Mechanism of Interlaminar Strengthening and Toughening of Al/CFRP/Al Composite Laminates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

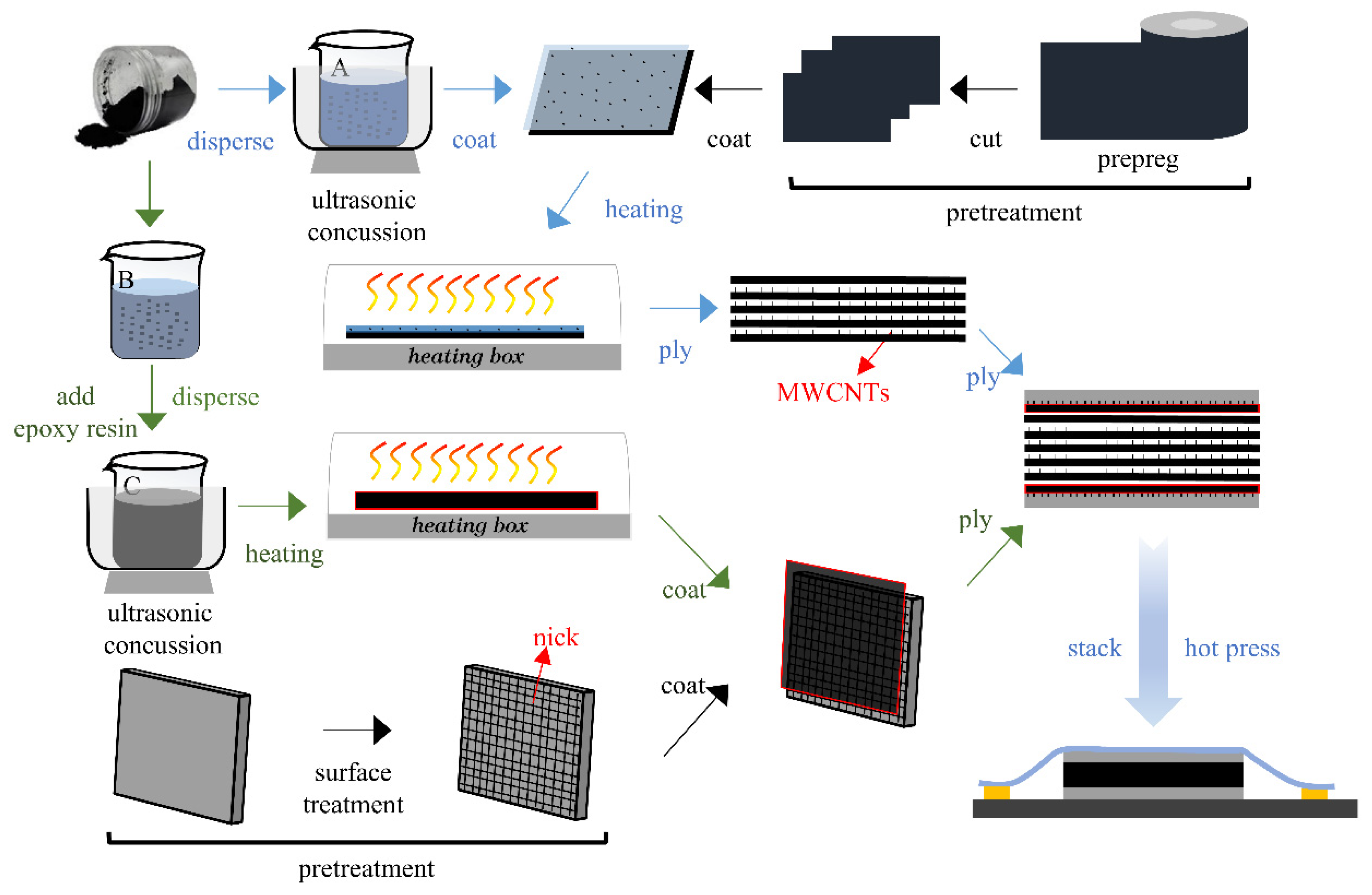

2.2. Preparation of Laminates

2.3. Hot Pressing Scheme

2.4. Shearing Experiment

2.5. Bending Test

2.6. Impact Test

2.7. Metallographic Test

3. Results and Discussion

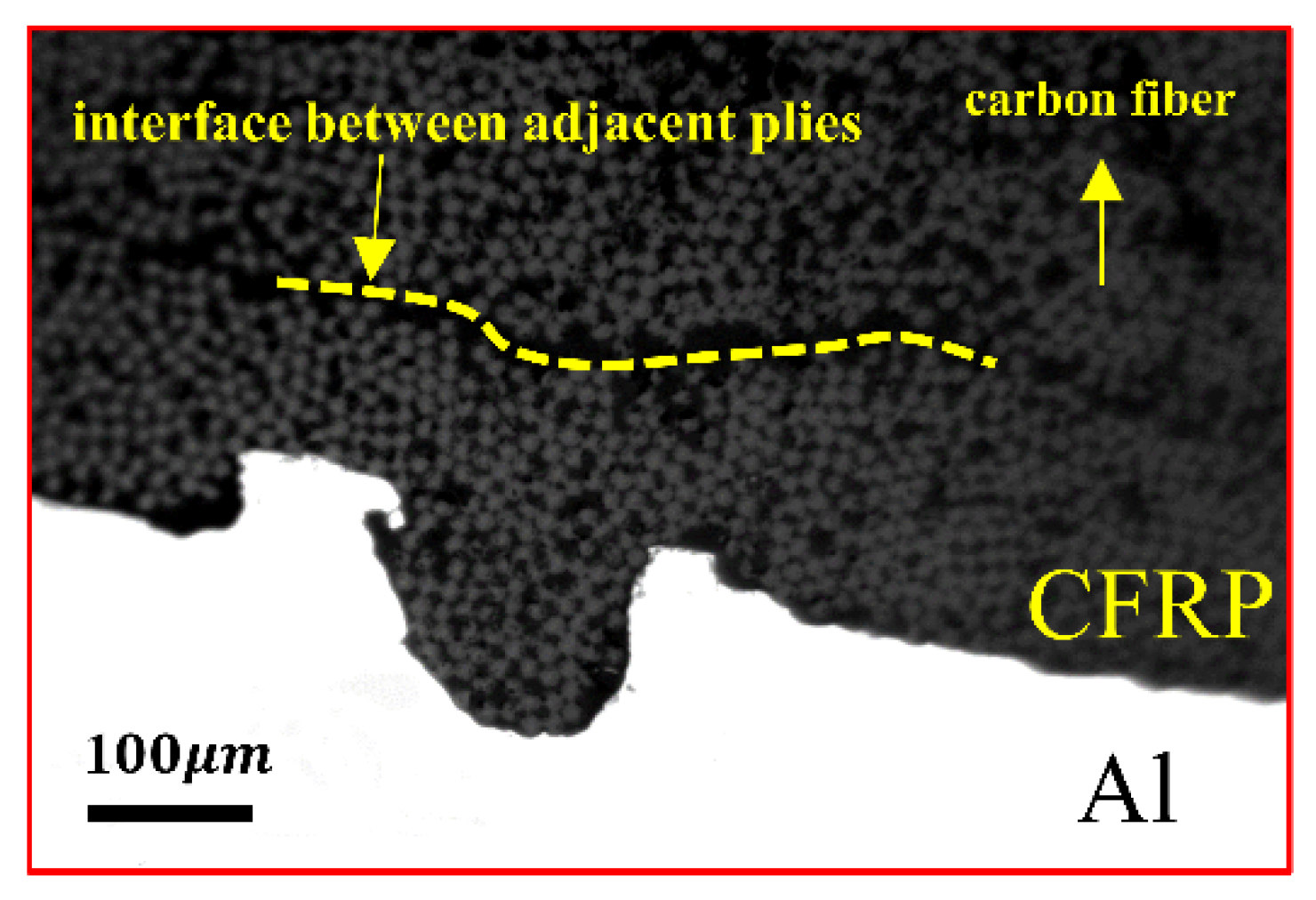

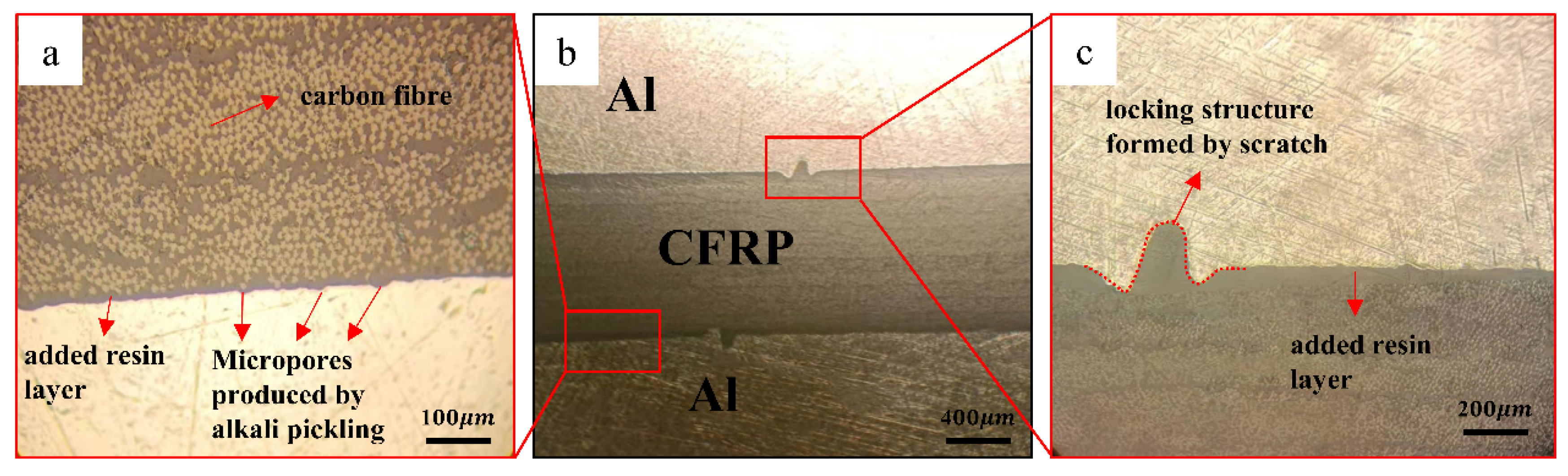

3.1. Laminate Manufacturing Effect

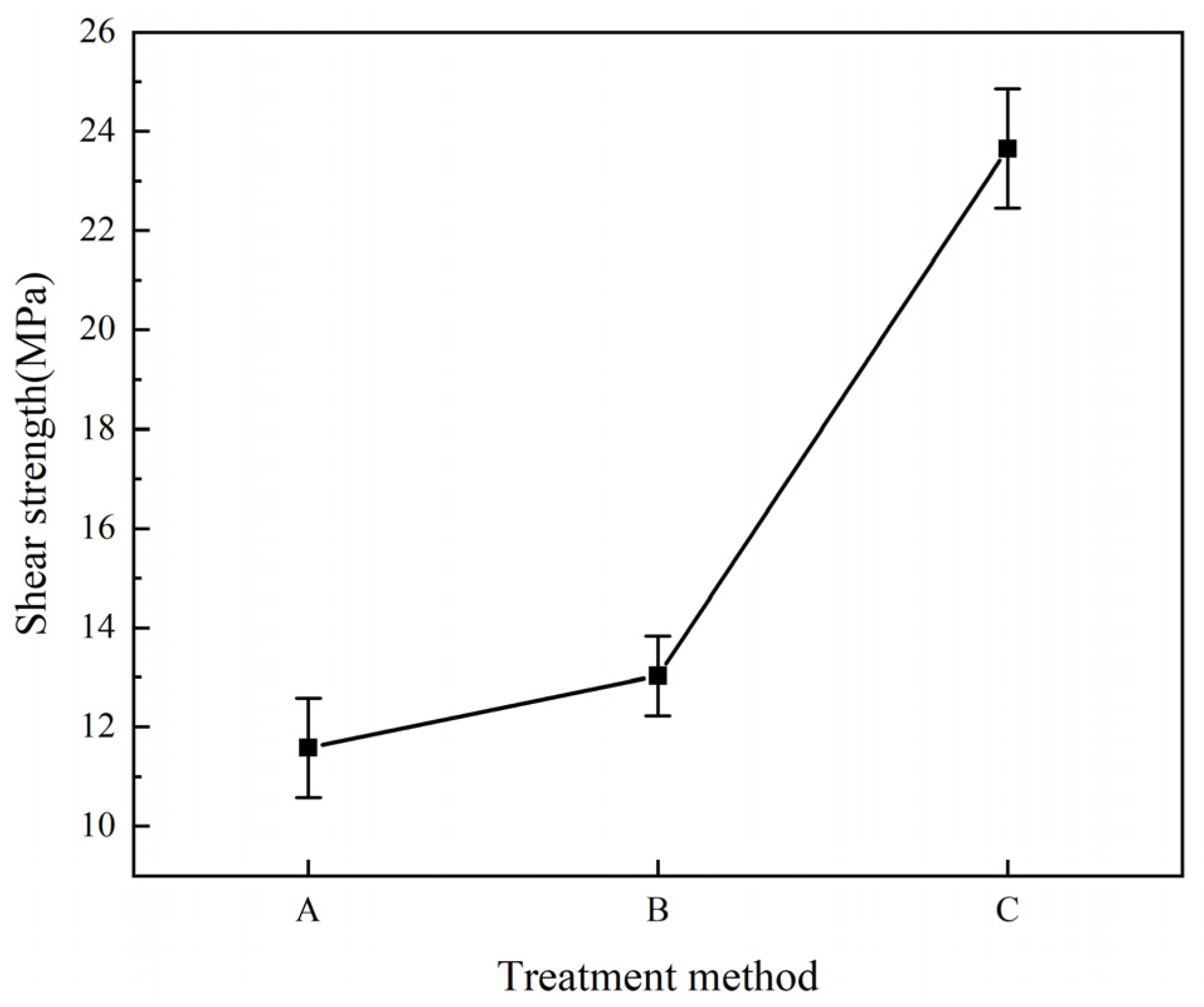

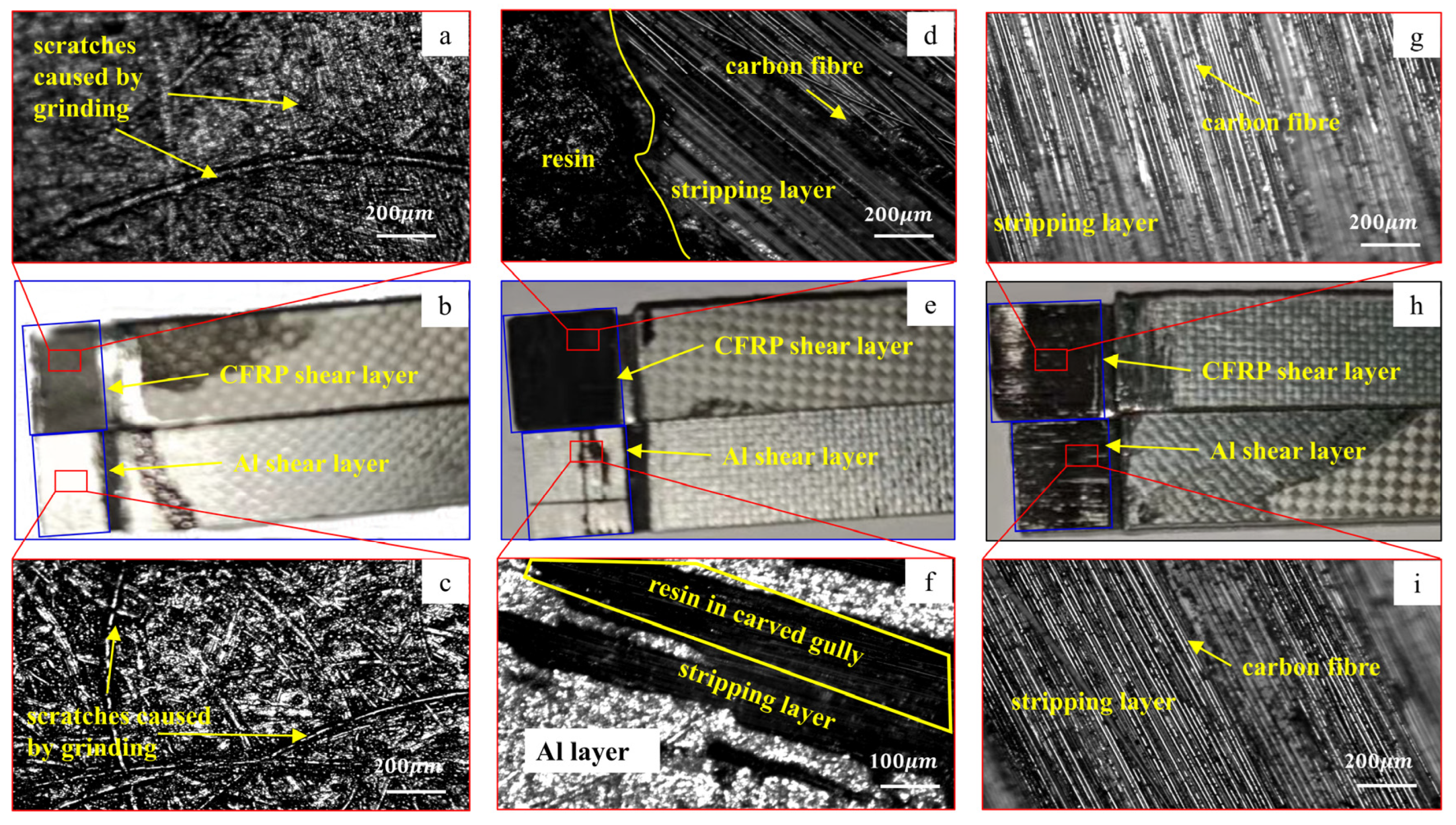

3.2. Shear Test Results

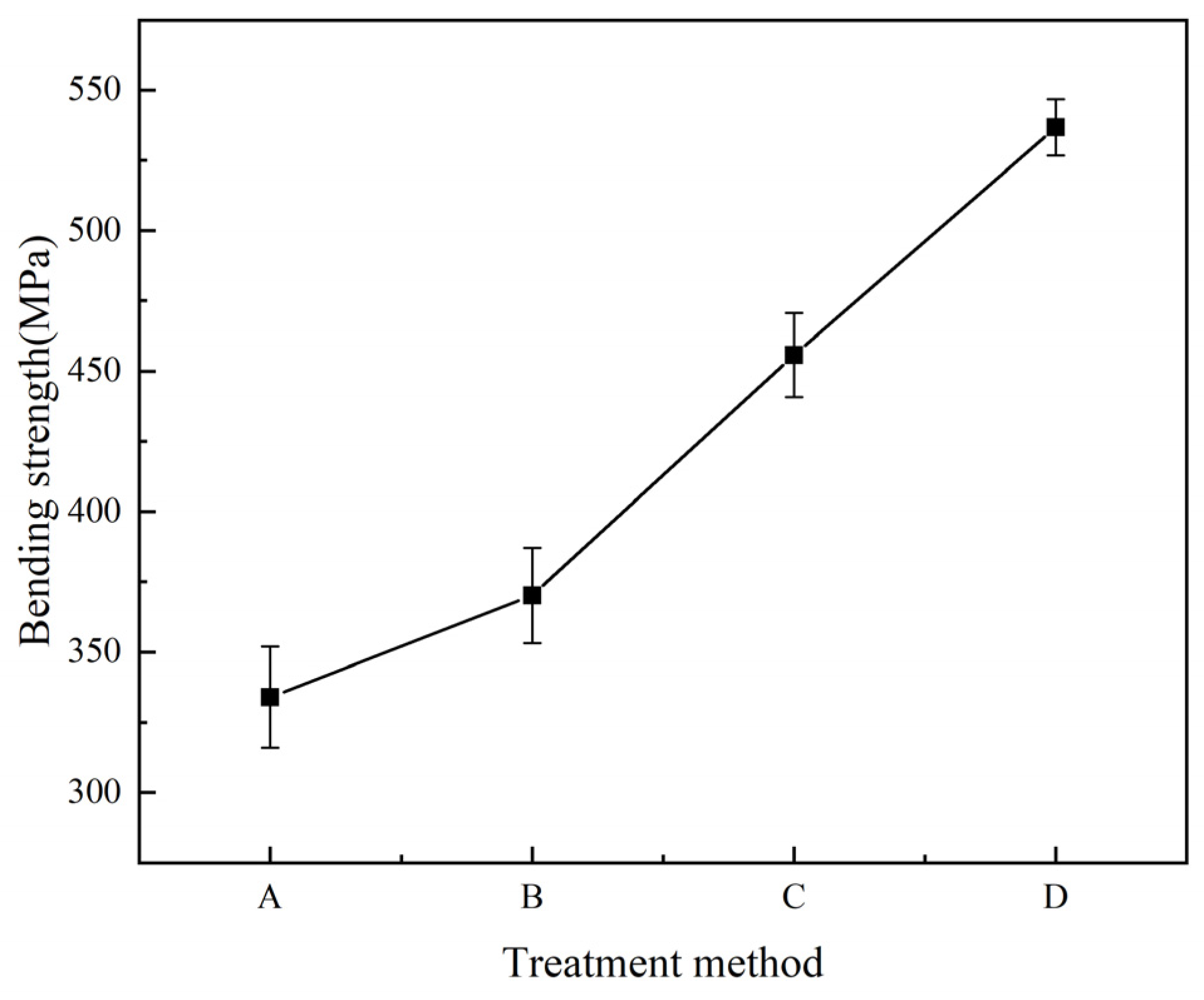

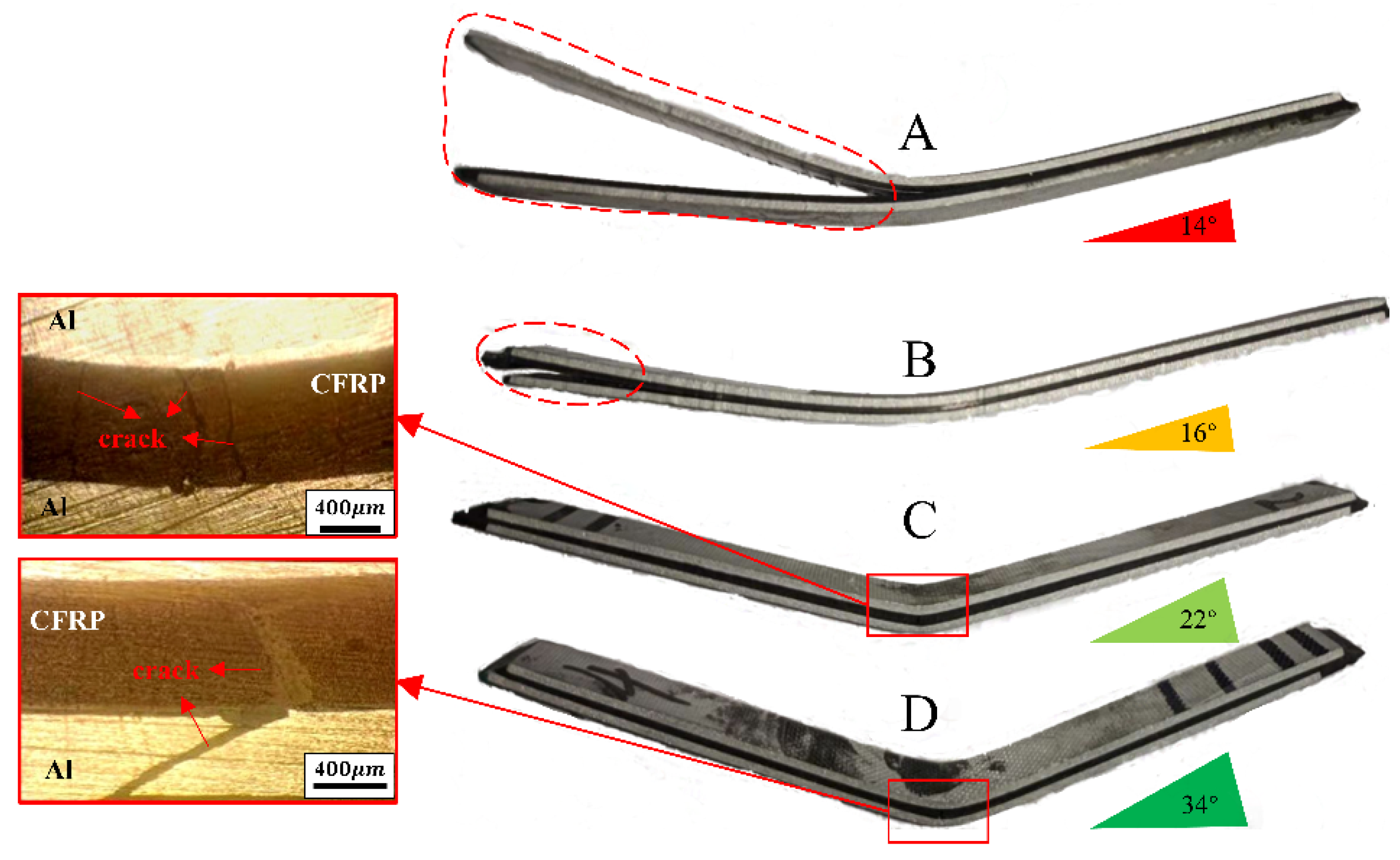

3.3. Bending Test Results

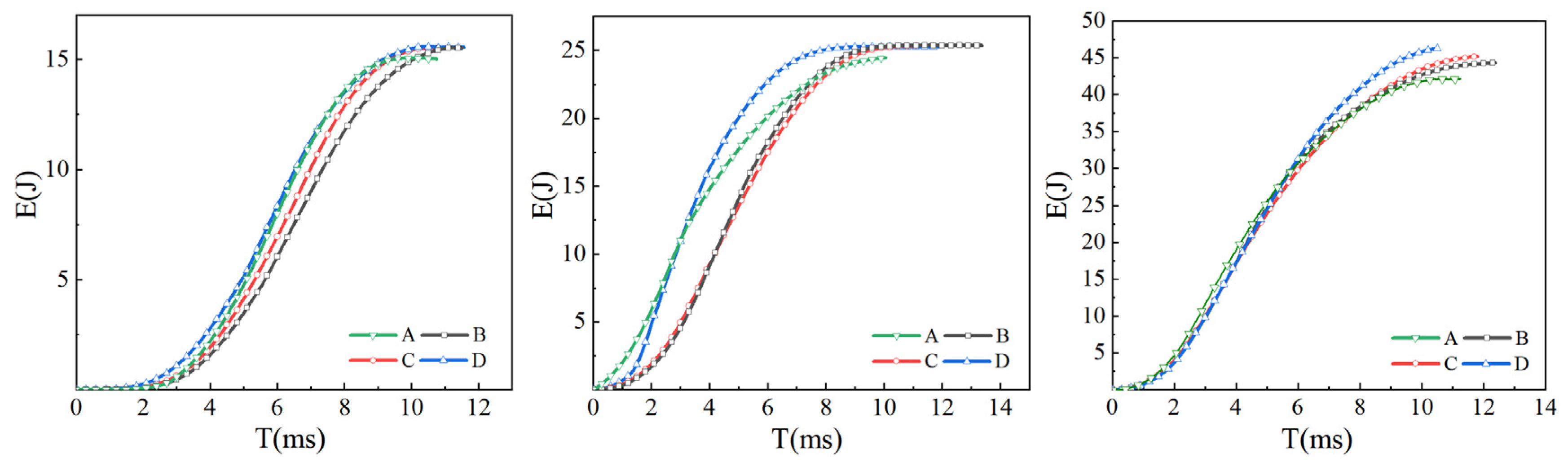

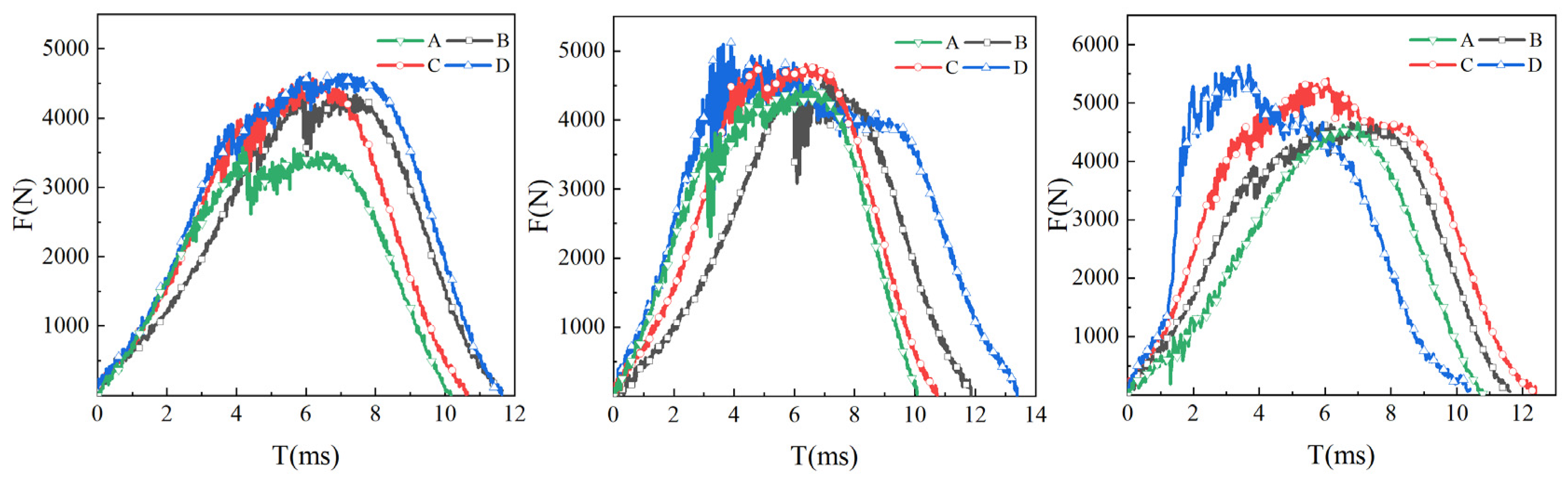

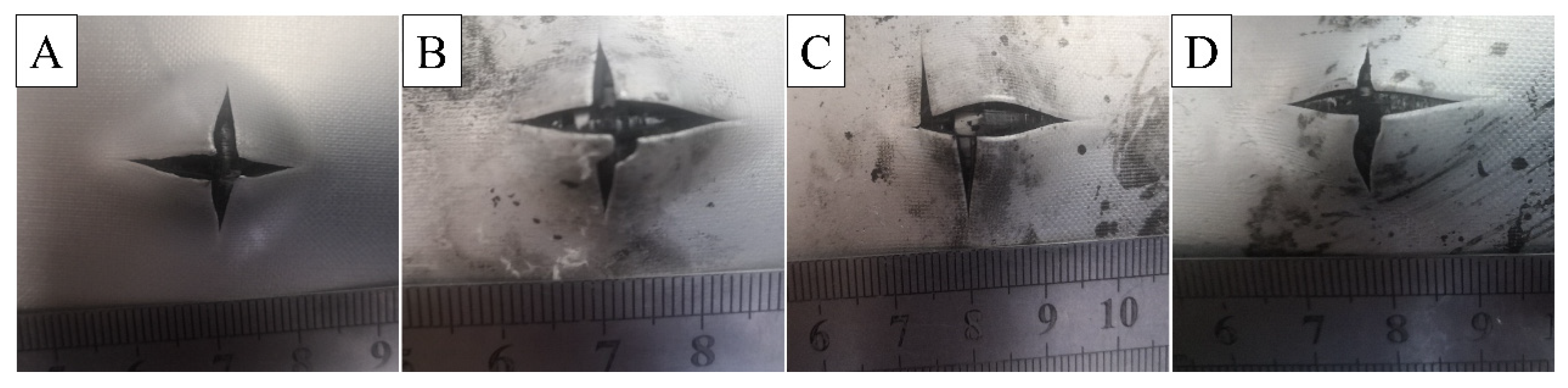

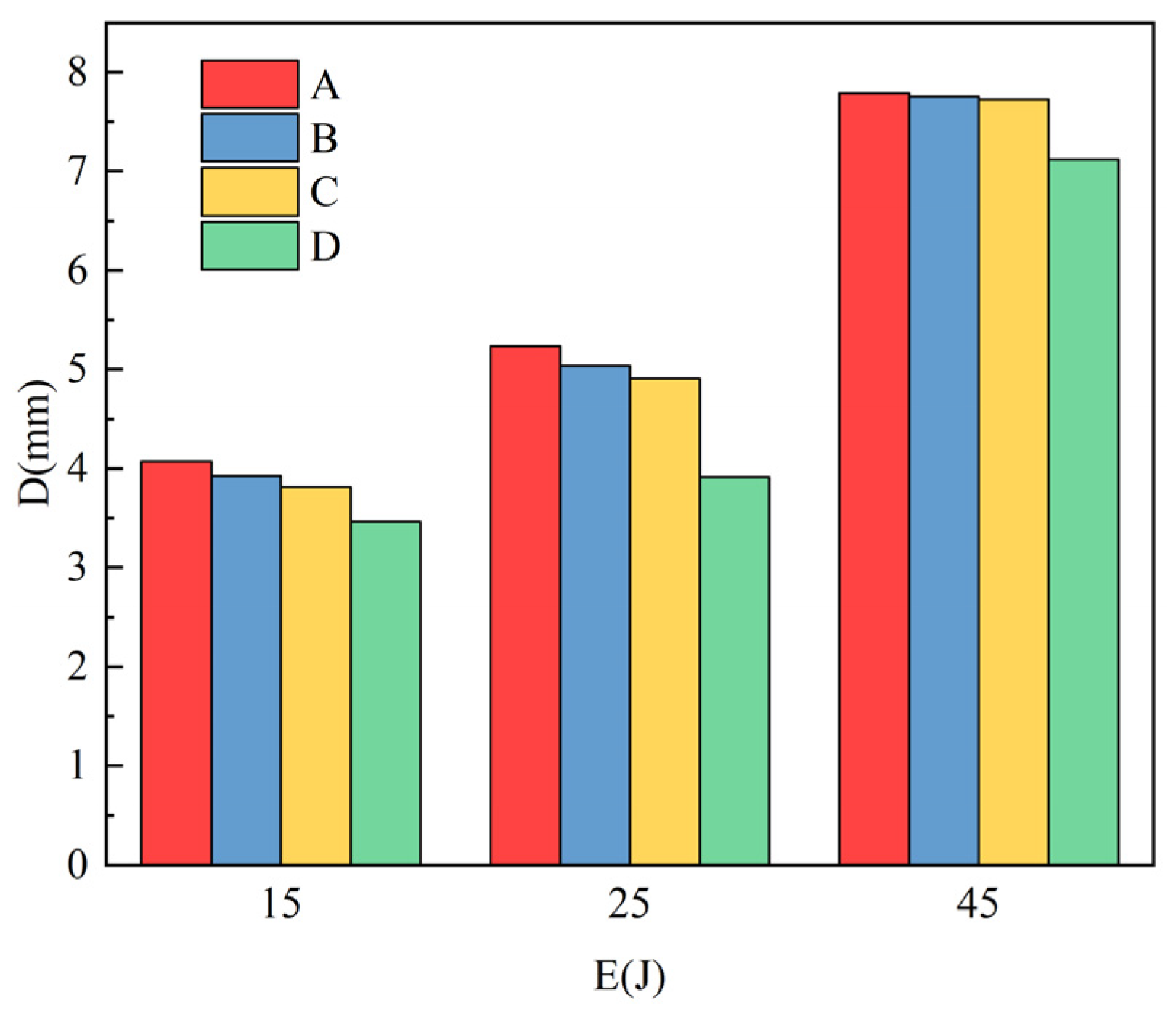

3.4. Impact Test Results

4. Conclusions

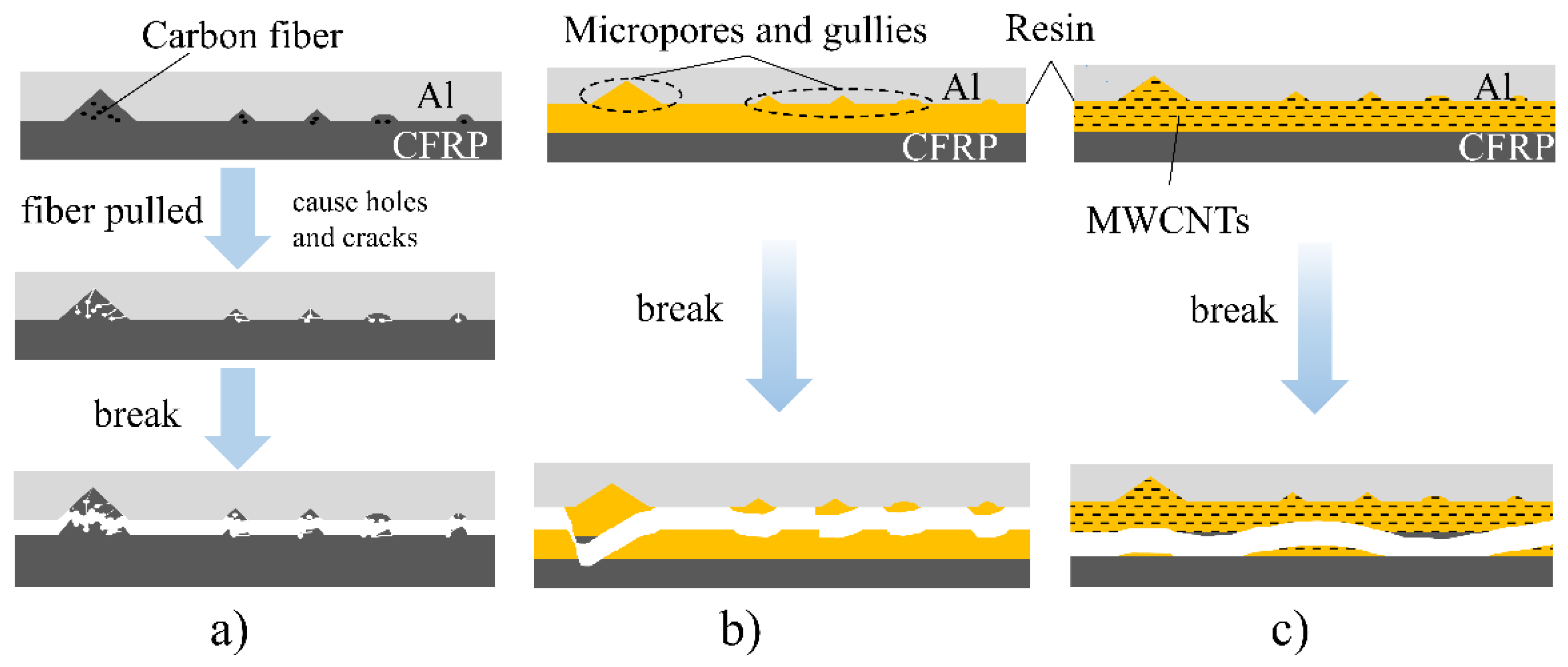

- After the surface treatment of the aluminum plate, “W”-type gullies and micropores are produced on the surface of the aluminum plate. When compounding, it will form an interlock structure with resin to improve the interface strength.

- Adding epoxy resin and epoxy resin with carbon nanotubes between Al/CFRP interface layers can improve interlayer shear strength, which can enhance the bending strength and impact resistance of laminates. The bending strength and impact resistance of laminates are positively correlated with the shear strength between layers. The bending strength of laminates can get an improvement of about 104% after adding epoxy resin and epoxy resin with carbon nanotubes between Al/CFRP interface layers.

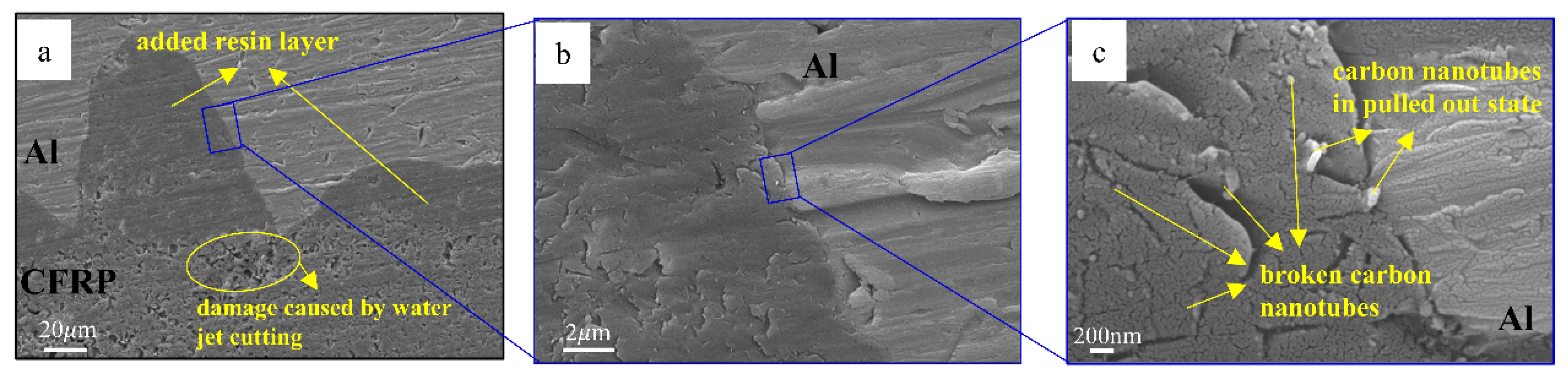

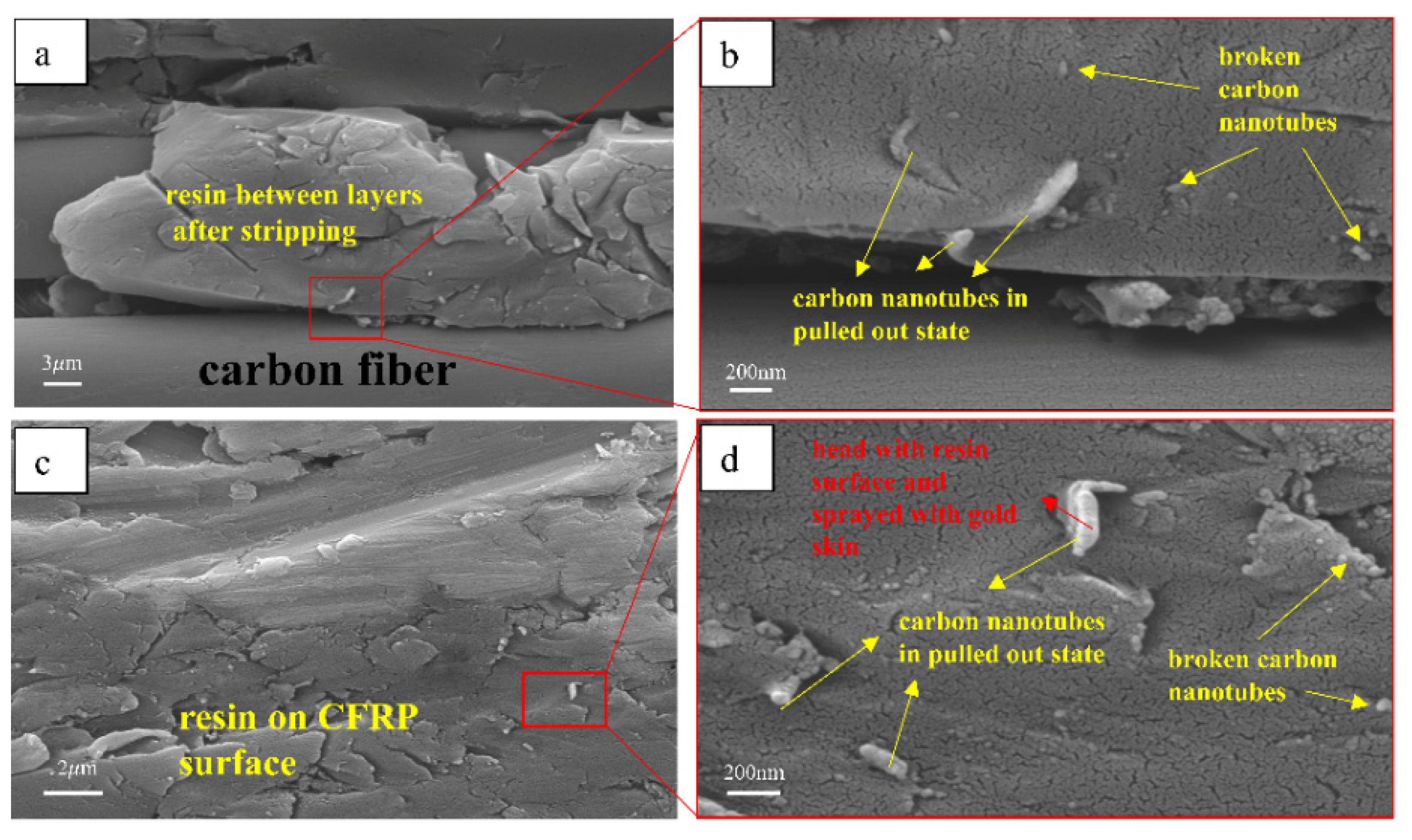

- After carbon nanotubes are added between CFRP layers, the matrix of adjacent layers will wrap the carbon nanotubes, which will toughen CFRP and further enhance the bending strength and impact resistance of toughened laminates. When the laminates are damaged by shearing, bending, and impacting, the resin between the layers will resist the damage in the form of cracking. The added carbon nanotubes will also resist the damage and the extension of cracks at the interface in the form of pulling out and breaking.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vlot, A.; Alderliesten, R.; Hooijmeijer, P.; de Kanter, J.; Sinke, J.; Ypma, M.S. Fibre metal laminates: A state of the art. Int. J. Mater. Prod. Technol. 2002, 17, 79–98. [Google Scholar] [CrossRef]

- Lin, C.T.; Kao, P.W.; Yang, F.S. Fatigue behaviour of carbon fibre-reinforced aluminium laminates. Composites 1991, 22, 135–141. [Google Scholar] [CrossRef]

- Zhong, Y.; Joshi, S. Response of hygrothermally aged GLARE 4A laminates under static and cyclic loadings. Mater. Des. 2015, 87, 138–148. [Google Scholar] [CrossRef]

- Mardiha, P.; Bahrami, A.; Mohammadnejad, A. An investigation on the microstructure, interface, and mechanical properties of spark plasma sintered Ni/Ni-Ni3Al/Ni compound. J. Mater. Eng. Perform. 2020, 31, 1163–1169. [Google Scholar] [CrossRef]

- Fontes, O.P.M.; Bastian, F.; Castrodeza, E. Crack growth resistance curves of GLARE 3 5/4 0.3 fiber–metal laminates at low temperature. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 268–275. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Wang, A.; Wang, T.; Li, J.; Yanagimoto, J. Interfacial strengthening mechanism of SS/CFRTP/SS composite components prepared by mixed co-punch. J. Mater. Process. Technol. 2022, 301, 117458. [Google Scholar] [CrossRef]

- Zhu, W.; Xiao, H.; Wang, J.; Li, X. Effect of Different Coupling Agents on Interfacial Properties of Fibre-Reinforced Aluminum Laminates. Materials 2021, 14, 1019. [Google Scholar] [CrossRef] [PubMed]

- Wei, R.; Wang, X.; Chen, C.; Zhang, X.; Xu, X.; Du, S. Effect of surface treatment on the interfacial adhesion performance of aluminum foil/CFRP laminates for cryogenic propellant tanks. Mater. Des. 2017, 116, 188–198. [Google Scholar] [CrossRef]

- Rothwell, G.; Sykes, J. Metal Finishing. In Mechanical Engineer’s Reference Book; Elsevier: Amsterdam, The Netherlands, 1973; pp. 6-94–6-142. [Google Scholar] [CrossRef]

- Xie, J.; Chen, Y.; Yin, L.; Zhang, T.; Wang, S.; Wang, L. Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. J. Manuf. Process. 2021, 64, 473–480. [Google Scholar] [CrossRef]

- Hamill, L.; Hofmann, D.; Nutt, S. Galvanic corrosion and mechanical behavior of fiber metal laminates of metallic glass and carbon fiber composites. Adv. Eng. Mater. 2018, 20, 1700711. [Google Scholar] [CrossRef]

- Hara, D.; Özgen, G.O. Investigation of weight reduction of automotive body structures with the use of sandwich materials. Transp. Res. Procedia 2016, 14, 1013–1020. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Zhang, X.; Zhang, H.; Yang, J.; Nia, A.B.; Chai, G.B. Mechanical behaviors of Ti/CFRP/Ti laminates with different surface treatments of titanium sheets. Compos. Struct. 2017, 163, 21–31. [Google Scholar] [CrossRef]

- Zhu, W.; Xiao, H.; Wang, J.; Fu, C. Characterization and properties of AA6061-based fiber metal laminates with different aluminum-surface pretreatments. Compos. Struct. 2019, 227, 111321. [Google Scholar] [CrossRef]

- Kovacs, J.Z.; Andresen, K.; Pauls, J.R.; Garcia, C.P.; Schossig, M.; Schulte, K.; Bauhofer, W. Analyzing the quality of carbon nanotube dispersions in polymers using scanning electron microscopy. Carbon 2007, 45, 1279–1288. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Pervin, F.; Lewis, L.; Jeelani, S. Fabrication and characterization of carbon/epoxy composites mixed with multi-walled carbon nanotubes. Mater. Sci. Eng. A 2008, 475, 157–165. [Google Scholar] [CrossRef]

- Shen, J.; Huang, W.; Wu, L.; Hu, Y.; Ye, M. The reinforcement role of different amino-functionalized multi-walled carbon nanotubes in epoxy nanocomposites. Compos. Sci. Technol. 2007, 67, 3041–3050. [Google Scholar] [CrossRef]

- Srivastava, V.K. Modeling and mechanical performance of carbon nanotube/epoxy resin composites. Mater. Des. 2012, 39, 432–436. [Google Scholar] [CrossRef]

- Rahmanian, S.; Suraya, A.R.; Shazed, M.A.; Zahari, R.; Zainudin, E.S. Mechanical characterization of epoxy composite with multiscale reinforcements: Carbon nanotubes and short carbon fibers. Mater. Des. 2014, 60, 34–40. [Google Scholar] [CrossRef] [Green Version]

- Aghamohammadi, H.; Eslami-Farsani, R.; Tcharkhtchi, A. The effect of multiwalled carbon nanotubes on the mechanical behavior of basalt fibers metal laminates: An experimental study. Int. J. Adhes. Adhes. 2020, 98, 102538. [Google Scholar] [CrossRef]

- Xu, H.; Tong, X.; Zhang, Y.; Li, Q.; Lu, W. Mechanical and electrical properties of laminated composites containing continuous carbon nanotube film interleaves. Compos. Sci. Technol. 2016, 127, 113–118. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, Y.; Li, H.; Tian, J.; Fu, X.; Xu, Y.; Lu, Y.; Chen, Y.; Qin, L.; Tao, J. Effect of multi-walled carbon nanotubes addition on the interfacial property of titanium-based fiber metal laminates. Polym. Compos. 2018, 39, E1159–E1168. [Google Scholar] [CrossRef]

| Laminate Label | Laminate Structure |

|---|---|

| A | Al/CFRP/Al |

| B | Al/e/CFRP/e/Al |

| C | Al/ec/CFRP/ec/Al |

| D | Al/ec/CFRPc/ec/Al |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Qiao, T.; Wang, A.; Li, X.; Wang, T. Mechanism of Interlaminar Strengthening and Toughening of Al/CFRP/Al Composite Laminates. Materials 2023, 16, 560. https://doi.org/10.3390/ma16020560

Wang J, Qiao T, Wang A, Li X, Wang T. Mechanism of Interlaminar Strengthening and Toughening of Al/CFRP/Al Composite Laminates. Materials. 2023; 16(2):560. https://doi.org/10.3390/ma16020560

Chicago/Turabian StyleWang, Jian, Tianqi Qiao, Aidong Wang, Xiudong Li, and Tao Wang. 2023. "Mechanism of Interlaminar Strengthening and Toughening of Al/CFRP/Al Composite Laminates" Materials 16, no. 2: 560. https://doi.org/10.3390/ma16020560

APA StyleWang, J., Qiao, T., Wang, A., Li, X., & Wang, T. (2023). Mechanism of Interlaminar Strengthening and Toughening of Al/CFRP/Al Composite Laminates. Materials, 16(2), 560. https://doi.org/10.3390/ma16020560