Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding

Abstract

1. Introduction

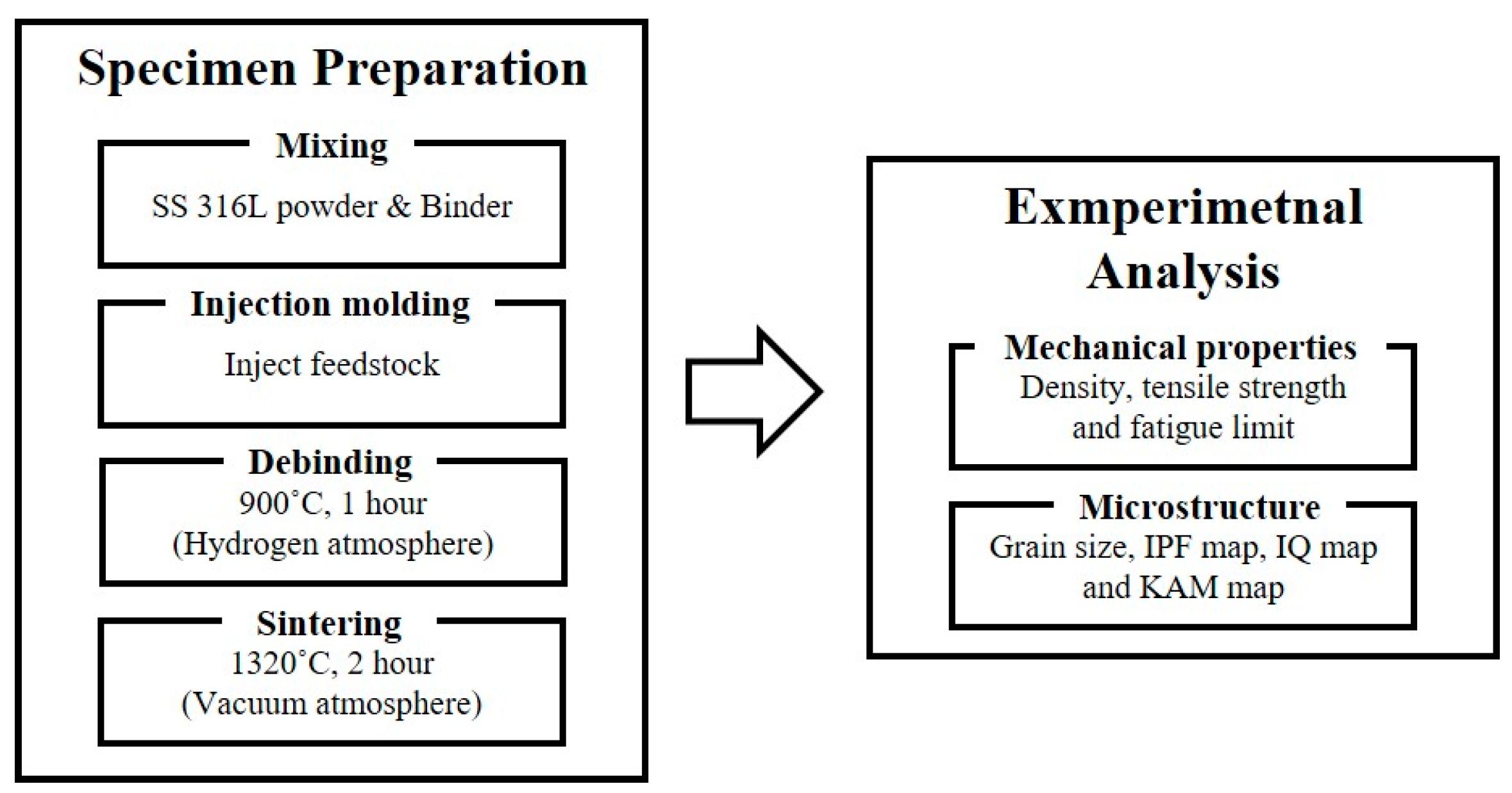

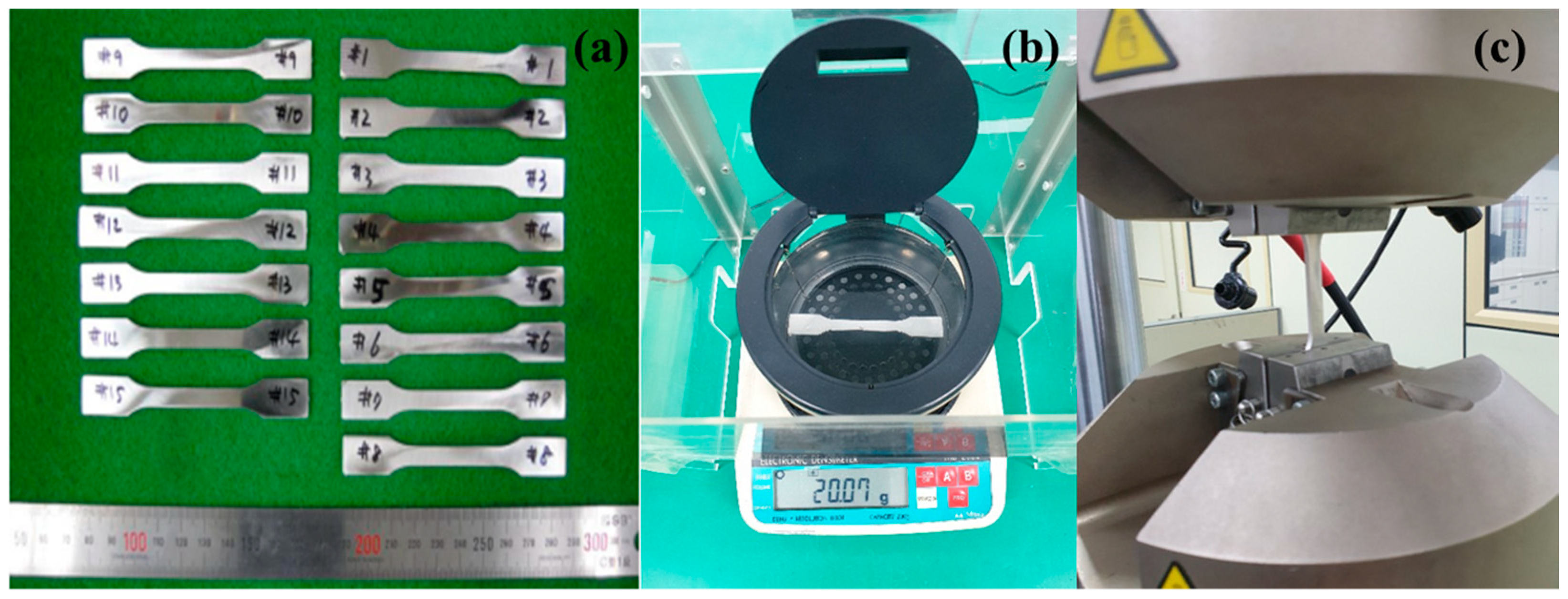

2. Materials and Methods

3. Results and Discussion

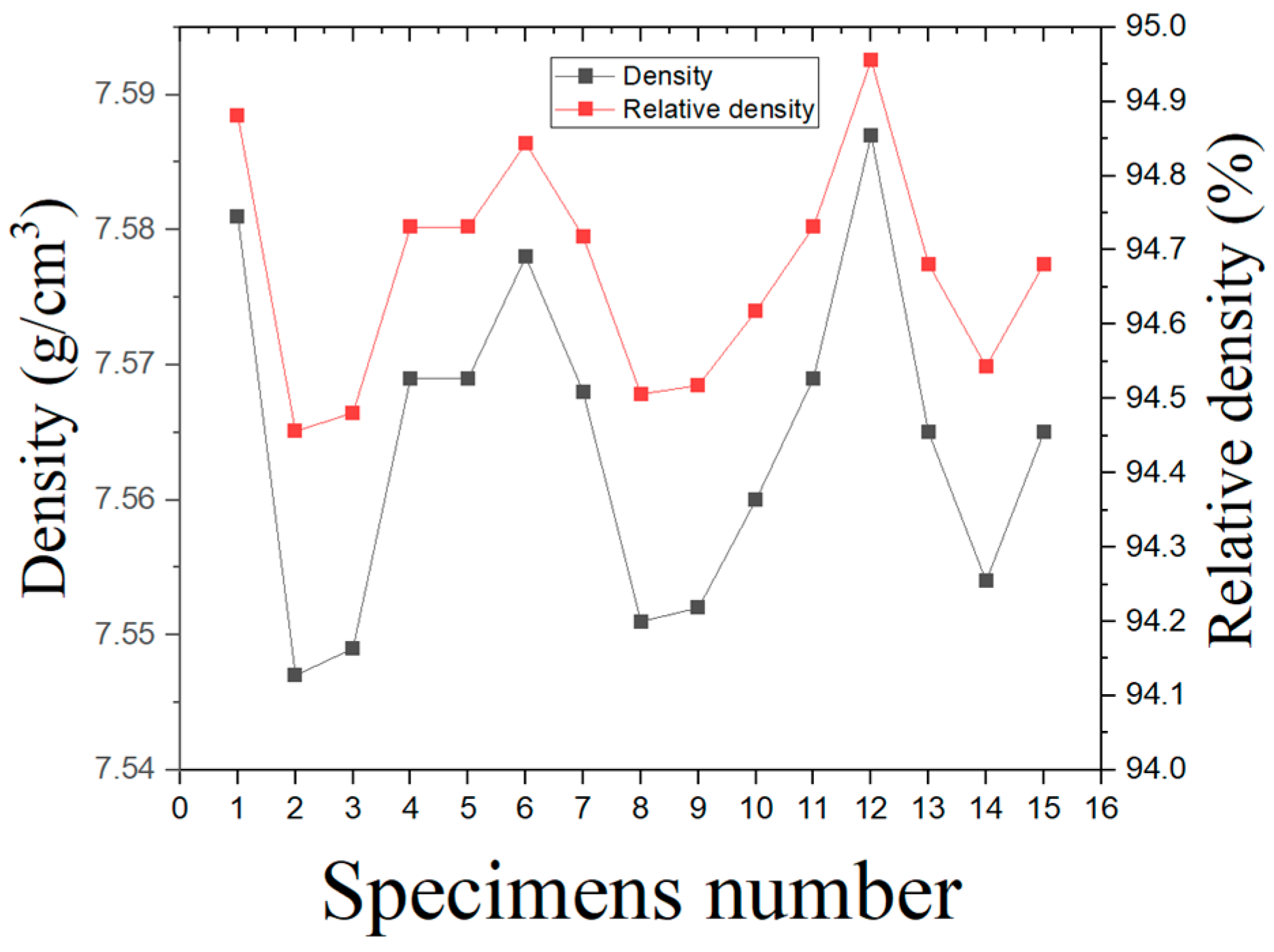

3.1. Density

3.2. Stress–Strain Diagram

3.3. Fatigue Life

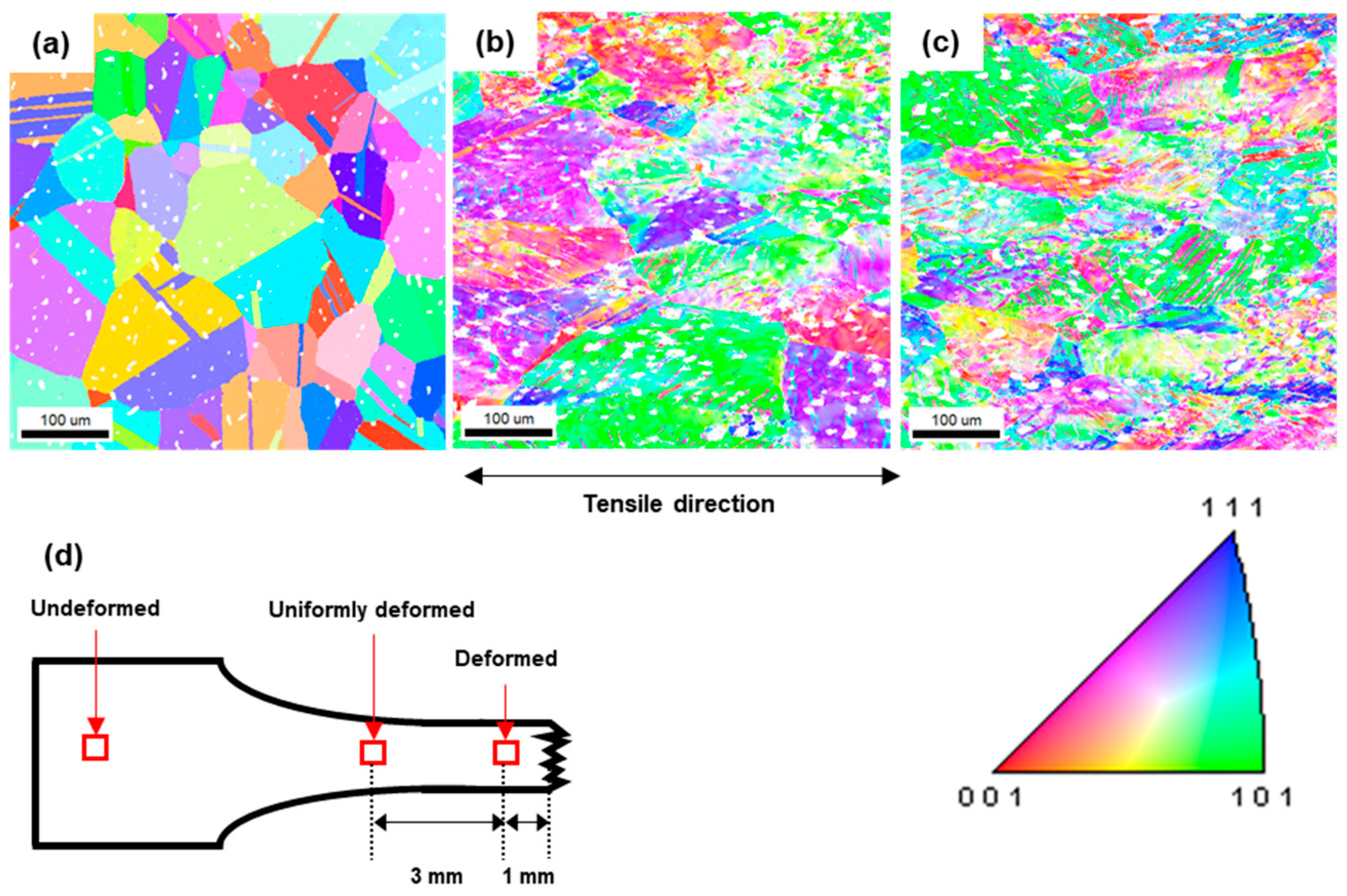

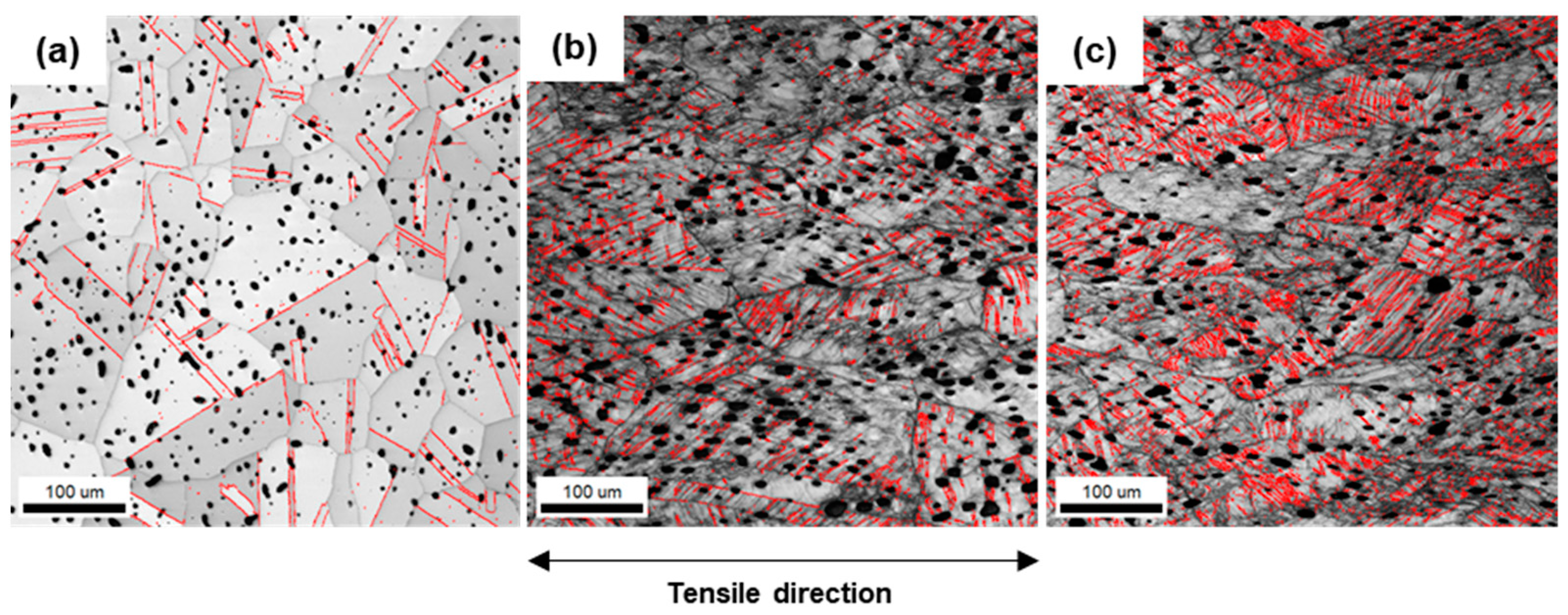

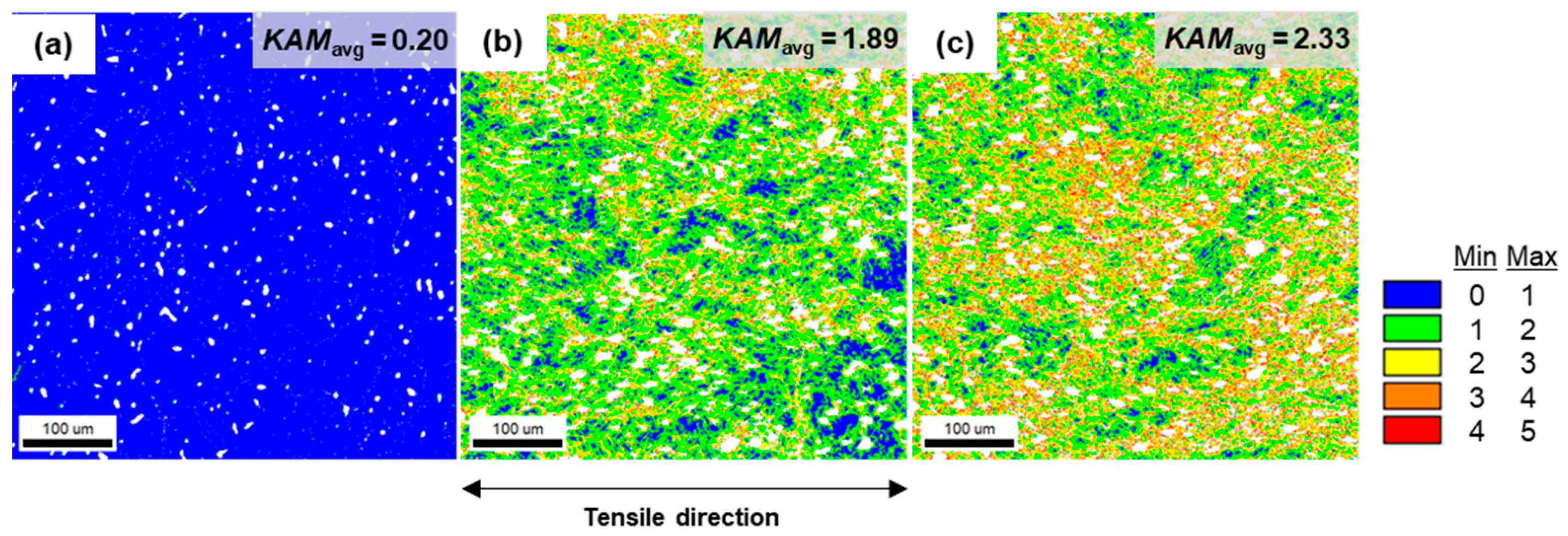

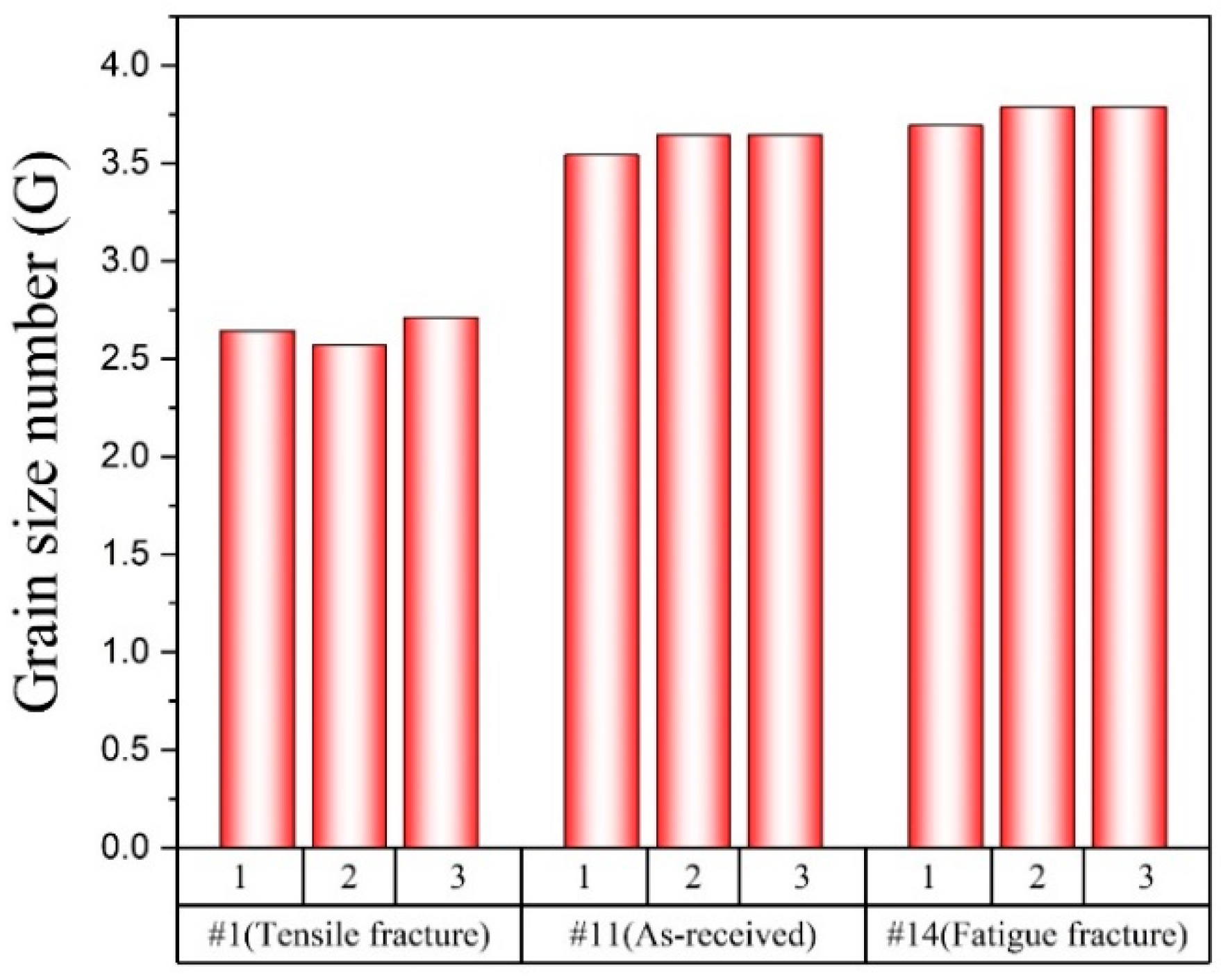

3.4. Microstructure

4. Conclusions

- The average density of MIM SS 316L specimens is 7.56 g/cm3. The relative density measured was 94.68% of the theoretical density.

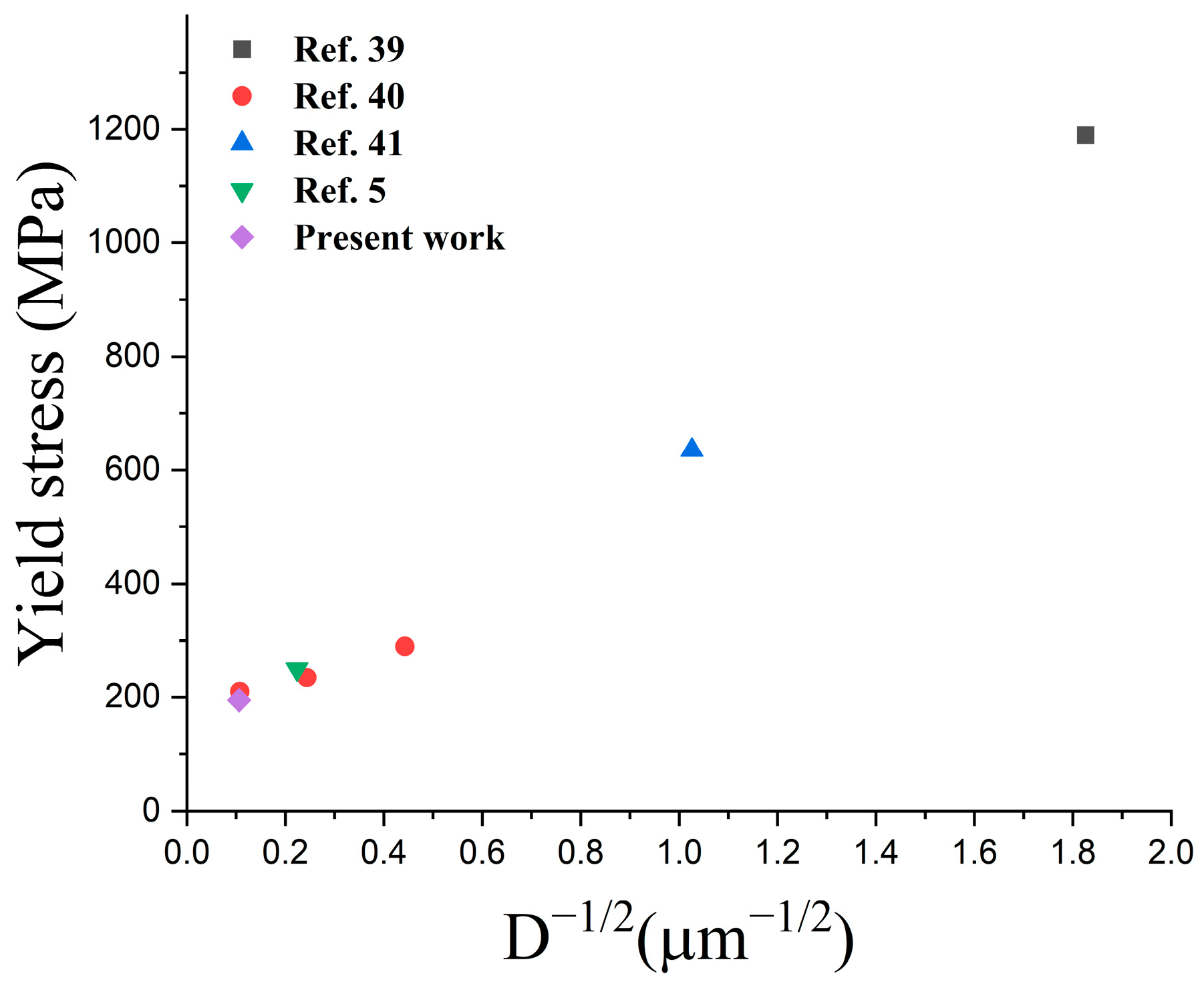

- The average tensile strength (539 MPa) of the MIM SS 316L specimen was lower than the tensile strength of the cold-rolled (620–795 MPa) and hot-rolled (580 MPa) specimens. The elongation was 92%, which was higher than the elongation (30%, 89%) of the specimen manufactured by cold rolling and hot rolling. Because of its high elongation, it has excellent impact resistance. The fatigue limit was measured at 297 MPa (55% of tensile strength), which is higher than SLM SS 316L and lower than cold-rolled SS 316L.

- With increasing deformation, the austenite grains become fragmented due to increases in misorientation, the density of the twin boundary, and the deformation band. Accordingly, these behaviors suppressed the dislocation movement during tensile stress, which thereby enhanced the mechanical properties.

- The average KAM value was a significantly increased at the relatively early stage of deformation. This result shows that a high density of dislocations was formed, which act as a soft barrier that restricts dislocation migration for increased strength, while also allowing for a continuous plastic flow to maintain ductility by transmitting partial dislocations.

- The grain size was almost the same between the one evaluated by the intercept method by lines through the grain boundaries and the one calculated by the EBSD. A precision of better than 0.25 grain size units was obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, B.; Liang, S.; Qu, X. The rheology of metal injection molding. J. Mater. Process. Technol. 2003, 137, 132–137. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.; Chung, S.; Ahn, S. A Study of STS 316L Threaded Elbow Fitting Fabrication by Metal Injection Molding. Trans. Mater. Process. 2015, 24, 121–129. [Google Scholar] [CrossRef]

- German, R.M. Metal powder injection molding (MIM): Key trends and markets. In Handbook of Metal Injection Molding; Heaney, D.F., Ed.; Woodhead Publishing: Sawston/Cambridgeshire, UK, 2012; pp. 1–25. [Google Scholar] [CrossRef]

- Ro, C.-S.; Park, J.-N.; Jung, H.-B. A Study on the Injection Molding Analysis of the Metal Powder Material. J. Korea Acad.-Ind. Coop. Soc. 2017, 18, 42–47. [Google Scholar] [CrossRef]

- Chen, X.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Aslam, M.; Ahmad, F.; Yusoff, P.S.M.B.M.; Altaf, K.; Omar, M.A.; M.German, R. Powder injection molding of biocompatible stainless steel biodevices. Powder Technol. 2016, 295, 84–95. [Google Scholar] [CrossRef]

- Alam, M.K.; Mehdi, M.; Urbanic, R.J.; Edrisy, A. Electron Backscatter Diffraction (EBSD) analysis of laser-cladded AISI 420 martensitic stainless steel. Mater. Charact. 2020, 161, 110138. [Google Scholar] [CrossRef]

- Maitland, T.; Sitzman, S. Electron backscatter diffraction (EBSD) technique and materials characterization examples. In Scanning Microscopy for Nanotechnology: Techniques and Applications; Zhou, W., Whang, Z.L., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 41–75. [Google Scholar]

- Suzuki, S. Features of transmission EBSD and its application. JOM 2013, 65, 1254–1263. [Google Scholar] [CrossRef]

- Wright, S.I.; Nowell, M.M. EBSD image quality mapping. Microsc. Microanal. 2006, 12, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Brewer, L.N.; Field, D.P.; Merriman, C.C. Mapping and Assessing Plastic Deformation Using EBSD. In Electron Backscatter Diffraction in Materials Science; Schwartz, A.J., Kumar, M., Adams, B.L., Field, D.P., Eds.; Springer: Boston, MA, USA, 2009; pp. 251–262. [Google Scholar] [CrossRef]

- Kamaya, M.; Kubushiro, K.; Sakakibara, Y.; Suzuki, S.; Morita, H.; Yoda, R.; Kobayashi, D.; Yamagiwa, K.; Nishioka, T.; Yamazaki, Y.; et al. Round robin crystal orientation measurement using EBSD for damage assessment. Mech. Eng. J. 2016, 3. [Google Scholar] [CrossRef]

- ASTM E112-10; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/e0112-10.html (accessed on 18 September 2022).

- Hall, E. The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- ASTM E8/E8M-13a; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013. Available online: https://www.astm.org/e0008_e0008m-13a.html (accessed on 7 May 2016).

- Majeed, A.; Zhang, Y.; Lv, J.; Peng, T.; Atta, Z.; Ahmed, A. Investigation of T4 and T6 heat treatment influences on relative density and porosity of AlSi10Mg alloy components manufactured by SLM. Comput. Ind. Eng. 2020, 139, 106194. [Google Scholar] [CrossRef]

- Zhang, Y.; Majeed, A.; Muzamil, M.; Lv, J.; Peng, T.; Patel, V. Investigation for macro mechanical behavior explicitly for thin-walled parts of AlSi10Mg alloy using selective laser melting technique. J. Manuf. Process. 2021, 66, 269–280. [Google Scholar] [CrossRef]

- Enneti, R.K.; Onbattuvelli, V.P.; Gulsoy, O.; Kate, K.H.; Atre, S.V. 4—Powder-binder formulation and compound manufacture in metal injection molding (MIM). In Handbook of Metal Injection Molding, 2nd ed.; Heaney, D.F., Ed.; Woodhead Publishing: Sawston/Cambridgeshire, UK, 2019; pp. 57–88. [Google Scholar] [CrossRef]

- Banerjee, S.; Joens, C.J. 7—Debinding and sintering of metal injection molding (MIM) components. In Handbook of Metal Injection Molding, 2nd ed.; Heaney, D.F., Ed.; Woodhead Publishing: Sawston/Cambridgeshire, UK, 2019; pp. 129–171. [Google Scholar] [CrossRef]

- Lobo, H. 10—Characterization of feedstock in metal injection molding (MIM). In Handbook of Metal Injection Molding, 2nd ed.; Heaney, D.F., Ed.; Woodhead Publishing: Sawston/Cambridgeshire, UK, 2019; pp. 205–217. [Google Scholar] [CrossRef]

- Omar, M.A.; Hassan, N. Effect of Stearic Acid on the Rheology and Moulding Behaviour of 316 L Stainless Steel Powder Using Thermoplastic Natural Rubber (TPNR) Binder. J. Eng. Sci. 2019, 15, 83–95. [Google Scholar] [CrossRef]

- Huang, M.-S.; Hsu, H.-C. Effect of backbone polymer on properties of 316L stainless steel MIM compact. J. Mater. Process. Technol. 2009, 209, 5527–5535. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Sintering of 17-4PH stainless steel feedstock for metal injection molding. Mater. Lett. 2008, 62, 3334–3336. [Google Scholar] [CrossRef]

- Heaney, D.F.; Binet, C. 9—Hot isostatic pressing (HIP) of metal injection molding (MIM). In Handbook of Metal Injection Molding, 2nd ed.; Heaney, D.F., Ed.; Woodhead Publishing: Sawston/Cambridgeshire, UK, 2019; pp. 195–202. [Google Scholar] [CrossRef]

- 316 Stainless Steel Mechanical Properties. Available online: https://www.ezlok.com/316-stainless-steel-properties (accessed on 5 January 2023).

- Ohtani, T.; Ogi, H.; Hirao, M. Change of ultrasonic attenuation and microstructure evolution during creep of a stainless steel. In Proceedings of the 16th World Conference, Montréal, QC, Canada, 30 August–3 September 2004; pp. 1–5. [Google Scholar]

- Huber, D.; Vogel, L.; Fischer, A. The effects of sintering temperature and hold time on densification, mechanical properties and microstructural characteristics of binder jet 3D printed 17-4 PH stainless steel. Addit. Manuf. 2021, 46, 102114. [Google Scholar] [CrossRef]

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Kalentics, N.; de Seijas, M.O.V.; Griffiths, S.; Leinenbach, C.; Loge, R.E. 3D laser shock peening–A new method for improving fatigue properties of selective laser melted parts. Addit. Manuf. 2020, 33, 101112. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Huang, Y.; Fan, C.; Peng, Z.; Gao, Z. Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM). Materials 2021, 14, 7544. [Google Scholar] [CrossRef] [PubMed]

- Qu, H.; Li, J.; Zhang, F.; Bai, J. Anisotropic cellular structure and texture microstructure of 316L stainless steel fabricated by selective laser melting via rotation scanning strategy. Mater. Des. 2022, 215, 110454. [Google Scholar] [CrossRef]

- Herrera, C.; Ponge, D.; Raabe, D. Design of a novel Mn-based 1 GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 2011, 59, 4653–4664. [Google Scholar] [CrossRef]

- Wilkinson, A.J.; Meaden, G.; Dingley, D.J. High resolution mapping of strains and rotations using electron backscatter diffraction. Mater. Sci. Technol. 2006, 22, 1271–1278. [Google Scholar] [CrossRef]

- Lee, T.-H.; Shin, E.; Oh, C.-S.; Ha, H.-Y.; Kim, S.-J. Correlation between stacking fault energy and deformation microstructure in high-interstitial-alloyed austenitic steels. Acta Mater. 2010, 58, 3173–3186. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Li, H.; Huang, M.-y. In-situ EBSD study of the degradation behavior in a type 316 Austenitic Stainless Steel during plastic deformation. J. Strain Anal. Eng. Des. 2021, 56, 587–597. [Google Scholar] [CrossRef]

- Legros, M.; Gianola, D.S.; Hemker, K.J. In situ TEM observations of fast grain-boundary motion in stressed nanocrystalline aluminum films. Acta Mater. 2008, 56, 3380–3393. [Google Scholar] [CrossRef]

- Üçok, İ.; Ando, T.; Grant, N.J. Property enhancement in Type 316L stainless steel by spray forming. Mater. Sci. Eng. A 1991, 133, 284–287. [Google Scholar] [CrossRef]

- Kashyap, B.P.; Tangri, K. On the Hall-Petch relationship and substructural evolution in type 316L stainless steel. Acta Metall. Mater. 1995, 43, 3971–3981. [Google Scholar] [CrossRef]

- Flipon, B.; Keller, C.; de la Cruz, L.G.; Hug, E.; Barbe, F. Tensile properties of spark plasma sintered AISI 316L stainless steel with unimodal and bimodal grain size distributions. Mater. Sci. Eng. A 2018, 729, 249–256. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass % | 0.024 | 0.79 | 0.79 | 0.009 | 0.006 | 12.58 | 16.43 | 2.11 | 0.05 | balance |

| Etchant | Time | |

|---|---|---|

| Glycerol | 45 mL | 1 m 30 s ~2 m |

| Hydrochloric acid | 15 mL | |

| Nitric acid | 30 mL | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, I.-S.; So, T.-Y.; Lee, D.-H.; Shin, C.-S. Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding. Materials 2023, 16, 2144. https://doi.org/10.3390/ma16062144

Hwang I-S, So T-Y, Lee D-H, Shin C-S. Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding. Materials. 2023; 16(6):2144. https://doi.org/10.3390/ma16062144

Chicago/Turabian StyleHwang, In-Seok, Tae-Yeong So, Do-Hoon Lee, and Chang-Seop Shin. 2023. "Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding" Materials 16, no. 6: 2144. https://doi.org/10.3390/ma16062144

APA StyleHwang, I.-S., So, T.-Y., Lee, D.-H., & Shin, C.-S. (2023). Characterization of Mechanical Properties and Grain Size of Stainless Steel 316L via Metal Powder Injection Molding. Materials, 16(6), 2144. https://doi.org/10.3390/ma16062144