Micro/Nano Structural Investigation and Characterization of Mussel Shell Waste in Thailand as a Feasible Bioresource of CaO

Abstract

1. Introduction

2. Materials and Methods

2.1. The Preparation of Shell Waste

2.2. The Calcination of Molluscan Waste Shells

2.3. The Characterization of Calcined and Non-Calcined Waste Shells

2.4. X-ray Diffraction (XRD) and Fourier Transform Infrared (FTIR) Spectroscopy Analysis

2.5. Scanning Electron Microscopy (SEM)

2.6. Elemental and Statisical Analysis

3. Results and Discussion

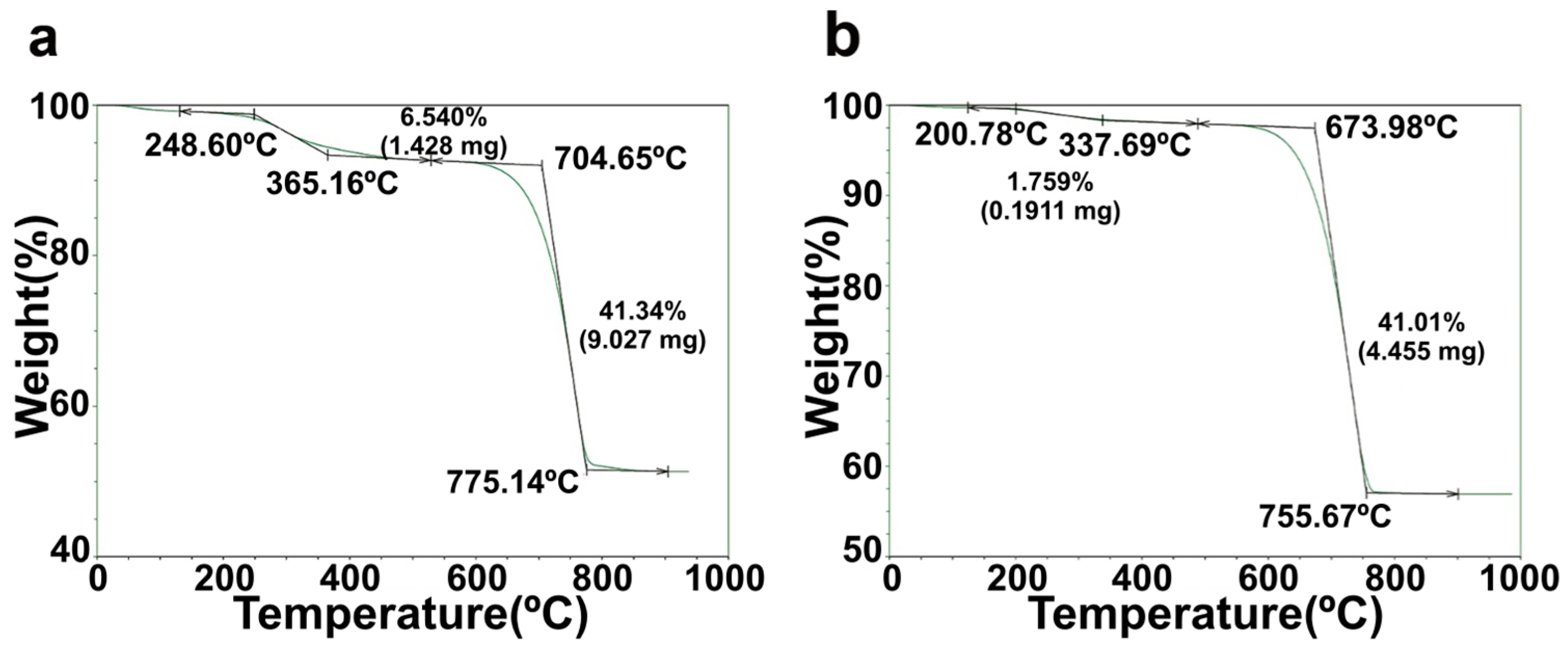

3.1. The Decomposition Characteristics of Green Mussel Shells and Mixed Shell Powder

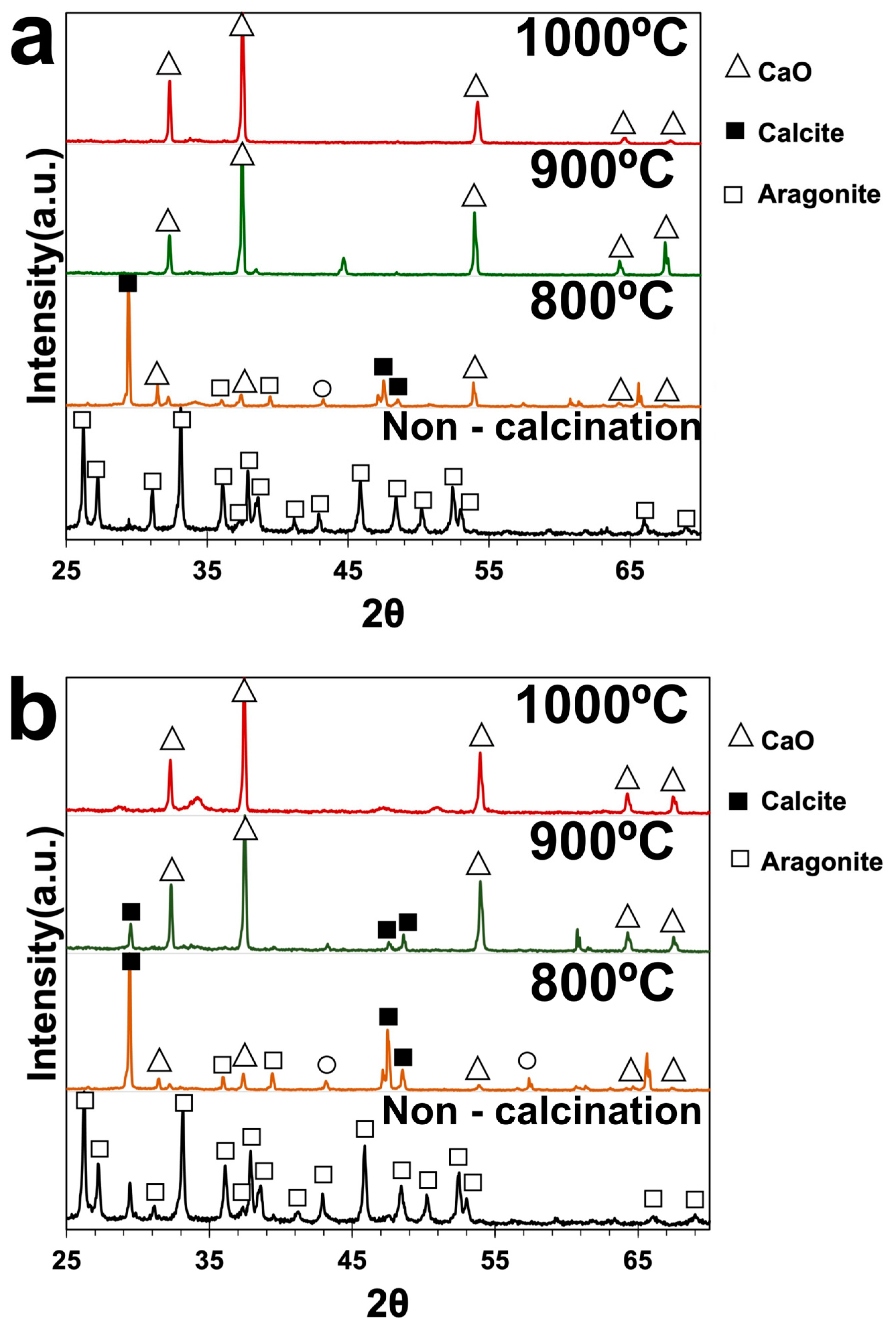

3.2. The Crystalline Phases of Green Mussel Shells and Mixed Shell Powder during Calcination

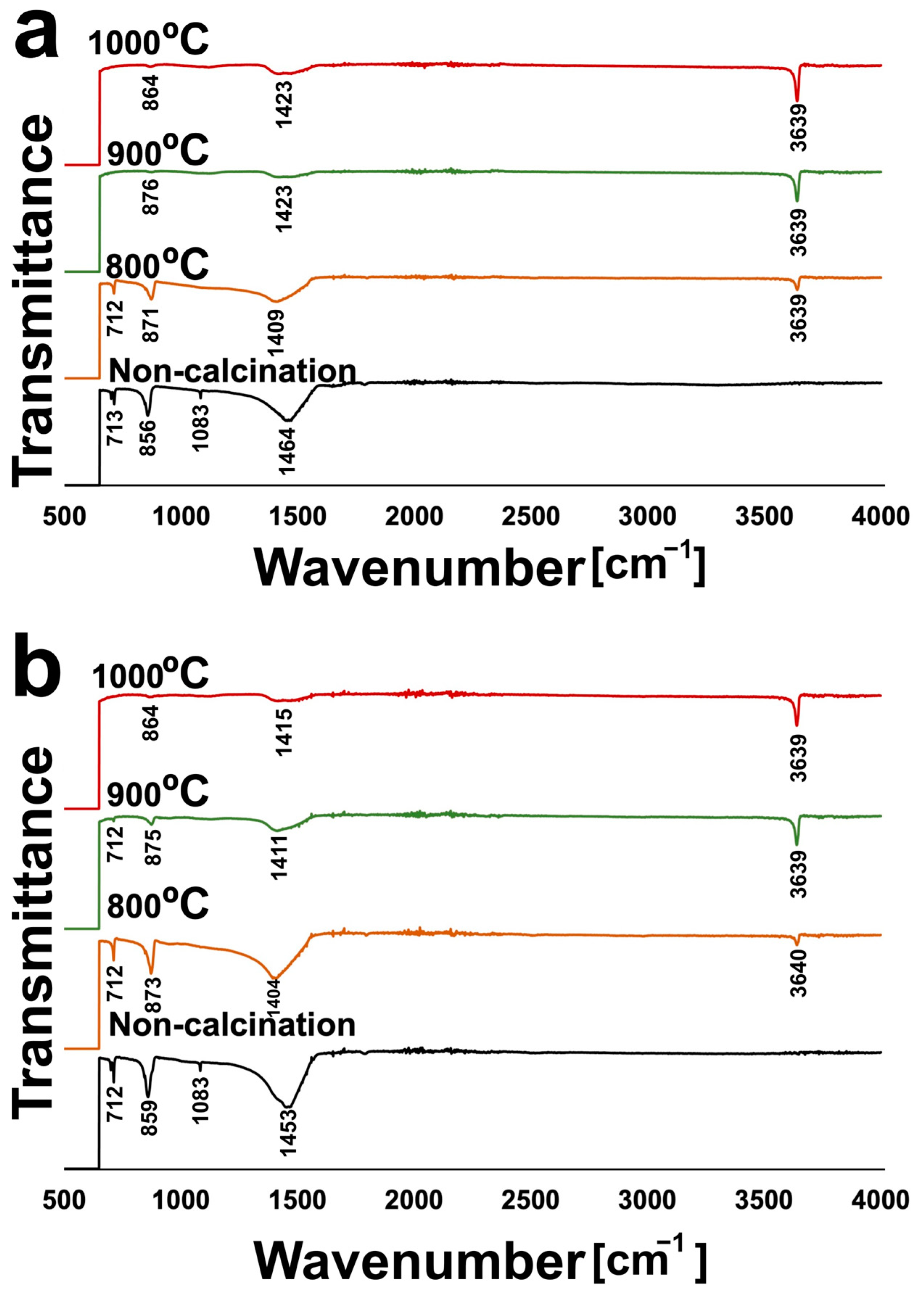

3.3. FTIR Spectra

3.4. Element Compositions

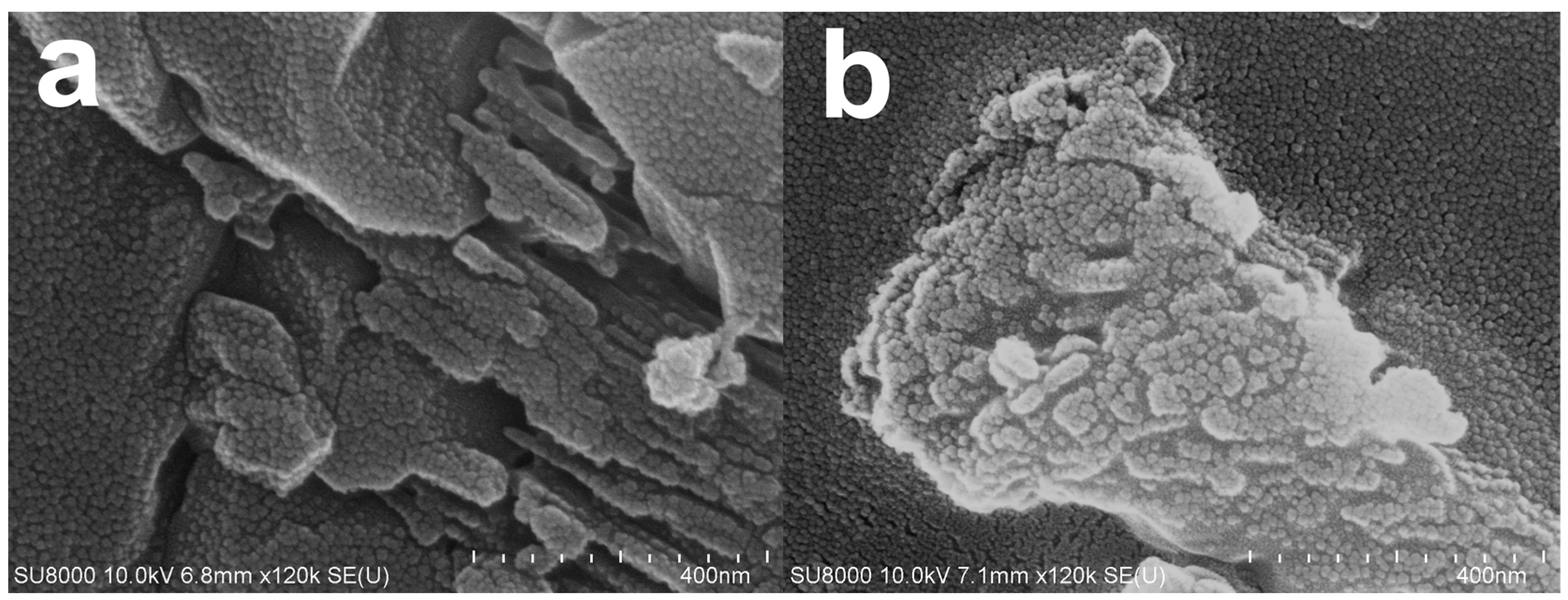

3.5. The Morphology of Green Mussel Shells and Mixed Shell Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Suryawanshi, N.; Jujjavarapu, S.E.; Ayothiraman, S. Marine shell industrial wastes–an abundant source of chitin and its derivatives: Constituents, pretreatment, fermentation, and pleiotropic applications-a revisit. Int. J. Environ. Sci. Technol. 2019, 16, 3877–3898. [Google Scholar] [CrossRef]

- Filho, A.N.; Almeida, A.C.; Riera, H.E.; Araújo, J.L.F.; Gouveia, V.J.P.; Carvalho, M.D.; Cardoso, A.V. Polymorphism of CaCO3 and microstructure of the shell of a brazilian invasive mollusc (Limnoperna fortunei). Mater. Res. 2014, 17 (Suppl. 1), 15–22. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Worawanitchaphong, P.; Trongyong, S. Calcium oxide derived from waste shells of mussel, cockle, and scallop as the heterogeneous catalyst for biodiesel production. Sci. World J. 2013, 2013, 460923. [Google Scholar] [CrossRef]

- Ni’mah, L.; Manurung, F.B.; Pramita, E. Lightweight concrete production by gypsum from waste materials of clamshell and eggshell. J. Appl. Environ. Biol. Sci. 2018, 8, 125–133. [Google Scholar]

- Zhang, Y.; Wu, H.; Liu, S. Analysis on the properties of calcined waste mussel shell. Anal. Chem. Indian J. 2013, 13, 167–171. [Google Scholar]

- Sari, M.; Yusuf, Y. Synthesis and characterization of hydroxyapatite based on green mussel shells (Perna viridis) with calcination temperature variation using the precipitation method. Int. J. Nanoelect. Mater. 2018, 11, 357–370. [Google Scholar]

- Kao, C.-Y.; Huang, Y.-C.; Chiu, S.-Y.; Kuo, K.-L.; Hwang, P.-A. Bacteriostatic effect of a calcined waste clamshell-activated plastic film for food packaging. Materials 2018, 11, 1370. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Fujimoto, R.; Sawai, J.; Kikuchi, M.; Yahata, S.; Satoh, S. Antibacterial characteristics of heated scallop-shell nano-particles. Biocontrol. Sci. 2014, 19, 93–97. [Google Scholar] [CrossRef]

- Sawai, J. Antimicrobial characteristics of eated scallop shell powder and its application. Biocontrol Sci. 2011, 16, 95–102. [Google Scholar] [CrossRef]

- Xing, R.; Qin, Y.; Guan, X.; Liu, S.; Yu, H.; Li, P. Comparison of antifungal activities of scallop shell, oyster shell and their pyrolyzed products. Egypt. J. Aquat. Res. 2013, 39, 83–90. [Google Scholar] [CrossRef]

- Chalermwat, K.; Szuster, B.W.; Flaherty, M. Shellfish aquaculture in Thailand. Aquacult. Econ. Manag. 2003, 2, 249–261. [Google Scholar] [CrossRef]

- Smithmaitriea, R.; Jaafarc, S.N.T.; Salaenoia, J. Shell structure investigation and utilization of bio-extract fermented from green mussel shell. Agric. Nat. Resour. 2020, 54, 415–422. [Google Scholar]

- Zhan, J.; Lu, J.; Wang, D. Review of shell waste reurilization to promote sustainable shellfish. Rev. Aquac. 2022, 14, 477–488. [Google Scholar] [CrossRef]

- Popović, N.T.; Lorencin, V.; Perović, I.S.; Rakovac, R. Shell waste management and utilization: Mitigating organic pollution and enhancing sustainability. Appl. Sci. 2023, 13, 623. [Google Scholar] [CrossRef]

- Nordin, N.; Hamzah, Z.; Hashim, O.; Kasim, F.H.; Abdullah, R. Effect of themperature in calcination process of seashells. Malaysian J. Anal. Sci. 2015, 19, 65–70. [Google Scholar]

- Kamba, A.; Ismail, M.; Ibrahim, T.; Abu Bakar, M.Z. Synthesis and characterisation of calcium carbonate aragonite nanocrystals from cockle shell powder (Anadara granosa). J. Nanomater. 2013, 2013, 398357. [Google Scholar]

- Mohamed, M.; Yousuf, S.; Maitra, S. Decomposition study of calcium carbonate in cockle shell. J. Eng. Sci. Technol. 2012, 7, 1–10. [Google Scholar]

- Islam, A.; Teo, S.H.; Chan, E.S.; Taufiq-Yap, Y.H. Enhancing the sorption performance of surfactant-assisted CaO nanoparticles. RSC Adv. 2014, 4, 65127–65136. [Google Scholar] [CrossRef]

- Anand, K.V.; Reshma, M.; Kannan, M.; Selvan, S.M.; Chaturvedi, S.; Shalan, A.E.; Govindaraju, K. Preparation and characterization of calcium oxide nanoparticles from marine molluscan shell waste as nutrient source for plant growth. J. Nanostruct. Chem. 2021, 11, 409–422. [Google Scholar] [CrossRef]

- Miculescu, F.; Mocanu, A.C.; Maidaniuc, A.; Dascălu, C.A.; Miculescu, M.; Voicu, S.I.; Ciocoiu, R.C. Hydroxyapatite-Advances in Composite Nanomaterials, Biomedical Applications and Its Technological Facets; Thirumalai, J., Ed.; IntechOpen: London, UK, 2018; p. 186. [Google Scholar]

- Tone, T.; Koga, N. Thermally induced aragonite–calcite transformation in freshwater pearl: A mutual relation with the thermal dehydration of included water. ACS Omega 2021, 6, 13904–13914. [Google Scholar] [CrossRef]

- Muhdarina, N.; Linggawati, A.; Anita, S.; Amri, T.A. Preparation and characterization of calcium oxide heterogeneous catalyst derived from Anadara granosa shell for biodiesel synthesis. KnE Eng. 2016, 1, 1–8. [Google Scholar]

- Nasir, N.F.; Hazri, M.M. Calcium oxide from waste shells as potential green catalyst for biodiesel production. Res. Prog. Mech. Manufac. Eng. 2020, 1, 44–55. [Google Scholar]

- Dampang, S.; Purwanti, E.; Destyorini, F.; Kurniawan, S.B.K.B.; Abdullah, S.R.S.; Imron, M.F. Analysis of optimum temperature and calcination time in the production of CaO using seashells waste as CaCO3 source. J. Ecol. Eng. 2021, 22, 221–228. [Google Scholar] [CrossRef]

- Laskar, I.B.; Rajkumari, K.; Gupta, R.; Chatterjee, S.; Paul, B.; Rokhum, S.L. Waste snail shell derived heterogeneous catalyst for biodiesel production by the transesterification of soybean oil. RSC Adv. 2018, 8, 20131–20142. [Google Scholar] [CrossRef]

- Saragih, A.S.; Pamungkas, A.; Noviyanto, A. Synthesis of hydroxyapatite from Indonesian green mussels (Perna viridis) via precipitation methods. Key Eng. Mater. 2020, 833, 199–203. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, J.; Liu, J.; Zhou, Z.; Huang, Z.; Cao, X.; Zhao, X.; Cen, K. Sulfur removal at high temperature during coal combustion in furnaces: A review. Prog. Energy Combust. Sci. 2003, 29, 381–405. [Google Scholar] [CrossRef]

- Ferraz, E.; Gamelas, J.A.F.; Coroado, J.; Monteiro, C.; Rocha, F. Recycling waste seashells to produce calcitic lime: Characterization and wet saking reactivity. Waste Biomass Valoriz. 2019, 10, 2397–2414. [Google Scholar] [CrossRef]

- Mititelu, M.; Stanciu, G.; Drăgănescu, D.; Ioniță, A.C.; Neacșu, S.M.; Dinu, M.; Stefan-van Staden, R.-I.; Moroșan, E. Mussel shells, a valuable calcium resource for the pharmaceutical industry. Mar. Drugs 2022, 20, 25. [Google Scholar] [CrossRef]

- Ismail, R.; Cionita, T.; Shing, W.L.; Fitriyana, D.F.; Siregar, J.P.; Bayuseno, A.P.; Nugraha, F.W.; Muhamadin, R.C.; Junid, R.; Endot, N.A. Synthesis and characterization of calcium carbonate obtained from green mussel and crab shells as a biomaterials candidate. Materials 2022, 15, 5712. [Google Scholar] [CrossRef]

- Ramakrishna, C.; Thenepalli, T.; Ahn, J.W. A brief review of aragonite precipitated calcium carbonate (PCC) synthesis methods and its applications. Korean Chem. Eng. Res. 2017, 55, 443–455. [Google Scholar]

- Hongxia, G.; Zhenping, Q.; Peng, Q.; Peng, Y.; Suping, C.; Wei, W. Crystallization of aragonite CaCO3 with complex structures. Adv. Powder Technol. 2011, 22, 777–783. [Google Scholar]

- Laonapakul, T.; Sutthi, R.; Chaikool, P.; Mutoh, Y.; Chindaprasirt, P. Optimum conditions for preparation of bio-calcium from blood cockle and golden apple snail shells and characterization. ScienceAsia 2019, 45, 10–20. [Google Scholar] [CrossRef]

| Green Mussel Shells | Composition (wt%) | ||||||

|---|---|---|---|---|---|---|---|

| Ca | Fe | K | Mn | S | Sn | Sr | |

| Non-calcination | 97.74 ± 0.17 | 0.26 ± 0.01 | 0.39 ± 0.01 | 0.10 ± 0.01 | 0.29 ± 0.01 | 0.58 ± 0.06 | 0.64 ± 0.08 |

| 800 °C | 98.15 ± 0.03 | 0.12 ± 0.02 | 0.39 ± 0.04 | 0.06 ± 0.01 | 0.09 ± 0.00 | 0.60 ± 0.04 | 0.58 ± 0.04 |

| 900 °C | 98.26 ± 0.02 | 0.13 ± 0.02 | 0.38 ± 0.00 | 0.07 ± 0.00 | 0.09 ± 0.01 | 0.67 ± 0.04 | 0.41 ± 0.02 |

| 1000 °C | 99.33 ± 0.01 | 0.09 ± 0.00 | 0.00 ± 0.00 | 0.06 ± 0.01 | 0.09 ± 0.01 | 0.00 ± 0.00 | 0.43 ± 0.01 |

| Mixed Shell Powder | |||||||

| Non-calcination | 98.09 ± 0.02 | 0.32 ± 0.00 | 0.43 ± 0.01 | 0.11 ± 0.01 | 0.10 ± 0.02 | 0.57 ± 0.08 | 0.38 ± 0.05 |

| 800 °C | 98.14 ± 0.48 | 0.22 ± 0.06 | 0.28 ± 0.14 | 0.07 ± 0.01 | 0.08 ± 0.01 | 0.37 ± 0.24 | 0.34 ± 0.04 |

| 900 °C | 98.61 ± 0.32 | 0.18 ± 0.02 | 0.24 ± 0.12 | 0.07 ± 0.00 | 0.09 ± 0.00 | 0.42 ± 0.21 | 0.38 ± 0.03 |

| 1000 °C | 99.42 ± 0.03 | 0.17 ± 0.01 | 0.00 ± 0.00 | 0.07 ± 0.01 | 0.01 ± 0.01 | 0.00 ± 0.00 | 0.25 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srichanachaichok, W.; Pissuwan, D. Micro/Nano Structural Investigation and Characterization of Mussel Shell Waste in Thailand as a Feasible Bioresource of CaO. Materials 2023, 16, 805. https://doi.org/10.3390/ma16020805

Srichanachaichok W, Pissuwan D. Micro/Nano Structural Investigation and Characterization of Mussel Shell Waste in Thailand as a Feasible Bioresource of CaO. Materials. 2023; 16(2):805. https://doi.org/10.3390/ma16020805

Chicago/Turabian StyleSrichanachaichok, Wiranchana, and Dakrong Pissuwan. 2023. "Micro/Nano Structural Investigation and Characterization of Mussel Shell Waste in Thailand as a Feasible Bioresource of CaO" Materials 16, no. 2: 805. https://doi.org/10.3390/ma16020805

APA StyleSrichanachaichok, W., & Pissuwan, D. (2023). Micro/Nano Structural Investigation and Characterization of Mussel Shell Waste in Thailand as a Feasible Bioresource of CaO. Materials, 16(2), 805. https://doi.org/10.3390/ma16020805