Mycelium-Based Composite Materials: Study of Acceptance

Abstract

1. Introduction

2. Materials and Methods

2.1. Organization of the Research

- Test A: assessing the organoleptic comfort (sight, touch, and smell) of MBCs with a three-degree scale;

- Test B: assessing the MBC product acceptance with a nine-degree scale—determining personal decision (methodology based on [19]);

- Test C: comparing the MBC wall cladding panels with reference panels made of chamotte clay (pairwise comparisons) (methodology based on [20]).

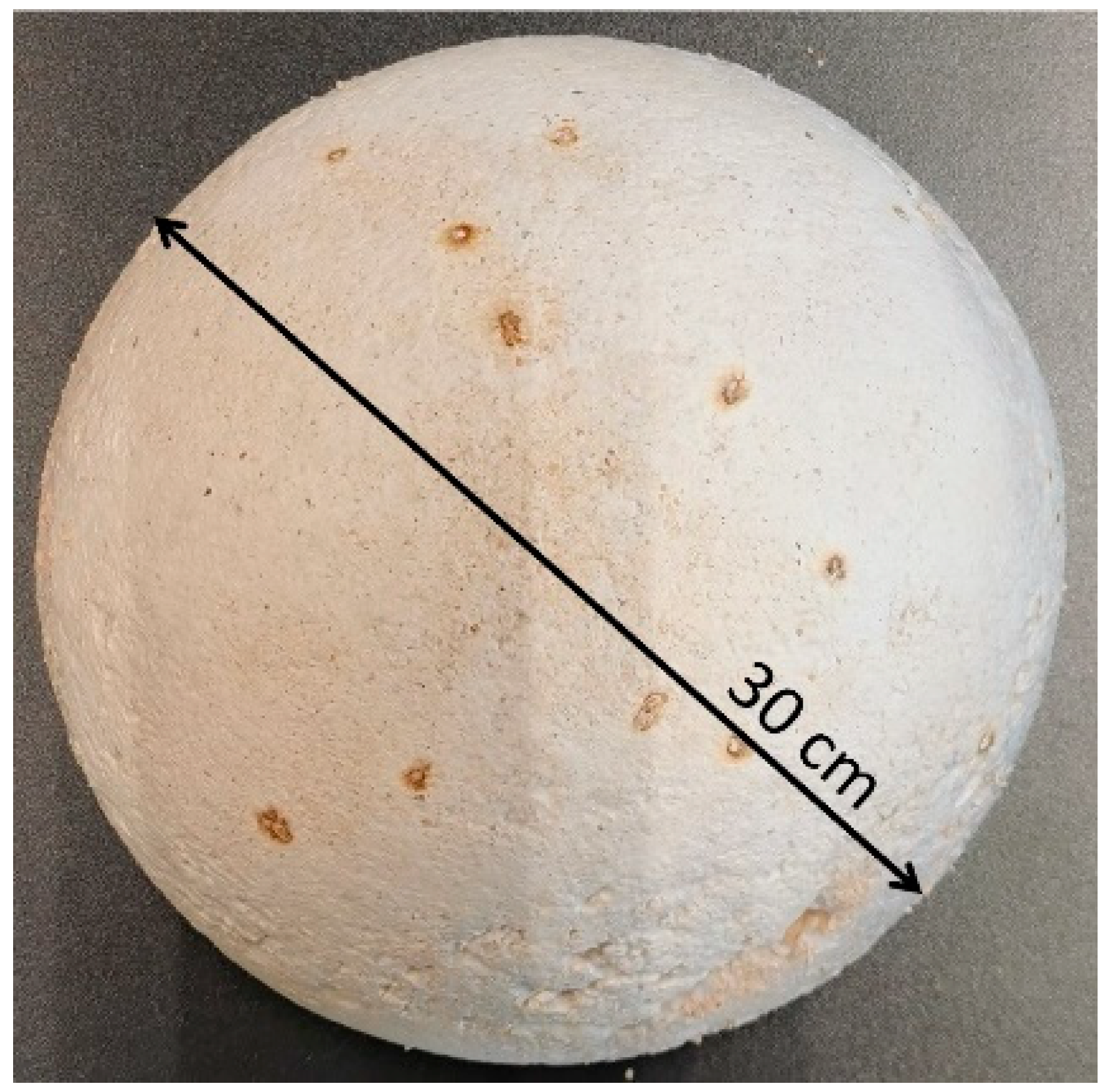

2.2. Production of Samples

2.3. Respondents

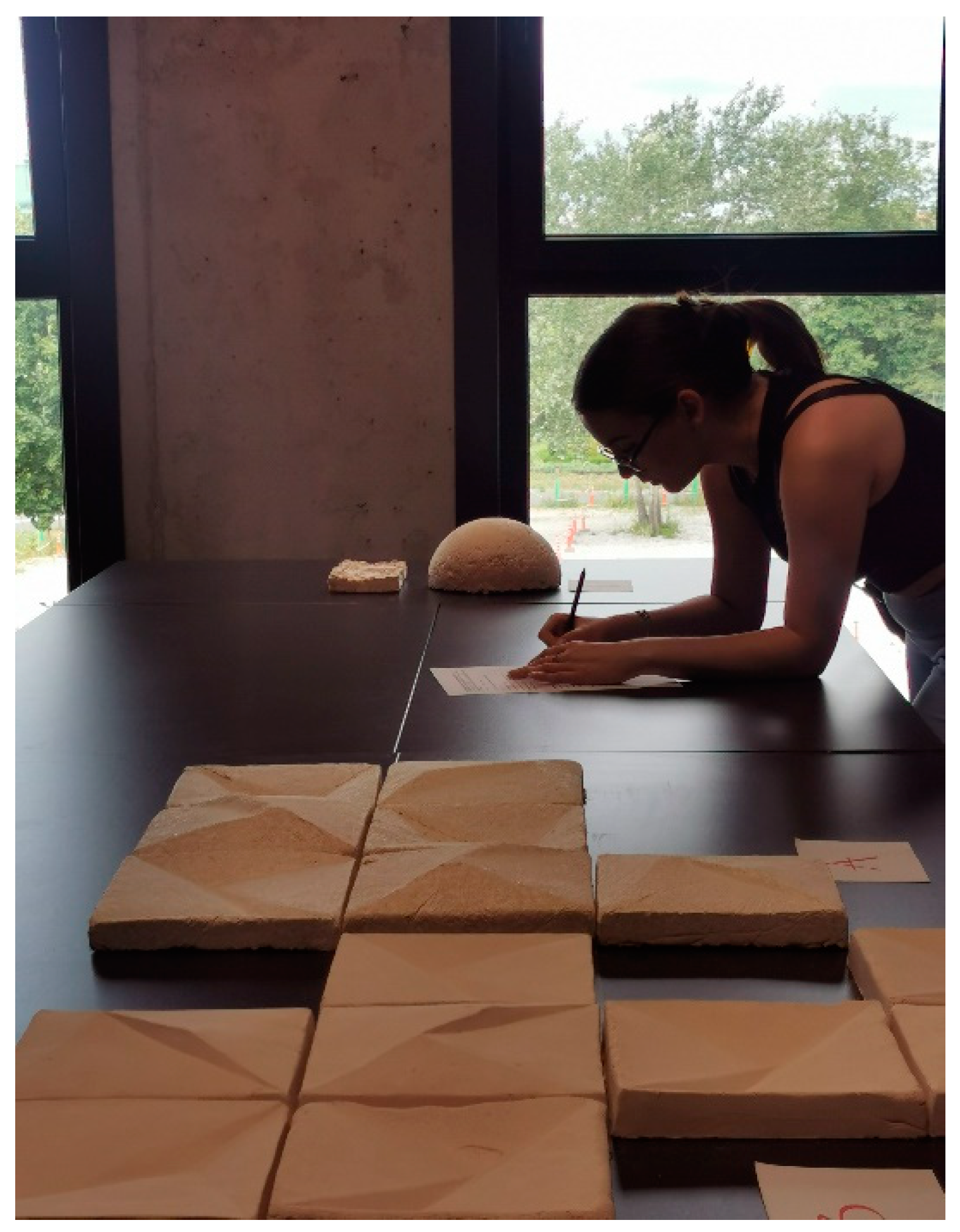

2.4. Tests Environment

2.5. Experimental

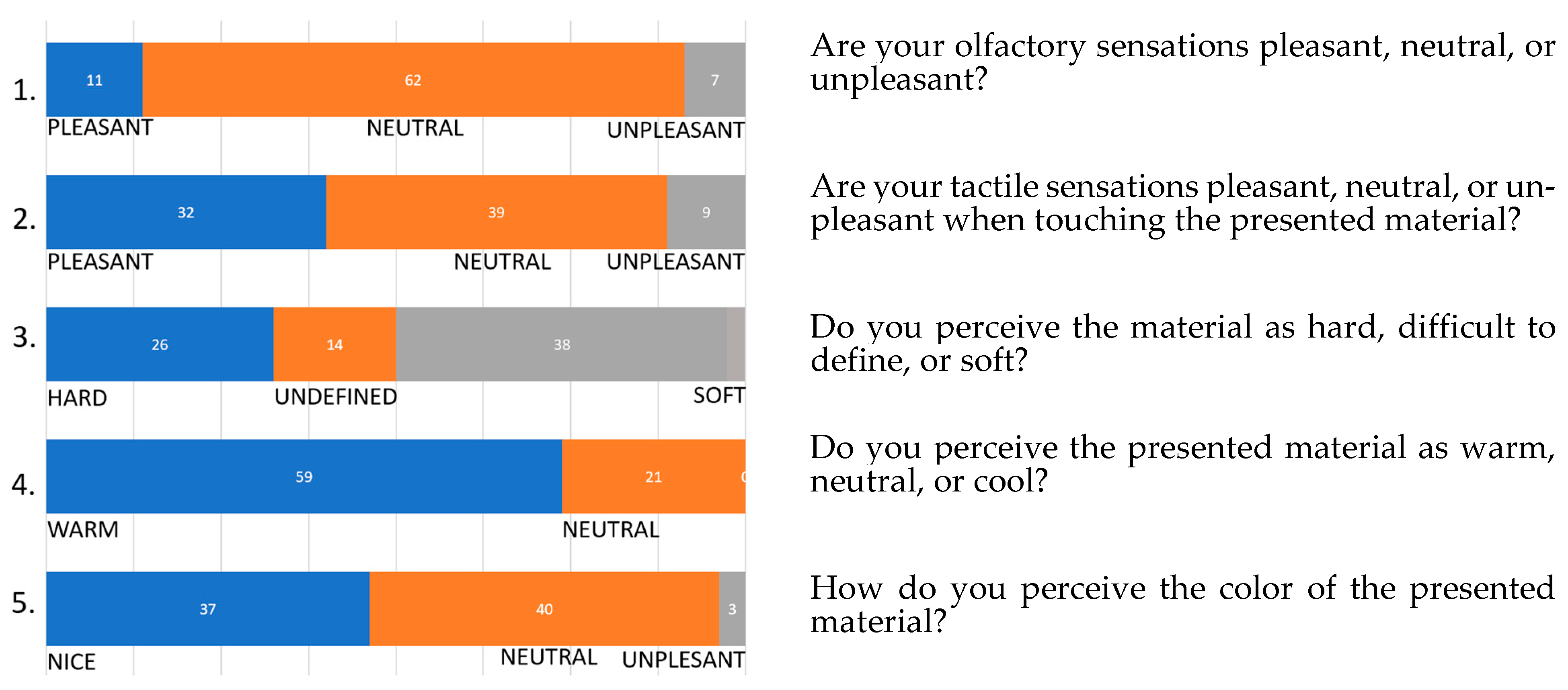

2.5.1. Test A: Consumer Test with a Three-Degree Scale

- Do you perceive the material’s color as pleasant, neutral, or ugly?

- Do you perceive the material as warm, neutral, or cold?

- Do you perceive the material surface as hard, difficult to define, or soft?

- Do you find your tactile sensation of it pleasant, neutral, or unpleasant?

- Do you find your olfactory sensation of it pleasant, neutral, or unpleasant?

2.5.2. Test B: Consumer Tests with a Nine-Degree Scale of Material Acceptance

- Would you accept the material in interior design elements in your own home?

- Would you accept the material in interior design elements in a home that you design with an ecological aesthetic?

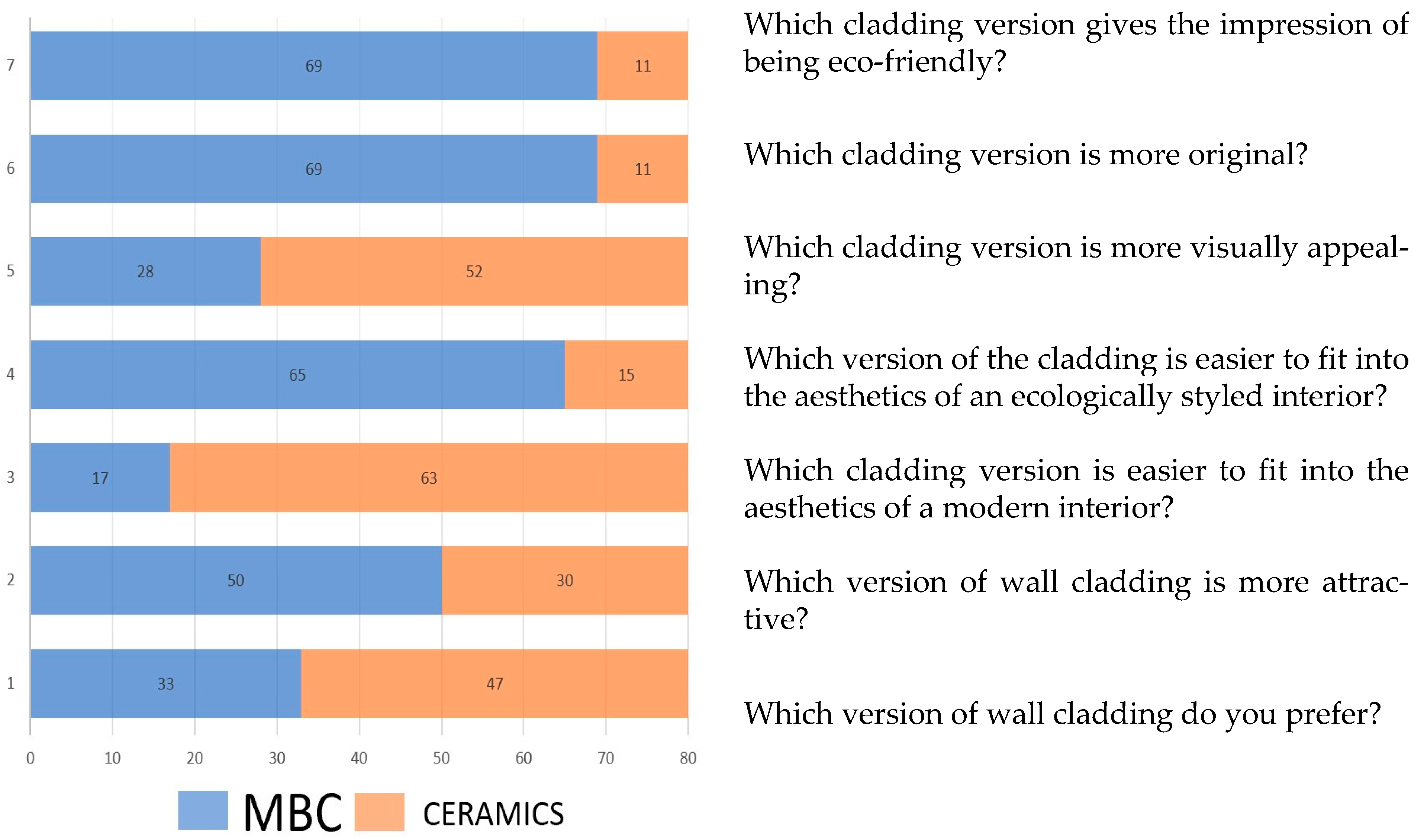

2.5.3. Test C: Consumer Tests with the Method of Pairwise Artifact Comparison of Wall Cladding Samples

- Which cladding version gives the impression of being eco-friendly?

- Which cladding version is more original?

- Which cladding version is more visually appealing?

- Which version of the cladding is easier to fit into the aesthetics of an ecologically styled interior?

- Which cladding version is easier to fit into the aesthetics of a modern interior?

- Which version of wall cladding is more attractive?

- Which version of wall cladding do you prefer?

3. Results and Discussion

3.1. Results and Interpretation of Test A: Consumer Test with a Three-Degree Scale

3.2. Results and Interpretation of Test B: Consumer Tests with a Nine-Degree Scale of Material Acceptance

3.3. Results and Interpretation of Test C—Consumer Tests Following the Method of Pairwise Artifact Comparison of Wall Cladding Samples

- Minimalism: This philosophy emphasizes simplicity and functionality, focusing on clean lines, neutral colors, and a lack of clutter. A lack of ornamentation and a focus on form and function characterize minimalist interiors.

- Modernism: Modernist interiors are characterized by a focus on functionality, technology, and the use of new materials and construction methods. They often feature simple, clean lines, and a neutral color palette.

- Scandinavian: Scandinavian interior design is known for its simplicity, functionality, and focus on natural materials. This style often features light colors, natural wood, and an emphasis on creating a cozy and comfortable living space.

- Art Deco: Art Deco interiors are characterized by their use of bold geometric shapes, strong colors, and luxurious materials. This style often features metallic accents, such as brass or chrome, and incorporates exotic motifs inspired by ancient cultures.

- Traditional: Traditional interiors are characterized by classic forms, such as ornate moldings, classic furniture styles, and rich colors and fabrics. This style often incorporates antiques and heirloom pieces and is designed to evoke a sense of timeless elegance.

- Conviction about riskiness: the natural origin of these materials and the fear of fungus can be challenging;

- Unproven ecological benefits: consumers may be unaware of MBCs and their benefits, such as their sustainable and eco-friendly nature;

- Perceived high cost: MBCs are still relatively new and are not yet widely available. As a result, consumers may perceive the cost of producing and using MBCs in interior design products as high, which could deter them from purchasing these products;

- Personal aesthetic preferences: the respondents may have specific aesthetic preferences regarding interior design, and MBCs may not fit their style or taste (as mentioned, the natural and organic look of these mycomaterials may not appeal to everyone.);

- Inaccessibility: The availability of interior design products made of MBCs is now limited, which could make it difficult for consumers to find these products in stores or online. This could lead to a lack of awareness and interest in mycomaterials among consumers;

- Material properties are unknown. The respondents may have concerns about the durability and performance of MBCs compared to those of traditional materials. They may worry that mycomaterials will not hold up over time or will not perform as well as other materials in certain conditions.

4. Summary and Conclusions

- Color uniformity: mycelium is a natural material whose color can vary, making it difficult to achieve a consistent appearance in furniture;

- Surface texture: the texture of mycelium can also vary, making it difficult to control the final appearance of furniture.

- The overall positive evaluation of the mycelium-based composite (MBC) among architecture and interior design students aged 19–24 years, i.e., Generation Z, demonstrated that continued research into the material in question could yield good commercialization results in the coming years. The main observation is that the younger generation of designers showed a high level of acceptance for the material itself and its products. According to study participants, the MBC material can be described as “likable” (test A) and highly ecological (test B). The wall cladding made of the MBC had advantages regarding its uniqueness, its consistency with eco-styled interiors, and the fact that it is interesting (test C). Further considerations should be given to optimizing the properties and its new applications that are not obvious today.

- The results of the experiments suggest double standards in the respondents. MBCs were generally accepted, but not in their own homes. It followed that MBCs were perceived as clearly ecological, but at the same time they raised some concerns. The fear of fungus is deeply ingrained in many cultures and can lead to skepticism or aversion towards products made from mycelium. Some people may be hesitant to use MBCs in their homes or in products they consume due to concerns about fungal growth and associated health risks. Additionally, MBCs are a relatively new technology, and there is still much to learn about their properties, durability, and potential applications. This can lead to uncertainty and skepticism among consumers and industry professionals alike.

- Working with this material and other bio-materials can lead to a paradigm shift in aesthetics in which the design mainstream has hitherto been defined by high technology and highly sophisticated design and production methods, which will perhaps soon take on a more casual, nature-like form.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tejero-Martin, D.; Rezvani Rad, M.; McDonald, A.; Hussain, T. Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019, 28, 598–644. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material Function of Mycelium-Based Bio-Composite: A Review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Howell, C.; Hunt, C.G. Insight into Mycelium-Lignocellulosic Bio-Composites: Essential Factors and Properties. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107125. [Google Scholar] [CrossRef]

- Bayer, E.; McIntyre, G.; Swersey, B.L. Method for Producing Grown Materials and Products Made Thereby. Patent Application US 2008/0145577 A1, 19 June 2008. Granted as US 9485917 B2 2016-11-08. [Google Scholar]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; Mooney, L.; Putney, S. Manufacturing of Mycelium-Based Biocomposites. In Proceedings of the International SAMPE Technical Conference, Covina, CA, USA, 6–9 May 2013; Beckwith, S.W., Ed.; Society for the Advancement of Material and Process Engineering: Long Beach, CA, USA, 2013; pp. 1944–1955. [Google Scholar]

- Abhijith, R.; Ashok, A.; Rejeesh, C.R. Sustainable Packaging Applications from Mycelium to Substitute Polystyrene: A Review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Adamatzky, A.; Ayres, P.; Beasley, A.E.; Chiolerio, A.; Dehshibi, M.M.; Gandia, A.; Albergati, E.; Mayne, R.; Nikolaidou, A.; Roberts, N.; et al. Fungal Electronics. Biosystems 2022, 212, 104588. [Google Scholar] [CrossRef] [PubMed]

- Bitting, S.; Derme, T.; Lee, J.; Van Mele, T.; Dillenburger, B.; Block, P. Challenges and Opportunities in Scaling up Architectural Applications of Mycelium-Based Materials with Digital Fabrication. Biomimetics 2022, 7, 44. [Google Scholar] [CrossRef] [PubMed]

- Cerimi, K.; Akkaya, K.C.; Pohl, C.; Schmidt, B.; Neubauer, P. Fungi as Source for New Bio-Based Materials: A Patent Review. Fungal Biol. Biotechnol. 2019, 6, 17. [Google Scholar] [CrossRef]

- Sydor, M.; Bonenberg, A.; Doczekalska, B.; Cofta, G. Mycelium-Based Composites in Art, Architecture, and Interior Design: A Review. Polymers 2022, 14, 145. [Google Scholar] [CrossRef]

- Fairus, M.J.B.M.; Bahrin, E.K.; Arbaain, E.N.N. Norhayati Ramli Mycelium-Based Composite: A Way Forward for Renewable Material. J. Sustain. Sci. Manag. 2022, 17, 271–280. [Google Scholar] [CrossRef]

- Sydor, M.; Cofta, G.; Doczekalska, B.; Bonenberg, A. Fungi in Mycelium-Based Composites: Usage and Recommendations. Materials 2022, 15, 6283. [Google Scholar] [CrossRef]

- Van den Brandhof, J.G.; Wösten, H.A.B. Risk Assessment of Fungal Materials. Fungal Biol. Biotechnol. 2022, 9, 3. [Google Scholar] [CrossRef]

- Brischke, C.; Humar, M. Performance of the Bio-Based Materials. In Performance of Bio-Based Building Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 249–333. ISBN 978-0-08-100982-6. [Google Scholar]

- Rifqiya, A.; Nasution, R.A. Sensory Marketing: The Effect of Tactile Cue on Product Packaging towards Perceived Novelty and Perceived Likeability. J. Bus. Manag. 2016, 5, 352–361. [Google Scholar]

- Kwak, H.S.; Ahn, B.-H.; Kim, H.-R.; Lee, S.-Y. Identification of Senory Attributes That Drive the Likeability of Korean Rice Wines by American Panelists: Drivers of Liking for Korean Rice Wines. J. Food Sci. 2015, 80, S161–S170. [Google Scholar] [CrossRef] [PubMed]

- Schifferstein, H.N.J.; Wastiels, L. Sensing Materials. In Materials Experience; Butterworth-Heinemann/Elsevier: Oxford, UK, 2014; pp. 15–26. ISBN 978-0-08-099359-1. [Google Scholar]

- Lim, J. Hedonic Scaling: A Review of Methods and Theory. Food Qual. Prefer. 2011, 22, 733–747. [Google Scholar] [CrossRef]

- Manuel, A.; Leonhart, R.; Broman, O.; Becker, G. Consumers’ Perceptions and Preference Profiles for Wood Surfaces Tested with Pairwise Comparison in Germany. Ann. For. Sci. 2015, 72, 741–751. [Google Scholar] [CrossRef]

- Delong, M.; Wu, J.; Park, J. Tactile Response and Shifting Touch Preference. Textile 2012, 10, 44–59. [Google Scholar] [CrossRef]

- Silvennoinen, J.M.; Rousi, R.; Jokinen, J.P.P.; Perälä, P.M.H. Apperception as a Multisensory Process in Material Experience. In Proceedings of the 19th International Academic Mindtrek Conference, Tampere, Finland, 22–24 September 2015; ACM: Tampere, Finland, 2015; pp. 144–151. [Google Scholar]

- Kagawa, F. Dissonance in Students’ Perceptions of Sustainable Development and Sustainability: Implications for Curriculum Change. Int. J. Sustain. High. Educ. 2007, 8, 317–338. [Google Scholar] [CrossRef]

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The Environmental Price of Fast Fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Bick, R.; Halsey, E.; Ekenga, C.C. The Global Environmental Injustice of Fast Fashion. Env. Health 2018, 17, 92. [Google Scholar] [CrossRef]

- Roozen, I.; Raedts, M. The Power of Negative Publicity on the Fast Fashion Industry. J. Glob. Fash. Mark. 2020, 11, 380–396. [Google Scholar] [CrossRef]

- Raizman, D.S. History of Modern Design: Graphics and Products since the Industrial Revolution; Laurence King: London, UK, 2003; ISBN 978-1-85669-348-6. [Google Scholar]

- Morteo, E. Grande Atlante del Design dal 1850 a oggi; Electa S.p.A.: Milano, Italy, 2008; ISBN 978-88-370-4897-6. [Google Scholar]

- Fiorentino, M.; de Amicis, R.; Monno, G.; Stork, A. Spacedesign: A Mixed Reality Workspace for Aesthetic Industrial Design. In Proceedings of the International Symposium on Mixed and Augmented Reality, Darmstadt, Germany, 30 September–1 October 2002; ISMAR 2002. The Institute of Electrical and Electronics Engineers, Inc.: Piscataway Township, NJ, USA, 2002; pp. 86–318. [Google Scholar]

- Vaughan, C.; Dessai, S. Climate Services for Society: Origins, Institutional Arrangements, and Design Elements for an Evaluation Framework. Wiley Interdiscip. Rev. Clim. Chang. 2014, 5, 587–603. [Google Scholar] [CrossRef] [PubMed]

- Proctor, R. 1000 New Eco Designs and Where to Find Them; Laurence King Publishing: London, UK, 2009; ISBN 1-85669-585-9. [Google Scholar]

- Melkozernov, A.N.; Sorensen, V. What Drives Bio-Art in the Twenty-First Century? Sources of Innovations and Cultural Implications in Bio-Art/Biodesign and Biotechnology. AI Soc. 2021, 36, 1313–1321. [Google Scholar] [CrossRef]

- Cicconi, P. Eco-Design and Eco-Materials: An Interactive and Collaborative Approach. Sustain. Mater. Technol. 2020, 23, e00135. [Google Scholar] [CrossRef]

- Kumar, D.S.; Purani, K.; Viswanathan, S.A. The Indirect Experience of Nature: Biomorphic Design Forms in Servicescapes. J. Serv. Mark. 2020, 34, 847–867. [Google Scholar] [CrossRef]

- Hayles, C.S. Environmentally Sustainable Interior Design: A Snapshot of Current Supply of and Demand for Green, Sustainable or Fair Trade Products for Interior Design Practice. Int. J. Sustain. Built Environ. 2015, 4, 100–108. [Google Scholar] [CrossRef]

- Munro, A.; Munro, G. Growing the Future. Full Grown Ltd.: Wirksworth, UK, 2022. Available online: https://fullgrown.co.uk (accessed on 10 February 2023).

- Dykes, T.H.; Rodgers, P.A.; Smyth, M. Towards a New Disciplinary Framework for Contemporary Creative Design Practice. CoDesign 2009, 5, 99–116. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonenberg, A.; Sydor, M.; Cofta, G.; Doczekalska, B.; Grygorowicz-Kosakowska, K. Mycelium-Based Composite Materials: Study of Acceptance. Materials 2023, 16, 2164. https://doi.org/10.3390/ma16062164

Bonenberg A, Sydor M, Cofta G, Doczekalska B, Grygorowicz-Kosakowska K. Mycelium-Based Composite Materials: Study of Acceptance. Materials. 2023; 16(6):2164. https://doi.org/10.3390/ma16062164

Chicago/Turabian StyleBonenberg, Agata, Maciej Sydor, Grzegorz Cofta, Beata Doczekalska, and Klaudia Grygorowicz-Kosakowska. 2023. "Mycelium-Based Composite Materials: Study of Acceptance" Materials 16, no. 6: 2164. https://doi.org/10.3390/ma16062164

APA StyleBonenberg, A., Sydor, M., Cofta, G., Doczekalska, B., & Grygorowicz-Kosakowska, K. (2023). Mycelium-Based Composite Materials: Study of Acceptance. Materials, 16(6), 2164. https://doi.org/10.3390/ma16062164