35 ± 0.14 | 17.6 ± 0.1 | 17.1 ± 0.1 | 46.15 ± 0.12 |

| * NDF/total fibers | 29.26 ± 0.19 | 21.2 ± 0.1 | 21.1 ± 0.1 | 94.58 ± 0.15 |

| ** ADF Lignocellulose | 22.52 ± 0.05 | 17.38 ± 0.03 | 17.36 ± 0.04 | 75.58 ± 0.10 |

| Hemicellulose | 6.75 ± 0.10 | 3.82 ± 0.11 | 3.85 ± 0.11 | 19.06 ± 0.10 |

| Lignin | 3.17 ± 0.12 | 2.78 ± 0.10 | 2.75 ± 0.12 | 29.17 ± 0.14 |

| Argan Byproducts | Granule Size (μm) | Span | Specific Surface Area (m²/kg) | |||

|---|---|---|---|---|---|---|

| D10 | D50 | D90 | D [4;3] | |||

| Shell | 18.0 | 62.2 | 144.0 | 73.0 | 2.0 | 217.9 |

| Pulp | 19.3 | 101.0 | 301.0 | 135.0 | 2.8 | 139.0 |

| Roasted Argan cake | 5.6 | 29.2 | 95.0 | 43.3 | 3.1 | 559.1 |

| Unroasted Argan cake | 4.7 | 26.2 | 131.0 | 53.0 | 4.8 | 646.7 |

| Polymer | ΔHm (J/g) | Tm (°C) | Tc (°C) | ΔHc (J/g) | Xc (%) |

|---|---|---|---|---|---|

| PE | 111 | 133 | 112 | 114.03 | 39.6 |

| PE 30% Shell | 73 | 134 | 112 | 66.53 | 23.1 |

| PE 30% Pulp | 56 | 132 | 112 | 74.78 | 25.9 |

| PE 30% Roasted Argan cake | 32 | 132 | 112 | 79.48 | 27.6 |

| PE 30% Unroasted Argan cake | 31 | 133 | 112 | 87.77 | 30.5 |

| Polymer | PE | PE 30% Shell | PE 30% Pulp | PE 30% Roasted Argan Cake | PE 30% Unroasted Argan Cake |

|---|---|---|---|---|---|

| E (Mpa) | 206 ± 36 | 498 ± 39 | 349 ± 47 | 324 ± 31 | 330 ± 41 |

| σmax (Mpa) | 10.15 ± 0.81 | 10.18 ± 0.57 | 9.58 ± 0.93 | 9.99 ± 0.67 | 9.99 ± 0.54 |

| εmax (%) | 5.83 ± 0.1 | 4.28 ± 0.2 | 5.86 ± 0.1 | 4.94 ± 0.1 | 5.13 ± 0.3 |

| εb (%) | 26.75 ± 0.32 | 7.82 ± 0.12 | 11.34 ± 0.10 | 9.01 ± 0.10 | 19.67 ± 0.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeghlouli, J.; Schiavone, N.; Askanian, H.; Guendouz, A.; El Modafar, C.; Michaud, P.; Delattre, C. Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers. Materials 2023, 16, 2241. https://doi.org/10.3390/ma16062241

Zeghlouli J, Schiavone N, Askanian H, Guendouz A, El Modafar C, Michaud P, Delattre C. Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers. Materials. 2023; 16(6):2241. https://doi.org/10.3390/ma16062241

Chicago/Turabian StyleZeghlouli, Jihane, Nicola Schiavone, Haroutioun Askanian, Amine Guendouz, Cherkaoui El Modafar, Philippe Michaud, and Cédric Delattre. 2023. "Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers" Materials 16, no. 6: 2241. https://doi.org/10.3390/ma16062241

APA StyleZeghlouli, J., Schiavone, N., Askanian, H., Guendouz, A., El Modafar, C., Michaud, P., & Delattre, C. (2023). Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers. Materials, 16(6), 2241. https://doi.org/10.3390/ma16062241