An Overview of Angle Deviations of Fiber-Reinforced Polymer Composite Angular Laminates

Abstract

1. Introduction

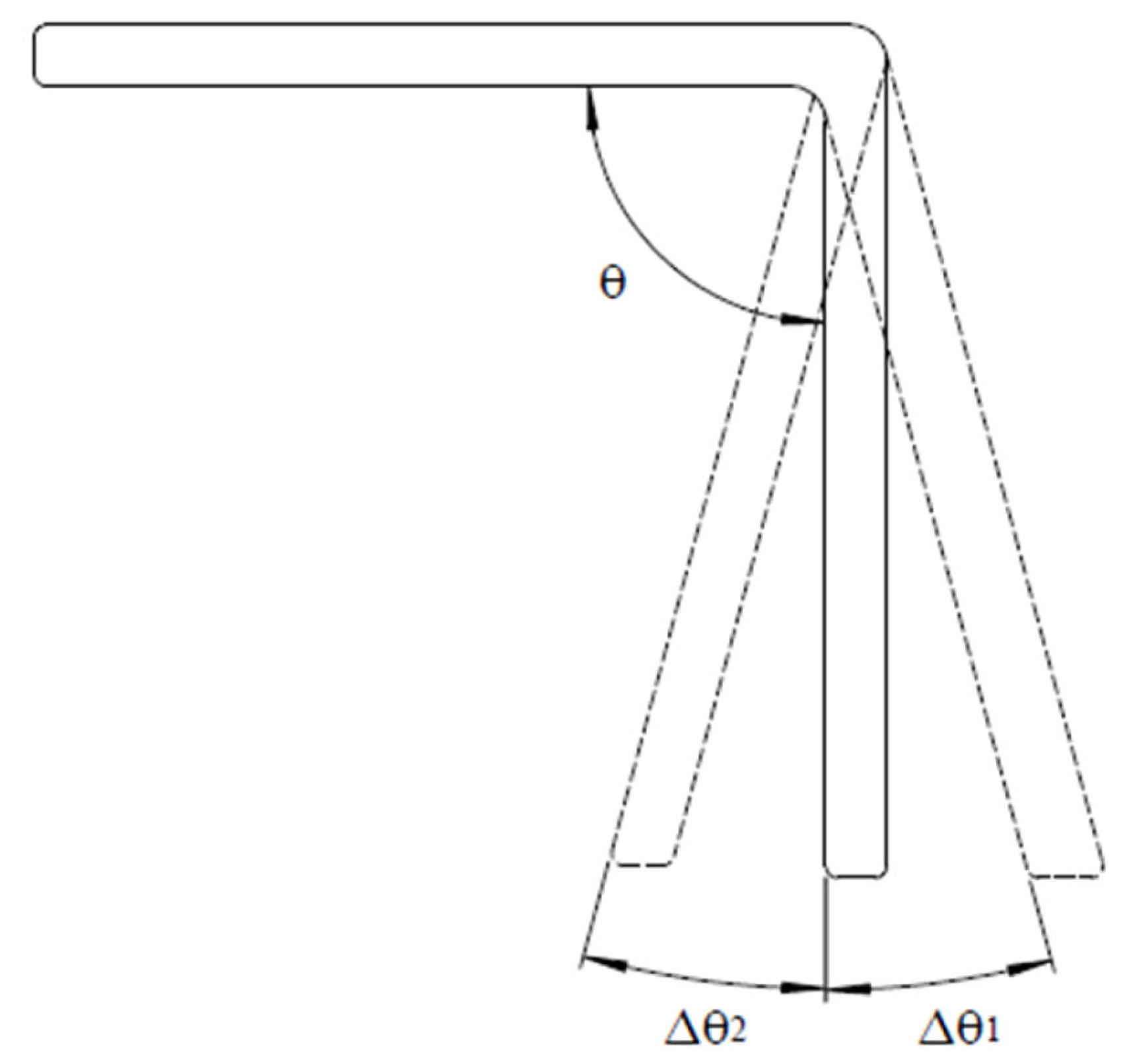

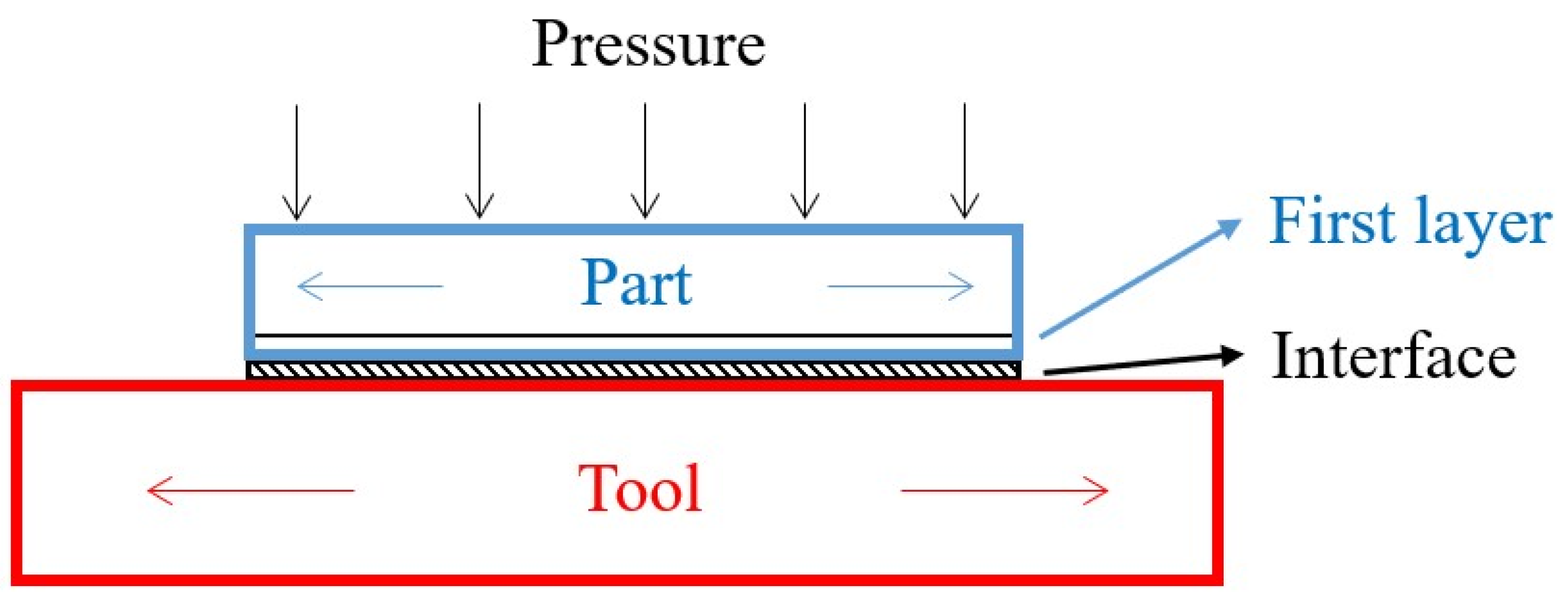

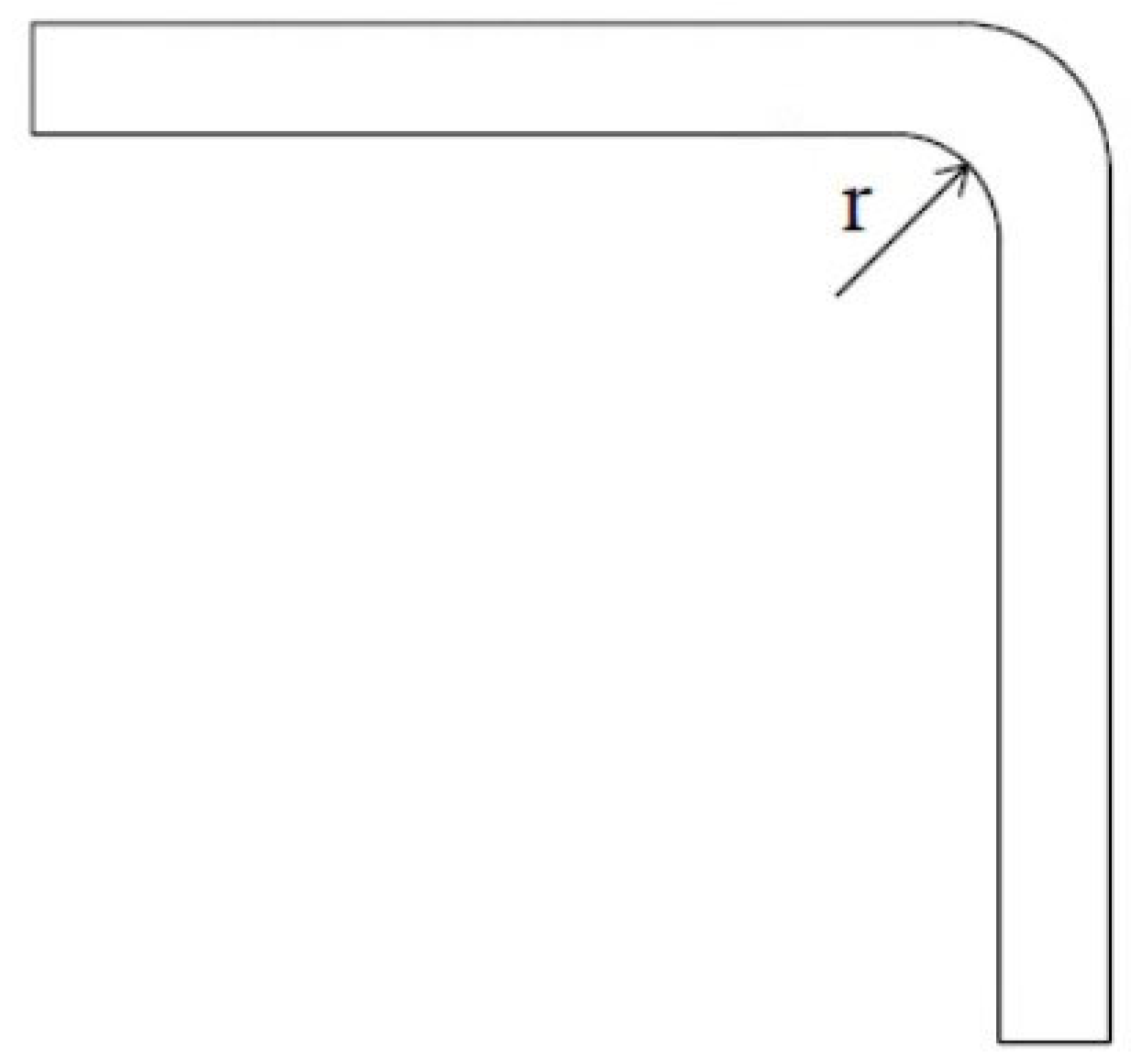

2. Parameter Effects from Experiments

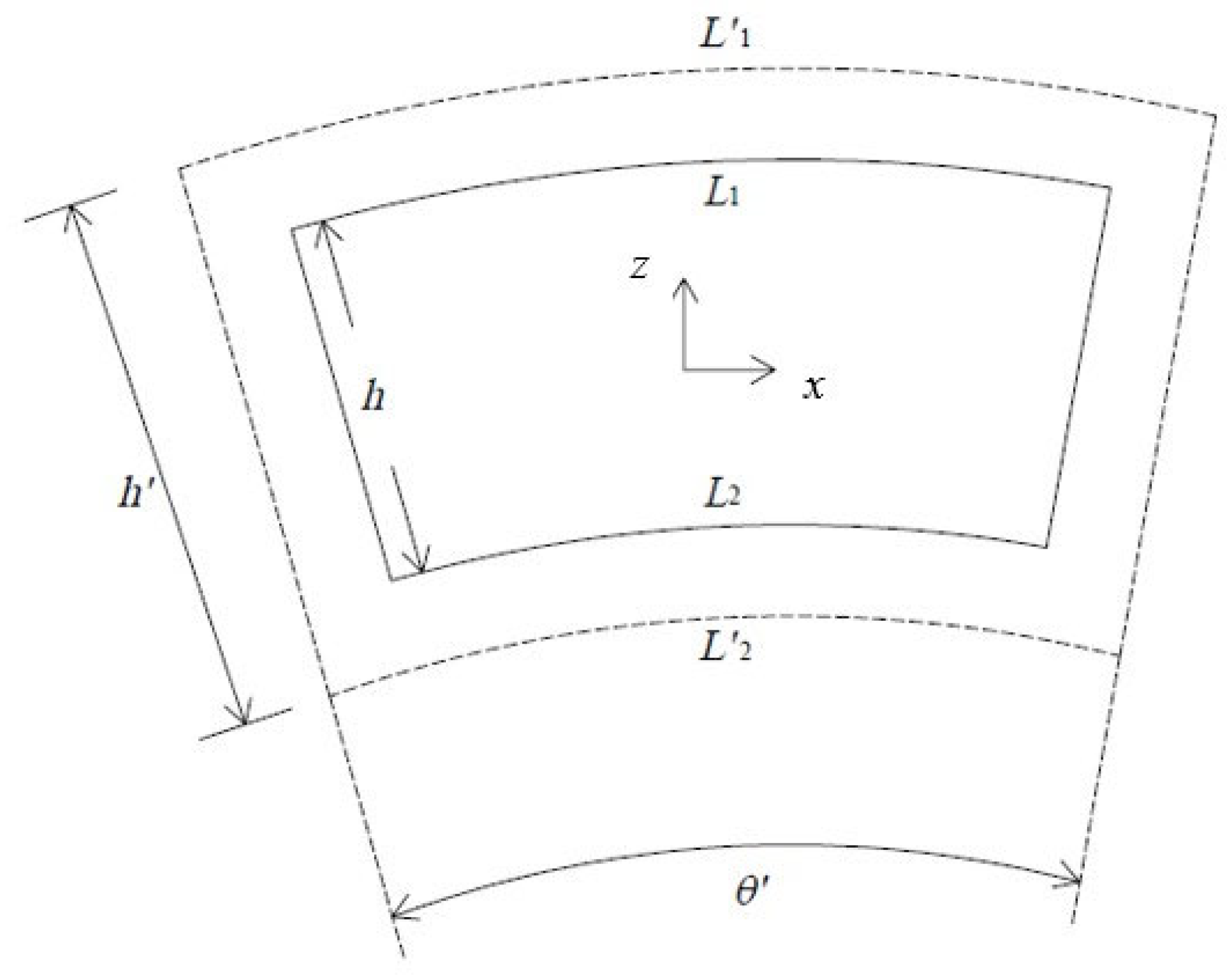

3. Simulation Methods for Angle Deviations

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mazumdar, S.K. Composites Manufacturing: Materials, Product, and Process Engineering; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Wang, B.; Fan, S.; Chen, J.; Yang, W.; Liu, W.; Li, Y. A review on prediction and control of curing process-induced deformation of continuous fiber-reinforced thermosetting composite structures. Compos. Part A Appl. Sci. Manuf. 2023, 165, 107321. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A review on the mechanical modeling of composite Manufacturing processes. Arch. Computat. Methods Eng. 2017, 24, 369–395. [Google Scholar] [CrossRef] [PubMed]

- Parlevliet, P.P.; Bersee, H.E.N.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature-part I: Formation of residual stresses. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1847–1857. [Google Scholar] [CrossRef]

- Parlevliet, P.P.; Bersee, H.E.N.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature-part II: Experimental techniques. Compos. Part A Appl. Sci. Manuf. 2007, 38, 651–665. [Google Scholar] [CrossRef]

- Parlevliet, P.P.; Bersee, H.E.N.; Beukers, A. Residual stresses in thermoplastic composites—A study of the literature-part III: Effect of thermal residual stresses. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1581–1596. [Google Scholar] [CrossRef]

- Albert, C.; Fernlund, G. Spring-in and warpage of angled composite laminates. Compos. Sci. Technol. 2002, 62, 1895–1912. [Google Scholar] [CrossRef]

- Hagnell, M.K.; Langbeck, B.; Akermo, M. Cost efficiency, integration and assembly of a generic composite aeronautical wing box. Compos. Struct. 2016, 152, 1014–1023. [Google Scholar] [CrossRef]

- Joosten, M.W.; Agius, S.; Hilditch, T.; Wang, C. Effect of residual stress on the matrix fatigue cracking of rapidly cured epoxt/anhydride composites. Compos. Part A Appl. Sci. Manuf. 2017, 101, 521–528. [Google Scholar] [CrossRef]

- Wang, H. Effect of spring-in deviation on fatigue life of composite elevator assembly. Appl. Compos. Mater. 2018, 25, 1357–1367. [Google Scholar] [CrossRef]

- Peng, X.; Xu, J.; Cheng, Y.; Li, Y.; Yang, J. The effect of curing deformation on the vibration behavior of laminated composite beams. Compos. Struct. 2021, 277, 114642. [Google Scholar] [CrossRef]

- Antunes, M.B.; Almeida, J.H.S., Jr.; Amico, S.C. Curing and seawater aging effects on mechanical and physical properties of glass/epoxy filament wound cylinders. Compos. Commun. 2020, 22, 100517. [Google Scholar] [CrossRef]

- Ma, H.L.; Tau, K.T.; Hui, D.; Shi, S.Q.; Poon, C.K. Theoretical analysis on the pullout behavior of carbon nanotube at cryogenic environment with the consideration of thermal residual stress. Compos. Part B Eng. 2017, 128, 67–75. [Google Scholar] [CrossRef]

- Nasir, M.N.M.; Mezeix, L.; Aminanda, Y.; Seman, M.A.; Rivai, A.; Ali, K.M. Spring-back simulation on unidirectional carbon/epoxy L-shaped laminate composites manufactured through autoclave processing. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012025. [Google Scholar] [CrossRef]

- Bapanapalli, S.K.; Smith, L.V. A linear finite element model to predict processing-induced distortion in FRP laminates. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1666–1674. [Google Scholar] [CrossRef]

- Peng, X.; Xu, J.; Cheng, Y.; Zhang, L.; Yang, J.; Li, Y. An analytical model for cure-induced deformation of composite Laminates. Polymers 2022, 14, 2903. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, Y.; Wang, J.; Wei, S.; Liu, T.; Cai, Y.; He, J.; Wang, W. A model on the curved shapes of unsymmetric laminates including tool-part interaction. Sci. Eng. Compos. Mater. 2018, 25, 1–8. [Google Scholar] [CrossRef]

- Radford, D.W.; Diefendorf, R.J. Shape instabilities in composites resulting from lamination anisotropy. J. Compos. Mater. 1993, 12, 58–75. [Google Scholar]

- Padovec, Z.; Ruzicka, M.; Chlup, H.; Stavrovsky, V. Springforward phenomenon of angular sections of composite materials—Analytical, numerical and experimental approach. Bull. Appl. Mech. 2011, 26, 31–36. [Google Scholar]

- Radford, D.W.; Rennic, T.S. Separating sources of manufacturing distortion in laminated composites. J. Reinf. Plast. Compos. 2000, 19, 621–641. [Google Scholar] [CrossRef]

- Zakaria, M.; Aminanda, Y.; Rashidi, S.A.; Mat Sah, M.A. Spring-back of thick uni-directional carbon fibre reinforced composite laminate for aircraft structure application. J. Phys. Conf. Ser. 2018, 1005, 012003. [Google Scholar] [CrossRef]

- Patel, A.; Kyavchenko, O.; Manas-Zloczower, I. Effect of curing rate on the microstructure and Macroscopic properties of epoxy fiberglass composites. Polymers 2018, 10, 125. [Google Scholar] [CrossRef]

- Nasir, M.N.M.; Seman, M.A.; Mezeix, L.; Aminanda, Y.; Rivai, A.; Ali, K.M. Effect of the corner angle on spring-back deformation for unidirectional L-shaped laminate composites manufactured through autoclave processing. ARPN J. Eng. Appl. Sci. 2016, 11, 315–318. [Google Scholar]

- Zakaria, M.; Shaik Dawood, M.S.I.; Aminanda, Y.; Rashidi, S.A.; Mat Sah, M.A. Spring-back of thick curved uni-directional carbon fibre reinforced composite laminate for aircraft structure application. Int. J. Recent Technol. Eng. 2019, 7, 224–228. [Google Scholar]

- Horberg, E.; Nyman, T.; Akermo, M.; Hallstrom, S. Thickness effect on spring-in of prepreg composite L-profiles—An experimental study. Compos. Struct. 2019, 209, 499–507. [Google Scholar] [CrossRef]

- Pereira, G.C.; LeBoulluec, P.; Lu, W.T.; Yoshida, M.I.; Alves, A.P.; Avila, A.F. Spring-back behavior on L-shaped composite structures: A statistical analysis of angular recovery as a function of time and residual cure. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105491. [Google Scholar] [CrossRef]

- Ersoy, N.; Garstka, T.; Potter, K.; Wisnom, M.R.; Porter, D.; Sringer, G. Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite. Compos. Part A Appl. Sci. Manuf. 2010, 41, 410–418. [Google Scholar] [CrossRef]

- Stephan, A.; Schwinge, E.; Muller, J.; Ory, H. On the springback effect of CFRP stringers: An experimental, analytical and numerical analysis. In Proceedings of the 28th International SAMPE Technical Conference, Covina, CA, USA, 25–28 March 1996; pp. 245–254. [Google Scholar]

- Patterson, J.M.; Springer, G.S.; Kollar, L.P. Experimental observations of the spring-in phenomenon. In Proceedings of the 8th International Conference on Composite Materials (ICCM8), Honolulu, HI, USA, 15–19 July 1991; pp. 10-D-1–10-D-8. [Google Scholar]

- Bellini, C.; Sorrentino, L.; Polini, W.; Corrado, A. Spring-in analysis of CFRP thin laminates: Numerical and experimental results. Compos. Struct. 2017, 173, 17–24. [Google Scholar] [CrossRef]

- Fernlund, G.; Rahman, N.; Courdji, R.; Bresslauer, M.; Poursartip, A.; Willden, K.; Nelson, K. Experimental and numerical study of the effect of cure cycle, tool surface, geometry, and the lay-up on the dimensional stability of autoclave-processed composite parts. Compos. Part A Appl. Sci. Manuf. 2002, 13, 341–351. [Google Scholar] [CrossRef]

- Horberg, E.; Akermo, M.; Hallstrom, S. Moisture effect on shape distortions of curved quasi-isotropic prepreg composite laminates. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106361. [Google Scholar] [CrossRef]

- Shah, D.B.; Patel, K.M.; Patel, A.I.; Pariyal, V.; Joshi, S.H. Experimental investigation on spring-back deformation during autoclave curing of parabolic antenna reflectors. Compos. Part A Appl. Sci. Manuf. 2018, 115, 134–146. [Google Scholar] [CrossRef]

- Kappel, E. Forced-interaction and spring-in—Relevant initiators of process-induced distortions in composite Manufacturing. Compos. Struct. 2016, 140, 217–229. [Google Scholar] [CrossRef]

- Sorrentino, L.; Bellini, C. Compaction influence on spring-in of thin composite parts: Experimental and numerical results. J. Compos. Mater. 2014, 49, 803–806. [Google Scholar] [CrossRef]

- White, S.R.; Hahn, H.T. Cure cycle optimization for the reduction of processing-induced residual stresses in composite materials. J. Compos. Mater. 1993, 27, 1352–1378. [Google Scholar] [CrossRef]

- Struzziero, G.; Nardi, D.; Sinke, J.; Teuwen, J.J.E. Cure-induced residual stresses for warpage reduction in thermoset laminates. J. Compos. Mater. 2020, 54, 3055–3065. [Google Scholar] [CrossRef]

- Mobarakian, M.; Safarabadi, M.; Farahani, M. Investigating the effects of cooling rate on distortion of asymmetric composite laminates. Compos. Struct. 2020, 236, 111875. [Google Scholar] [CrossRef]

- Salomi, A.; Garstka, T.; Potter, K.; Greco, A.; Maffezzoli, A. Spring-in angle as molding distortion for thermoplastic matrix composite. Compos. Sci. Technol. 2008, 68, 3047–3054. [Google Scholar] [CrossRef]

- Jain, L.K.; Hou, M.; Ye, L.; Mai, Y.W. Spring-in study of the aileron rib manufactured from advanced thermoplastic composite. Compos. Part A Appl. Sci. Manuf. 1998, 29, 973–979. [Google Scholar] [CrossRef]

- Engel, B.; Bruhmann, J. Mechanisms and sources of spring-in and spring-back of fiber reinforced thermoplastics. In Proceedings of the 58th Ilmenau Scientific Colloquium, Ilmenau, Germany, 8–12 September 2014. [Google Scholar]

- Han, P.; Butterfield, J.; Price, M.; Murphy, A.; Mullan, M. Part form prediction methods for carbon fibre reinforced composite materials. In Proceedings of the 18th International Conference on Composite Materials (ICCM-18), Jeju Island, Republic of Korea, 21–26 August 2011. [Google Scholar]

- Hwang, S.F.; Yu, C.X. Spring-in behavior of woven carbon fiber/polycarbonate thermoplastic composites. J. Thermoplast. Compos. Mater. 2023, 1–7. [Google Scholar] [CrossRef]

- Kim, C.G.; Kim, T.W.; Kim, I.G.; Jun, E.J. Spring-in deformation of composite laminated bends. In Proceedings of the 7th International Conference on Composite Materials (ICCM7), Guangzhou, China, 22–24 November 1989; pp. 83–88. [Google Scholar]

- Zhang, G.; Wang, J.; Ni, A. Process-induced stress and deformation of variable-stiffness composite cylinders during curing. Materials 2019, 12, 259. [Google Scholar] [CrossRef]

- Pagano, N.J. Thickness expansion coefficients of composite laminates. J. Compos. Mater. 1974, 8, 310–312. [Google Scholar] [CrossRef]

- Chamis, C. Simplified composite micromechanics equations for hygral thermal and mechanical properties. In Proceedings of the 38th Annual Conference, Reinforced Plastics/Composites Institute, Houston, TX, USA, 7–11 February 1983. [Google Scholar]

- Bogetti, T.A.; Gillespie, J.W., Jr. Process-induced stress and deformation in thick-section thermoset composite laminates. J. Compos. Mater. 1992, 26, 626–660. [Google Scholar] [CrossRef]

- Stango, R.J.; Wang, S.S. Process-induced residual thermal stresses in advanced fiber-reinforced composite laminates. J. Eng. Ind. Trans ASME 1984, 106, 48–54. [Google Scholar] [CrossRef]

- Ding, A.; Li, S.; Wang, J.; Zu, L. A three-dimensional thermoviscoelastic analysis of process-induced residual stress in composite laminates. Compos. Struct. 2015, 129, 60–69. [Google Scholar] [CrossRef]

- Kim, Y.K.; White, S.R. Stress relaxation behavior of 3501-6 epoxy resin during cure. Polym. Eng. Sci. 1996, 36, 2852–2862. [Google Scholar] [CrossRef]

- Kim, Y.K.; White, S.R. Viscoelastic analysis of processing-induced residual stresses in thick composite laminates. Mech. Compos. Mater. Struct. 1997, 4, 361–387. [Google Scholar] [CrossRef]

- White, S.R.; Kim, Y.K. Process-induced residual stress analysis of AS4/3501-6 composite material. Mech. Compos. Mater. Struct. 1998, 5, 153–186. [Google Scholar] [CrossRef]

- Kim, Y.K.; White, S.R. Cure-dependent viscoelastic residual stress analysis of filament-wound composite cylinders. Mech. Compos. Mater. Struct. 1999, 5, 327–354. [Google Scholar] [CrossRef]

- Svanberg, J.M.; Holmberg, J.A. Prediction of shape distortions Part I. FE-implementation of a path dependent constitutive model. Compos. Part A Appl. Sci. Manuf. 2004, 35, 711–721. [Google Scholar] [CrossRef]

- Svanberg, J.M.; Holmberg, J.A. Prediction of shape distortions Part II. Experimental validation and analysis of boundary conditions. Compos. Part A Appl. Sci. Manuf. 2004, 35, 723–734. [Google Scholar]

- Johnston, A.; Vaziri, R.; Poursartip, A. A plane strain model for process-induced deformation of laminated composite structures. J. Compos. Mater. 2001, 35, 1435–1469. [Google Scholar] [CrossRef]

- Johnston, A. An Integrated Model of the Development of Process-Induced Deformation in Autoclave Processing of Composite Structures; The University of British Columbia: Vancouver, BC, Canada, 1997. [Google Scholar]

- Wang, Q.; Yang, X.; Zhang, X.; Chang, X.; Yap, M.; Chen, Z.; Ren, M. Effect of cure cycles on residual stresses in thick composites using multi-physics coupled analysis with multiple constitutive models. Mater. Today Commun. 2022, 32, 104094. [Google Scholar] [CrossRef]

- Feng, Y.; Han, Z.; Li, R.; Zhang, W. Numerical modeling for curing of unidirectional carbon fiber reinforced polymer based on micromechanics in Laplace domain. Compos. Sci. Technol. 2022, 228, 109637. [Google Scholar] [CrossRef]

- Ersoy, N.; Garstka, T.; Potter, K.; Wisnom, M.R.; Porter, D.; Clegg, M.; Stringer, G. Development of the properties of a carbon fibre reinforced thermoset composite through cure. Compos. Part A Appl. Sci. Manuf. 2010, 41, 401–409. [Google Scholar] [CrossRef]

- Wiersma, H.W.; Peeters, L.J.B.; Akkerman, R. Prediction of springforward in continuous-fibre/polymer L-shaped parts. Compos. Part A Appl. Sci. Manuf. 1998, 29, 1333–1342. [Google Scholar] [CrossRef]

- Huetink, J.; Vreede, P.T.; van der Lugt, J. Progress in mixed Eulerian-Lagragian finite element simulation of forming processes. Int. J. Numer. Methods Eng. 1990, 30, 1441. [Google Scholar] [CrossRef]

- Kim, Y.K. Process-induced residual stress analysis by resin transfer molding. J. Compos. Mater. 2004, 38, 959–972. [Google Scholar] [CrossRef]

- Clifford, S.; Jansson, N.; Yu, W.; Michaud, V.; Manson, J.A. Thermoviscoelastic anisotropic analysis of process induced residual stresses and dimensional stability in real polymer matrix composite components. Compos. Part A Appl. Sci. Manuf. 2006, 37, 538–545. [Google Scholar] [CrossRef]

- Fiorina, M.; Seman, A.; Castanie, B.; Ali, K.M.; Schwob, C.; Mezeix, L. Spring-in prediction for carbon/epoxy aerospace composite structure, Compos. Struct. 2017, 168, 739–745. [Google Scholar]

- Mezeix, L.; Seman, A.; Nasir, M.N.M.; Aminanda, Y.; Rivai, A.; Castanie, B.; Olivier, P.; Ali, K.M. Spring-back simulation of unidirectional carbon/epoxy flat laminate composite manufactured through autoclave process. Compos. Struct. 2015, 124, 196–205. [Google Scholar] [CrossRef]

- Mezeix, L.; Nasir, M.N.M.; Aminanda, Y.; Rivai, A.; Ali, K.M. Parameter study of tool-laminate interface through simulation for composite manufacturing using autoclave process. Appl. Mech. Mater. 2014, 606, 113–117. [Google Scholar] [CrossRef]

- Patil, A.; Moheimani, R.; Shakhfeh, T.; DAlir, H. Analysis of spring-in for composite plates using ANSYS composite cure simulation. In Proceedings of the American Society for Composites—Thirty-Fourth Technical Conference, Atlanta, GA, USA, 23–25 September 2019. [Google Scholar]

- Khoun, L.; Centea, T.; Hubert, P. Characterization methodology of thermoset resins for the processing of composite materials- case study: CYCOM 890 RTM epoxy resin. J. Compos. Mater. 2009, 44, 1397–1415. [Google Scholar] [CrossRef]

- Liu, X.; Guan, Z.; Wang, X.; Jiang, T.; Geng, K.; Li, Z. Study on cure-induced residual stresses and spring-in deformation of L-shaped composite laminates using a simplified constitutive model considering stress relaxation. Compos. Struct. 2021, 272, 114203. [Google Scholar] [CrossRef]

- Courtois, A.; Marcin, L.; Benavente, M.; Ruiz, E.; Levesque, M. Numerical multiscale homogenization approach for linearly viscoelastic 3d interlock woven composites. Int. J. Solids Struct. 2019, 163, 61–74. [Google Scholar] [CrossRef]

- Qiao, W.; Yao, W. Modelling of process-induced deformation for composite parts considering tool-part interaction. Materials 2020, 13, 4503. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, S.W.; Lee, I. Evaluation of curing process-induced deformation in plain woven composite structures based on cure kinetics considering various fabric parameters. Compos. Struct. 2022, 287, 115379. [Google Scholar] [CrossRef]

- Jain, L.K.; Mai, Y.W. Stresses and deformations induced during manufacturing, part I: Theoretical analysis of composite cylinders and shells. J. Compos. Mater. 1997, 31, 672–695. [Google Scholar] [CrossRef]

- Jain, L.K.; Lutton, B.G.; Mai, Y.W.; Paton, R. Stresses and deformations induced during manufacturing, part II: A study of the spring-in phenomenon. J. Compos. Mater. 1997, 31, 696–719. [Google Scholar] [CrossRef]

| Spring-in | Spring-back | ||||

|---|---|---|---|---|---|

| Increase | Little | Decrease | Increase | Decrease | |

| Part angle | [14,23] | [24] | |||

| Part thickness | [28] | [29] | [7,20,25,26,27,44] | [24,33] | |

| Flange size | [7] | [24] | |||

| Corner radius | [29,30] | ||||

| Lay-up sequence (cross-ply, quasi-isotropic) | [7,27,30,31] | [29] | [33] | ||

| Tool material | [7] (Al) | [33] (Invar) | |||

| Tool surface (release agent + FEP) | [31] | [7,31] | |||

| Cure cycle (two-stage) | [7,31] | [33] | |||

| Ref. | Resin | Micro. | Macro. | Interface | Shape | Error |

|---|---|---|---|---|---|---|

| [40] | Equation (3) | SC | CTM | Shear layer (tool) | L, U | Good, Bad |

| [13] | Equation (5) | FEM | CTM | Sliding (no tool) | C | Good |

| [46] | Equation (4) | CTM | No slip (tool) | L | Bad | |

| [51] | Equation (4) | CTM | Contact (tool) | V | Bad | |

| [52] | CTM | Shear layer (no tool) | L, U | Reasonable | ||

| [53] | Global + Local | Interface (tool) | Rib | Reasonable | ||

| [8] | TM | Interface (tool) | L | Good | ||

| [16] | Equation (5) | TC + TM | Contact (tool) | L, U | Reasonable | |

| [17] | CTM | Shear layer (tool) | L, C | Good, Bad | ||

| [56] | TC + TM | Frictionless support | L | Reasonable | ||

| [71] | Equations (3) and (5) | FEM | CTM | Friction (tool) | L | Reasonable |

| [73] | Equation (5) | SC | CTM | Shear layer (tool) | L, U | Good |

| [74] | Equation (4) | SC | CTM | Fixed corner (no tool) | L |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, S.-F. An Overview of Angle Deviations of Fiber-Reinforced Polymer Composite Angular Laminates. Materials 2023, 16, 4844. https://doi.org/10.3390/ma16134844

Hwang S-F. An Overview of Angle Deviations of Fiber-Reinforced Polymer Composite Angular Laminates. Materials. 2023; 16(13):4844. https://doi.org/10.3390/ma16134844

Chicago/Turabian StyleHwang, Shun-Fa. 2023. "An Overview of Angle Deviations of Fiber-Reinforced Polymer Composite Angular Laminates" Materials 16, no. 13: 4844. https://doi.org/10.3390/ma16134844

APA StyleHwang, S.-F. (2023). An Overview of Angle Deviations of Fiber-Reinforced Polymer Composite Angular Laminates. Materials, 16(13), 4844. https://doi.org/10.3390/ma16134844