Stress–Dilatancy Behaviourof Fibre-Reinforced Sand

Abstract

1. Introduction

2. The General Stress–Plastic Dilatancy Relationship

3. Methodology

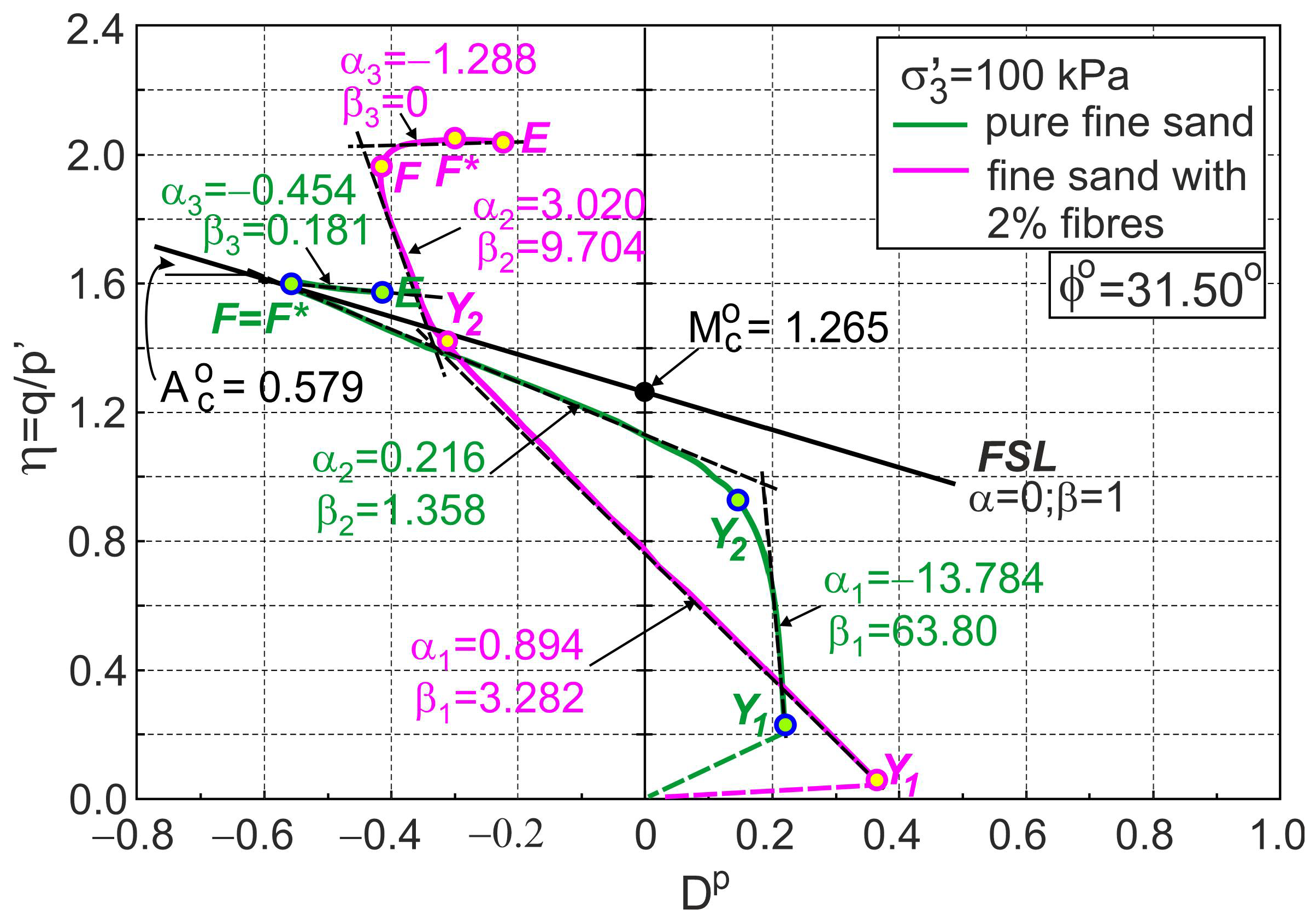

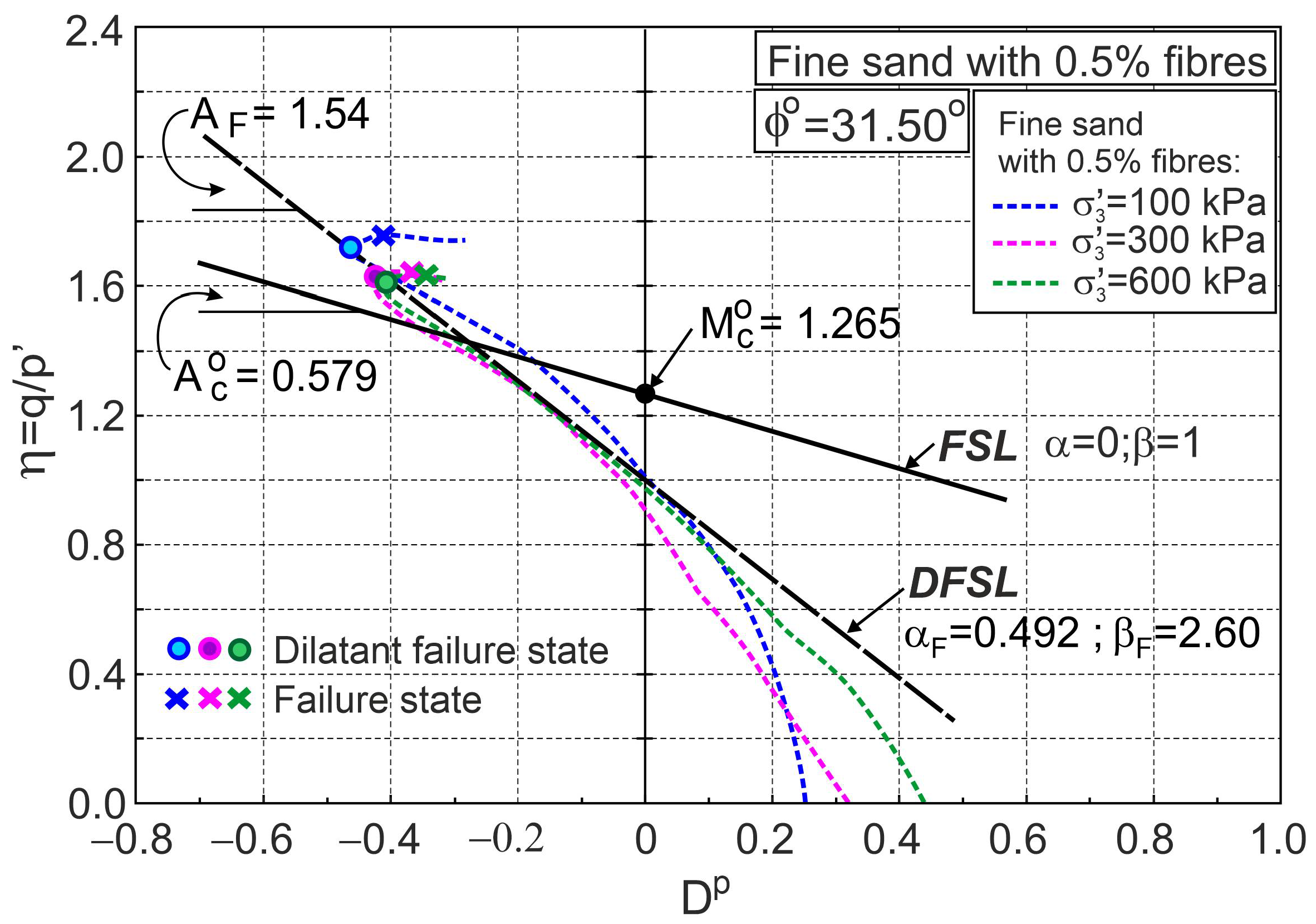

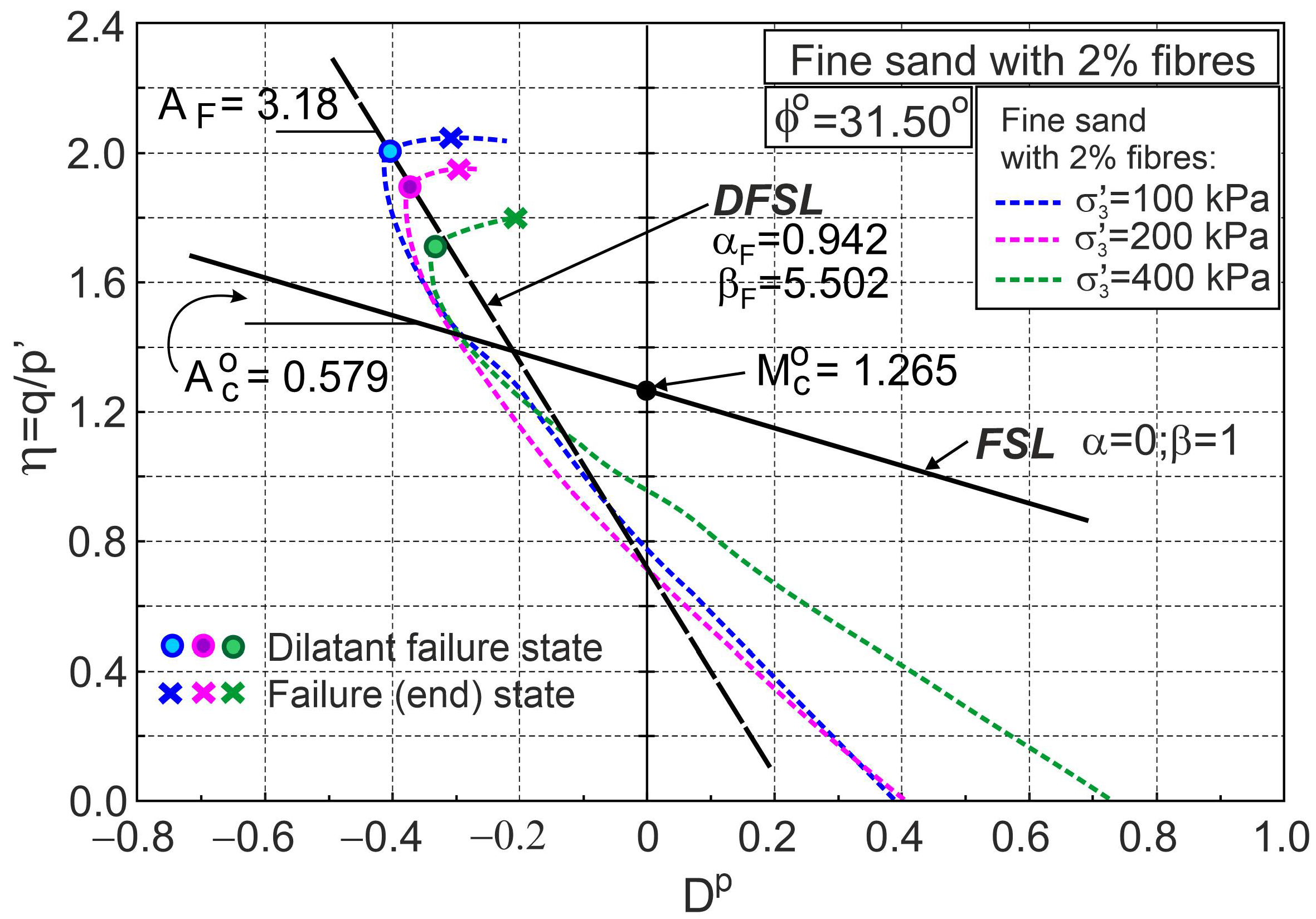

4. Stress–Plastic Dilatancy Relationships for Sand with Polyamide Fibres

4.1. Analysed Tests

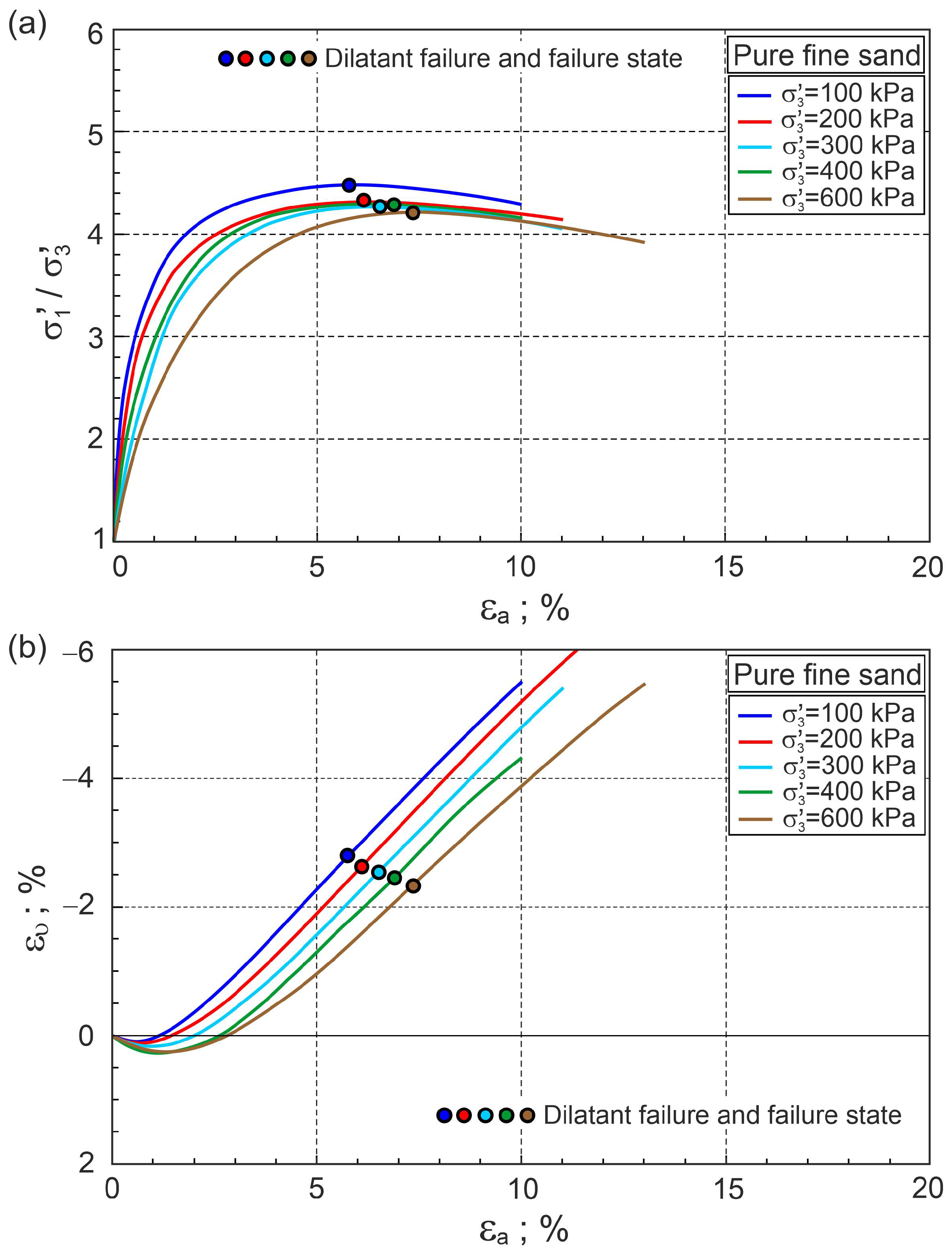

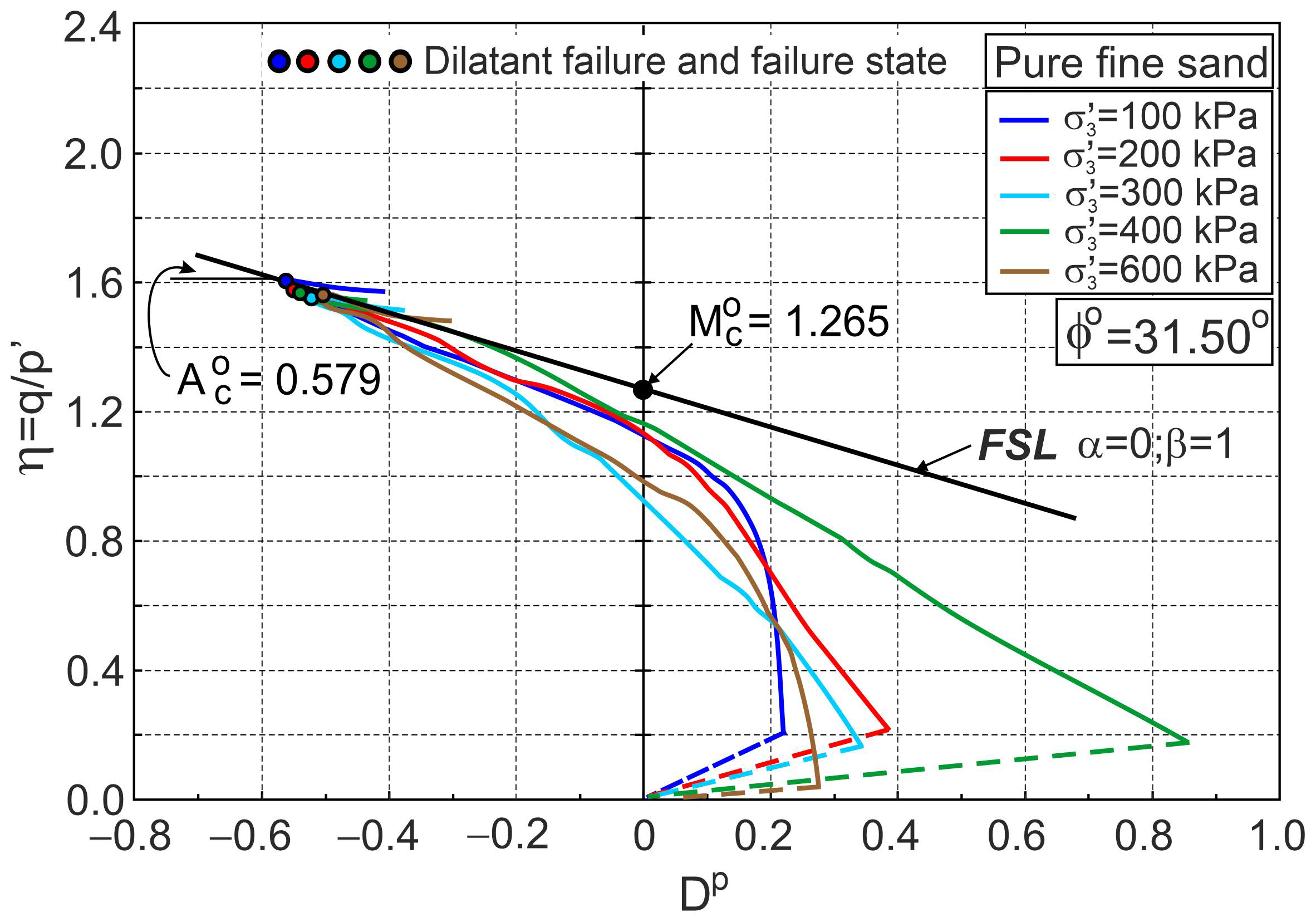

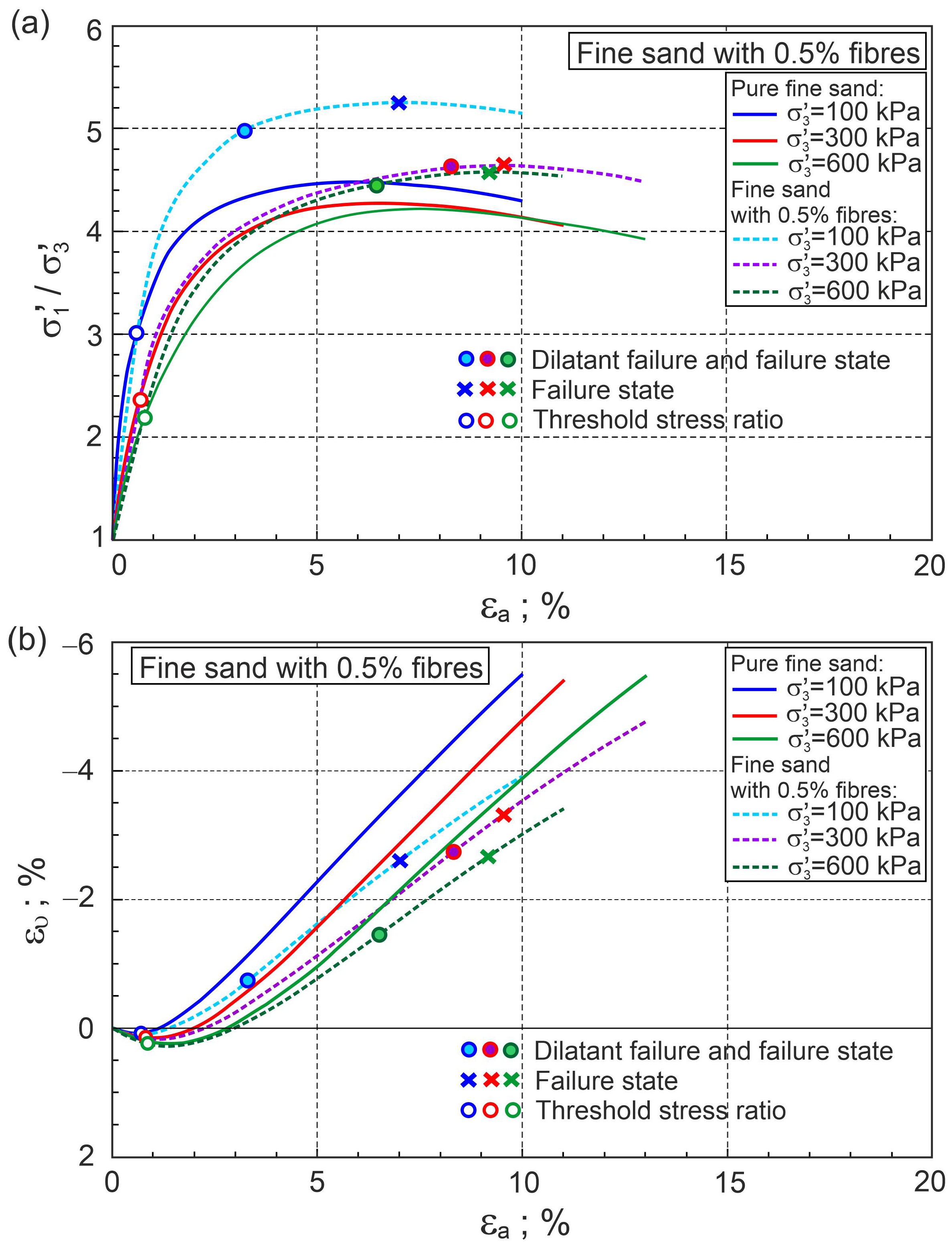

4.2. Characteristic Stages of Shearing

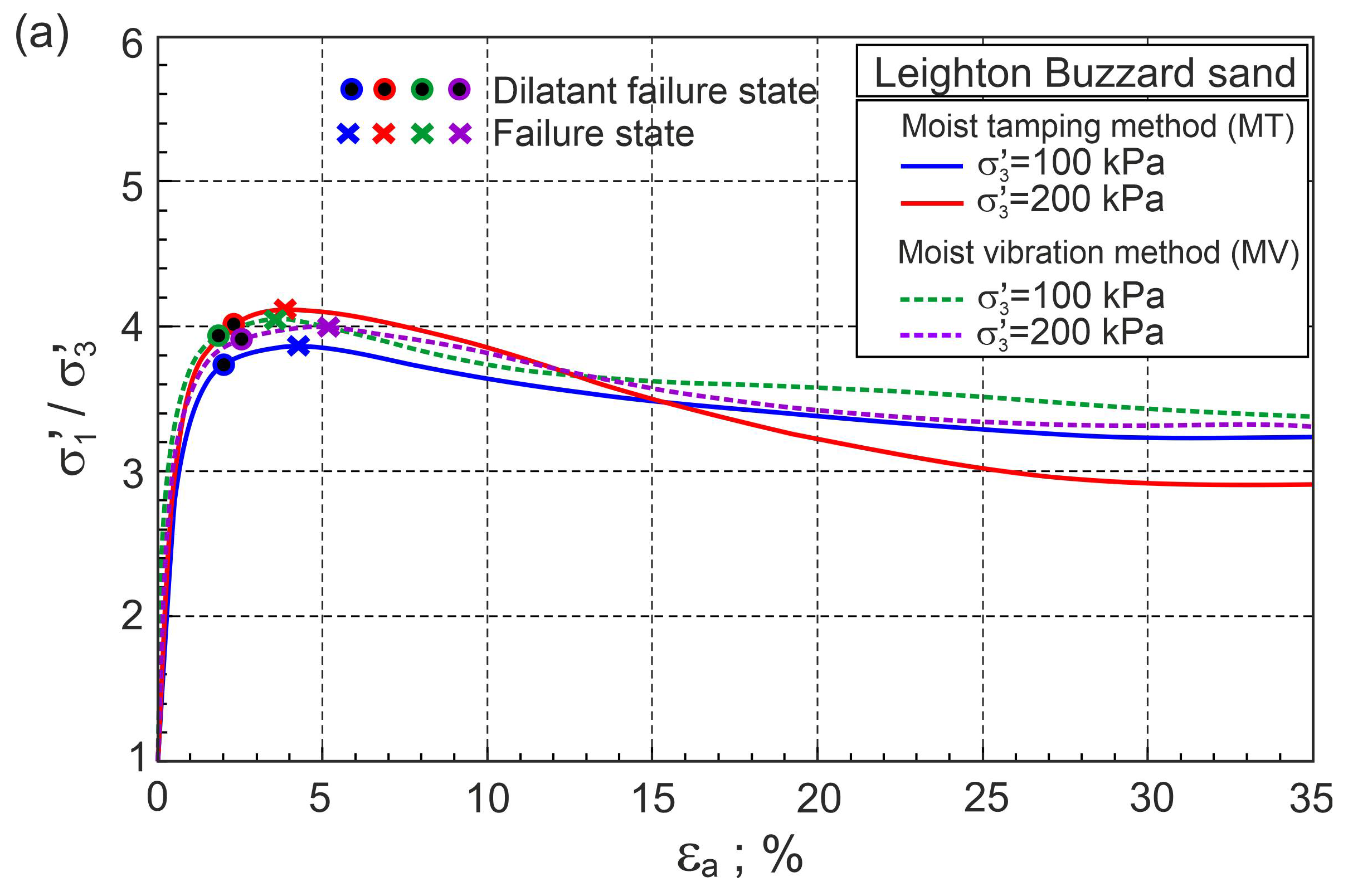

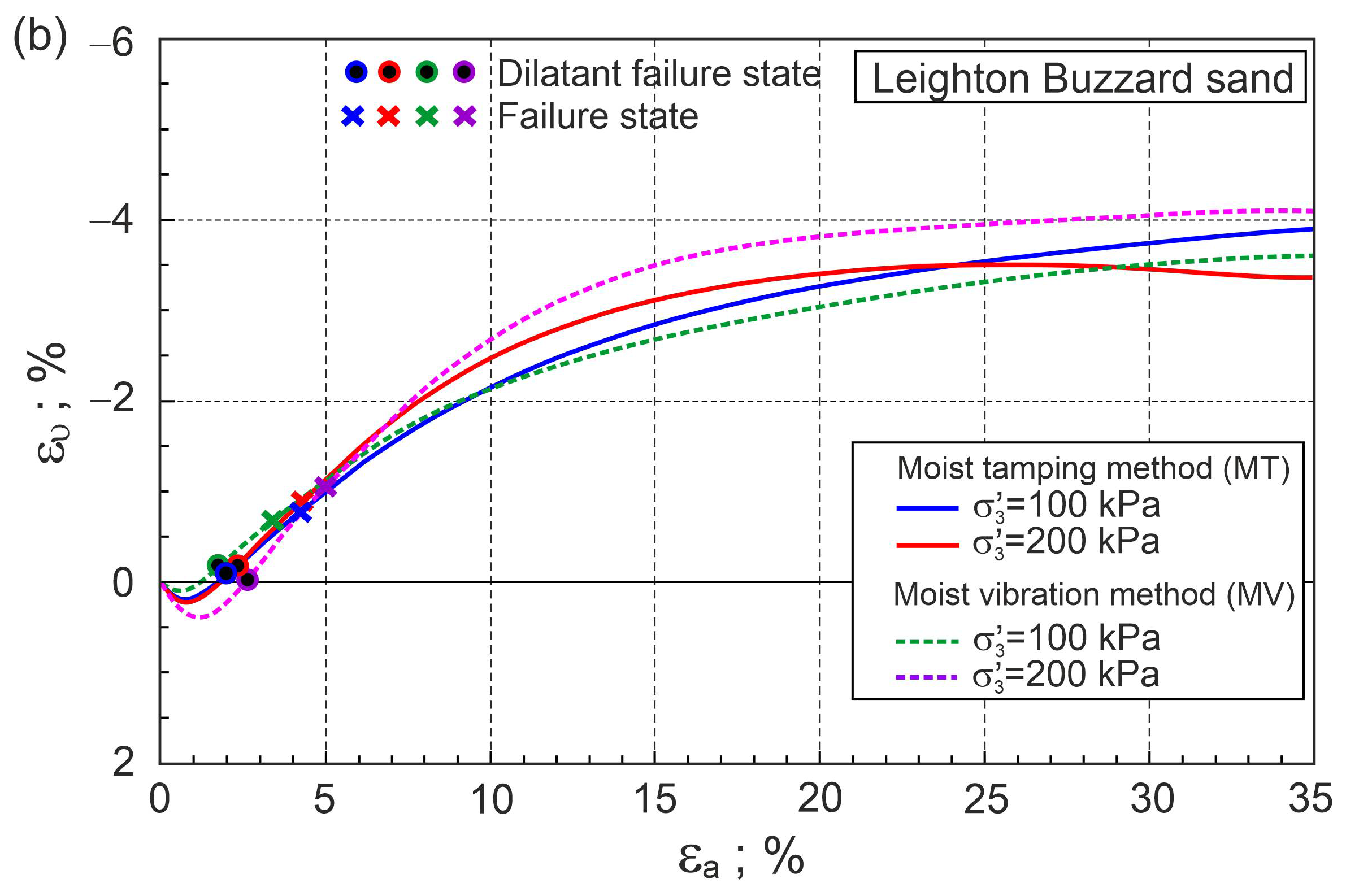

4.3. Stress–Strain Behaviour of Pure Fine Sand

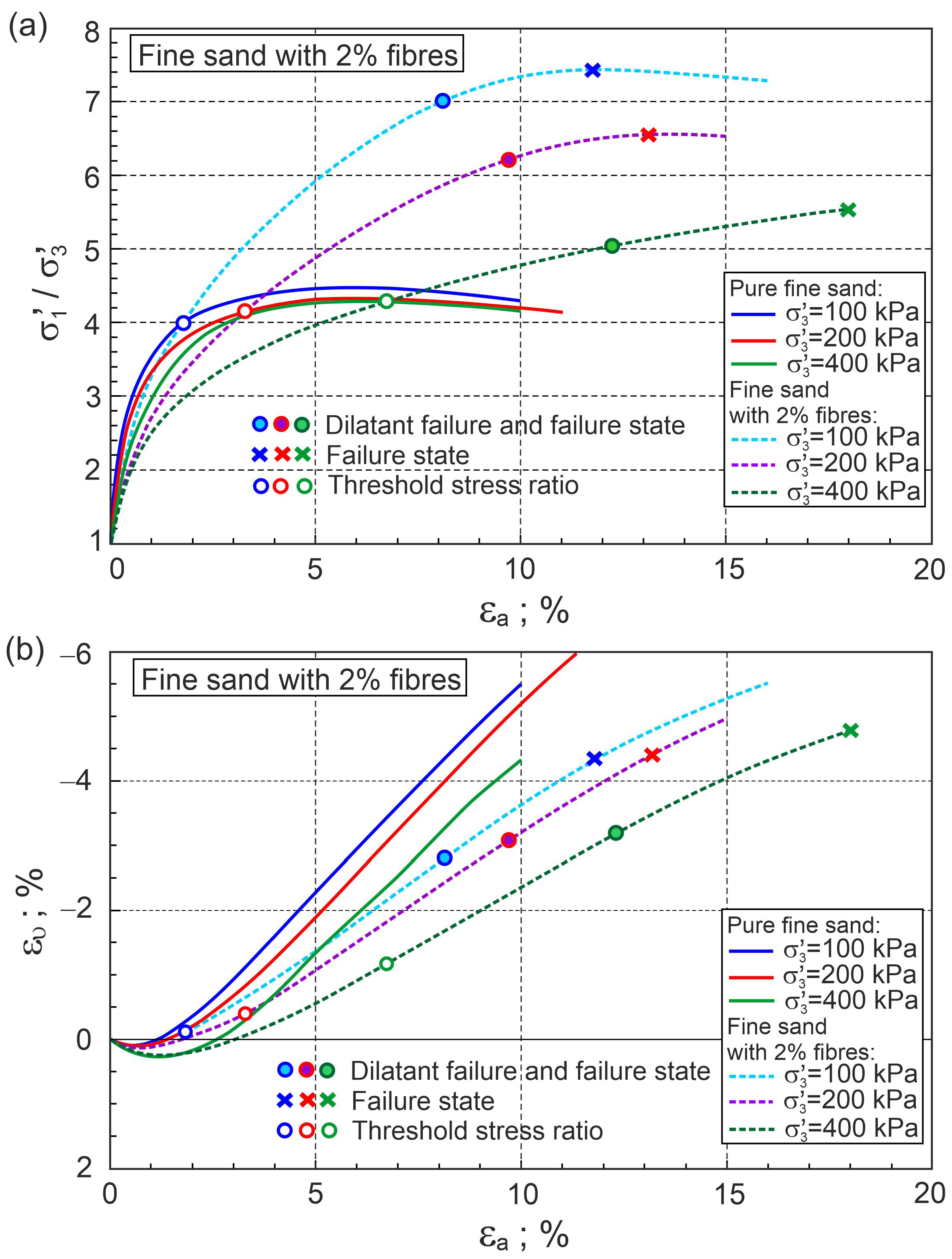

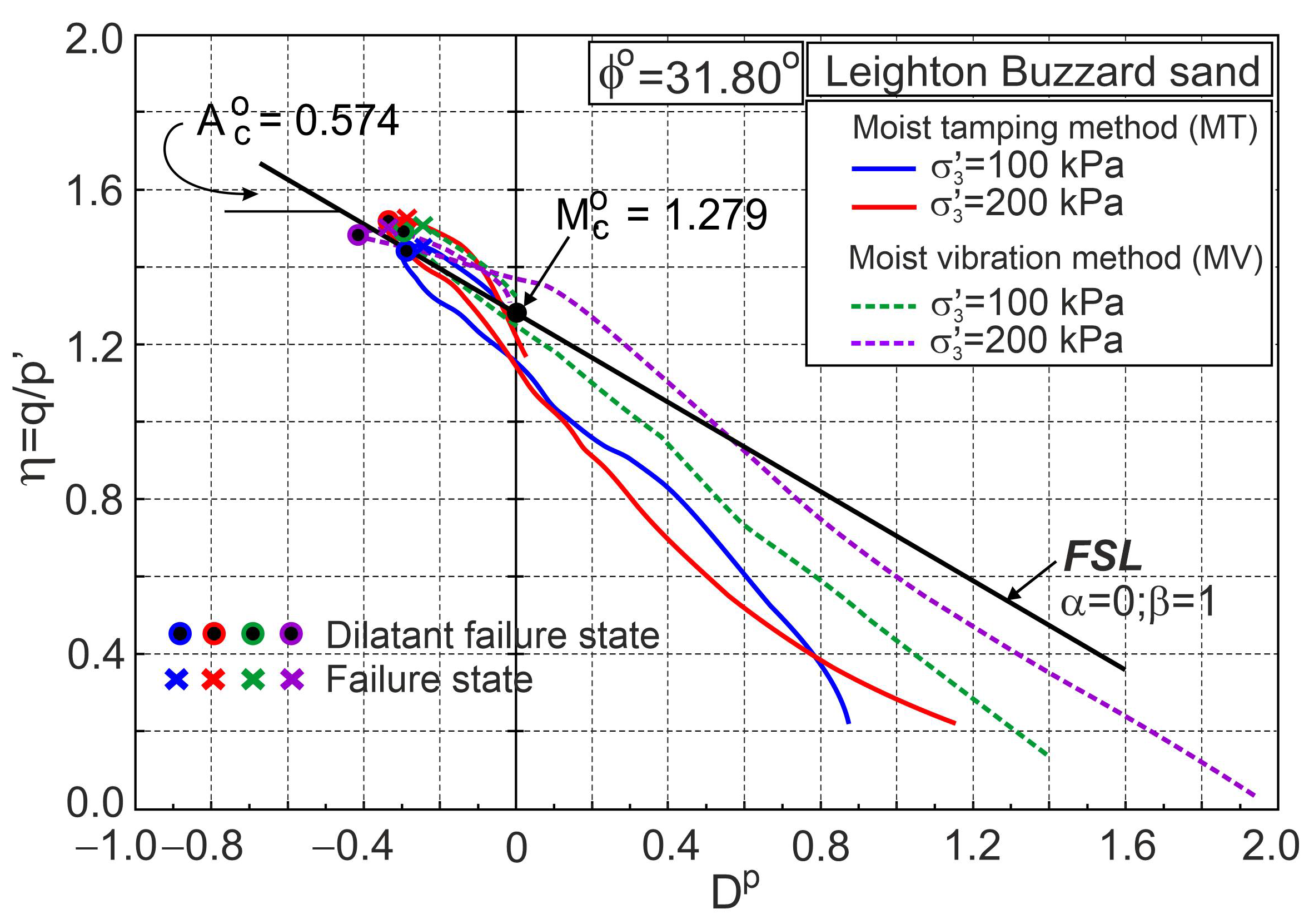

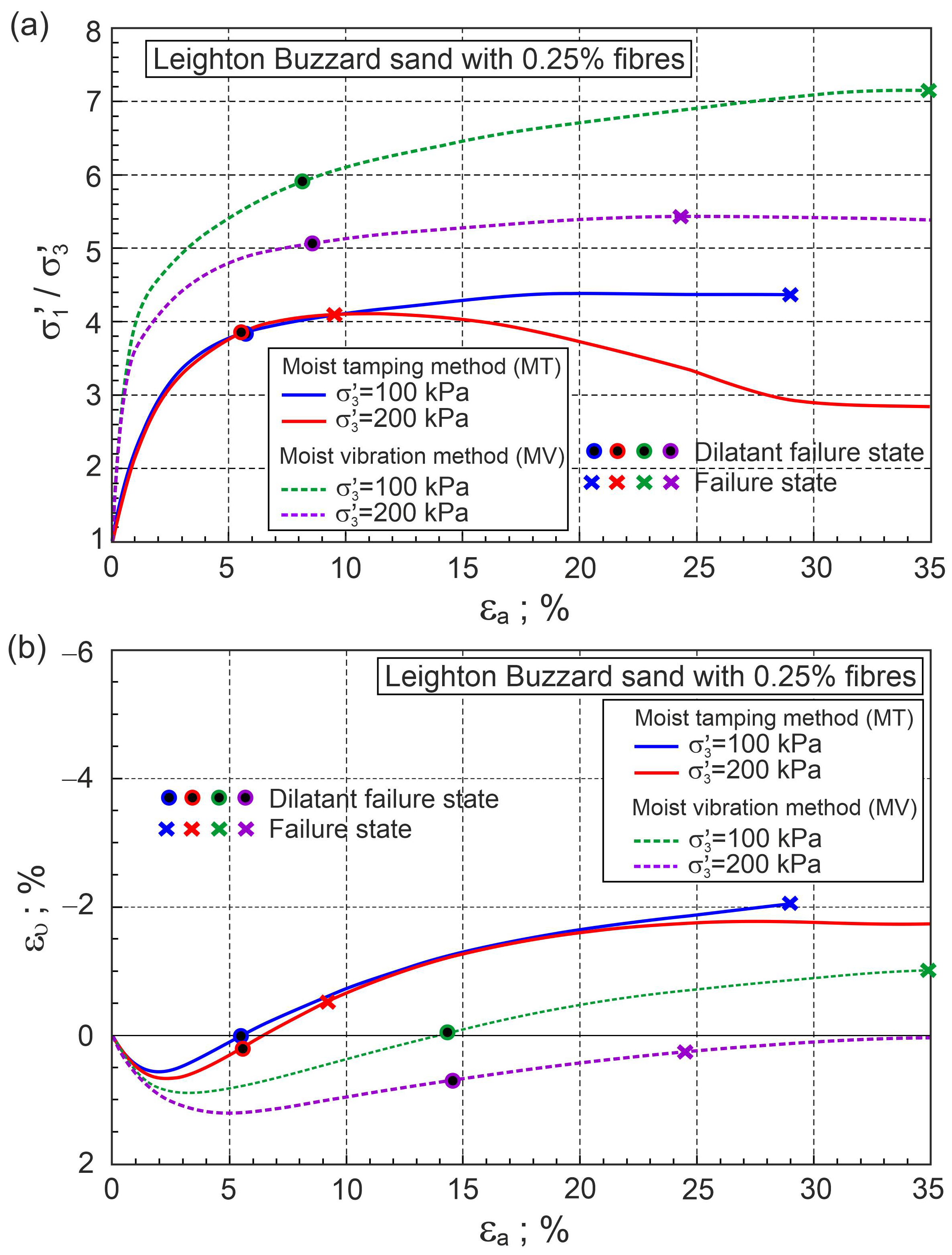

4.4. Stress–Strain Behaviour of Fibre-Reinforced Sand

5. Effect of Sample Preparation Methods

6. Conclusions

- (1)

- Only a few of the triaxial compression test results presented in the literature for two sands with different fibres were analysed, and it is possible to formulate only general conclusions;

- (1)

- The general stress–plastic dilatancy () equation of the Frictional State Concept can correctly approximate the behaviour of fibre-reinforcement sand in different shear stages;

- (3)

- The behaviour of pure sand can be taken as a reference for the behaviour of sand with fibres;

- (4)

- The dilatant failure states of fiber-reinforced sand and artificially cemented soils differ. Dilatant failure states represent the more characteristic stress–plastic dilatancy behaviour;

- (5)

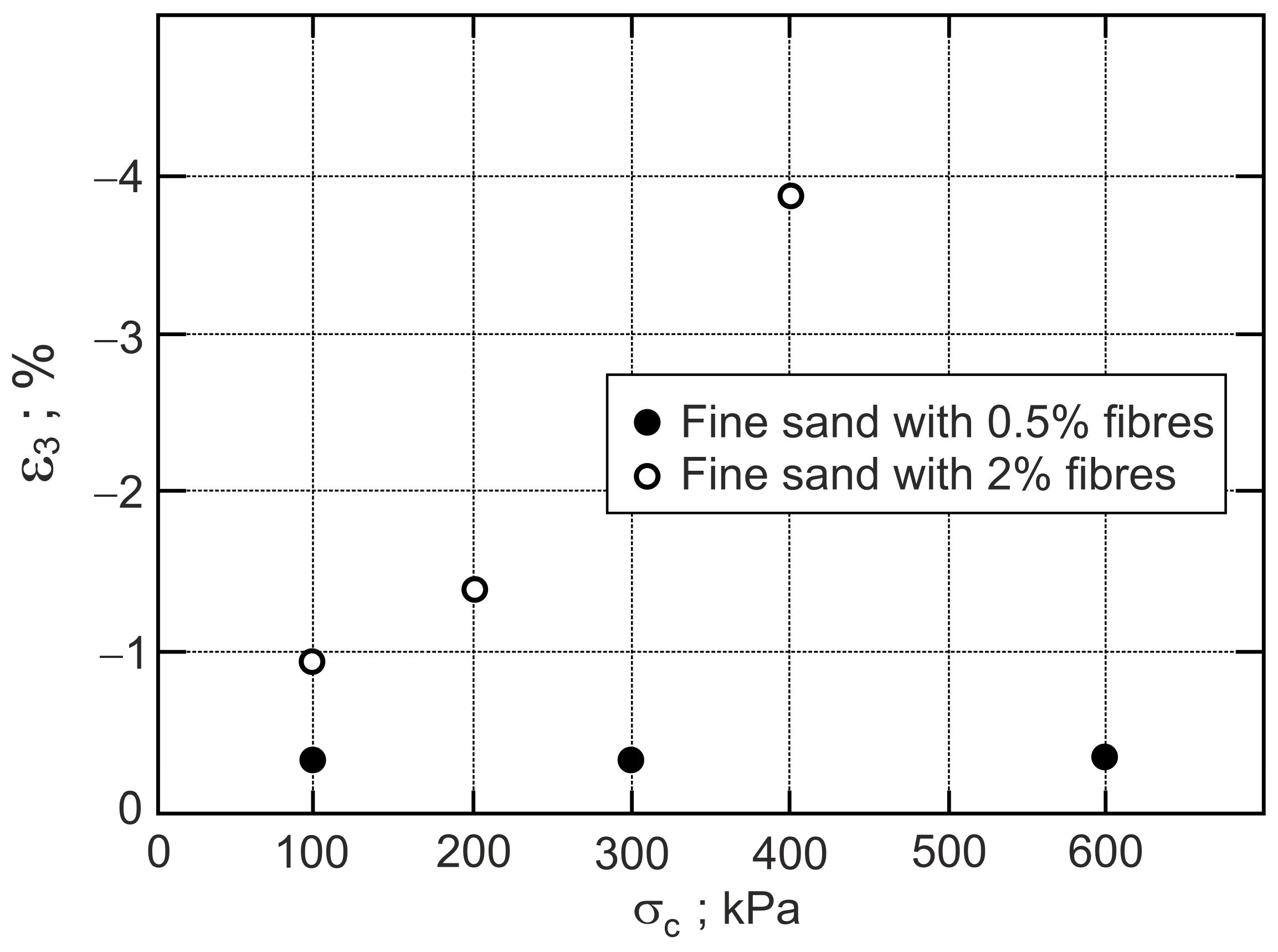

- Fibre concentration, stress level, and the method of sample preparation significantly affect the behaviour of fibre–sand composites during shear;

- (6)

- Tensile strains must be present in order to produce a reinforced effect in a fibre–sand composite. A reduction in the stiffness of the fibre sand composite is observed in the absence of tensile strains below a certain threshold value.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Gong, L.; Nie, L.; Liu, C.; Xu, Y. Modelling Triaxial Tests on Fibre-Reinforced Sands with Different Fibre Orientations Using the Discrete Element Method. KSCE J. Civ. Eng. 2020, 24, 2268–2280. [Google Scholar] [CrossRef]

- Medina-Martinez, C.J.; Sandoval-Herazo, L.C.; Zamora-Castro, S.A.; Vivar-Ocampo, R.; Reyes-Gonzalez, D. Natural Fibers: An Alternative for the Reinforcement of Expansive Soils. Sustainability 2022, 14, 9275. [Google Scholar] [CrossRef]

- Gong, Y.; He, Y.; Han, C.; Shen, Y.; Tan, G. Stability Analysis of Soil Embankment Slope Reinforced with Polypropylene Fiber under Freeze-Thaw Cycles. Adv. Mater. Sci. Eng. 2019, 2019, 5725708. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Čermák, J. Triaxial Compression of Sand Reinforced with Fibers. J. Geotech. Geoenviron. Eng. 2003, 129, 125–136. [Google Scholar] [CrossRef]

- Consoli, N.C.; Casagrande, M.D.; Coop, M.R. Effect of Fiber Reinforcement on the Isotropic Compression Behavior of a Sand. J. Geotech. Geoenviron. Eng. 2005, 131, 1434–1436. [Google Scholar] [CrossRef]

- Sadek, S.; Najjar, S.S.; Freiha, F. Shear Strength of Fiber-Reinforced Sands. J. Geotech. Geoenviron. Eng. 2010, 136, 490–499. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.L.; Liu, J. Experimental Study on the Shear Behaviors of Polypropylene Fiber-Reinforced Sand. KSCE J. Civ. Eng. 2019, 23, 4992–5001. [Google Scholar] [CrossRef]

- Santoni, R.L.; Tingle, J.S.; Webster, S.L. Engineering Properties of Sand-Fiber Mixtures for Road Construction. J. Geotech. Geoenviron. Eng. 2001, 127, 258–268. [Google Scholar] [CrossRef]

- Belheine, N.; Plassiard, J.-P.; Denze, F.V.; Darve, F.; Saridi, A. Numerical Simulation of Drained Triaxial Testing Using 3D Discrete Element Modeling. Comput. Geotech. 2009, 36, 320–331. [Google Scholar] [CrossRef]

- Velloso, R.Q.; Casagrande, M.D.T.; Vargas Junior, E.A.; Consoli, N.C. Simulation of the Mechanical Behavior of Fiber Reinforced Sand Using the Discrete Element Method. Soils Rocks 2012, 35, 201–206. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E. Fibre-reinforced sand: Interaction at the fibre and grain scale. Géotechnique 2015, 65, 296–308. [Google Scholar] [CrossRef]

- Zornberg, J.G. Discrete framework for limit equilibrium analysis of fibre-reinforced soil. Géotechnique 2002, 52, 593–604. [Google Scholar] [CrossRef]

- Zhao, Y.; Ling, X.; Gong, W.; Li, P.; Li, G.; Wang, L. Mechanical Properties of Fiber-Reinforced Soil under Triaxial Compression and Parameter Determination Based on the Duncan-Chang Model. Appl. Sci. 2020, 10, 9043. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E. Modelling of fibre–cohesive soil mixtures. Acta Geotech. 2014, 9, 1029–1043. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E.; Muir Wood, D.; Russel, A.R. Fibre-reinforced sands: Experimental and modelling. Geotext. Geomembr. 2010, 28, 238–250. [Google Scholar] [CrossRef]

- Lirer, S.; Flora, A.; Consoli, N.C. On the Strength of Fibre-Reinforced Soils. Soils Found. 2011, 51, 601–609. [Google Scholar] [CrossRef]

- Li, C. Mechanical Response of Fiber-Reinforced Soil. Ph.D. Thesis, University of Texas, Austin, TX, USA, May 2005. Available online: https://repositories.lib.utexas.edu/bitstream/handle/2152/1781/lic25697.pdf?sequence=2&isAllowed=y (accessed on 20 November 2022).

- DeSimone, A.; Tamagnini, C. Stress–dilatancy based modelling of granular materials and extensions to soils with crushable grains. Int. J. Numer. Anal. Methods Geomech. 2005, 29, 73–101. [Google Scholar] [CrossRef]

- Rahimi, M. Review of Proposed Stress-dilatancy Relationships and Plastic Potential Functions for Uncemented and Cemented Sands. J. Geol. Res. 2019, 1, 19–34. [Google Scholar] [CrossRef]

- Rowe, P.W. The stress-dilatancy relation for static equilibrium if an assembly of particles in contact. Proc. R. Soc. Lond. Ser. A 1962, 269, 500–527. [Google Scholar] [CrossRef]

- Bolton, M.D. The strength and dilatancy of sands. Géotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Wang, X.; Wu, Y.; Lu, Y.; Cui, J.; Wang, X.; Zhu, C. Strength and dilatancy of coral sand in the South China Sea. Bull. Eng. Geol. Environ. 2021, 80, 8279–8299. [Google Scholar] [CrossRef]

- Wang, X.; Shan, I.; Cui, J.; Zhong, Y.; Shen, J.-H.; Wang, X.-Z.; Zhu, C.-Q. Dilatancy of the foundation filling material of island-reefs in the South China Sea. Constr. Build. Mater. 2022, 323, 126524. [Google Scholar] [CrossRef]

- Kong, Y.; Shen, F. Stress-Dilatancy Behaviour for Fiber-Reinforced. In Proceedings of the GeoShanghai 2018 International Conference: Fundamentals of Soil Behaviours GSIC 2018, Shanghai, China, 25–27 May 2018; pp. 480–489. [Google Scholar] [CrossRef]

- Kong, Y.; Zhou, A.; Shen, F.; Yao, Y. Stress-dilatancy relationship for fiber-reinforced sand and its modeling. Acta Geotech. 2019, 14, 1871–1881. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress–dilatancy for soils. Part I:The frictional state theory. Stud. Geotech. Mech. 2016, 38, 51–58. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress–dilatancy for soils. Part II: Experimental validation for triaxial tests. Stud. Geotech. Mech. 2016, 38, 59–65. [Google Scholar] [CrossRef]

- Dołżyk-Szypcio, K. Stress-dilatancy relationship for railway ballast. Stud. Geotech. Mech. 2018, 40, 79–85. [Google Scholar] [CrossRef]

- Szypcio, Z. Stress–dilatancy of gravel for triaxial compression tests. Ann. Warsaw Univ. Life Sci. SGGW Land Reclam. 2018, 50, 119–128. [Google Scholar] [CrossRef]

- Dołżyk-Szypcio, K. Stress–dilatancy relationship of Erksak sand under drained triaxial compression. Geosciences 2020, 10, 353. [Google Scholar] [CrossRef]

- Szypcio, Z.; Dołżyk -Szypcio, K. The Stress-Dilatancy Behaviour of Artificially Bonded Soils. Materials 2022, 15, 7068. [Google Scholar] [CrossRef]

- Been, K.; Jefferies, M.G. Stress–dilatancy in very loose sand. Can. Geotech. J. 2004, 5, 972–985. [Google Scholar] [CrossRef]

- Gao, Z.; Huang, M. Effect of sample preparation method on mechanical behaviour of fibre-reinforced sand. Comput. Geotech. 2021, 133, 104007. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szypcio, Z.; Dołżyk-Szypcio, K.; Chmielewska, I. Stress–Dilatancy Behaviourof Fibre-Reinforced Sand. Materials 2023, 16, 609. https://doi.org/10.3390/ma16020609

Szypcio Z, Dołżyk-Szypcio K, Chmielewska I. Stress–Dilatancy Behaviourof Fibre-Reinforced Sand. Materials. 2023; 16(2):609. https://doi.org/10.3390/ma16020609

Chicago/Turabian StyleSzypcio, Zenon, Katarzyna Dołżyk-Szypcio, and Iwona Chmielewska. 2023. "Stress–Dilatancy Behaviourof Fibre-Reinforced Sand" Materials 16, no. 2: 609. https://doi.org/10.3390/ma16020609

APA StyleSzypcio, Z., Dołżyk-Szypcio, K., & Chmielewska, I. (2023). Stress–Dilatancy Behaviourof Fibre-Reinforced Sand. Materials, 16(2), 609. https://doi.org/10.3390/ma16020609