The Effects of Hemisphere Dome Orientation on the Structure of Diamond-like Carbon Film Prepared Using Ion Beam Assisted Deposition

Abstract

1. Introduction

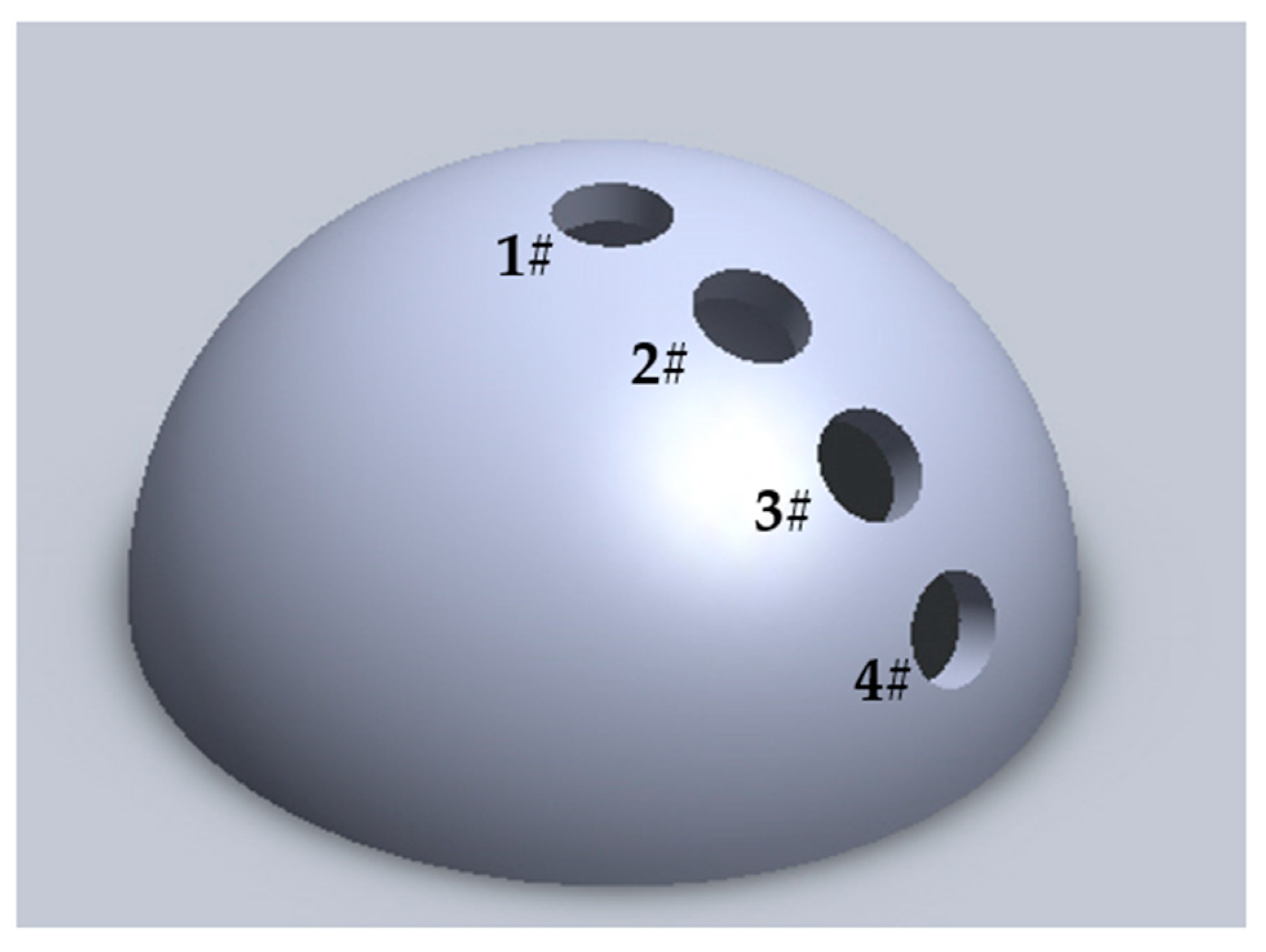

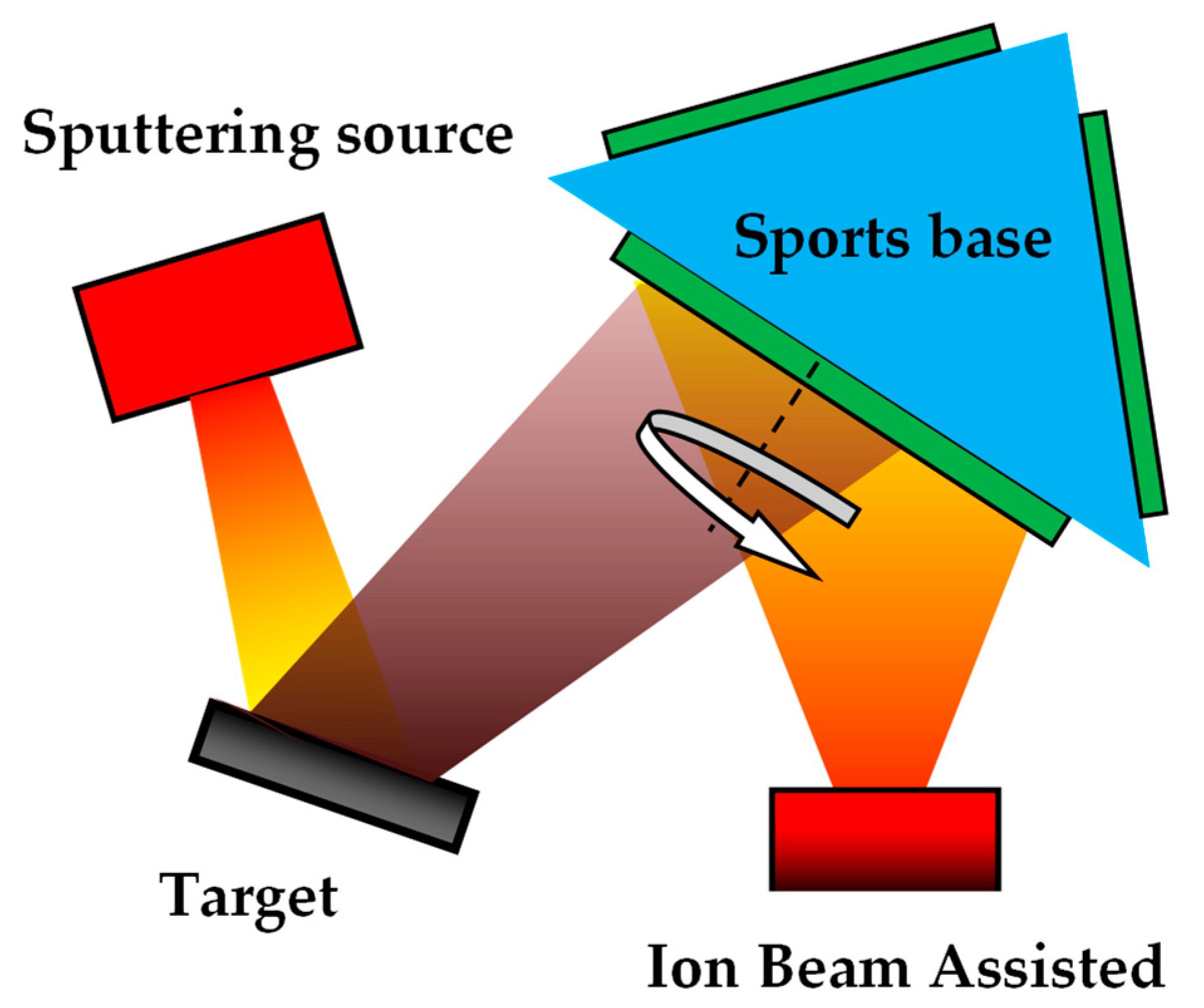

2. Materials and Methods

3. Results and Discussion

3.1. Thickness Measurements with SEM

3.2. Studies of Surface Characterization

3.3. Raman Studies of Diamonds at Various Temperatures

3.4. Residual Stress

3.5. Optical Constant

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grill, A. Diamond-like carbon: State of the art. Diam. Relat. Mater. 1999, 8, 428–434. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Lifshitz, Y. Diamond-like carbon—Present status. Diam. Relat. Mater. 1999, 8, 1659–1676. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311. [Google Scholar] [CrossRef]

- Xu, D.; Qing, L.; Xiang, K. Optical and electrical properties evolution of diamond-like carbon thin films with deposition temperature. Chin. Phys. Lett. 2009, 26, 027802. [Google Scholar]

- Hainsworth, S.V.; Uhure, N.J. Diamond like carbon coatings for tribology: Production techniques, characterisation methods and applications. Int. Mater. Rev. 2007, 52, 153–174. [Google Scholar] [CrossRef]

- Xu, J.; Fan, H.; Liu, W.; Hang, L. Large-area uniform hydrogen-free diamond-like carbon films prepared by unbalanced magnetron sputtering for infrared anti-reflection coatings. Diam. Relat. Mater. 2008, 17, 194–198. [Google Scholar] [CrossRef]

- Song, J.S.; Park, Y.S.; Kim, N.H. Hydrophobic anti-reflective coating of plasma-enhanced chemical vapor deposited diamond-like carbon thin films with various thicknesses for dye-sensitized solar cells. Appl. Sci. 2021, 11, 358. [Google Scholar] [CrossRef]

- Swec, D.M.; Mirtich, M.J. Diamondlike carbon protective coatings for optical windows. Window Dome Technol. Mater. 1989, 1112, 162–175. [Google Scholar]

- Harshavardhan, K.S.; Iyer, S.B. Diamond-like carbon coating for optical windows. IETE J. Res. 1994, 40, 97–100. [Google Scholar] [CrossRef]

- Chowdhury, S.; Laugier, M.T.; Rahman, I.Z. Characterization of DLC coatings deposited by rf magnetron sputtering. J. Mater. Process. Technol. 2004, 153, 804–810. [Google Scholar] [CrossRef]

- Sanchez, N.A.; Rincon, C.; Zambrano, G.; Galindo, H.; Prieto, P. Characterization of diamond-like carbon (DLC) thin films prepared by rf magnetron sputtering. Thin Solid Film. 2000, 373, 247–250. [Google Scholar] [CrossRef]

- Li, D.J.; Cui, F.Z.; Gu, H.Q. Studies of diamond-like carbon films coated on PMMA by ion beam assisted deposition. Appl. Surf. Sci. 1999, 137, 30–37. [Google Scholar] [CrossRef]

- Kitagawa, T.; Yamada, I.; Toyoda, N.; Tsubakino, H.; Matsuo, J.; Takaoka, G.H.; Kirkpatrick, A. Hard DLC film formation by gas cluster ion beam assisted deposition. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 201, 405–412. [Google Scholar] [CrossRef]

- Li, D.J.; Cui, F.Z.; Gu, H.Q. Diamond-like carbon coating on poly (methylmethacrylate) prepared by ion beam deposition and ion beam-assisted deposition and its effect on cell adhesion. J. Adhes. Sci. Technol. 1999, 13, 169–177. [Google Scholar] [CrossRef]

- Kimock, F.M.; Knapp, B.J. Commercial applications of ion beam deposited diamond-like carbon (DLC) coatings. Surf. Coat. Technol. 1993, 56, 273–279. [Google Scholar] [CrossRef]

- Mangla, O.; Roy, S. Synthesis of nano-diamond-like carbon for protective optical window coating applications. Bull. Mater. Sci. 2021, 44, 1–8. [Google Scholar] [CrossRef]

- Sun, P.; Liu, H.; Cheng, J.; Liu, D.; Leng, J.; Ji, Y. Germanium carbon (Ge1-xCx)/diamond-like carbon (DLC) antireflective and protective coating on zinc sulfide window. Opt. Mater. 2022, 124, 111984. [Google Scholar] [CrossRef]

- Li, Z.L.; Fu, X.H.; Lu, J.; Yang, Y.L.; Sun, D.G. Modelling and Optimization of DLC Film Thickness Variation for PECVD Processes. Key Eng. Mater. 2013, 552, 214–220. [Google Scholar] [CrossRef]

- Cuomo, J.J.; Pappas, D.L.; Lossy, R.; Doyle, J.P.; Bruley, J.; Di Bello, G.W.; Krakow, W. Energetic carbon deposition at oblique angles. J. Vac. Sci. Technol. A Vac. Surf. Film. 1992, 10, 3414–3418. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Goebbels, N.; Yilmaz, K. Effect of the substrate geometry on plasma synthesis of DLC coatings. Plasma Process. Polym. 2009, 6, S425–S428. [Google Scholar] [CrossRef]

- Ding, X.Z.; Zeng, X.T.; Hu, Z.Q. Substrate geometry effect on the uniformity of amorphous carbon films deposited by unbalanced magnetron sputtering. Thin Solid Film. 2004, 461, 282–287. [Google Scholar] [CrossRef]

- Nelson, N.; Rakowski, R.T.; Franks, J.; Woolliams, P.; Weaver, P.; Jones, B.J. The effect of substrate geometry and surface orientation on the film structure of DLC deposited using PECVD. Surf. Coat. Technol. 2014, 254, 73–78. [Google Scholar] [CrossRef]

- Laumer, J.; O’Leary, S.K. An adhesion analysis of thin carbon films deposited onto curved and flat Ti6Al4V substrates using rf magnetron sputtering and plasma enhanced chemical vapor deposition techniques. J. Mater. Sci. Mater. Electron. 2019, 30, 5185–5193. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. London. Ser. A Contain. Pap. A Math. Phys. Character 1909, 82, 172–175. [Google Scholar]

- Annett, D.; Andy, E.; Stefan, S.; Christian, S.; Steffen, W. Laser structuring of hydrogenated DLC scaffolds: Raman spectroscopy and nanotribology. Diam. Relat. Mater. 2020, 108, 107787. [Google Scholar]

| Samples | Peak Type | Peak Position (cm−1) | FWHM (cm−1) | ID/IG |

|---|---|---|---|---|

| 1 | D | 1347 | 246 | 0.37 |

| G | 1530 | 174 | ||

| 2 | D | 1336 | 251 | 0.41 |

| G | 1528 | 172 | ||

| 3 | D | 1360 | 258 | 0.52 |

| G | 1536 | 155 | ||

| 4 | D | 1371 | 267 | 0.56 |

| G | 1543 | 152 |

| Sample | Film Thickness/nm | Vertical Displacement/nm | Stress/Mpa |

|---|---|---|---|

| Sample 1 | 381.8 | −1155.30 | −875 |

| Sample 2 | 341.6 | −704.05 | −596 |

| Sample 3 | 214.4 | −131.46 | −177 |

| Sample 4 | 156.3 | −42.34 | −78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shang, P.; Ma, Y.; Zhang, Z.; Sun, P.; Liu, H.; Shi, H.; Lin, Q.; Xue, T.; Ji, Y. The Effects of Hemisphere Dome Orientation on the Structure of Diamond-like Carbon Film Prepared Using Ion Beam Assisted Deposition. Materials 2023, 16, 1773. https://doi.org/10.3390/ma16051773

Shang P, Ma Y, Zhang Z, Sun P, Liu H, Shi H, Lin Q, Xue T, Ji Y. The Effects of Hemisphere Dome Orientation on the Structure of Diamond-like Carbon Film Prepared Using Ion Beam Assisted Deposition. Materials. 2023; 16(5):1773. https://doi.org/10.3390/ma16051773

Chicago/Turabian StyleShang, Peng, Yuanfei Ma, Zhenyun Zhang, Peng Sun, Huasong Liu, Hongchun Shi, Quan Lin, Tao Xue, and Yiqin Ji. 2023. "The Effects of Hemisphere Dome Orientation on the Structure of Diamond-like Carbon Film Prepared Using Ion Beam Assisted Deposition" Materials 16, no. 5: 1773. https://doi.org/10.3390/ma16051773

APA StyleShang, P., Ma, Y., Zhang, Z., Sun, P., Liu, H., Shi, H., Lin, Q., Xue, T., & Ji, Y. (2023). The Effects of Hemisphere Dome Orientation on the Structure of Diamond-like Carbon Film Prepared Using Ion Beam Assisted Deposition. Materials, 16(5), 1773. https://doi.org/10.3390/ma16051773