Effects of the Gas-Atomization Pressure and Annealing Temperature on the Microstructure and Performance of FeSiBCuNb Nanocrystalline Soft Magnetic Composites

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Preparation of the Powders

2.2. Preparation and Heat-Treatment of the NSMCs

2.3. Characterization Techniques

3. Results and Discussion

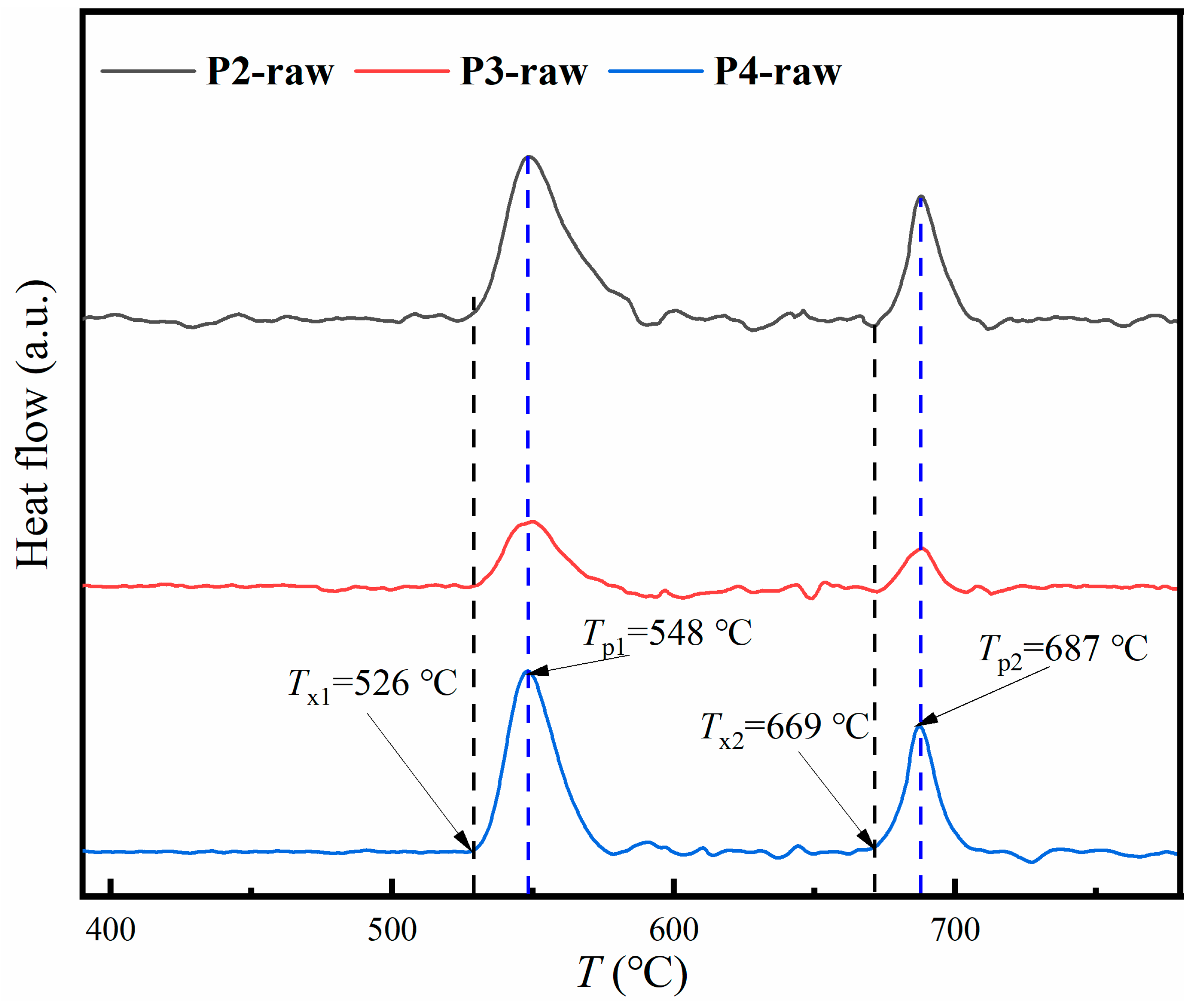

3.1. Structure and Soft-Magnetic Properties of the Gas-Atomized Powders

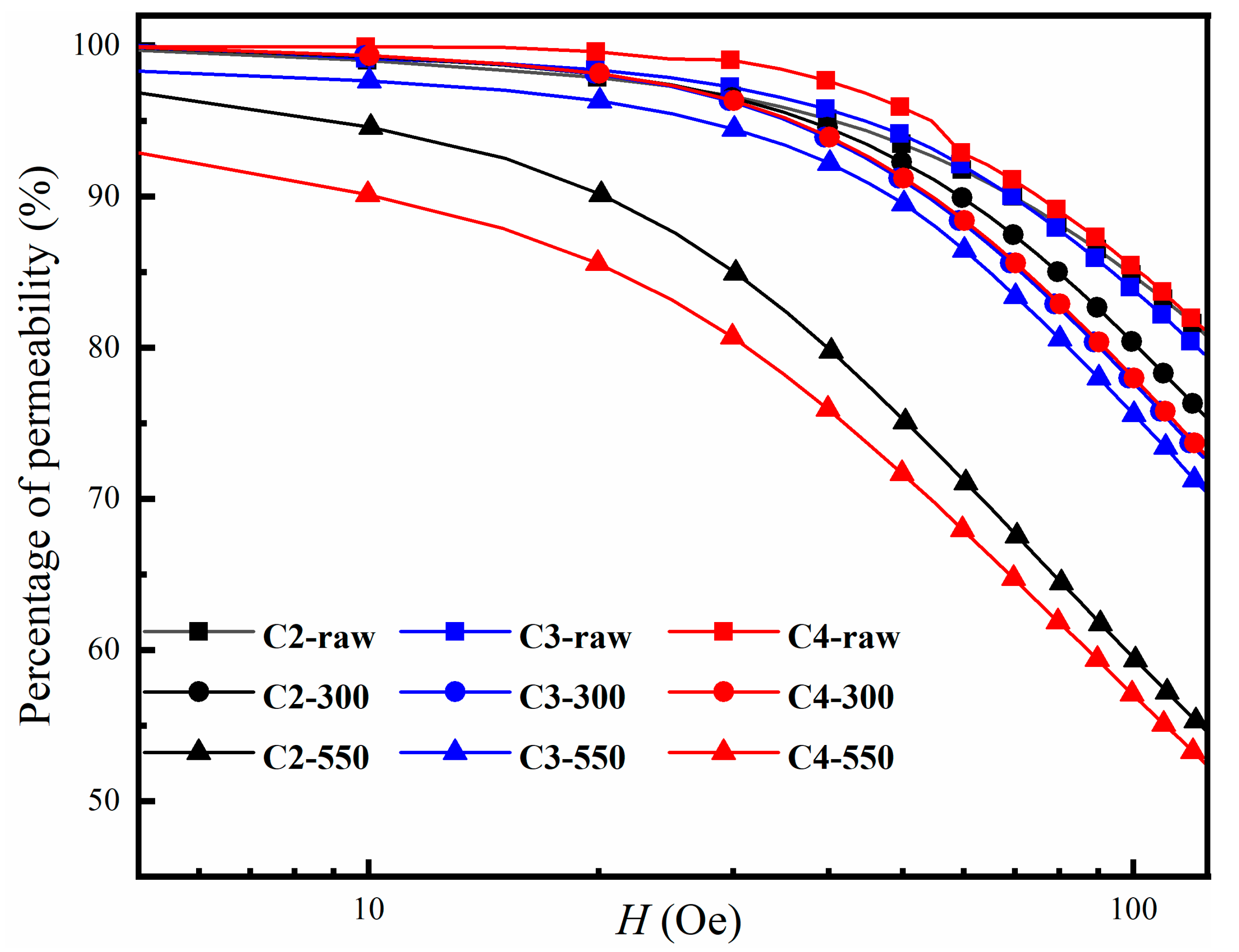

3.2. Soft-Magnetic Properties of the NSMCs

4. Conclusions

- (1)

- The obtained powders contain the amorphous phase and the α-Fe (Si) phase. With the increasing gas-atomization pressure, the soft-magnetic properties of the corresponding powders and NSMCs tend to be better, which can be attributed to the smaller d and the larger amorphous ratio of the powders. The powders prepared by the 4 MPa gas-atomization pressure without annealing treatment show the highest amorphous ratio of 92% in this study.

- (2)

- After annealing treatment, the μe of NSMCs increases compared with the raw NSMCs, while Hc and Pcv decrease. In addition, the nanocrystallization annealing treatment at 550 °C can largely optimize the soft magnetic properties of the NSMCs, which is better than the stress-relief annealing treatment at 300 °C. It can thus be suspected that the improvement of soft magnetic properties resulting from the precipitation of the α-Fe(Si) nanocrystals largely overwhelms the deterioration caused by the grain growth.

- (3)

- After being annealed at 550 °C, the NSMCs made by the powders using the 4 MPa gas-atomization pressure show the best performance among this work with μe = 33.32 (f = 100 kHz), Hc = 73.08 A/m, and Pcv = 33.242 mW/cm3 (f = 100 kHz, Bm = 20 mT, sine wave), resulting from the stress relief and the smallest d of the precipitated α-Fe (Si) nanocrystalline.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Y.; Wei, R.; Li, Z.; Li, F.; Wang, A.; Chang, C.; Wang, X. Improvement of magnetic properties for V-substituted Fe73.5Si13.5B9Cu1Nb3-xVx nanocrystalline alloys. J. Mater. Sci. 2017, 28, 10555–10563. [Google Scholar] [CrossRef]

- Gao, S.; Yan, X.; Chang, C.; Aubry, E.; He, P.; Liu, M.; Liao, H.; Nouredine, F. Microstructure and magnetic properties of FeSiBCrC soft magnetic alloy manufactured by selective laser melting. Mater. Lett. 2021, 290, 129469. [Google Scholar] [CrossRef]

- Xiao, Z.; Tang, C.; Zhao, H.; Zhang, D.; Li, Y. Effects of sintering temperature on microstructure and property evolution of Fe81Cu2Nb3Si14 soft magnetic materials fabricated from amorphous melt-spun ribbons by spark plasma sintering technique. J. Non. Cryst. Solids. 2012, 358, 114–118. [Google Scholar] [CrossRef]

- Liu, M.; Liu, L.; Cai, P.; Dong, Y.; Wang, X. Fabrication and magnetic properties of novel Fe-based amorphous powder and corresponding powder cores. J. Mater. Sci. Mater. Electron. 2018, 29, 6092–6097. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Pauly, S.; Chang, C.; Wei, R.; Li, F.; Wang, X. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Anhalt, M. Systematic investigation of particle size dependence of magneticproperties in soft magnetic composites. J. Magn. Magn. Mater. 2008, 320, e366–e369. [Google Scholar] [CrossRef]

- Shi, Y.; Lu, W.; Sun, W.; Zhang, S.; Yang, B.; Wang, J. Pressure-dependent microstructure evolution of Fe-based amorphous alloy powders via high-pressure gas atomization. J. Alloys Compd. 2022, 920, 166038. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, Z.; Zou, H.; Liu, Z.; Chen, J.; Li, S.; Zhang, D. Characterization of spherical AlSi10Mg powder produced by double-nozzle gas atomization using different parameters. T. Nonferr. Metal Soc. 2019, 29, 374–384. [Google Scholar] [CrossRef]

- Alvarez, K.L.; Martin, J.M.; Lpatov, M.; Gonzalez, J. Soft magnetic amorphous alloys (Fe-rich) obtained by gas atomisation technique. J. Alloys Compd. 2017, 735, 2646–2652. [Google Scholar] [CrossRef]

- Ciftci, N.; Ellendt, N.; Barreto, E.S.; Mädler, L.; Uhlenwinkel, V. Increasing the amorphous yield of {(Fe0.6Co0.4)(0.75)B0.2Si0.05}(96)Nb4 powders by hot gas atomization. Adv. Powder Technol. 2018, 29, 380–385. [Google Scholar] [CrossRef]

- Cao, C.; Wang, Y.; Zhu, L.; Meng, Y.; Dai, Y.; Chen, J. Evolution of structural and magnetic properties of the FeCuBP amorphous alloy during annealing. J. Alloys Compd. 2017, 722, 394–399. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Zheng, Z.; Qiu, Z.; Li, K.; Xu, J.; Lu, K.; Zeng, D. Reduction of core loss for FeSi soft magnetic composites prepared using atomic layer deposition-based coating and high-temperature annealing. J. Alloys Compd. 2022, 909, 164655. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, H.; Sun, C.; Chen, C.; Hao, J. Effects of the substitution of Si with P on the glass forming ability, crystallization behavior, and magnetic properties of FeCuNbSiBP atomized powder. J. Magn. Magn. Mater. 2022, 550, 169087. [Google Scholar] [CrossRef]

- Meng, Y.; Pang, S.; Chang, C.; Bai, X.; Zhang, T. Nanocrystalline Fe83Si4B10P2Cu1 ribbons with improved soft magnetic properties and bendability prepared via rapid annealing of the amorphous precursor. J. Magn. Magn. Mater. 2021, 523, 167583. [Google Scholar] [CrossRef]

- Li, Y.; Shen, N.; Wu, Y.; Zhang, S.; He, Z.; Li, F.; Hui, X. High Bs Fe-B-P-C-Cu nanocrystalline alloy with longtime annealing stability and low heating rate sensitivity. J. Magn. Magn. Mater. 2022, 543, 168623. [Google Scholar] [CrossRef]

- Luo, Q.; Li, D.; Cai, M.; Di, S.; Zhang, Z.; Zeng, Q.; Wang, Q.; Shen, B. Excellent magnetic softness-magnetization synergy and suppressed defect activation in soft magnetic amorphous alloys by magnetic field annealing. J. Mater. Sci. Technol. 2022, 116, 72–82. [Google Scholar] [CrossRef]

- Xing, Y.; Dong, B.; Zhou, S.; Dong, Y.; Chen, W.; Cui, H.; Wang, L.; Wang, J. Soft magnetic properties of Co-doped FeSiBC amorphous and nanocrystalline alloys. J. Magn. Magn. Mater. 2022, 565, 170249. [Google Scholar] [CrossRef]

- Yadav, K.; Sangwan, R.; Barala, M.; Mohan, D.; Sanghi, S. Effect of antimony dopant on the structural properties of CdSe crystalline chalcogenides. Mater. Today Proc. 2022, 54, 656–659. [Google Scholar] [CrossRef]

- Henzer, G. Soft magnetic nanocrystalline materials. Handb. Magn. Mater. 1997, 10, 415–462. [Google Scholar]

- Li, Y.; Dou, Z.; Chen, X.; Lv, K.; Li, F.; Hui, X. Improving the amorphous forming ability and magnetic properties of FeSiBPCu amorphous and nanocrystalline alloys by utilizing carbon. J. Alloys Compd. 2020, 844, 155767. [Google Scholar] [CrossRef]

- Shi, L.; Yao, K. Composition design for Fe-based soft magnetic amorphous and nanocrystalline alloys with high Fe content. Mater. Des. 2020, 189, 108511. [Google Scholar] [CrossRef]

- Wu, C.; Chen, H.; Lv, H.; Yan, M. Interplay of crystallization, stress relaxation and magnetic properties for FeCuNbSiB soft magnetic composites. J. Alloys Compd. 2016, 673, 228–282. [Google Scholar] [CrossRef]

- Atnami, H.; Grognet, S.; Teillet, J. Crystallization-nitriding process of FeSiB and FeSiBCuNb ribbons: Influence of additive (Cu, Nb) pair and nitrogen on structure, magnetic and magnetostrictive parameters. J. Mater. Sci. 2001, 290, 194–207. [Google Scholar]

- Lee, S.; Kato, H.; Kubota, T.; Makino, A.; Inoue, A. Fabrication and soft magnetic properties of Fe–B–Nb–Y glassy powder compacts by spark plasma sintering technique. Intermetallics 2009, 17, 218–221. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Qu, C.; Song, K.; Wang, L. Effects of Nb on the precipitation of α-Fe, glass forming ability and magnetic properties of Fe85B10P5 alloys. J. Alloys Compd. 2017, 694, 643–646. [Google Scholar] [CrossRef]

- Herzer, G. Soft magnetic nanocrystalline materials. Scr. Mater. 1995, 33, 1741–1756. [Google Scholar] [CrossRef]

- Tian, M.; Xu, J.; Yang, S.; Wang, J.; Yang, T.; Li, G.; Chen, Q.; Liu, X. Effects of heat treatment and compaction pressure on the microstructure and magnetic properties of core-shell structured FeSiBNbCu/SiO2 soft magnetic composites. J. Alloys Compd. 2022, 923, 166394. [Google Scholar] [CrossRef]

- Korvánek, I.; Kim, C.G.; Kováč, J.; Švec, P.; Sato-Turtelli, R. Soft magnetic behaviour and permeability spectra in amorphous and nanocrystalline Fe80.5Nb7B12.5 alloys. J. Magn. Magn. Mater. 2000, 215–216, 440–442. [Google Scholar] [CrossRef]

- Zhao, R.; Huang, J.; Yang, Y.; Jiao, L.; Dong, Y.; Liu, X.; Liu, Z.; Wu, S.; Li, X.; He, A.; et al. The influence of FeNi nanoparticles on the microstructures and soft magnetic properties of FeSi soft magnetic composites. Adv. Powder Technol. 2022, 33, 103663. [Google Scholar] [CrossRef]

- Li, X.; Dong, Y.; Wu, S.; Zhao, R.; Ding, Q.; Jia, X.; He, A.; Li, J.; Liu, X. Evolution of magnetic domain structure and magnetic properties of Fe-based nanocrystalline powder cores during transverse magnetic field annealing. Adv. Powder Technol. 2022, 33, 103823. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Shi, G.; Miao, H.; Liu, D.; Li, Z.; Wang, M.; Wang, L. Effects of the Gas-Atomization Pressure and Annealing Temperature on the Microstructure and Performance of FeSiBCuNb Nanocrystalline Soft Magnetic Composites. Materials 2023, 16, 1284. https://doi.org/10.3390/ma16031284

Li G, Shi G, Miao H, Liu D, Li Z, Wang M, Wang L. Effects of the Gas-Atomization Pressure and Annealing Temperature on the Microstructure and Performance of FeSiBCuNb Nanocrystalline Soft Magnetic Composites. Materials. 2023; 16(3):1284. https://doi.org/10.3390/ma16031284

Chicago/Turabian StyleLi, Guanzhi, Guibing Shi, Hongyi Miao, Dan Liu, Zongzhen Li, Mingxu Wang, and Li Wang. 2023. "Effects of the Gas-Atomization Pressure and Annealing Temperature on the Microstructure and Performance of FeSiBCuNb Nanocrystalline Soft Magnetic Composites" Materials 16, no. 3: 1284. https://doi.org/10.3390/ma16031284

APA StyleLi, G., Shi, G., Miao, H., Liu, D., Li, Z., Wang, M., & Wang, L. (2023). Effects of the Gas-Atomization Pressure and Annealing Temperature on the Microstructure and Performance of FeSiBCuNb Nanocrystalline Soft Magnetic Composites. Materials, 16(3), 1284. https://doi.org/10.3390/ma16031284