(Magneto)Transport Properties of (TiZrNbNi)1−xCux and (TiZrNbCu)1−xCox Complex Amorphous Alloys

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

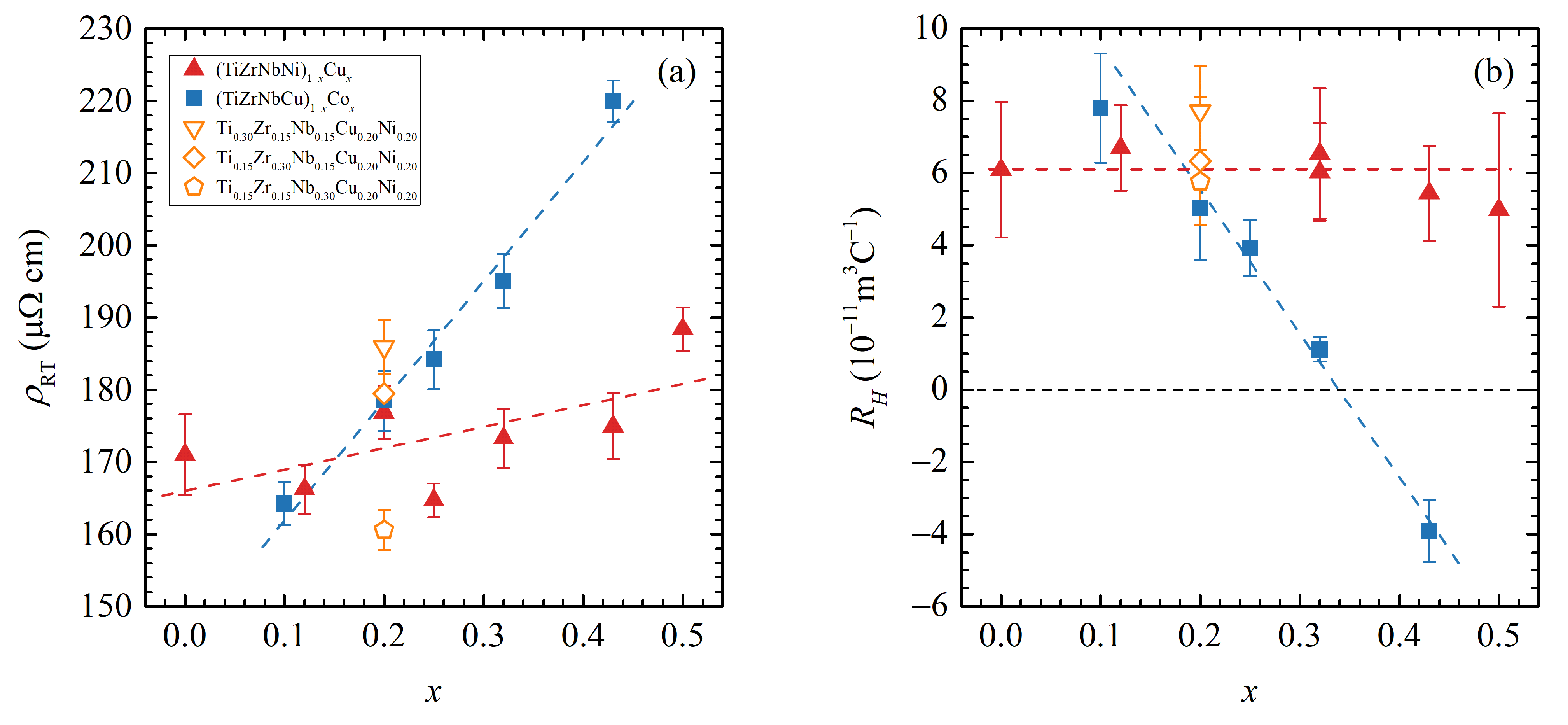

3.1. Room Temperature Resistivity and Hall Effect

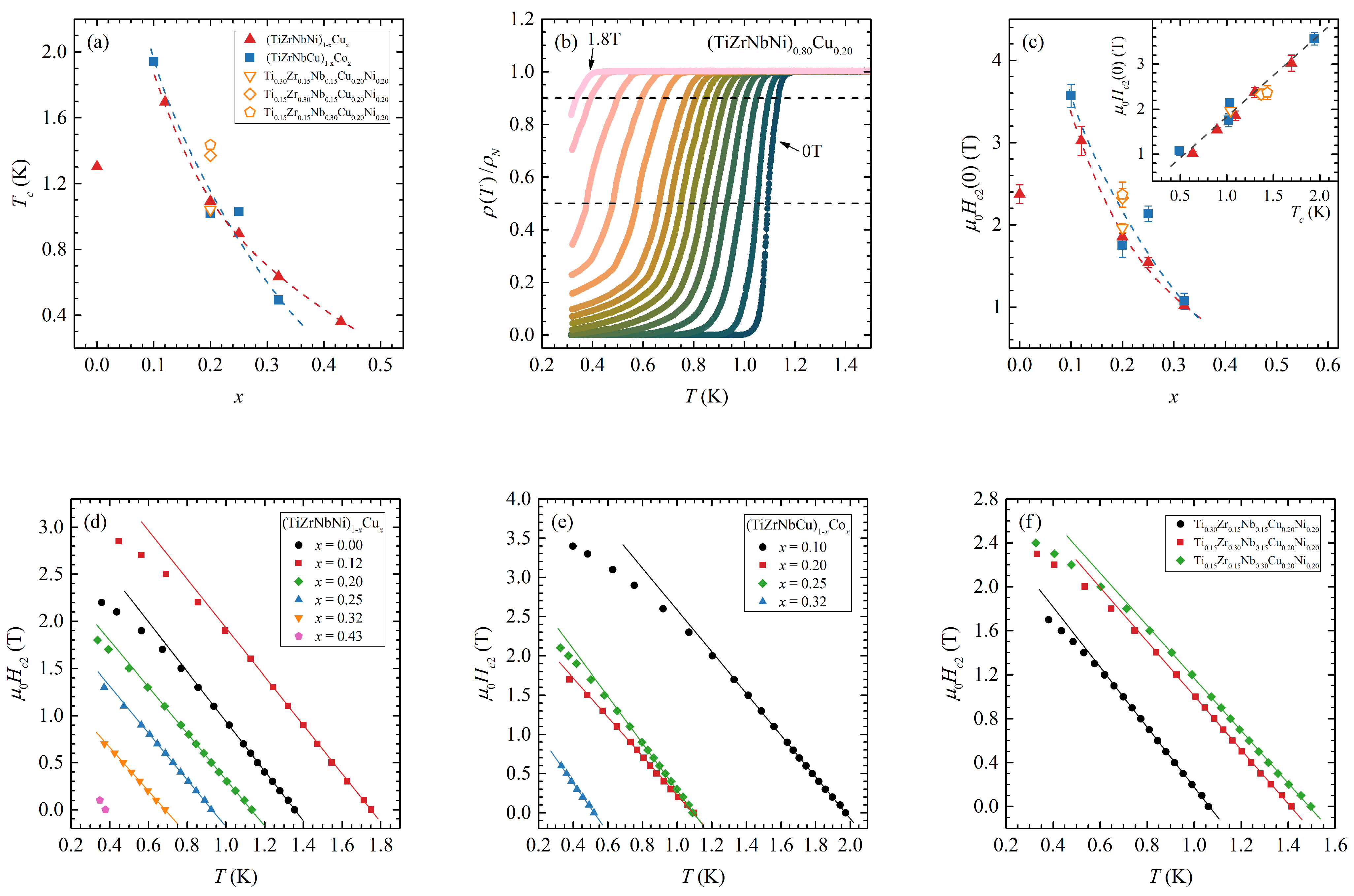

3.2. Superconductivity

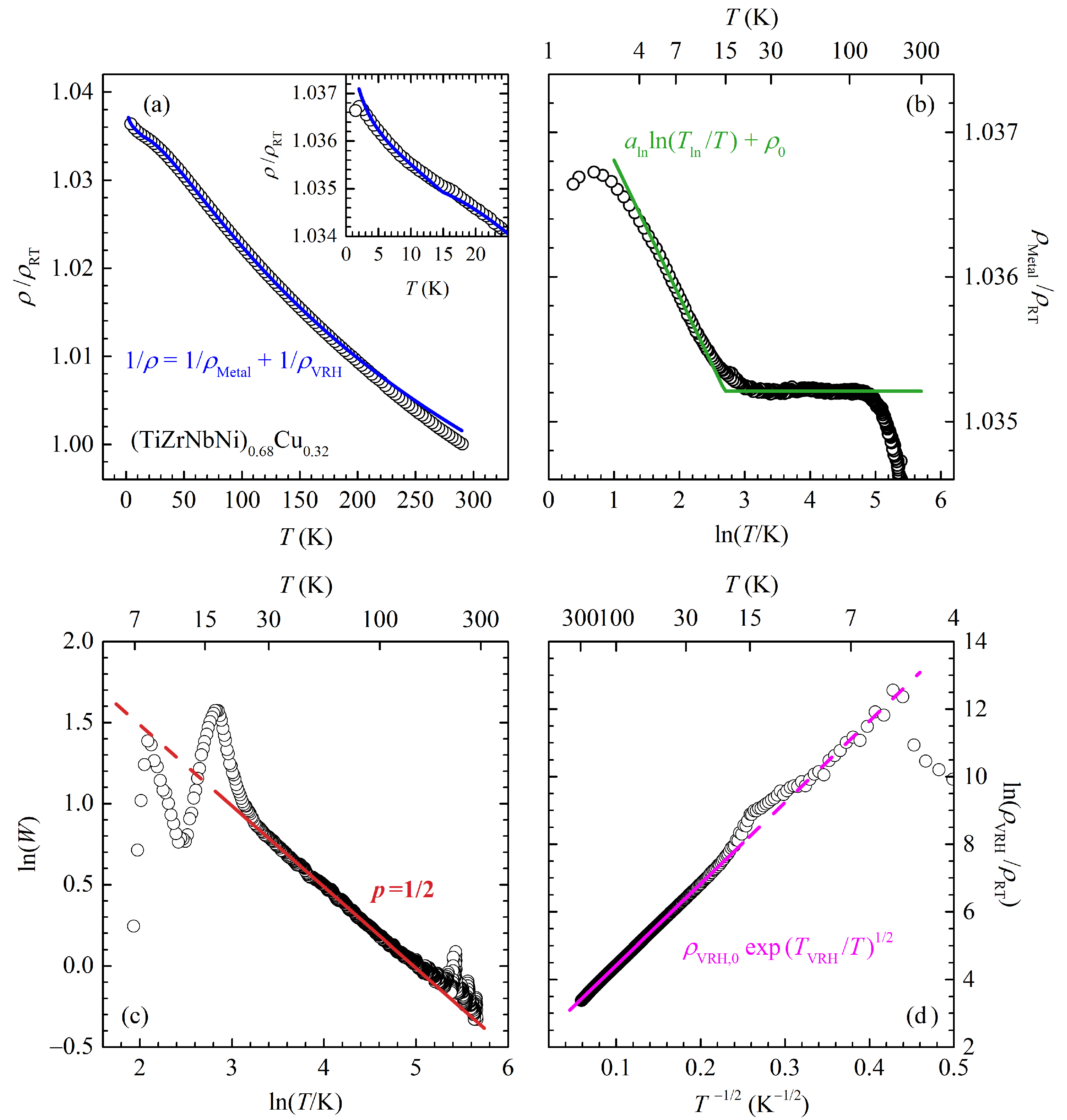

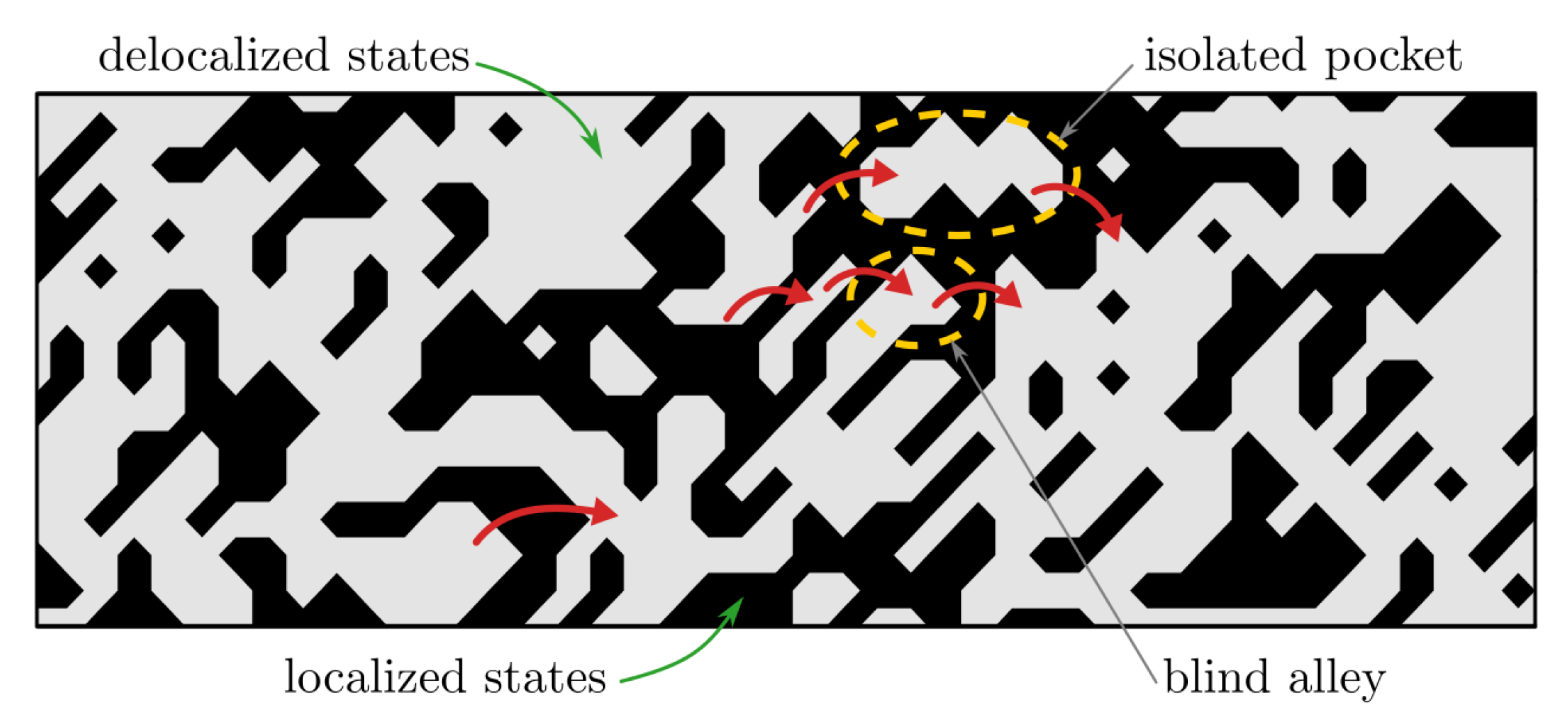

3.3. Temperature Dependence of Resistivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Güntherodt, H.J.; Beck, H. (Eds.) Glassy Metals I; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1981; Volume 46. [Google Scholar] [CrossRef]

- Beck, H.; Güntherodt, H.J. (Eds.) Glassy Metal II; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1983; Volume 53. [Google Scholar] [CrossRef]

- Beck, H.; Güntherodt, H.J. (Eds.) Glassy Metals III; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1994; Volume 72. [Google Scholar] [CrossRef]

- Inoue, A.; Zhang, W.; Zhang, T.; Kurosaka, K. High-Strength Cu-based Bulk Glassy Alloys in Cu–Zr–Ti and Cu–Hf–Ti Ternary Systems. Acta Mater. 2001, 49, 2645–2652. [Google Scholar] [CrossRef]

- Buschow, K.H.J. Short-Range Order and Thermal Stability in Amorphous Alloys. J. Phys. F Met. Phys. 1984, 14, 593. [Google Scholar] [CrossRef]

- Cantor, B.; Kim, K.B.; Warren, P.J. Novel Multicomponent Amorphous Alloys. Mater. Sci. Forum 2002, 386–388, 27–32. [Google Scholar] [CrossRef]

- Ma, L.; Wang, L.; Zhang, T.; Inoue, A. Bulk Glass Formation of Ti-Zr-Hf-Cu-M (M=Fe, Co, Ni) Alloys. Mater. Trans. 2002, 43, 277–280. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y. (Eds.) High-Entropy Alloys; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.W.; Ranganathan, S.; Bhattacharjee, P.P. High-Entropy Alloys, 2nd ed.; Elsevier: Amsterdam, The Netherlands; Cambridge, MA, USA, 2019. [Google Scholar]

- Babić, E.; Drobac, Đ.; Figueroa, I.A.; Laurent-Brocq, M.; Marohnić, Ž.; Mikšić Trontl, V.; Pajić, D.; Perrière, L.; Pervan, P.; Remenyi, G.; et al. Transition from High-Entropy to Conventional Alloys: Which Are Better? Materials 2021, 14, 5824. [Google Scholar] [CrossRef]

- Nagase, T.; Takeuchi, A.; Amiya, K.; Egami, T. Solid State Amorphization of Metastable Al0.5TiZrPdCuNi High Entropy Alloy Investigated by High Voltage Electron Microscopy. Mater. Chem. Phys. 2018, 210, 291–300. [Google Scholar] [CrossRef]

- Meng, Y.H.; Duan, F.H.; Pan, J.; Li, Y. Phase Stability of B2-ordered ZrTiHfCuNiFe High Entropy Alloy. Intermetallics 2019, 111, 106515. [Google Scholar] [CrossRef]

- Yin, H.; Law, J.Y.; Huang, Y.; Shen, H.; Jiang, S.; Guo, S.; Franco, V.; Sun, J. Enhancing the Magnetocaloric Response of High-Entropy Metallic-Glass by Microstructural Control. Sci. China Mater. 2022, 65, 1134–1142. [Google Scholar] [CrossRef]

- Arshad, M.; Amer, M.; Hayat, Q.; Janik, V.; Zhang, X.; Moradi, M.; Bai, M. High-Entropy Coatings (HEC) for High-Temperature Applications: Materials, Processing, and Properties. Coatings 2022, 12, 691. [Google Scholar] [CrossRef]

- Biljaković, K.; Remenyi, G.; Figueroa, I.A.; Ristić, R.; Pajić, D.; Kuršumović, A.; Starešinić, D.; Zadro, K.; Babić, E. Electronic Structure and Properties of (TiZrNbCu)1−xNix High Entropy Amorphous Alloys. J. Alloys Compd. 2017, 695, 2661–2668. [Google Scholar] [CrossRef]

- Figueroa, I.A.; Ristić, R.; Kuršumović, A.; Biljaković, K.; Starešinić, D.; Pajić, D.; Remenyi, G.; Babić, E. Properties of (TiZrNbCu)1−xNix Metallic Glasses. J. Alloys Compd. 2018, 745, 455–459. [Google Scholar] [CrossRef]

- Babić, E.; Pajić, D.; Zadro, K.; Biljaković, K.; Trontl, V.M.; Pervan, P.; Starešinić, D.; Figueroa, I.A.; Kuršumović, A.; Michalik, Š.; et al. Structure Property Relationship in (TiZrNbCu)1−xNix Metallic Glasses. J. Mater. Res. 2018, 33, 3170–3183. [Google Scholar] [CrossRef]

- Ristić, R.; Figueroa, I.A.; Lachová, A.; Michalik, Š.; Mikšić Trontl, V.; Pervan, P.; Zadro, K.; Pajić, D.; Babić, E. Transition from High-Entropy to Cu-based (TiZrNbNi)1−xCux Metallic Glasses. J. Appl. Phys. 2019, 126, 154105. [Google Scholar] [CrossRef]

- Kuveždić, M.; Tafra, E.; Basletić, M.; Ristić, R.; Pervan, P.; Mikšić Trontl, V.; Figueroa, I.A.; Babić, E. Change of Electronic Properties on Transition from High-Entropy to Ni-rich (TiZrNbCu)1−xNix Alloys. J. Non-Cryst. Solids 2020, 531, 119865. [Google Scholar] [CrossRef]

- Ristić, R.; Figueroa, I.A.; Salčinović Fetić, A.; Zadro, K.; Mikšić Trontl, V.; Pervan, P.; Babić, E. Transition from High-Entropy to Conventional (TiZrNbCu)1−xCox Metallic Glasses. J. Appl. Phys. 2021, 130, 195102. [Google Scholar] [CrossRef]

- Babić, E.; Figueroa, I.A.; Michalik, S.; Mikšić-Trontl, V.; Pervan, P.; Ristić, R.; Salčinović-Fetić, A.; Starešinić, D.; Zadro, K. Influence of early transition metals on properties of Ti-Zr-Nb-Cu-Ni complex glassy alloys. J. Appl. Phys. manuscript in preparation.

- Ristić, R.; Babić, E.; Šaub, K.; Miljak, M. Electrical and Magnetic Properties of Amorphous Zr100−xCux Alloys. Fizika 1983, 15, 363–373. [Google Scholar]

- Šaub, K.; Babić, E.; Ristić, R. Quantum Corrections to Conductivity of Glassy Zr100−xCux Alloys. Solid State Commun. 1985, 53, 269–272. [Google Scholar] [CrossRef]

- Babić, E.; Šaub, K. Universal Conductivity Variation in Glassy Zr-M Alloys. Solid State Commun. 1985, 56, 111–115. [Google Scholar] [CrossRef]

- Altounian, Z.; Strom-Olsen, J.O. Superconductivity and Spin Fluctuations in M − Zr metallic glasses (M = Cu, Ni, Co, and Fe). Phys. Rev. B 1983, 27, 4149–4156. [Google Scholar] [CrossRef]

- Tafra, E.; Basletić, M.; Ristić, R.; Babić, E.; Hamzić, A. Enhanced Superconductivity in Hf-base Metallic Glasses. J. Phys. Condens. Matter 2008, 20, 425215. [Google Scholar] [CrossRef]

- Gallagher, B.L.; Greig, D. The Thermoelectric Powers and Resistivities of Amorphous Transition Metal Alloys. J. Phys. F Met. Phys. 1982, 12, 1721. [Google Scholar] [CrossRef]

- Pavuna, D. On the Concentration Dependence of Transport Coefficients in Amorphous Transition Metal Alloys. Solid State Commun. 1985, 54, 771–774. [Google Scholar] [CrossRef]

- Ristić, R.; Cooper, J.R.; Zadro, K.; Pajić, D.; Ivkov, J.; Babić, E. Ideal Solution Behaviour of Glassy Cu–Ti, Zr, Hf Alloys and Properties of Amorphous Copper. J. Alloys Compd. 2015, 621, 136–145. [Google Scholar] [CrossRef]

- Howson, M.A.; Gallagher, B.L. The Electron Transport Properties of Metallic Glasses. Phys. Rep. 1988, 170, 265–324. [Google Scholar] [CrossRef]

- Mooij, J.H. Electrical Conduction in Concentrated Disordered Transition Metal Alloys. Phys. Status Solidi A 1973, 17, 521–530. [Google Scholar] [CrossRef]

- Ivkov, J.; Babic, E.; Jacobs, R.L. Hall Effect and Electronic Structure of Glassy Zr 3d Alloys. J. Phys. F Met. Phys. 1984, 14, L53–L57. [Google Scholar] [CrossRef]

- Ivkov, J.; Babic, E. On the Origin of the Positive Hall Coefficient in Disordered TE-TL Alloys. J. Phys. Condens. Matter 1990, 2, 3891–3896. [Google Scholar] [CrossRef]

- Howson, M.A.; Greig, D.; Gallagher, B.L.; Morgan, G.J. The Hall Coefficients of CuTi and CuHf Amorphous Metal Alloys. J. Non-Cryst. Solids 1984, 61–62, 1261–1265. [Google Scholar] [CrossRef]

- Babić, E.; Ristić, R.; Miljak, M.; Scott, M.G.; Gregan, G. Superconductivity in Zirconium-Nickel Glasses. Solid State Commun. 1981, 39, 139–141. [Google Scholar] [CrossRef]

- Samwer, K.v.; Löhneysen, H. Amorphous Superconducting ZrxCu1−x: Electronic Properties, Stability, and Low-Energy Excitations. Phys. Rev. B 1982, 26, 107–123. [Google Scholar] [CrossRef]

- Karkut, M.G.; Hake, R.R. Upper Critical Fields and Superconducting Transition Temperatures of Some Zirconium-Base Amorphous Transition-Metal Alloys. Phys. Rev. B 1983, 28, 1396–1418. [Google Scholar] [CrossRef]

- Stolze, K.; Tao, J.; von Rohr, F.O.; Kong, T.; Cava, R.J. Sc–Zr–Nb–Rh–Pd and Sc–Zr–Nb–Ta–Rh–Pd High-Entropy Alloy Superconductors on a CsCl-Type Lattice. Chem. Mater. 2018, 30, 906–914. [Google Scholar] [CrossRef]

- Sun, L.; Cava, R.J. High-Entropy Alloy Superconductors: Status, Opportunities, and Challenges. Phys. Rev. Mater. 2019, 3, 090301. [Google Scholar] [CrossRef]

- Werthamer, N.R.; Helfand, E.; Hohenberg, P.C. Temperature and Purity Dependence of the Superconducting Critical Field, Hc2. III. Electron Spin and Spin-Orbit Effects. Phys. Rev. 1966, 147, 295–302. [Google Scholar] [CrossRef]

- Howson, M.A. Incipient Localisation and Electron-Electron Correlation Effects in Metallic Glass Alloys. J. Phys. F Met. Phys. 1984, 14, L25. [Google Scholar] [CrossRef]

- Čulo, M.; Tafra, E.; Mihaljević, B.; Basletić, M.; Kuveždić, M.; Ivek, T.; Hamzić, A.; Tomić, S.; Hiramatsu, T.; Yoshida, Y.; et al. Hall Effect Study of the κ-(ET)2X Family: Evidence for Mott-Anderson Localization. Phys. Rev. B 2019, 99, 045114. [Google Scholar] [CrossRef]

- Khondaker, S.I.; Shlimak, I.S.; Nicholls, J.T.; Pepper, M.; Ritchie, D.A. Two-Dimensional Hopping Conductivity in a δ-doped GaAs/AlxGa1−xAs Heterostructure. Phys. Rev. B 1999, 59, 4580–4583. [Google Scholar] [CrossRef]

- Mott, S.N.F.; Davis, E.A. Electronic Processes in Non-Crystalline Materials; Clarendon Press: Oxford, UK, 1979. [Google Scholar]

- Shklovskii, B.I.; Efros, A.L. Electronic Properties of Doped Semiconductors; Springer Series in Solid-State Sciences; Springer: Berlin/Heidelberg, Germany, 1984; Volume 45. [Google Scholar] [CrossRef]

- Gantmakher, V.F. Electrons and Disorder in Solids; Oxford University Press: New York, NY, USA, 2005. [Google Scholar] [CrossRef]

- Abeles, B.; Sheng, P.; Coutts, M.; Arie, Y. Structural and Electrical Properties of Granular Metal Films. Adv. Phys. 1975, 24, 407–461. [Google Scholar] [CrossRef]

- Abeles, B. Granular Metal Films. In Applied Solid State Science; Wolfe, R., Ed.; Elsevier: Amsterdam, The Netherlands, 1976; Volume 6, pp. 1–117. [Google Scholar] [CrossRef]

- Sheng, P. Feature Article: Electronic Transport in Granular Metal Films. Philos. Mag. B 1992, 65, 357–384. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuveždić, M.; Tafra, E.; Figueroa, I.A.; Basletić, M. (Magneto)Transport Properties of (TiZrNbNi)1−xCux and (TiZrNbCu)1−xCox Complex Amorphous Alloys. Materials 2023, 16, 1711. https://doi.org/10.3390/ma16041711

Kuveždić M, Tafra E, Figueroa IA, Basletić M. (Magneto)Transport Properties of (TiZrNbNi)1−xCux and (TiZrNbCu)1−xCox Complex Amorphous Alloys. Materials. 2023; 16(4):1711. https://doi.org/10.3390/ma16041711

Chicago/Turabian StyleKuveždić, Marko, Emil Tafra, Ignacio A. Figueroa, and Mario Basletić. 2023. "(Magneto)Transport Properties of (TiZrNbNi)1−xCux and (TiZrNbCu)1−xCox Complex Amorphous Alloys" Materials 16, no. 4: 1711. https://doi.org/10.3390/ma16041711

APA StyleKuveždić, M., Tafra, E., Figueroa, I. A., & Basletić, M. (2023). (Magneto)Transport Properties of (TiZrNbNi)1−xCux and (TiZrNbCu)1−xCox Complex Amorphous Alloys. Materials, 16(4), 1711. https://doi.org/10.3390/ma16041711