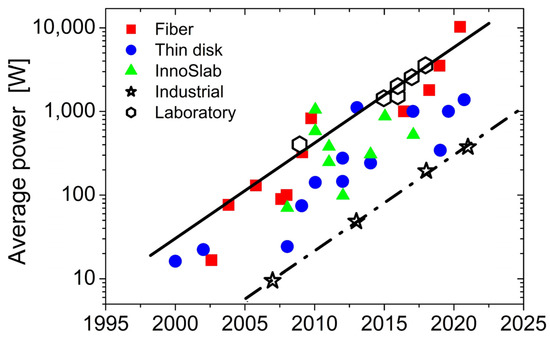

“Advanced Pulse Laser Machining Technology” is a rapidly growing field that can be tailored to special industrial and scientific applications. This is significantly driven by the availability of high-repetition-rate laser sources and novel beam delivery concepts. In recent publications, Saraceno et al. [1], Schille and Löschner [2], and Weber and Graf [3] presented graphs of the development of ultrashort-pulse laser technology over the past few decades (see the synthesis of data from [2,3] provided in Figure 1). Obviously, the average power of ultrafast lasers follows a type of Moore’s law, leading to the doubling of the average power of these lasers every two years [4]. Additionally, the average power attained by the lasers in research laboratories precedes the average power of standard industrial lasers by about ten years [3], visualized here as the horizontal separation between the two lines in Figure 1. The impressive progress in laser technology currently culminates in the availability of a fiber-laser-based average power of 10.4 kW at a 1.4 µm wavelength, 254 fs pulse duration, and 80 MHz repetition rate [5]. Currently, the industrial standard is ultrashort-pulse lasers emitting average powers of the order of 100 W.

Figure 1.

Progress in ultrafast laser technology featuring an exponential increase in the average output power over the past 20 years. The plot is a synthesis of data, indicating the related laser technology (fiber, thin disk, and InnoSlab) as fully colored data points [2], as well as their realization in laboratories or as commercial industrial products as open black data points [3]. The black lines guide the eye.

For industrial use, the high output power of ultrafast lasers must be directed to the workpieces to be machined by appropriate beam guidance and deflection systems [6]. For many materials such as metals and semiconductors, moderate laser fluences (i.e., laser pulse energies) are sufficient to process the workpiece with high precision and efficiency [7,8,9]. Therefore, high laser pulse repetition rates up to the above-mentioned MHz level can be utilized to significantly reduce the processing times. This requires extremely fast beam deflection systems, possibly coupled with optics for multibeam processing. In a recent study, an area processing rate up to 3.8 m2/min was demonstrated with a single-pass raster on steel sheets with a scanning speed of the laser beam of 950 m/s [10]. The key element of the experimental setup was a polygon scanner [11] in connection with a MHz laser system.

The Special Issue addresses not only the advantages of modern laser processing using short and ultrashort laser pulses, but also limitations caused by unwanted secondary hazards such as X-ray emissions. This phenomenon is not completely new and was described for laser machining applications using ultrashort laser pulses with repetition rates of the order of 1 kHz two decades ago [12,13,14]. However, the use of high pulse repetition rates in the multi-100 kHz range and burst pulses has recently exacerbated the problem [15,16,17,18,19,20,21]. Therefore, it is a pleasant fact that five publications in this Special Issue discuss this problem area in detail and, thus, make an important contribution to the field of combined laser and radiation protection for improving work safety aspects [22,23,24,25,26].

The use of laser pulse bursts enables new process regimes for metals and allows for an increase in the structuring rates and surface quality of machined samples. Results of both experimental and numerical investigations in this context are reviewed by Förster et al. [27]. The machining strategies using pulse bursts with intraburst repetition frequencies in the MHz up to GHz regime must consider an increased risk of secondary X-ray emissions with this mode of operation [21,25,26].

This Special Issue bundles together 1 review paper [27], 1 perspective article [28], and 14 original research articles [22,23,24,25,26,29,30,31,32,33,34,35,36,37], all focusing on the latest achievements in areas of surface and volume laser material processing, including laser-induced forward transfer and laser printing technologies [28], spatial and temporal beam shaping [29,30,31,32], Bessel-beam structuring of high-aspect-ratio void channels inside glass [34], direct laser interference patterning [35], pulse burst machining [27], waveguide writing [36], fs-pulse laser-induced amorphization and recrystallization of single-crystalline silicon [37], and a comparison of different beam shuttering technologies [33]—an aspect that is often neglected, but most practically relevant.

Author Contributions

Conceptualization, J.K. and J.B.; methodology, J.K. and J.B.; software, not applicable; validation, J.K. and J.B.; formal analysis, J.K. and J.B.; investigation, not applicable; resources, not applicable; data curation, not applicable; writing—original draft preparation, J.K. and J.B.; writing—review and editing, J.K. and J.B.; visualization, J.B.; supervision, J.K. and J.B.; project administration, J.K. and J.B.; funding acquisition, not applicable. All authors have read and agreed to the published version of the manuscript.

Funding

This Editorial received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

Administrative and technical support of Anson Geng and the editorial staff of Materials is to be acknowledged here.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Saraceno, J.C.; Sutter, D.; Metzger, T.; Ahmed, M.A. The amazing progress of high-power ultrafast thin-disk lasers. J. Eur. Opt. Soc. Rapid publ. 2019, 15, 15. [Google Scholar] [CrossRef]

- Schille, J.; Löschner, U. Ultrashort pulse lasers in high-rate laser micro processing—Quo vadis? Adv. Opt. Technol. 2021, 10, 233–237. [Google Scholar] [CrossRef]

- Weber, R.; Graf, T. The challenges of productive materials processing with ultrafast lasers. Adv. Opt. Technol. 2021, 10, 239–245. [Google Scholar] [CrossRef]

- Han, M.; Smith, D.; Ng, S.H.; Anand, V.; Katkus, T.; Juodkazis, S. Ultra-short-pulse lasers—Materials—Applications. Eng. Proc. 2021, 11, 44. [Google Scholar]

- Müller, M.; Aleshire, C.; Klenke, A.; Haddad, E.; Légaré, F.; Tünnermann, A.; Limpert, J. 10.4 kW coherently combined ultrafast fiber laser. Opt. Lett. 2020, 45, 3083–3086. [Google Scholar] [CrossRef] [PubMed]

- Račiukaitis, G. Ultra-short pulse lasers for microfabrication: A review. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1100112. [Google Scholar] [CrossRef]

- Kautek, W.; Krüger, J. Femtosecond pulse laser ablation of metallic, semiconducting, ceramic, and biological materials. Proc. SPIE 1994, 2207, 600–611. [Google Scholar]

- Račiukaitis, G.; Brikas, M.; Gecys, P.; Voisiat, B.; Gedvilas, M. Use of high repetition rate and high power lasers in microfabrication: How to keep the efficiency high? J. Laser Micro Nanoeng. 2009, 4, 186–191. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Jäggi, B.; Schmid, M.; Hennig, G. Surface structuring with ultra-short laser pulses: Basics, limitations and needs for high throughput. Phys. Procedia 2014, 56, 1047–1058. [Google Scholar] [CrossRef]

- Schille, J.; Schneider, L.; Mauersberger, S.; Szokup, S.; Höhn, S.; Pötschke, J.; Reiß, F.; Leidich, E.; Löschner, U. High-rate laser surface texturing for advanced tribological functionality. Lubricants 2020, 8, 33. [Google Scholar] [CrossRef]

- De Loor, R. Polygon scanner system for ultra short pulsed laser micro-machining applications. Phys. Procedia 2013, 41, 544–551. [Google Scholar] [CrossRef]

- Thogersen, J.; Borowiec, A.; Haugen, H.K.; McNeill, F.E.; Stronach, I.M. X-ray emission from femtosecond laser micromachining. Appl. Phys. A 2001, 73, 361–363. [Google Scholar] [CrossRef]

- Bunte, J.; Barcikowski, S.; Püster, T.; Burmester, T.; Brose, M.; Ludwig, T. Secondary hazards: Particle and X-ray emission. Topics Appl. Phys. 2004, 96, 309–321. [Google Scholar]

- Prieto-Pena, J.; Gómez, F.; González-Castaño, D.M.; Flores-Arias, M.T.; Arines, J.; Bao-Varela, C.; Cambronero-López, F.; Martínez Maqueira, A. X-ray emission from femtosecond laser micromachining. J. Radiol. Prot. 2018, 38, 716–730. [Google Scholar] [CrossRef]

- Legall, H.; Schwanke, C.; Pentzien, S.; Dittmar, G.; Bonse, J.; Krüger, J. X-ray emission as a potential hazard during ultrashort pulse laser material processing. Appl. Phys. A 2018, 124, 407. [Google Scholar] [CrossRef]

- Behrens, R.; Pullner, B.; Reginatto, M. X-ray emission from materials processing lasers. Radiat. Prot. Dosim. 2019, 183, 361–374. [Google Scholar] [CrossRef]

- Weber, R.; Giedl-Wagner, R.; Förster, D.J.; Pauli, A.; Graf, T.; Balmer, J.E. Expected X-ray dose rates resulting from industrial ultrafast laser applications. Appl. Phys. A 2019, 125, 635. [Google Scholar] [CrossRef]

- Legall, H.; Schwanke, C.; Bonse, J.; Krüger, J. X-ray radiation protection aspects during ultrashort laser processing. J. Laser Appl. 2020, 32, 022004. [Google Scholar] [CrossRef]

- Freitag, C.; Giedl-Wagner, R. X-ray protection in an industrial production environment. PhotonicsViews 2020, 17, 37–41. [Google Scholar] [CrossRef]

- Legall, H.; Bonse, J.; Krüger, J. Review of X-ray exposure and safety issues arising from ultra-short pulse laser material pro-cessing. J. Radiol. Prot. 2021, 41, R28–R42. [Google Scholar] [CrossRef]

- Metzner, D.; Olbrich, M.; Lickschat, P.; Horn, A.; Weißmantel, S. X-ray generation by laser ablation using MHz to GHz pulse bursts. J. Laser Appl. 2021, 33, 032014. [Google Scholar] [CrossRef]

- Mosel, P.; Sankar, P.; Düsing, J.F.; Dittmar, G.; Püster, T.; Jäschke, P.; Vahlbruch, J.-W.; Morgner, U.; Kovacev, M. X-ray dose rate and spectral measurements during ultrafast laser machining using a calibrated (high-sensitivity) novel X-ray detector. Materials 2021, 14, 4397. [Google Scholar] [CrossRef]

- Schille, J.; Kraft, S.; Pflug, T.; Scholz, C.; Clair, M.; Horn, A.; Löschner, U. Study on X-ray emission using ultrashort pulsed lasers in materials processing. Materials 2021, 14, 4537. [Google Scholar] [CrossRef]

- Stolzenberg, U.; Schmitt Rahner, M.; Pullner, B.; Legall, H.; Bonse, J.; Kluge, M.; Ortner, A.; Hoppe, B.; Krüger, J. X-ray emission hazards from ultrashort pulsed laser material processing in an industrial setting. Materials 2021, 14, 7163. [Google Scholar] [CrossRef]

- Schille, J.; Kraft, S.; Kattan, D.; Löschner, U. Enhanced X-ray emissions arising from high pulse repetition frequency ultrashort pulse laser materials processing. Materials 2022, 15, 2748. [Google Scholar] [CrossRef] [PubMed]

- Böttcher, K.; Schmitt Rahner, M.; Stolzenberg, U.; Kraft, S.; Bonse, J.; Feist, C.; Albrecht, D.; Pullner, B.; Krüger, J. Worst-case X-ray photon energies in ultrashort pulse laser processing. Materials 2022, 15, 8996. [Google Scholar] [CrossRef]

- Förster, D.J.; Jäggi, B.; Michalowski, A.; Neuenschwander, B. Review on experimental and theoretical investigations of ultra-short pulsed laser ablation of metals with burst pulses. Materials 2021, 14, 3331. [Google Scholar] [CrossRef]

- Florian, C.; Serra, P. Printing via laser-induced forward transfer and the future of digital manufacturing. Materials 2023, 16, 698. [Google Scholar] [CrossRef]

- Hauschwitz, P.; Stoklasa, B.; Kuchařík, J.; Turčičová, H.; Písařík, M.; Brajer, J.; Rostohar, D.; Mocek, T.; Duda, M.; Lucianetti, A. Micromachining of invar with 784 Beams using 1.3 ps laser source at 515 nm. Materials 2020, 13, 2962. [Google Scholar] [CrossRef]

- Wenisch, C.; Engel, S.; Gräf, S.; Müller, F.A. Dual laser beam processing of semiconducting thin films by excited state absorption. Materials 2021, 14, 1256. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Kraft, S.; Perrie, W.; Schille, J.; Löschner, U.; Edwardson, S.; Dearden, G. Backward flux re-deposition patterns during multi-spot laser ablation of stainless steel with picosecond and femtosecond pulses in air. Materials 2021, 14, 2243. [Google Scholar] [CrossRef] [PubMed]

- Schlutow, H.; Fuchs, U.; Müller, F.A.; Gräf, S. Squared focal intensity distributions for applications in laser material processing. Materials 2021, 14, 4981. [Google Scholar] [CrossRef] [PubMed]

- Aboud, D.G.K.; Wood, M.J.; Zeppetelli, G.; Joy, N.; Kietzig, A.-M. A practical comparison of beam shuttering technologies for pulsed laser micromachining applications. Materials 2022, 15, 897. [Google Scholar] [CrossRef] [PubMed]

- Vetter, C.; Giust, R.; Furfaro, L.; Billet, C.; Froehly, L.; Courvoisier, F. High aspect ratio structuring of glass with ultrafast Bessel beams. Materials 2021, 14, 6749. [Google Scholar] [CrossRef]

- El-Khoury, M.; Voisiat, B.; Kunze, T.; Lasagni, A.F. Prediction of optimum process parameters fabricated by direct laser interference patterning based on central composite design. Materials 2020, 13, 4101. [Google Scholar] [CrossRef]

- Macias-Montero, M.; Moreno-Zárate, P.; Muñoz, F.; Sotillo, B.; Garcia-Pardo, M.; Serna, R.; Fernandez, P.; Solis, J. Competition effects during femtosecond laser induced element redistribution in Ba- and La-migration based laser written waveguides. Materials 2021, 14, 3185. [Google Scholar] [CrossRef]

- Florian, C.; Fischer, D.; Freiberg, K.; Duwe, M.; Sahre, M.; Schneider, S.; Hertwig, A.; Krüger, J.; Rettenmayr, M.; Beck, U.; et al. Single femtosecond laser-pulse-induced superficial amorphization and re-crystallization of silicon. Materials 2021, 14, 1651. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).