A Preliminary Study on the Improvement of Gangue/Tailing Cemented Fill by Bentonite: Flow Properties, Mechanical Properties and Permeability

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material Characteristics

2.2. Sample Preparation and Maintenance

2.3. Testing Method

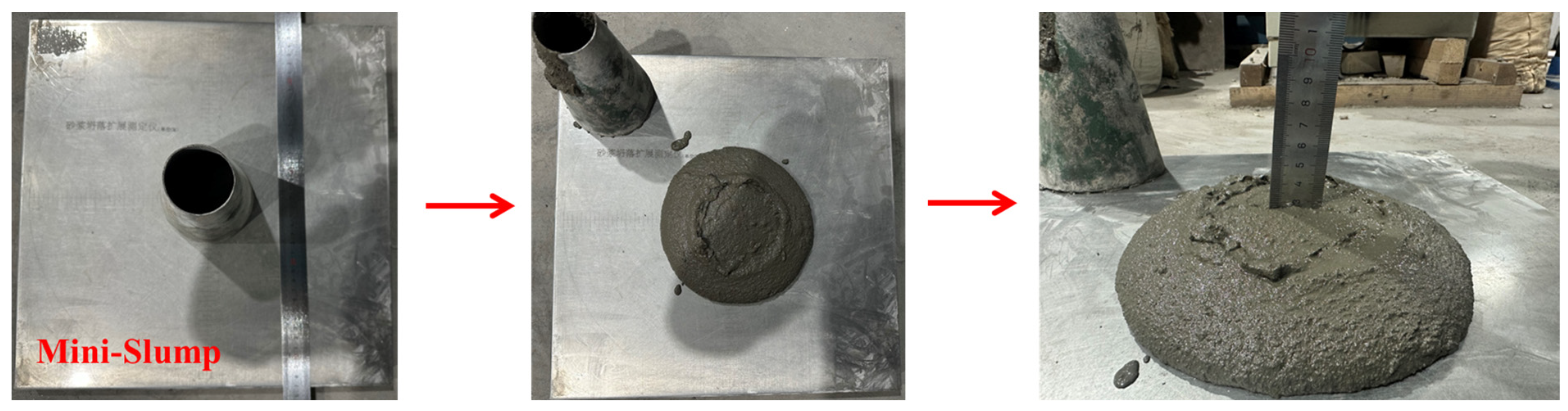

2.3.1. Slump Test

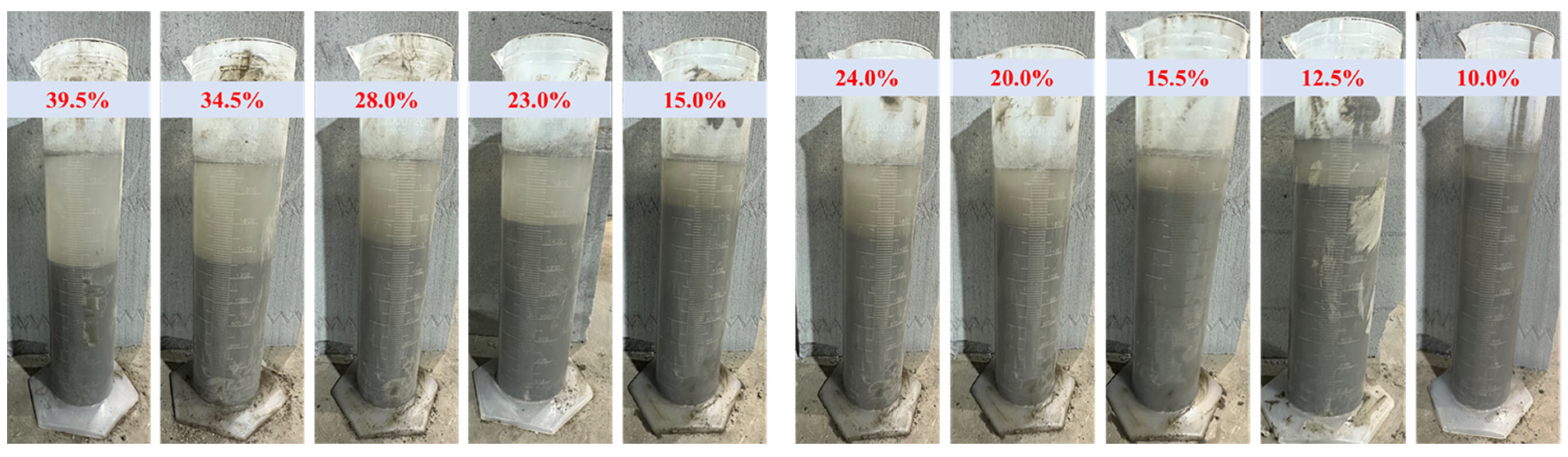

2.3.2. Bleeding Rate Test

2.3.3. Unconfined Compressive Strength Test

2.3.4. Porosity Test

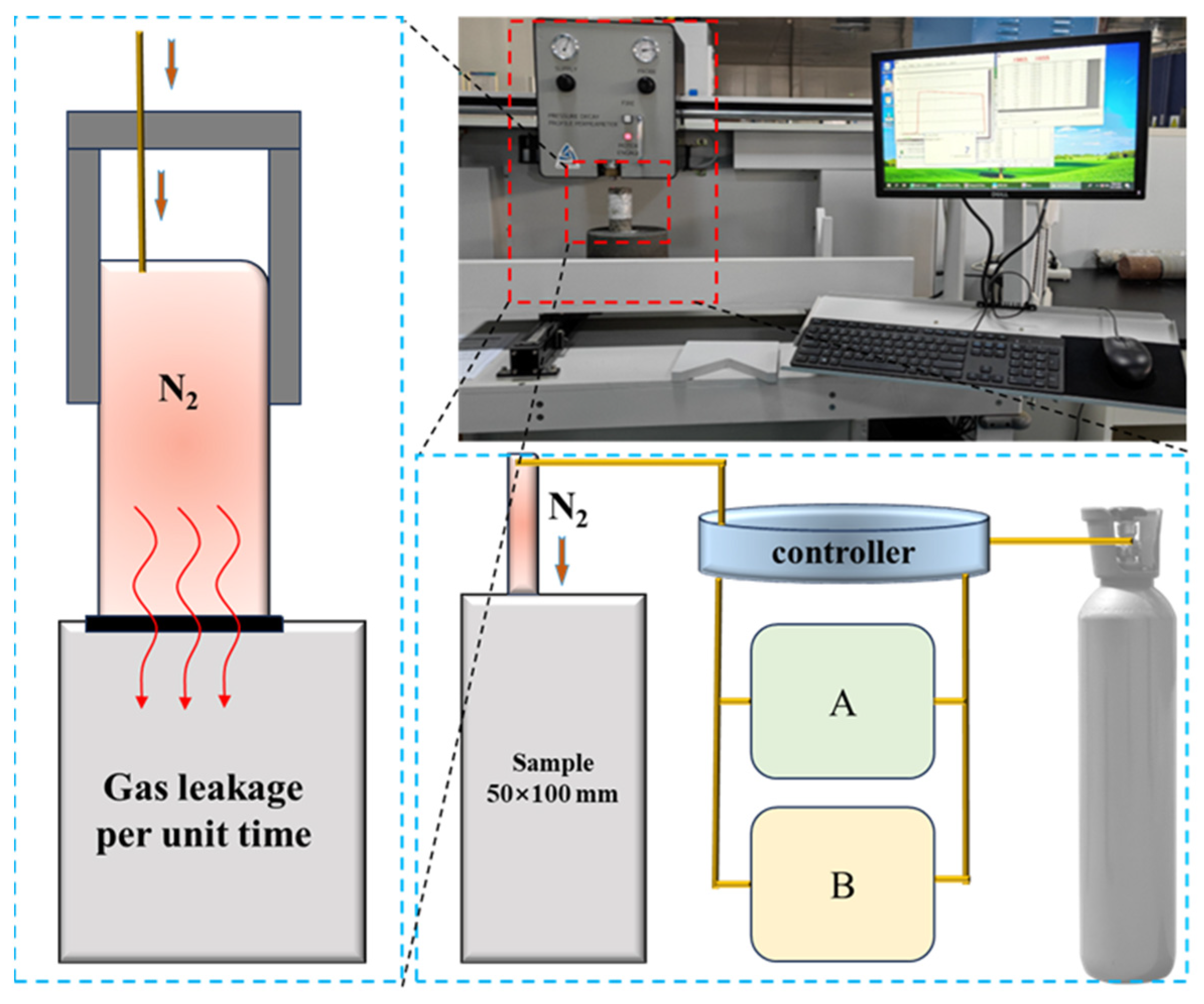

2.3.5. Permeability Test

3. Results and Discussion

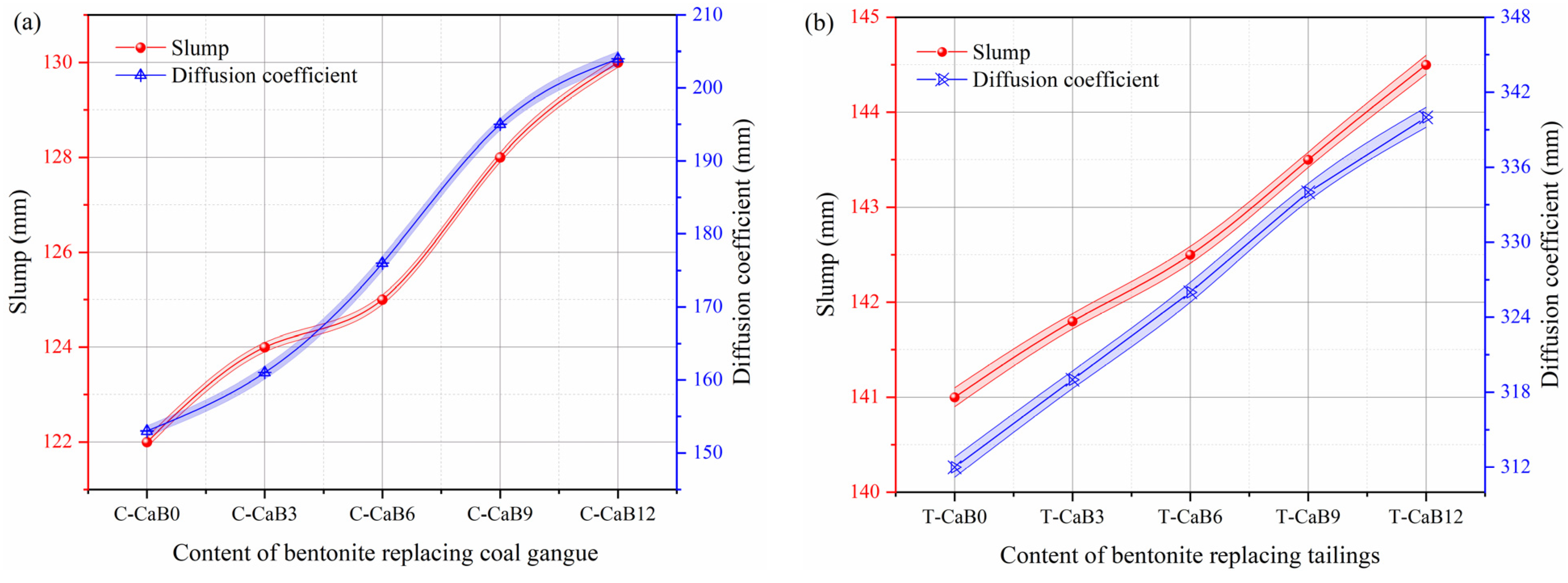

3.1. Slump

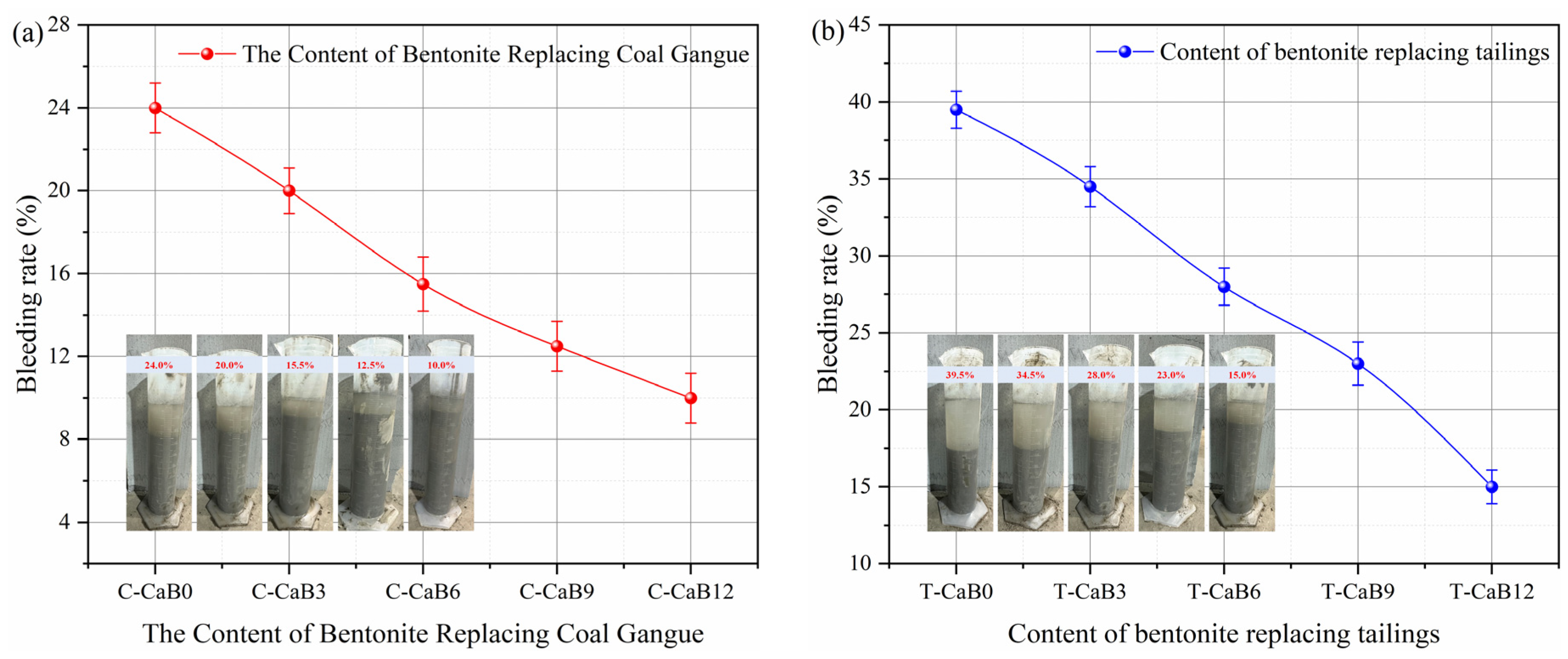

3.2. Bleeding Rate

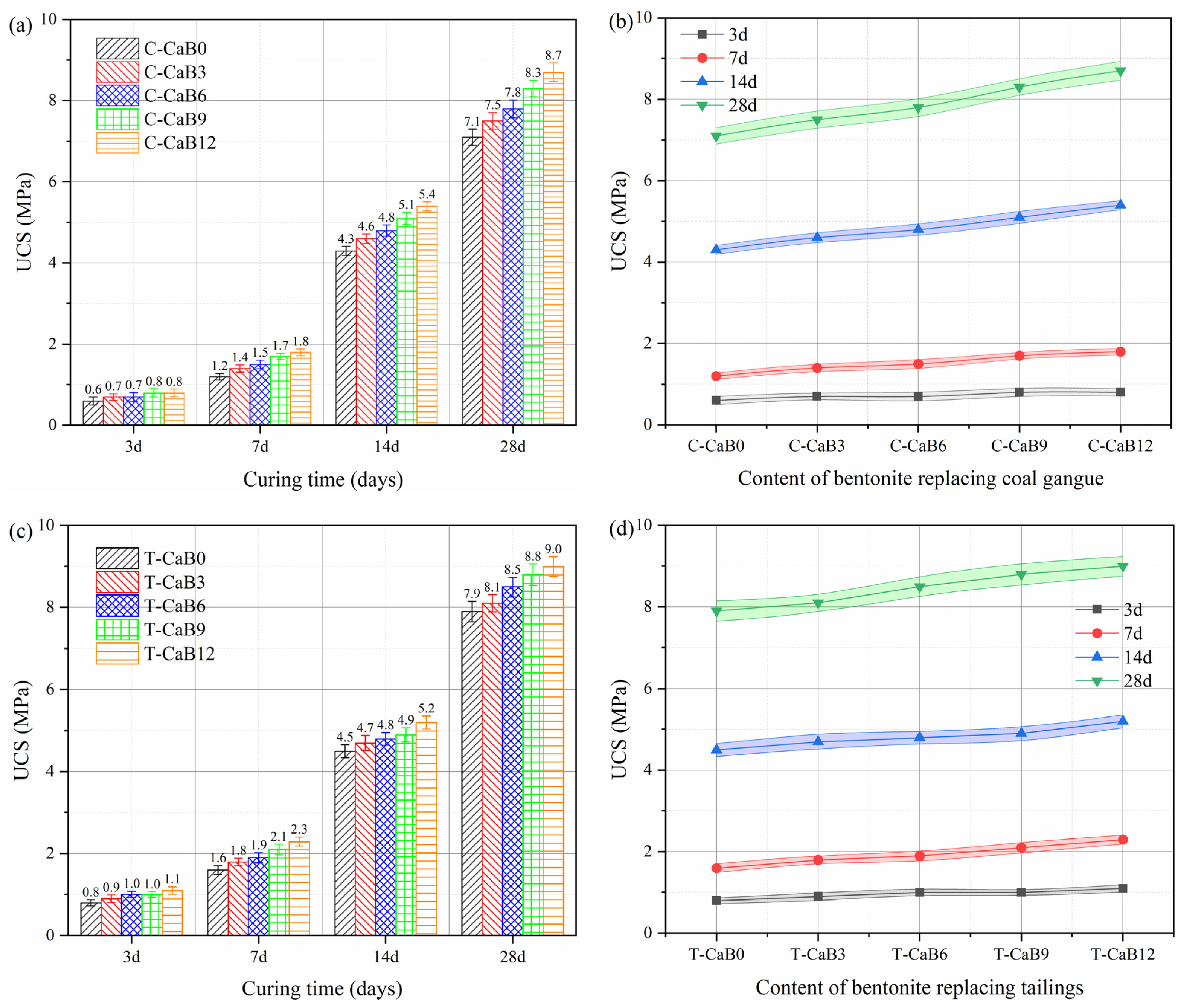

3.3. Mechanical Property

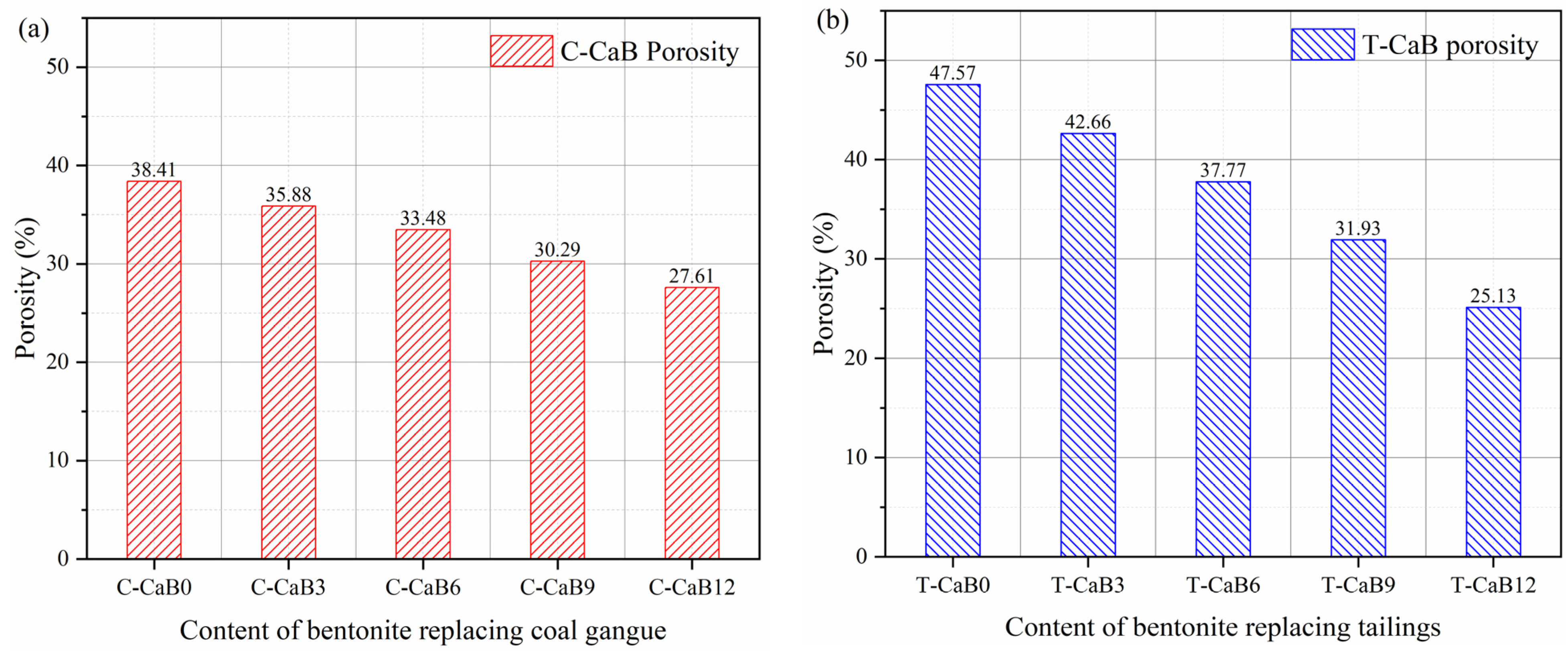

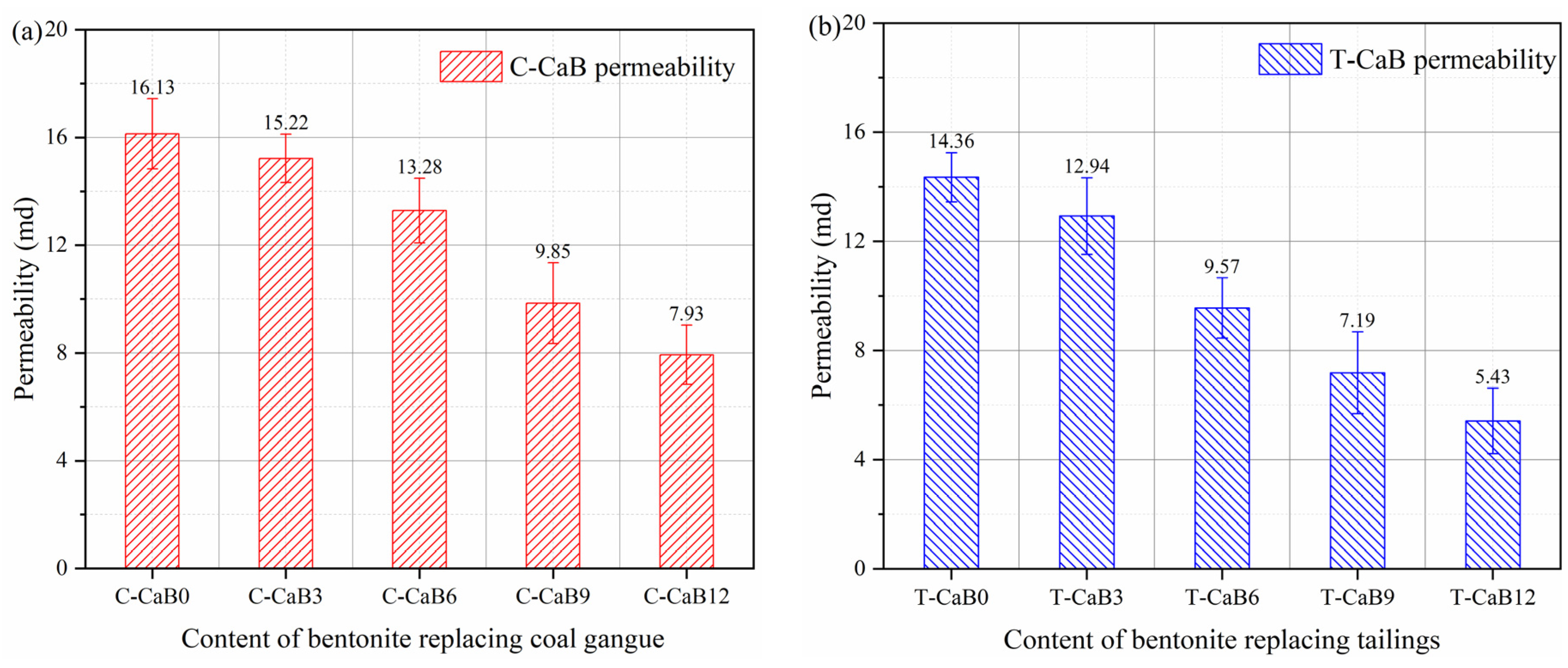

3.4. Porosity and Permeability

4. Conclusions

- (1)

- After the addition of bentonite into the gangue/tailings consolidated backfill, the bleeding rate is significantly reduced, while the slump value is increased and the fluidity is improved. The bleeding rate of gangue and tailing cemented backfill decreased to 10% and 15%, respectively, and slump value increased to 130 mm and 144.5 mm, respectively. Bentonite can improve the fluidity of cemented backfill, especially its bleeding rate, and promote the long-term development of cemented backfill;

- (2)

- After adding bentonite into the gangue/tailing cemented backfill, the mechanical properties are significantly improved. The early improvement effect was not obvious, mainly concentrated in the middle and late curing of cemented backfill. With the increase of bentonite content, the 28-day uniaxial compressive strength increased from 7.1 MPa and 7.9 MPa to 8.7 MPa and 9.0 MPa, respectively.

- (3)

- Bentonite is filled between the pores of the cemented backfill with its fine particles and swelling in water, which can reduce the porosity of both gangue and tailings cemented backfill. The porosity of gangue cemented backfill decreased from 38.41% to 27.61%, and the porosity of tailing cemented backfill decreased from 47.57% to 25.13%;

- (4)

- Bentonite has a significant improvement effect on the permeability of gangue and tailing cemented backfill. Bentonite and cementified material can produce better adhesive force, fill the pore structure, reduce the porosity through, and thus reduce the permeability of cemented backfill. In engineering application, it will effectively prevent the leaching and migration of heavy metal ions in the filled aggregate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Wang, S.; Zhu, M.; Zhang, B.; Hou, D.; Xun, C.; Zhao, Y.; Zhang, X.; Wang, X.; Wang, M. CO2 storage-cavern construction and storage method based on functional backfill. J. China Coal Soc. 2022, 47, 1072–1086. [Google Scholar]

- Wang, S.; Shen, Y.; Sun, Q.; Liu, L.; Shi, Q.; Zhu, M.; Zhang, B.; Cui, S. Exploration on underground CO2 storage ways and technical problems in coal mining area under the background of “dual carbon” target. J. China Coal Soc. 2022, 47, 45–60. [Google Scholar]

- Sang, S.; Yuan, L.; Liu, S.; Han, S.; Zheng, S.; Liu, T.; Zhou, X.; Wang, R. Geological technology for carbon neutrality and its application prospect for low carbon coal exploitation and utilization. J. China Coal Soc. 2022, 47, 1430–1451. [Google Scholar]

- Li, S.; Zhang, J.; Shang, J.; Lin, H.; Wang, S.; Ding, Y.; Hou, E.; Zhao, H. Conception and connotation of coal and gas co-extraction technology system under the goal of carbon peak and carbon neutrality. J. China Coal Soc. 2022, 47, 1416–1429. [Google Scholar]

- Jialin, X.; Dayang, X.; Weibing, Z.; Xiaozhen, W.; Binglong, W.; Hao, T. Study and application of coal mining with partial backfilling. J. China Coal Soc. 2015, 40, 1303–1312. [Google Scholar]

- Guo, F.; Guo, Y.; Chen, L.; Jia, W.; Zhu, Y.; Li, Y.; Wang, H.; Yao, X.; Zhang, Y.; Wu, J. Multitudinous components recovery, heavy metals evolution and environmental impact of coal gasification slag: A review. Chemosphere 2023, 338, 139473. [Google Scholar] [CrossRef]

- Song, W.; Xu, R.; Li, X.; Min, X.; Zhang, J.; Zhang, H.; Hu, X.; Li, J. Soil reconstruction and heavy metal pollution risk in reclaimed cultivated land with coal gangue filling in mining areas. Catena 2023, 228, 107147. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, S.; Feng, T.; Yi, B.; Liu, J. Research on reuse of silty fine sand in backfill grouting material and optimization of backfill grouting material proportions. Tunn. Undergr. Space Technol. 2022, 130, 104751. [Google Scholar] [CrossRef]

- Cheng, Y.; Shen, H.; Zhang, J. Understanding the effect of high-volume fly ash on micro-structure and mechanical properties of cemented coal gangue paste backfill. Constr. Build. Mater. 2023, 378, 131202. [Google Scholar] [CrossRef]

- Feng, Y.; Qi, W.; Zhao, Q.; Huang, Y.; Ren, Q.; Qi, W.; Kong, F. Synthesis and characterization of cemented paste backfill: Reuse of multiple solid wastes. J. Clean. Prod. 2023, 383, 135376. [Google Scholar] [CrossRef]

- Yang, P.; Liu, L.; Suo, Y.; Zhu, M.; Xie, G.; Deng, S. Mechanical properties, pore characteristics and microstructure of modified magnesium slag cemented coal-based solid waste backfill materials: Affected by fly ash addition and curing temperature. Process Saf. Environ. Prot. 2023, 176, 1007–1020. [Google Scholar] [CrossRef]

- Yang, S.; Wu, J.; Jing, H.; Zhang, X.; Chen, W.; Wang, Y.; Yin, Q.; Ma, D. Molecular mechanism of fly ash affecting the performance of cemented backfill material. Int. J. Miner. Metall. Mater. 2023, 30, 1560–1572. [Google Scholar] [CrossRef]

- Visvalingam, S.; Saengsoy, W.; Tangtermsirikul, S. Effects of free lime content in fly ash on sulfate expansion of cement-fly ash mixtures. J. Mater. Cycles Waste Manag. 2022, 24, 2002–2014. [Google Scholar] [CrossRef]

- Chen, Q.; Luo, K.; Wang, Y.; Li, X.; Zhang, Q.; Liu, Y. In-situ stabilization/solidification of lead/zinc mine tailings by cemented paste backfill modified with low-carbon bentonite alternative. J. Mater. Res. Technol. 2022, 17, 1200–1210. [Google Scholar] [CrossRef]

- Qin, Z.; Jin, J.; Lü, X.; Zhang, X.; Chen, Y.; Li, M.; Zuo, S.; Shi, J. Insights into mechanical property and damage evaluation of a novel waste-based coal gangue-filled backfill. Constr. Build. Mater. 2023, 389, 131802. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T. Long-term ageing characteristics of cemented paste backfill: Usability of sand as a partial substitute of hazardous tailings. J. Clean. Prod. 2023, 401, 136723. [Google Scholar] [CrossRef]

- Fang, L.; Xinju, L.; Le, H.; Anran, S. A long-term study on the soil reconstruction process of reclaimed land by coal gangue filling. Catena 2020, 195, 104874. [Google Scholar] [CrossRef]

- Shirin, S.; Jamal, A.; Emmanouil, C.; Singh, V.P.; Yadav, A.K. Assessment and characterization of waste material used as backfilling in an abandoned mine. Int. J. Coal Prep. Util. 2023, 43, 1–9. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, J.; He, M.; Li, M.; Wang, C.; Feng, W.; Li, F. Mechanical properties and damage evolution characteristics based on the acoustic emission of gangue and high-water-content materials based cemented paste backfill. Constr. Build. Mater. 2023, 395, 132324. [Google Scholar] [CrossRef]

- Qiu, J.; Cheng, K.; Zhang, R.; Gao, Y.; Guan, X. Study on the influence mechanism of activated coal gangue powder on the properties of filling body. Constr. Build. Mater. 2022, 345, 128071. [Google Scholar] [CrossRef]

- Yu, L.; Xia, J.; Xia, Z.; Chen, M.; Wang, J.; Zhang, Y. Study on the mechanical behavior and micro-mechanism of concrete with coal gangue fine and coarse aggregate. Constr. Build. Mater. 2022, 338, 127626. [Google Scholar] [CrossRef]

- Fu, X.-L.; Zhuang, H.; Reddy, K.R.; Jiang, N.-J.; Du, Y.-J. Novel composite polymer-amended bentonite for environmental containment: Hydraulic conductivity, chemical compatibility, enhanced rheology and polymer stability. Constr. Build. Mater. 2023, 378, 131200. [Google Scholar] [CrossRef]

- Wang, Q.; Meng, Y.; Su, W.; Ye, W.; Chen, Y. Analyzing of the hydration crack evolution in compacted GMZ bentonite with consideration of technological void ratio. Constr. Build. Mater. 2022, 323, 126399. [Google Scholar] [CrossRef]

- Qiu, H.; Liang, C.; Tu, B.; Liu, L.; Zhang, F.; Lv, W. Study on mechanical properties of cemented backfill with different mineral admixtures. Constr. Build. Mater. 2023, 367, 130251. [Google Scholar] [CrossRef]

- Liu, H.; Fu, T.; Sarwar, M.T.; Yang, H. Recent progress in radionuclides adsorption by bentonite-based materials as ideal adsorbents and buffer/backfill materials. Appl. Clay Sci. 2023, 232, 106796. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, J.; Du, Y.; Zhang, Y.; Zhen, Z.; Liu, Y.; Zhan, L. Seismic behaviors of tailings and recycled aggregate concrete-filled steel tube columns. Constr. Build. Mater. 2023, 365, 130115. [Google Scholar] [CrossRef]

- Song, X.; Hao, Y.; Huang, J.; Wang, S.; Liu, W. Study on mechanical properties and destabilization mechanism of unclassified tailings consolidation body under the action of dry-wet cycle. Constr. Build. Mater. 2023, 365, 130022. [Google Scholar] [CrossRef]

- Zhong, X.; Chen, Z.; Li, Y.; Ding, K.; Liu, W.; Liu, Y.; Yuan, Y.; Zhang, M.; Baker, A.J.M.; Yang, W.; et al. Factors influencing heavy metal availability and risk assessment of soils at typical metal mines in Eastern China. J. Hazard. Mater. 2020, 400, 123289. [Google Scholar] [CrossRef]

- Qiu, H.; Zhang, F.; Liu, L.; Huan, C.; Hou, D.; Kang, W. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2021, 315, 125278. [Google Scholar] [CrossRef]

- He, W.; Liu, L.; Fang, Z.; Gao, Y.; Sun, W. Effect of polypropylene fiber on properties of modified magnesium-coal-based solid waste backfill materials. Constr. Build. Mater. 2023, 362, 129695. [Google Scholar] [CrossRef]

- Wu, H.-L.; Jin, F.; Zhou, A.-N.; Du, Y.-J. The engineering properties and reaction mechanism of MgO-activated slag cement-clayey sand-bentonite (MSB) cutoff wall backfills. Constr. Build. Mater. 2021, 271, 121890. [Google Scholar] [CrossRef]

- Pang, J. Preparation and Performance Study of Heavy Metal Adsorbents for Coal Associated Minerals. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar]

- Zhang, L.; Lu, Z.; Tan, X.; Zhang, X. Resources survey and exploitation situation of coal-derived minerals in China. China Min. 2012, 21, 3. [Google Scholar]

- Fan, R.-D.; Du, Y.; Reddy, K.R.; Liu, S.; Yang, Y. Compressibility and hydraulic conductivity of clayey soil mixed with calcium bentonite for slurry wall backfill: Initial assessment. Appl. Clay Sci. 2014, 101, 119–127. [Google Scholar] [CrossRef]

- Yin, S.; Yan, Z.; Chen, X.; Yan, R.; Chen, D.; Chen, J. Mechanical properties of cemented tailings and waste-rock backfill (CTWB) materials: Laboratory tests and deep learning modeling. Constr. Build. Mater. 2023, 369, 130610. [Google Scholar] [CrossRef]

- Hou, J.; Guo, Z.; Liu, W.; Zhang, Y. Mechanical properties and meso-structure response of cemented gangue-fly ash backfill with cracks under seepage- stress coupling. Constr. Build. Mater. 2020, 250, 118863. [Google Scholar] [CrossRef]

- Cui, Q.; Maierdan, Y.; Chen, B.; Ge, J.; Liu, N. Comparative research on the application of slag as an alternative to cement in binder-bentonite cutoff wall backfills. Constr. Build. Mater. 2022, 325, 126817. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and UrbanRural Development of the PRC: Beijing, China, 2019.

- Zhang, C.-L. Deformation and water/gas flow properties of claystone/bentonite mixtures. J. Rock Mech. Geotech. Eng. 2021, 13, 864–874. [Google Scholar] [CrossRef]

- Demdoum, A.; Gueddouda, M.K.; Goual, I.; Souli, H.; Ghembaza, M.S. Effect of landfill leachate on the hydromechanical behavior of bentonite-geomaterials mixture. Constr. Build. Mater. 2019, 234, 117356. [Google Scholar] [CrossRef]

- GB/T17671-2021; Test Method of Cement Mortar Strength. State Administration for Market Regulation. Standardization Administration: Beijing, China, 2021.

- Liu, Z.; Cui, Y.; Ye, W.; Wang, Q.; Zhang, Z.; Chen, Y. Buffer/backfill materials: Research progress of bentonite particles and their mixtures. Chin. J. Geotech. Eng. 2019, 42, 1401–1410. [Google Scholar]

- González-Santamaría, D.E.; Fernández, R.; Ruiz, A.; Ortega, A.; Cuevas, J. High-pH/low pH ordinary Portland cement mortars impacts on compacted bentonite surfaces: Application to clay barriers performance. Appl. Clay Sci. 2020, 193, 105672. [Google Scholar] [CrossRef]

- Li, H.; Chen, M.; Fu, B.; Liang, B. Evaluation on the thermal and moisture diffusion behavior of sand/bentonite. Appl. Therm. Eng. 2019, 151, 55–65. [Google Scholar] [CrossRef]

- Kim, J.-W.; Chong, S.-H.; Kim, J.-S.; Kim, G.-Y. Investigation of long-wavelength elastic wave propagation through wet bentonite-filled rock joints. J. Rock Mech. Geotech. Eng. 2023, 15, 2496–2507. [Google Scholar] [CrossRef]

- Harrington, J.F.; Daniels, K.A.; Wiseall, A.C.; Sellin, P. Bentonite homogenisation during the closure of void spaces. Int. J. Rock Mech. Min. Sci. 2020, 136, 104535. [Google Scholar] [CrossRef]

- Oppong, F.; Yao, N.; Zhang, W.; Liu, Y.; Kolawole, O. Tentative application of expansive cementitious materials in grouting—A systematic review. Case Stud. Constr. Mater. 2023, 18, e02113. [Google Scholar] [CrossRef]

- Liu, J.; An, S.; Zhang, Y. Mechanism of regulating the mechanical properties and paste structure of supersulfated cement through ultrafine iron tailings powder. Cem. Concr. Compos. 2023, 140, 105061. [Google Scholar] [CrossRef]

- Cheng, A.; Xie, S.; Ji, M.; Huang, S.; Ye, Z. Micro-mechanism on strength development and failure mode of cemented ultra-fine tailing backfill: Influence of binder. Constr. Build. Mater. 2023, 394, 132245. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, J.; Lai, W.; Li, M.; Huo, B. Microstructure and mechanical behaviors of coal gangue—Coal slime water backfill cementitious materials. J. Mater. Res. Technol. 2022, 20, 3772–3783. [Google Scholar] [CrossRef]

- Li, Z.; Sun, W.; Gao, T.; Zhao, J.; Lu, K.; Cheng, H. Experimental study on evolution of pore structure of inclined layered cemented tailings backfill based on X-ray CT. Constr. Build. Mater. 2023, 366, 130242. [Google Scholar] [CrossRef]

- Yang, H.; Long, D.; Zhenyu, L.; Yuanjin, H.; Tao, Y.; Xin, H.; Jie, W.; Zhongyuan, L.; Shuzhen, L. Effects of bentonite on pore structure and permeability of cement mortar. Constr. Build. Mater. 2019, 224, 276–283. [Google Scholar] [CrossRef]

- Yang, Y.-L.; Reddy, K.R.; Zhang, T.; Fan, R.-D.; Fu, X.-L.; Du, Y.-J. Enhanced contaminant retardation by novel modified calcium bentonite backfill in slurry trench cutoff walls. Constr. Build. Mater. 2022, 320, 126285. [Google Scholar] [CrossRef]

- Wang, Y.; Na, Q.; Zhang, L. Monitoring of in-situ properties for cemented tailings backfill that under drainage condition. Constr. Build. Mater. 2022, 356, 129254. [Google Scholar] [CrossRef]

- Najser, J.; Mašín, D.; Svoboda, J.; Vašíček, R.; Hanusová, I.; Hausmannová, L.; Kruis, J.; Krejčí, T.; Sun, H. The homogenisation behaviour of BCV bentonite—A laboratory and numerical study. Appl. Clay Sci. 2023, 241, 106969. [Google Scholar] [CrossRef]

- Middelhoff, M.; Cuisinier, O.; Gaboreau, S.; Masrouri, F.; Talandier, J.; Michau, N. Hydraulic conductivity, microstructure and texture of compacted claystone/ bentonite mixtures saturated with different solutions. Appl. Clay Sci. 2023, 241, 106982. [Google Scholar] [CrossRef]

- Idiart, A.; Laviña, M.; Cochepin, B.; Pasteau, A. Hydro-chemo-mechanical modelling of long-term evolution of bentonite swelling. Appl. Clay Sci. 2020, 195, 105717. [Google Scholar] [CrossRef]

| Composition | CaO | SiO2 | MgO | Fe2O3 | Al2O3 | SO3 | TiO2 | Loss |

|---|---|---|---|---|---|---|---|---|

| Cement | 50.8 | 26.45 | 4.58 | 3.01 | 7.94 | 1.18 | 0.31 | 5.73 |

| FA | 15.13 | 40.12 | 1.29 | 13.15 | 16.24 | 4.91 | 1.01 | 8.15 |

| Coal Gangue | 1.79 | 59.94 | 1.78 | 7.59 | 22.15 | 0.61 | 0.15 | 5.99 |

| Tailings | 0.67 | 71.11 | 0.11 | 0.51 | 14.03 | 0.23 | 0.01 | 13.33 |

| Bentonite | 3.41 | 63.52 | 2.83 | 6.07 | 15.44 | 0.03 | 0.99 | 7.71 |

| Sample Name | Montmorillonite | Quartz | Quartz | Albite |

|---|---|---|---|---|

| Bentonite | 96.20 | 0.60 | 2.10 | 1.10 |

| No. | Alternative | Aggregate | FA | Cement | Bentonite | Water |

|---|---|---|---|---|---|---|

| C-CaB0 | Coal Gangue | 620 | 200 | 180 | 0 | 334 |

| C-CaB3 | 590 | 30 | ||||

| C-CaB6 | 560 | 60 | ||||

| C-CaB9 | 530 | 90 | ||||

| C-CaB12 | 500 | 120 | ||||

| T-CaB0 | Tailings | 620 | 200 | 180 | 0 | 334 |

| T-CaB3 | 590 | 30 | ||||

| T-CaB6 | 560 | 60 | ||||

| T-CaB9 | 530 | 90 | ||||

| T-CaB12 | 500 | 120 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Chen, D.; Guo, R.; Tian, J.; Li, B. A Preliminary Study on the Improvement of Gangue/Tailing Cemented Fill by Bentonite: Flow Properties, Mechanical Properties and Permeability. Materials 2023, 16, 6802. https://doi.org/10.3390/ma16206802

Wang H, Chen D, Guo R, Tian J, Li B. A Preliminary Study on the Improvement of Gangue/Tailing Cemented Fill by Bentonite: Flow Properties, Mechanical Properties and Permeability. Materials. 2023; 16(20):6802. https://doi.org/10.3390/ma16206802

Chicago/Turabian StyleWang, Hongsheng, Dengfeng Chen, Ruihong Guo, Jiahao Tian, and Bin Li. 2023. "A Preliminary Study on the Improvement of Gangue/Tailing Cemented Fill by Bentonite: Flow Properties, Mechanical Properties and Permeability" Materials 16, no. 20: 6802. https://doi.org/10.3390/ma16206802

APA StyleWang, H., Chen, D., Guo, R., Tian, J., & Li, B. (2023). A Preliminary Study on the Improvement of Gangue/Tailing Cemented Fill by Bentonite: Flow Properties, Mechanical Properties and Permeability. Materials, 16(20), 6802. https://doi.org/10.3390/ma16206802