Influence of Carbonation on the Properties of Steel Slag–Magnesium Silicate Hydrate (MSH) Cement

Abstract

:1. Introduction

2. Materials and Methods

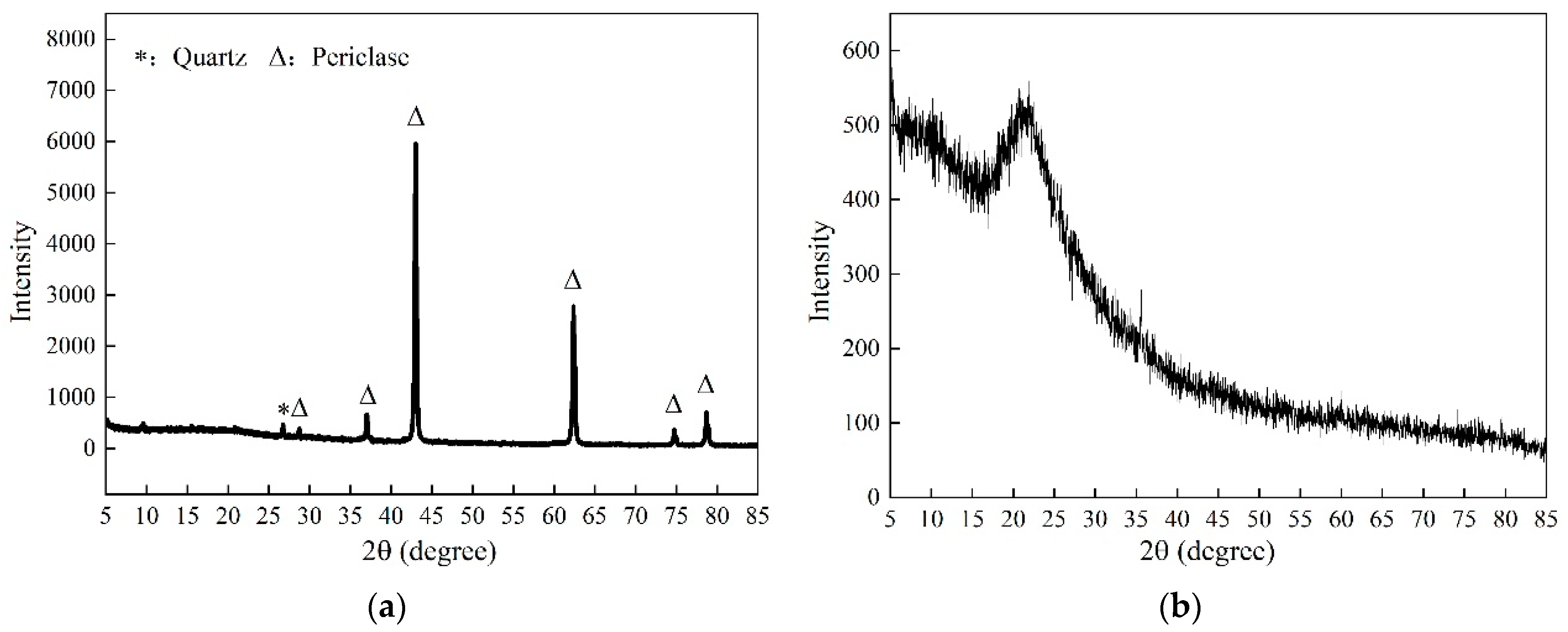

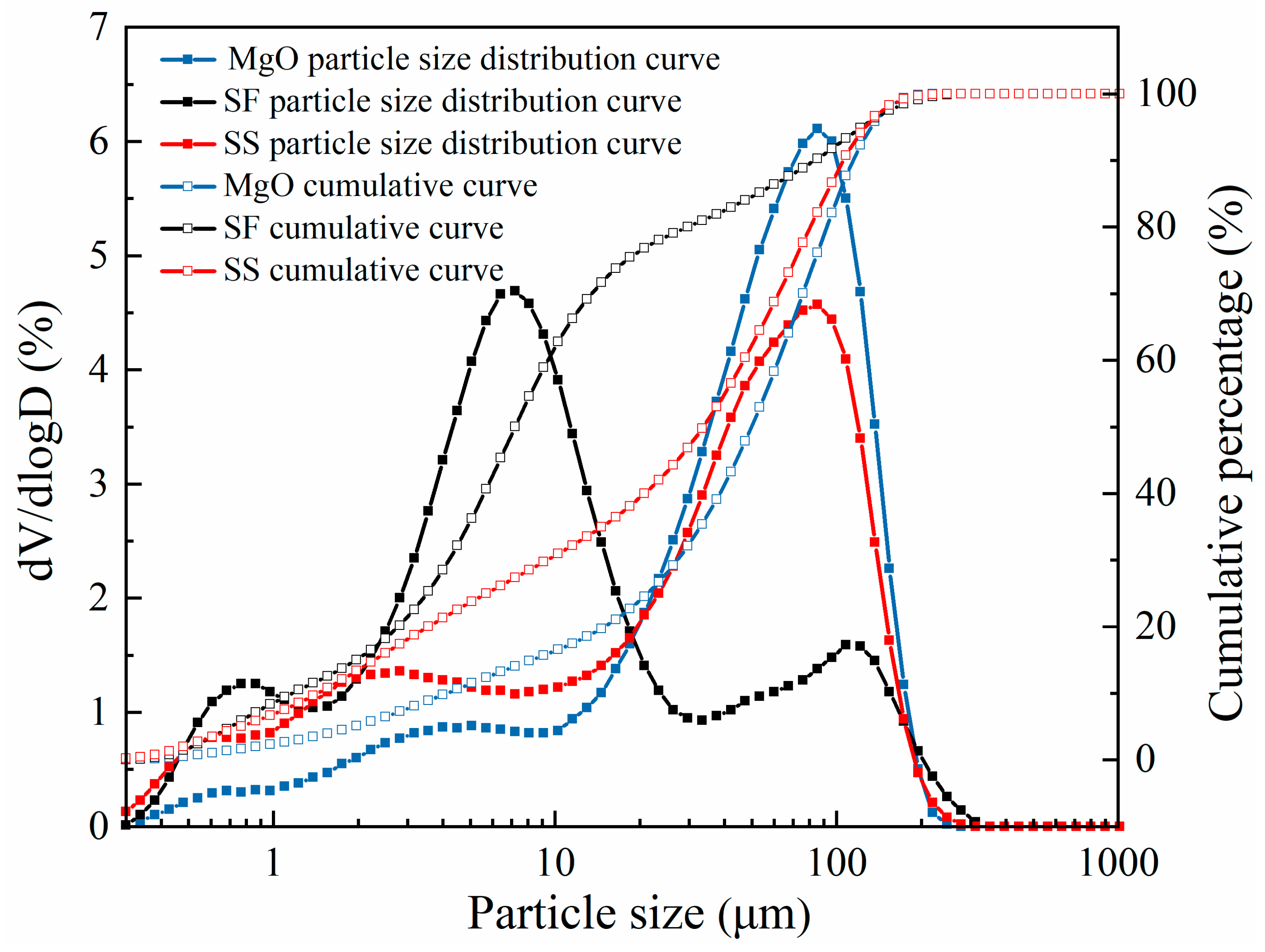

2.1. Raw Materials

2.2. Experimental Methods

2.3. Test and Analysis Methods

3. Results and Discussion

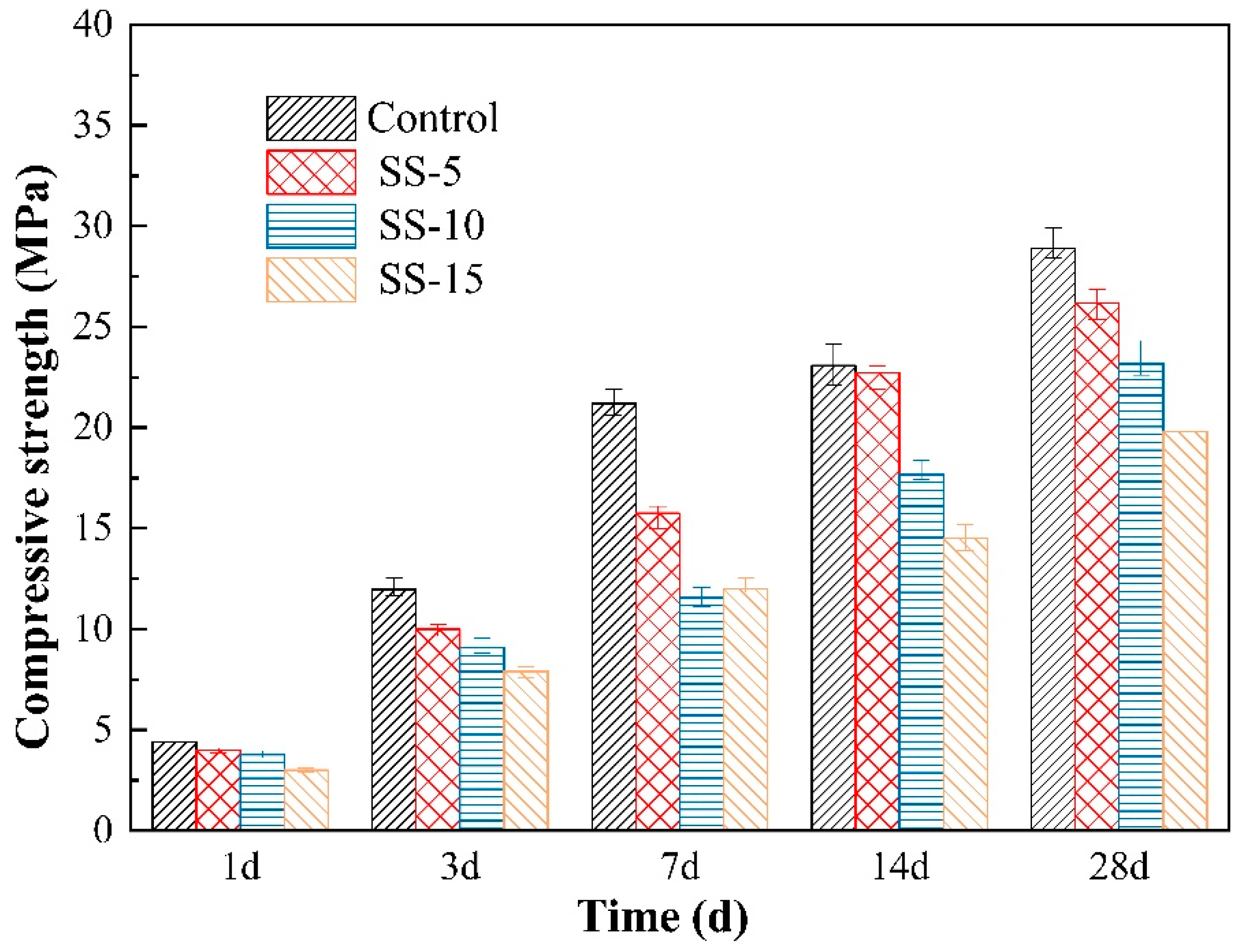

3.1. Effect of Atmospheric Carbonation on SS–MSH Cement

3.1.1. Setting Time

3.1.2. Compressive Strength

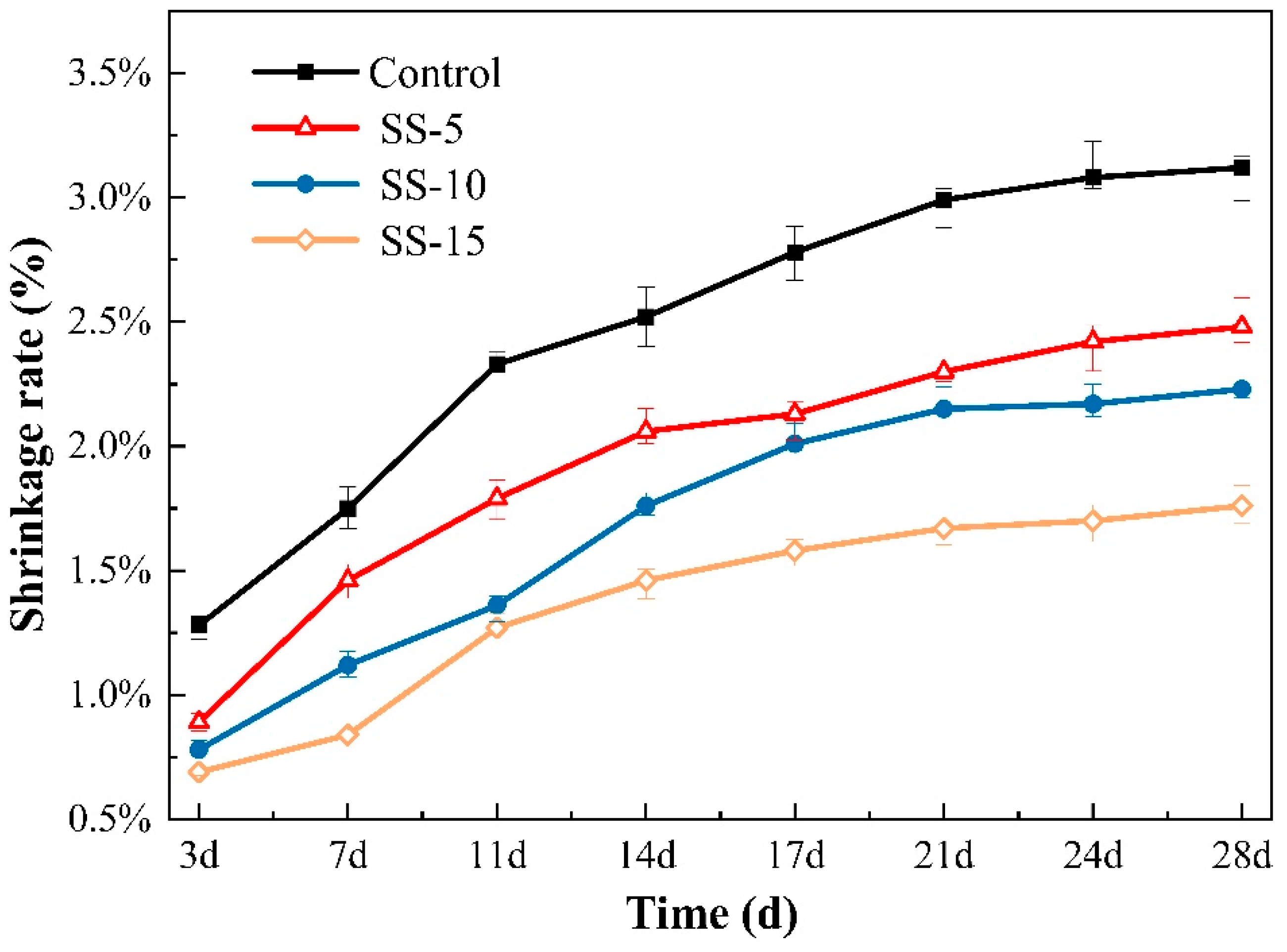

3.1.3. Shrinkage Rate

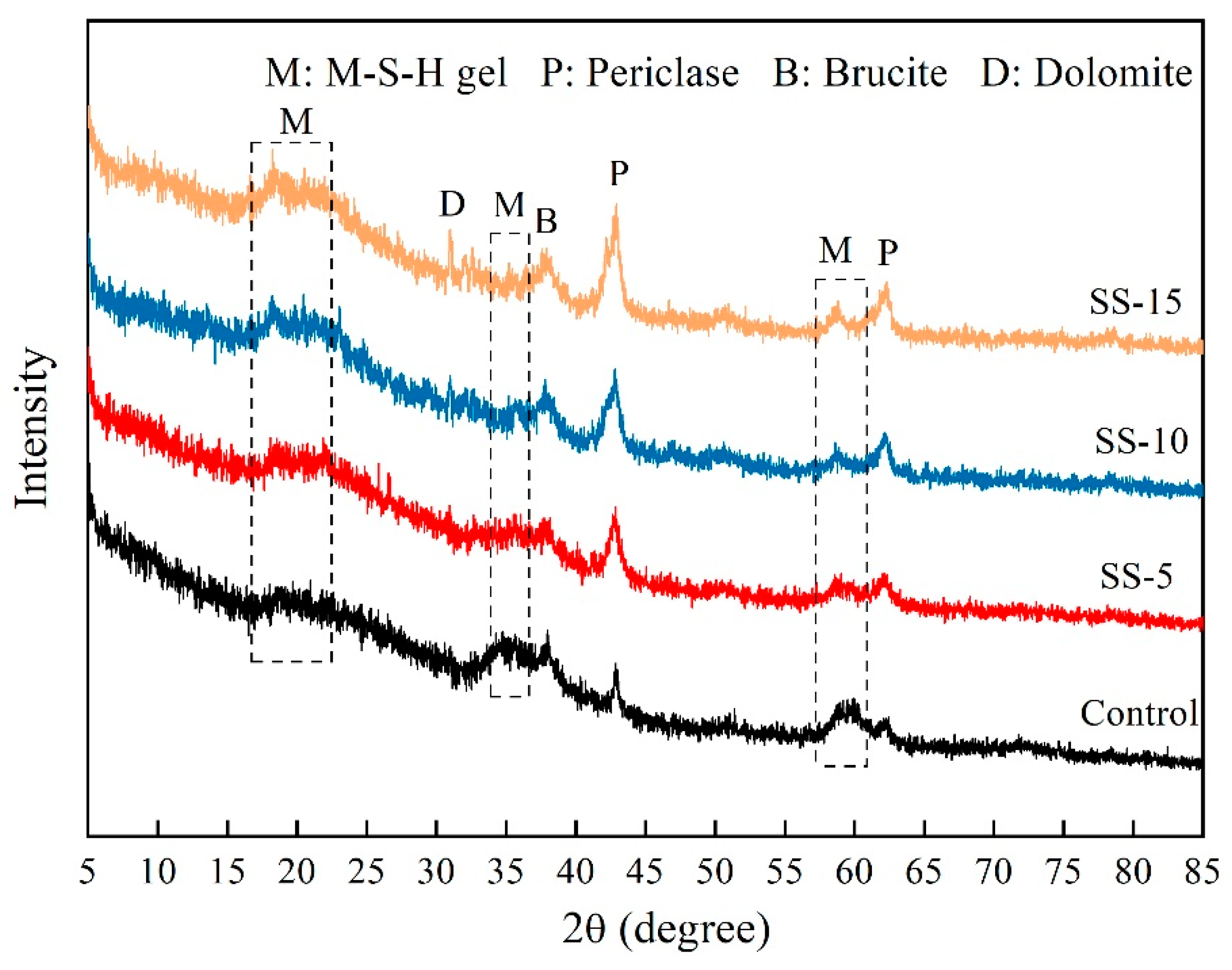

3.1.4. XRD Analysis

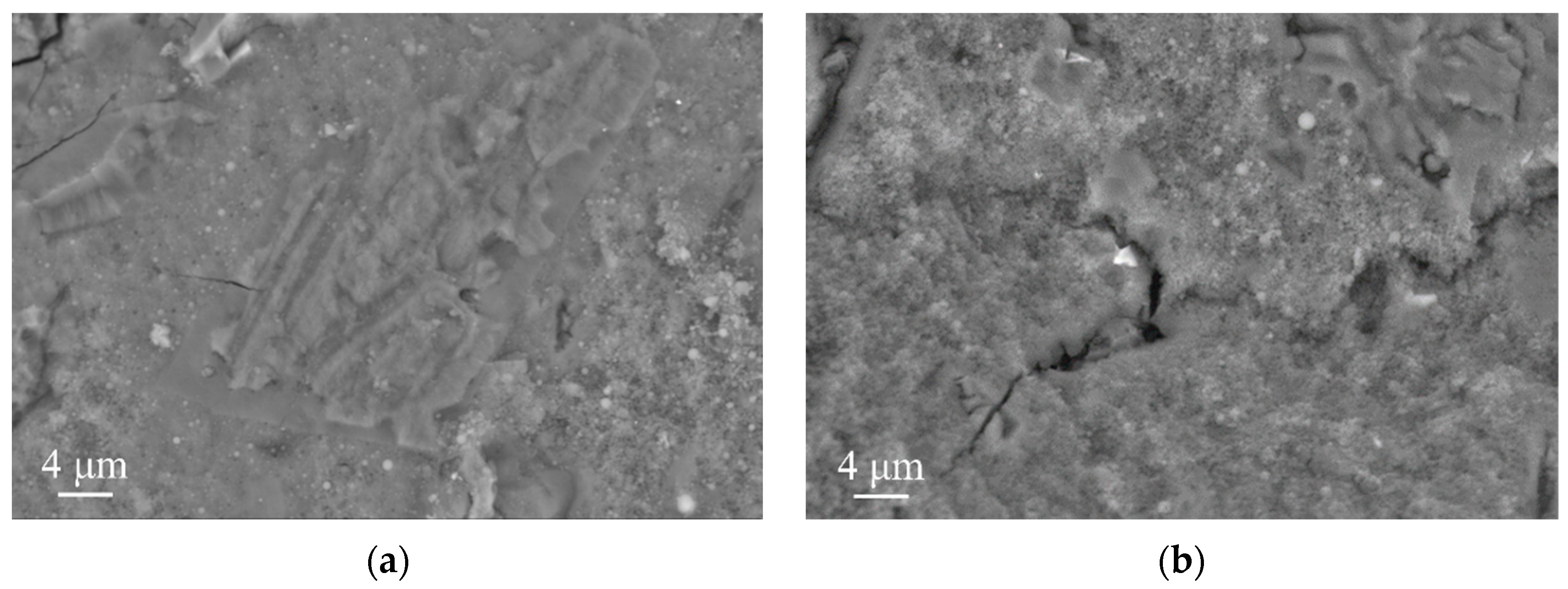

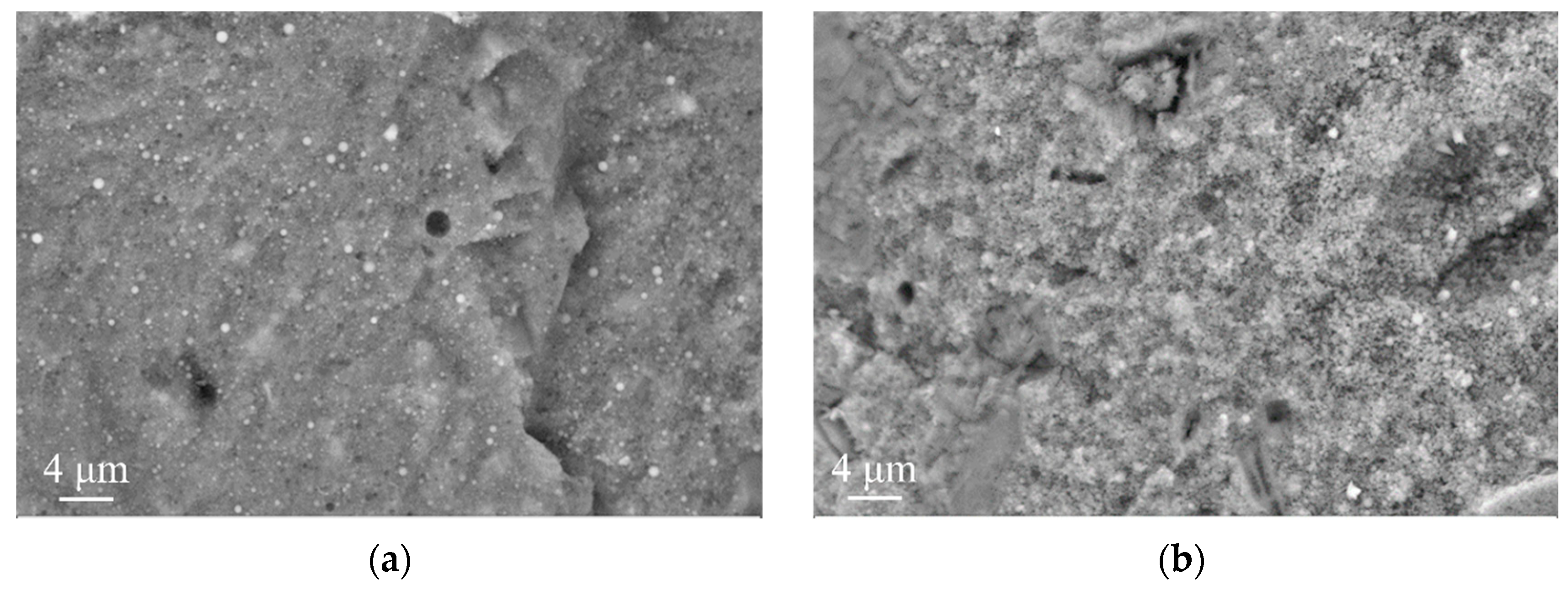

3.1.5. SEM Analysis

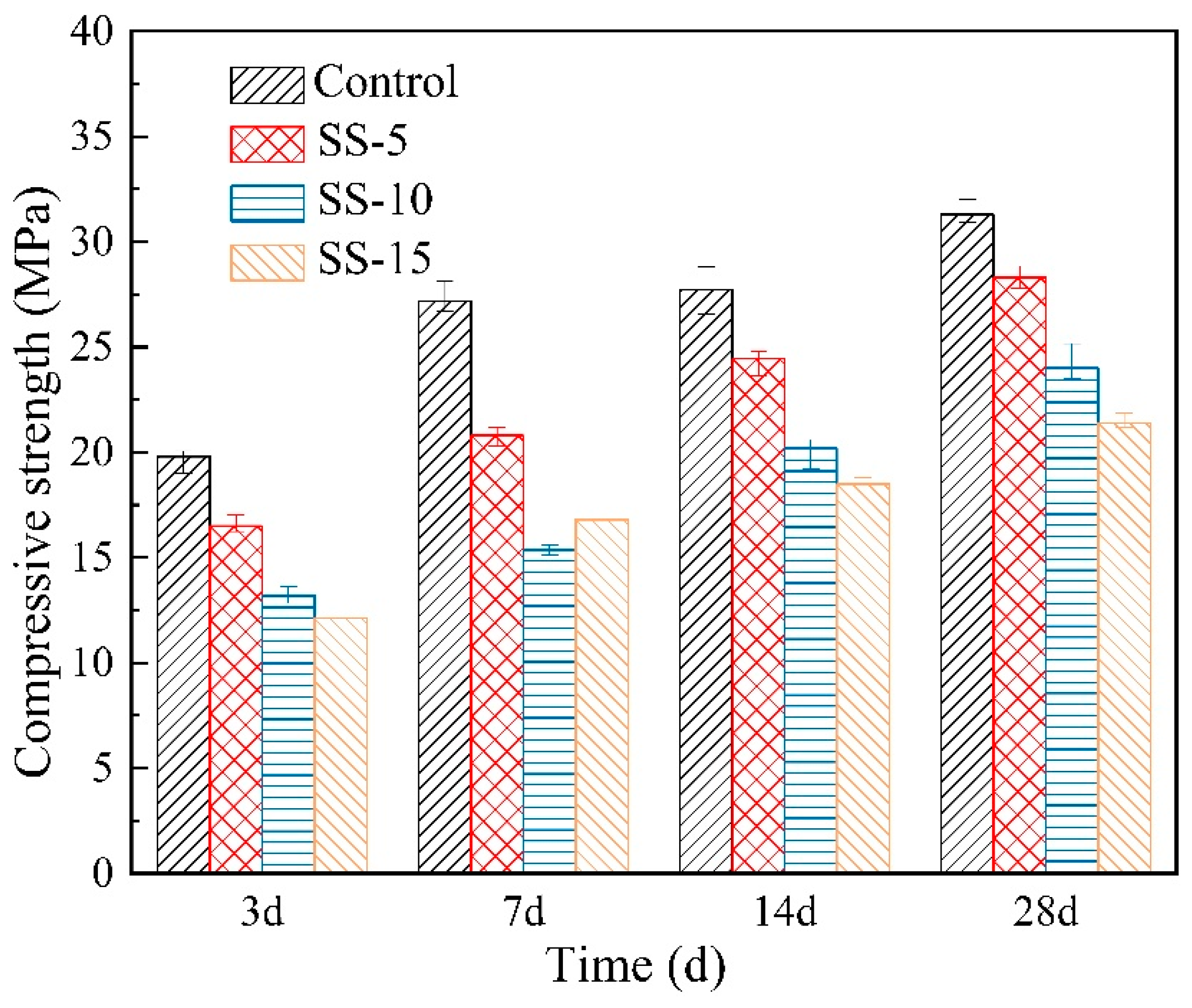

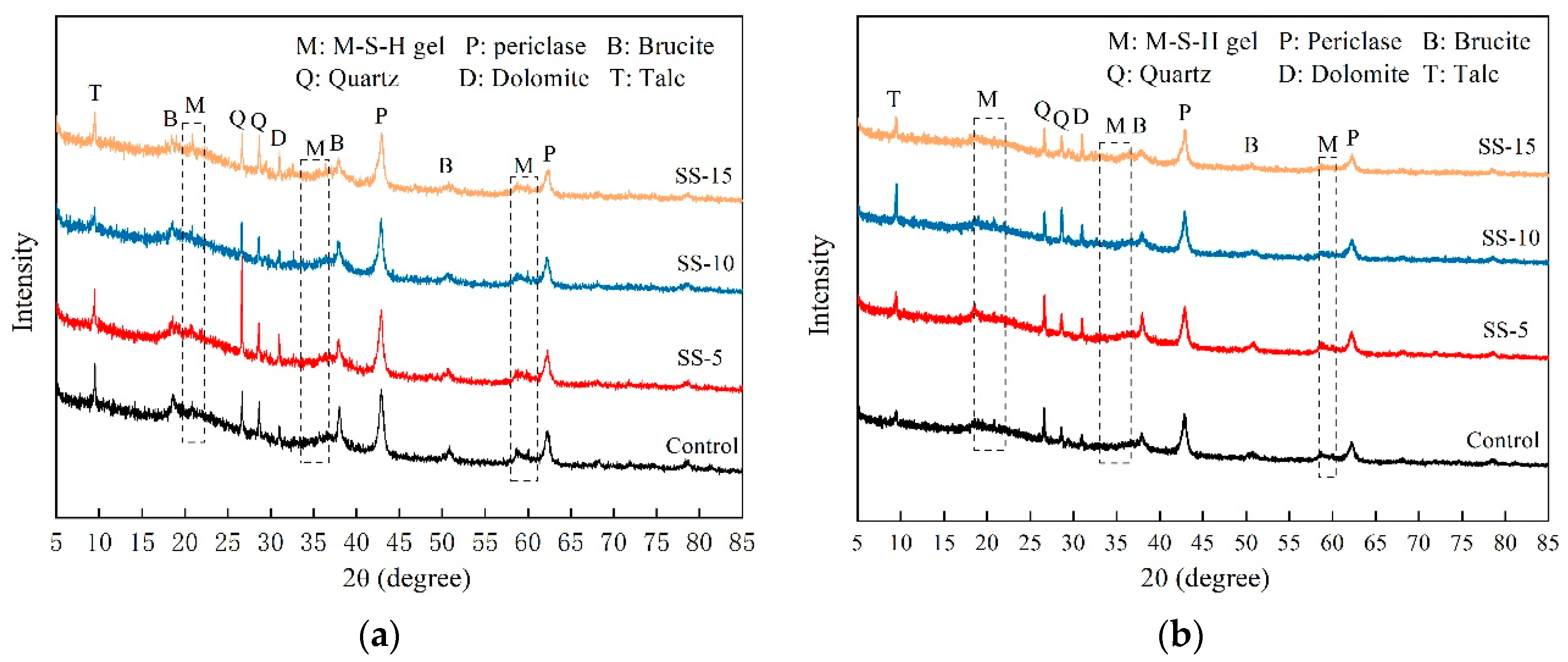

3.2. Effect of High-Pressure Carbonation on SS–MSH Cement

3.2.1. Compressive Strength

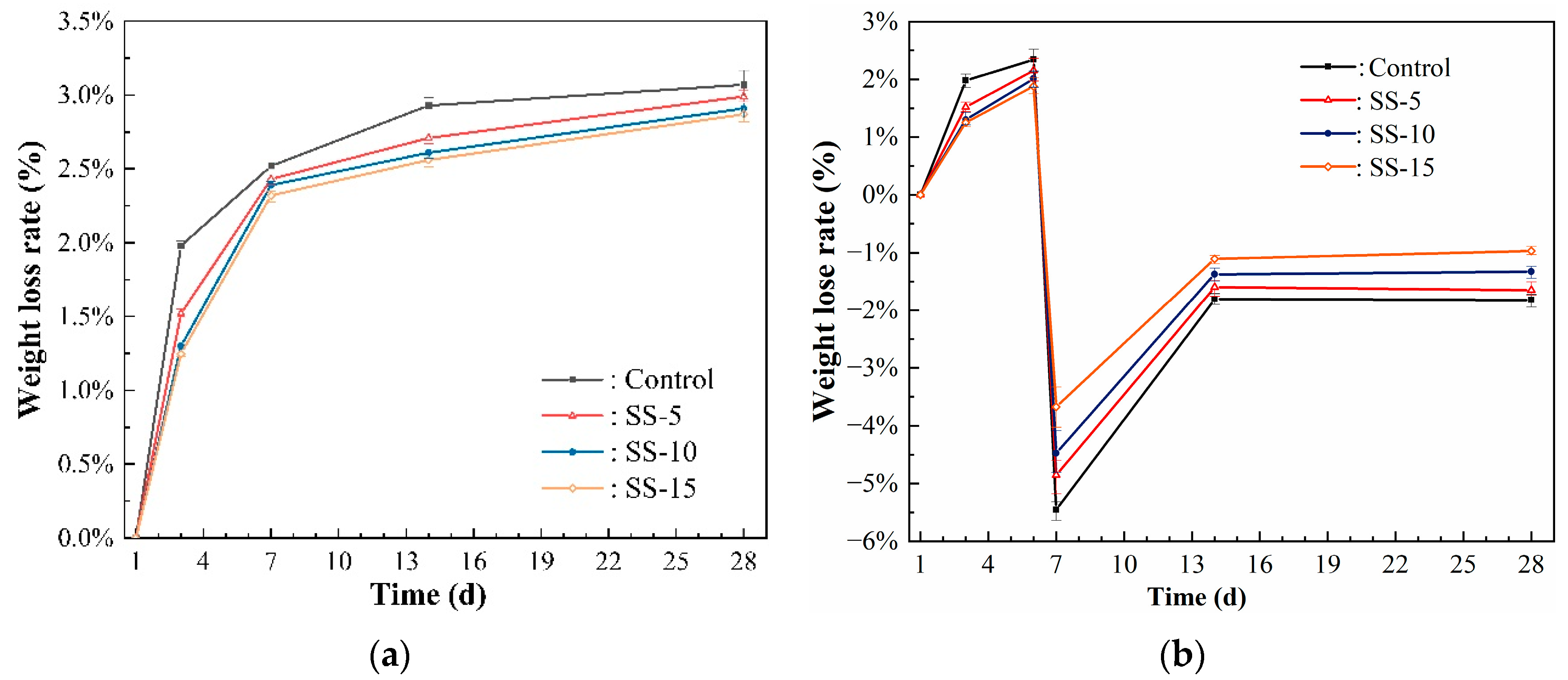

3.2.2. Mass Loss

3.2.3. Shrinkage Rate

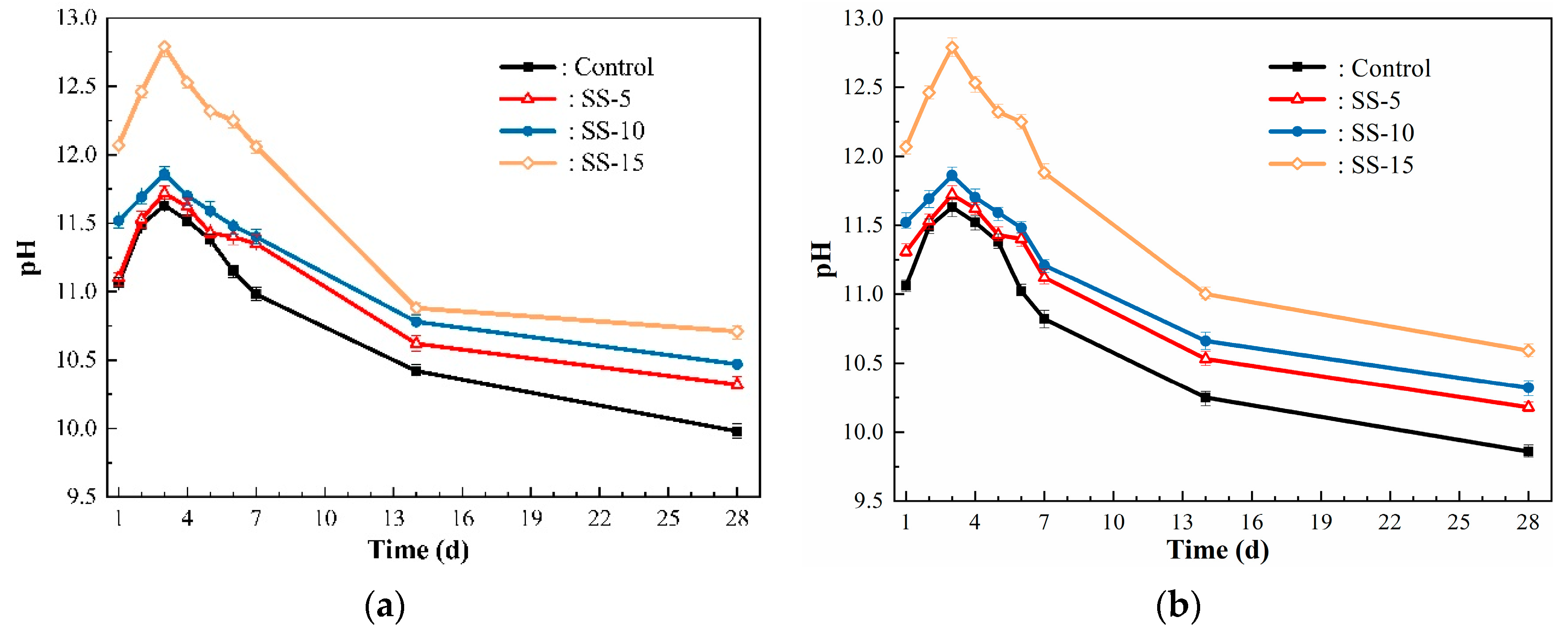

3.2.4. pH Change

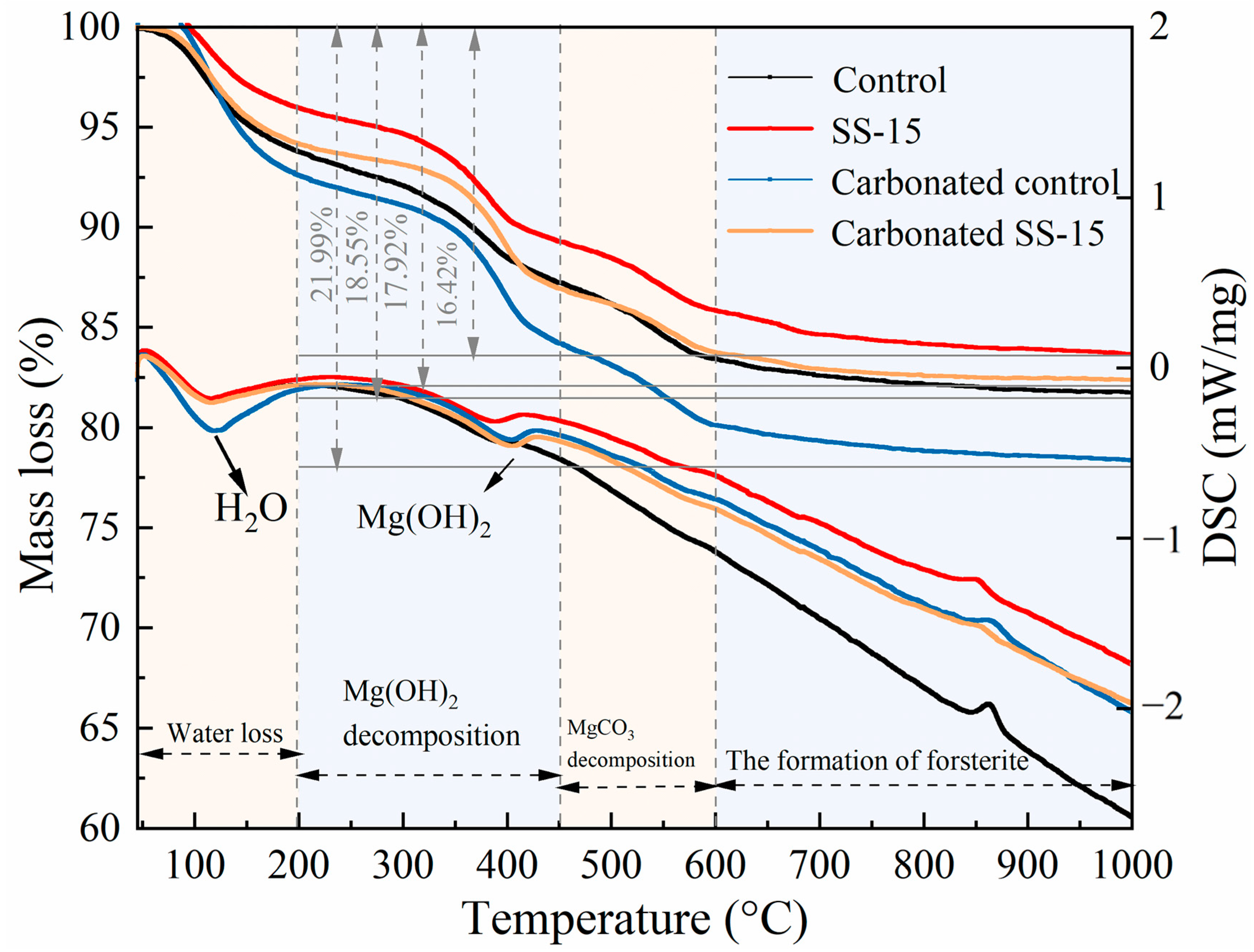

3.2.5. TG–DSC Analysis

3.2.6. Porosity

4. Conclusions

- Under atmospheric conditions, MSH cement mixed with different SS contents experiences a decline in strength at all ages, decreasing progressively with increasing SS content—from 28.9 MPa down to 19.8 MPa. The greater the SS amount incorporated into MSH cement, the less shrinkage is observed at various aging periods. After carbonation treatment, the compressive strength increases compared with the uncarbonized samples with the same SS content, and shrinkage rates also decrease, with the MSH cement containing 15 wt.% SS showing the most significant improvements.

- Upon the addition of SS, the presence of free calcium oxide and alkali metal ions in the SS elevates the pH of the MSH cement system. Furthermore, the pH increases in correlation with the amount of SS added. As the pH rises, the solubility of SF decreases, affecting the formation of the M–S–H gel and consequently leading to a reduction in the compressive strength. As the hydration reaction progresses, the pH of MSH cement reaches its peak at 3 days and subsequently decreases as hydration continues. After undergoing pressurized carbonation treatment, the pH of the SS–MSH cement decreases. For example, the pH value of MSH cement with a 15 wt.% SS addition decreases from 10.71 to 10.59 at 28 days, which is beneficial for gel growth. This is one of the reasons for the observed improvement in the compressive strength following carbonation.

- Microscopic characterization methods such as XRD, TG–DSC, and SEM were employed to analyze the products before and after carbonation. XRD results reveal that the primary hydration products in SS–MSH cement are M–S–H gel, small amounts of Mg(OH)2, and some unreacted MgO and SiO2. Following carbonation treatment, HMCs are formed within the SS–MSH system. Simultaneously, the C2S in the SS undergoes hydration and carbonation to form amorphous Ca–Mg–C substances that fill the pores, thereby enhancing the matrix density. Consequently, the compressive strength of the specimens improves while the shrinkage rate decreases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Demediuk, T.; Cole, W.F. A study of mangesium oxysulphates. Aust. J. Chem. 1957, 10, 287–294. [Google Scholar] [CrossRef]

- Chen, X.; Wang, S.; Zhou, Y.; Cheeseman, C.; Bi, W.; Zhang, T. Improved low-carbon magnesium oxysulfate cement pastes containing boric acid and citric acid. Cem. Concr. Compos. 2022, 134, 104813. [Google Scholar] [CrossRef]

- Sorel, S. On a new magnesium cement. CR Acad. Sci. 1867, 65, 102–104. [Google Scholar]

- Finch, T.; Sharp, J.H. Chemical reactions between magnesia and aluminium orthophosphate to form magnesia-phosphate cements. J. Mater. Sci. 1989, 24, 4379–4386. [Google Scholar] [CrossRef]

- Odegard, C.; Feldborg, H.; Myhre, B. Magnesia-silica-hydrate bonded MgO castables. In Proceedings of the UNITECR’01, Unified International Technical Conference on Refractories: 7th Biennial Worldwide Congress, Cancun, Mexico, 4–7 November 2001; Volume 1, pp. 220–235. [Google Scholar]

- Wang, N.; Yu, H.; Bi, W.; Tan, Y.; Zhang, N.; Wu, C.; Ma, H.; Hua, S. Effects of sodium citrate and citric acid on the properties of magnesium oxysulfate cement. Constr. Build. Mater. 2018, 169, 697–704. [Google Scholar] [CrossRef]

- Tan, Y.; Wu, C.; Yu, H.; Li, Y.; Wen, J. Review of reactive magnesia-based cementitious materials: Current developments and potential applicability. J. Build. Eng. 2021, 40, 102342. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Jiang, T.; Zhang, J.; Lau, D.; Chang, J. Understanding the role of carbon nanotubes in low-carbon concrete: From experiment to molecular dynamics. Cem. Concr. Compos. 2023, 142, 105189. [Google Scholar] [CrossRef]

- Cui, K.; Lu, D.; Jiang, T.; Zhang, J.; Jiang, Z.; Zhang, G.; Chang, J.; Lau, D. Understanding the role of carbon nanotubes in low carbon sulfoaluminate cement-based composite. J. Clean. Prod. 2023, 416, 137843. [Google Scholar] [CrossRef]

- Jiang, T.; Cui, K.; Chang, J. Development of low-carbon cement: Carbonation of compounded C2S by β-C2S and γ-C2S. Cem. Concr. Compos. 2023, 139, 105071. [Google Scholar] [CrossRef]

- Zhang, T.; Cheeseman, C.R.; Vandeperre, L.J. Development of low pH cement systems forming magnesium silicate hydrate (MSH). Cem. Concr. Res. 2011, 41, 439–442. [Google Scholar] [CrossRef]

- Zhang, T.; Vandeperre, L.J.; Cheeseman, C.R. Formation of magnesium silicate hydrate (MSH) cement pastes using sodium hexametaphosphate. Cem. Concr. Res. 2014, 65, 8–14. [Google Scholar] [CrossRef]

- Huaiwei, Z.; Xin, H. An overview for the utilization of wastes from stainless steel industries. Resour. Conserv. Recycl. 2011, 55, 745–754. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Na, H.; Wang, Y.; Zhang, X.; Li, J.; Zeng, Y.; Liu, P. Hydration activity and carbonation characteristics of dicalcium silicate in steel slag: A review. Metals 2021, 11, 1580. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Y.; Dong, J.; Gan, L.; Tong, Z. Roles of mineralogical phases in aqueous carbonation of steelmaking slag. Metals 2016, 6, 117. [Google Scholar] [CrossRef]

- Fang, Y.; Chang, J. Microstructure changes of waste hydrated cement paste induced by accelerated carbonation. Constr. Build. Mater. 2015, 76, 360–365. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Zhao, X.; He, T. Cementitious property modification of basic oxygen furnace steel slag. Constr. Build. Mater. 2013, 48, 575–579. [Google Scholar] [CrossRef]

- Pan, S.Y.; Adhikari, R.; Chen, Y.H.; Li, P.; Chiang, P.C. Integrated and innovative steel slag utilization for iron reclamation, green material production and CO2 fixation via accelerated carbonation. J. Clean. Prod. 2016, 137, 617–631. [Google Scholar] [CrossRef]

- Hu, Z.; Guan, Y.; Chang, J.; Bi, W.; Zhang, T. Effect of Carbonation on the Water Resistance of Steel Slag—Magnesium Oxysulfate (MOS) Cement Blends. Materials 2020, 13, 5006. [Google Scholar] [CrossRef]

- Berger, R.L.; Young, J.F.; Leung, K. Acceleration of hydration of calcium silicates by carbon dioxide treatment. Nat. Phys. Sci. 1972, 240, 16–18. [Google Scholar] [CrossRef]

- Ghouleh, Z.; Guthrie, R.I.L.; Shao, Y. Production of carbonate aggregates using steel slag and carbon dioxide for carbon-negative concrete. J. CO2 Util. 2017, 18, 125–138. [Google Scholar] [CrossRef]

- Ghouleh, Z.; Guthrie, R.I.L.; Shao, Y. High-strength KOBM steel slag binder activated by carbonation. Constr. Build. Mater. 2015, 99, 175–183. [Google Scholar] [CrossRef]

- Mo, L.; Zhang, F.; Deng, M.; Jin, F.; Al-Tabbaa, A.; Wang, A. Accelerated carbonation and performance of concrete made with steel slag as binding materials and aggregates. Cem. Concr. Compos. 2017, 83, 138–145. [Google Scholar] [CrossRef]

- Bodor, M.; Santos, R.M.; Kriskova, L.; Elsen, J.; Vlad, M.; Van Gerven, T. Susceptibility of mineral phases of steel slags towards carbonation: Mineralogical, morphological and chemical assessment. Eur. J. Mineral. 2013, 25, 533–549. [Google Scholar] [CrossRef]

- Mo, L.; Panesar, D.K. Effects of accelerated carbonation on the microstructure of Portland cement pastes containing reactive MgO. Cem. Concr. Res. 2012, 42, 769–777. [Google Scholar] [CrossRef]

- Kuenzel, C.; Zhang, F.; Ferrandiz-Mas, V.; Cheeseman, C.R.; Gartner, E.M. The mechanism of hydration of MgO-hydromagnesite blends. Cem. Concr. Res. 2018, 103, 123–129. [Google Scholar] [CrossRef]

- Ba, M.; Xue, T.; He, Z.; Wang, H.; Liu, J. Carbonation of magnesium oxysulfate cement and its influence on mechanical performance. Constr. Build. Mater. 2019, 223, 1030–1037. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.; Gao, X.; Zhang, J. Effect of pulverized fuel ash, ground granulated blast-furnace slag and CO2 curing on performance of magnesium oxysulfate cement. Constr. Build. Mater. 2020, 230, 116990. [Google Scholar] [CrossRef]

- Walling, S.A.; Provis, J.L. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef]

- Ruan, S.; Unluer, C. Influence of mix design on the carbonation, mechanical properties and microstructure of reactive MgO cement-based concrete. Cem. Concr. Compos. 2017, 80, 104–114. [Google Scholar] [CrossRef]

- JC/T 729-2005; Cement Slurry Mixer. National Standardization Technical Committee Cement: Suzhou, China, 2005.

- JC/T 603-2004; Standard Test Method for Drying Shinkage of Mortar. National Standardization Technical Committee Cement: Suzhou, China, 2004.

- GB/T 1346–2001; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. Standardization Administration of China (SAC): Beijing, China, 2001.

- Guan, Y.; Chang, J.; Hu, Z.; Bi, W. Performance of magnesium hydroxide gel at different alkali concentrations and its effect on properties of magnesium oxysulfate cement. Constr. Build. Mater. 2022, 348, 128669. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, C.; Li, Z.; Liu, G.; Zhang, W.; Xie, G.; Xing, F. Carbonation of steel slag at low CO2 concentrations: Novel biochar cold-bonded steel slag artificial aggregates. Sci. Total Environ. 2023, 902, 166065. [Google Scholar] [CrossRef] [PubMed]

- Boone, M.A.; Nielsen, P.; De Kock, T.; Boone, M.N.; Quaghebeur, M.; Cnudde, V. Monitoring of stainless-steel slag carbonation using X-ray computed microtomography. Environ. Sci. Technol. 2014, 48, 674–680. [Google Scholar] [CrossRef]

- Li, Z.; Lin, L.; Yu, J.; Tang, H.; Qin, J.; Qian, J. Performance of magnesium silicate hydrate cement modified with dipotassium hydrogen phosphate. Constr. Build. Mater. 2022, 323, 126389. [Google Scholar] [CrossRef]

- Zhang, T.; Zou, J.; Wang, B.; Wu, Z.; Jia, Y.; Cheeseman, C.R. Characterization of magnesium silicate hydrate (MSH) gel formed by reacting MgO and silica fume. Materials 2018, 11, 909. [Google Scholar] [CrossRef]

- Ding, Z.; Li, Z. Effect of aggregates and water contents on the properties of magnesium phospho-silicate cement. Cem. Concr. Compos. 2005, 27, 11–18. [Google Scholar] [CrossRef]

| Component | Content (wt.%) | |||||

|---|---|---|---|---|---|---|

| MgO | SiO2 | CaO | Al2O3 | Fe2O3 | Others | |

| LBM | 87.63 | 2.34 | 2.91 | 0.42 | 0.47 | 6.23 |

| SF | 1.19 | 95.73 | 0.68 | 0.22 | 0.25 | 1.93 |

| SS | 9.19 | 18.20 | 37.85 | 3.66 | 25 | 6.10 |

| Samples | Mixture Design (wt.%) | |||

|---|---|---|---|---|

| SS | MgO | Water | SF | |

| Control | 0 | 40 | 50 | 60 |

| SS-5 | 5 | 40 | 52.5 | 60 |

| SS-10 | 10 | 40 | 55 | 60 |

| SS-15 | 15 | 40 | 57.5 | 60 |

| Samples | Total Intrusion Volume | Total Porosity Porosity | Volume of Pores in Each Range (%) | ||

|---|---|---|---|---|---|

| (mL/g) | (%) | >100 nm | 10–100 nm | <10 nm | |

| Control | 0.2122 | 21.2238 | 34.13 | 62.42 | 3.45 |

| Carbonated control | 0.2092 | 20.9186 | 54.07 | 44.83 | 1.10 |

| SS-15 | 0.2717 | 27.1681 | 53.17 | 46.07 | 0.96 |

| Carbonated SS-15 | 0.2658 | 26.5781 | 47.03 | 49.91 | 3.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, T.; Hu, Z.; Huang, C.; Chang, J. Influence of Carbonation on the Properties of Steel Slag–Magnesium Silicate Hydrate (MSH) Cement. Materials 2023, 16, 6737. https://doi.org/10.3390/ma16206737

Zeng T, Hu Z, Huang C, Chang J. Influence of Carbonation on the Properties of Steel Slag–Magnesium Silicate Hydrate (MSH) Cement. Materials. 2023; 16(20):6737. https://doi.org/10.3390/ma16206737

Chicago/Turabian StyleZeng, Tian, Zhiqi Hu, Chengran Huang, and Jun Chang. 2023. "Influence of Carbonation on the Properties of Steel Slag–Magnesium Silicate Hydrate (MSH) Cement" Materials 16, no. 20: 6737. https://doi.org/10.3390/ma16206737

APA StyleZeng, T., Hu, Z., Huang, C., & Chang, J. (2023). Influence of Carbonation on the Properties of Steel Slag–Magnesium Silicate Hydrate (MSH) Cement. Materials, 16(20), 6737. https://doi.org/10.3390/ma16206737