Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel

Abstract

:1. Introduction

2. Experimental

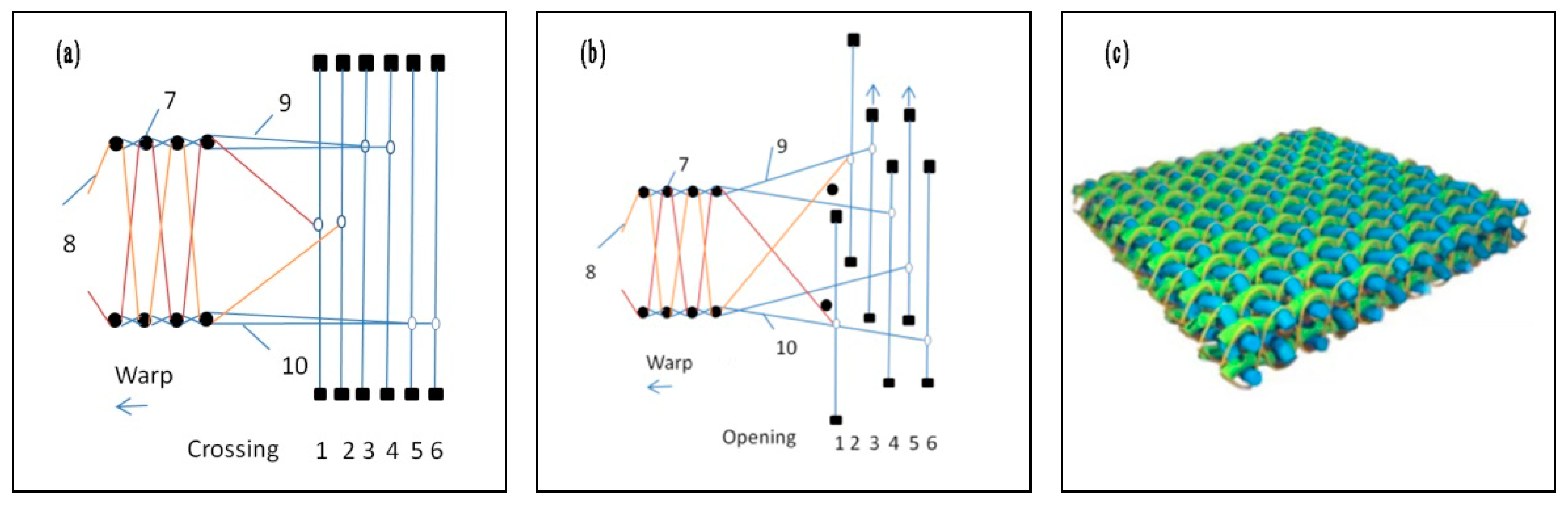

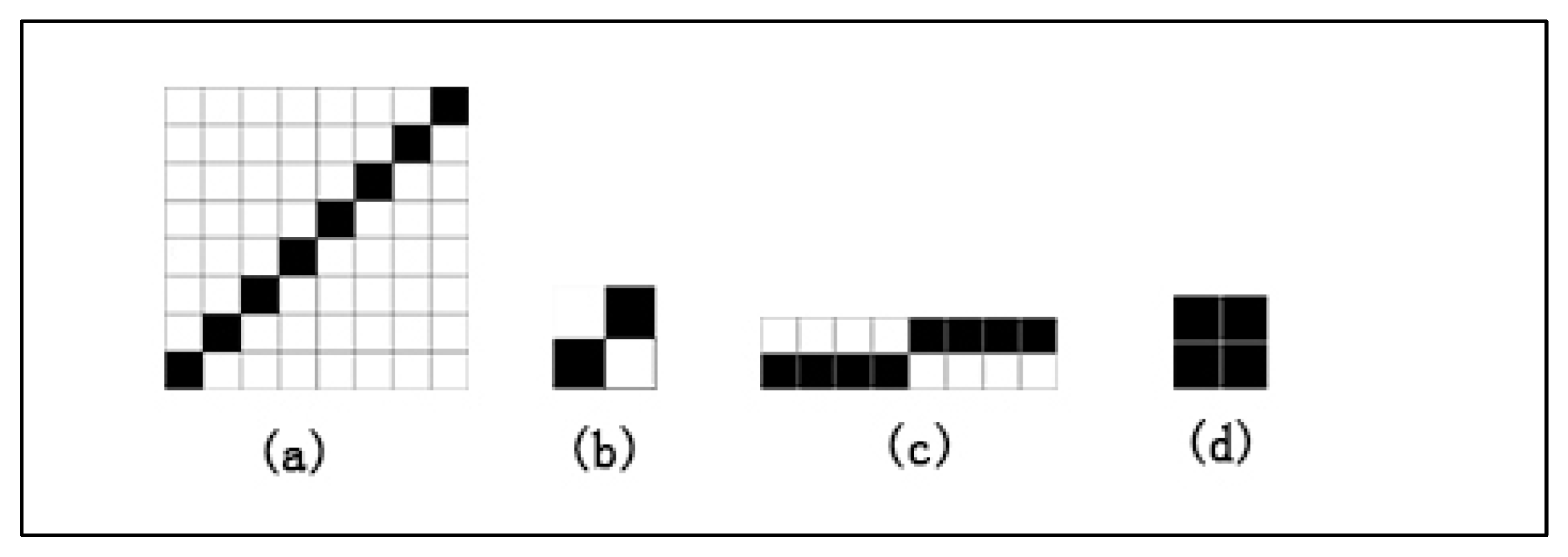

2.1. Preparation of 3D Spacer Jacquard Fabric

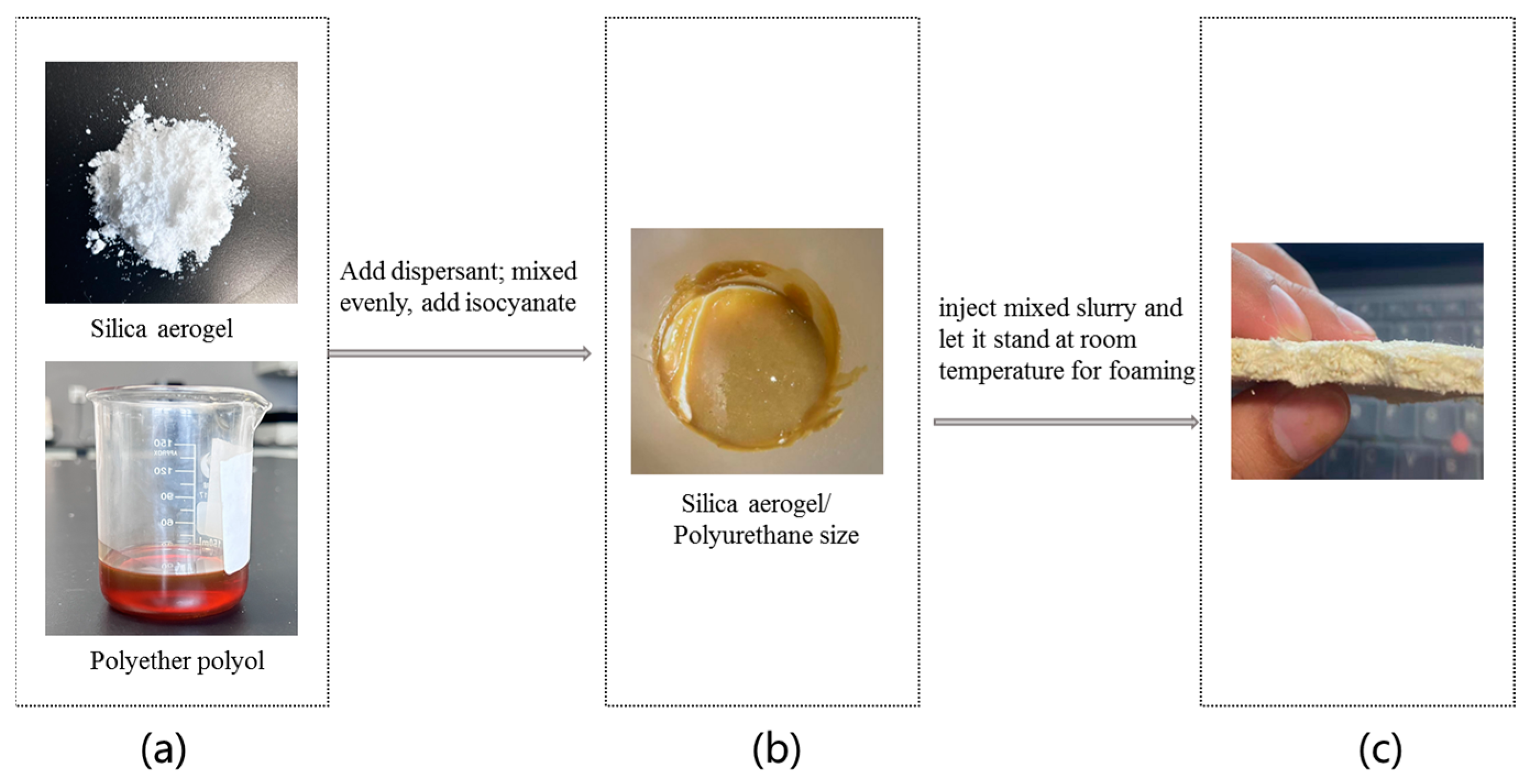

2.2. Preparation of Silica Aerogel Composite Spacer Jacquard Fabric

3. Testing Process

3.1. Mechanical Tests

3.2. Characterizations

3.3. Thermal Insulation Tests

4. Results and Discussion

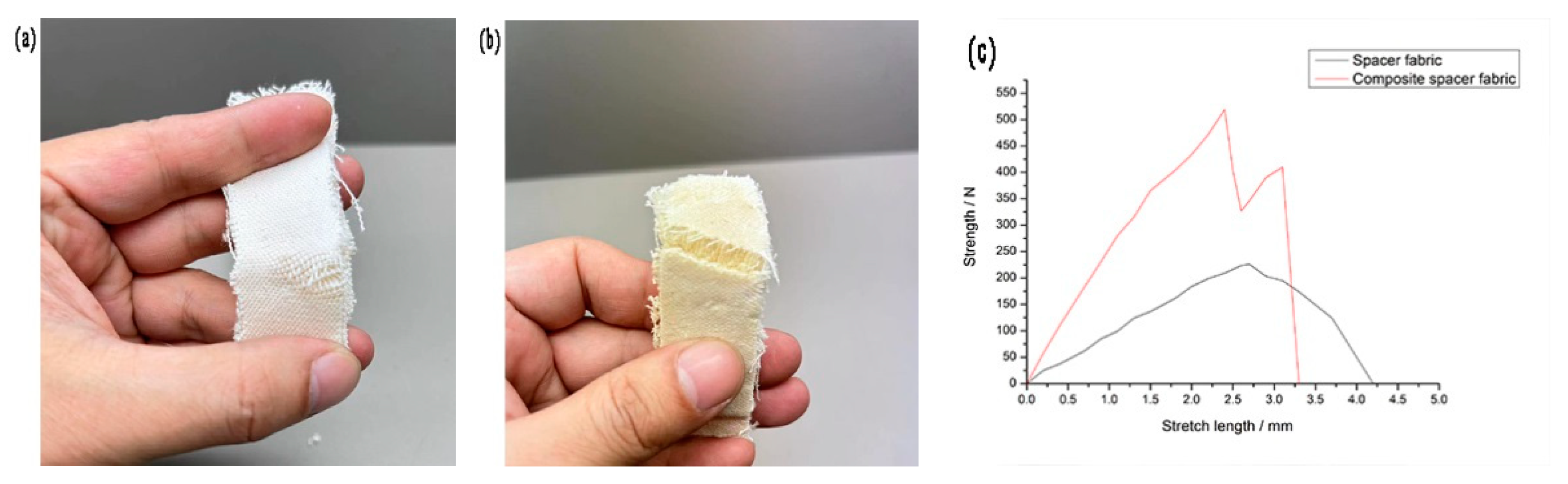

4.1. Mechanical Properties of Spacer Jacquard Fabric

4.2. Morphological Analysis of Spacer Jacquard Fabric

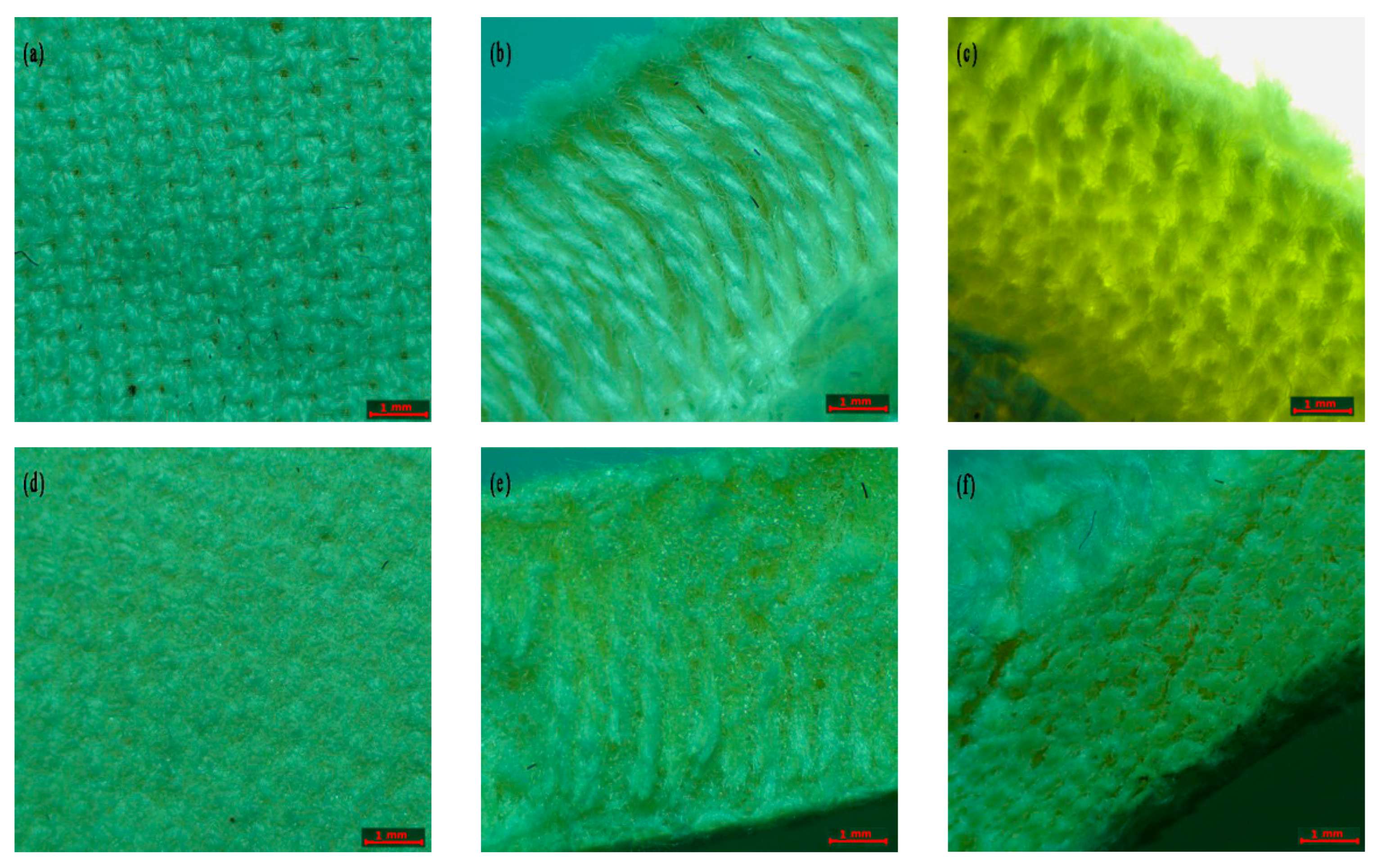

4.2.1. Optical Microscope Analysis

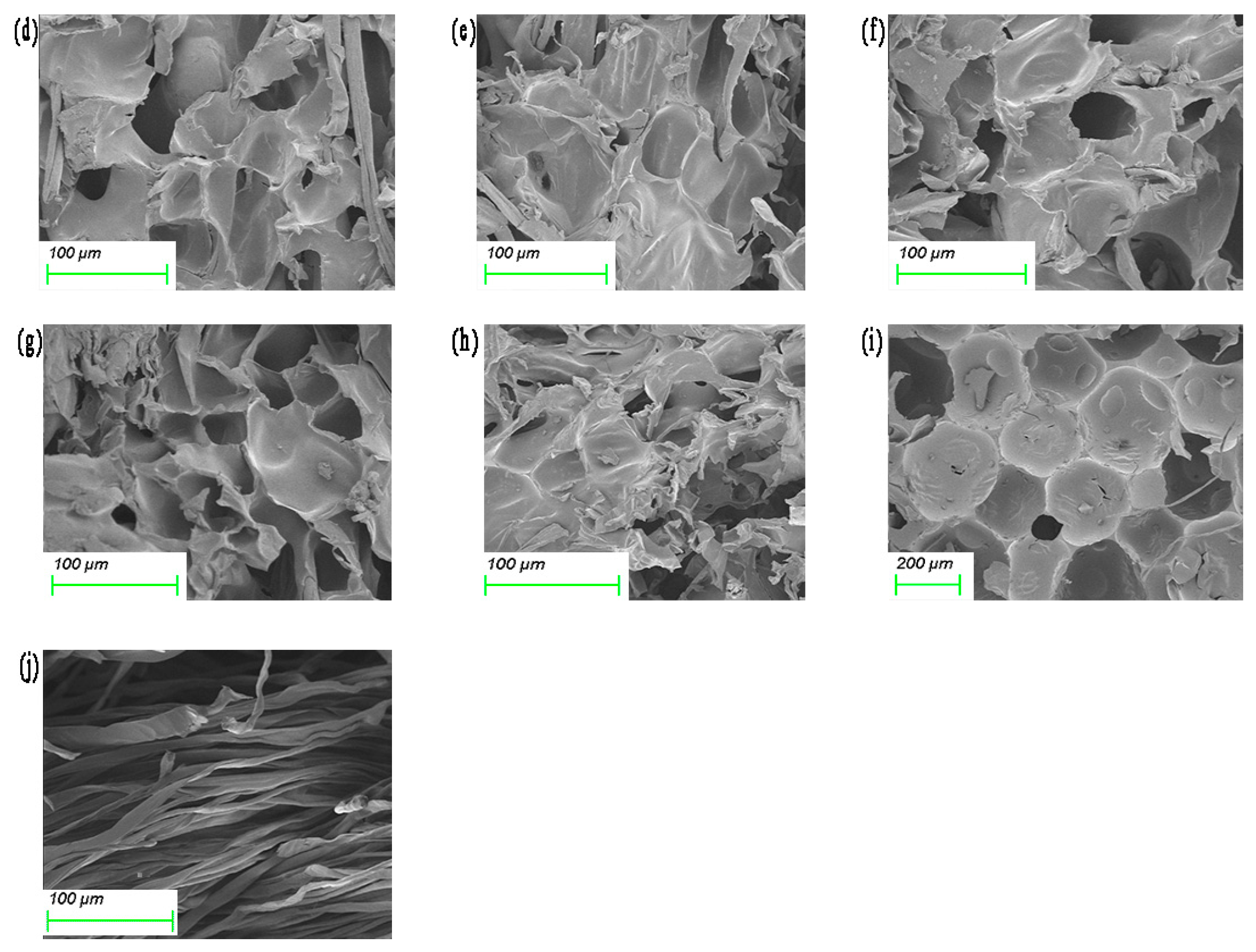

4.2.2. SEM Analysis

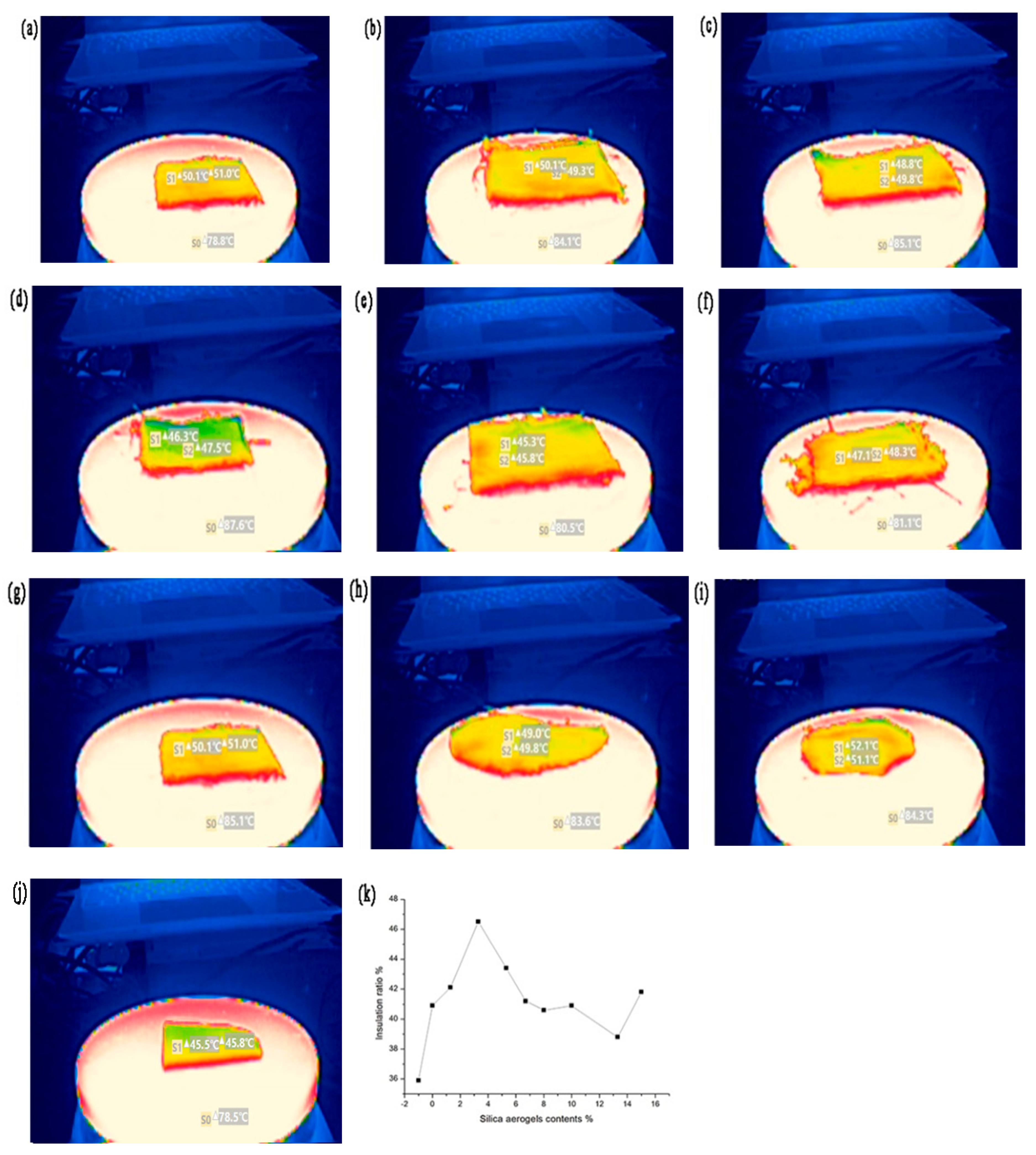

4.3. Thermal Insulation Performance

5. Conclusions

- (1)

- Through the modification of the Jacquard loom, the 3D spacer Jacquard fabric was successfully prepared. The silica aerogel was compounded with the spacer fabric using polyurethane foam as an intermediate. The breaking strength of the composite fabric increased from 200 CN to 519.3 CN, and the breaking elongation decreased by about 20%. The results of the optical microscope present that the structure of the composite fabric is compact, which avoids the powder dropping phenomenon of the silica aerogel during use. According to the SEM results, as the aerogel content increased, the system viscosity increased, leading to a reduction in the foam pore size. Furthermore, an increase in the aerogel content resulted in an agglomeration, uneven dispersion in the slurry, affecting foam nucleation. When the content of silica aerogel is 13%, the foam will be broken seriously.

- (2)

- The insulation performance test results sketch that the insulation rate of the unfilled 3D spacing fabric is 35.9%. Only the thermal insulation rate of the polyurethane foam composite fabric is 40.9%, which is slightly lower than 41.8% of the polyurethane foam of the same thickness. When the content of silica aerogel is 3.3%, the thermal insulation effect is optimal, and the thermal insulation rate is 46.5%. With the increase in aerogel content, the thermal insulation performance of the composite fabric decreases. When the content of the silica aerogel is 13.3%, the thermal insulation rate is 38.8%, which is lower than the composite fabric without silica aerogel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z. Research on Preparation and Performance of Building Insulation Materials. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Chudzik, S. Measurement of thermal parameters of a heat insulating material using infrared thermography. Infrared Phys. Technol. 2012, 55, 73–83. [Google Scholar] [CrossRef]

- Wang, X.; Huang, J.; Zhang, Y.; Long, W.; Xia, L.; Li, S. Current situation and development of thermal insulation refractories. Refractories 2016, 50, 75–80. [Google Scholar]

- Moghaddas, J. Thermal conductivities of silica aerogel composite insulating material. Adv. Mater. 2016, 7, 296–301. [Google Scholar]

- Vaidya, A.S.; Vaidya, U.K.; Uddin, N. Impact response of 3D multifunctional sandwich composite. Mater. Sci. Eng. A 2007, 472, 52–58. [Google Scholar] [CrossRef]

- Zhou, Z.X.; Chen, S. The mathematical study of compression behaviours of silicone rubber composites reinforced by warp-knitted spacer fabrics. Ind. Textila 2023, 74, 303–309. [Google Scholar]

- Han, G.J. Research progress in mechanical properties of three-dimensional woven composites. China High-Tech. 2018, 69–70. [Google Scholar]

- Wang, L.Y.; Zhang, K.; Farha, F.I.; Ma, H.; Qiu, Y.; Xu, F. Compressive strength and thermal insulation properties of the 3D woven spacer composites with connected spacer yarn structure. J. Mater. Sci. 2020, 55, 2380–2388. [Google Scholar] [CrossRef]

- Kus, A.; Durgun, I.; Ertan, R. Experimental study on the flexural properties of 3D integrated woven spacer composites at room and subzero temperatures. J. Sandw. Struct. Mater. 2018, 20, 517–530. [Google Scholar] [CrossRef]

- Liu, Z.; Ding, Y.; Shu, X.; Liu, N. Preparation, characterization and properties of SiO2 aerogel composite thermal insulation coating. Chem. Eng. Trans. 2016, 55, 259–264. [Google Scholar]

- Islam, S.R.; Yu, W.; Naveed, T. Influence of silica aerogels on fabric structural feature for thermal isolation properties of weft-knitted spacer fabrics. J. Eng. Fibers Fabr. 2019, 14. [Google Scholar] [CrossRef]

- Ban, J. Design and Performance Study of Low Melting Point PET/PU Multifunctional Composites. Master’s Thesis, Tianjin Polytechnic University, Tianjin, China, 2019. [Google Scholar]

- Wang, X.; Huang, J.; Zheng, Z. Preparation of TiO2/SiO2 aerogel thermal insulation coating tent material. China Dye. Finish. 2020, 46, 52–55. [Google Scholar]

- Zhong, Z.; Wan, J.; Zhang, X.; Shi, R. Weaving and composite preparation practice of double-layer basalt filament/Kevlar woven spacer fabric. Shanghai Text. Sci. Technol. 2018, 46, 34–36. [Google Scholar]

- Rijavec, T. Silica aerogel-Thermal superinsulation material. Tekstilec 2015, 55, 314–322. [Google Scholar]

- Kueh, A.B.H.; Razali, A.W.; Lee, Y.Y.; Hamdan, S.; Yakub, I.; Suhaili, N. Acoustical and mechanical characteristics of mortars with pineapple leaf fiber and silica aerogel infills—Measurement and modeling. Mater. Today Commun. 2023, 35, 105540. [Google Scholar] [CrossRef]

- Islam, S.R.; Patoary, M.K.; Estifanos, H.D.; Lugoloobi, I.; Yousif, A.H.D.; Jiang, J.; Shao, H. Hydrophobic and oleophilic 3D weft-knitted spacer fabrics coated by silica aerogels with five different concentrations. J. Ind. Text. 2022, 52, 15280837221118063. [Google Scholar] [CrossRef]

- Daryabeigi, K. Heat transfer in high-temperature fibrousinsulation. J. Thermophys. Heat Tr. 2003, 17, 10–20. [Google Scholar] [CrossRef]

- Bhuiyan, M.A.R.; Wang, L.; Shaid, A.; Jahan, I.; Shanks, R.A. Silica aerogel-integrated nonwoven protective fabrics for chemical and thermal protection and thermophysiological wear comfort. J. Mater. Sci. 2020, 55, 2405–2418. [Google Scholar] [CrossRef]

- Bhyiyan, M.A.R.; Waang, L.; Shaid, A.; Shanks, R.A.; Ding, J. Polyurethane-aerogel incorporated coating on cotton fabric for chemical protection. Prog. Org. Coat. 2019, 131, 100–110. [Google Scholar] [CrossRef]

- Zhao, L.; Sui, X.; Mao, Z.; Li, W.; Feng, X. Research progress in aerogel materials application for textiles. J. Text. Res. 2022, 43, 181–189, 196. [Google Scholar]

- Liu, Z.; Liu, L.; Zhong, Z.; Ran, Y.; Xi, J.; Wang, J. Ultralight hybrid silica aerogels derived from supramolecular hydrogels selfassembled from insoluble nano building blocks. RSC Adv. 2021, 11, 7331–7337. [Google Scholar] [CrossRef]

- Cheng, Y.; Xu, Z.; Chen, S.; Ji, Y.; Zhang, D.; Liang, J. The influence of closed pore ratio on sound absorption of plant-based polyurethane foam using control unit model. Appl. Acoust. 2021, 180, 108083. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, C.; Zhang, H.; Hong, X.; Zhou, Z. Design and weaving of 3D spacer fabric based on rapier loom. J. Text. Res. 2021, 42, 166–170. [Google Scholar]

- Zhou, Z.; Zhou, J.; Peng, X.; Huang, J. Weaving process design for 3D changeable spacer jacquard fabrics. J. Text. Res. 2023, 44, 67–72. [Google Scholar]

| Weaving Parameters | Ground Weave Warp | Ground Weave Weft | longitudinal Warp | Ground Weave Warp Density | Ground Weave Weft Density | Spacer Distances |

|---|---|---|---|---|---|---|

| Spacer fabric | 28 tex polyester | 28 tex polyester | 28 tex polyester | 22/cm | 24/cm | 5 mm |

| Fabrics | Breaking Strength/N | Breaking Elongation/% | ||

|---|---|---|---|---|

| Warp Direction | Weft Direction | Warp Direction | Weft Direction | |

| Spacer fabric | 160.34 | 226.16 | 35.62 | 36.18 |

| Spacer fabric with 3.3% silica aerogel | 290.37 | 519.30 | 6.34 | 6.69 |

| No. | Silica Aerogel Content/% | Test Temperature/°C | Difference in Temperature/°C | Insulation Rate/% | CV% |

|---|---|---|---|---|---|

| a | −1 (blank) | 78.8 | 28.3 | 35.9 | 0.9 |

| b | 0 | 84.1 | 34.4 | 40.9 | 0.8 |

| c | 1.3 | 85.1 | 35.8 | 42.1 | 1.0 |

| d | 3.3 | 87.6 | 40.7 | 46.5 | 1.3 |

| e | 5.3 | 80.5 | 35.0 | 43.4 | 0.5 |

| f | 6.7 | 81.1 | 33.4 | 41.2 | 1.3 |

| g | 8.0 | 85.1 | 34.6 | 40.6 | 0.9 |

| h | 10.0 | 83.6 | 34.2 | 40.9 | 0.8 |

| i | 13.3 | 84.3 | 32.7 | 38.8 | 1.0 |

| j | 15.0 | 78.5 | 32.9 | 41.8 | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Zhou, J.; Lu, S. Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel. Materials 2023, 16, 6954. https://doi.org/10.3390/ma16216954

Zhou Z, Zhou J, Lu S. Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel. Materials. 2023; 16(21):6954. https://doi.org/10.3390/ma16216954

Chicago/Turabian StyleZhou, Zhifang, Jiu Zhou, and Shuangyi Lu. 2023. "Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel" Materials 16, no. 21: 6954. https://doi.org/10.3390/ma16216954

APA StyleZhou, Z., Zhou, J., & Lu, S. (2023). Research on the Thermal Insulation Properties of Three-Dimensional Spacer Jacquard Fabric Treated with Silica Aerogel. Materials, 16(21), 6954. https://doi.org/10.3390/ma16216954