Plasticity Improvement in a Co-Rich Co40Fe25Cr20Ni15 High-Entropy Alloy via Al Alloying

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental

2.2. Computational Simulations

3. Results

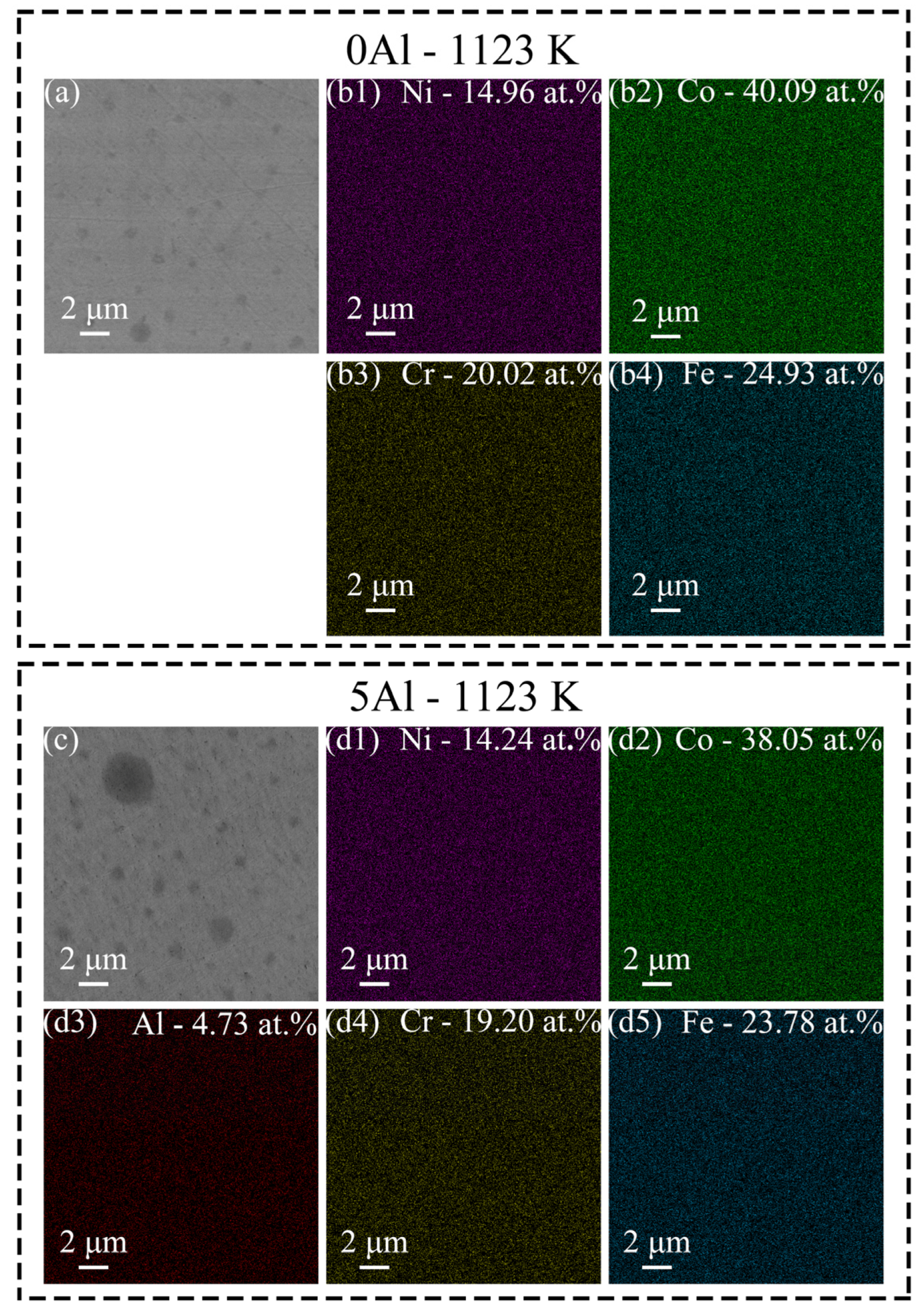

3.1. Starting Annealing Microstructures

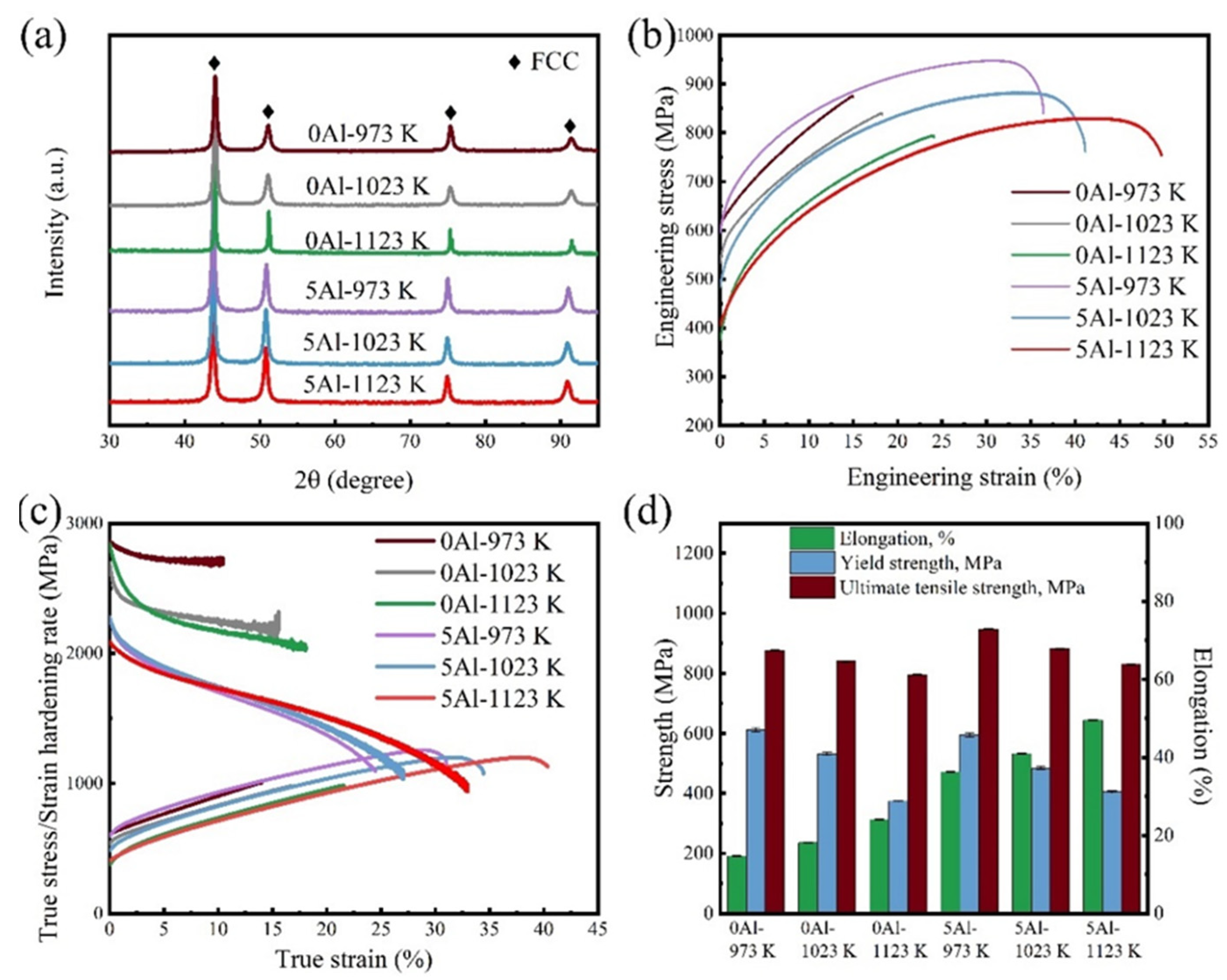

3.2. Tensile Behaviors

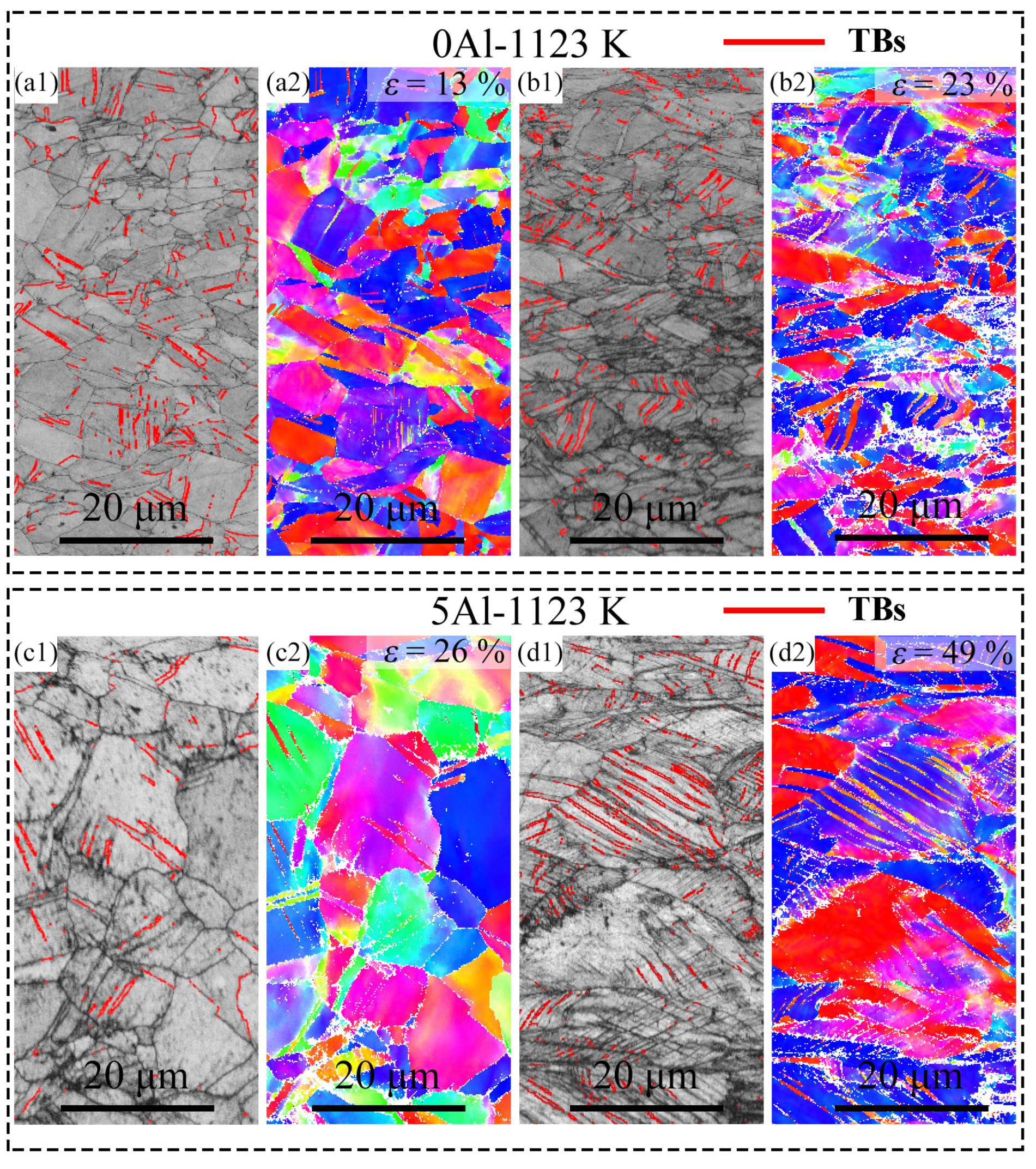

3.3. Deformation Microstructures

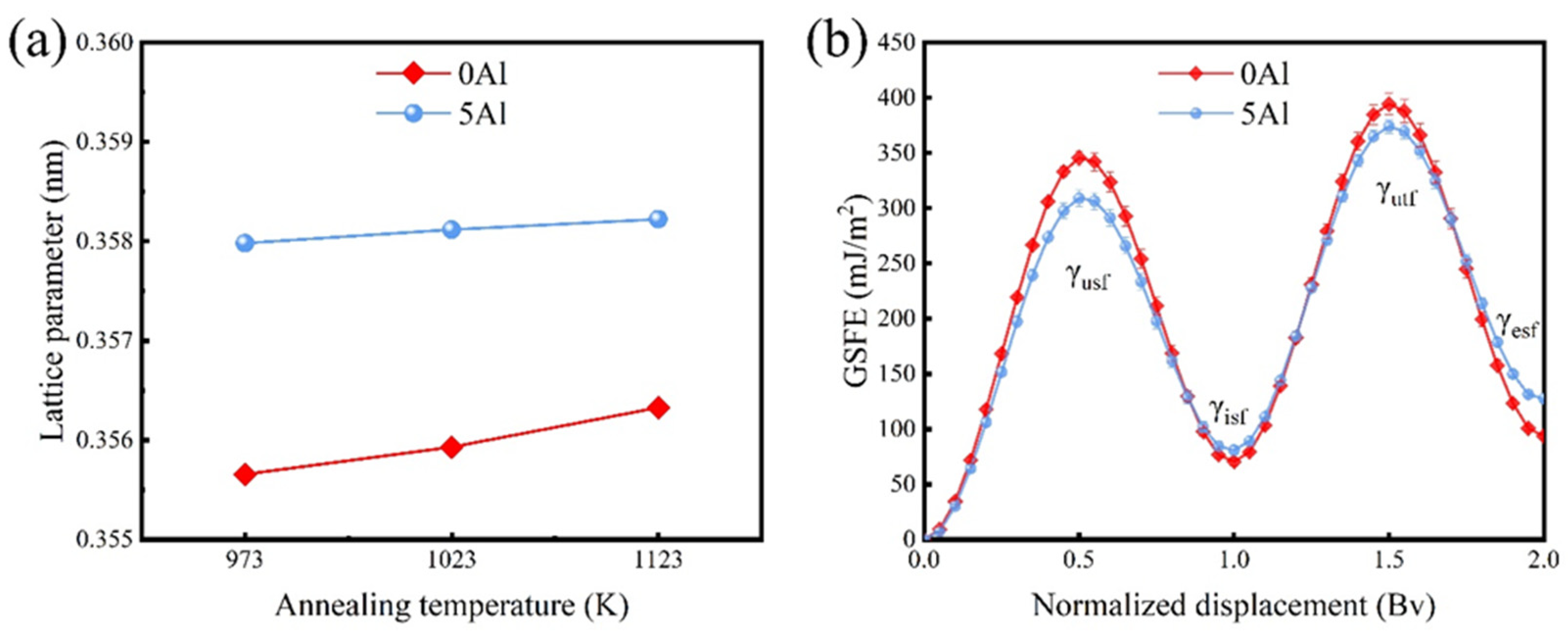

4. Discussion

5. Conclusions

- (1)

- By alloying with 5 at.% Al, the fcc microstructure of the Co-rich HEA was retained. Annealing at 973 K, 1023 K, and 1123 K resulted in grain sizes ranging from ~2.5 µm to ~5.3 µm for the 0Al samples and ~3.4 µm to 10.6 µm for the 5Al samples.

- (2)

- The relationship between the tensile strength and plasticity followed the classical strength-ductility tradeoff in both alloy samples. As the annealing temperature increased, the tensile strength decreased from 876 MPa to 795 MPa while the plasticity increased from ~14% to 24% for the 0Al samples. Similarly, the tensile strength decreased from 947 MPa to 830 MPa and the plasticity increased from ~36% to 50% as the annealing temperature increased for the 5Al samples.

- (3)

- The addition of the Al significantly modified the fracture mechanism from a dominant quasi-cleavage to a ductile dimple fracture mode. This was attributed to the prolonged strain hardening and the fulfillment of Considere’s criterion for uniform elongation by the 5Al samples.

- (4)

- EBSD analyses of the deformation microstructures revealed both alloys were deformed primarily by deformation twinning. However, the twin fraction for the 5Al alloy was considerably higher relative to the 0Al alloy. The higher twinning propensity by the 5Al sample was further verified by MD simulations, and the significant difference in the plasticity of the alloys was ascribed to the difficulty in slip mobility for the 0Al alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2019, 102, 296–345. [Google Scholar] [CrossRef]

- Nutor, R.K.; Cao, Q.; Wang, X.; Zhang, D.; Fang, Y.; Zhang, Y.; Jiang, J.-Z. Phase Selection, Lattice Distortions, and Mechanical Properties in High-Entropy Alloys. Adv. Eng. Mater. 2020, 22, 2000466. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Liu, S.F.; Wu, Y.; Wang, H.T.; He, J.Y.; Liu, J.B.; Chen, C.X.; Wang, H.; Liu, X.J.; Lu, Z.P. Stacking fault energy of face-centered-cubic high entropy alloys. Intermetallics 2018, 93, 269–273. [Google Scholar] [CrossRef]

- Zhao, S.; Stocks, G.M.; Zhang, Y. Stacking fault energies of face-centered cubic concentrated solid solution alloys. Acta Mater. 2017, 134, 334–345. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Tasan, C.; Pradeep, K.; Springer, H.; Kostka, A.; Raabe, D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Wei, D.; Li, X.; Jiang, J.; Heng, W.; Koizumi, Y.; Choi, W.-M.; Lee, B.-J.; Kim, H.S.; Kato, H.; Chiba, A. Novel Co-rich high performance twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) high-entropy alloys. Scr. Mater. 2019, 165, 39–43. [Google Scholar] [CrossRef]

- Wei, D.; Li, X.; Heng, W.; Koizumi, Y.; He, F.; Choi, W.-M.; Lee, B.-J.; Kim, H.S.; Kato, H.; Chiba, A. Novel Co-rich high entropy alloys with superior tensile properties. Mater. Res. Lett. 2019, 7, 82–88. [Google Scholar] [CrossRef]

- Kao, Y.-F.; Chen, T.-J.; Chen, S.-K.; Yeh, J.-W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloys Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Wang, W.-R.; Wang, W.-L.; Wang, S.-C.; Tsai, Y.-C.; Lai, C.-H.; Yeh, J.-W. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 2012, 26, 44–51. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bae, J.W.; Kim, D.H.; Jo, Y.H.; Lee, S.; Kim, H.S. Role of BCC phase on tensile behavior of dual-phase Al0.5CoCrFeMnNi high-entropy alloy at cryogenic temperature. Mater. Sci. Eng. A 2019, 746, 443–447. [Google Scholar] [CrossRef]

- Gangireddy, S.; Gwalani, B.; Soni, V.; Banerjee, R.; Mishra, R.S. Contrasting mechanical behavior in precipitation hardenable AlxCoCrFeNi high entropy alloy microstructures: Single phase FCC vs. dual phase FCC-BCC. Mater. Sci. Eng. A 2019, 739, 158–166. [Google Scholar] [CrossRef]

- Wu, S.; Xu, L.; Ma, X.; Jia, Y.; Mu, Y.; Wang, G.; Liu, C. Effect of annealing temperatures on microstructure and deformation behavior of Al0.1CrFeCoNi high-entropy alloy. Mater. Sci. Eng. A 2021, 805, 140523. [Google Scholar] [CrossRef]

- Nutor, R.K.; Cao, Q.; Wei, R.; Su, Q.; Du, G.; Wang, X.; Li, F.; Zhang, D.; Jiang, J.-Z. A dual-phase alloy with ultrahigh strength-ductility synergy over a wide temperature range. Sci. Adv. 2021, 7, eabi4404. [Google Scholar] [CrossRef]

- Liu, J.; Chen, C.; Xu, Y.; Wu, S.; Wang, G.; Wang, H.; Fang, Y.; Meng, L. Deformation twinning behaviors of the low stacking fault energy high-entropy alloy: An in-situ TEM study. Scr. Mater. 2017, 137, 9–12. [Google Scholar] [CrossRef]

- Xu, X.; Liu, P.; Tang, Z.; Hirata, A.; Song, S.; Nieh, T.; Liaw, P.; Liu, C.; Chen, M. Transmission electron microscopy characterization of dislocation structure in a face-centered cubic high-entropy alloy Al0.1CoCrFeNi. Acta Mater. 2018, 144, 107–115. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Babicheva, R.; Jarlöv, A.; Zheng, H.; Dmitriev, S.; Korznikova, E.; Nai, M.L.S.; Ramamurty, U.; Zhou, K. Effect of short-range ordering and grain boundary segregation on shear deformation of CoCrFeNi high-entropy alloys with Al addition. Comput. Mater. Sci. 2022, 215, 111762. [Google Scholar] [CrossRef]

- Vu, T.-N.; Pham, V.-T.; Fang, T.-H. Influences of grain size, temperature, and strain rate on mechanical properties of Al0.3CoCrFeNi high–entropy alloys. Mater. Sci. Eng. A 2022, 858, 144158. [Google Scholar] [CrossRef]

- Farkas, D.; Caro, A. Model interatomic potentials for Fe–Ni–Cr–Co–Al high-entropy alloys. J. Mater. Res. 2020, 35, 3031–3040. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, Q.; Ji, H.; Cai, W.; Liu, Z.; Cai, Y. Multi-scale modeling method for polycrystalline materials considering grain boundary misorientation angle. Mater. Des. 2022, 221, 110998. [Google Scholar] [CrossRef]

- Hoover, W.G. Constant-pressure equations of motion. Phys. Rev. A 1986, 34, 2499–2500. [Google Scholar] [CrossRef] [PubMed]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Madivala, M.; Schwedt, A.; Wong, S.L.; Roters, F.; Prahl, U.; Bleck, W. Temperature dependent strain hardening and fracture behavior of TWIP steel. Int. J. Plast. 2018, 104, 80–103. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Diao, H.; Feng, R.; Dahmen, K.; Liaw, P. Fundamental deformation behavior in high-entropy alloys: An overview. Curr. Opin. Solid State Mater. Sci. 2017, 21, 252–266. [Google Scholar] [CrossRef]

- Li, W.; Liaw, P.K.; Gao, Y. Fracture resistance of high entropy alloys: A review. Intermetallics 2018, 99, 69–83. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Wu, S.W.; Wang, G.; Yi, J.; Jia, Y.D.; Hussain, I.; Zhai, Q.J.; Liaw, P.K. Strong grain-size effect on deformation twinning of an Al0.1CoCrFeNi high-entropy alloy. Mater. Res. Lett. 2017, 5, 276–283. [Google Scholar] [CrossRef]

- Sohn, S.S.; Hong, S.; Lee, J.; Suh, B.-C.; Kim, S.-K.; Lee, B.-J.; Kim, N.J.; Lee, S. Effects of Mn and Al contents on cryogenic-temperature tensile and Charpy impact properties in four austenitic high-Mn steels. Acta Mater. 2015, 100, 39–52. [Google Scholar] [CrossRef]

- Varvenne, C.; Luque, A.; Curtin, W.A. Theory of strengthening in fcc high entropy alloys. Acta Mater. 2016, 118, 164–176. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Yan, J.-A.; Wang, C.-Y.; Wang, S.-Y. Generalized-stacking-fault energy and dislocation properties in bcc Fe: A first-principles study. Phys. Rev. B 2004, 70, 174105. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Asghari-Rad, P.; Park, J.M.; Moon, J.; Bae, J.W.; Zargaran, A.; Kim, H.S. Exceptional cryogenic strength-ductility synergy in Al0.3CoCrNi medium-entropy alloy through heterogeneous grain structure and nano-scale precipitates. Mater. Sci. Eng. A 2019, 766, 138372. [Google Scholar] [CrossRef]

- Walsh, F.; Asta, M.; Ritchie, R.O. Magnetically driven short-range order can explain anomalous measurements in CrCoNi. Proc. Natl. Acad. Sci. USA 2021, 118, e2020540118. [Google Scholar] [CrossRef]

- Ding, J.; Yu, Q.; Asta, M.; Ritchie, R.O. Tunable stacking fault energies by tailoring local chemical order in CrCoNi medium-entropy alloys. Proc. Natl. Acad. Sci. USA 2018, 115, 8919–8924. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Li, X.; Schönecker, S.; Jiang, J.; Choi, W.-M.; Lee, B.-J.; Kim, H.S.; Chiba, A.; Kato, H. Development of strong and ductile metastable face-centered cubic single-phase high-entropy alloys. Acta Mater. 2019, 181, 318–330. [Google Scholar] [CrossRef]

- Qiu, S.; Zhang, X.-C.; Zhou, J.; Cao, S.; Yu, H.; Hu, Q.-M.; Sun, Z. Influence of lattice distortion on stacking fault energies of CoCrFeNi and Al-CoCrFeNi high entropy alloys. J. Alloys Compd. 2020, 846, 156321. [Google Scholar] [CrossRef]

- Chen, X.-T.; Shao, L.; Fan, T.-W.; Duan, J.-M.; Tang, B.-Y. Investigation of aluminum concentration on stacking fault energies of hexagonal close-packed high-entropy alloys Hf0.25Ti0.25Zr0.25Sc0.25−xAlx (x < 15%). J. Alloy. Compd. 2021, 887, 161412. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Idrissi, H.; Renard, K.; Ryelandt, L.; Schryvers, D.; Jacques, P. On the mechanism of twin formation in Fe–Mn–C TWIP steels. Acta Mater. 2010, 58, 2464–2476. [Google Scholar] [CrossRef]

- Remy, L. Kinetics of f.c.c. deformation twinning and its relationship to stress-strain behaviour. Acta Met. 1978, 26, 443–451. [Google Scholar] [CrossRef]

- Nutor, R.K.; Azeem, M.; Cao, Q.P.; Wang, X.D.; Zhang, D.X.; Jiang, J.-Z. Microstructure and properties of a Co-free Fe50Mn27Ni10Cr13 high entropy alloy. J. Alloys Compd. 2021, 851, 156842. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Chen, Y.; Nutor, R.K.; Wang, N.; Cao, Q.; Wang, X.; Zhang, D.; Jiang, J.-Z. Plasticity Improvement in a Co-Rich Co40Fe25Cr20Ni15 High-Entropy Alloy via Al Alloying. Materials 2023, 16, 1149. https://doi.org/10.3390/ma16031149

Li Y, Chen Y, Nutor RK, Wang N, Cao Q, Wang X, Zhang D, Jiang J-Z. Plasticity Improvement in a Co-Rich Co40Fe25Cr20Ni15 High-Entropy Alloy via Al Alloying. Materials. 2023; 16(3):1149. https://doi.org/10.3390/ma16031149

Chicago/Turabian StyleLi, Yuxiao, Yu Chen, Raymond Kwesi Nutor, Nan Wang, Qingping Cao, Xiaodong Wang, Dongxian Zhang, and Jian-Zhong Jiang. 2023. "Plasticity Improvement in a Co-Rich Co40Fe25Cr20Ni15 High-Entropy Alloy via Al Alloying" Materials 16, no. 3: 1149. https://doi.org/10.3390/ma16031149

APA StyleLi, Y., Chen, Y., Nutor, R. K., Wang, N., Cao, Q., Wang, X., Zhang, D., & Jiang, J.-Z. (2023). Plasticity Improvement in a Co-Rich Co40Fe25Cr20Ni15 High-Entropy Alloy via Al Alloying. Materials, 16(3), 1149. https://doi.org/10.3390/ma16031149