Experimental and Numerical Study of Healing Effect on Delamination Defect in Infusible Thermoplastic Composite Laminates

Abstract

1. Introduction

2. Material and Experimental Description

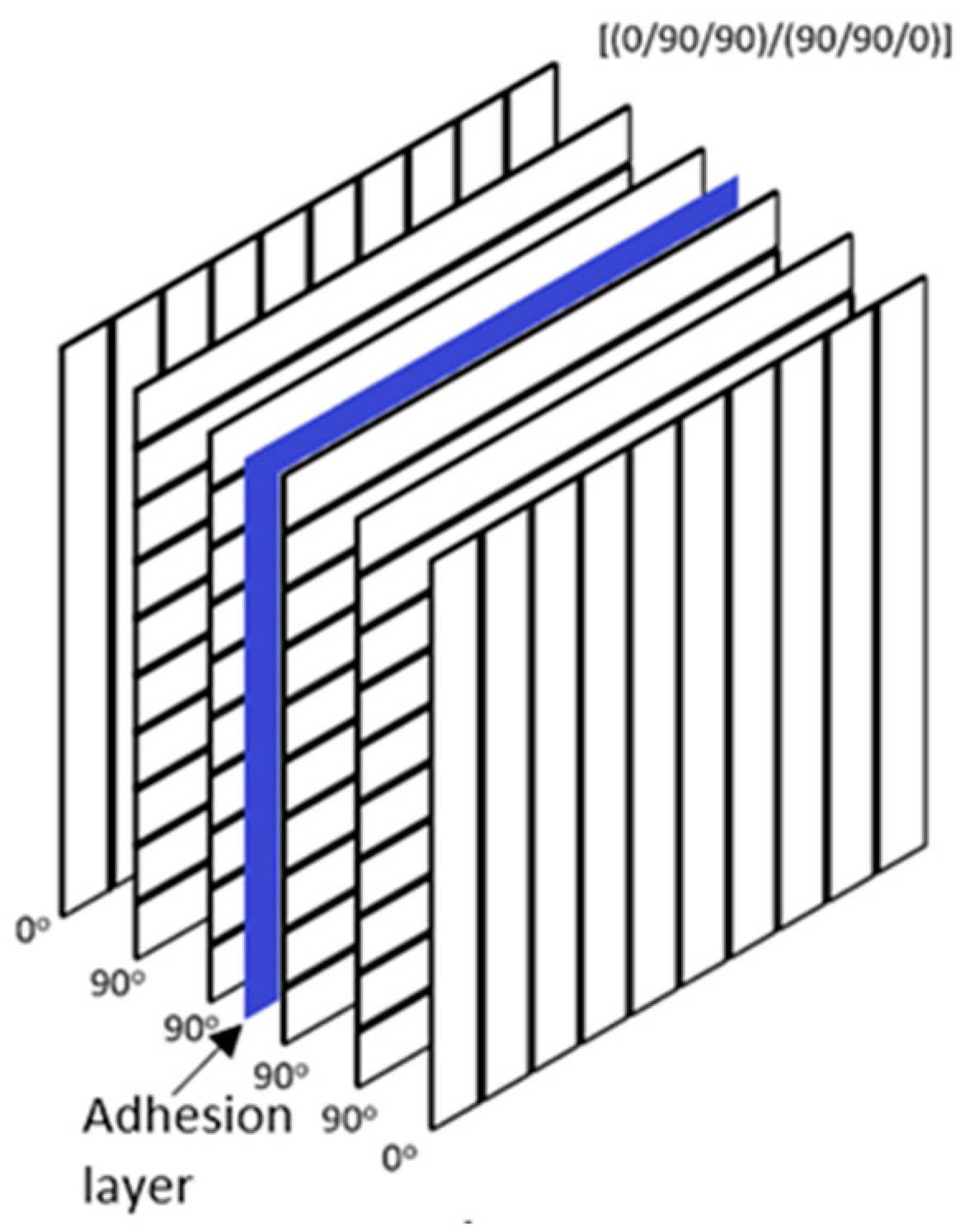

2.1. Materials and Specimens

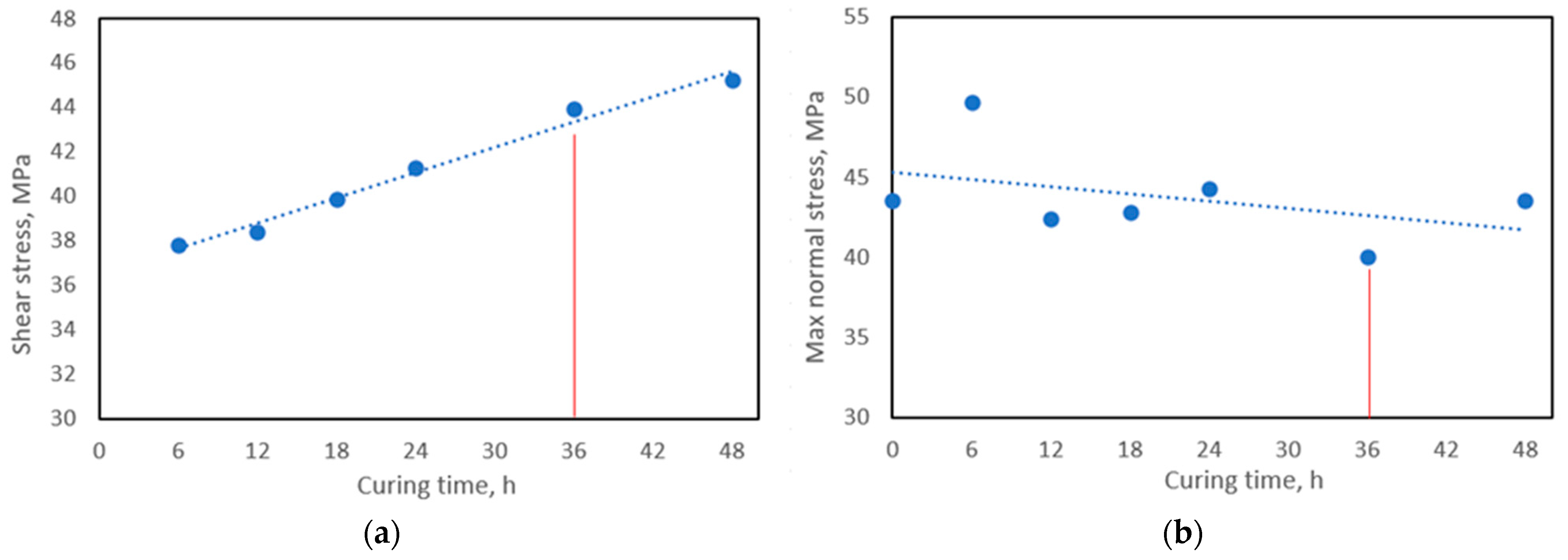

2.2. Thermal Healing Parameters

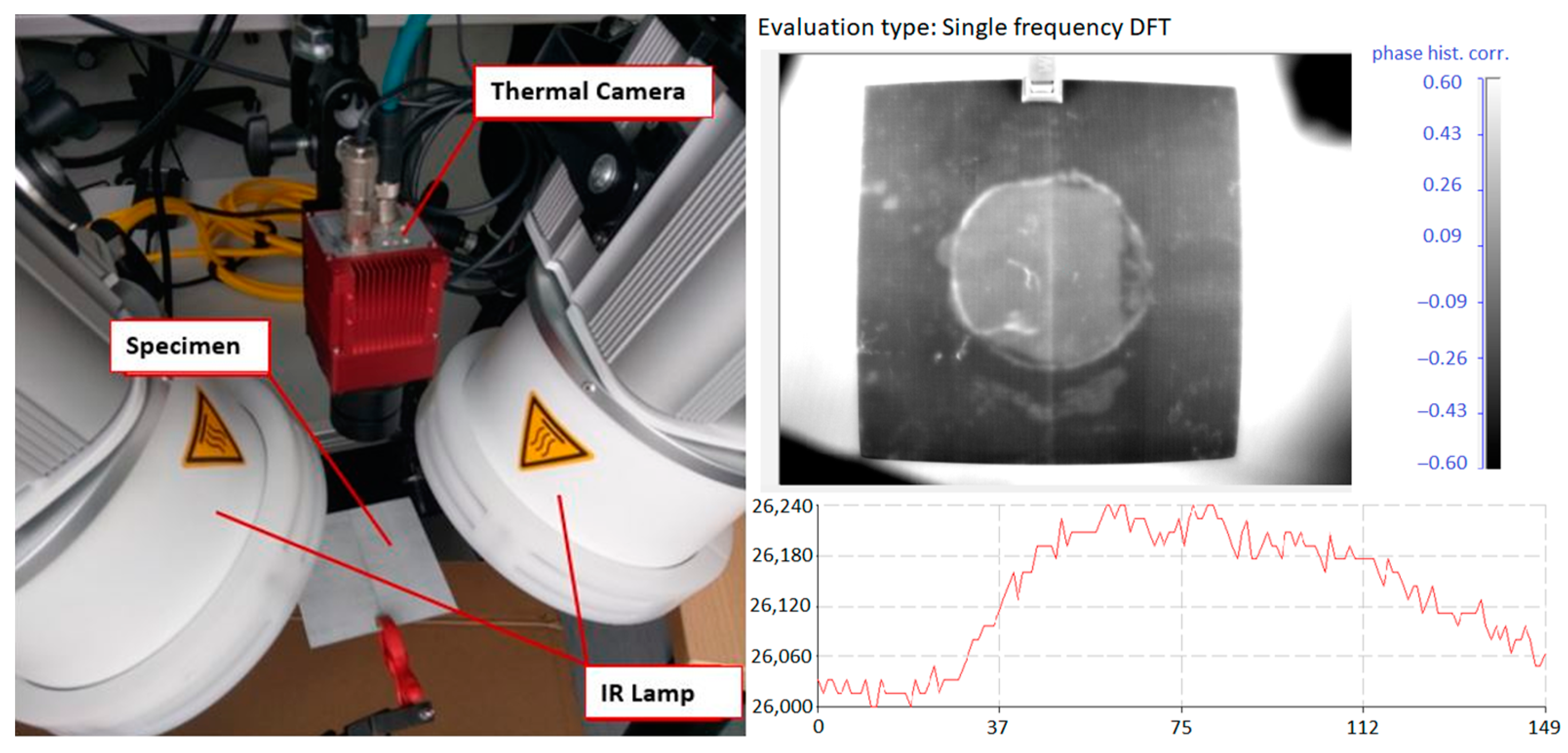

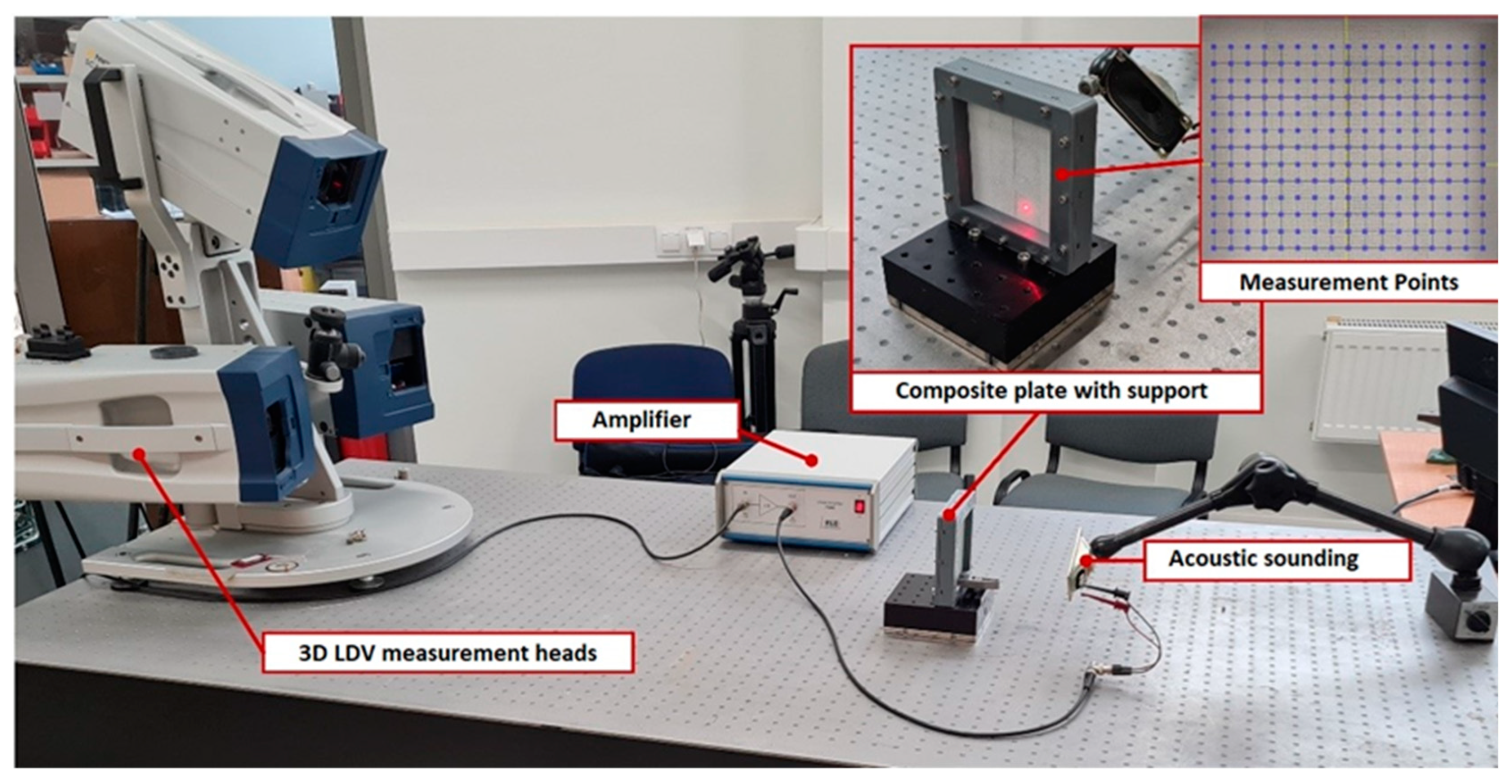

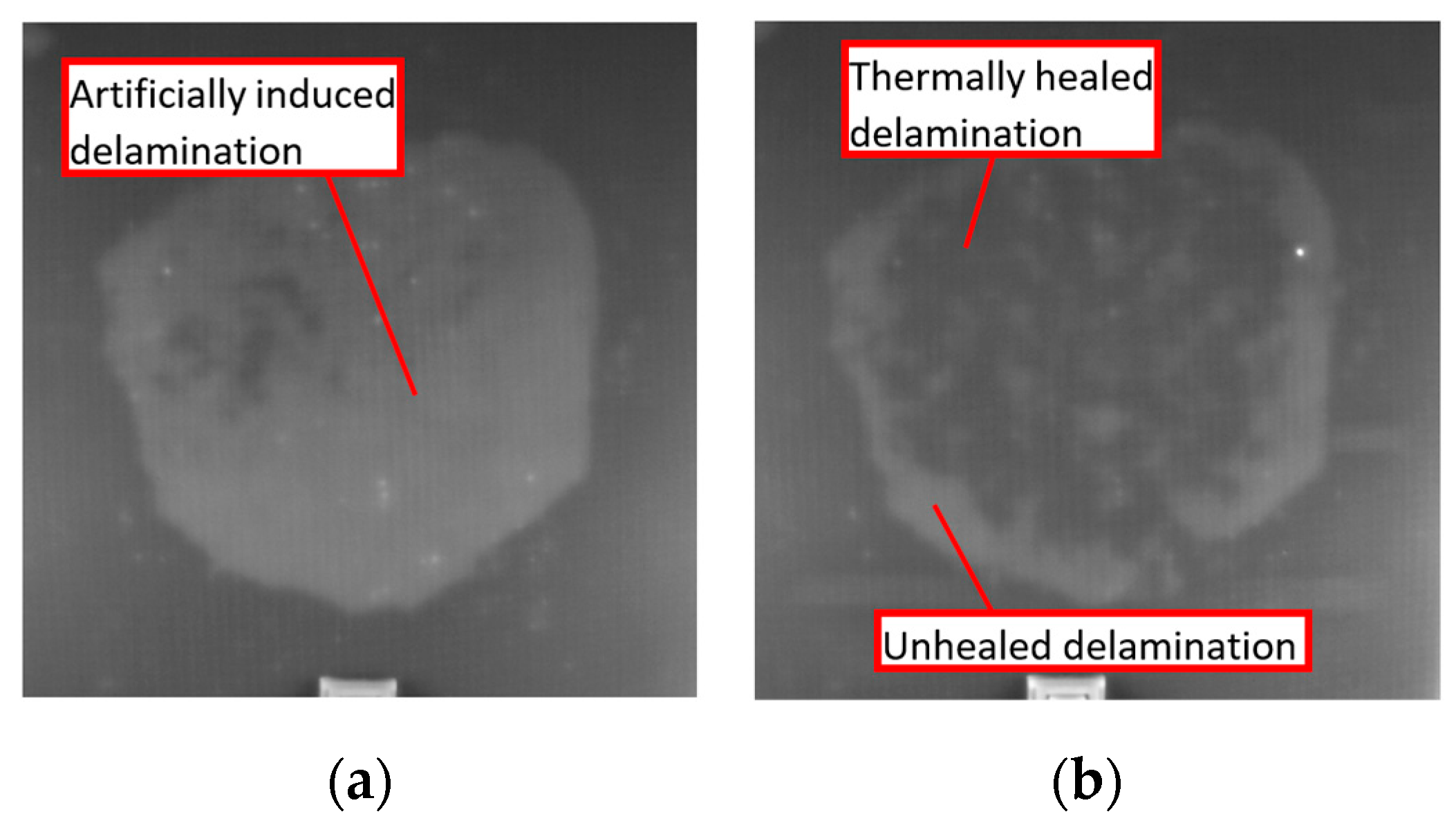

2.3. Non-Destructive Testing

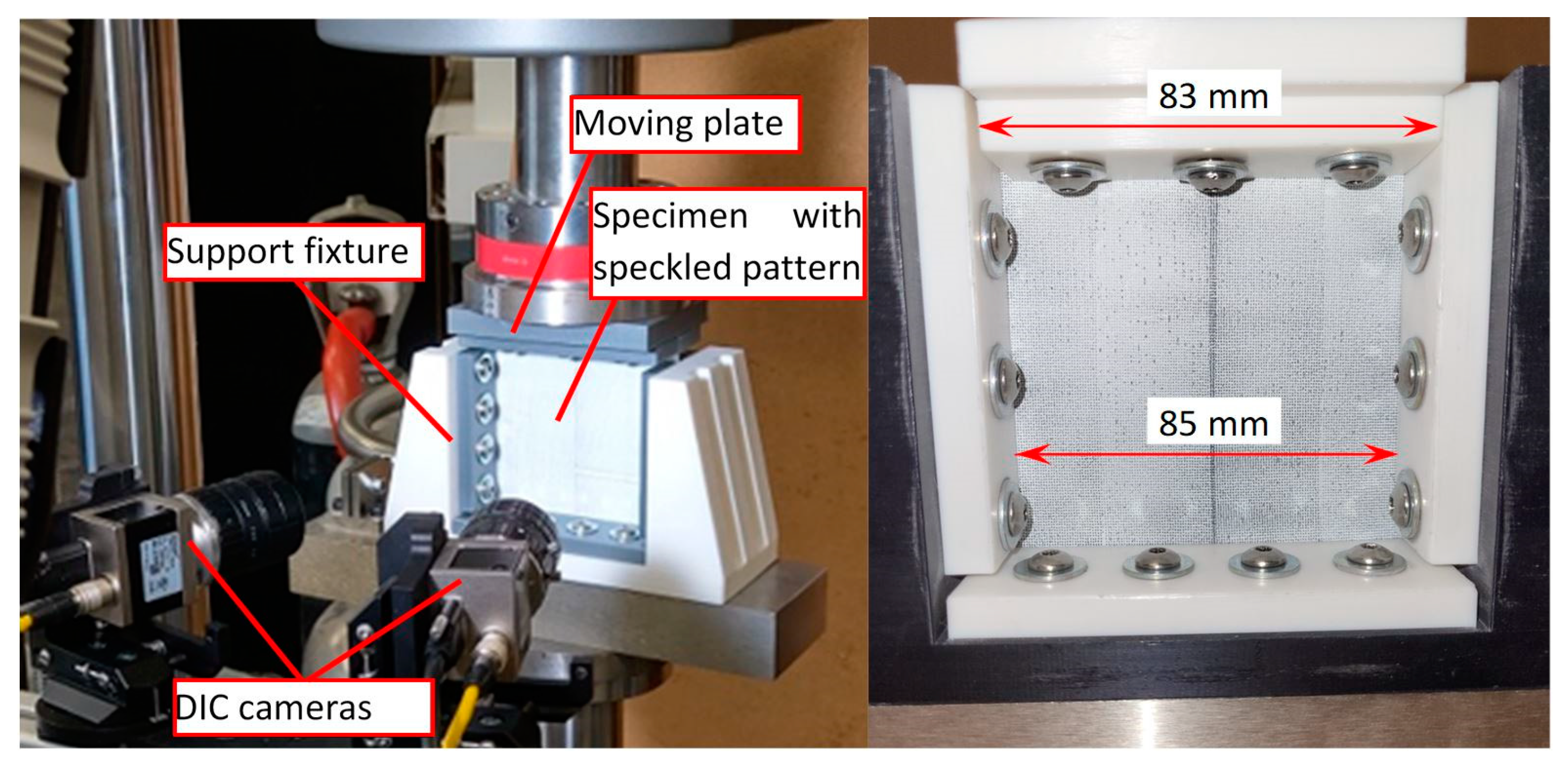

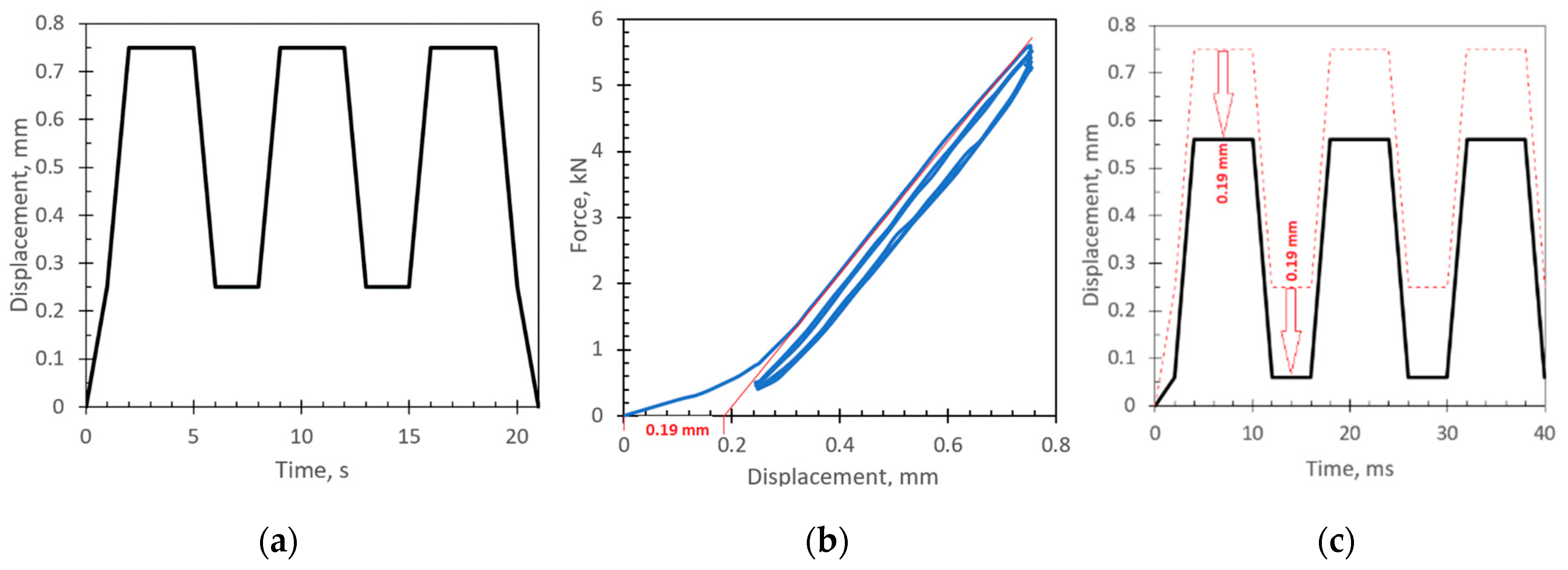

2.4. Compression after Impact Test

3. Results and Discussion

4. Conclusions

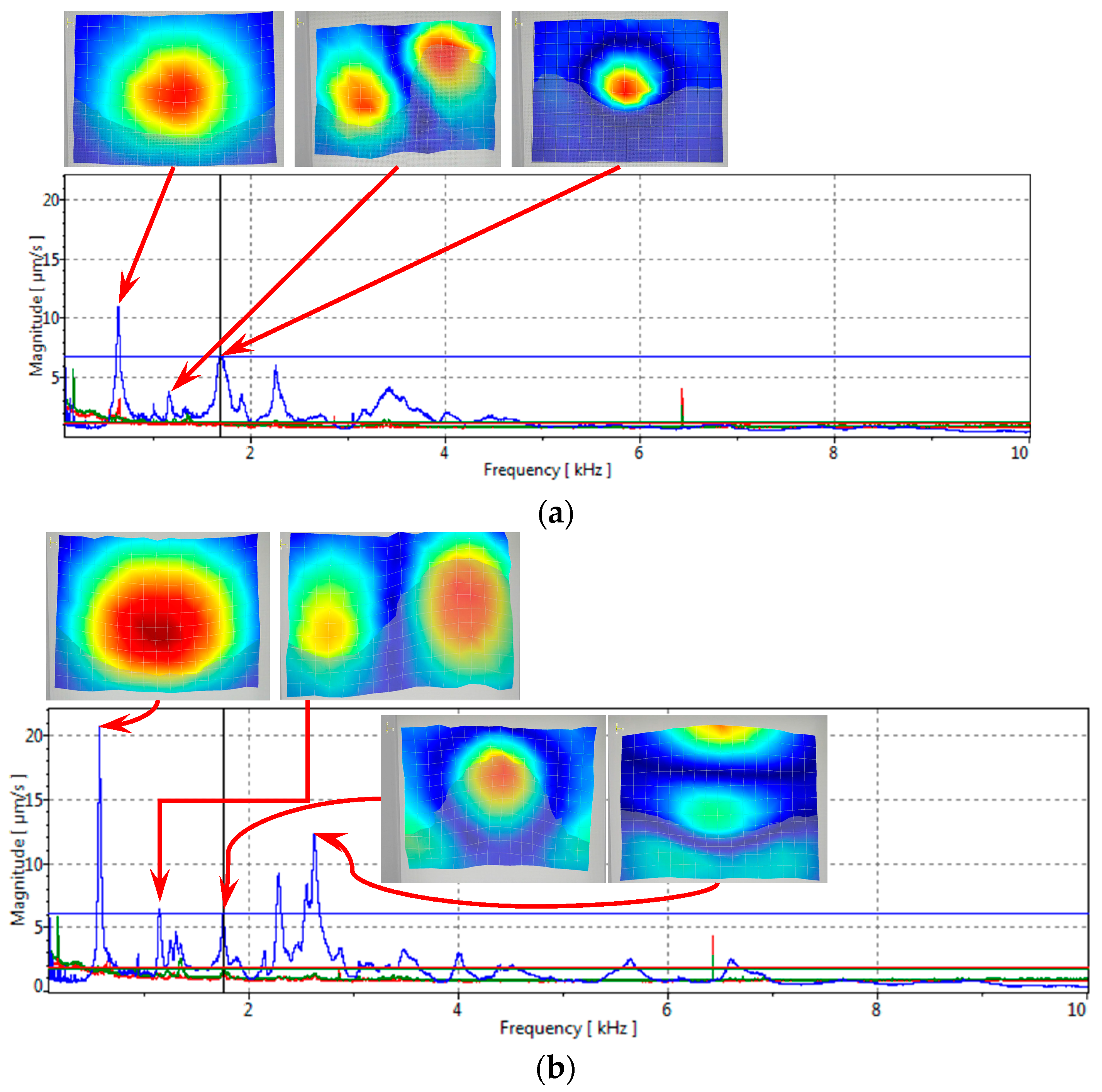

- The non-destructive testing by active thermography was useful to determine the size of delamination and see the presence of thermal healing, but it did not allow for a quantitative evaluation of the strength of the adhesion joint and confirm that healed areas are not the consequence of the kissing bond. Dynamical analysis performed by the 3D Laser Doppler Vibrometer shows the differences in amplitudes of surface velocities. The healed specimens having about 20% higher amplitudes compared to specimens with delamination confirms that the healed specimens being stiffer in the out-of-plane direction exhibit higher surface velocities;

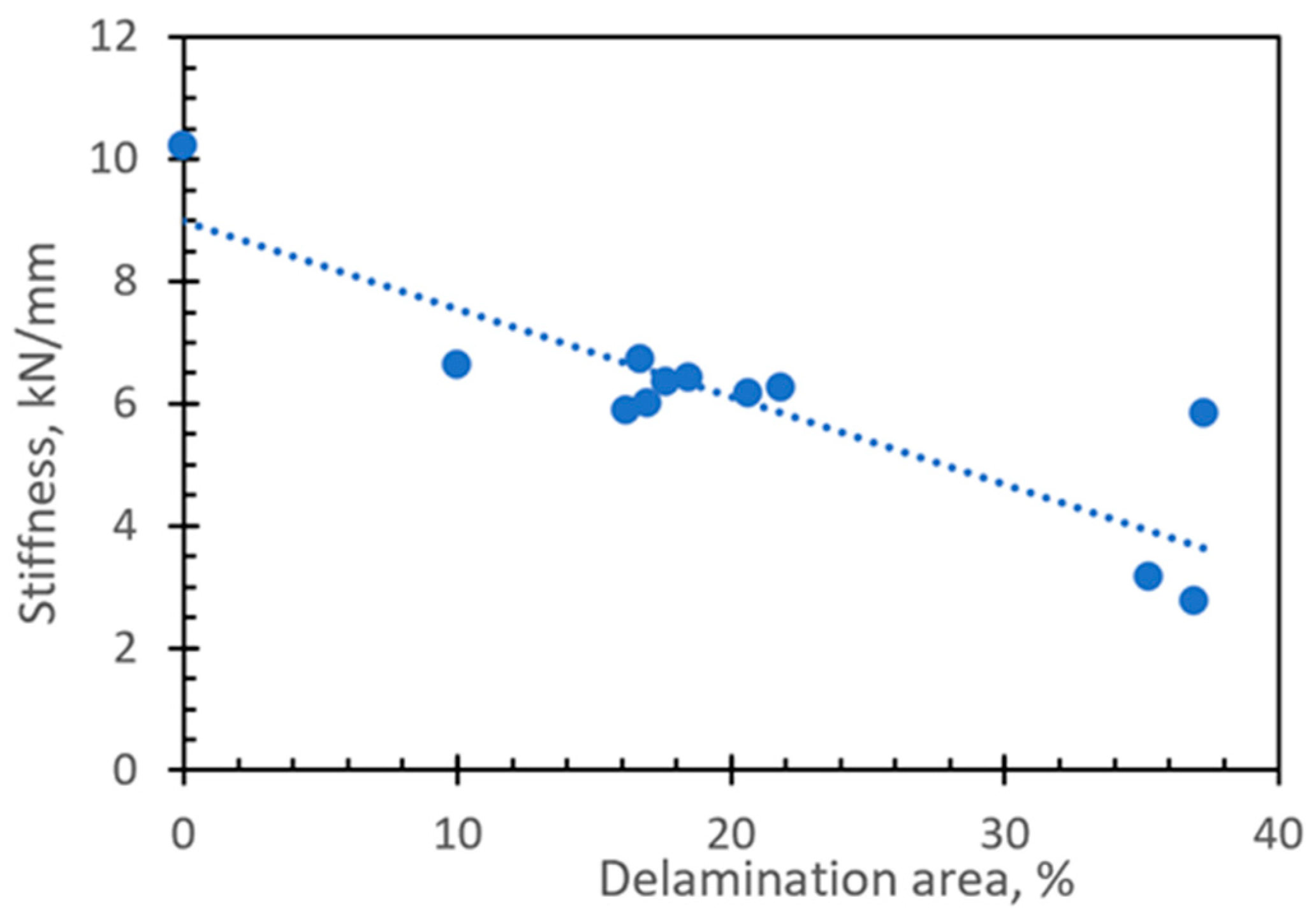

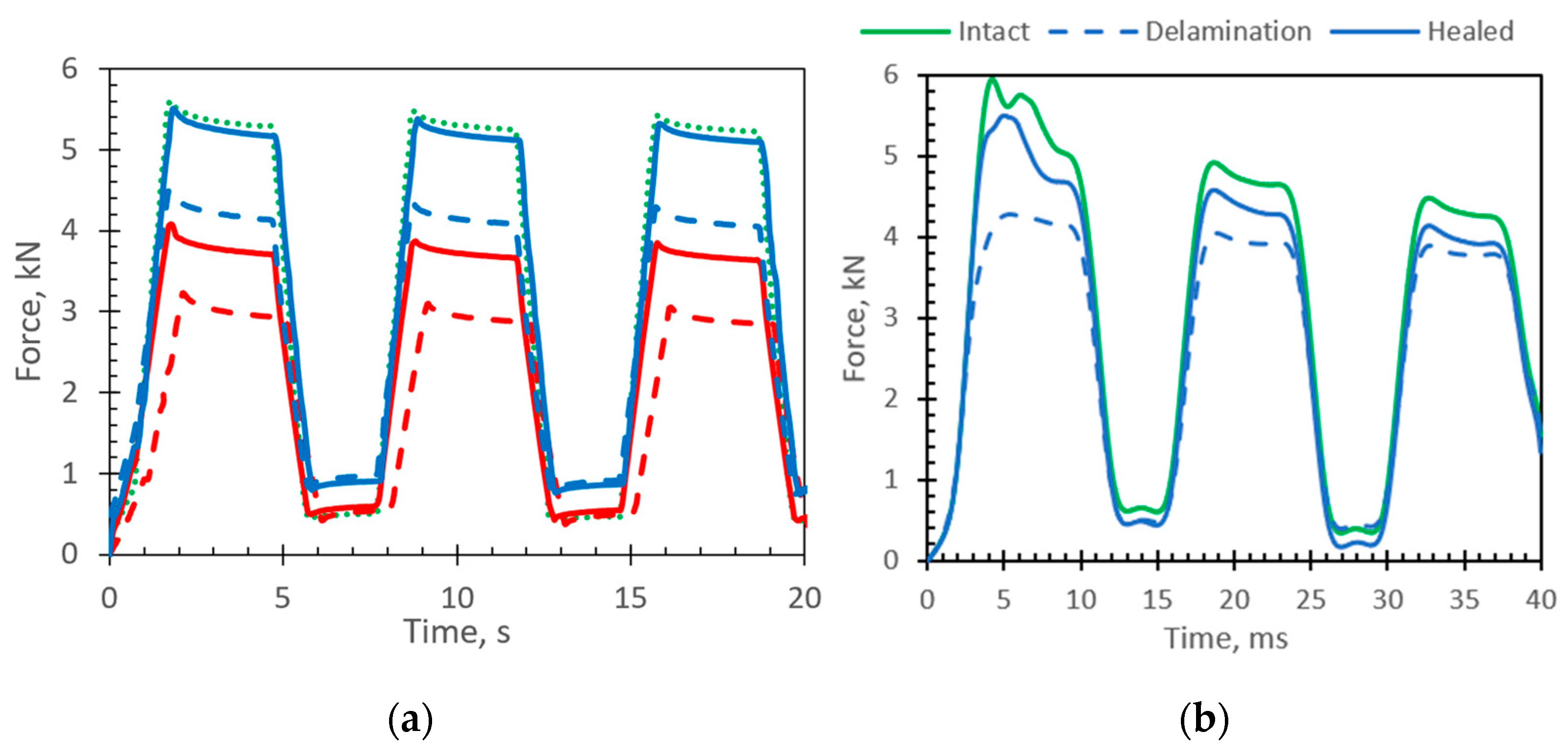

- Comparing experimentally obtained force vs. displacement curves, the correlation between the longitudinal stiffness of the composite plate and the delamination area was obtained. The stiffness of the specimen decreases with the increase in the size of the delamination area. Comparing the experimentally obtained responses of damaged and healed specimens to the cycling loading, the average effectiveness of healing was 29%;

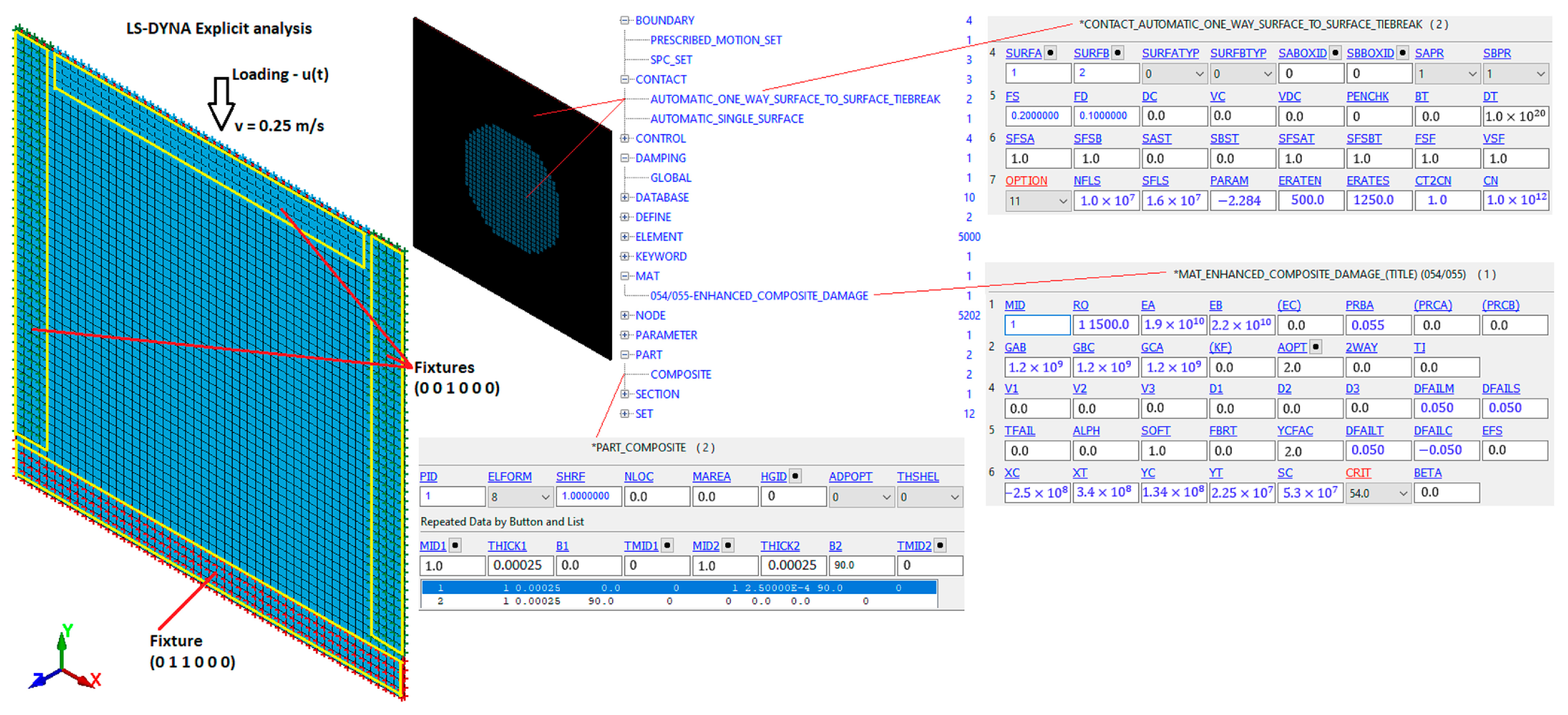

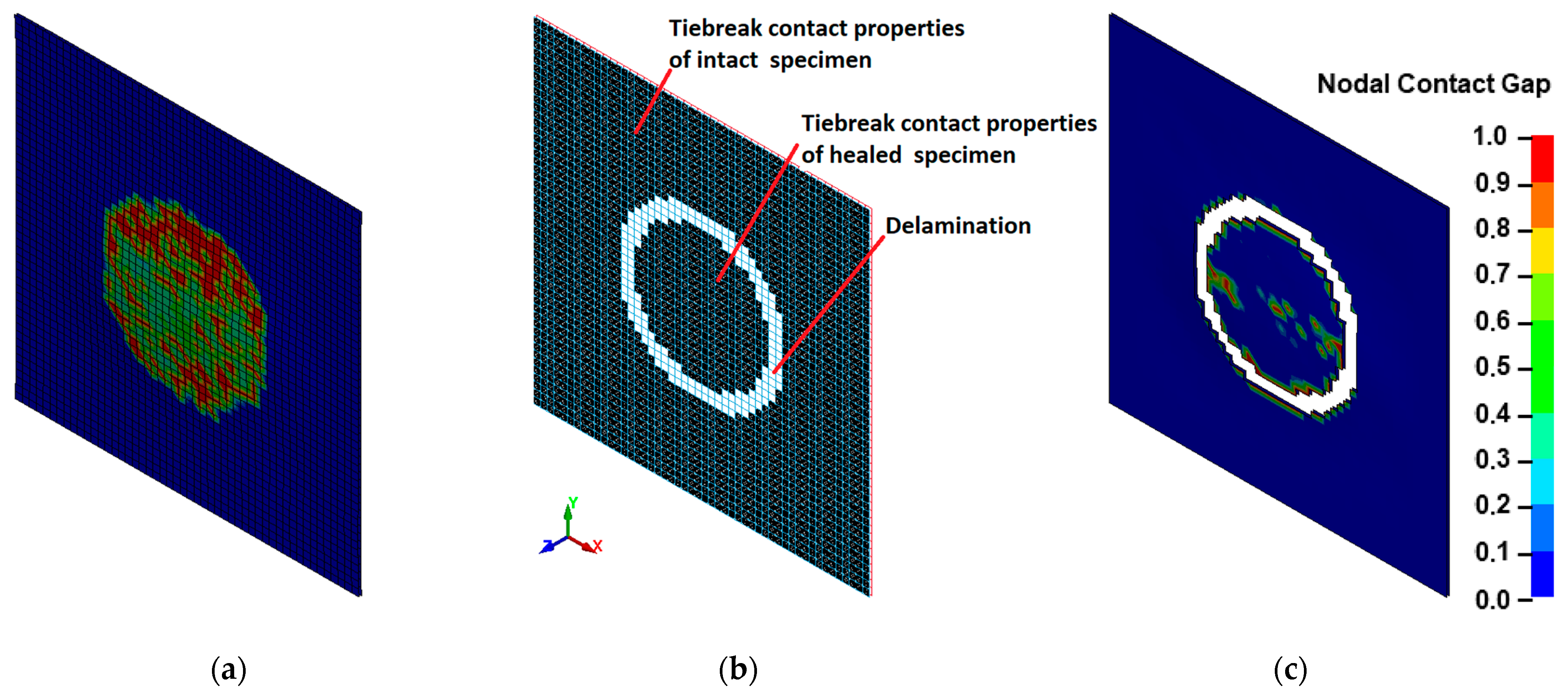

- To perform numerical analysis of composite plate delamination, the finite element model was developed with two layers of shell elements connected by tiebreak contact. The numerical model effectively captured the experimentally obtained shapes of the first buckling mode, which differs for intact and damaged specimens. The variation of reaction force well matches the experimentally obtained response. In cases of incompletely healed regions, the delamination damage starts around the unhealed areas and propagates towards the most stressed regions. It can be concluded that a numerical model with a tiebreak contact approach could be used to simulate and predict the behavior of intact, damaged, and healed composite plates.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Stewart, R. Thermoplastic composites—Recyclable and fast to process. Reinf. Plast. 2011, 55, 22–28. [Google Scholar] [CrossRef]

- Yousefpour, A.; Hojjati, M.; Immarigeon, J.-P. Fusion Bonding/Welding of Thermoplastic Composites. J. Thermoplast. Compos. Mater. 2004, 17, 303–341. [Google Scholar] [CrossRef]

- Process and Performance Evaluation of Ultrasonic, Induction and Resistance Welding of Advanced Thermoplastic Composites—Irene Fernandez Villegas, Lars Moser, Ali Yousefpour, Peter Mitschang, Harald EN Bersee. 2013. Available online: https://journals.sagepub.com/doi/10.1177/0892705712456031 (accessed on 30 August 2023).

- Robles, J.B.; Dubé, M.; Hubert, P.; Yousefpour, A.; Dub, M. Repair of thermoplastic composites: An overview. Adv. Manuf. Polym. Compos. Sci. 2022, 8, 68–96. [Google Scholar] [CrossRef]

- Nijhuis, P. Repair of thin walled thermoplastic structures by melting, an experimental research. Seico 2013, 13, 86–91. Available online: http://www.nlr.nl (accessed on 7 June 2023).

- Khan, T.; Hafeez, F.; Umer, R. Repair of Aerospace Composite Structures Using Liquid Thermoplastic Resin. Polymers 2023, 15, 1377. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Mode I fracture toughness and fractographic investigation of carbon fibre composites with liquid Methylmethacrylate thermoplastic matrix. Compos. B Eng. 2018, 134, 246–253. [Google Scholar] [CrossRef]

- Pini, T.; Caimmi, F.; Briatico-Vangosa, F.; Frassine, R.; Rink, M. Fracture initiation and propagation in unidirectional CF composites based on thermoplastic acrylic resins. Eng. Fract. Mech. 2017, 184, 51–58. [Google Scholar] [CrossRef][Green Version]

- Wong, J.; Altassan, A.; Rosen, D.W. Additive manufacturing of fiber-reinforced polymer composites: A technical review and status of design methodologies. Compos. B Eng. 2003, 255, 110603. [Google Scholar] [CrossRef]

- Obande, W.; Brádaigh, C.M.Ó.; Ray, D. Continuous Fibre-Reinforced Thermoplastic Acrylic-Matrix Composites Prepared by Liquid Resin Infusion—A Review. Compos. B Eng. 2021, 215, 108771. [Google Scholar] [CrossRef]

- Khan, T.; Irfan, M.S.; Cantwell, W.J.; Umer, R. Crack healing in infusible thermoplastic composite laminates. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106896. [Google Scholar] [CrossRef]

- Ouyang, T.; Sun, W.; Bao, R.; Tan, R. Effects of matrix cracks on delamination of composite laminates subjected to low-velocity impact. Compos. Struct. 2021, 262, 113354. [Google Scholar] [CrossRef]

- Li, W.; Palardy, G. Damage monitoring methods for fiber-reinforced polymer joints: A review. Compos. Struct. 2022, 299, 116043. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.M.; Farahani, M.; Zangl, H. Structural health monitoring of adhesive joints under pure mode I loading using the electrical impedance measurement. Eng. Fract. Mech. 2021, 245, 107585. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Roshanghias, A.; Araee, A.; Baniassadi, M.; Oberlercher, H.; Zangl, H. Impedance analysis for condition monitoring of single lap CNT-epoxy adhesive joint. Int. J. Adhes. Adhes. 2019, 88, 59–65. [Google Scholar] [CrossRef]

- Frederick, H.; Li, W.; Sands, W.; Tsai, E.; Palardy, G. Multifunctional Films For Fusion Bonding And Structural Health Monitoring of Thermoplastic Composite Joints. In Proceedings of the SAMPE 2020 Virtual Series, Virtual, 8 June 2020. [Google Scholar]

- Hua, J.; Xing, S.; An, S.; Chen, D.; Tang, J. Stitching Repair for Delaminated Carbon Fiber/Bismaleimide Composite Laminates. Polymers 2022, 14, 3557. [Google Scholar] [CrossRef]

- Cang, Y.; Hu, W.; Zhu, D.; Yang, L.; Hu, C.; Yuan, Y.; Wang, F.; Yang, B. In Situ Thermal Ablation Repair of Delamination in Carbon Fiber-Reinforced Thermosetting Composites. Energies 2022, 15, 6927. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2021, 32, 839–857. [Google Scholar] [CrossRef]

- Aïssa, B.; Therriault, D.; Haddad, E.; Jamroz, W. Self-Healing Materials Systems: Overview of Major Approaches and Recent Developed Technologies. Adv. Mater. Sci. Eng. 2012, 2012, 854203. [Google Scholar] [CrossRef]

- Post, W.; Cohades, A.; Michaud, V.; van der Zwaag, S.; Garcia, S.J. Healing of a glass fibre reinforced composite with a disulphide containing organic-inorganic epoxy matrix. Compos. Sci. Technol. 2017, 152, 85–93. [Google Scholar] [CrossRef]

- Javierre, E. Modeling self-healing mechanisms in coatings: Approaches and perspectives. Coatings 2019, 9, 122. [Google Scholar] [CrossRef]

- Wang, S.; Urban, M.W. Self-healing polymers. Nat. Rev. Mater. 2020, 5, 562–583. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.B.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Pittala, R.K.; Dhanaraju, G.; Ben, B.S.; Ben, B.A. Self-healing of matrix cracking and delamination damage assessment in microcapsules reinforced carbon fibre epoxy composite under flexural loading. Compos. Struct. 2022, 291, 115691. [Google Scholar] [CrossRef]

- Ahangaran, F.; Hayaty, M.; Navarchian, A.H.; Pei, Y.; Picchioni, F. Development of self-healing epoxy composites via incorporation of microencapsulated epoxy and mercaptan in poly(methyl methacrylate) shell. Polym. Test 2019, 73, 395–403. [Google Scholar] [CrossRef]

- Patrick, J.F.; Hart, K.R.; Krull, B.P.; Diesendruck, C.E.; Moore, J.S.; White, S.R.; Sottos, N.R. Continuous self-healing life cycle in vascularized structural composites. Adv. Mater. 2014, 26, 4302–4308. [Google Scholar] [CrossRef]

- Norris, C.J.; Bond, I.P.; Trask, R.S. The role of embedded bioinspired vasculature on damage formation in self-healing carbon fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 639–648. [Google Scholar] [CrossRef]

- Pittala, R.K.; Ben, B.S.; Ben, B.A. Self-healing performance assessment of epoxy resin and amine hardener encapsulated polymethyl methacrylate microcapsules reinforced epoxy composite. J. Appl. Polym. Sci. 2021, 138, 50550. [Google Scholar] [CrossRef]

- Chuang, Y.F.; Wu, H.C.; Yang, F.; Yang, T.J.; Lee, S. Cracking and healing in poly(methyl methacrylate): Effect of solvent. J. Polym. Res. 2016, 24, 2. [Google Scholar] [CrossRef]

- Post, W.; Kersemans, M.; Solodov, I.; Van Den Abeele, K.; García, S.J.; van der Zwaag, S. Non-destructive monitoring of delamination healing of a CFRP composite with a thermoplastic ionomer interlayer. Compos. Part A Appl. Sci. Manuf. 2017, 101, 243–253. [Google Scholar] [CrossRef]

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-healing composites: A state-of-the-art review. Compos. Part A Appl. Sci. Manuf. 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Madsen, B.; Lilholt, H. Physical and mechanical properties of unidirectional plant fibre composites—An evaluation of the influence of porosity. Compos. Sci. Technol. 2003, 63, 1265–1272. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Moshrefzadeh-Sani, H. On the constant parameters of Halpin-Tsai equation. Polymer 2016, 106, 14–20. [Google Scholar] [CrossRef]

- Affdl, J.C.H.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Naik, N.K.; Kumar, R.S. Compressive strength of unidirectional composites: Evaluation and comparison of prediction models. Compos. Struct. 1999, 46, 299–308. [Google Scholar] [CrossRef]

- Budiansky, B. Micromechanics. Comput. Struct. 1983, 16, 3–12. [Google Scholar] [CrossRef]

- Wool, R.P.; O’Connor, K.M. A theory crack healing in polymers. J. Appl. Phys. 1981, 52, 5953–5963. [Google Scholar] [CrossRef]

- Lin, C.B.; Lee, S.; Liu, K.S. Methanol-Induced crack healing in poly(methyl methacrylate). Polym. Eng. Sci. 1990, 30, 1399–1406. [Google Scholar] [CrossRef]

- Wei, L.; Chen, J. Characterization of delamination features of orthotropic CFRP laminates using higher harmonic generation technique: Experimental and numerical studies. Compos. Struct. 2022, 285, 115239. [Google Scholar] [CrossRef]

- Segers, J.; Kersemans, M.; Hedayatrasa, S.; Calderon, J.; Van Paepegem, W. Towards in-plane local defect resonance for non-destructive testing of polymers and composites. NDT E Int. 2018, 98, 130–133. [Google Scholar] [CrossRef]

- Solodov, I.; Kreutzbruck, M. Ultrasonic frequency mixing via local defect resonance for defect imaging in composites. Ultrasonics 2020, 108, 106221. [Google Scholar] [CrossRef] [PubMed]

- Segers, J.; Kersemans, M.; Verboven, E.; Hedayatrasa, S.; Calderon, J.; Van Paepegem, W. Investigation to local defect resonance for non-destructive testing of composites. Proceedings 2018, 2, 406. [Google Scholar]

- Lu, T.; Shen, H.-S.; Wang, H.; Chen, X. Compression-after-impact effect on postbuckling behavior of thermoplastic composite laminated plates. Aerosp. Sci. Technol. 2022, 121, 107384. [Google Scholar] [CrossRef]

- ASTM D7137; Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates. ASTM International: West Conshohocken, PA, USA, 2007.

- Wu, X.-F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2012, 129, 1383–1393. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. A Progressive Damage Model for Laminated Composites Containing Stress Concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Hashin, Z. Failure Criteria for Unidirectional Fiber Composites. J. Appl. Mech. 1980, 47, 329–334. [Google Scholar] [CrossRef]

- Tabiei, A.; Zhang, W. A Zero Thickness Cohesive Element Approach for Dynamic Crack Propagation using LS-DYNA®. In Proceedings of the 15th International LS-DYNA Conference, Dearborn, MI, USA, 10–12 June 2018. [Google Scholar]

- Dempsey, J.P.; Wei, Y. Fracture Toughness of S2 Columnar Freshwater Ice: Crack Length and Specimen Size Effects-Part II. 1989. Available online: https://www.researchgate.net/profile/John-Dempsey-4/publication/304010858_Fracture_toughness_of_S2_columnar_freshwater_ice_crack_length_and_specimen_size_effects_-_Part_II/links/5762a65008aee61395bef19a/Fracture-toughness-of-S2-columnar-freshwater-ice-crack-length-and-specimen-size-effects-Part-II.pdf (accessed on 3 August 2023).

- Yu, R.C.; Pandolfi, A.; Ortiz, M. A 3D cohesive investigation on branching for brittle materials. In IUTAM Symposium on Discretization Methods for Evolving Discontinuities; Springer: Berlin/Heidelberg, Germany, 2007; pp. 139–151. [Google Scholar]

- Turon, A.; Davila, C.G.; Camanho, P.P.; Costa, J. An engineering solution for mesh size effects in the simulation of delamination using cohesive zone models. Eng. Fract. Mech. 2007, 74, 1665–1682. [Google Scholar] [CrossRef]

- Aradian, A.; Raphaël, E.; De Gennes, P.G. Strengthening of a polymer interface: Interdiffusion and cross-linking. Macromolecules 2000, 33, 9444–9451. [Google Scholar] [CrossRef]

- Awaja, F. Autohesion of polymers. Polymer 2016, 97, 387–407. [Google Scholar] [CrossRef]

| Parameter | Units | Glass Fiber | PMMA (Exp) | UD Composite Ply | |||

|---|---|---|---|---|---|---|---|

| Exp | ROMMicromechanics | Calibrated | |||||

| Density | g/cm3 | 2.60 * | 1.185 | 1.47 | |||

| Fiber volume fraction | 0.34 | ||||||

| Matrix volume fraction | 0.50 | ||||||

| Void volume fraction | 0.16 | ||||||

| Tensile modulus | GPa | 73 * | 2.45 | 23.2 | 18.4 | 19.0 | |

| 2.1 | 2.53 | 2.2 | |||||

| Poisson ratio | 0.18 * | 0.4 | 0.18 | 0.26 | 0.26 | ||

| Shear modulus | GPa | 30.9 | 0.875 | - | 1.21 | 1.18 | |

| Tensile strength | MPa | 3400 * | 45 | 325 | 643 | 340 | |

| 16.7 | 15.4 | 22.5 | |||||

| Compressive strength | MPa | 117 | 242 | 250 | |||

| 134 | |||||||

| Shear strength | MPa | 53 | |||||

| Elongation at break | DFAILT | % | 3.5 * | 1.9 | 3.5 | 2.6 | |

| DFAILC | % | 2.5 | |||||

| DFAILM | % | 2.1 | 4.0 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Griskevicius, P.; Spakauskas, K.; Mahato, S.; Grigaliunas, V.; Raisutis, R.; Eidukynas, D.; Perkowski, D.M.; Vilkauskas, A. Experimental and Numerical Study of Healing Effect on Delamination Defect in Infusible Thermoplastic Composite Laminates. Materials 2023, 16, 6764. https://doi.org/10.3390/ma16206764

Griskevicius P, Spakauskas K, Mahato S, Grigaliunas V, Raisutis R, Eidukynas D, Perkowski DM, Vilkauskas A. Experimental and Numerical Study of Healing Effect on Delamination Defect in Infusible Thermoplastic Composite Laminates. Materials. 2023; 16(20):6764. https://doi.org/10.3390/ma16206764

Chicago/Turabian StyleGriskevicius, Paulius, Kestutis Spakauskas, Swarup Mahato, Valdas Grigaliunas, Renaldas Raisutis, Darius Eidukynas, Dariusz M. Perkowski, and Andrius Vilkauskas. 2023. "Experimental and Numerical Study of Healing Effect on Delamination Defect in Infusible Thermoplastic Composite Laminates" Materials 16, no. 20: 6764. https://doi.org/10.3390/ma16206764

APA StyleGriskevicius, P., Spakauskas, K., Mahato, S., Grigaliunas, V., Raisutis, R., Eidukynas, D., Perkowski, D. M., & Vilkauskas, A. (2023). Experimental and Numerical Study of Healing Effect on Delamination Defect in Infusible Thermoplastic Composite Laminates. Materials, 16(20), 6764. https://doi.org/10.3390/ma16206764