Characterization of Microstructural Evolution in Heat-Affected Zone of Cu-Bearing Ultra-High-Strength Steel with Lamellar Microstructure

Abstract

1. Introduction

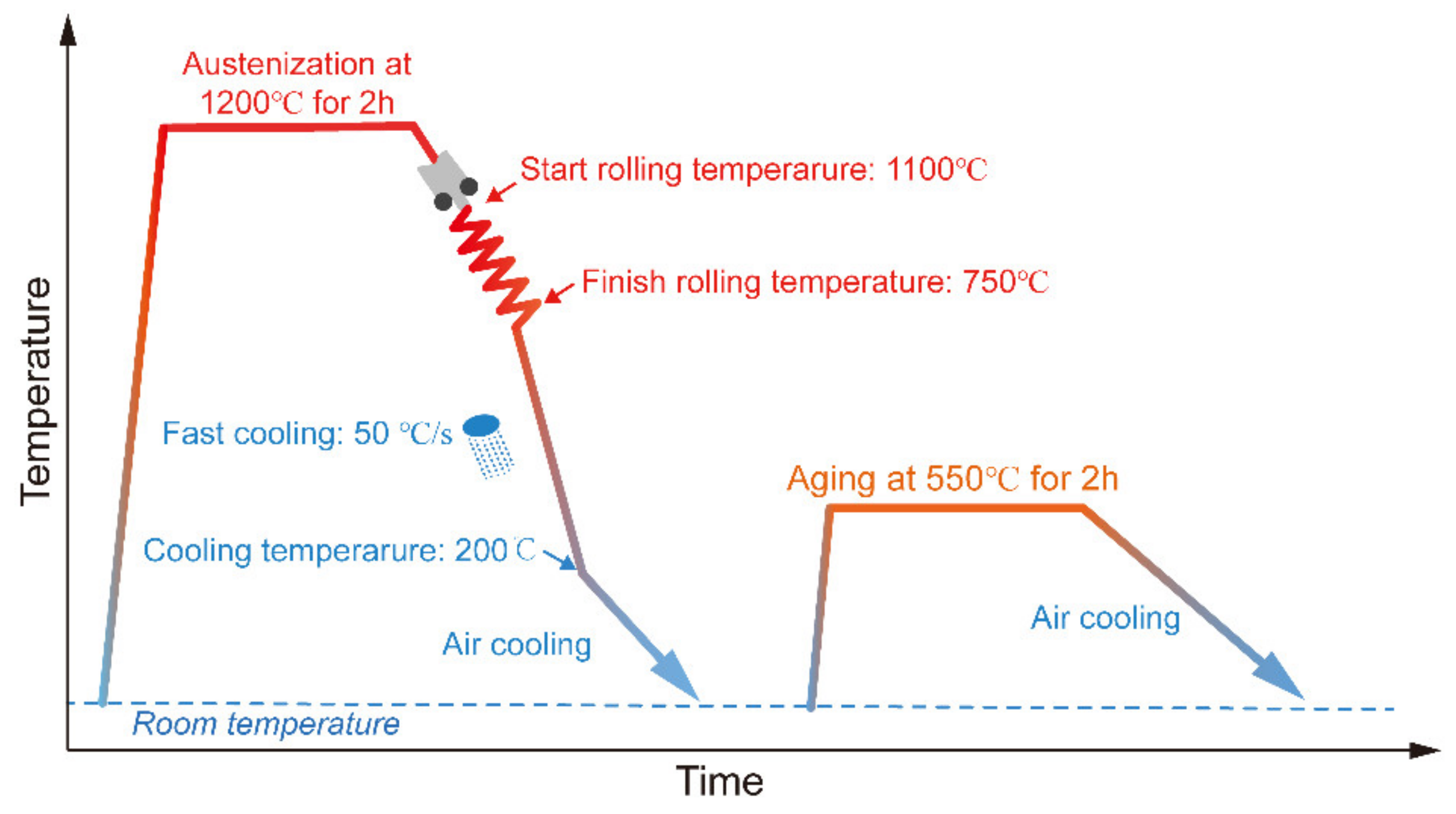

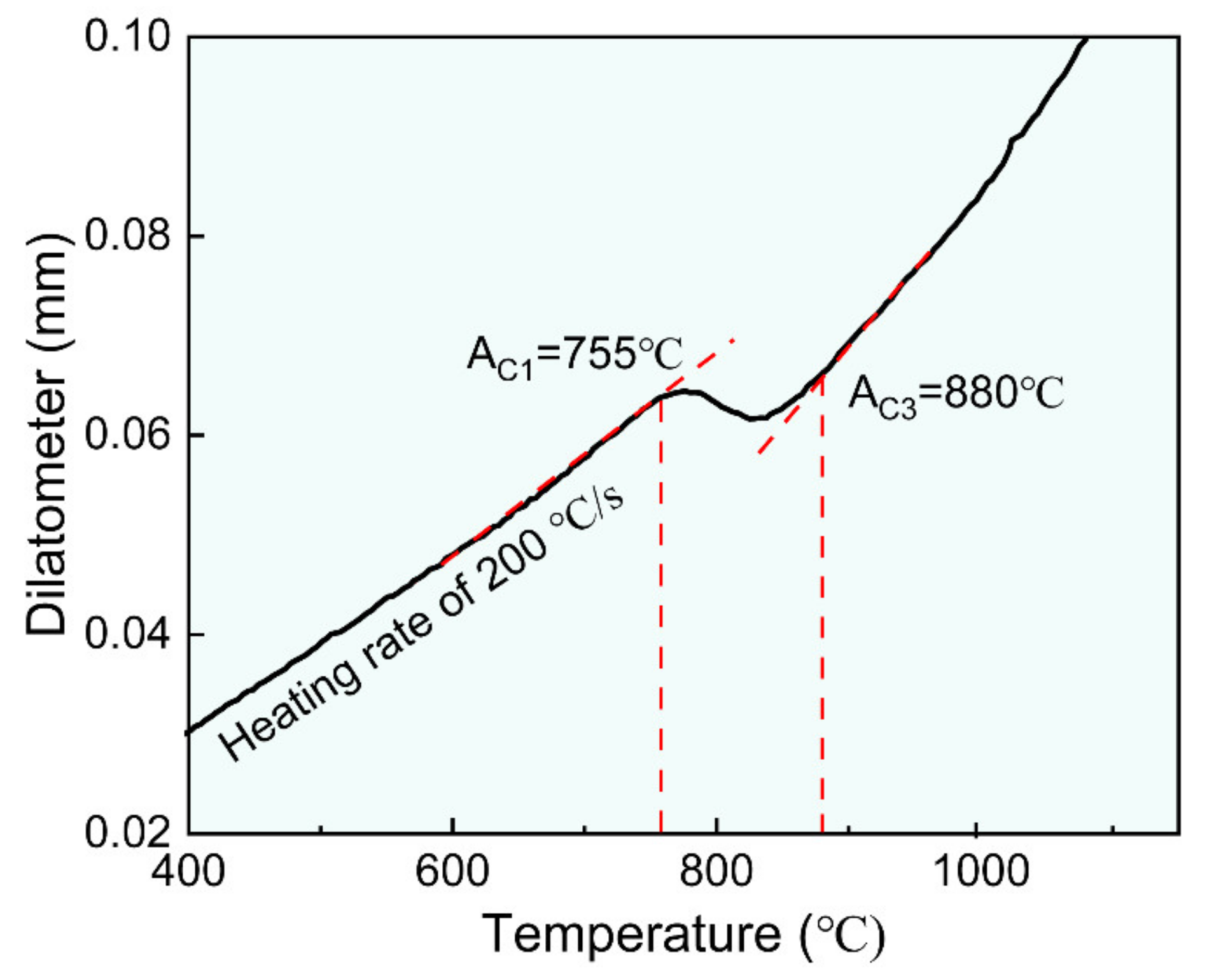

2. Materials and Methods

3. Results and Discussion

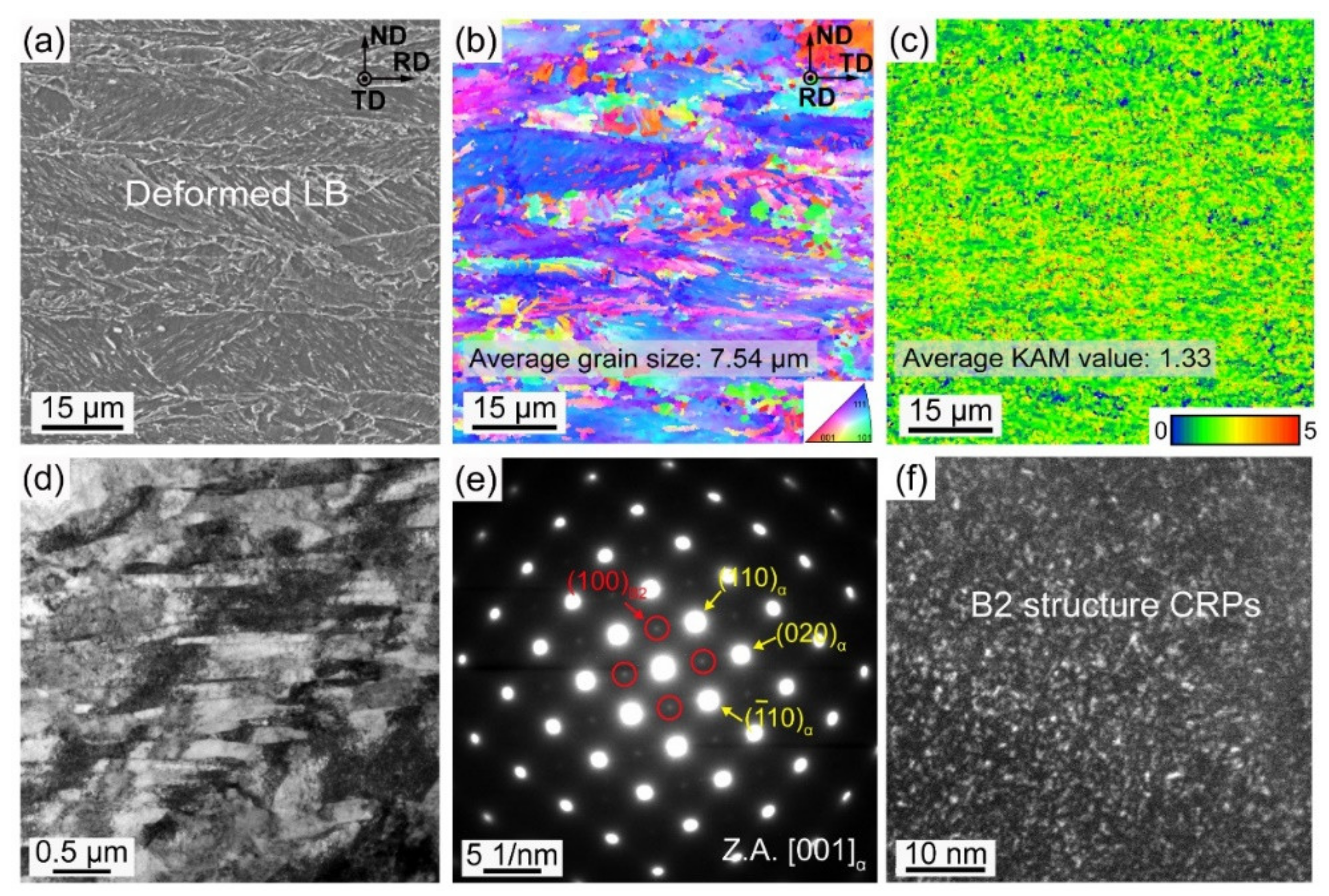

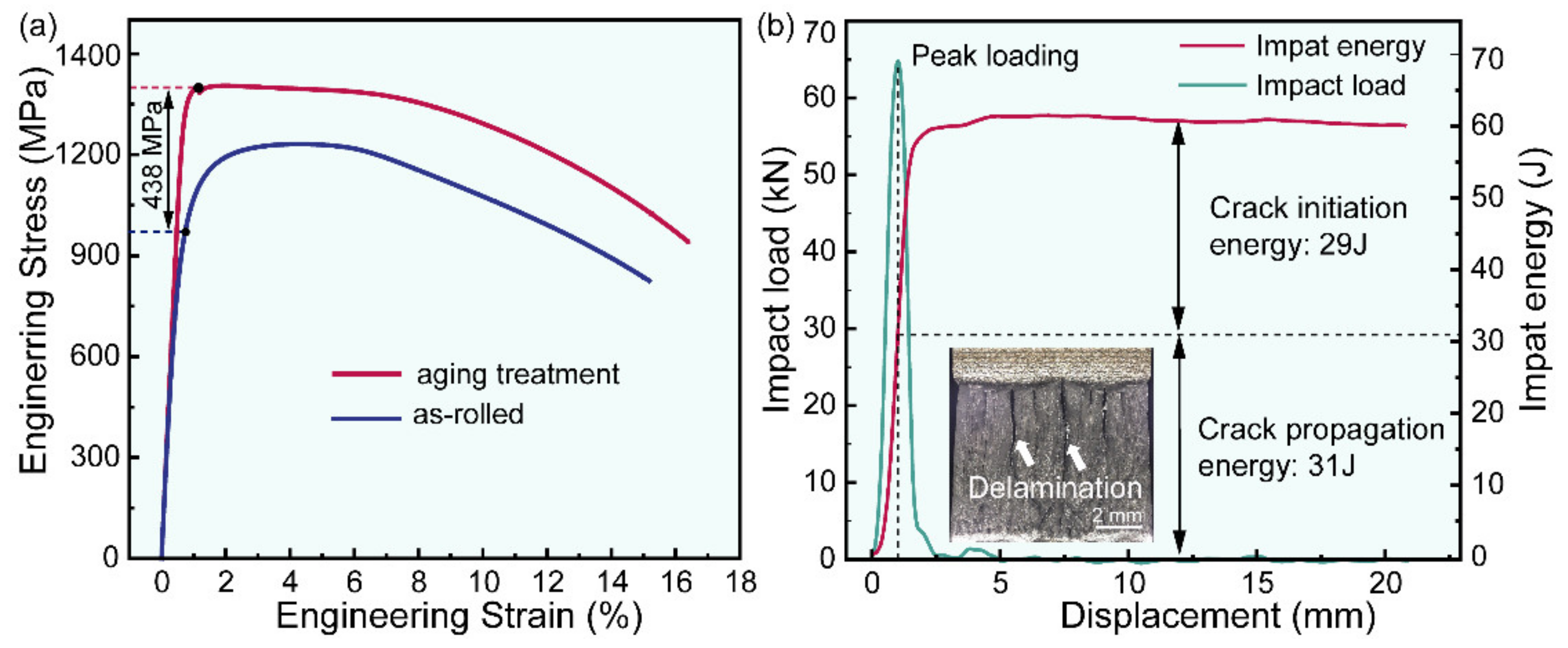

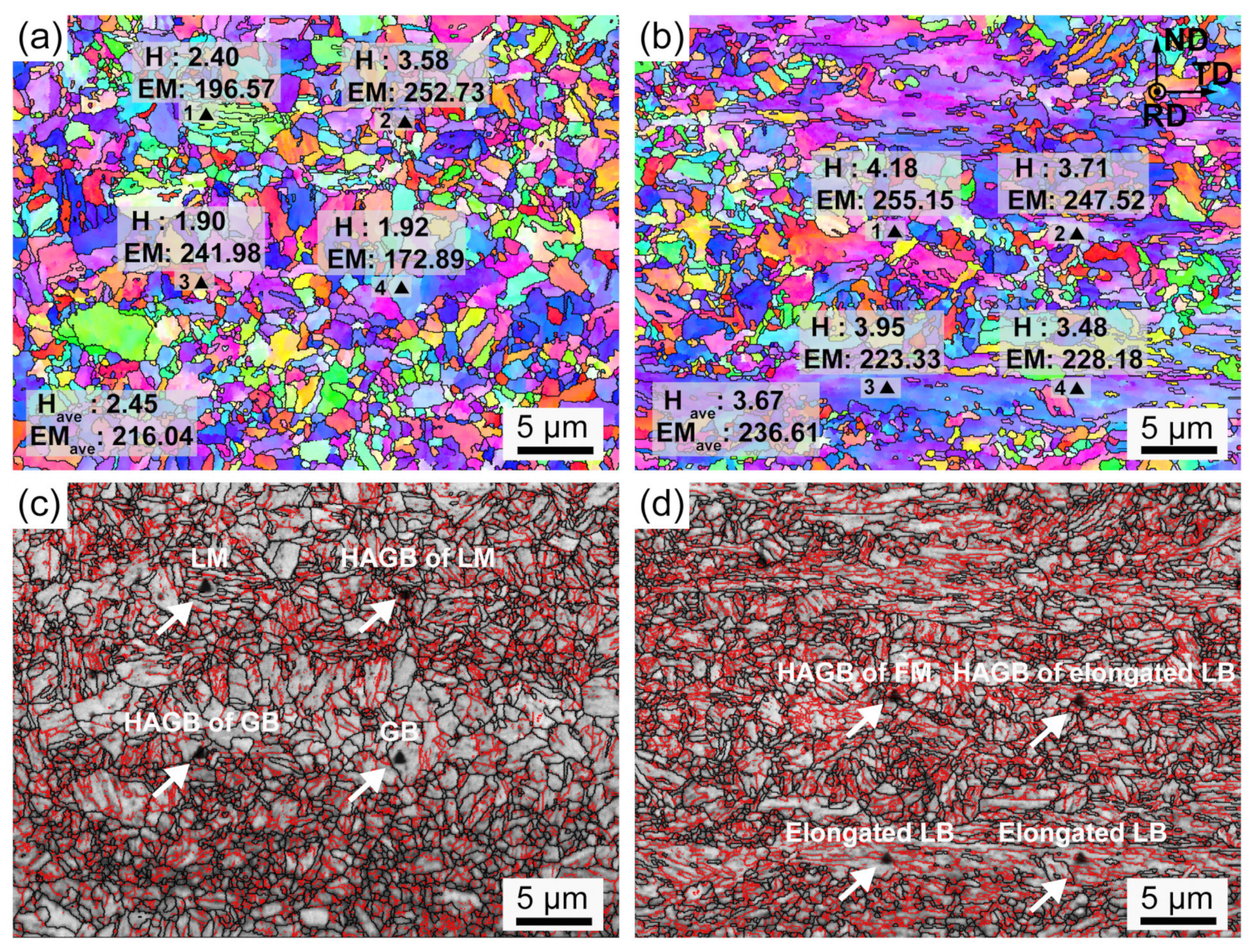

3.1. Microstructure Characteristics and Mechanical Properties of the Base Material

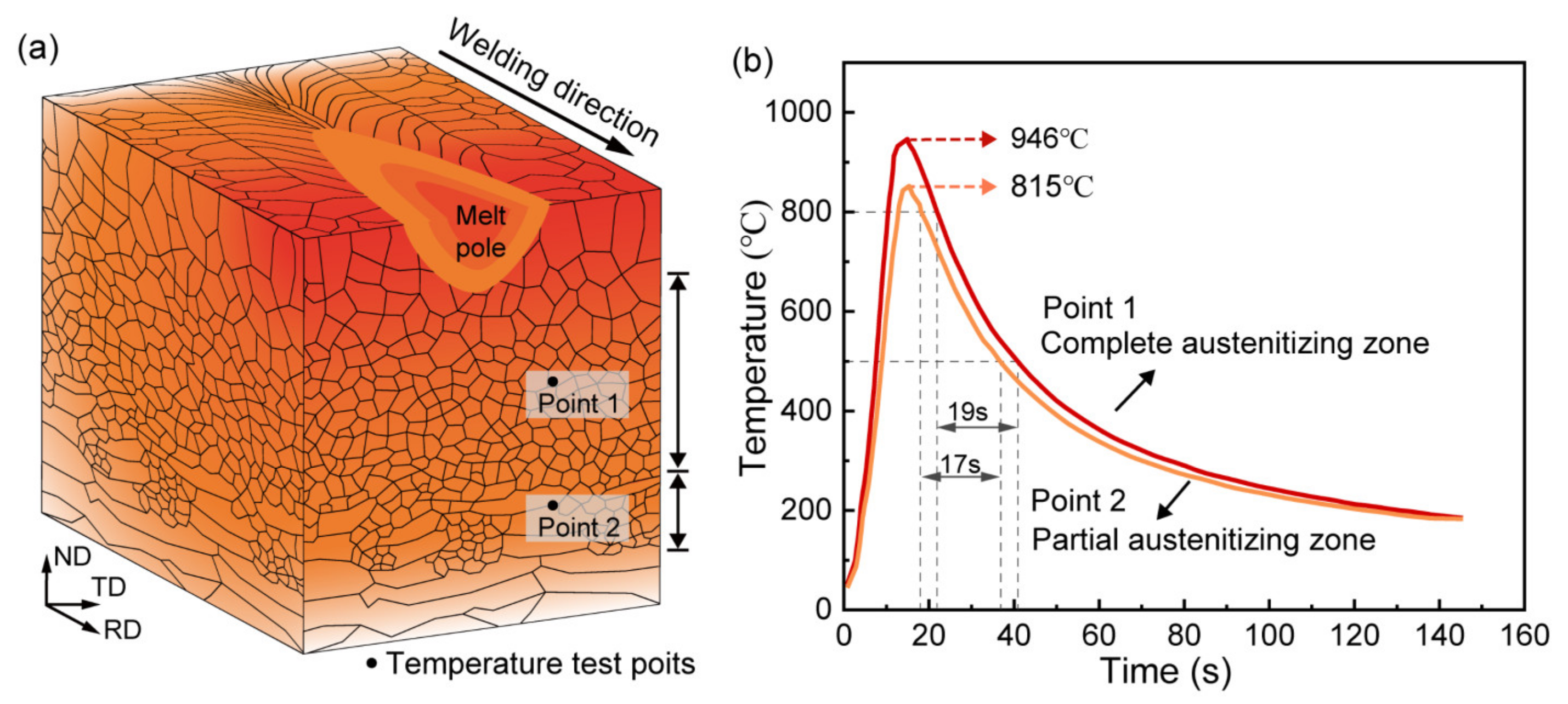

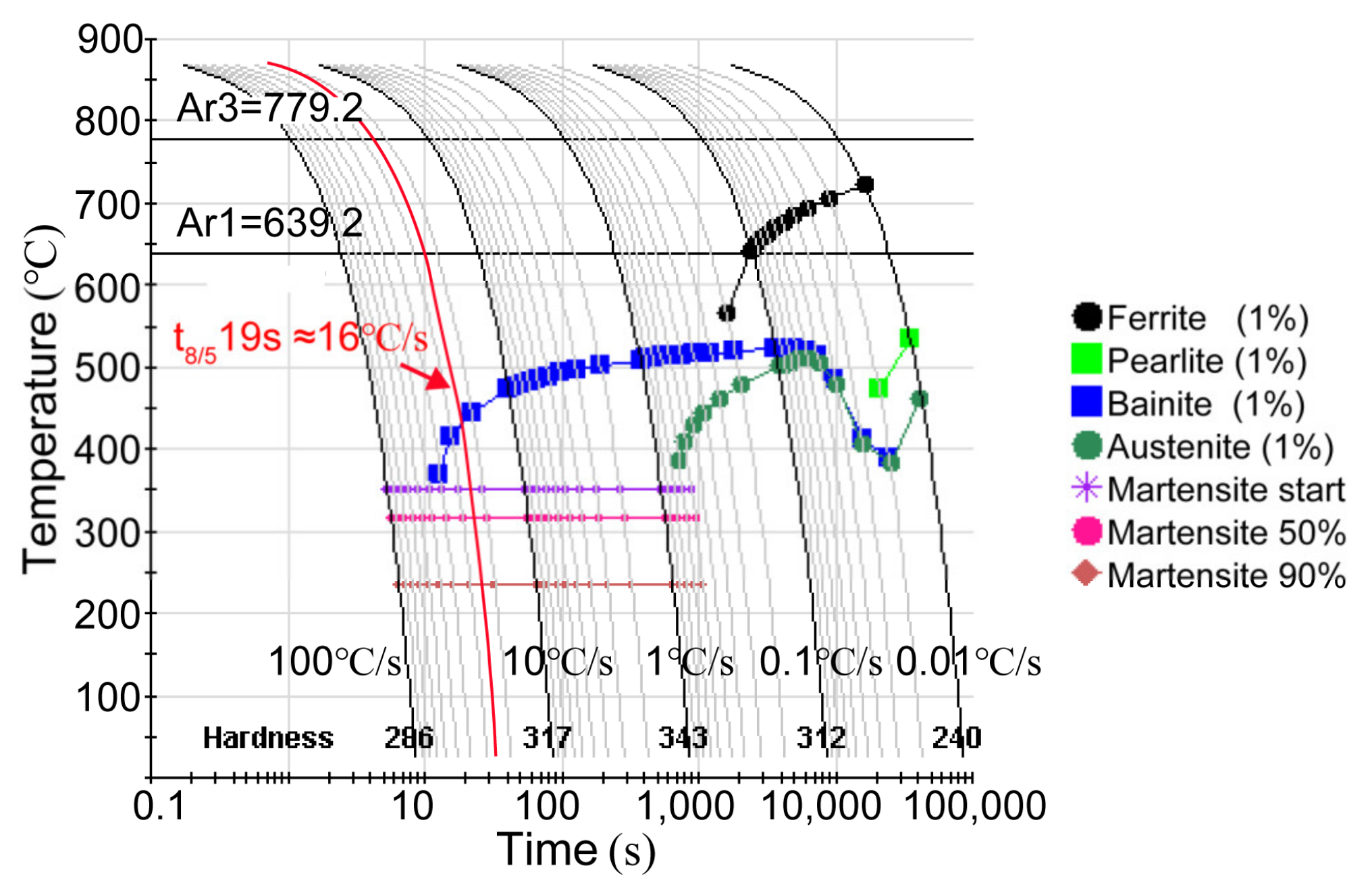

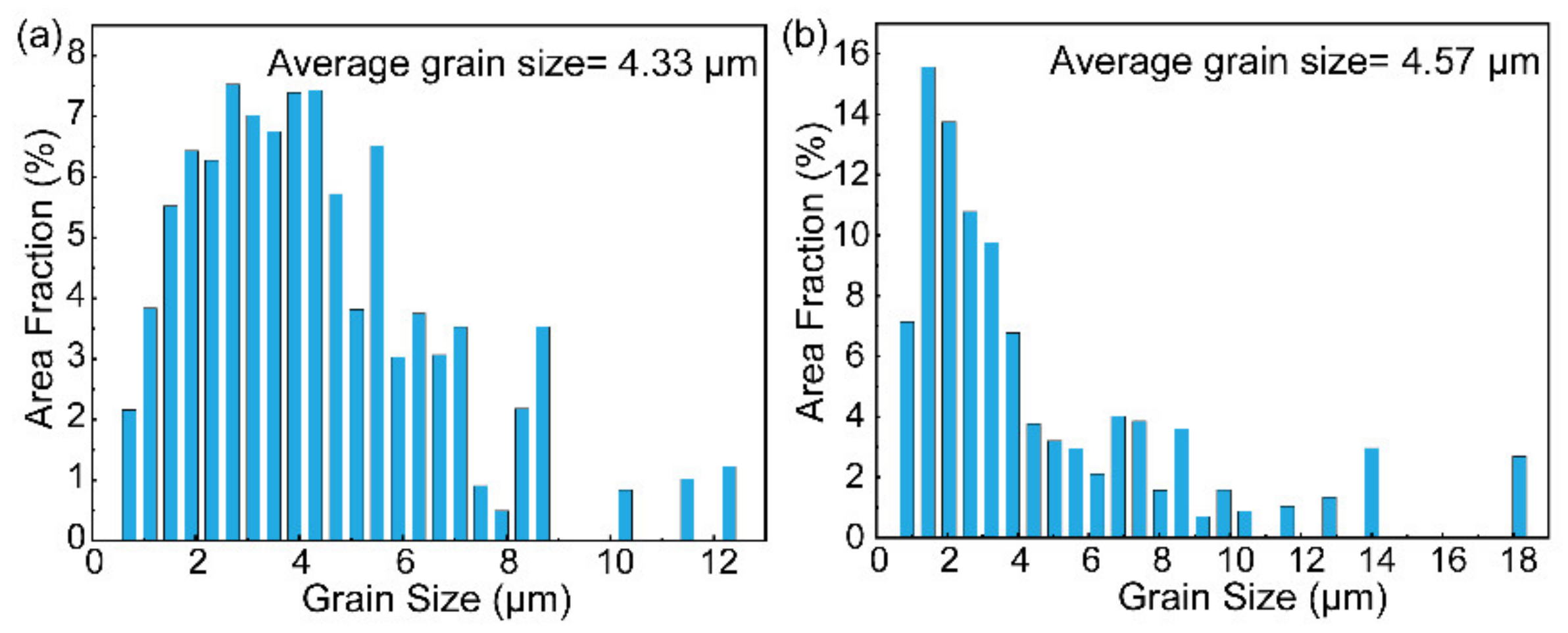

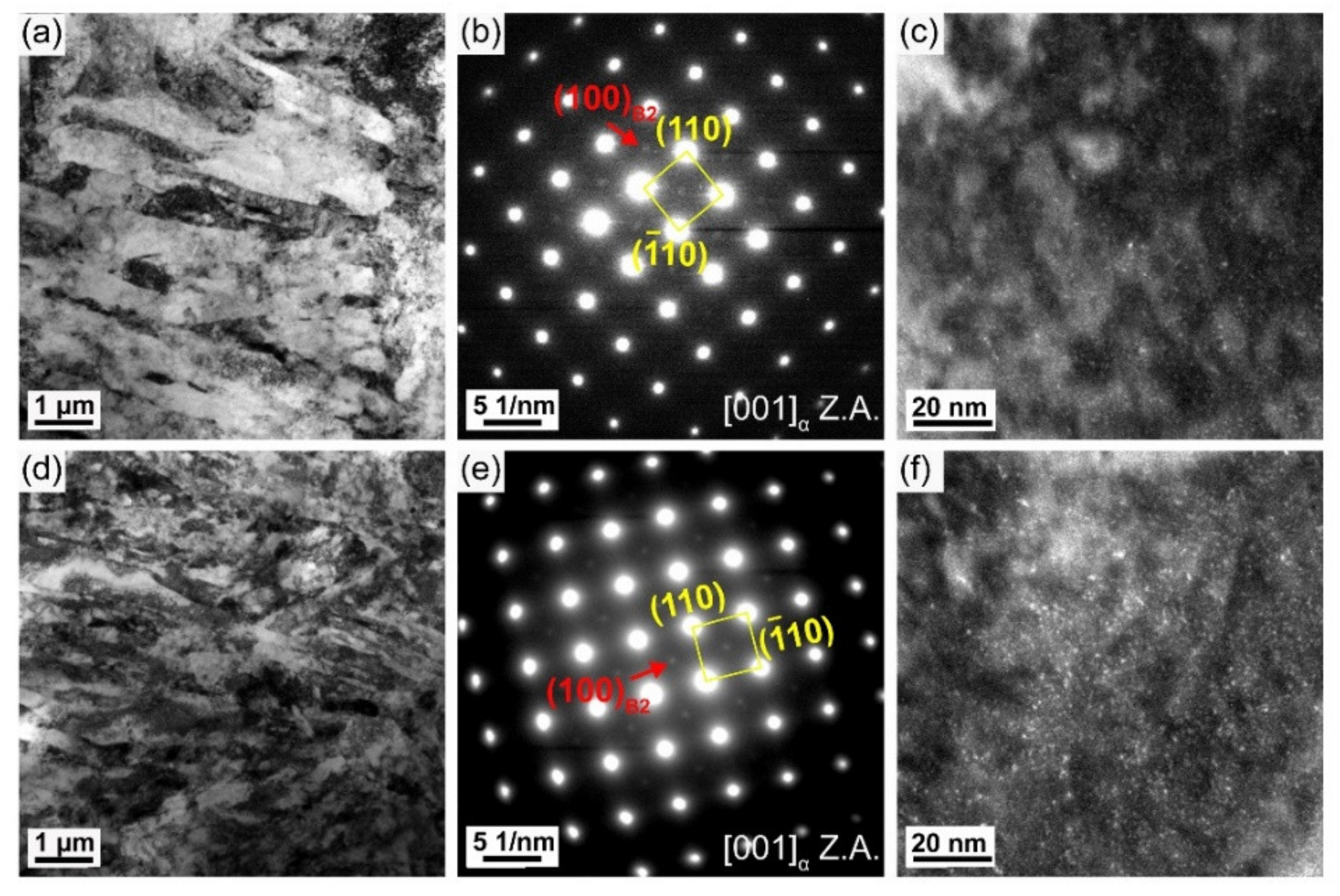

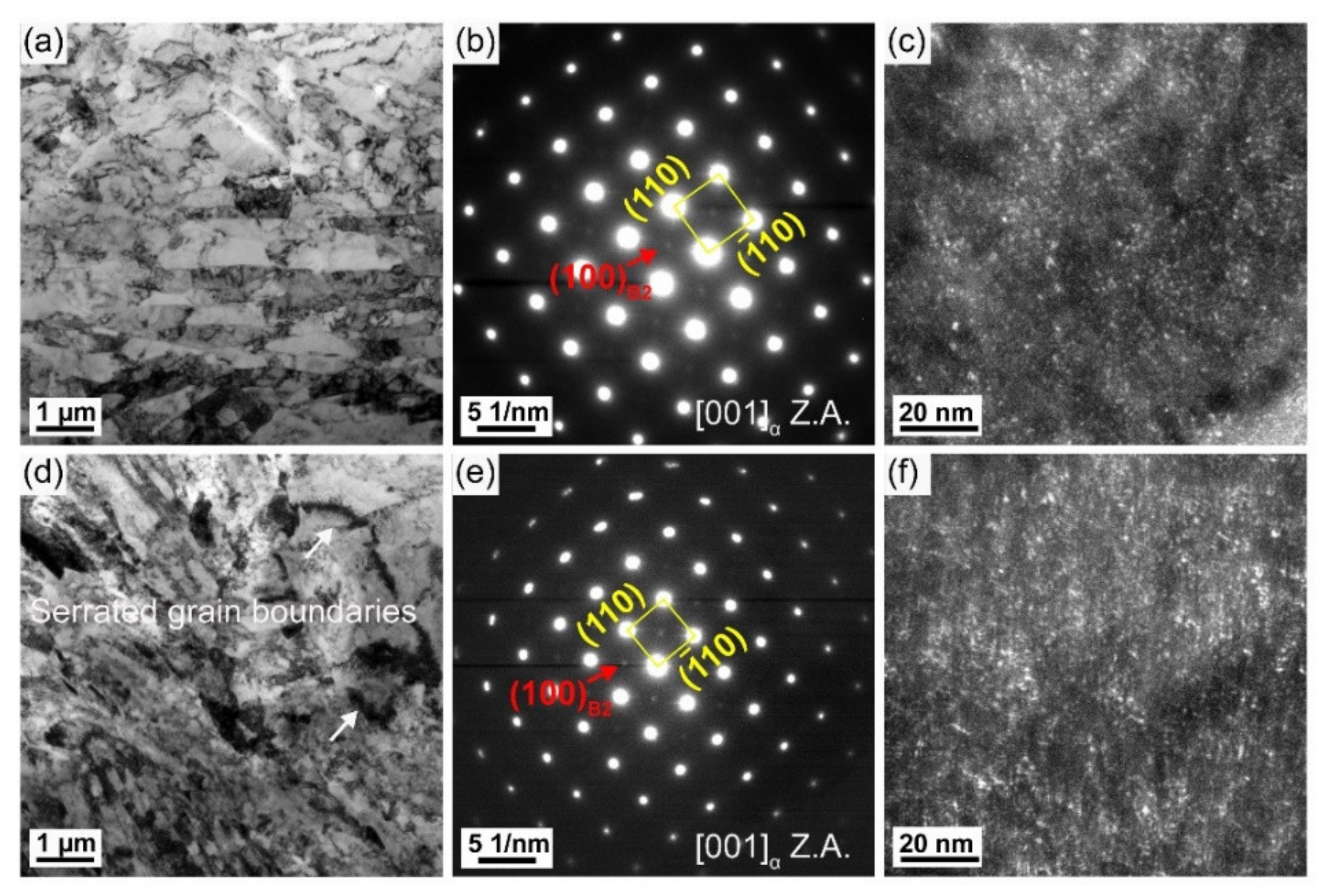

3.2. Microstructure Evolution of HAZ during Welding and PWHT

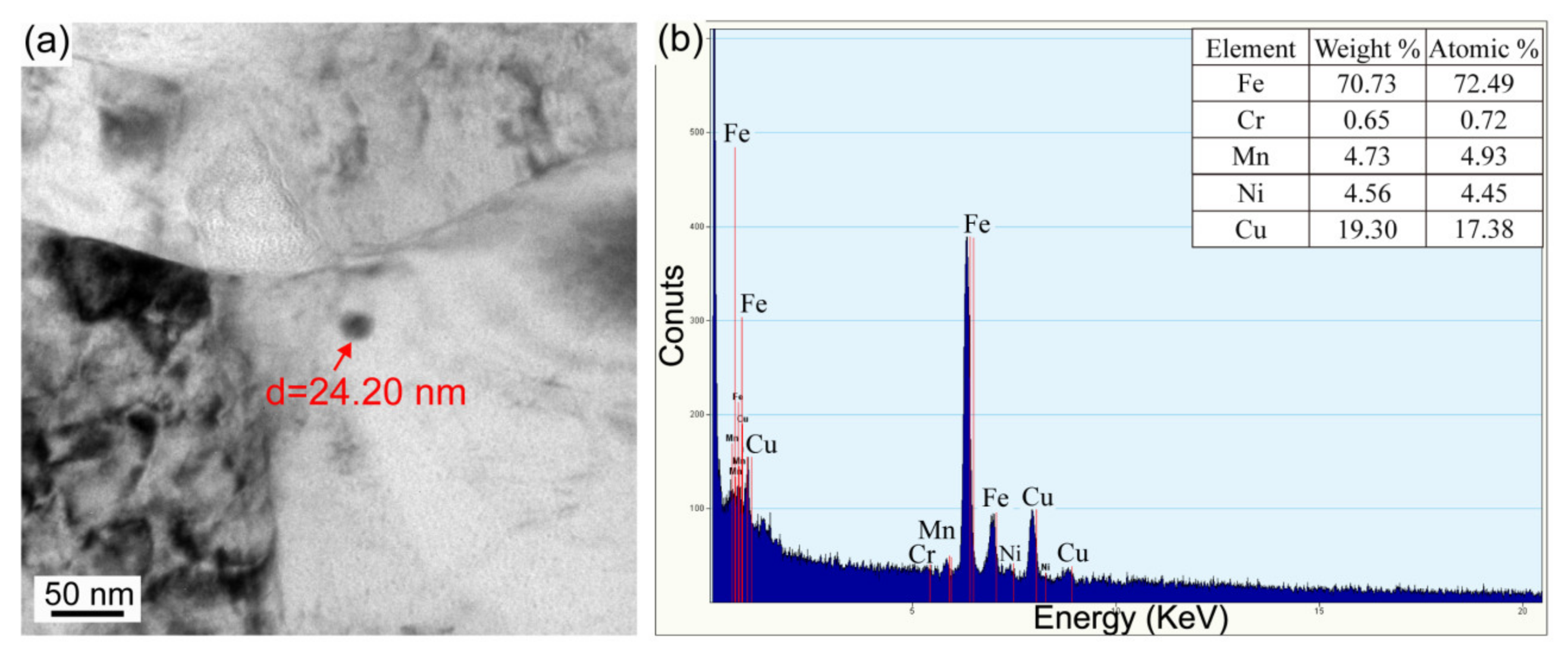

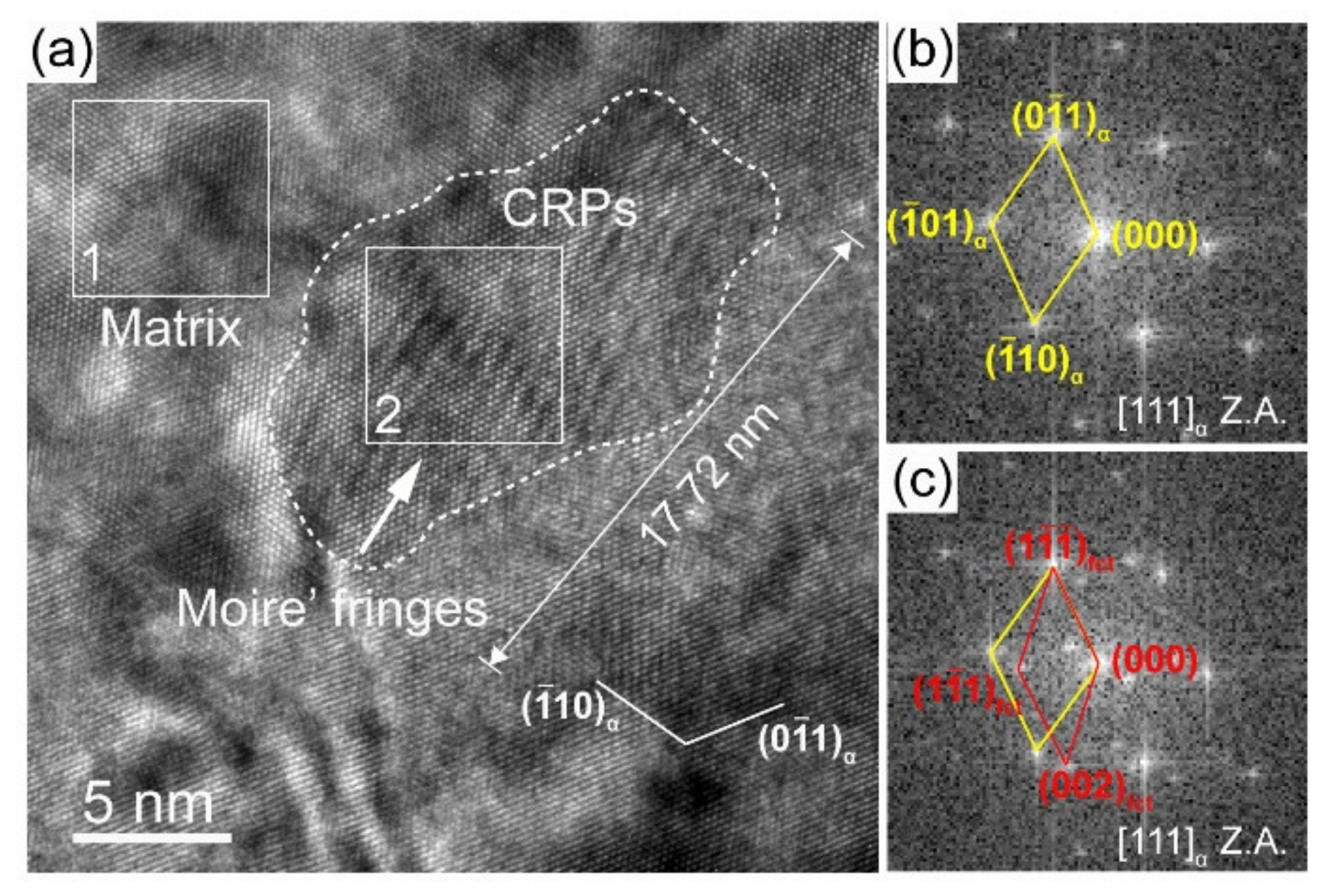

3.3. Precipitates Evolution of HAZ during Welding and PWHT

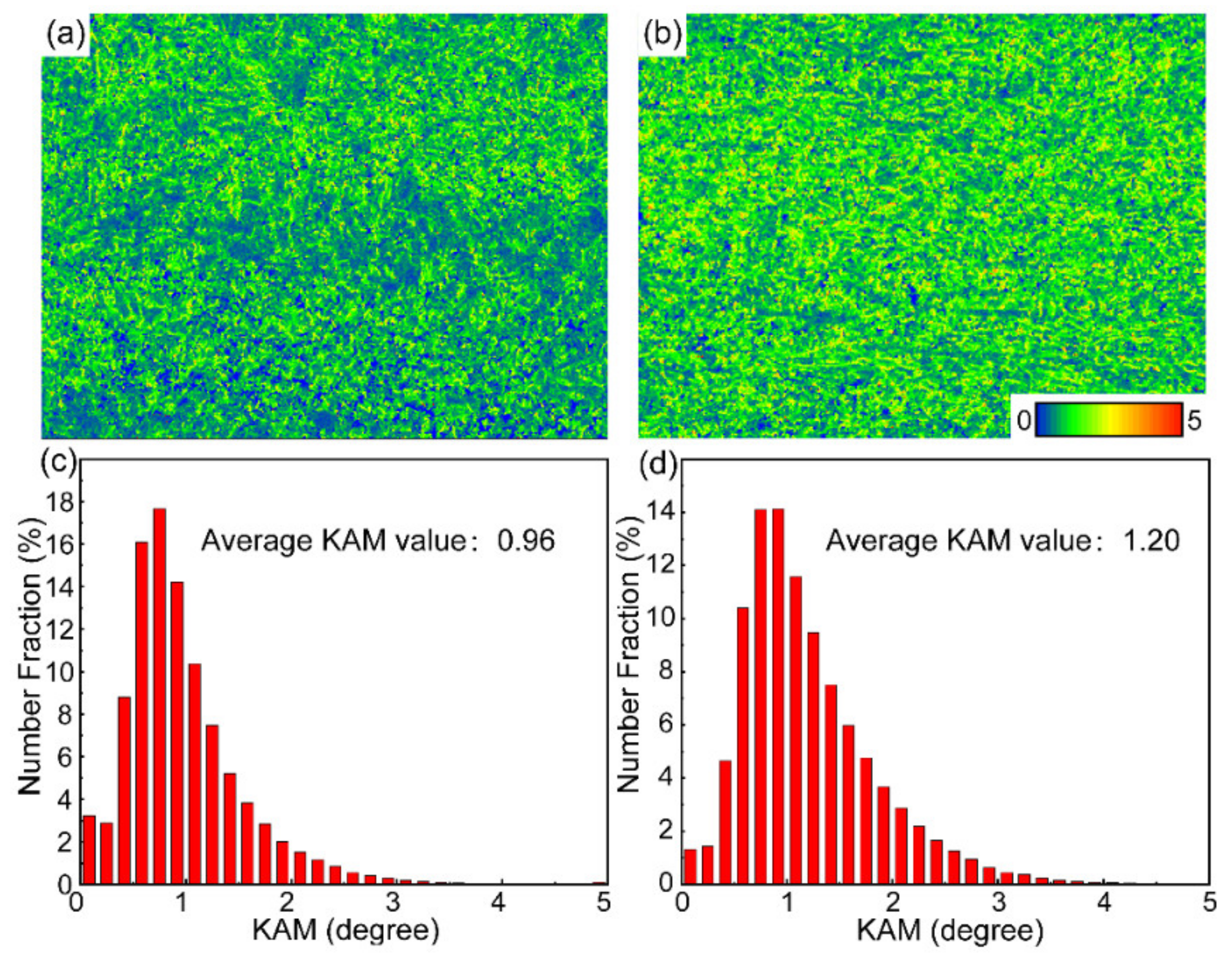

3.4. Effect of Microstructure on Hardness and Micromechanical Properties

4. Conclusions

5. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xi, X.; Wang, J.; Chen, L.; Wang, Z. On the Microstructural Strengthening and Toughening of Heat-Affected Zone in a Low-Carbon High-Strength Cu-Bearing Steel. Acta Met. Sin. Eng. 2020, 34, 617–627. [Google Scholar] [CrossRef]

- Niu, M.; Zhou, G.; Wang, W.; Shahzad, M.B.; Shan, Y.; Yang, K. Precipitate evolution and strengthening behavior during aging process in a 2.5 GPa grade maraging steel. Acta Mater. 2019, 179, 296–307. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Chung, Y.W.; Liu, C.T. Co-precipitation of nanoscale particles in steels with ultra-high strength for a new era. Mater. Today 2017, 20, 142–154. [Google Scholar] [CrossRef]

- Li, C.; Duan, R.; Fu, W.; Gao, H.; Wang, D.; Di, X. Improvement of mechanical properties for low carbon ultra-high strength steel strengthened by Cu-rich multistructured precipitation via modification to bainite. Mater. Sci. Eng. A 2021, 817, 141337. [Google Scholar] [CrossRef]

- Xu, S.S.; Zhao, Y.; Chen, D.; Sun, L.W.; Chen, L.; Tong, X.; Liu, C.T.; Zhang, Z.W. Nanoscale precipitation and its influence on strengthening mechanisms in an ultra-high strength low-carbon steel. Inter. J. Plast. 2019, 113, 99–110. [Google Scholar] [CrossRef]

- Fu, W.; Li, C.; Duan, R.; Gao, H.; Di, X.; Wang, D. Formation mechanism of CuNiAl-rich multi-structured precipitation and its effect on mechanical properties for ultra-high strength low carbon steel obtained via direct quenching and tempering process. Mater. Sci. Eng. A 2022, 833, 142567. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Miller, M.K.; Liu, C.T. Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles. Acta Mater. 2015, 97, 58–67. [Google Scholar] [CrossRef]

- Du, Y.; Hu, X.; Zhang, S.; Song, Y.; Jiang, H.; Rong, L. Precipitation behavior of Cu-NiAl nanoscale particles and their effect on mechanical properties in a high strength low alloy steel. Mater. Charact. 2022, 190, 112014. [Google Scholar] [CrossRef]

- Han, G.; Xie, Z.J.; Lei, B.; Liu, W.Q.; Zhu, H.H.; Yan, Y.; Misra, R.D.K.; Shang, C.J. Simultaneous enhancement of strength and plasticity by nano B2 clusters and nano-γ phase in a low carbon low alloy steel. Mater. Sci. Eng. A 2018, 730, 119–136. [Google Scholar] [CrossRef]

- Sun, H.; Li, D.; Diao, Y.; He, Y.; Yan, L.; Pang, X.; Gao, K. Nanoscale Cu particle evolution and its impact on the mechanical properties and strengthening mechanism in precipitation-hardening stainless steel. Mater. Charact. 2022, 188, 111885. [Google Scholar] [CrossRef]

- Sun, M.; Xu, Y. Age Hardening Characteristics of an Ultra-Low Carbon Cu Bearing Steel. Materials 2020, 13, 4104. [Google Scholar] [CrossRef]

- Kong, H.J.; Xu, C.; Bu, C.C.; Da, C.; Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions. Acta Mater. 2019, 172, 150–160. [Google Scholar] [CrossRef]

- Du, Y.; Hu, X.; Song, Y.; Zhang, Y.; Rong, L. Effect of Nanoscale Cu-Riched Clusters on Strength and Impact Toughness in a Tempered Cu-Bearing HSLA Steel. Acta Metal. Sin. Eng. 2021, 35, 537–550. [Google Scholar] [CrossRef]

- Niu, G.; Zurob, H.S.; Misra, R.D.K.; Tang, Q.; Zhang, Z.; Nguyen, M.-T.; Wang, L.; Wu, H.; Zou, Y. Superior fracture toughness in a high-strength austenitic steel with heterogeneous lamellar microstructure. Acta Mater. 2022, 226, 17642. [Google Scholar] [CrossRef]

- Sun, J.; Wang, H.; Xu, B.; Jiang, L.; Guo, S.; Sun, X.; Yu, D.; Liu, F.; Liu, Y. Making low-alloyed steel strong and tough by designing a dual-phase layered structure. Acta Mater. 2022, 227, 117701. [Google Scholar] [CrossRef]

- Dolzhenko, A.; Kaibyshev, R.; Belyakov, A. Outstanding impact toughness of low-alloyed steel with fine lamellar microstructure. Mater. Lett. 2021, 303, 130547. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, S.; Li, J.; Zhang, J.; Sun, L.; Chen, L.; Sun, G.; Peng, S.; Zhang, Z. Enhancement of low temperature toughness of nanoprecipitates strengthened ferritic steel by delamination structure. Mater. Sci. Eng. A 2017, 691, 162–167. [Google Scholar] [CrossRef]

- Yu, X.; Caron, J.L.; Babu, S.S.; Lippold, J.C.; Isheim, D.; Seidman, D.N. Characterization of microstructural strengthening in the heat-affected zone of a blast-resistant naval steel. Acta Mater. 2010, 58, 5596–5609. [Google Scholar] [CrossRef]

- Fu, W.; Li, C.; Di, X.; Jin, Y.; Fu, K.; Gao, H.; Fang, C.; Lou, S.; Ding, T.; Wang, D. Strengthening and toughening mechanism of coarse-grained heat-affected zone for the Cr-/Mo-free Cu-bearing HSLA steel under high heat input welding conditions. J. Mater. Sci. 2022, 57, 16471–16489. [Google Scholar] [CrossRef]

- Yurioka, N. Physical Metallurgy of Steel Weldability. ISIJ Int. 2001, 41, 566–570. [Google Scholar] [CrossRef]

- Zou, Y.; Xu, Y.B.; Han, D.T.; Hu, Z.P.; Song, H.; Misra, R.D.K.; Cao, L.F.; Chen, S.Q. Aging characteristics and strengthening behavior of a low-carbon medium-Mn Cu-bearing steel. Mater. Sci. Eng. A 2018, 729, 423–432. [Google Scholar] [CrossRef]

- Liu, Q.; Wen, H.; Zhang, H.; Gu, J.; Li, C.; Lavernia, E.J. Effect of Multistage Heat Treatment on Microstructure and Mechanical Properties of High-Strength Low-Alloy Steel. Met. Maters Trans. A. 2016, 47, 1960–1974. [Google Scholar] [CrossRef]

- Skoufari-Themistou, L.; Crowther, D.N.; Mintz, B. Strength and impact behaviour of age hardenable copper containing steels. Mater. Sci. Tech. Lond. 2013, 15, 1069–1079. [Google Scholar] [CrossRef]

- Di, X.; Tong, M.; Li, C.; Zhao, C.; Wang, D. Microstructural evolution and its influence on toughness in simulated inter-critical heat affected zone of large thickness bainitic steel. Mater. Sci. Eng. A 2019, 743, 67–76. [Google Scholar] [CrossRef]

- Zhang, X.; Di, X.; Jing, W.; Zhou, X.; Zhang, C.; Li, C. Effect of Microstructural Evolution on the Mechanical Properties of Intercritical Heat-Affected Zone of Quenched-and-Tempered Ultrahigh-Strength Steel. Steel. Res. Int. 2022, 93, 2100776. [Google Scholar] [CrossRef]

- Moeinifar, S.; Kokabi, A.H.; Madaah Hosseini, H.R. Influence of peak temperature during simulation and real thermal cycles on microstructure and fracture properties of the reheated zones. Mater. Des. 2010, 31, 2948–2955. [Google Scholar] [CrossRef]

- Kan, L.Y.; Ye, Q.B.; Wang, Q.H.; Tian, Y.; Wang, Z.D.; Wang, Y.M.; Hu, J. Refinement of Cu-M2C precipitates and improvement of strength and toughness by Ti microalloying in a Cu-bearing steel. Mater. Sci. Eng. A 2021, 802, 140678. [Google Scholar] [CrossRef]

- Han, G.; Shang, C.J.; Misra, R.D.K.; Xie, Z.J. Solid phase transition of Cu precipitates in a low carbon TRIP assisted steel. Phys. B 2019, 569, 68–79. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, W.; Liu, Z.; Wang, G. Direct observations on the crystal structure evolution of nano Cu-precipitates in an extremely low carbon steel. Mater. Lett. 2017, 187, 49–52. [Google Scholar] [CrossRef]

- Xu, C.; Dai, W.J.; Chen, Y.; Qi, Z.X.; Zheng, G.; Cao, Y.D.; Zhang, J.P.; Bu, C.C.; Chen, G. Control of dislocation density maximizing precipitation strengthening effect. J. Mater. Sci. Technol. 2022, 712, 573–578. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Guo, W.; Poplawsky, J.D.; Liu, C.T. Effects of welding and post-weld heat treatments on nanoscale precipitation and mechanical properties of an ultra-high strength steel hardened by NiAl and Cu nanoparticles. Acta Mater. 2016, 120, 216–227. [Google Scholar] [CrossRef]

- Hunter, A.H.; Farren, J.D.; DuPont, J.N.; Seidman, D.N. Multi-component Cu-Strengthened Steel Welding Simulations: Atom Probe Tomography and Synchrotron X-ray Diffraction Analyses. Met. Mater. Trans. A. 2015, 46, 3117–3131. [Google Scholar] [CrossRef]

- Afkhami, S.; Javaheri, V.; Amraei, M.; Skriko, T.; Piili, H.; Zhao, X.-L.; Björk, T. Thermomechanical simulation of the heat-affected zones in welded ultra-high strength steels: Microstructure and mechanical properties. Mater. Des. 2022, 213, 110336. [Google Scholar] [CrossRef]

- Amraei, M.; Afkhami, S.; Javaheri, V.; Larkiola, J.; Skriko, T.; Björk, T.; Zhao, X.-L. Mechanical properties and microstructural evaluation of the heat-affected zone in ultra-high strength steels. Thin. Wall. Struc. 2020, 157, 107072. [Google Scholar] [CrossRef]

- Jiao, Z.B.; Luan, J.H.; Guo, W.; Poplawsky, J.D.; Liu, C.T. Atom-probe study of Cu and NiAl nanoscale precipitation and interfacial segregation in a nanoparticle-strengthened steel. Mater. Res. Lett. 2017, 5, 562–568. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | Ni | Al | Cu | S + P + N | Fe | CE |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.045 | 0.228 | 1.05 | 0.60 | 0.58 | 3.77 | 0.70 | 1.903 | ≤0.015 | balance | 0.295 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, C.; Li, C.; Ji, F.; Fu, W.; Hu, W.; Di, X. Characterization of Microstructural Evolution in Heat-Affected Zone of Cu-Bearing Ultra-High-Strength Steel with Lamellar Microstructure. Materials 2023, 16, 550. https://doi.org/10.3390/ma16020550

Fang C, Li C, Ji F, Fu W, Hu W, Di X. Characterization of Microstructural Evolution in Heat-Affected Zone of Cu-Bearing Ultra-High-Strength Steel with Lamellar Microstructure. Materials. 2023; 16(2):550. https://doi.org/10.3390/ma16020550

Chicago/Turabian StyleFang, Chao, Chengning Li, Fengqin Ji, Wen Fu, Wenyi Hu, and Xinjie Di. 2023. "Characterization of Microstructural Evolution in Heat-Affected Zone of Cu-Bearing Ultra-High-Strength Steel with Lamellar Microstructure" Materials 16, no. 2: 550. https://doi.org/10.3390/ma16020550

APA StyleFang, C., Li, C., Ji, F., Fu, W., Hu, W., & Di, X. (2023). Characterization of Microstructural Evolution in Heat-Affected Zone of Cu-Bearing Ultra-High-Strength Steel with Lamellar Microstructure. Materials, 16(2), 550. https://doi.org/10.3390/ma16020550