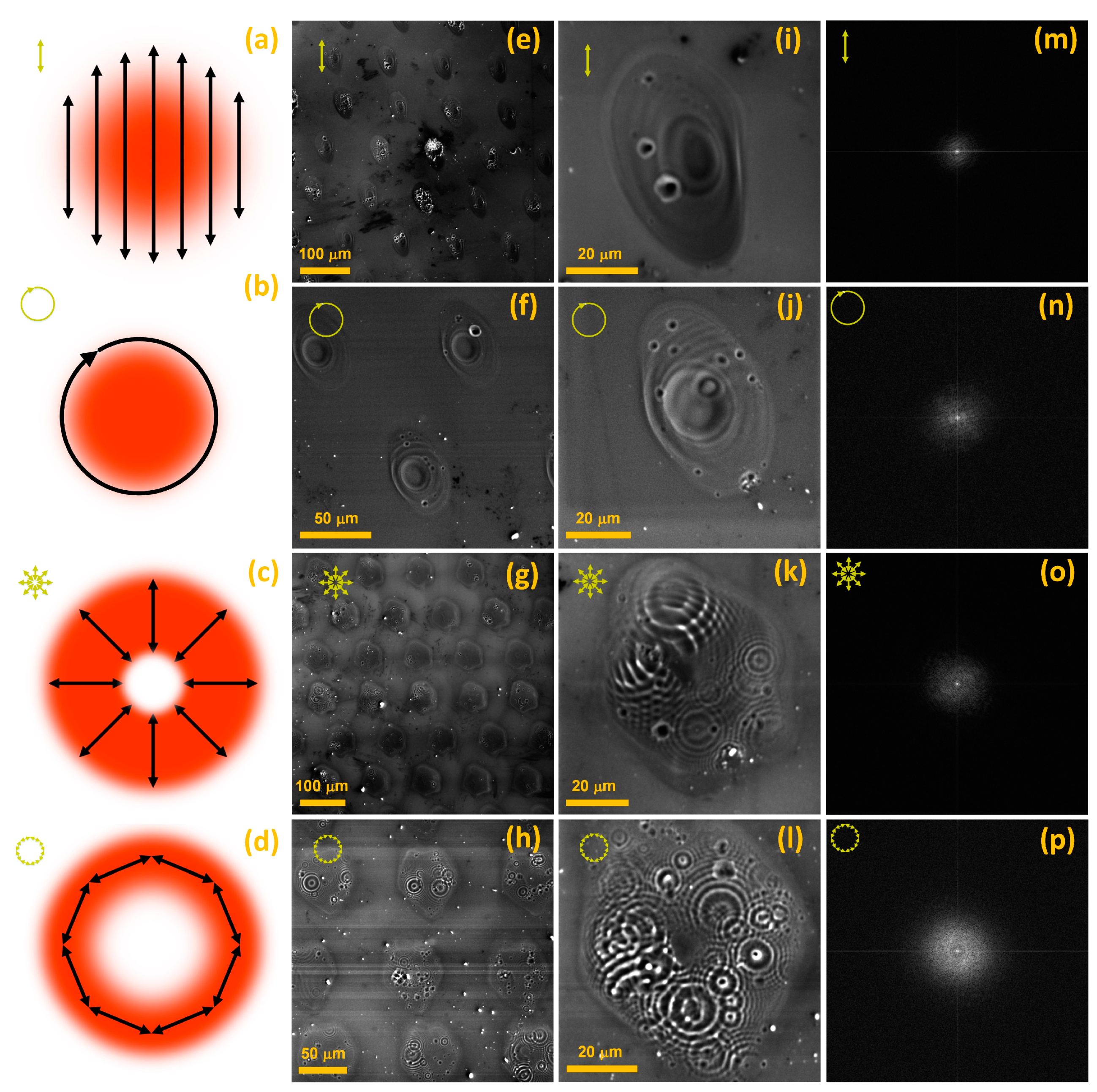

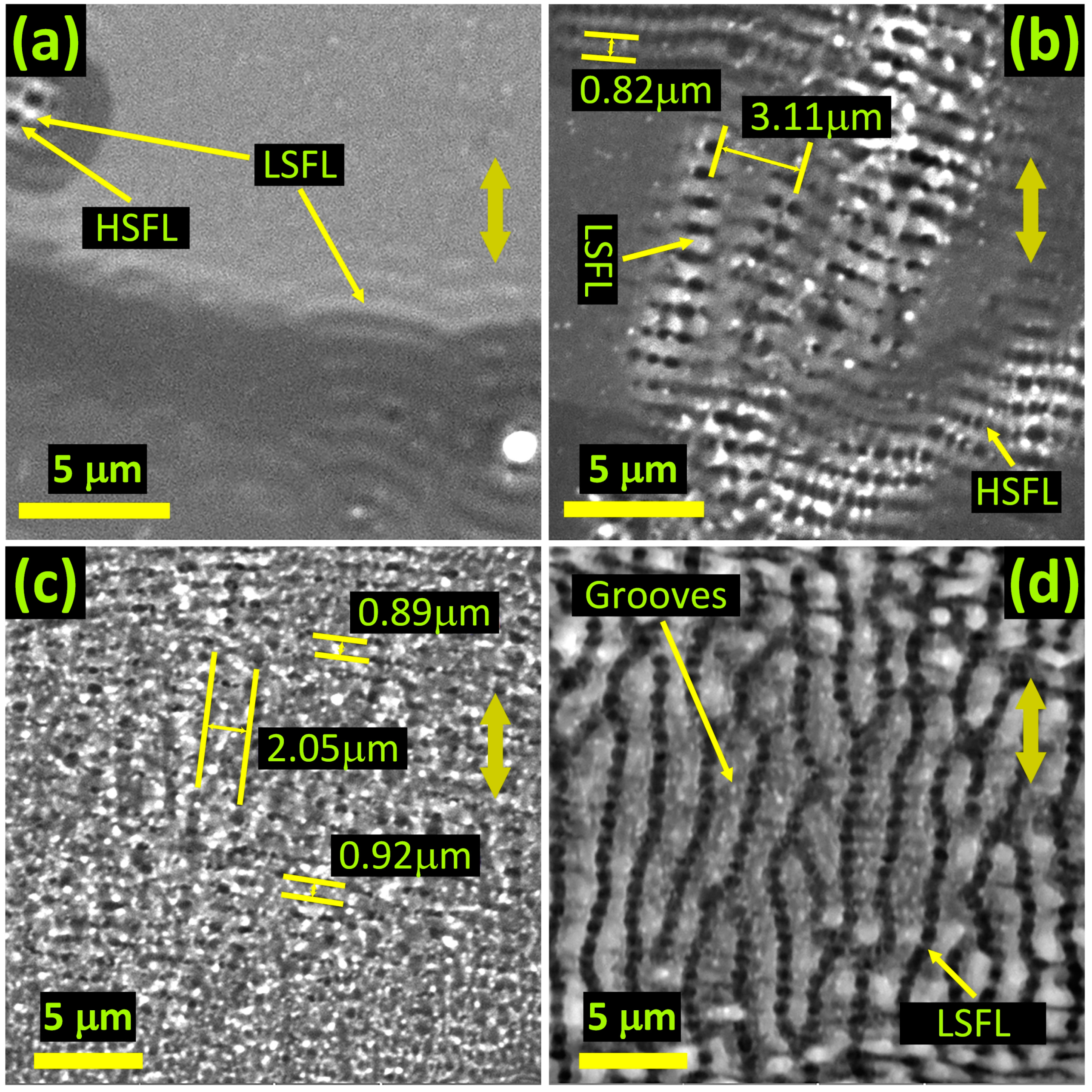

Study on the Origin and Evolution of Femtosecond Laser-Induced Surface Structures: LIPSS, Quasi-Periodic Grooves, and Aperiodic Micro-Ridges

Abstract

1. Introduction

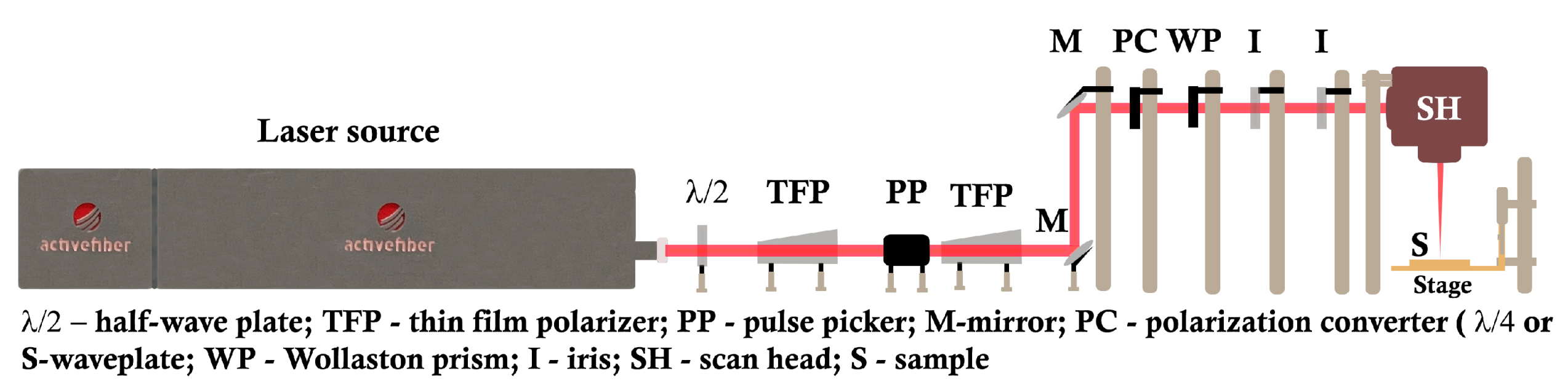

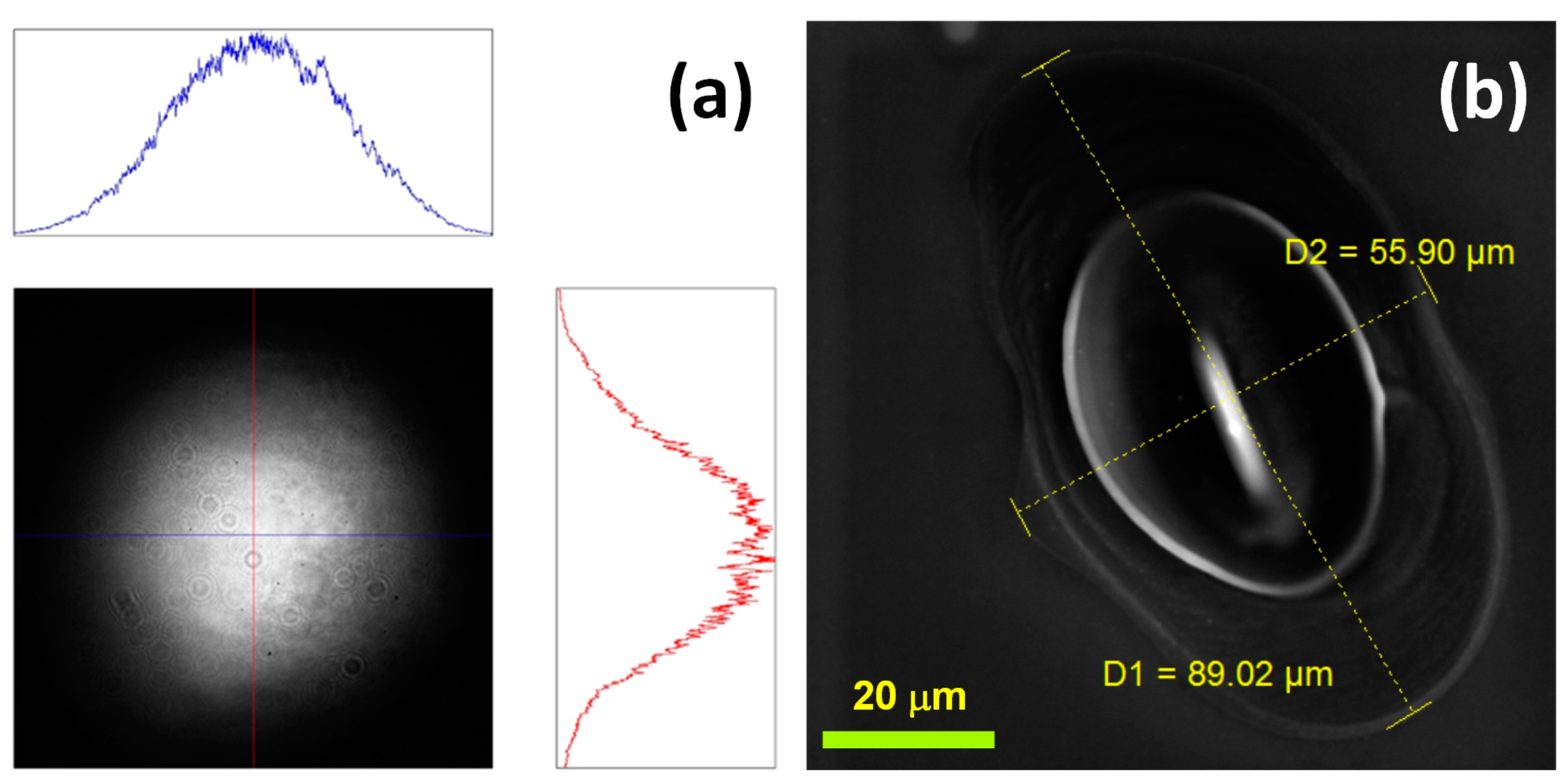

2. Experimental

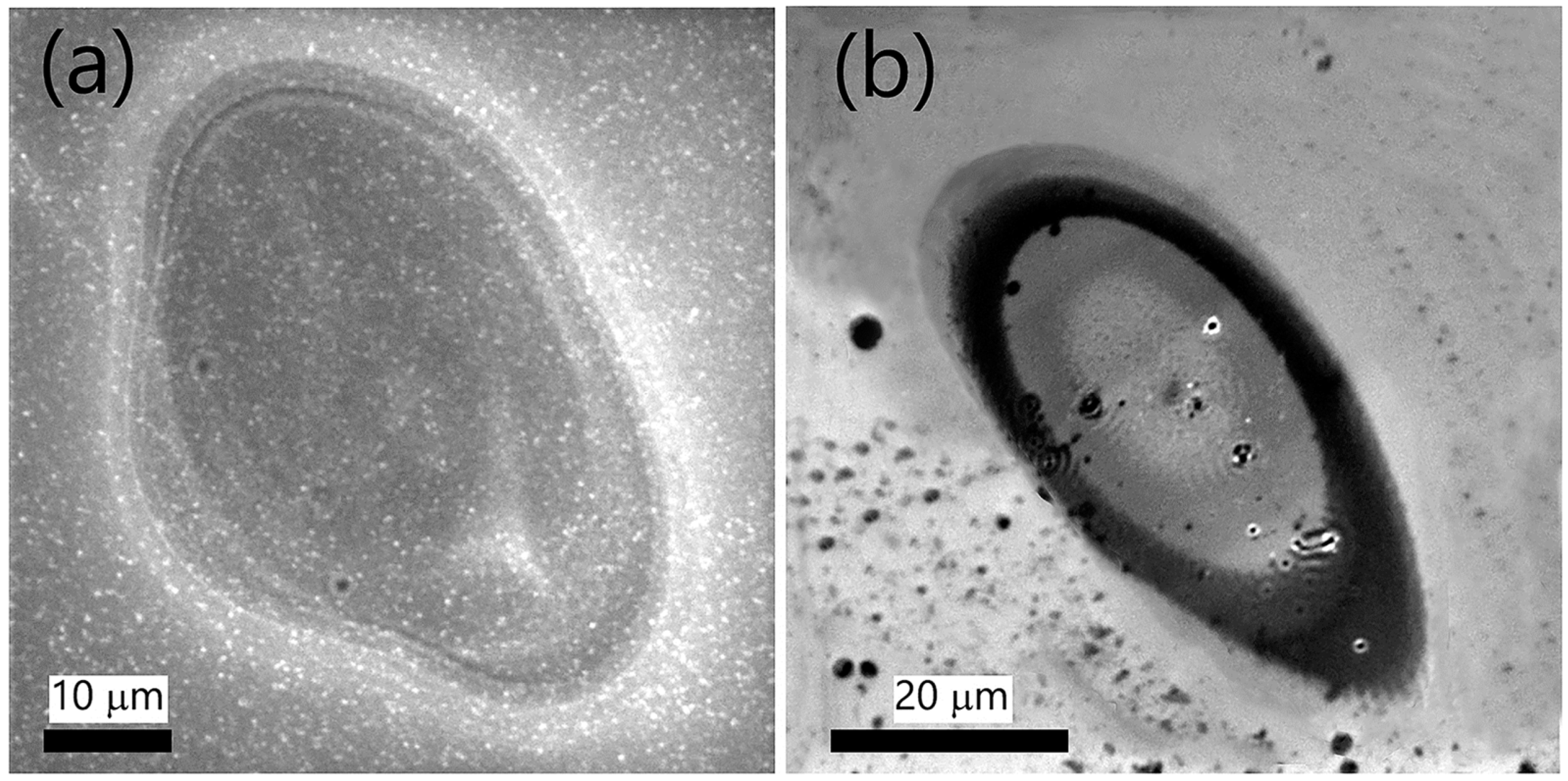

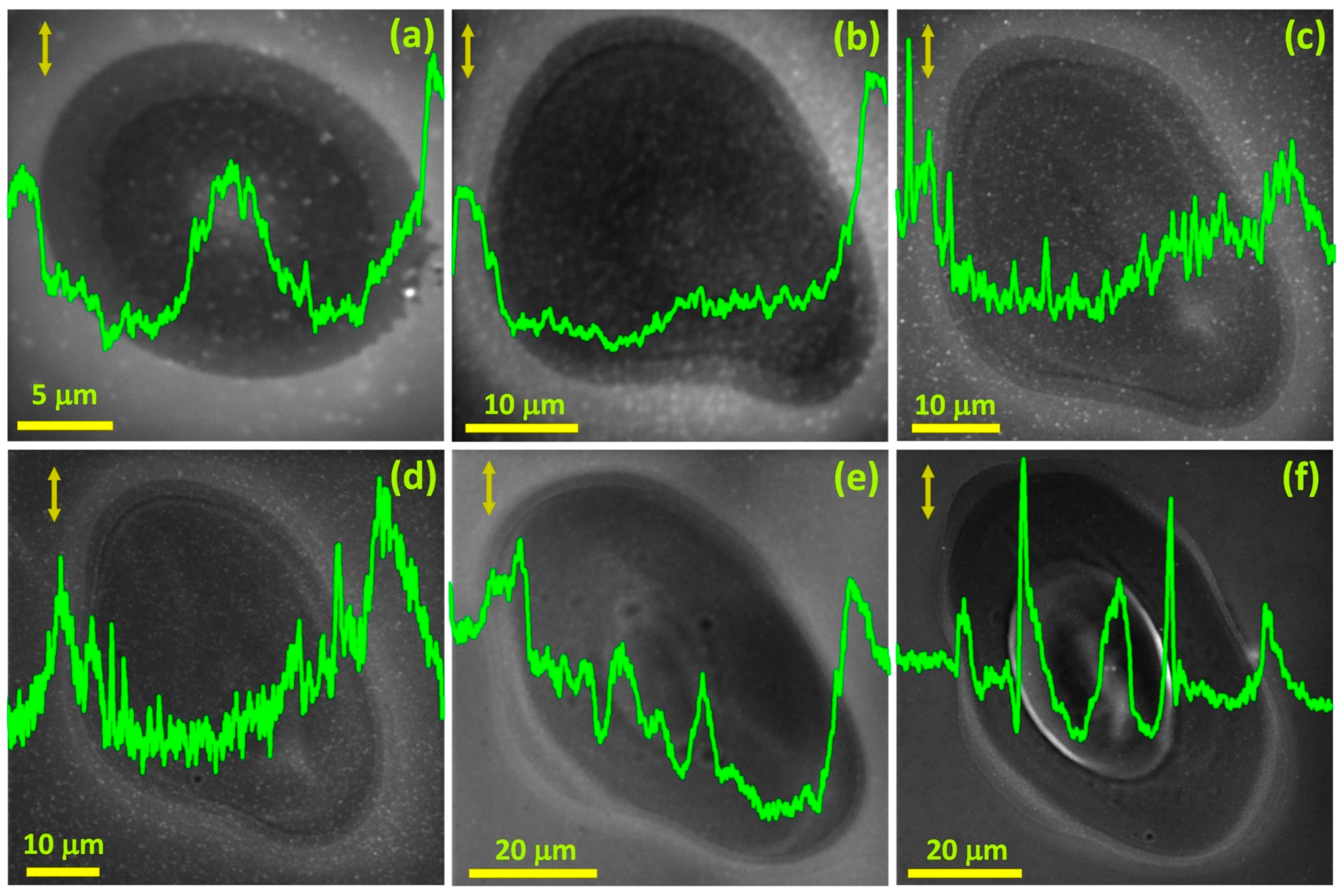

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Wu, Q.; Chen, Z.; Zhang, B.; Tang, B.; Yao, J.; Drevensek-Olenik, I.; Xu, J. Generation and erasure of femtosecond laser-induced periodic surface structures on nanoparticle-covered silicon by a single laser pulse. Opt. Lett. 2014, 39, 343–346. [Google Scholar] [CrossRef]

- Cheng, K.; Liu, J.; Cao, K.; Chen, L.; Zhang, Y.; Jiang, Q.; Feng, D.; Zhang, S.; Sun, Z.; Jia, T. Ultrafast dynamics of single-pulse femtosecond laser-induced periodic ripples on the surface of a gold film. Phys. Rev. B 2018, 98, 184106. [Google Scholar] [CrossRef]

- He, S.; Nivas, J.J.; Anoop, K.; Vecchione, A.; Hu, M.; Bruzzese, R.; Amoruso, S. Surface structures induced by ultrashort laser pulses: Formation mechanisms of ripples and grooves. Appl. Surf. Sci. 2015, 353, 1214–1222. [Google Scholar] [CrossRef]

- Huang, M.; Cheng, Y.; Zhao, F.; Xu, Z. The significant role of plasmonic effects in femtosecond laser-induced grating fabrication on the nanoscale. Ann. Phys. 2012, 525, 74–86. [Google Scholar] [CrossRef]

- Moser, R.; Domke, M.; Winter, J.; Huber, H.P.; Marowsky, G. Single pulse femtosecond laser ablation of silicon—A comparison between experimental and simulated two-dimensional ablation profiles. Adv. Opt. Technol. 2018, 7, 255–264. [Google Scholar] [CrossRef]

- Nivas, J.J.; Cardano, F.; Song, Z.; Rubano, A.; Fittipaldi, R.; Vecchione, A.; Paparo, D.; Marrucci, L.; Bruzzese, R.; Amoruso, S. Surface Structuring with Polarization-Singular Femtosecond Laser Beams Generated by a q-plate. Sci. Rep. 2017, 7, srep42142. [Google Scholar] [CrossRef]

- Juodkazis, S.; Mizeikis, V.; Misawa, H. Three-dimensional microfabrication of materials by femtosecond lasers for photonics applications. J. Appl. Phys. 2009, 106, 051101. [Google Scholar] [CrossRef]

- Ostendorf, A.; Cronauer, C.; Popall, M.; Domann, G.; Houbertz, R.; Fröhlich, L.; Serbin, J.; Egbert, A.; Chichkov, B.N.; Schulz, J. Femtosecond laser-induced two-photon polymerization of inorganic–organic hybrid materials for applications in photonics. Opt. Lett. 2003, 28, 301–303. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Azkona, J.J.; Casquero, N.; Rodríguez, A.; Domke, M.; Gómez-Aranzadi, M.; Olaizola, S.M.; Granados, E. Tailoring diamond’s optical properties via direct femtosecond laser nanostructuring. Sci. Rep. 2018, 8, 14262. [Google Scholar] [CrossRef]

- Mastellone, M.; Pace, M.L.; Curcio, M.; Caggiano, N.; De Bonis, A.; Teghil, R.; Dolce, P.; Mollica, D.; Orlando, S.; Santagata, A.; et al. LIPSS Applied to Wide Bandgap Semiconductors and Dielectrics: Assessment and Future Perspectives. Materials 2022, 15, 1378. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Chen, D.; Liu, F.; Yang, Z.; Li, X.; Yu, H.; Liu, H.; Zhou, W. Laser Synthesis and Microfabrication of Micro/Nanostructured Materials Toward Energy Conversion and Storage. Nano-Micro Lett. 2021, 13, 1–48. [Google Scholar] [CrossRef]

- Gao, Y.; Lu, C.; Guohui, Y.; Sha, J.; Tan, J.; Xuan, F.-Z. Laser micro-structured pressure sensor with modulated sensitivity for electronic skins. Nanotechnology 2019, 30, 325502. [Google Scholar] [CrossRef]

- Goya, K.; Shiraishi, M.; Fuchiwaki, Y.; Watanabe, K.; Ooie, T. Femtosecond Laser-Induced Surface Modification and its Application. In Applications of Laser Ablation-Thin Film Deposition, Nanomaterial Synthesis and Surface Modification; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Carvalho, A.; Grenho, L.; Fernandes, M.H.; Daskalova, A.; Trifonov, A.; Buchvarov, I.; Monteiro, F.J. Femtosecond laser microstructuring of alumina toughened zirconia for surface functionalization of dental implants. Ceram. Int. 2020, 46, 1383–1389. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, L.-C.; Ueki, M.; Ito, Y.; Sugioka, K. Femtosecond laser shockwave peening ablation in liquids for hierarchical micro/nanostructuring of brittle silicon and its biological application. Int. J. Extrem. Manuf. 2020, 2, 045001. [Google Scholar] [CrossRef]

- Kumar, D.; Sauer, M.; Ching, K.K.; Kalss, G.; dos Santos, A.C.V.; Ramer, G.; Foelske, A.; Lendl, B.; Liedl, G.; Otto, A. Wettability transition of femtosecond laser patterned nodular cast iron (NCI) substrate. Appl. Surf. Sci. 2021, 559, 149897. [Google Scholar] [CrossRef]

- Wong, W.S.Y.; Hauer, L.; Cziko, P.A.; Meister, K. Cryofouling avoidance in the Antarctic scallop Adamussium colbecki. Commun. Biol. 2022, 5, 1–8. [Google Scholar] [CrossRef]

- Li, C.-C.; Wu, J.-N.; Yang, Y.-Q.; Zhu, R.-G.; Yan, S.-Z. Drag reduction effects facilitated by microridges inside the mouthparts of honeybee workers and drones. J. Theor. Biol. 2016, 389, 1–10. [Google Scholar] [CrossRef]

- Kumar Das, S.; Messaoudi, H.; Debroy, A.; McGlynn, E.; Grunwald, R.; Shen, M.; Carey, J.E.; Crouch, C.H.; Kandyla, M.; Stone, H.A.; et al. Multiphoton excitation of surface plasmon-polaritons and scaling of nanoripple formation in large bandgap materials. Opt. Mater. Express 2013, 3, 1705–1715. [Google Scholar] [CrossRef]

- Rebollar, E.; de Aldana, J.R.V.; Martín-Fabiani, I.; Hernández, M.; Rueda, D.R.; Ezquerra, T.A.; Domingo, C.; Moreno, P.; Castillejo, M. Assessment of femtosecond laser induced periodic surface structures on polymer films. Phys. Chem. Chem. Phys. 2013, 15, 11287–11298. [Google Scholar] [CrossRef]

- Teichmann, M.; Lorbeer, J.; Ziberi, B.; Ono, K.; Nakazaki, N.; Wagner, R.; Gottmann, J. Sub-wavelength ripple formation on various materials induced by tightly focused femtosecond laser radiation. J. Phys. Conf. Ser. 2007, 59, 333–337. [Google Scholar] [CrossRef]

- Wu, Q.; Ma, Y.; Fang, R.; Liao, Y.; Yu, Q.; Chen, X.; Wang, K. Femtosecond laser-induced periodic surface structure on diamond film. Appl. Phys. Lett. 2003, 82, 1703–1705. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Large area uniform nanostructures fabricated by direct femtosecond laser ablation. Opt. Express 2008, 16, 19354–19365. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.; Sharafudeen, K.N.; Yue, Y.; Qiu, J. Femtosecond laser induced phenomena in transparent solid materials: Fundamentals and applications. Prog. Mater. Sci. 2016, 76, 154–228. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of Laser-Induced Near-Subwavelength Ripples: Interference between Surface Plasmons and Incident Laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef]

- Bonse, J.; Gräf, S. Maxwell Meets Marangoni—A Review of Theories on Laser-Induced Periodic Surface Structures. Laser Photon- Rev. 2020, 14, 2000215. [Google Scholar] [CrossRef]

- Birnbaum, M. Semiconductor Surface Damage Produced by Ruby Lasers. J. Appl. Phys. 2004, 36, 3688–3689. [Google Scholar] [CrossRef]

- Sipe, J.E.; Young, J.F.; Preston, J.; Van Driel, H.M. Laser-induced periodic surface structure. I. Theory. Phys. Rev. B 1983, 27, 1141–1154. [Google Scholar] [CrossRef]

- Colombier, J.-P.; Rudenko, A.; Silaeva, E.; Zhang, H.; Sedao, X.; Bévillon, E.; Reynaud, S.; Maurice, C.; Pigeon, F.; Garrelie, F.; et al. Mixing periodic topographies and structural patterns on silicon surfaces mediated by ultrafast photoexcited charge carriers. Phys. Rev. Res. 2020, 2, 043080. [Google Scholar] [CrossRef]

- Trtica, M.; Gakovic, B.; Radak, B.; Batani, D.; Desai, T.; Bussoli, M. Periodic surface structures on crystalline silicon created by 532nm picosecond Nd:YAG laser pulses. Appl. Surf. Sci. 2007, 254, 1377–1381. [Google Scholar] [CrossRef]

- Buividas, R.; Rosa, L.; Šliupas, R.; Kudrius, T.; Šlekys, G.; Datsyuk, V.; Juodkazis, S. Mechanism of fine ripple formation on surfaces of (semi)transparent materials via a half-wavelength cavity feedback. Nanotechnology 2010, 22, 055304. [Google Scholar] [CrossRef]

- Lu, Y.F.; Choi, W.K.; Aoyagi, Y.; Kinomura, A.; Fujii, K. Controllable laser-induced periodic structures at silicon–dioxide/silicon interface by excimer laser irradiation. J. Appl. Phys. 1998, 80, 7052–7056. [Google Scholar] [CrossRef]

- Reif, J.; Costache, F.; Henyk, M.; Pandelov, S.V. Ripples revisited: Non-classical morphology at the bottom of femtosecond laser ablation craters in transparent dielectrics. Appl. Surf. Sci. 2002, 197–198, 891–895. [Google Scholar] [CrossRef]

- Bhardwaj, V.R.; Simova, E.; Rajeev, P.P.; Hnatovsky, C.; Taylor, R.S.; Rayner, D.M.; Corkum, P.B. Optically Produced Arrays of Planar Nanostructures inside Fused Silica. Phys. Rev. Lett. 2006, 96, 057404. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast lasers—Reliable tools for advanced materials processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Direct femtosecond laser surface nano/microstructuring and its applications. Laser Photonics Rev. 2013, 7, 385–407. [Google Scholar] [CrossRef]

- Borowiec, A.; Haugen, H.K. Subwavelength ripple formation on the surfaces of compound semiconductors irradiated with femtosecond laser pulses. Appl. Phys. Lett. 2003, 82, 4462–4464. [Google Scholar] [CrossRef]

- Wang, C.; Huo, H.; Johnson, M.; Shen, M.; Mazur, E.; Wang, C.; Huo, H.; Johnson, M.; Shen, M.; Mazur, E. The thresholds of surface nano-/micro-morphology modifications with femtosecond laser pulse irradiations. Nanotechnology 2010, 21, 75304. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Barberoglou, M.; Loukakos, P.A.; Stratakis, E.; Fotakis, C. Dynamics of ripple formation on silicon surfaces by ultrashort laser pulses in subablation conditions. Phys. Rev. B 2011, 86, 115316. [Google Scholar] [CrossRef]

- Young, J.F.; Sipe, J.E.; Preston, J.S.; van Driel, H.M. Laser-induced periodic surface damage and radiation remnants. Appl. Phys. Lett. 1998, 41, 261–264. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, L.; Sun, J.; Pan, C.; Han, W.; Wang, G.; Wang, F.; Zhang, K.; Li, M.; Lu, Y. Structure-Mediated Excitation of Air Plasma and Silicon Plasma Expansion in Femtosecond Laser Pulses Ablation. Research 2018, 2018, 5709748. [Google Scholar] [CrossRef]

- Young, J.F.; Sipe, J.E.; van Driel, H.M. Laser-induced periodic surface structure. III. Fluence regimes, the role of feedback, and details of the induced topography in germanium. Phys. Rev. B 1984, 30, 2001–2015. [Google Scholar] [CrossRef]

- Giust, G.K.; Sigmon, T.W. New ripple patterns observed in excimer-laser irradiated SiO2/polycrystalline silicon/SiO2 structures. Appl. Phys. Lett. 1997, 70, 3552–3554. [Google Scholar] [CrossRef]

- Tsukamoto, M.; Asuka, K.; Nakano, H.; Hashida, M.; Katto, M.; Abe, N.; Fujita, M. Periodic microstructures produced by femtosecond laser irradiation on titanium plate. Vacuum 2006, 80, 1346–1350. [Google Scholar] [CrossRef]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of Micro/Nano Structures on Metals by Femtosecond Laser Micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Mimidis, A.; Skoulas, E.; Kirner, S.V.; Krüger, J.; Bonse, J.; Stratakis, E. Modelling periodic structure formation on 100Cr6 steel after irradiation with femtosecond-pulsed laser beams. Appl. Phys. A 2018, 124, 27. [Google Scholar] [CrossRef]

- Papadopoulos, A.; Skoulas, E.; Tsibidis, G.D.; Stratakis, E. Formation of periodic surface structures on dielectrics after irradiation with laser beams of spatially variant polarisation: A comparative study. Appl. Phys. A 2018, 124, 146. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J. Pulse number dependence of laser-induced periodic surface structures for femtosecond laser irradiation of silicon. J. Appl. Phys. 2010, 108, 034903. [Google Scholar] [CrossRef]

- Bonse, J.; Munz, M.; Sturm, H. Structure formation on the surface of indium phosphide irradiated by femtosecond laser pulses. J. Appl. Phys. 2004, 97, 013538. [Google Scholar] [CrossRef]

- He, S.; Nivas, J.J.; Vecchione, A.; Hu, M.; Amoruso, S. On the generation of grooves on crystalline silicon irradiated by femtosecond laser pulses. Opt. Express 2016, 24, 3238–3247. [Google Scholar] [CrossRef]

- Nivas, J.; Amoruso, S. Generation of Supra-Wavelength Grooves in Femtosecond Laser Surface Structuring of Silicon. Nanomaterials 2021, 11, 174. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Skoulas, E.; Papadopoulos, A.; Stratakis, E. Convection roll-driven generation of supra-wavelength periodic surface structures on dielectrics upon irradiation with femtosecond pulsed lasers. Phys. Rev. B 2016, 94, 081305. [Google Scholar] [CrossRef]

- Nivas, J.J.; He, S.; Rubano, A.; Vecchione, A.; Paparo, D.; Marrucci, L.; Bruzzese, R.; Amoruso, S. Direct Femtosecond Laser Surface Structuring with Optical Vortex Beams Generated by a q-plate. Sci. Rep. 2015, 5, 17929. [Google Scholar] [CrossRef]

- Tsibidis, G.D.; Fotakis, C.; Stratakis, E. From ripples to spikes: A hydrodynamical mechanism to interpret femtosecond laser-induced self-assembled structures. Phys. Rev. B 2015, 92, 041405. [Google Scholar] [CrossRef]

- Allahyari, E.; Nivas, J.J.; Skoulas, E.; Bruzzese, R.; Tsibidis, G.; Stratakis, E.; Amoruso, S. On the formation and features of the supra-wavelength grooves generated during femtosecond laser surface structuring of silicon. Appl. Surf. Sci. 2020, 528, 146607. [Google Scholar] [CrossRef]

- Bonse, J.; Baudach, S.; Krüger, J.; Kautek, W.; Lenzner, M. Femtosecond laser ablation of silicon–modification thresholds and morphology. Appl. Phys. A 2002, 74, 19–25. [Google Scholar] [CrossRef]

- Cho, W.; Hwang, S.I.; Nam, C.H.; Bionta, M.R.; Lassonde, P.; Schmidt, B.E.; Ibrahim, H.; Légaré, F.; Kim, K.T. Temporal characterization of femtosecond laser pulses using tunneling ionization in the UV, visible, and mid-IR ranges. Sci. Rep. 2019, 9, 16067. [Google Scholar] [CrossRef]

- Volkov, A.N.; Zhigilei, L.V. Melt dynamics and melt-through time in continuous wave laser heating of metal films: Contributions of the recoil vapor pressure and Marangoni effects. Int. J. Heat Mass Transf. 2017, 112, 300–317. [Google Scholar] [CrossRef]

- Hörstmann-Jungemann, M. Nano- and Microstructuring of SiO2 and Sapphire with Fs-laser Induced Selective Etching. J. Laser Micro/Nanoeng. 2009, 4, 135–140. [Google Scholar] [CrossRef]

- Ashkenasi, D.; Rosenfeld, A.; Varel, H.; Wähmer, M.; Campbell, E. Laser processing of sapphire with picosecond and sub-picosecond pulses. Appl. Surf. Sci. 1997, 120, 65–80. [Google Scholar] [CrossRef]

- Siew, S.Y.; Li, B.; Gao, F.; Zheng, H.Y.; Zhang, W.; Guo, P.; Xie, S.W.; Song, A.; Dong, B.; Luo, L.W.; et al. Review of Silicon Photonics Technology and Platform Development. J. Lightwave Technol. 2021, 39, 4374–4389. [Google Scholar] [CrossRef]

- Margalit, N.; Xiang, C.; Bowers, S.M.; Bjorlin, A.; Blum, R.; Bowers, J.E. Perspective on the future of silicon photonics and electronics. Appl. Phys. Lett. 2021, 118, 220501. [Google Scholar] [CrossRef]

- Köhler, M.; Pomaska, M.; Procel, P.; Santbergen, R.; Zamchiy, A.; Macco, B.; Lambertz, A.; Duan, W.; Cao, P.; Klingebiel, B.; et al. A silicon carbide-based highly transparent passivating contact for crystalline silicon solar cells approaching efficiencies of 24%. Nat. Energy 2021, 6, 529–537. [Google Scholar] [CrossRef]

- Tyndall, N.F.; Stievater, T.H.; Kozak, D.A.; Pruessner, M.W.; Rabinovich, W.S. Germanium-on-silicon waveguides for long-wave integrated photonics: Ring resonance and thermo-optics. Opt. Express 2021, 29, 15443–15451. [Google Scholar] [CrossRef]

- Ge, M.; Cao, C.; Biesold, G.M.; Sewell, C.D.; Hao, S.; Huang, J.; Zhang, W.; Lai, Y.; Lin, Z. Recent Advances in Silicon-Based Electrodes: From Fundamental Research toward Practical Applications. Adv. Mater. 2021, 33, e2004577. [Google Scholar] [CrossRef]

- Budiman, A.; Anbazhagan, S.; Illya, G.; Song, W.; Sahay, R.; Tippabhotla, S.; Tay, A. Enabling curvable silicon photovoltaics technology using polycarbonate-sandwiched laminate design. Sol. Energy 2021, 220, 462–472. [Google Scholar] [CrossRef]

- Qin, F.; Huang, K.; Wu, J.; Jiao, J.; Luo, X.; Qiu, C.; Hong, M. Shaping a Subwavelength Needle with Ultra-long Focal Length by Focusing Azimuthally Polarized Light. Sci. Rep. 2015, 5, 9977. [Google Scholar] [CrossRef]

- Chen, M.; Pethö, L.; Sologubenko, A.S.; Ma, H.; Michler, J.; Spolenak, R.; Wheeler, J.M. Achieving micron-scale plasticity and theoretical strength in Silicon. Nat. Commun. 2020, 11, 2681. [Google Scholar] [CrossRef]

- Rudenko, A.; Mauclair, C.; Garrelie, F.; Stoian, R.; Colombier, J. Light absorption by surface nanoholes and nanobumps. Appl. Surf. Sci. 2019, 470, 228–233. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Piatkowski, P.; Alnaser, A.S. Study on the Origin and Evolution of Femtosecond Laser-Induced Surface Structures: LIPSS, Quasi-Periodic Grooves, and Aperiodic Micro-Ridges. Materials 2023, 16, 2184. https://doi.org/10.3390/ma16062184

Ali A, Piatkowski P, Alnaser AS. Study on the Origin and Evolution of Femtosecond Laser-Induced Surface Structures: LIPSS, Quasi-Periodic Grooves, and Aperiodic Micro-Ridges. Materials. 2023; 16(6):2184. https://doi.org/10.3390/ma16062184

Chicago/Turabian StyleAli, Asghar, Piotr Piatkowski, and Ali S. Alnaser. 2023. "Study on the Origin and Evolution of Femtosecond Laser-Induced Surface Structures: LIPSS, Quasi-Periodic Grooves, and Aperiodic Micro-Ridges" Materials 16, no. 6: 2184. https://doi.org/10.3390/ma16062184

APA StyleAli, A., Piatkowski, P., & Alnaser, A. S. (2023). Study on the Origin and Evolution of Femtosecond Laser-Induced Surface Structures: LIPSS, Quasi-Periodic Grooves, and Aperiodic Micro-Ridges. Materials, 16(6), 2184. https://doi.org/10.3390/ma16062184