Drop Weight Testing of Samples Made of Different Building Materials Designed for the Protection of Classified Information

Abstract

1. Introduction

- Top secret—information and material the unauthorized publication of which could cause extremely serious damage to the essential interests of the European Union or of one or more of its Member States

- Secret—information and material the unauthorized disclosure of which could seriously damage the essential interests of the European Union or of one or more Member States

- Confidential—information and material the unauthorized disclosure of which could damage the essential interests of the European Union or of one or more Member States

- Restricted—information and material the unauthorized disclosure of which could be disadvantageous to the interests of the European Union or of one or more Member States

Security Barriers—Walls

- Lightweight buildings—are those buildings where the penetration resistance is low or the time of penetration resistance is short; they are used for enclosing the space. These include plasterboard or plasterboard partitions and fillings, walls and partitions made of autoclaved aerated concrete blocks, partitions and walls made of chipboard, wool and steel sheets, concrete walls without reinforcement up to 50 mm, etc.

- Solid building structures—are characterized by high break-through resistance. Materials such as concrete, stone, reinforced concrete blocks, brick, etc., are used for solid structures.

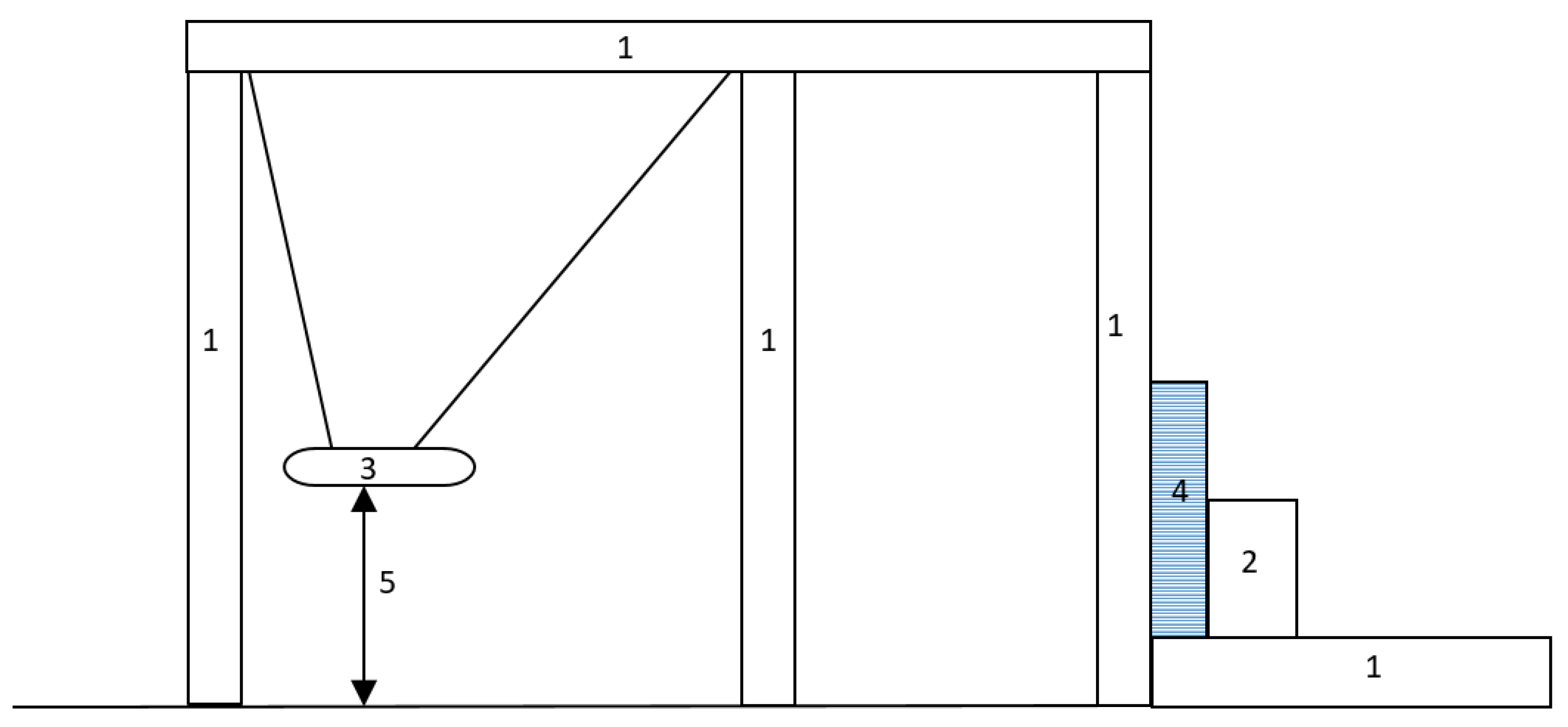

2. Materials and Methods

- gradual increase in drop height (5, 10, 15…cm),

- maximum drop height,

- constant drop height.

3. Results

3.1. Masonry of Autoclaved Aerated Concrete

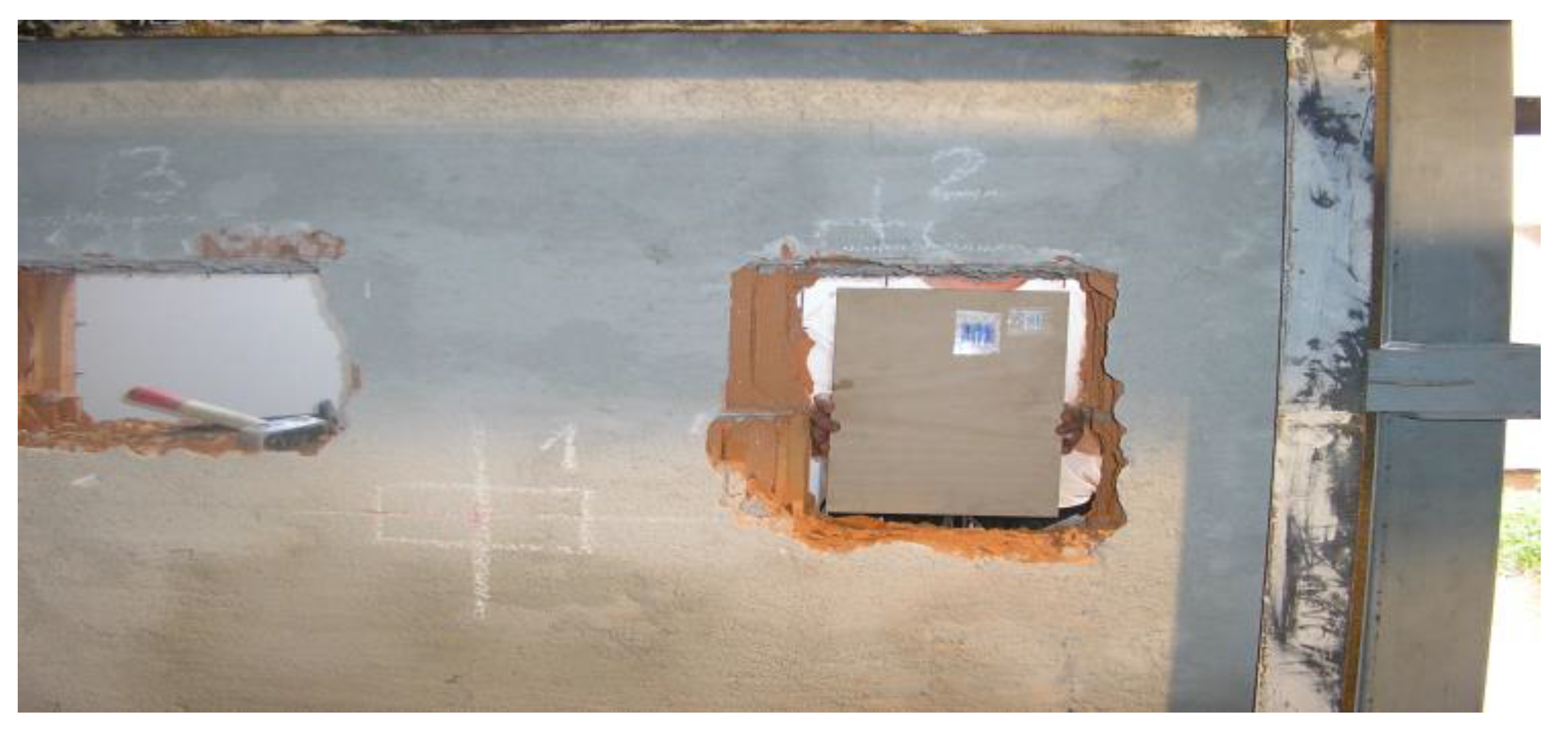

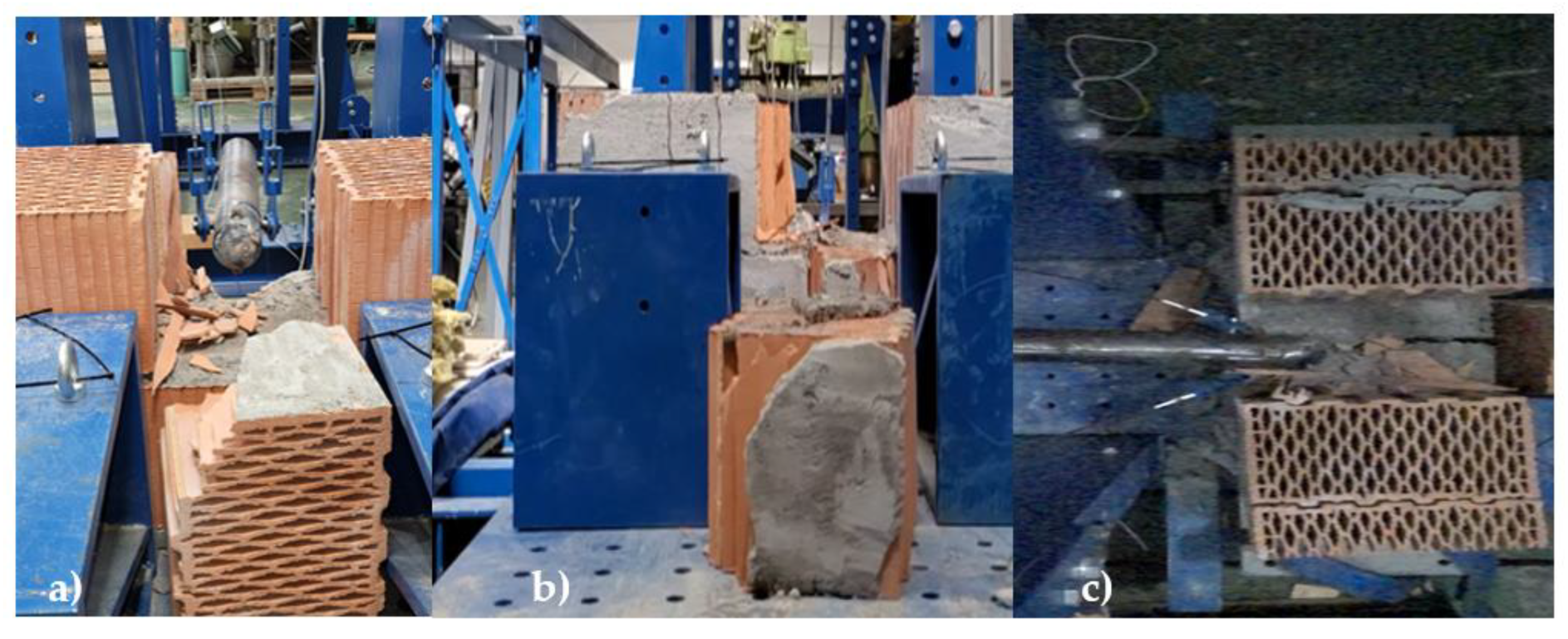

3.2. Masonry Made of Ceramic Blocks

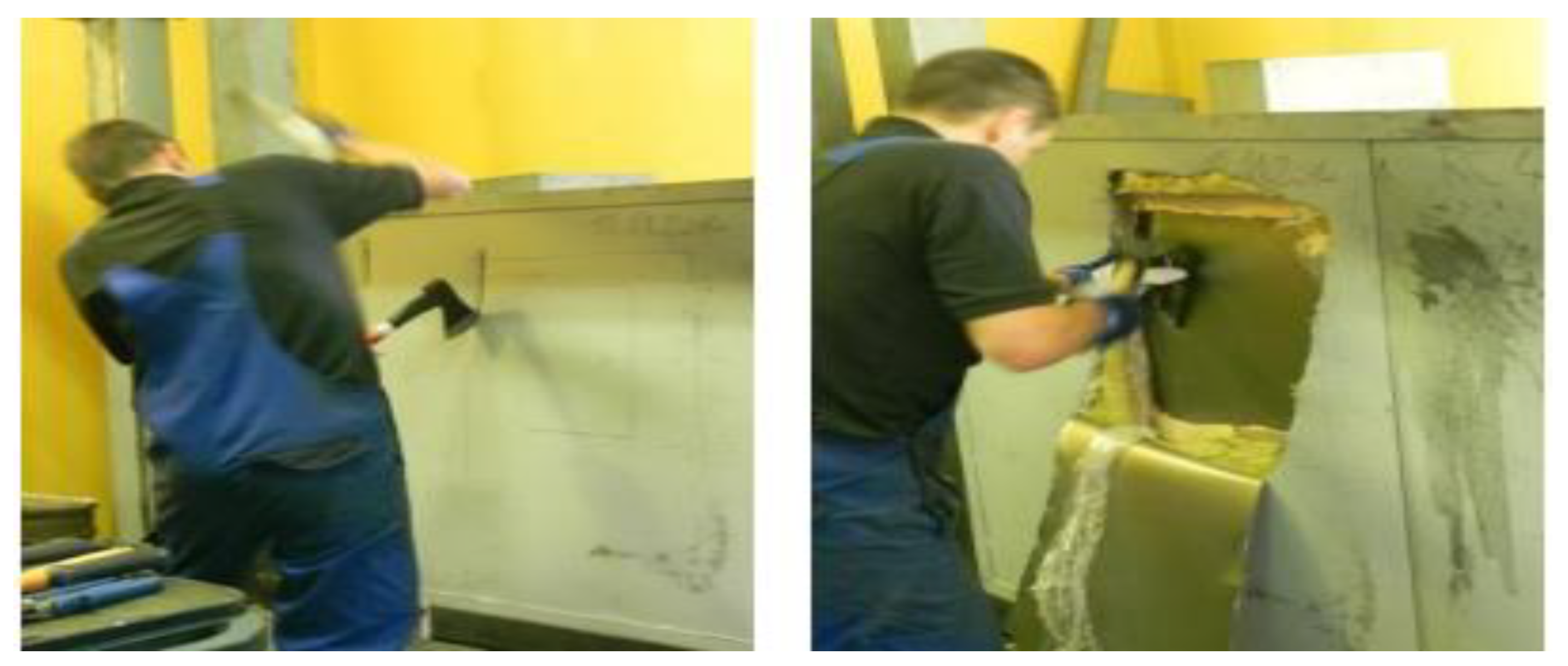

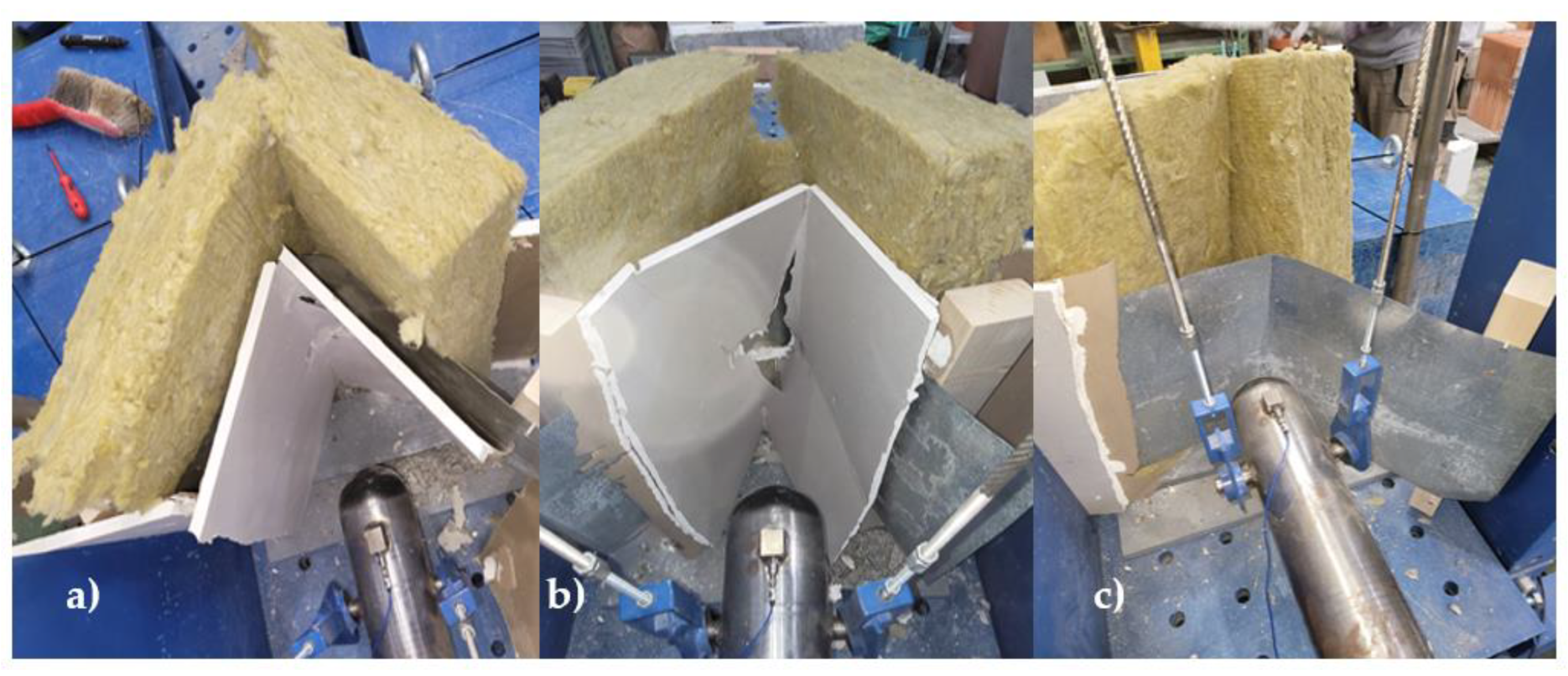

3.3. Partition Made of Plasterboard Reinforced with 1 mm Thick Sheet Metal

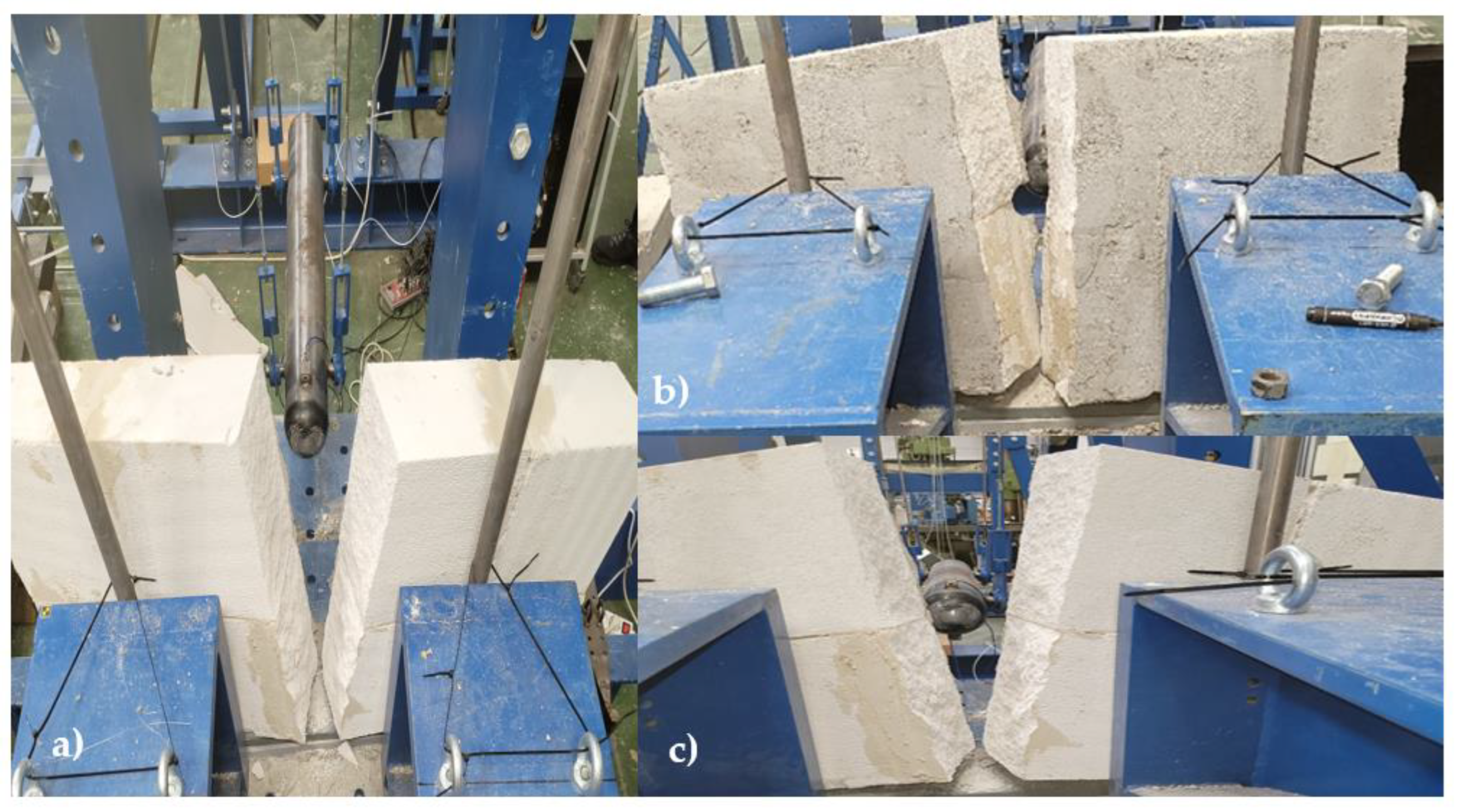

3.4. Reinforced Concrete

4. Discussion and Conclusions

- In terms of puncture resistance, aerated concrete, which cracked in the brick and broke in two pieces in all three tests, was the least resistant. Reinforced concrete was the most durable, but the concrete itself cracked and formed a hole even though it was still held together by reinforcement. The weakness of the masonry of ceramic blocks was the masonry mortar, which complete failure and the ceramic block, which fell out. It was characteristic of the plasterboard partition specimens reinforced with 1 mm thick sheet metal on the attack side that in neither test method did the impactor penetrate the sheet metal, but the plasterboards were broken on both sides, and the bolts reinforcing the construction did not hold.

- A future outlook for a possible methodology for testing security walls. The shape and weight of the impactor need to be considered, as the impactor did not penetrate the 1 mm thick sheet metal with the rounded tip impactor but assume that penetration would not be a problem with the sharp tip impactor.

- The measured force does not constantly increase as the drop height increases. However, accelerometer measurements can give us information about the maximum force and correspond to the loss of stiffness of the samples.

- The test results were surprising to us as they are the same security class. They should therefore have approximately the same resistance. However, this does not account for the fact that the aerated concrete specimen broke in two parts after two impacts from a height of 5 cm and that it took three impacts from a height of 80 cm to break the reinforced concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Act 215/2003—Act on the Protection of Classified Information and on Amendments to Certain Acts; National Security Authority: Bratislava, Slovakia, 2003.

- 50 U.S. Code § 834—“Classified Information” Defined; U.S. Government Publishing Office: Washington, DC, USA, 2014.

- Topolewski, S. Classified Information Protection in Poland: Traditions and the Present Day. In Safety and Defense Scientific and Technical Journal; Building Expertise Center Sp.: Warsaw, Poland, 2020; Volume 1, pp. 48–62. ISSN 2450-551X. [Google Scholar]

- Act 412/ 2005—On the Protection of Classified Information; National Security Authority: Prague, Czech Republic, 2005.

- Council Decision 2014/488/EU—Council Decision of 23 September 2013 on the Security Rules for Protecting EU Classified Information; European Union: Brussels, Belgium, 2014.

- Siser, A.; Maris, L.; Rehak, D.; Pellowski, W. The use of expert judgement as the method to obtain delay time values of passive barriers in the context of the physical protection system. In Proceedings of the 52nd Annual IEEE International Carnahan Conference on Security Technology, Montreal, QC, Canada, 22–25 October 2018. [Google Scholar]

- Boros, M.; Mach, V.; Durica, J. Mechanicke Zabranne Prostriedky; EDIS–University of Zilina: Zilina, Slovakia, 2022; ISBN 978-80-554-1885-8. [Google Scholar]

- Tugnolia, A.; Iaiania, M.; Olivab, G.; Salzanoa, E.; Setolab, R.; Cozzania, V. Physical Security Barriers and Protection Distances for Seveso Sites. Chem. Eng. Trans. 2019, 77. [Google Scholar]

- Peeters, M.P. Assessing the Vulnerability of Targets for Burglary. Creating a Multilevel Observational Instrument. In Crime, Violence, Justice and Social Order; Maklu: Antwerpen, Belgium, 2013. [Google Scholar]

- Pallister-Wilkins, P. How walls do work: Security barriers as devices of interruption and data capture. Secur. Dialogue 2016, 46, 151–164. [Google Scholar] [CrossRef]

- Soltes, V.; Stofkova, Z. Security as an aspect of the quality management in local self-government in age of globalization. In Proceedings of the 16th International Scientific Conference on Globalization and its Socio-Economic Consequences, Rajecke Teplice, Slovakia, 5–6 October 2016; pp. 2060–2067. [Google Scholar]

- Smith, C.L.; Brooks, D.J. Security Science: The Theory and Practice of Security, 1st ed.; Butterworth-Heinemann: Oxford, UK, 2013; ISBN 978-0-12-394436-8. [Google Scholar]

- Garcia, M.L. The Design and Evaluation of Physical Protection Systems, 2nd ed; Burtterworth-Heinemann: Oxford, UK, 2007; ISBN 978-0-7506-8352-4. [Google Scholar]

- Moseley, K.; Coleman, A.; Sinclaird, W.G. Barriers. Police Scientific Development Branch, Home Office. In Proceedings of the IEEE 34th Annual 2000 International Carnahan Conference on Security Technology (Cat. No.00CH37083), Ottawa, ON, Canada, 23–25 October 2000. [Google Scholar]

- Mach, V. Bezpečnostné Systémy: Mechanicke Zabranné Prostriedky, 1st ed.; Multiprint s.r.o.: Kosice, Slovakia, 2010; ISBN 978-80-970410-6-9. [Google Scholar]

- Lovecek, T.; Reitspis, J. Projektovanie a Hodnotenie Systemov Ochrany Objektov, 1st ed.; EDIS–University of Zilina: Zilina, Slovakia, 2011; ISBN 978-80-554-0457-8. [Google Scholar]

- Mach, V. Testovanie Prielomovej Odolnosti Vybratých Mechanických Zábranných Prostriedkov. In Krízový Manažment; University of Zilina: Zilina, Slovakia, 2015; Volume 2. [Google Scholar]

- Certest s.r.o.—Building Construction Testing. Face-To-Face Communication. Available online: http://www.certest.sk/en/index.php (accessed on 30 October 2022).

- Gunasekaran, M.; Thangavel, M.; Nemichandran, N.K.; Ravikumar, I.; Glarance, H.J.; Kothandapani, J. Impact Response and Strength Reliability of Green High Performance Fibre Reinforced Concrete Subjected to Freeze-thaw Cycles in NaCl Solution. Constr. Mater. 2017, 23, 384–388. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vasilev, Y. Experimental Tests and Reliability Analysis of the Cracking Impact Resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Abid, S.R.; Gunasekaran, M.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Karelina, M. Impact Performance of Steel Fiber-Reinforced Self-Compacting Concrete against Repeated Drop Weight Impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Vatin, N.I.; Fediuk, R. Drop weight impact test on prepacked aggregate fibrous concrete—An experimental study. Materials 2022, 15, 3096. [Google Scholar] [CrossRef] [PubMed]

- Decree No. 336/2004—Of the National Security Authority; National Security Authority: Bratislava, Slovakia, 2004.

| Confidential | ||||

|---|---|---|---|---|

| Construction Material | Thickness [mm] | Building Material | Reinforcement | Note |

| Masonry of autoclaved aerated concrete | 150 | Autoclaved aerated concrete blocks | - | Thin-layer bonding mortar |

| Masonry made of ceramic blocks | 400 | Ceramic blocks 380 × 250 × 238 mm, 10 MPa | - | Masonry mortar up to 5 MPa, plaster up to 15 mm |

| Partition made of plasterboard | 100 | Plasterboard of 12.5 mm thickness with construction | 1 mm thick steel plate | Self-tapping screws every 150–200 mm |

| Reinforced Concrete | 75 | Concrete C16/20 | 1 row max 215 mm apart | V10 425 Ø 6 mm in two rows |

| Drop Height (cm) | Force (kN) |

|---|---|

| gradual increase method | |

| 5 | 7.67 |

| 10 | 11.55 |

| maximum height method | |

| 30 | 15.39 |

| constant height method | |

| 5 | 6.94 |

| 5 | 9.39 |

| Drop Height (cm) | Force (kN) |

|---|---|

| gradual increase method | |

| 5 | 8.05 |

| 10 | 11.66 |

| 15 | 8.62 |

| 20 | 6.09 |

| 25 | 5.15 |

| 30 | 4.80 |

| maximum height method | |

| 50 | 8.19 |

| Constant height method | |

| 40 | 21.09 |

| 40 | 12.10 |

| 40 | 4.86 |

| Drop Height (cm) | Force (kN) |

|---|---|

| gradual increase method | |

| 5 | 0.95 |

| 10 | 0.94 |

| 15 | 1.30 |

| 20 | 1.40 |

| 25 | 1.22 |

| 30 | 1.62 |

| maximum height method | |

| 50 | 1.87 |

| constant height method | |

| 40 | 1.36 |

| 40 | 1.25 |

| 40 | 1.94 |

| Drop Height (cm) | Force (kN) |

|---|---|

| gradual increase method | |

| 5 | 3.87 |

| 10 | 43.72 |

| 15 | 40.24 |

| 20 | 32.47 |

| 25 | 31.63 |

| 30 | 34.13 |

| 35 | 17.86 |

| 40 | 28.05 |

| 45 | 26.67 |

| 50 | 37.02 |

| 55 | 30.25 |

| maximum height method | |

| 80 | 104.80 |

| 80 | 53.06 |

| 80 | 35.38 |

| constant height method | |

| 55 | 90.70 |

| 55 | 45.69 |

| 55 | 41.05 |

| 55 | 33.12 |

| 55 | 34.26 |

| 55 | 35.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durica, J.; Velas, A.; Boros, M.; Sovjak, R.; Konrad, P.; Kheml, P. Drop Weight Testing of Samples Made of Different Building Materials Designed for the Protection of Classified Information. Materials 2023, 16, 1219. https://doi.org/10.3390/ma16031219

Durica J, Velas A, Boros M, Sovjak R, Konrad P, Kheml P. Drop Weight Testing of Samples Made of Different Building Materials Designed for the Protection of Classified Information. Materials. 2023; 16(3):1219. https://doi.org/10.3390/ma16031219

Chicago/Turabian StyleDurica, Jakub, Andrej Velas, Martin Boros, Radoslav Sovjak, Petr Konrad, and Premysl Kheml. 2023. "Drop Weight Testing of Samples Made of Different Building Materials Designed for the Protection of Classified Information" Materials 16, no. 3: 1219. https://doi.org/10.3390/ma16031219

APA StyleDurica, J., Velas, A., Boros, M., Sovjak, R., Konrad, P., & Kheml, P. (2023). Drop Weight Testing of Samples Made of Different Building Materials Designed for the Protection of Classified Information. Materials, 16(3), 1219. https://doi.org/10.3390/ma16031219