Mechanical Properties of Titanium/Nano-Fluorapatite Parts Produced by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Powder Preparation

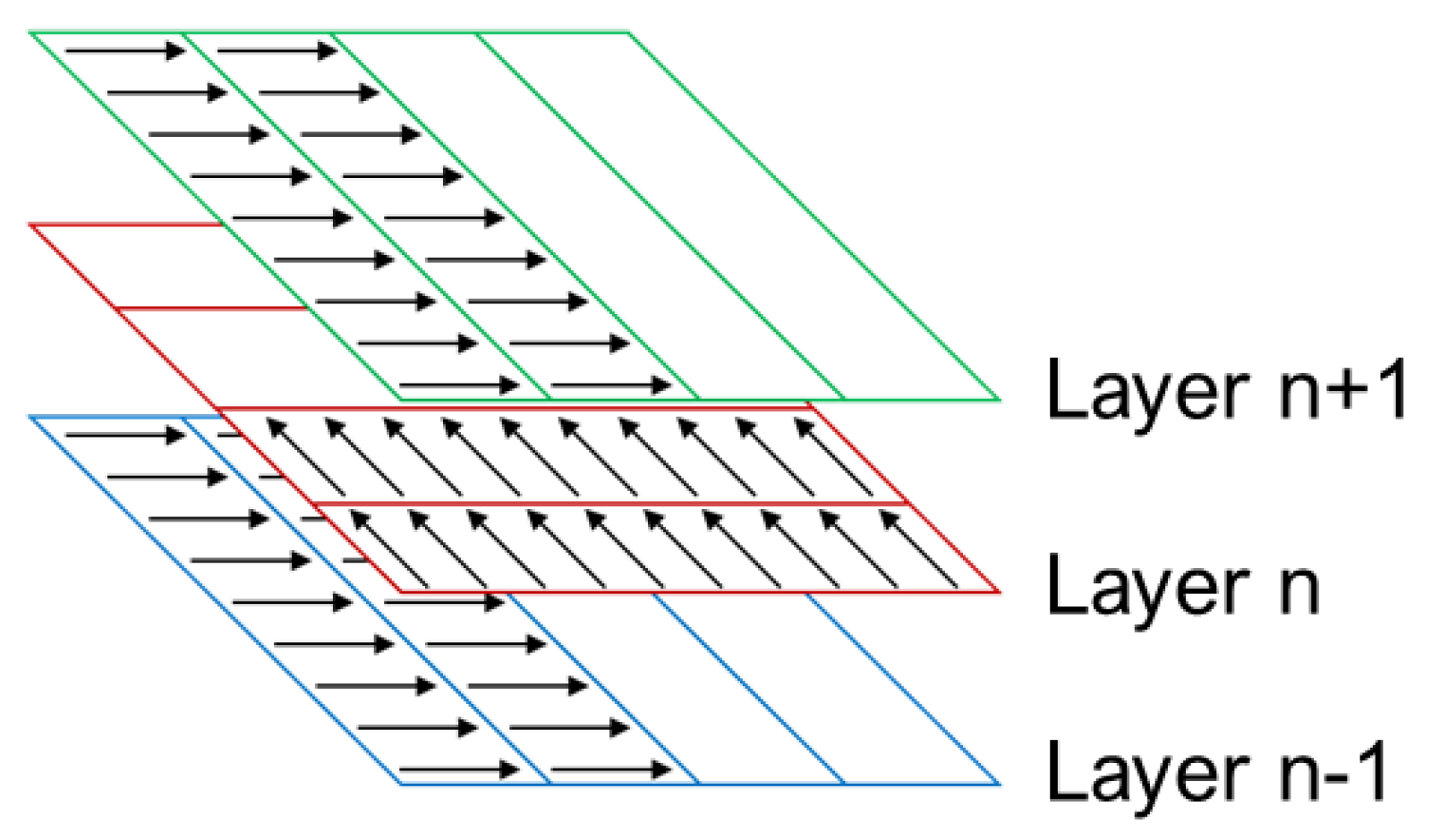

2.2. Laser Powder Bed Fusion Processing

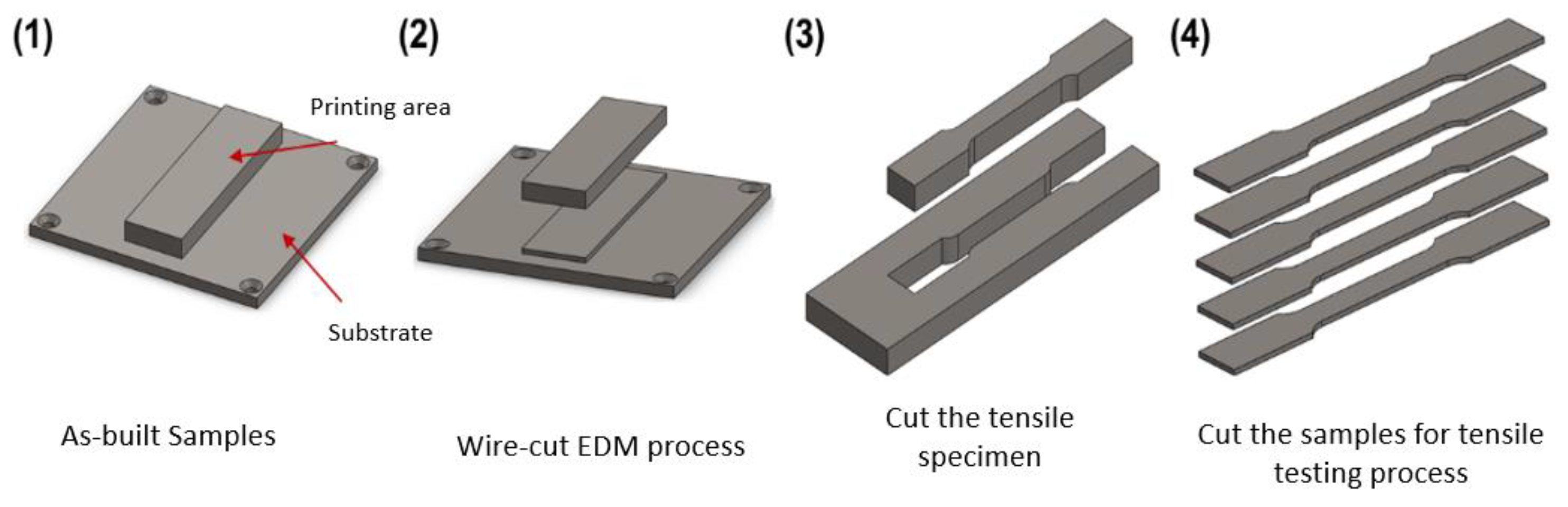

2.3. Mechanical Properties

2.4. Microstructural Characterization

3. Results and Discussion

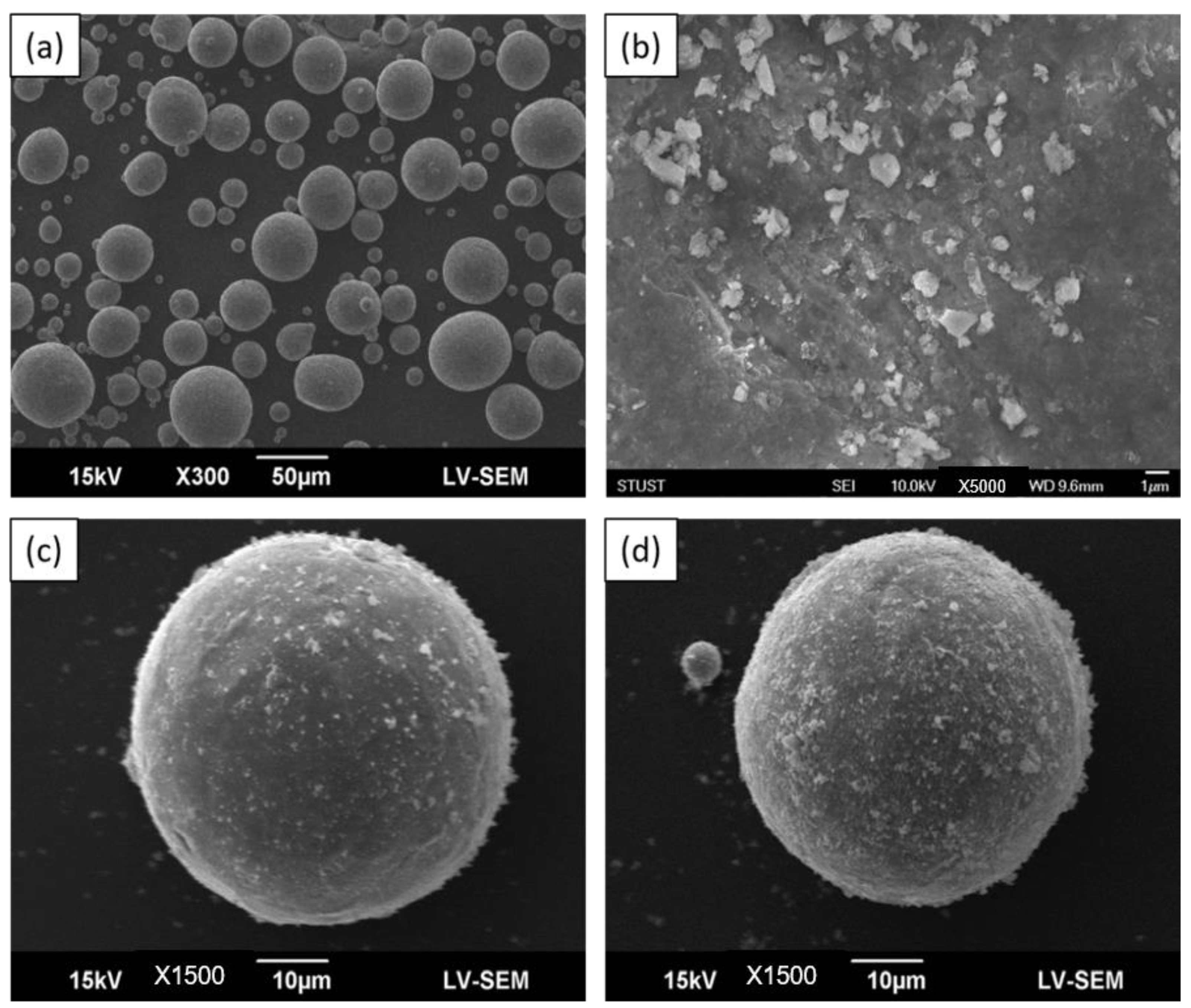

3.1. Composite Powders

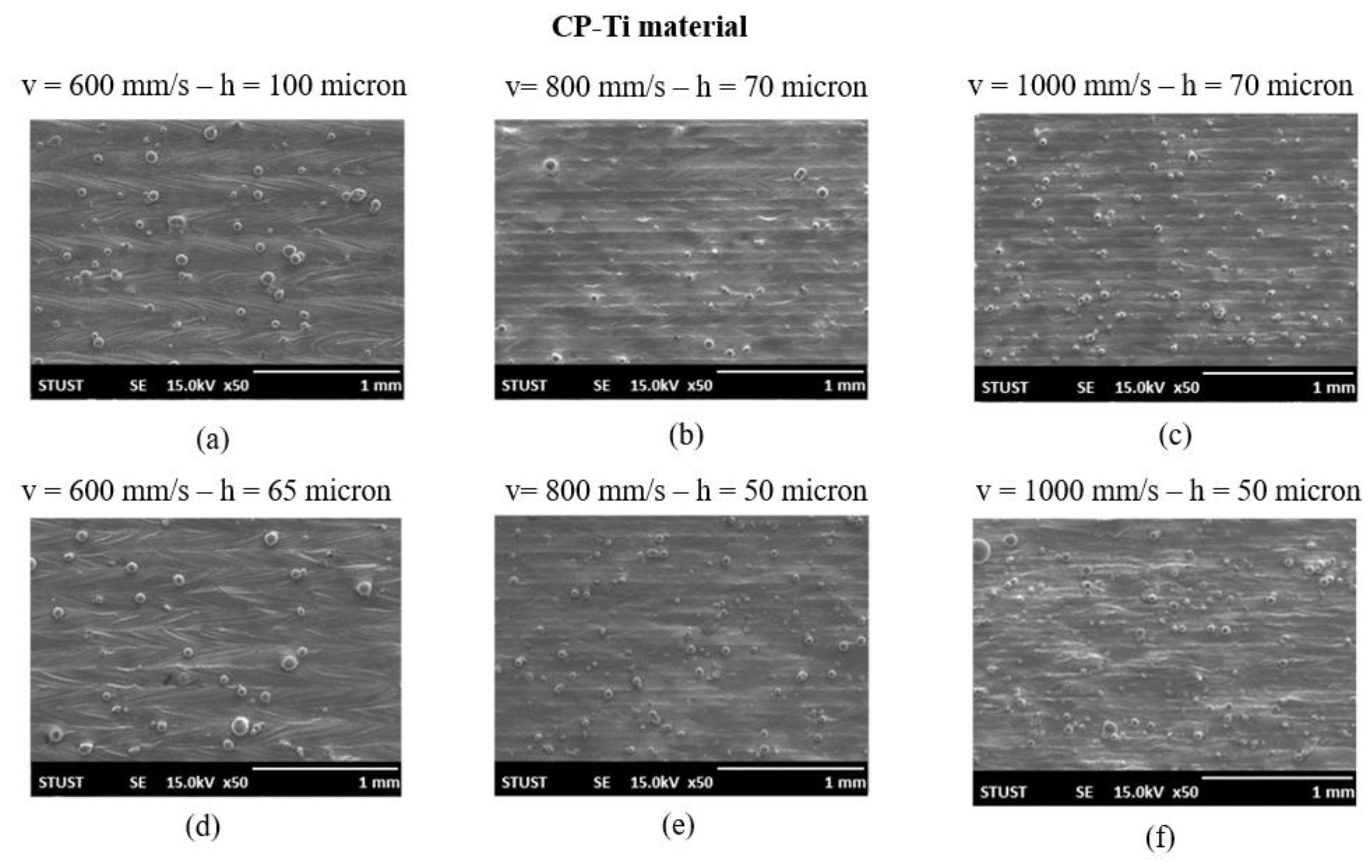

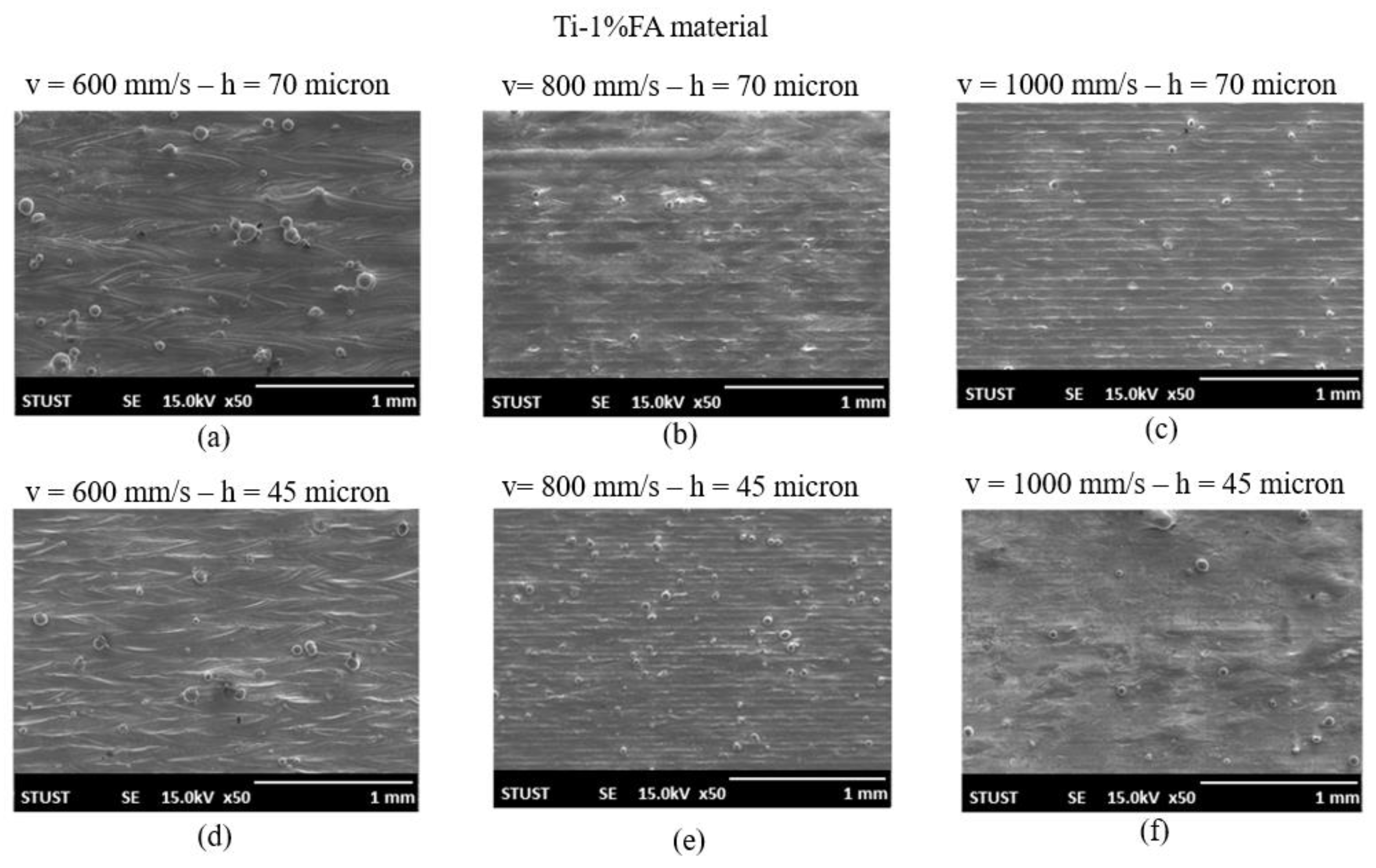

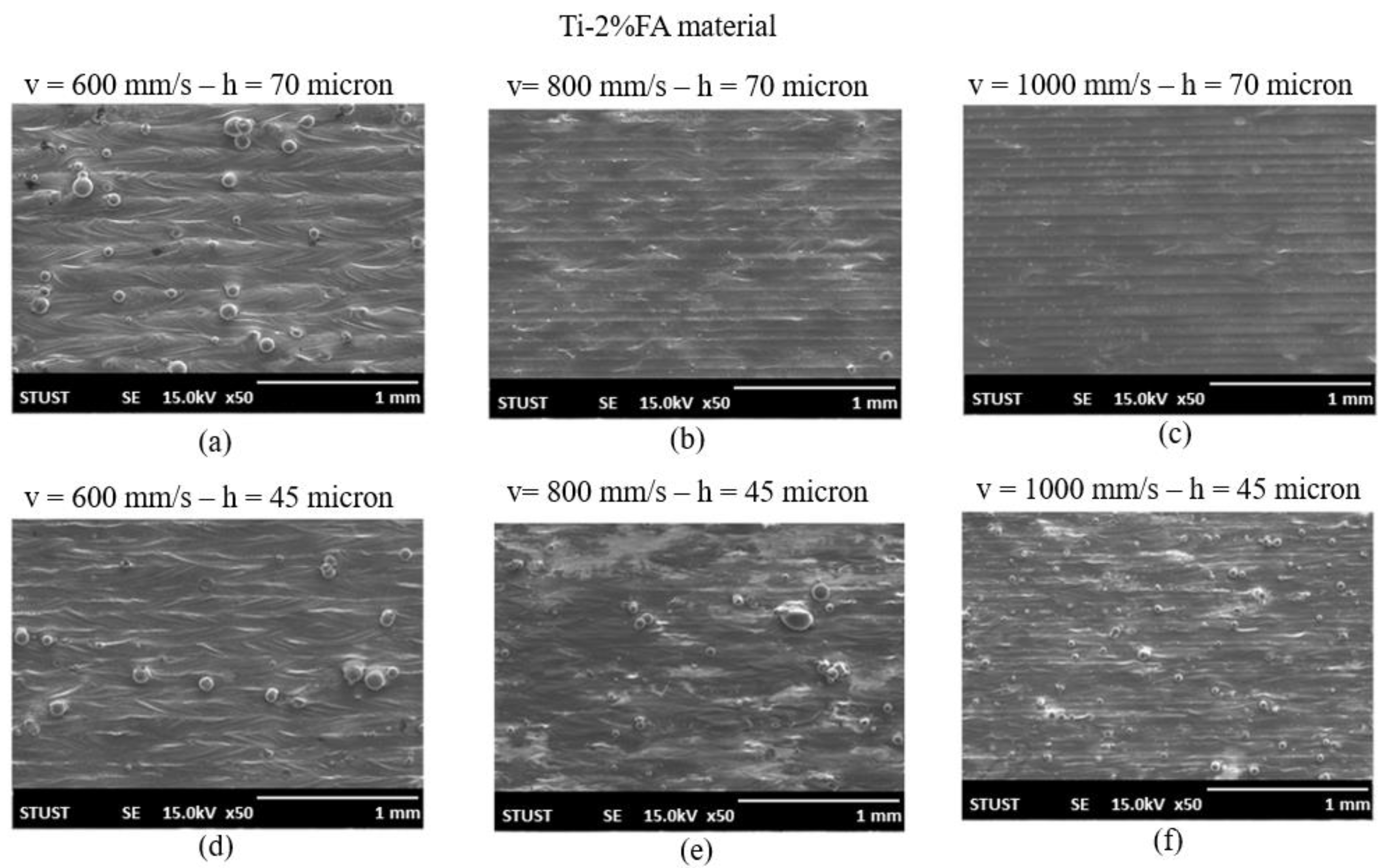

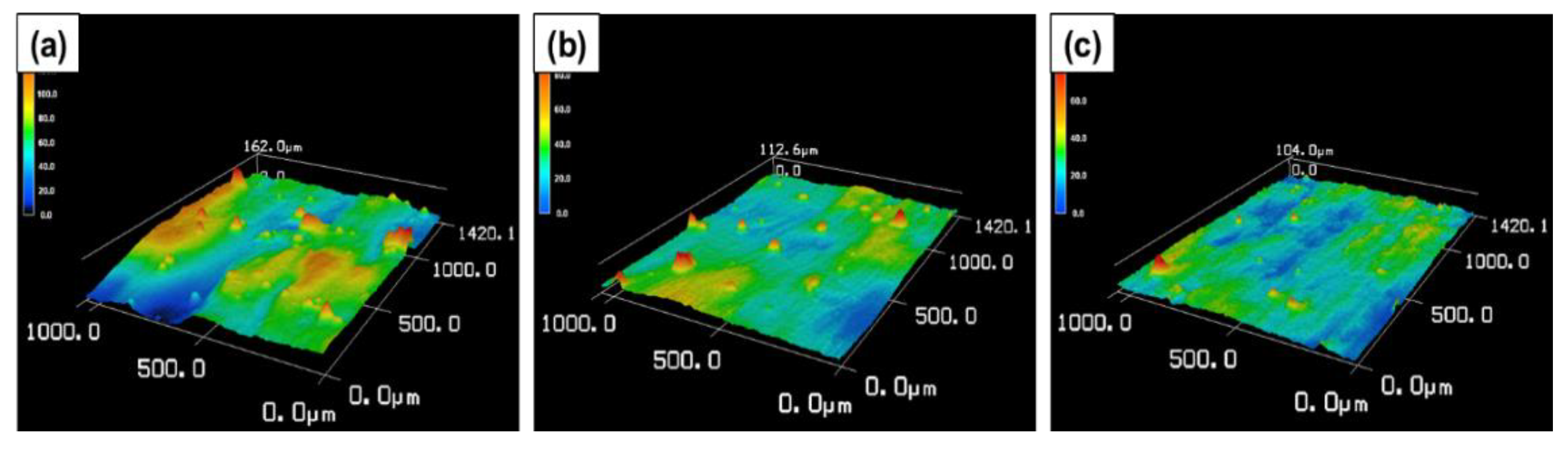

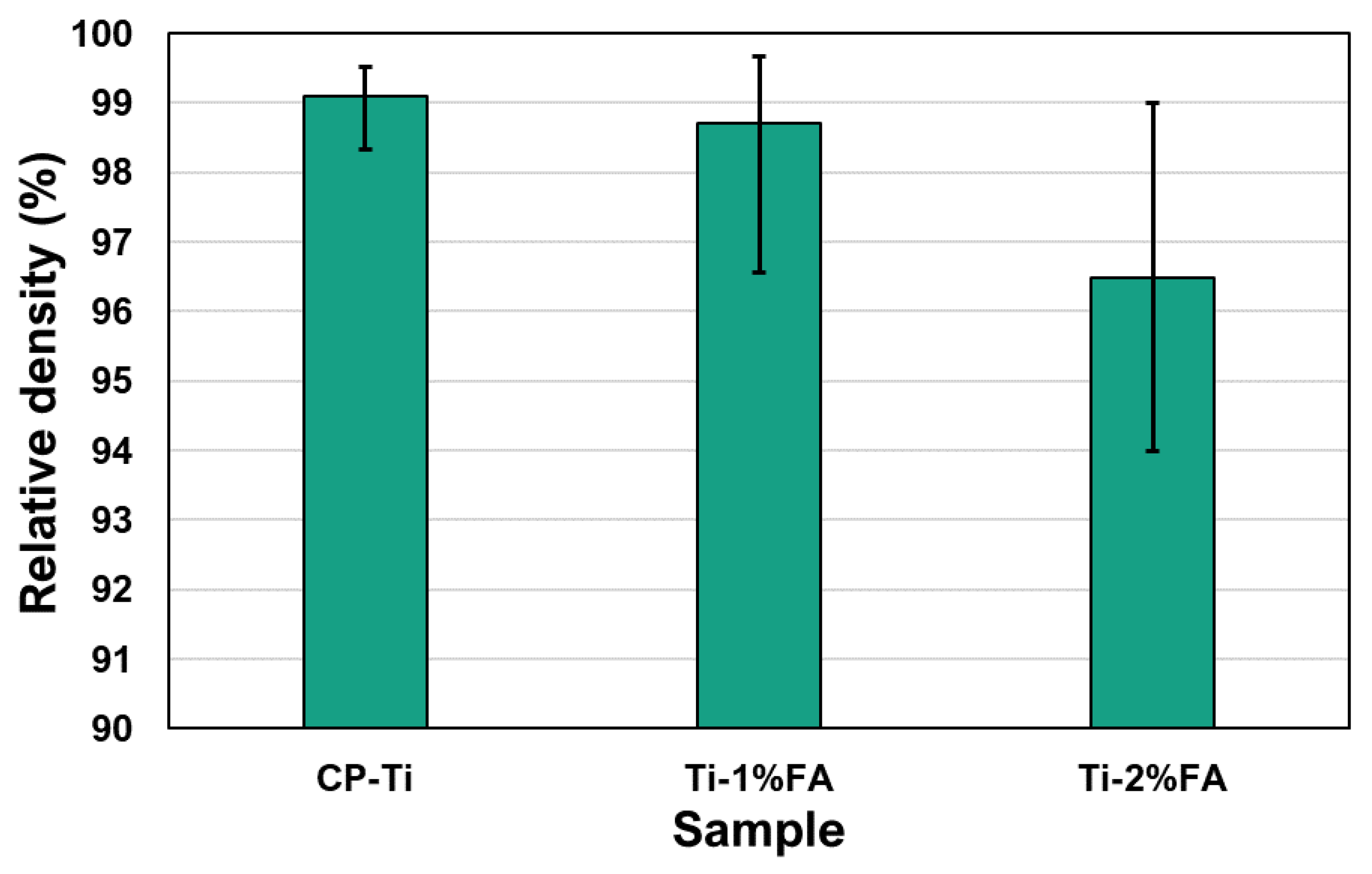

3.2. Determination of Optimal Processing Parameters for L-PBF Experiments

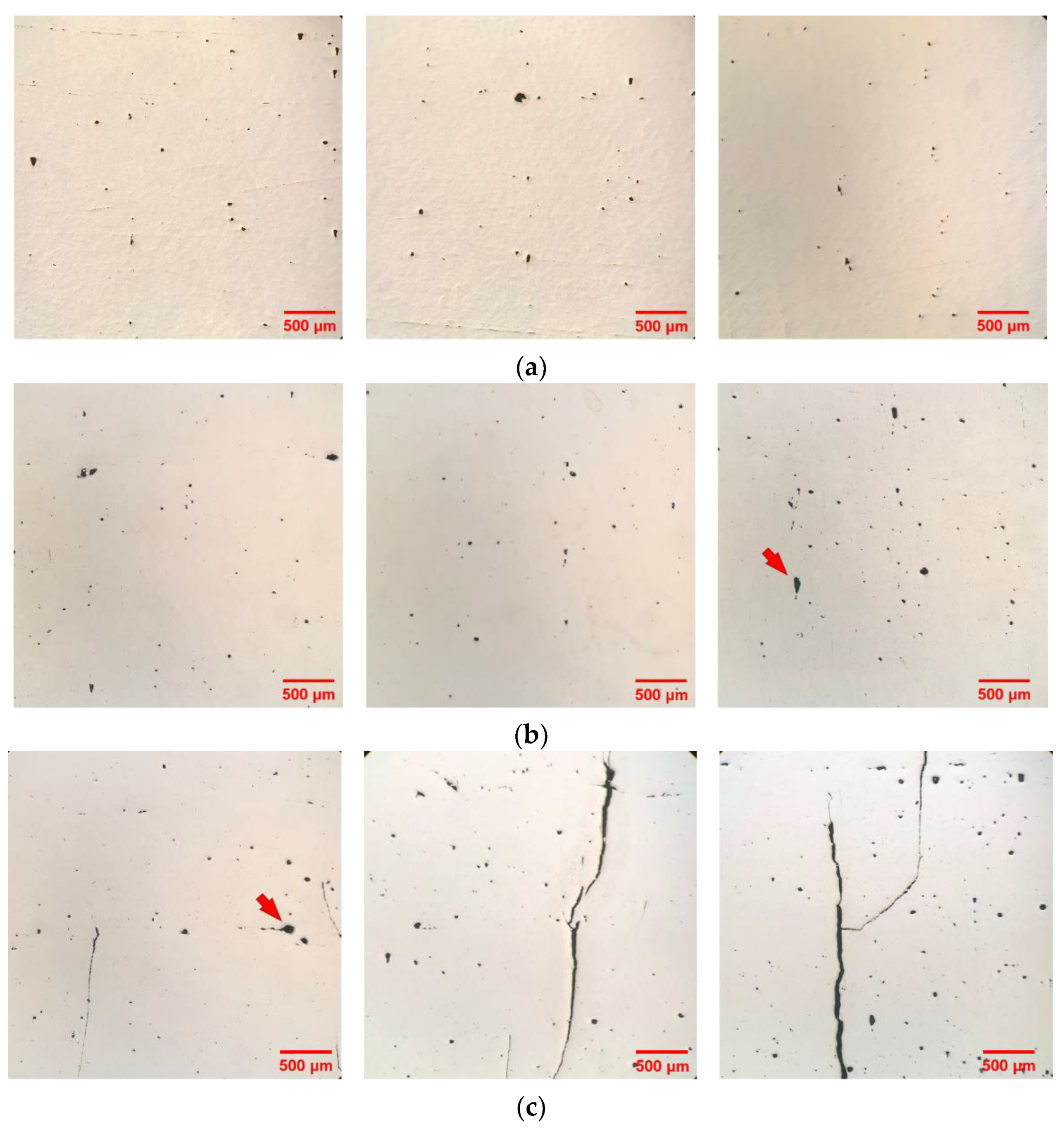

3.3. Microstructure Analysis of L-PBF Parts Fabricated Using Optimal Processing Conditions

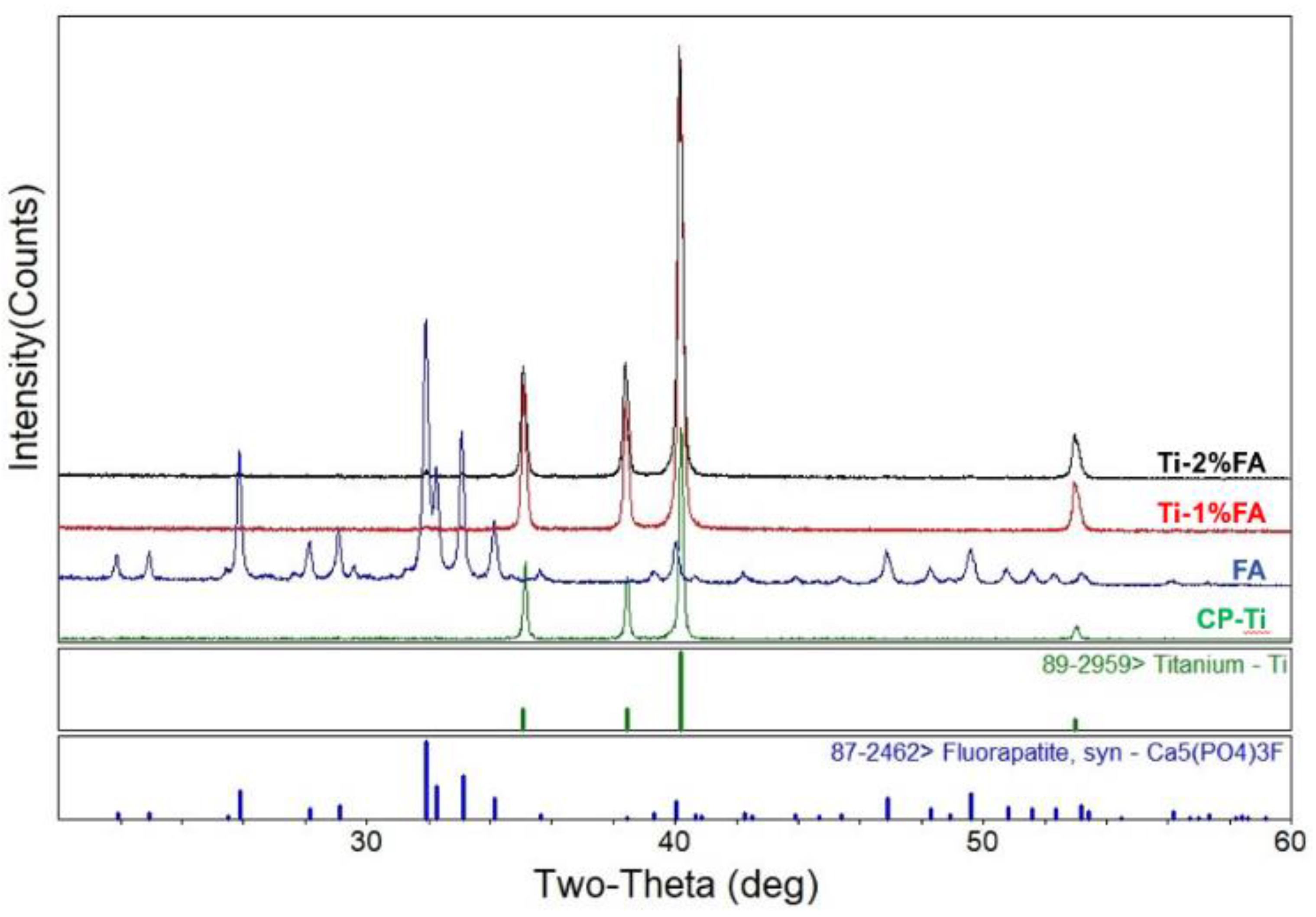

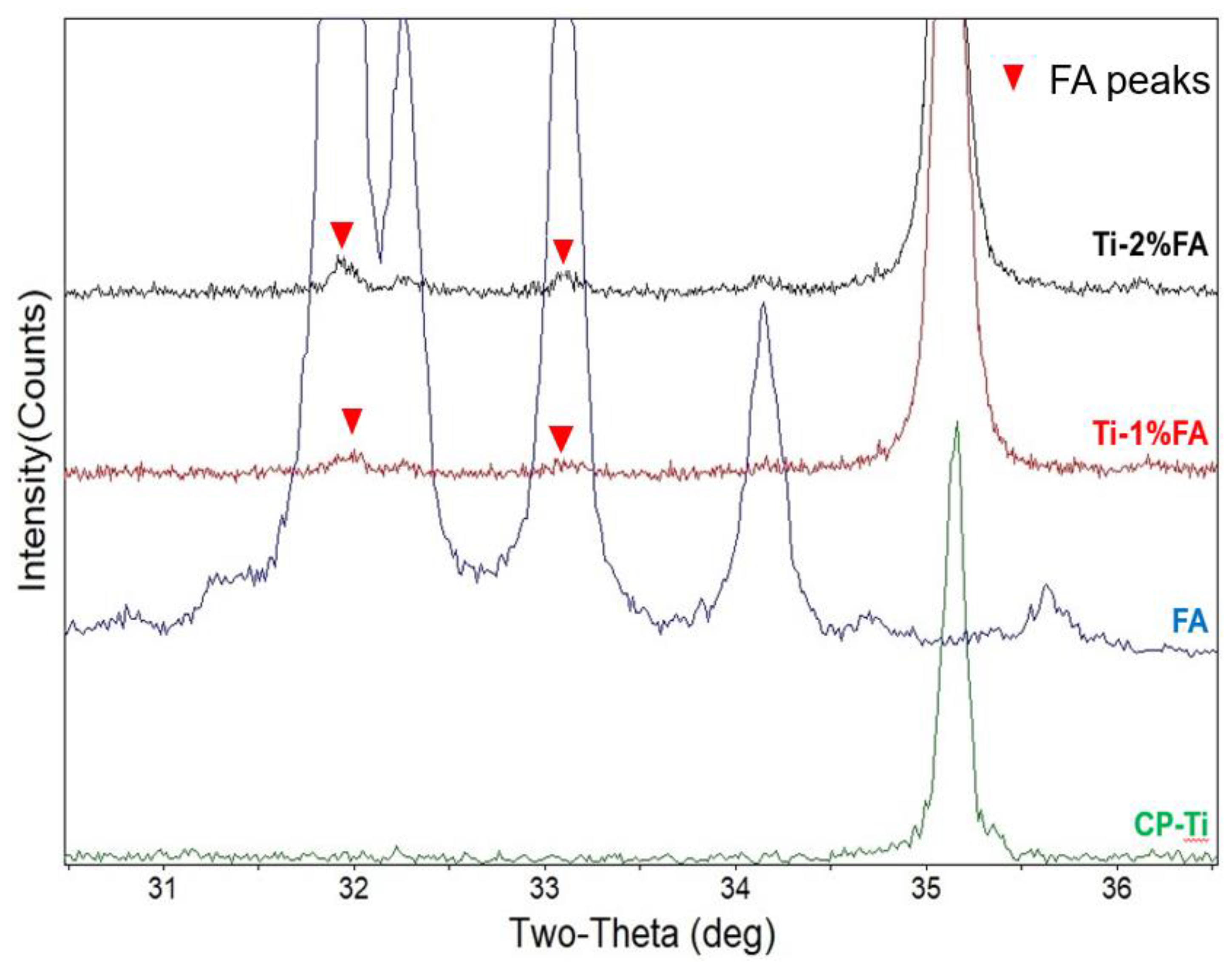

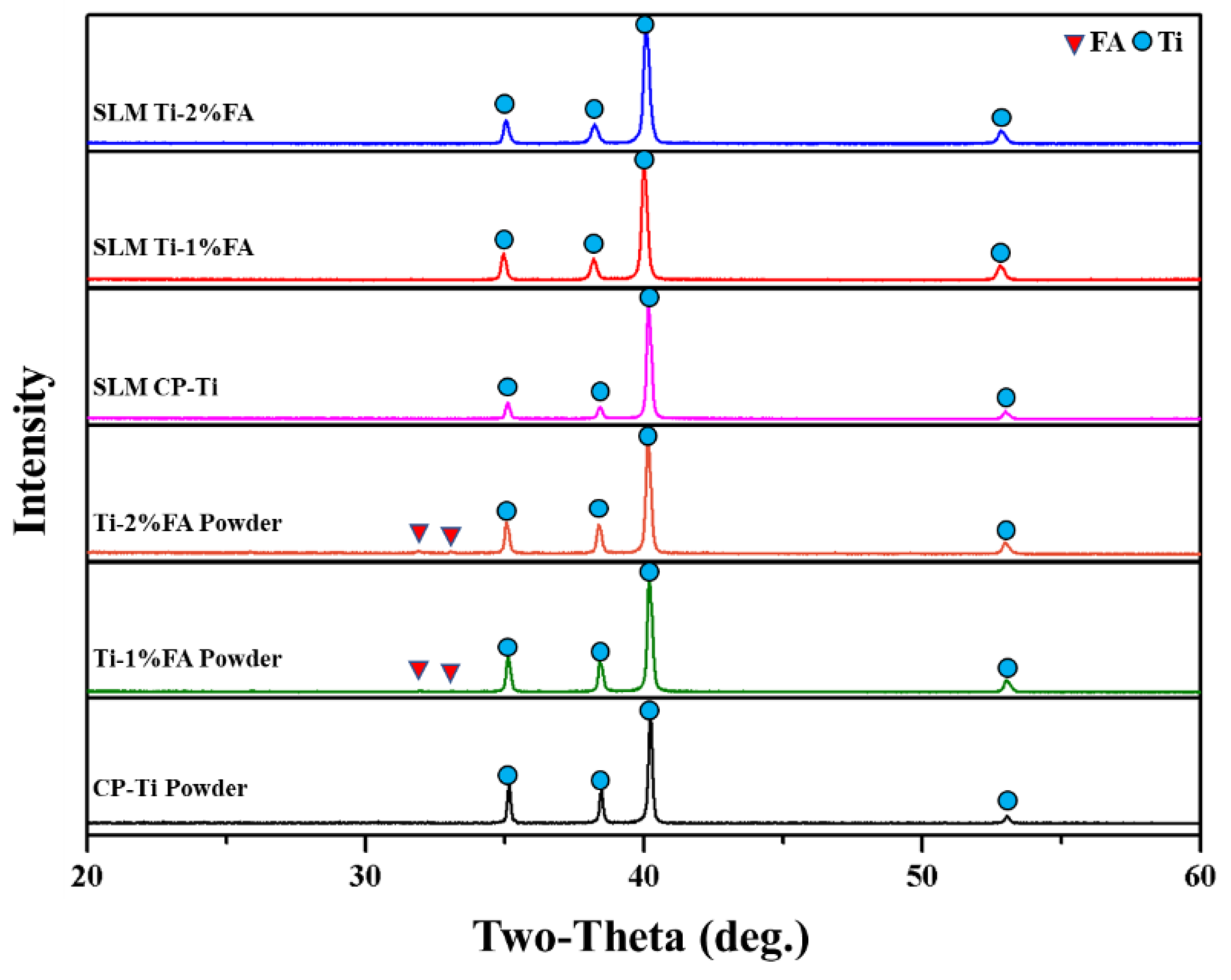

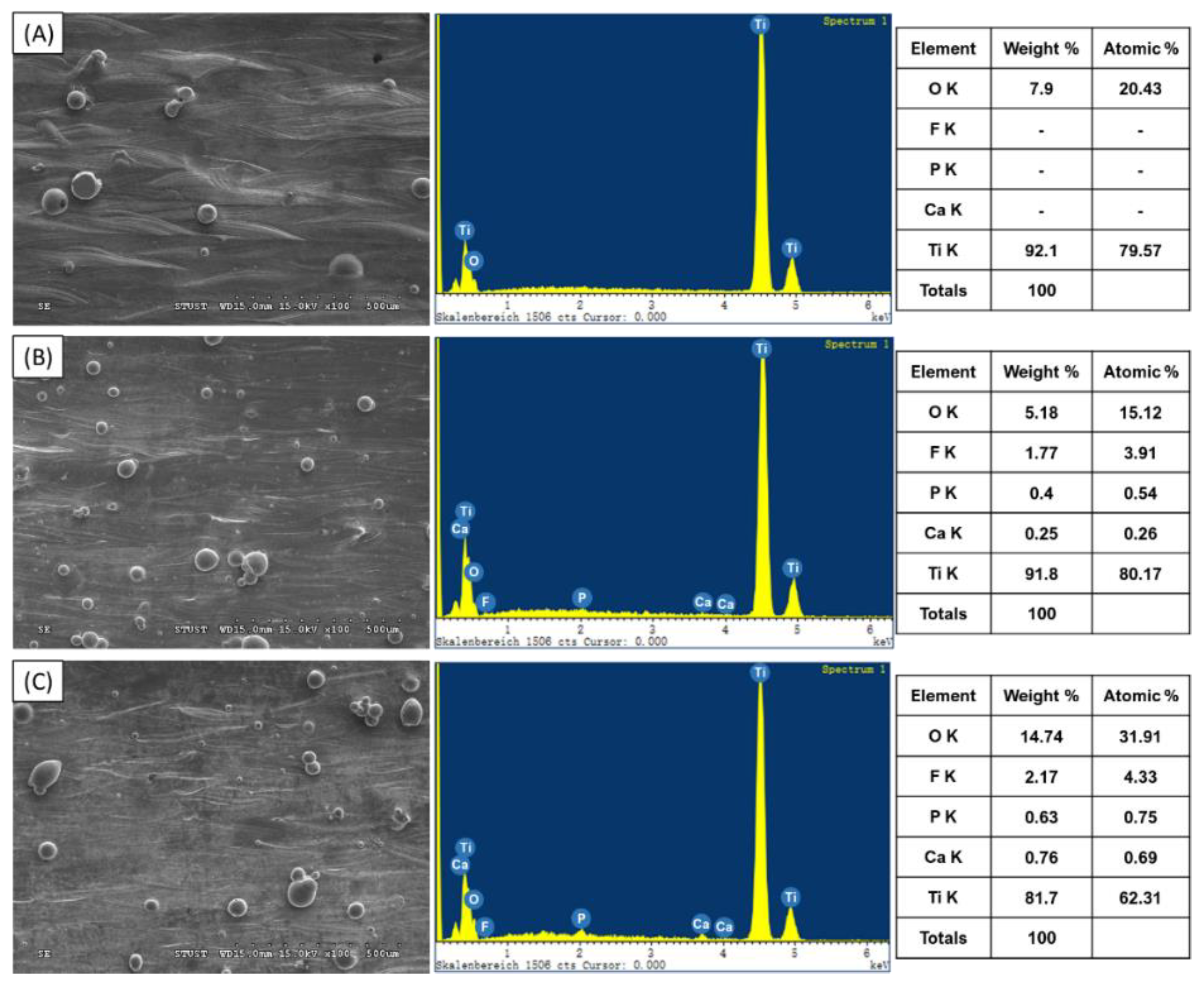

3.4. XRD and EDS Analysis

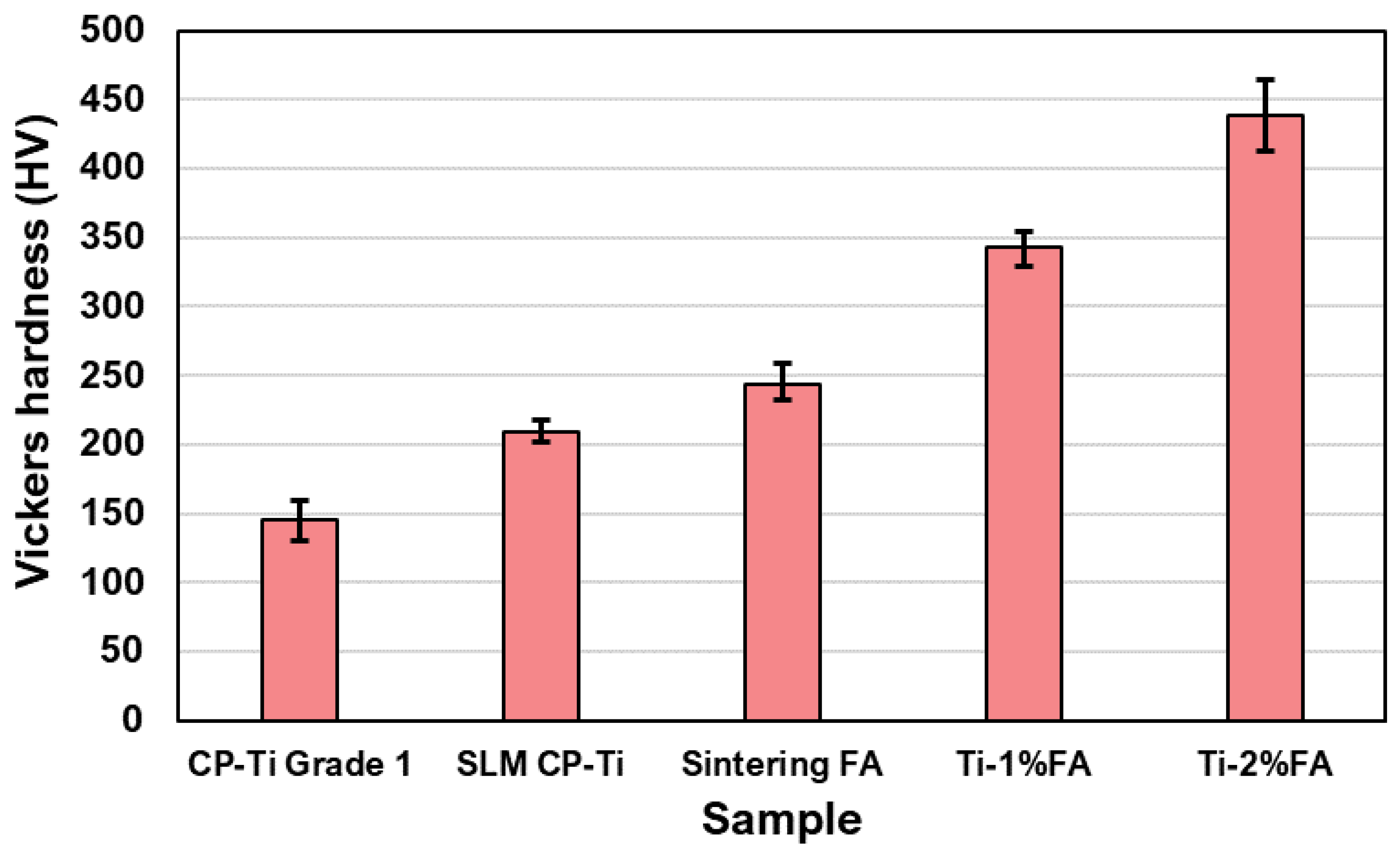

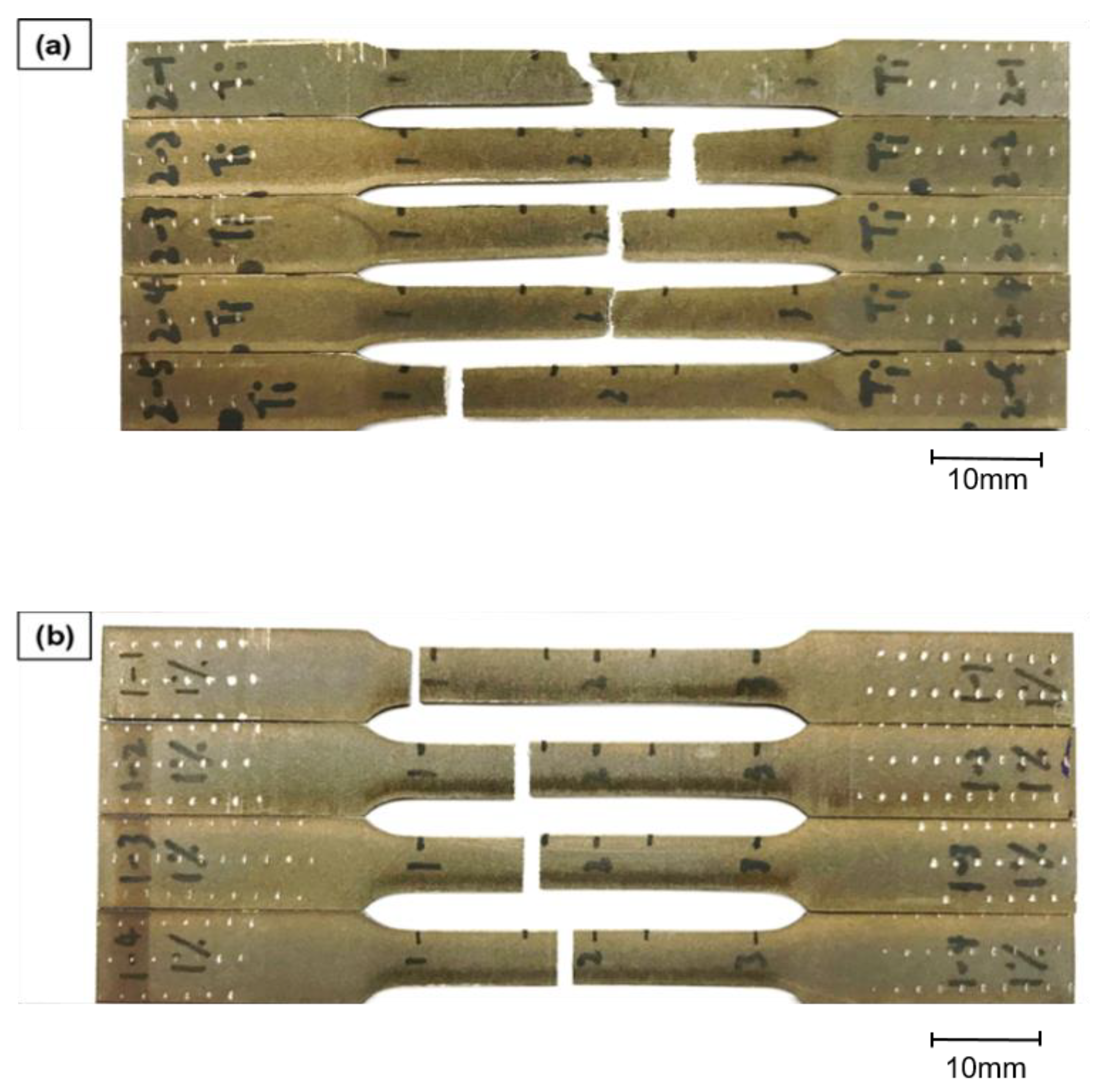

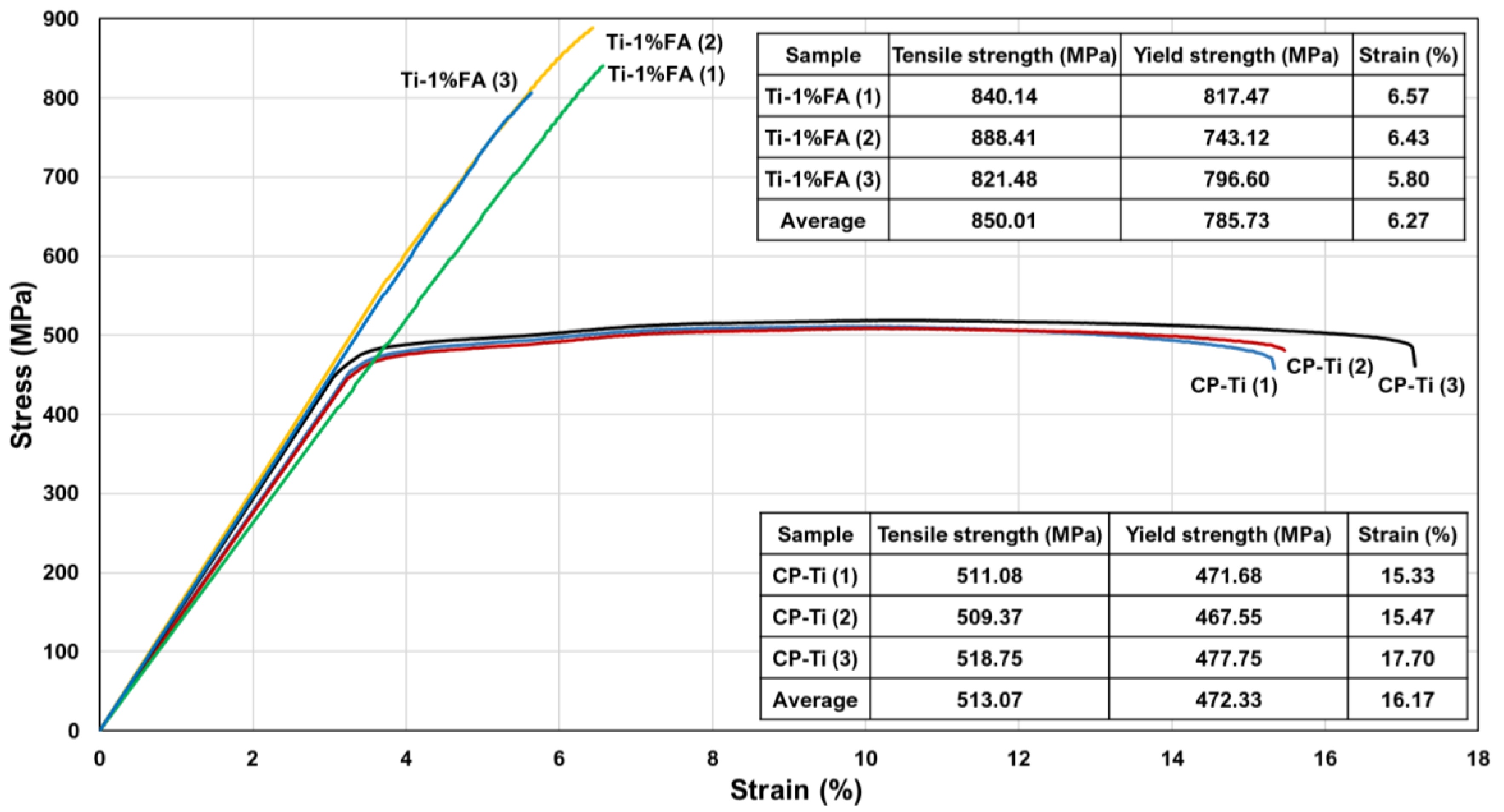

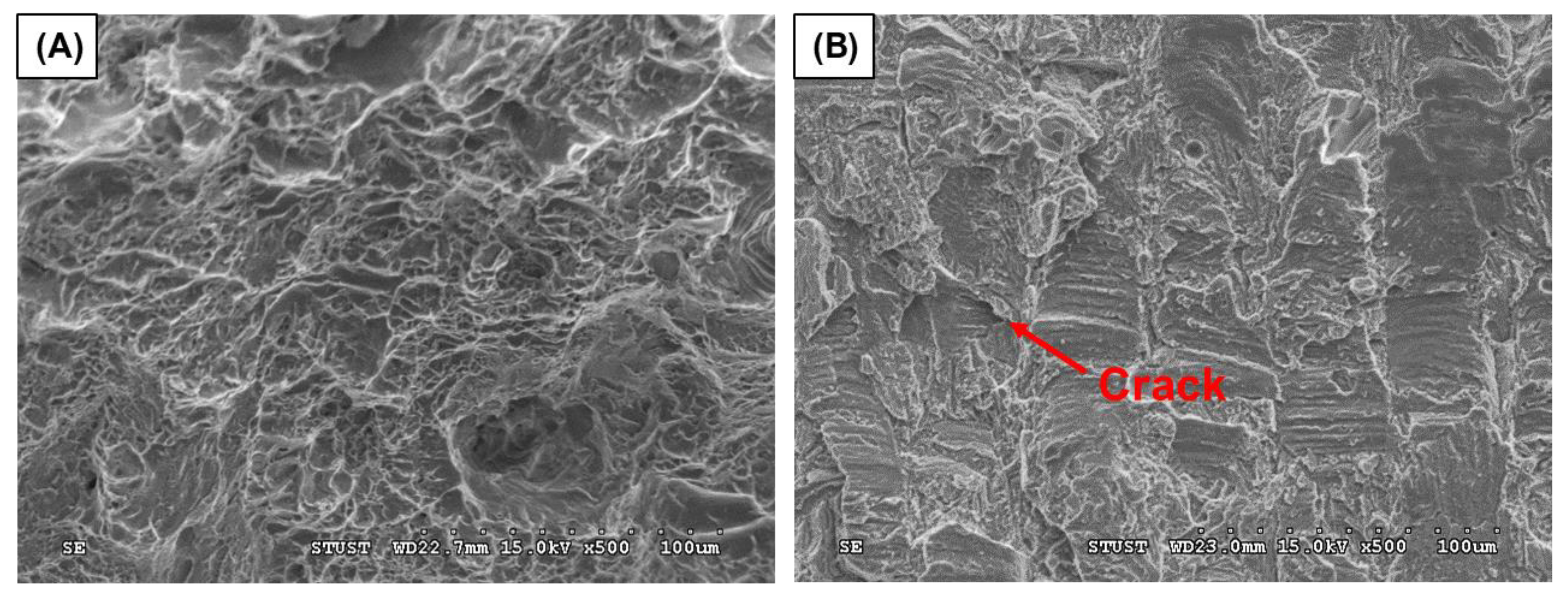

3.5. Hardness and Tensile Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Chen, S.; Huang, J.; Pan, C.; Lin, C.; Yang, T.; Huang, Y.; Ou, C.; Chen, L.; Lin, D.; Lin, H.; et al. Microstructure and mechanical properties of open-cell porous Ti-6Al-4V fabricated by selective laser melting. J. Alloys Compd. 2017, 713, 248–254. [Google Scholar] [CrossRef]

- Depboylu, F.N.; Yasa, E.; Poyraz, Ö.; Minguella-Canela, J.; Korkusuz, F.; De los Santos López, M.A. Titanium based bone implants production using laser powder bed fusion technology. J. Mater. Res. Technol. 2022, 17, 1408–1426. [Google Scholar] [CrossRef]

- Dzogbewu, T.C. Laser powder bed fusion of Ti6Al4V lattice structures and their applications. J. Met. Mater. Miner. 2020, 30, 68–78. [Google Scholar] [CrossRef]

- Nespoli, A.; Bennato, N.; Villa, E.; Passaretti, F. Study of anisotropy through microscopy, internal friction and electrical resistivity measurements of Ti-6Al-4V samples fabricated by selective laser melting. Rapid Prototyp. J. 2022, 28, 1060–1075. [Google Scholar] [CrossRef]

- Patel, N.R.; Gohil, P.P. A review on biomaterials: Scope, applications & human anatomy significance. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 91–101. [Google Scholar]

- Yadroitsava, I.; du Plessis, A.; Yadroitsev, I. Bone regeneration on implants of titanium alloys produced by laser powder bed fusion: A review. Titan. Consum. Appl. 2019, 2019, 197–233. [Google Scholar] [CrossRef]

- Hollander, D.A.; von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohlfing, B.; Paar, O.; Erli, H.J. Structural, mechanical and in vitro characterization of individually structured Ti-6Al-4V produced by direct laser forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Al-Rub, R.K.A. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Ti6Al4V lightweight lattice structures manufactured by laser powder bed fusion for load-bearing applications. Opt. Laser Technol. 2018, 108, 521–528. [Google Scholar] [CrossRef]

- Ravalji, J.M.; Raval, S.J. Review of quality issues and mitigation strategies for metal powder bed fusion. Rapid Prototyp. J. 2022. ahead of print. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.-N.; Leong, K.F.; Wei, J. Compressive properties of Ti-6Al-4V lattice structures fabricated by selective laser melting: Design, orientation and density. Addit. Manuf. 2017, 16, 213–224. [Google Scholar] [CrossRef]

- Wang, P.; Chen, D.; Fan, J.; Sun, K.; Wu, S.; Li, J.; Sun, Y. Study on the influence of process parameters on high performance Ti-6Al-4V parts in laser powder bed fusion. Rapid Prototyp. J. 2022. ahead of print. [Google Scholar] [CrossRef]

- Han, C.; Wang, Q.; Song, B.; Li, W.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Microstructure and property evolutions of titanium/nano-hydroxyapatite composites in-situ prepared by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 71, 85–94. [Google Scholar] [CrossRef]

- Marcu, T.; Menapace, C.; Girardini, L.; Leordean, D.; Popa, C. Selective laser melting of Ti6Al7Nb with hydroxyapatite addition. Rapid Prototyp. J. 2014, 20, 301–310. [Google Scholar] [CrossRef]

- Huang, S.; Sing, S.L.; de Looze, G.; Wilson, R.; Yeong, W.Y. Laser powder bed fusion of titanium-tantalum alloys: Compositions and designs for biomedical applications. J. Mech. Behav. Biomed. Mater. 2020, 108, 103775. [Google Scholar] [CrossRef]

- Mojumdar, S.; Kozánková, J.; Chocholoušek, J.; Majling, J.; Fábryová, D. Fluoroapatite-material for medicine, Growth, morphology and thermoanalytical properties. J. Therm. Anal. Calorim. 2004, 78, 73–82. [Google Scholar] [CrossRef]

- Chen, Y.; Miao, X. Thermal and chemical stability of fluorohydroxyapatite ceramics with different fluorine contents. Biomaterials 2005, 26, 1205–1210. [Google Scholar] [CrossRef]

- Ayed, F.B.; Bouaziz, J. Sintering of tricalcium phosphate-fluorapatite composites by addition of alumina. Ceram. Int. 2008, 34, 1885–1892. [Google Scholar] [CrossRef]

- Bhadang, K.A.; Gross, K.A. Influence of fluorapatite on the properties of thermally sprayed hydroxyapatite coatings. Biomaterials 2004, 25, 4935–4945. [Google Scholar] [CrossRef]

- Tran, H.-C.; Lo, Y.-L.; Yang, H.-C.; Hsiao, H.-C.; Cheng, F.-T.; Kuo, T.-H. Intelligent Additive Manufacturing Architecture for Enhancing Uniformity of Surface Roughness and Mechanical Properties of Laser Powder Bed Fusion Components. IEEE Trans. Autom. Sci. Eng. 2022, 1–12. [Google Scholar] [CrossRef]

- Tran, H.-C.; Lo, Y.-L. Heat transfer simulations of selective laser melting process based on volumetric heat source with powder size consideration. J. Mater. Process. Technol. 2018, 255, 411–425. [Google Scholar] [CrossRef]

- Hopkins, R.H.; Damon, D.H.; Piotrowski, P.; Walker, M.S.; Uphoff, J.H. Thermal Properties of Synthetic Fluorapatite Crystals. J. Appl. Phys. 1971, 42, 272–275. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Sawston, United Kingdom, 2002. [Google Scholar]

- Kurzynowski, T.; Chlebus, E.; Kuźnicka, B.; Reiner, J. Parameters in selective laser melting for processing metallic powders. In High Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications, Proceedings of the SPIE LASE, San Francisco, CA, USA, 21–26 January 2012; Beyer, E., Morris, T., Eds.; SPIE Digital Library: Bellingham, WA, USA, 2012; pp. 317–322. [Google Scholar]

- Young, Z.A.; Guo, Q.; Parab, N.D.; Zhao, C.; Qu, M.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Sun, T.; Chen, L. Types of spatter and their features and formation mechanisms in laser powder bed fusion additive manufacturing process. Addit. Manuf. 2020, 36, 101438. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; Sharabian, E.; Cordova, L.; Gibson, I.; Downing, D.; Bateman, S.; Brandt, M.; Rolfe, B. The effect of absorption ratio on meltpool features in laser-based powder bed fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Han, C.; Li, Y.; Wang, Q.; Cai, D.; Wei, Q.; Yang, L.; Wen, S.; Liu, J.; Shi, Y. Titanium/hydroxyapatite (Ti/HA) gradient materials with quasi-continuous ratios fabricated by SLM: Material interface and fracture toughness. Mater. Des. 2018, 141, 256–266. [Google Scholar] [CrossRef]

- Tran, H.-C.; Lo, Y.-L. Systematic approach for determining optimal processing parameters to produce parts with high density in selective laser melting process. Int. J. Adv. Manuf. Technol. 2019, 105, 4443–4460. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Lo, Y.-L.; Tran, H.-C.; Raza, M.M.; Le, T.-N. Systematic approach for reducing micro-crack formation in Inconel 713LC components fabricated by laser powder bed fusion. Rapid Prototyp. J. 2021, 27, 1548–1561. [Google Scholar] [CrossRef]

- Pal, S.; Lojen, G.; Kokol, V.; Drstvensek, I. Evolution of metallurgical properties of Ti-6Al-4V alloy fabricated in different energy densities in the Selective Laser Melting technique. J. Manuf. Process. 2018, 35, 538–546. [Google Scholar] [CrossRef]

- Tran, H.-C.; Lo, Y.-L.; Le, T.-N.; Lau, A.K.-T.; Lin, H.-Y. Multi-scale simulation approach for identifying optimal parameters for fabrication of high-density Inconel 718 parts using selective laser melting. Rapid Prototyp. J. 2021, 28, 109–125. [Google Scholar] [CrossRef]

- Le, T.-N.; Lo, Y.-L.; Tran, H.-C. Multi-scale modeling of selective electron beam melting of Ti6Al4V titanium alloy. Int. J. Adv. Manuf. Technol. 2019, 105, 545–563. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Tran, H.-C.; Lo, Y.-L.; Chang, Y.-C.; Lin, H.-Y.; Liang, S. Mechanics Modeling of Residual Stress Considering Effect of Preheating in Laser Powder Bed Fusion. J. Manuf. Mater. Process. 2021, 5, 46. [Google Scholar] [CrossRef]

- Wasz, M.; Brotzen, F.; McLellan, R.; Griffin, A. Effect of oxygen and hydrogen on mechanical properties of commercial purity titanium. Int. Mater. Rev. 1996, 41, 1–12. [Google Scholar] [CrossRef]

| Element | N | H | O | C | Fe | Ti |

|---|---|---|---|---|---|---|

| Wt% | 0.04 max | 0.0125 max | 0.13 max | 0.08 max | 0.2 max | Bal. |

| Fixed Processing Conditions for All Materials | ||

|---|---|---|

| Powder size (µm) | <55 | |

| Diameter of laser beam (µm) | 78 | |

| Layer thickness (µm) | 40 | |

| Oxygen concentration (ppm) | O2 < 1000 ppm | |

| Laser power (W) | 150 | |

| Parameter Settings for Different Materials | ||

| CP-Ti | Scanning Speed (mm/s) | Hatching Space (µm) |

| 600 | 100 | |

| 65 | ||

| 800 | 70 | |

| 50 | ||

| 1000 | 70 | |

| 50 | ||

| Ti-1%FA Ti-2%FA | 600 | 70 |

| 45 | ||

| 800 | 60 | |

| 40 | ||

| 1000 | 60 | |

| 40 | ||

| Fixed Processing Conditions for All Materials | ||

|---|---|---|

| Powder size (µm) | <55 | |

| Diameter of laser beam (µm) | 78 | |

| Layer thickness (µm) | 40 | |

| Oxygen concentration (ppm) | O2 < 1000 ppm | |

| Laser power (W) | 150 | |

| Parameter Settings for Different Materials | ||

| CP-Ti | Scanning Speed (mm/s) | Hatching Space (µm) |

| 800 | 70 | |

| Ti-1%FA | 1000 | 70 |

| Ti-2%FA | 1000 | 70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, P.-K.; Lin, W.-T.; Lin, J.-W.; Tran, H.-C.; Kuo, T.-Y.; Chien, C.-S.; Vo, V.-L.; Lin, R.-L. Mechanical Properties of Titanium/Nano-Fluorapatite Parts Produced by Laser Powder Bed Fusion. Materials 2023, 16, 1502. https://doi.org/10.3390/ma16041502

Wu P-K, Lin W-T, Lin J-W, Tran H-C, Kuo T-Y, Chien C-S, Vo V-L, Lin R-L. Mechanical Properties of Titanium/Nano-Fluorapatite Parts Produced by Laser Powder Bed Fusion. Materials. 2023; 16(4):1502. https://doi.org/10.3390/ma16041502

Chicago/Turabian StyleWu, Po-Kuan, Wei-Ting Lin, Jia-Wei Lin, Hong-Chuong Tran, Tsung-Yuan Kuo, Chi-Sheng Chien, Vi-Long Vo, and Ru-Li Lin. 2023. "Mechanical Properties of Titanium/Nano-Fluorapatite Parts Produced by Laser Powder Bed Fusion" Materials 16, no. 4: 1502. https://doi.org/10.3390/ma16041502

APA StyleWu, P.-K., Lin, W.-T., Lin, J.-W., Tran, H.-C., Kuo, T.-Y., Chien, C.-S., Vo, V.-L., & Lin, R.-L. (2023). Mechanical Properties of Titanium/Nano-Fluorapatite Parts Produced by Laser Powder Bed Fusion. Materials, 16(4), 1502. https://doi.org/10.3390/ma16041502