Erosion–Corrosion Failure Analysis of a Mild Steel Nozzle Pipe in Water–Sand Flow

Abstract

:1. Introduction

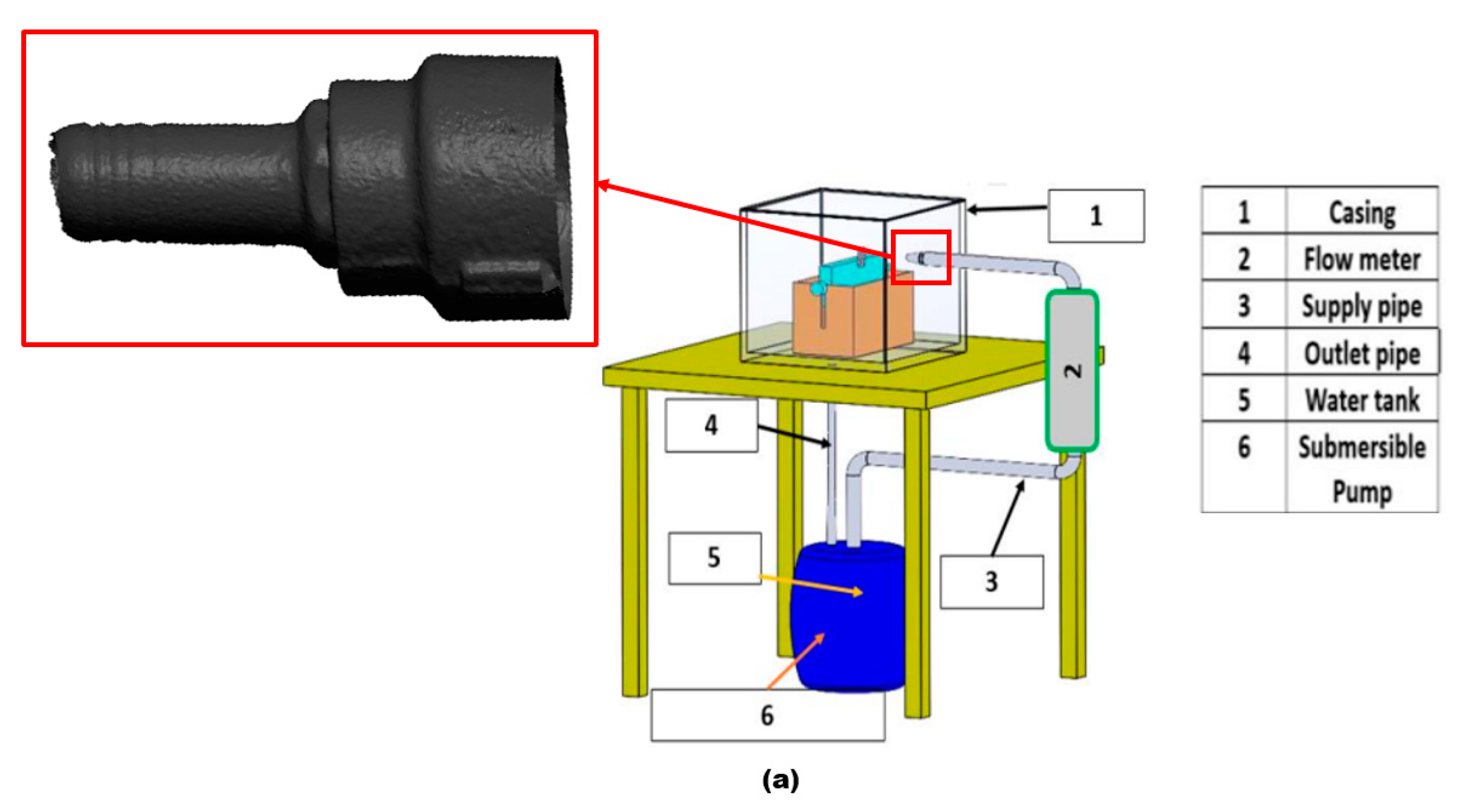

2. Materials and Methods

Numerical Setup and Computational Mesh

3. Results and Discussion

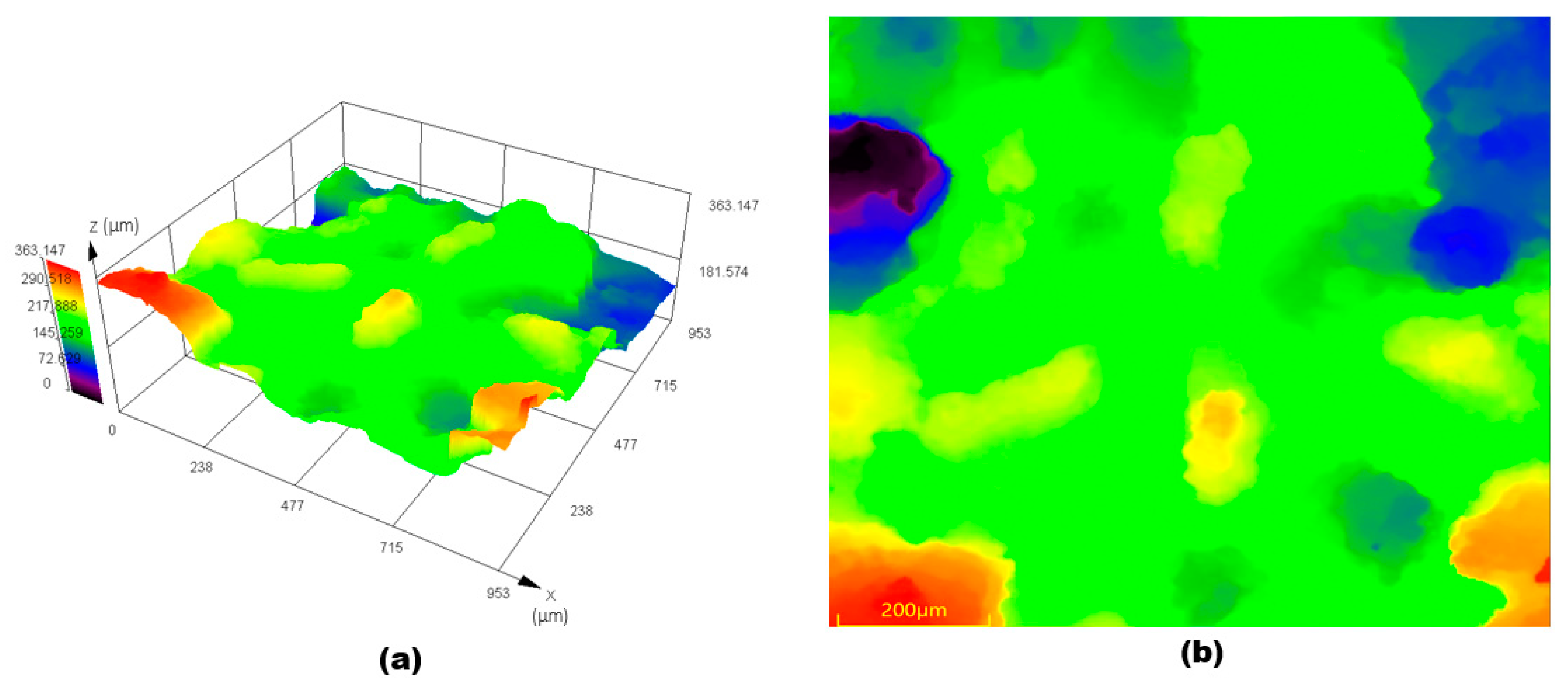

3.1. Morphology Analysis

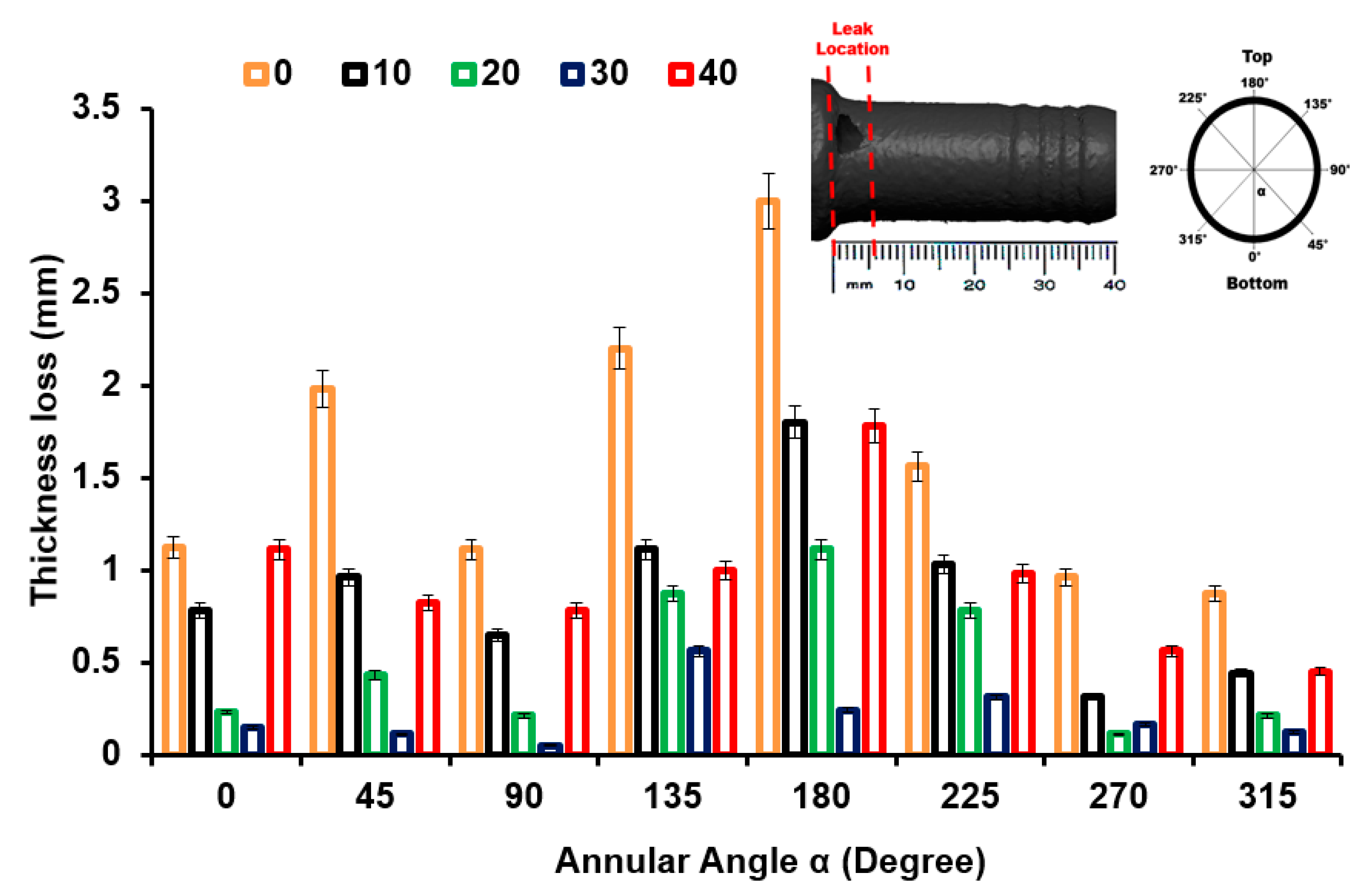

3.2. Thickness Measurements

3.3. CFD-DPM Simulation Results

3.4. Root Cause Analysis

4. Conclusions and Preventive Actions

- Microscopic and simulation analyses of nozzle pipes reveal that pitting corrosion, cutting, and wall thinning due to highly turbulent water flow carrying sand particles are the primary causes of pipeline failure.

- Erosion–corrosion is a progressive martial degradation phenomenon; it is recommended that ultrasonic non-intrusive inspection of nozzle pipes connected to direct impact test rigs is carried out at regular intervals. In addition, increased pipe thickness and the use of alloy materials are recommended.

- CFD-DPM shows that the flow of the carrier phase with the disperse phase impacts more frequently at the inlet location and results in high turbulence at the inlet of the pipe. The simulation results reveal that the maximum erosion rate in Design 3 is five times less than that in Design 1. Based on numerical analysis, Design 1 can be replaced with Design 3 to mitigate the erosion–corrosion rate and consequently decrease the severity of leak failure on the elbow surface during operation.

- Simulation results indicate that maximum erosion occurs in designs similar to failed pipe nozzles, while minimum erosion occurs in designs with a chamfer reducer section. CFD-DPM can effectively simulate the erosion zone and turbulence inside nozzle pipe configurations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kartal, V.; Emiroglu, M.E. Effect of nozzle type on local scour in water jets: An experimental study. Ocean Eng. 2023, 277, 114323. [Google Scholar] [CrossRef]

- Khan, R.; Petru, J.; Seikh, A.H. Erosion prediction due to micron-sized particles in the multiphase flow of T and Y pipes of oil and gas fields. Int. J. Press. Vessel. Pip. 2023, 206, 105041. [Google Scholar] [CrossRef]

- Khan, R.; Mourad, A.H.I.; Seikh, A.H.; Petru, J.; Ya, H. Erosion impact on mild steel elbow pipeline for different orientations under liquid-gas-sand annular flow. Eng. Fail. Anal. 2023, 153, 107565. [Google Scholar] [CrossRef]

- Peng, W.; Ma, L.; Wang, P.; Cao, X.; Xu, K.; Miao, Y. Experimental and CFD investigation of flow behavior and sand erosion pattern in a horizontal pipe bend under annular flow. Particuology 2023, 75, 11–25. [Google Scholar] [CrossRef]

- Qin, M.; Liao, K.; Chen, S.; He, G.; Zhang, S. Numerical simulation of gas-liquid flow in inclined shale gas pipelines. Chem. Eng. Res. Des. 2023, 190, 605–618. [Google Scholar] [CrossRef]

- Chung, R.J.; Jiang, J.; Pang, C.; Yu, B.; Eadie, R.; Li, D.Y. Erosion-corrosion behaviour of high manganese steel used in slurry pipelines. Wear 2023, 530–531, 204885. [Google Scholar] [CrossRef]

- Latif, N.; Johny Wahyuadi, M.S.; Triwibowo; Riastuti, R. Erosion corrosion failure on elbow distillate heater system in the petrochemical industry. Mater. Today Proc. 2022, 62, 4235–4241. [Google Scholar] [CrossRef]

- Hong, B.; Li, Y.; Li, Y.; Gong, J.; Yu, Y.; Huang, A.; Li, X. Numerical simulation of solid particle erosion in the gas-liquid flow of key pipe fittings in shale gas fields. Case Stud. Therm. Eng. 2023, 42, 102742. [Google Scholar] [CrossRef]

- Zheng, R.; Zhao, X.; Dong, L.; Liu, G.; Huang, Y.; Xu, Y. On the cavitation erosion-corrosion of pipeline steel at different locations of Venturi pipe. Eng. Fail. Anal. 2022, 138, 106333. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Yang, T.; Zhang, Z.; Zheng, Q.; Xiong, J. Evaluation of erosion–corrosion process of Ti(C, N)-based cermets in acidic SiO2 slurry. Int. J. Refract. Met. Hard Mater. 2023, 115, 106264. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, S.; Long, J.; Liu, H.; Han, P.; Qiao, Y.; Zheng, K. Revealing the influence of zirconium content on the cavitation erosion-corrosion of a wear-resistant steel in sodium chloride solution. Tribol. Int. 2023, 189, 108942. [Google Scholar] [CrossRef]

- Wang, W.; Hu, J.; Yuan, X.; Zhou, L.; Yu, J.; Zhang, Z.; Zhong, X. Understanding the effect of tensile stress on erosion-corrosion of X70 pipeline steel. Constr. Build. Mater. 2022, 342, 127972. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, L.; Zhang, P.; Sun, W.; Yang, Z.; Liu, B.; Tian, J.; Shu, X.; He, Y.; Liu, G. Failure analysis of Erosion-Corrosion of the bend pipe at sewage stripping units. Eng. Fail. Anal. 2021, 129, 105675. [Google Scholar] [CrossRef]

- Meng, L.; Zhu, Y.; Wu, D.; Ding, J. Experimental and simulation research of performance degradation of jet pipe servo valve under wedge erosion of jet amplifier. Eng. Fail. Anal. 2023, 154, 107602. [Google Scholar] [CrossRef]

- Elemuren, R.; Evitts, R.; Oguocha, I.; Kennell, G.; Gerspacher, R.; Odeshi, A. Slurry erosion-corrosion of 90° AISI 1018 steel elbow in saturated potash brine containing abrasive silica particles. Wear 2018, 410–411, 149–155. [Google Scholar] [CrossRef]

- Li, Q.; Liu, B. Erosion-Corrosion of Gathering Pipeline Steel in Oil-Water-Sand Multiphase Flow. Metals 2023, 13, 80. [Google Scholar] [CrossRef]

- Liu, X.q.; Liu, F.; Ji, H.; Li, N.; Wang, C.; Lin, G. Particle erosion transient process visualization and influencing factors of the hydraulic servo spool valve orifice. Flow Meas. Instrum. 2023, 89, 102273. [Google Scholar] [CrossRef]

- Zheng, S.; Cheng, H.; Bie, Q.; Zhong, L.; Tong, J. Erosion hot spots of drain valve under higher particle flow rates. Nat. Gas Ind. B 2022, 9, 289–307. [Google Scholar] [CrossRef]

- Lin, Z.; Yu, H.; Yu, T.; Zhu, Z. Numerical study of solid–liquid two-phase flow and erosion in ball valves with different openings. Adv. Powder Technol. 2022, 33, 103542. [Google Scholar] [CrossRef]

- Liu, X.; Ji, H.; Min, W.; Zheng, Z.; Wang, J. Erosion behavior and influence of solid particles in hydraulic spool valve without notches. Eng. Fail. Anal. 2020, 108, 104262. [Google Scholar] [CrossRef]

- Tandel, R.R.; Patel, R.N.; Jain, S.V. Correlation development of erosive wear and silt erosion failure mechanisms for pump as turbine. Eng. Fail. Anal. 2023, 153, 107610. [Google Scholar] [CrossRef]

- Chen, M.; Tan, L. Solid-liquid multiphase flow and erosion in the energy storage pump using modified drag model and erosion model. J. Energy Storage 2023, 73, 108859. [Google Scholar] [CrossRef]

- Bandi, S.; Banka, J.; Kumar, A.; Rai, A.K. Effects of sediment properties on abrasive erosion of a centrifugal pump. Chem. Eng. Sci. 2023, 277, 118873. [Google Scholar] [CrossRef]

- Chen, M.; Tan, L.; Fan, H.; Wang, C.; Liu, D. Solid-liquid multiphase flow and erosion characteristics of a centrifugal pump in the energy storage pump station. J. Energy Storage 2022, 56, 105916. [Google Scholar] [CrossRef]

- Liu, J.; Pang, J.; Liu, X.; Huang, Y.; Deng, H. Analysis of Sediment and Water Flow and Erosion Characteristics of Large Pelton Turbine Injector. Processes 2023, 11, 1011. [Google Scholar] [CrossRef]

- Rafae Alomar, O.; Maher Abd, H.; Mohamed Salih, M.M.; Aziz Ali, F. Performance analysis of Pelton turbine under different operating conditions: An experimental study. Ain Shams Eng. J. 2022, 13, 101684. [Google Scholar] [CrossRef]

- Pang, J.; Liu, H.; Liu, X.; Yang, H.; Peng, Y.; Zeng, Y.; Yu, Z. Study on sediment erosion of high head Francis turbine runner in Minjiang River basin. Renew. Energy 2022, 192, 849–858. [Google Scholar] [CrossRef]

- Xiao, Y.; Guo, B.; Rai, A.K.; Liu, J.; Liang, Q.; Zhang, J. Analysis of hydro-abrasive erosion in Pelton buckets using a Eulerian-Lagrangian approach. Renew. Energy 2022, 197, 472–485. [Google Scholar] [CrossRef]

- Mirzaei, M.; Clausen, S.; Wu, H.; Nakhaei, M.; Zhou, H.; Jønck, K.; Jensen, P.A.; Lin, W. Investigation of erosion in an industrial cyclone preheater by CFD simulations. Powder Technol. 2023, 421, 118424. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, J.; Zhang, P.; Gao, F.; Chen, G.; Li, J. Effect of local erosion on the flow field and separation performance of the cyclone separator. Powder Technol. 2023, 413, 118007. [Google Scholar] [CrossRef]

- Dehdarinejad, E.; Bayareh, M. Impact of non-uniform surface roughness on the erosion rate and performance of a cyclone separator. Chem. Eng. Sci. 2022, 249, 117351. [Google Scholar] [CrossRef]

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 1: Effects of impact parameters on a predictive equation. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Hosseini, F.; Meghdadi Isfahani, A.H.; Davazdah Emami, M.; Mohseni, E. The effect of excessive penetration of welding on sand erosion pattern due to high speed gas-solid flows in elbows and reducers. Eng. Fail. Anal. 2022, 131, 105902. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, R.; Wieczorowski, M.; Damjanović, D.; Karim, M.R.; Alnaser, I.A. Erosion–Corrosion Failure Analysis of a Mild Steel Nozzle Pipe in Water–Sand Flow. Materials 2023, 16, 7084. https://doi.org/10.3390/ma16227084

Khan R, Wieczorowski M, Damjanović D, Karim MR, Alnaser IA. Erosion–Corrosion Failure Analysis of a Mild Steel Nozzle Pipe in Water–Sand Flow. Materials. 2023; 16(22):7084. https://doi.org/10.3390/ma16227084

Chicago/Turabian StyleKhan, Rehan, Michał Wieczorowski, Darko Damjanović, Mohammad Rezaul Karim, and Ibrahim A. Alnaser. 2023. "Erosion–Corrosion Failure Analysis of a Mild Steel Nozzle Pipe in Water–Sand Flow" Materials 16, no. 22: 7084. https://doi.org/10.3390/ma16227084

APA StyleKhan, R., Wieczorowski, M., Damjanović, D., Karim, M. R., & Alnaser, I. A. (2023). Erosion–Corrosion Failure Analysis of a Mild Steel Nozzle Pipe in Water–Sand Flow. Materials, 16(22), 7084. https://doi.org/10.3390/ma16227084