Mechanical Testing of Epoxy Resin Modified with Eco-Additives

Abstract

1. Introduction

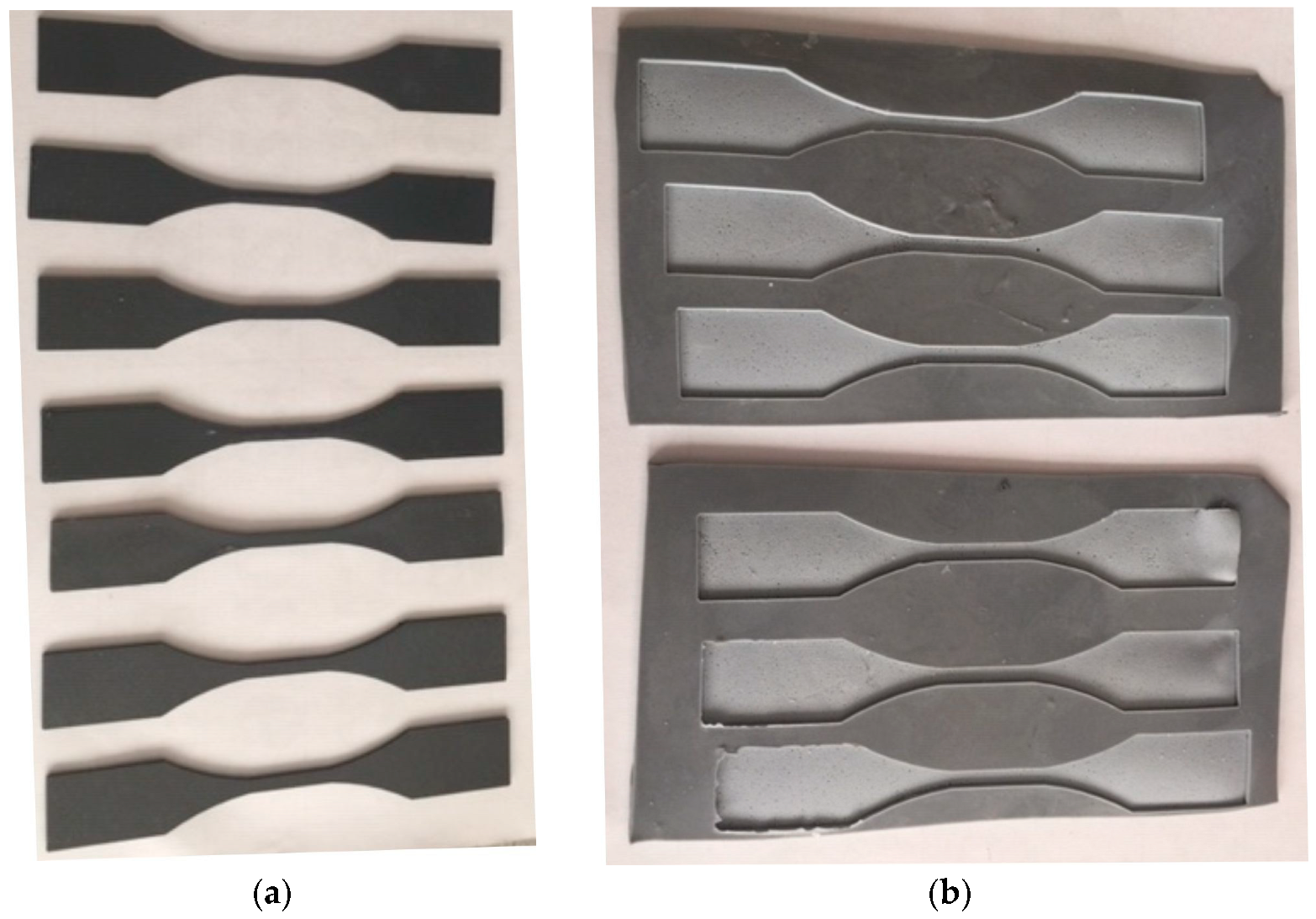

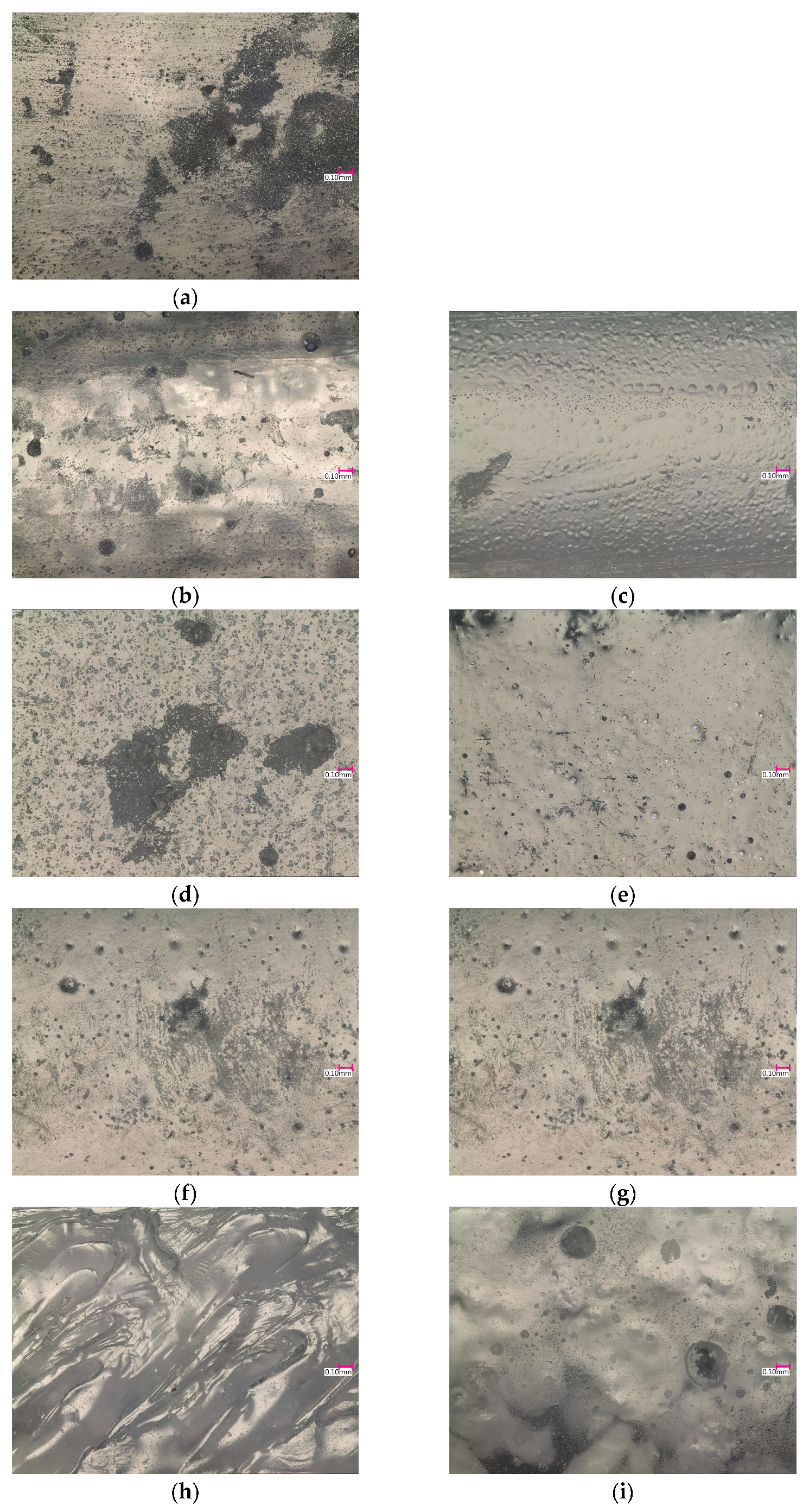

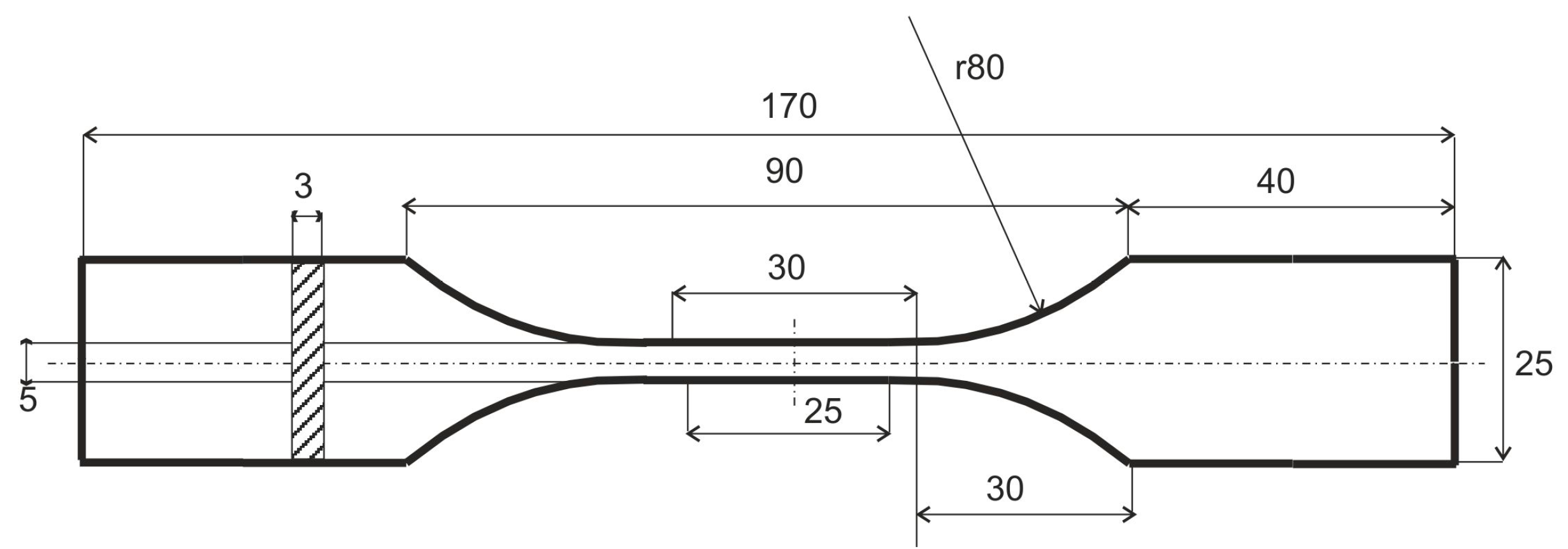

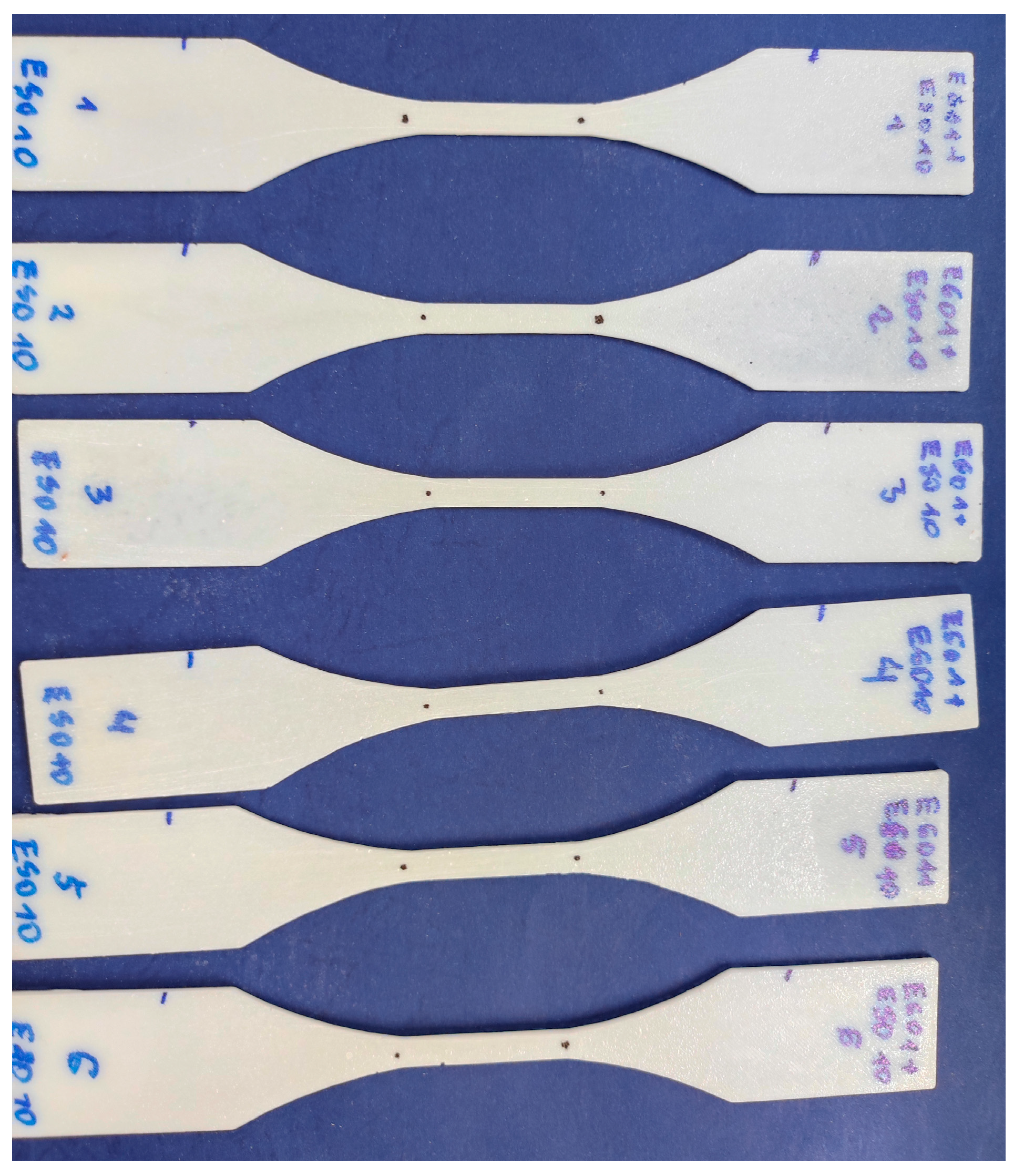

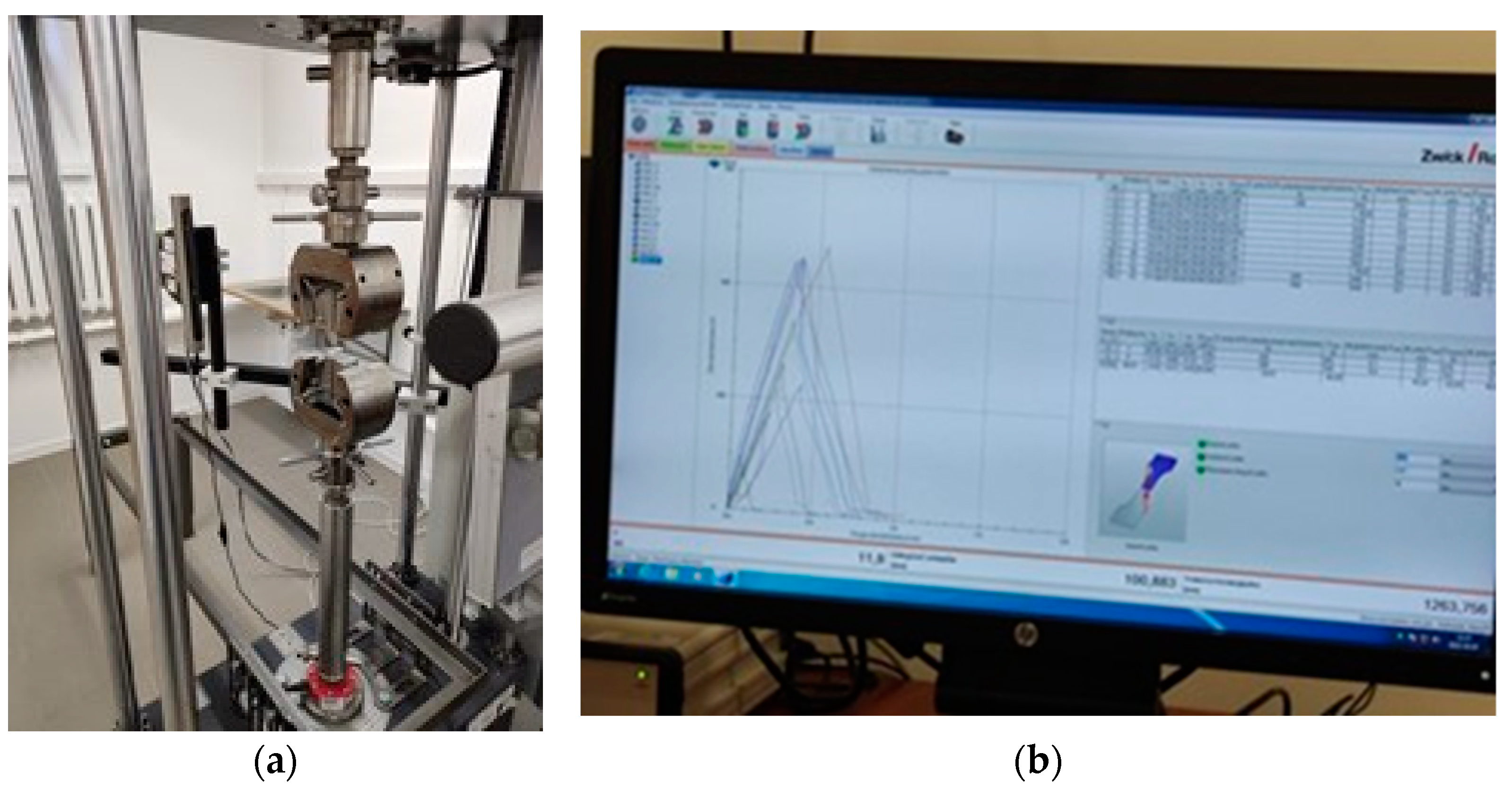

2. Materials and Methods

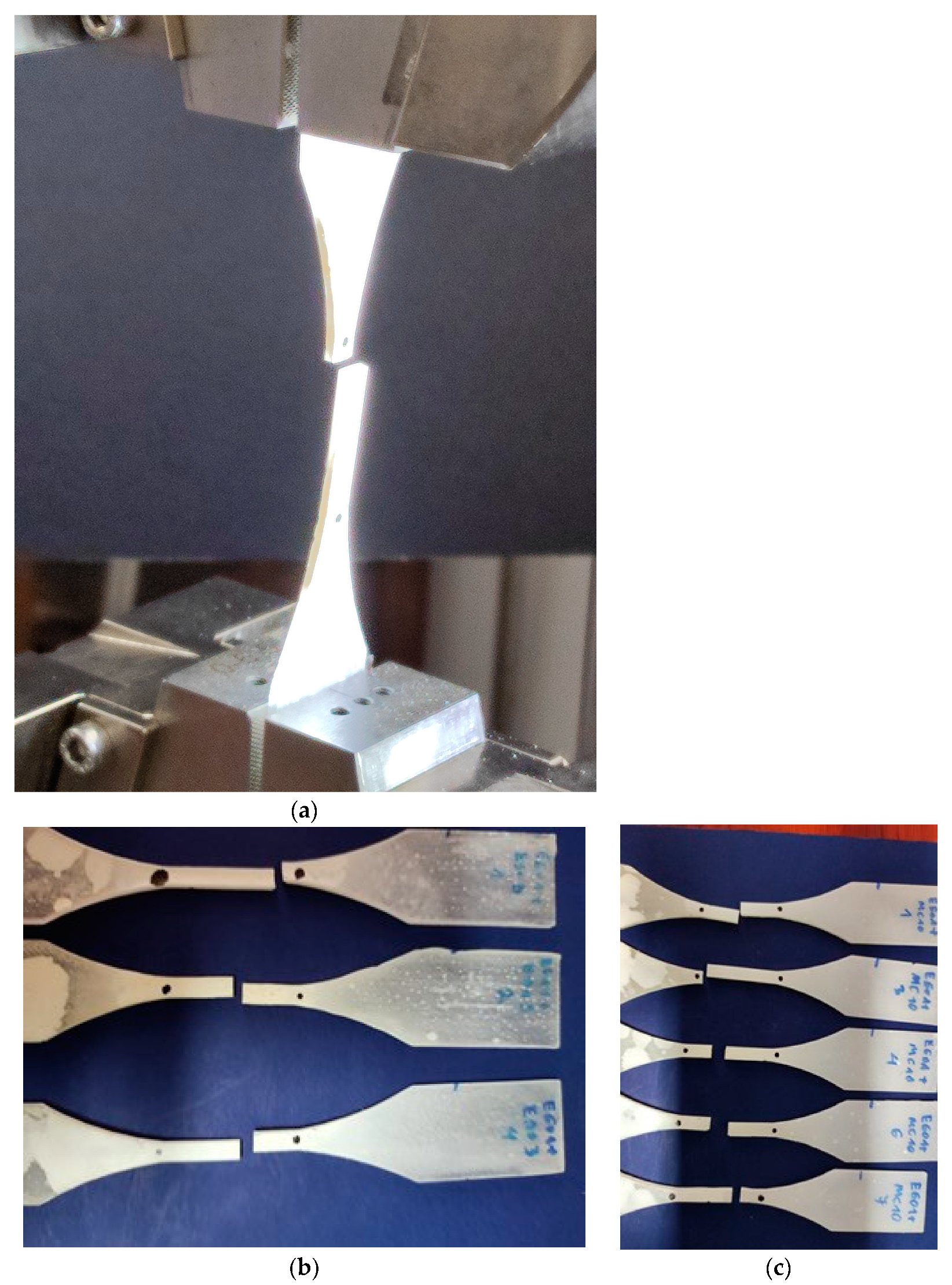

3. Uniaxial Stretching Tests

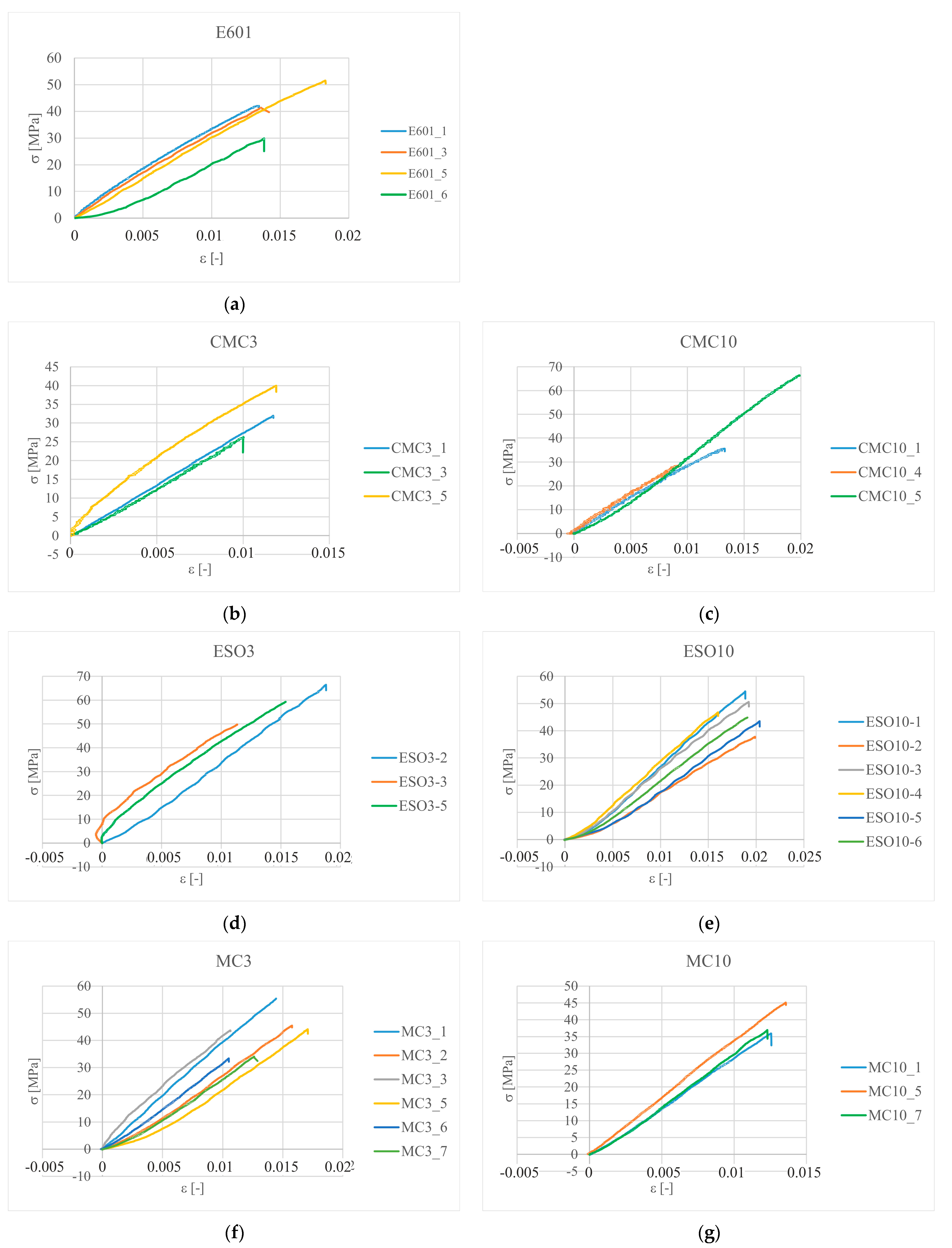

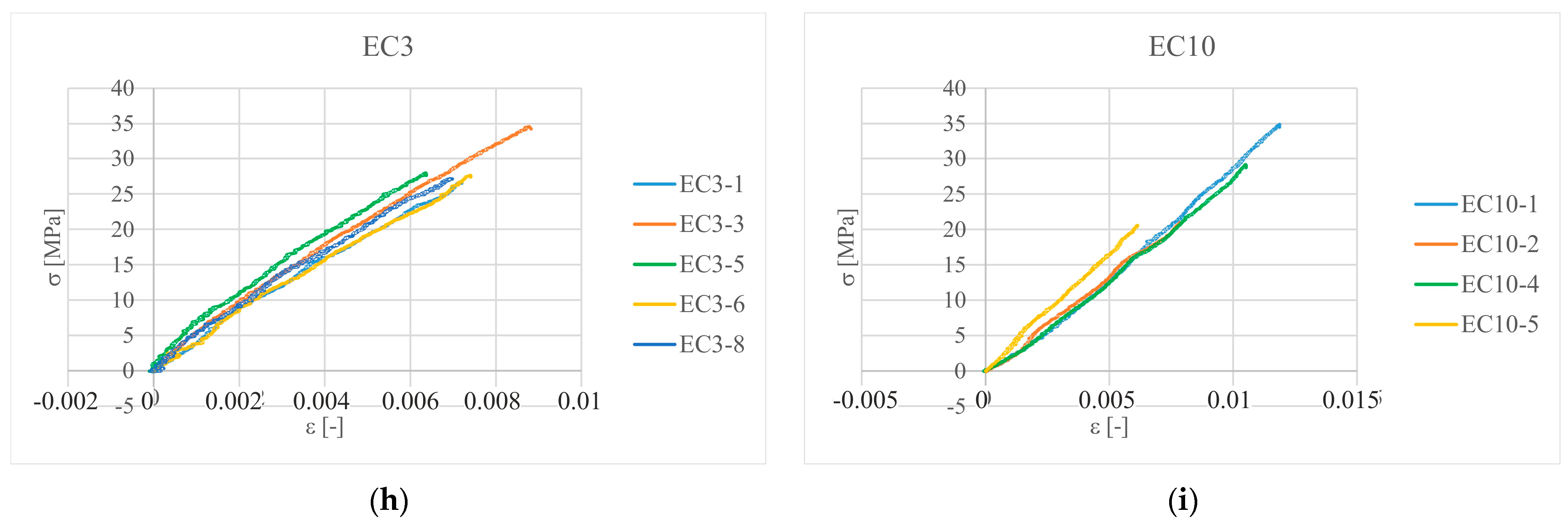

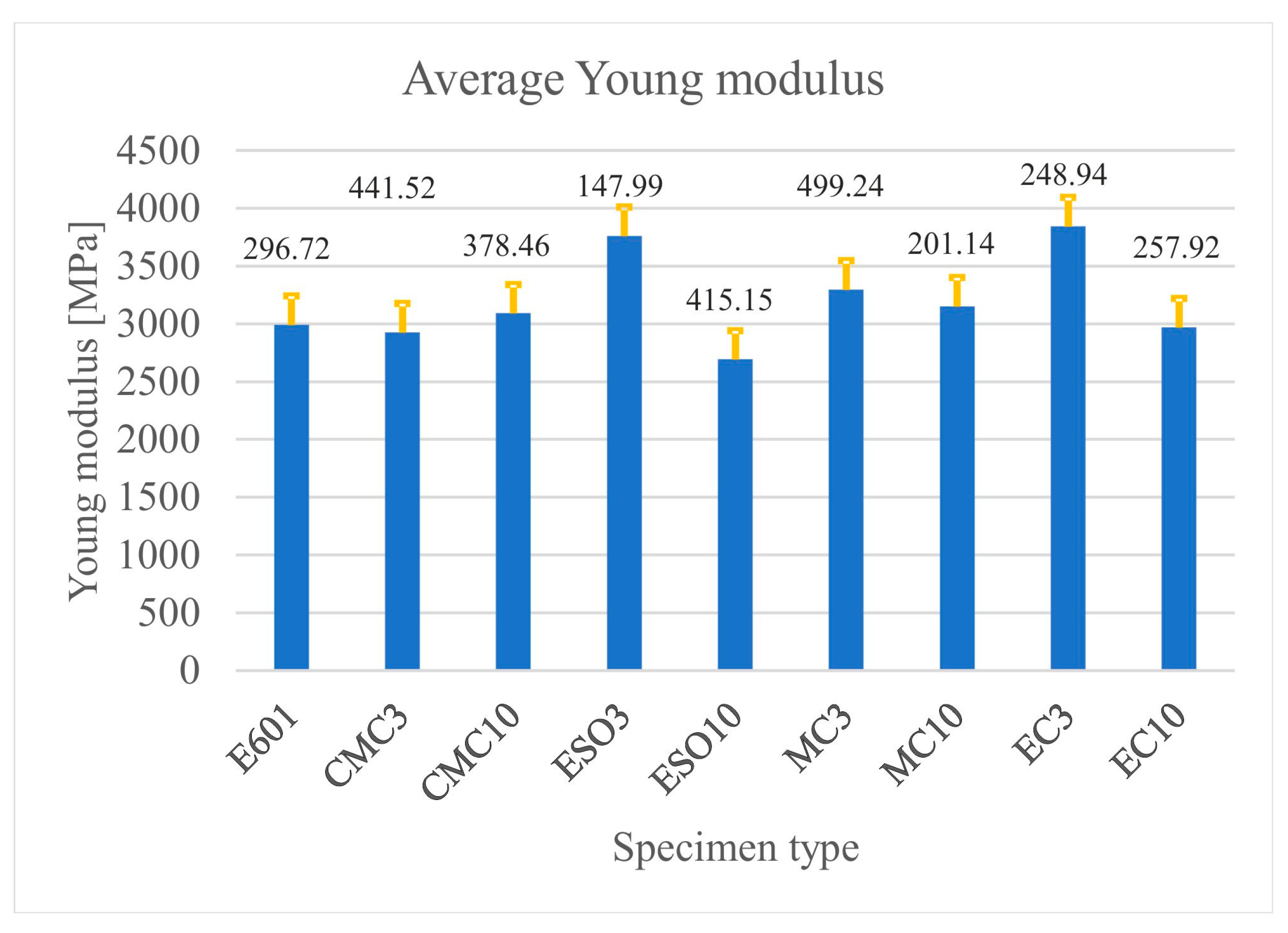

4. Results and Discussion

5. Conclusions

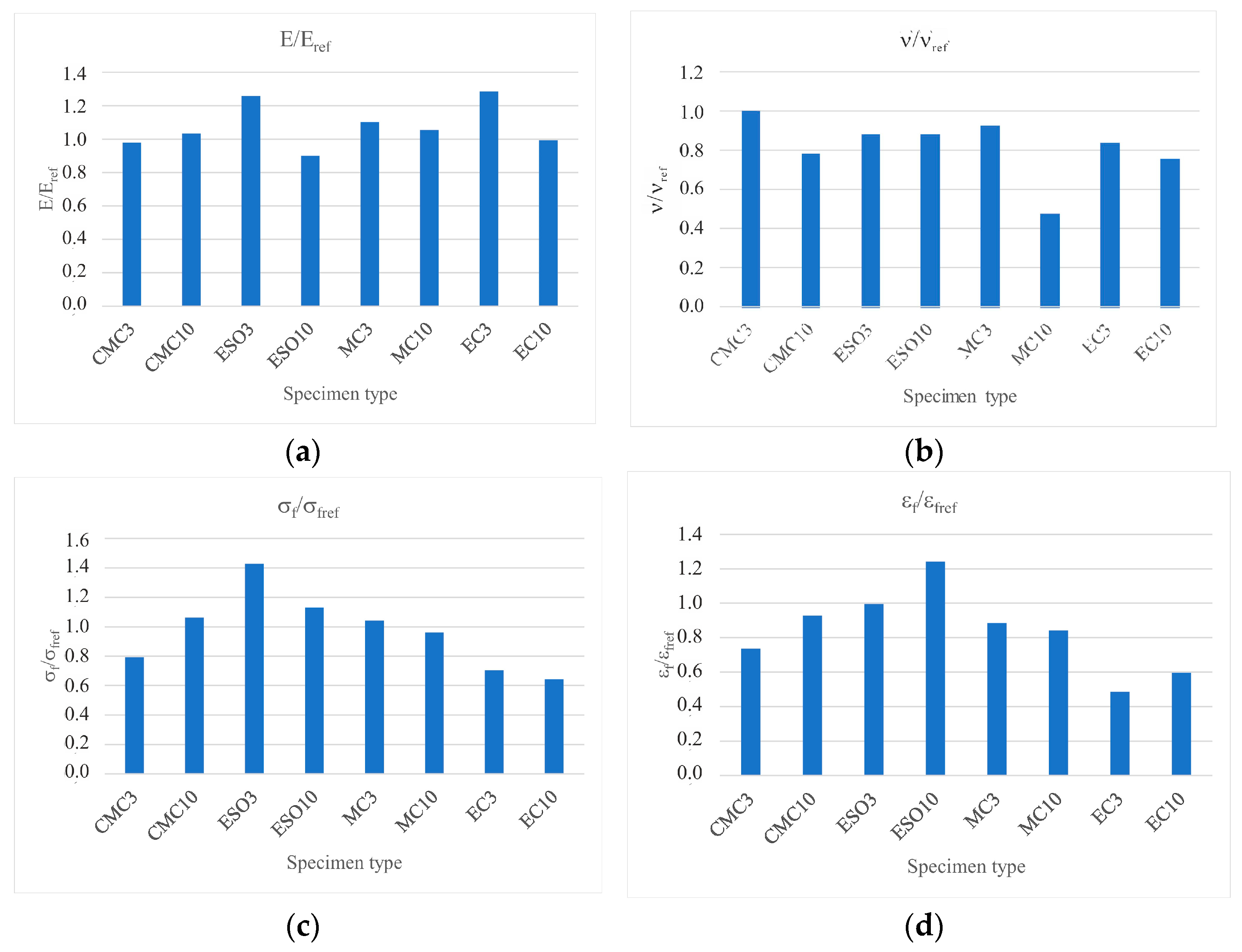

- We do not recommend ethyl cellulose (EC) as an additive to the epoxy resin due to its poor miscibility. The best miscibility with epoxy resin and the best-looking test specimens were observed when using carboxymethyl cellulose (CMC) additives.

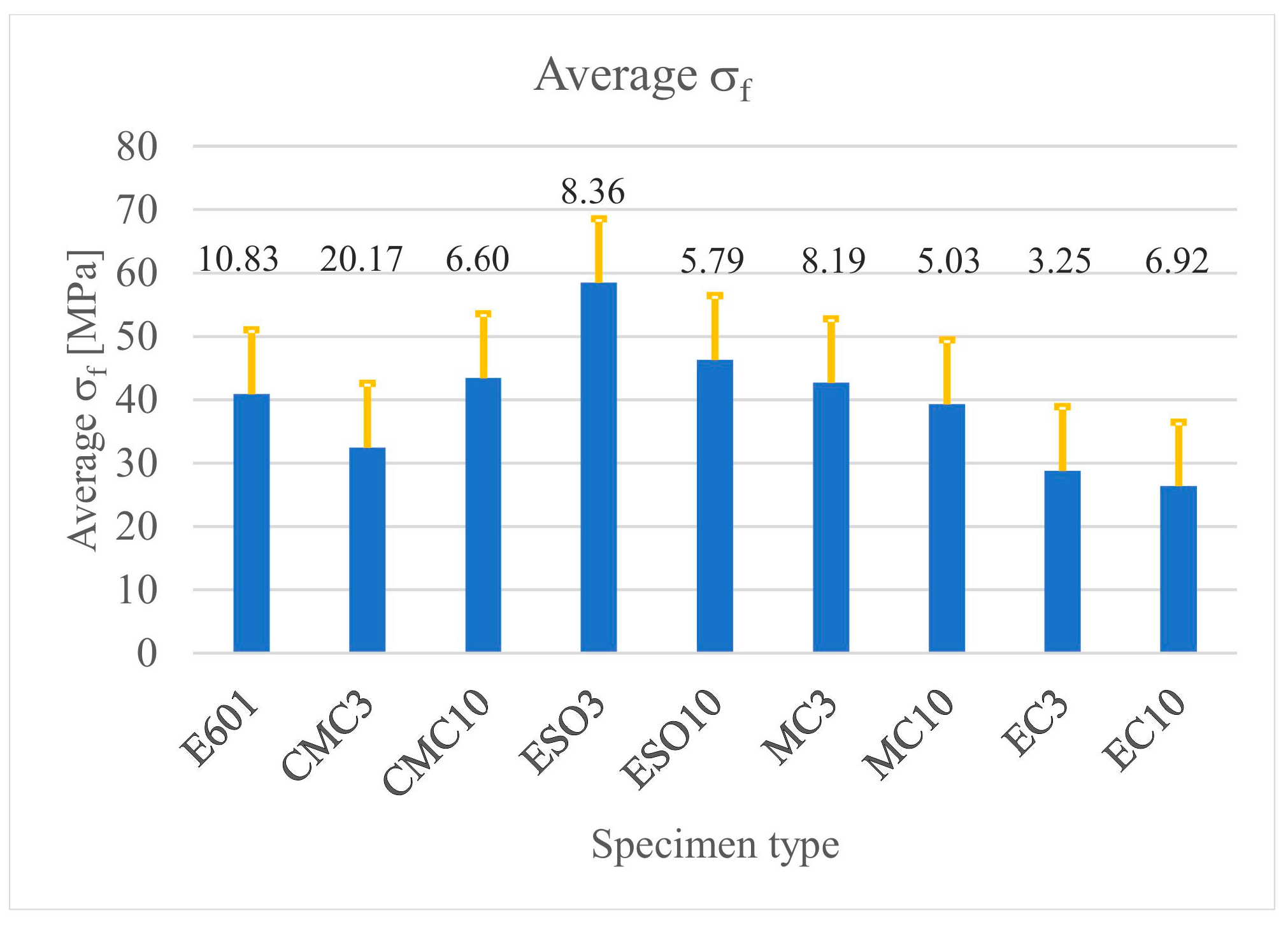

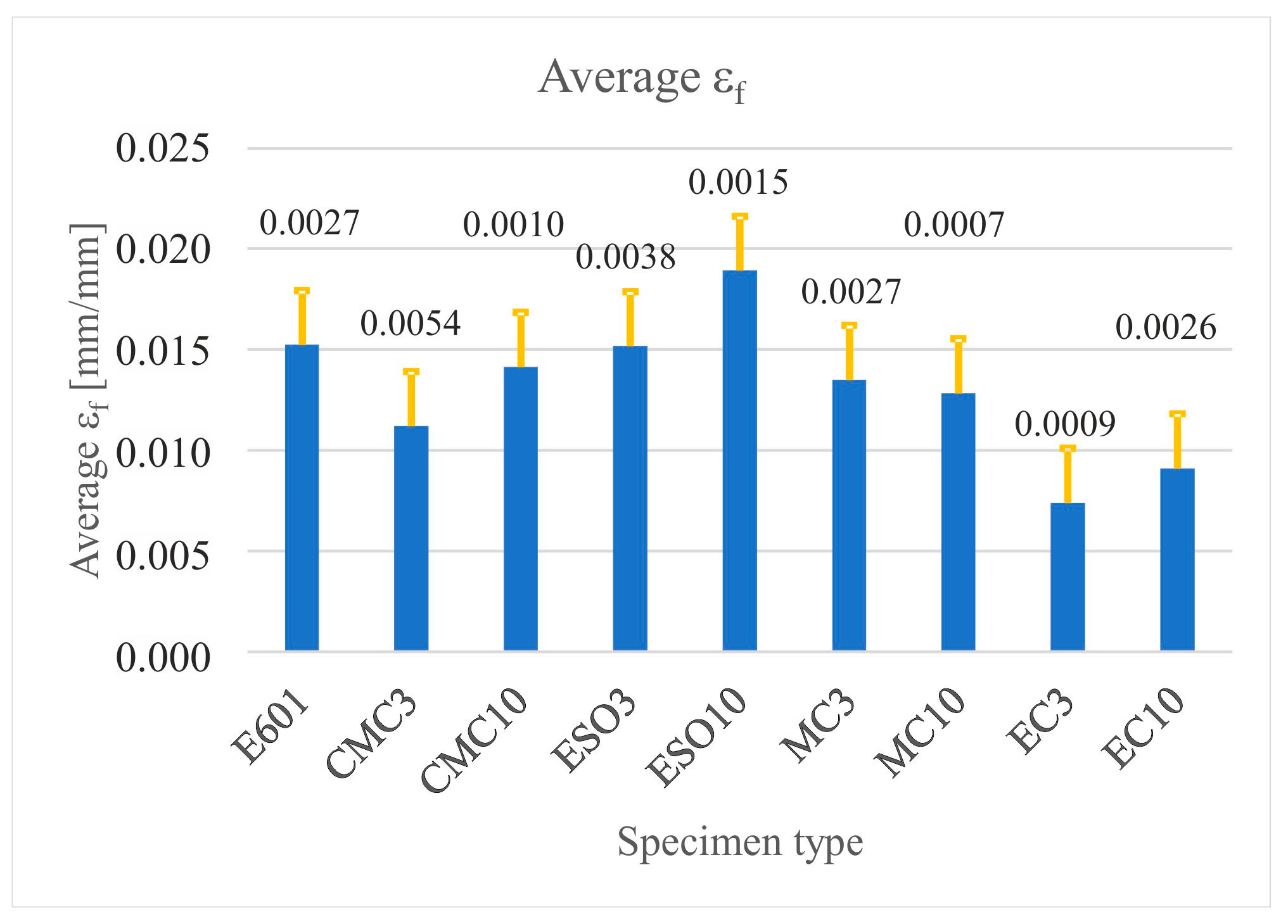

- Both maximum values of strains and stresses in the stress–strain curves, higher than for epoxy resin, were observed for epoxy resins modified with epoxidized soya oil. The highest stresses were detected for epoxy E601 resin modified with 3 phr soya oil (ESO3), whereas the highest strains occurred for epoxy modified with 10 phr soya oil (ESO10) specimens.

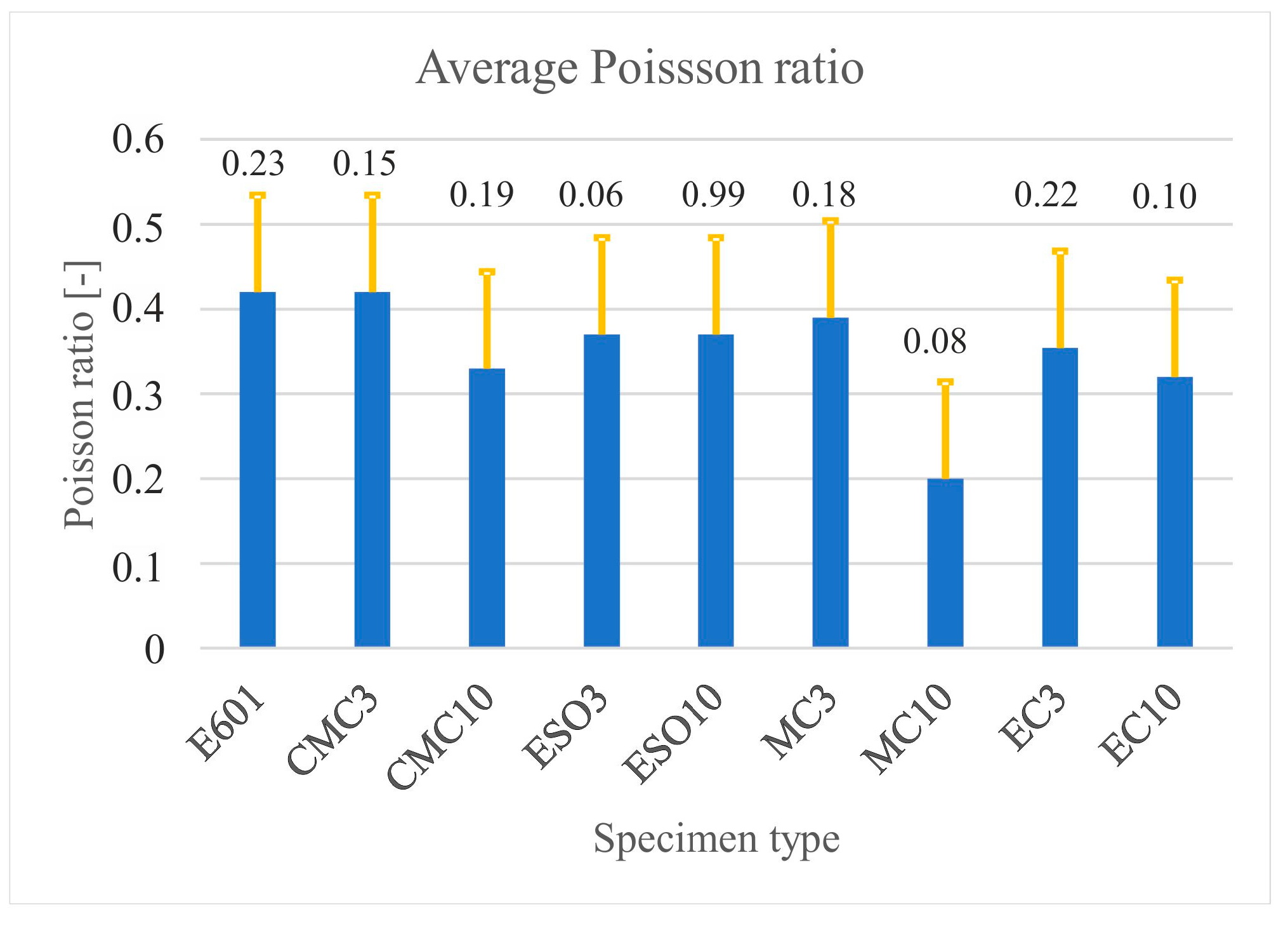

- The smallest standard deviation values of Young’s modulus, Poisson’s ratio and stress and strain values were observed for epoxy resins modified with 3 phr added epoxidized soya oil (ESO3).

- Despite the imperfections of the prepared specimens and the small population of the tests carried out, the obtained results seem interesting and indicate the desirability of further extended research in biodegradation testing. We propose continuing research with epoxy resin modified with 3 phr epoxidized soya oil (ESO3) and 10 phr of methyl cellulose (MC10).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kramer, C.A.; Loloee, R.; Wichman, I.S.; Ghosh, R.N. Time Resolved Measurements of Pyrolysis Products from Thermoplastic Poly-Methyl-Methacrylate (PMMA). In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; pp. 99–105. [Google Scholar] [CrossRef]

- Żyłowska, A. Bisfenol A (BPA)—Gdzie Występuje, Jak Go Unikać? 2019. Available online: https://www.poradnikzdrowie.pl/diety-i-zywienie/zdrowe-odzywianie/bisfenol-a-bpa-gdzie-wystepuje-jak-go-unikac-aa-uTuv-sCmq-E8pN.html (accessed on 17 April 2020).

- Fouad, H.; Mourad, A.-H.I.; ALshammari, B.A.; Hassan, M.K.; Abdallah, M.Y.; Hashem, M. Fracture toughness, vibration modal analysis and viscoelastic behavior of Kevlar, glass, and carbon fiber/epoxy composites for dental-post applications. J. Mech. Behav. Biomed. Mater. 2020, 101, 1034–1056. [Google Scholar] [CrossRef]

- Di Boon, Y.; Joshi, S.C. A review of methods for improving interlaminar interfaces and fracture toughness of laminated composites. Mater. Today Commun. 2020, 22, 100830. [Google Scholar] [CrossRef]

- Fu, Y.; Zhong, W.-H. Cure kinetics behavior of a functionalized graphitic nanofiber modified epoxy resin. Thermochim. Acta 2011, 516, 58–63. [Google Scholar] [CrossRef]

- Wang, J.; Ma, C.; Chen, G.; Dai, P. Interlaminar fracture toughness and conductivity of carbon fiber/epoxy resin composite laminate modified by carbon black-loaded polypropylene non-woven fabric interleaves. Compos. Struct. 2020, 234, 111649. [Google Scholar] [CrossRef]

- Wang, J.; Pozegica, T.R.; Xub, Z.; Nigmatullina, R.; Harnimanc, R.L.; Eichhorna, S.J. Cellulose nanocrystal-polyetherimide hybrid nanofibrous interleaves for enhanced interlaminar fracture toughness of carbon fibre/epoxy composites. Compos. Sci. Technol. 2019, 182, 107744. [Google Scholar] [CrossRef]

- Sugiman, S.; Salman, S.; Maryudi, M. Effects of volume fraction on water uptake and tensile properties on epoxy filled with inorganic fillers having different reactivity to water. Mater. Today Commun. 2020, 24, 101360. [Google Scholar] [CrossRef]

- Uthaman, A.; Lal, H.M.; Li, C.; Xian, G.; Thomas, S. Mechanical and Water Uptake Properties of Epoxy Nanocomposites with Surfactant-Modified Functionalized Multiwalled Carbon Nanotubes. Nanomaterials 2021, 11, 1234. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Hailatihan, B.; Mi, L.; Baheti, Y.; Yan, Y. Effect of the Addition of Thermoplastic Resin and Composite on Mechanical and Thermal Properties of Epoxy Resin. Polymers 2022, 14, 1087. [Google Scholar] [CrossRef]

- Bellini, C.; Di Cocco, V.; Iacoviello, F.; Sorrentino, L. Influence of structural characteristics on the interlaminar shear strength of CFRP/Al fibre metal laminates. Procedia Struct. Integr. 2019, 18, 373–378. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, M.; Guo, X.; Liu, C.; Xin, J.; Zhan, J. Mild chemical recycling of aerospace fiber/epoxy composite wastes and utilization of the decomposed resin. Polym. Degrad. Stab. 2017, 139, 20–27. [Google Scholar] [CrossRef]

- Kalita, D.J.; Tarnavchyk, I.; Chisholm, B.J.; Webster, D.C. Novel bio-based epoxy resins from eugenol as an alternative to BPA epoxy and high throughput screening of the cured coatings. Polymer 2021, 233, 124191. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Toughening of Petroleum Based (DGEBA) Epoxy Resins with Various Renewable Resources Based Flexible Chains for High Performance Applications: A Review. Ind. Eng. Chem. Res. 2018, 57, 2711–2726. [Google Scholar] [CrossRef]

- Jin, F.-L.; Park, S.-J. Impact-strength improvement of epoxy resins reinforced with a biodegradable polymer. Mater. Sci. Eng. 2008, 478, 402–405. [Google Scholar] [CrossRef]

- Kadam, A.; Pawar, M.; Yemul, O.; Thamke, V.; Kodam, K. Biodegradable biobased epoxy resin from karanja oil. Polymer 2015, 72, 82–92. [Google Scholar] [CrossRef]

- Mahnken, R.; Dammann, C. A three-scale framework for fibre-reinforced-polymer curing Part I: Microscopic modeling and mesoscopic effective properties. Int. J. Solids Struct. 2016, 100–101, 341–355. [Google Scholar] [CrossRef]

- Skrzyńska, E.; Matyja, M. Porównanie właściwości fizykochemicznych wybranych tłuszczy naturalnych oraz ich estrów metylowych. Chemik 2011, 65, 923–935. [Google Scholar]

- Ferenc, Z.; Pikoń, K. Przegląd rodzajów i ilości odpadów tłuszczowych i olejowych w Polsce. Arch. Waste Manag. Environ. Prot. 2005, 2, 69–80. [Google Scholar]

- Cortés-Triviño, E.; Valencia, C.; Delgado, M.A.; Franco, J.M. Rheology of epoxidized cellulose pulp gel-like dispersions in castor oil: Influence of epoxidation degree and the epoxide chemical structure. Carbohydr. Polym. 2018, 199, 563–571. [Google Scholar] [CrossRef]

- Chen, X.; Chen, S.; Xu, Z.; Zhang, J.; Miao, M.; Zhang, D. Degradable and recyclable bio-based thermoset epoxy resins. Green Chem. 2020, 22, 4187–4198. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, H.; Wang, H.; Sun, A.; Kan, Z. Creation of fully degradable poly(lactic acid) composite by using biosourced poly(4-hydroxybutyrate) as bioderived toughening additives. Express Polym. Lett. 2022, 16, 996–1010. [Google Scholar] [CrossRef]

- Bardelli, T.; Marano, C.; Vangosa, F.B. Influence of curing thermal history on cross-linking degree of a polydimethylsiloxane: Swelling and mechanical analyses. Express Polym. Lett. 2022, 16, 924–932. [Google Scholar] [CrossRef]

- Tanks, J.; Arao, Y.; Kubouchi, M. Network-level analysis of damage in amine-crosslinked diglycidyl ether resins degraded by acid. Express Polym. Lett. 2022, 16, 488–499. [Google Scholar] [CrossRef]

- Ferrari, F.; Esposito Corcione, C.; Striani, R.; Saitta, L.; Cicala, G.; Greco, A. Fully Recyclable Bio-Based Epoxy Formulations Using Epoxidized Precursors from Waste Flour: Thermal and Mechanical Characterization. Polymers 2021, 13, 2768. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Anastasiou, D.E. Development of environmentally friendly epoxy and composite adhesives and applications in single and mixed-modulus joints. J. Adhes. Sci. Technol. 2021, 35, 1138–1153. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Skórczewska, K. Characteristics and Application of Eugenol in the Production of Epoxy and Thermosetting Resin Composites: A review. Materials 2022, 15, 4824. [Google Scholar] [CrossRef]

- TeKrony, D.M. Accelerated Aging Test: Principles and Procedures. Seed Technol. 2005, 27, 135–146. [Google Scholar]

- Farbyjachtowe pl. Epidian® 601—Żywica Epoksydowa o Niskiej Lepkości 1kg. Available online: https://www.farbyjachtowe.pl/epidian-601-zywica-epoksydowa-o-niskiej-lepkosci-1kg-p-1365.html (accessed on 20 February 2023).

| No. | Epoxy Resin | Additive | Phr | Remarks |

|---|---|---|---|---|

| 1 | Epidian 601 | Without additive | - | - |

| 2 | Epidian 601 | ESO | 3 | Ref. [28] |

| 3 | Epidian 601 | ESO | 10 | Ref. [28] |

| 4 | Epidian 601 | MC | 3 | Ref. [20] |

| 5 | Epidian 601 | MC | 10 | Ref. [20] |

| 6 | Epidian 601 | CMC | 3 | Ref. [20] |

| 7 | Epidian 601 | CMC | 10 | Ref. [20] |

| 8 | Epidian 601 | EC | 3 | Ref. [20] |

| 9 | Epidian 601 | EC | 10 | Ref. [20] |

| Property | Unites | Value | Remarks |

|---|---|---|---|

| Colour | - | Yellow, slightly opaque | - |

| Boiling point | °C | 210 | Starts decomposition |

| Fire point | °C | 180 | - |

| Epoxide number | Mol/100 g | 0.5–0.55 | - |

| Density | g/cm3 at 25 °C | 1.14 | - |

| Viscosity | mPas at 25 °C | 700–1100 | - |

| Gelling time | min | 40 | After addition of 13 phr Z1; RT |

| Name | E (MPa) | SD E | ν (-) | SD ν | σf (MPa) | SD σf | εf (MPa) | SD εf | No. of Specimens |

|---|---|---|---|---|---|---|---|---|---|

| E601 | 2991.5 | 296.72 | 0.42 | 0.2281 | 40.94 | 10.83 | 0.0152 | 0.0027 | 4 |

| CMC3 | 2926.4 | 441.52 | 0.42 | 0.1457 | 32.49 | 20.17 | 0.0112 | 0.0054 | 3 |

| CMC10 | 3091.7 | 378.46 | 0.33 | 0.1909 | 43.48 | 6.60 | 0.0141 | 0.0010 | 3 |

| ESO3 | 3761.3 | 147.99 | 0.37 | 0.0635 | 58.50 | 8.36 | 0.0152 | 0.0038 | 3 |

| ESO10 | 2692.6 | 415.15 | 0.37 | 0.0988 | 46.32 | 5.79 | 0.0189 | 0.0015 | 6 |

| MC3 | 3297.3 | 499.24 | 0.39 | 0.1832 | 42.69 | 8.19 | 0.0135 | 0.0027 | 6 |

| MC10 | 3152.1 | 201.14 | 0.2 | 0.0794 | 39.33 | 5.03 | 0.0128 | 0.0007 | 3 |

| EC3 | 3845.5 | 284.94 | 0.35 | 0.22 | 28.81 | 3.25 | 0.0074 | 0.0009 | 5 |

| EC10 | 2969.6 | 257.92 | 0.82 | 0.26 | 26.37 | 6.92 | 0.0091 | 0.0026 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Derewonko, A.; Fabianowski, W.; Siczek, J. Mechanical Testing of Epoxy Resin Modified with Eco-Additives. Materials 2023, 16, 1854. https://doi.org/10.3390/ma16051854

Derewonko A, Fabianowski W, Siczek J. Mechanical Testing of Epoxy Resin Modified with Eco-Additives. Materials. 2023; 16(5):1854. https://doi.org/10.3390/ma16051854

Chicago/Turabian StyleDerewonko, Agnieszka, Wojciech Fabianowski, and Jerzy Siczek. 2023. "Mechanical Testing of Epoxy Resin Modified with Eco-Additives" Materials 16, no. 5: 1854. https://doi.org/10.3390/ma16051854

APA StyleDerewonko, A., Fabianowski, W., & Siczek, J. (2023). Mechanical Testing of Epoxy Resin Modified with Eco-Additives. Materials, 16(5), 1854. https://doi.org/10.3390/ma16051854