3.1. Crystal Phase Analysis

Figure 1 shows the XRD patterns of different calcium sources and their composite samples.

Figure 1a,b show that the XRD pattern of 400–500 mesh ground calcium carbonate shows strong characteristic peaks of the calcite crystalline phase ((JCPDS #99-0022, 2θ = 23.06°, 29.40°, 35.97°, 39.41°, 43.16°, 47.50°, 48.51°, and 57.40°). Its composite sample shows additional diffraction peaks at 17.28° and 18.50°, which can be ascribed to the (211) crystalline planes of the 3CaO·Al

2O

3·6H

2O (C

3AH

6) phase [

18] (JCPDS #77-0240) and (002) crystalline planes of the Al(OH)

3 (AH

3) phase (JCPDS #85-1049). As shown in

Figure 1c,d, the ground calcium carbonate with a particle size less than 500 mesh also shows diffraction peaks at 23.06°, 29.40°, 35.97°, 39.41°, 43.16°, 47.50°, 48.51°, and 57.40°, which can be attributed to the crystalline planes of the calcite phase. The ground calcium carbonate composite sample with a particle size of less than 500 mesh showed new strong diffraction peaks at 17.28° and 18.50°, which can be ascribed to the C

3AH

6 and Al(OH)

3 (AH

3) phases, respectively. In addition, only a weak peak was observed at 11.71°, which belongs to the (011) crystalline planes of the 3CaO·Al

2O

3·CaCO

3·11H

2O (C

4AcH

11) phase [

19] (JCPDS #87-0493).

Figure 1e,f display the XRD patterns of the precipitated calcium carbonate that was prepared from the CaCl

2 solution and its composite with Al(OH)

3. The diffraction peaks at 23.06°, 29.40°, 35.97°, 39.41°, 43.16°, 47.50°, 48.51°, and 57.40° can be attributed to the crystalline planes of the calcite phase, while those at 11.71°, 17.28°, and 18.50° can be attributed to the crystalline planes of C

4AcH

11, Al(OH)

3, and C

3AH

6, respectively. In comparison with the ground calcium carbonate composite with a particle size of less than 500 mesh, the diffraction peaks at 11.71° were obviously stronger, indicating that the composite from calcite-type precipitated calcium carbonate contains more C

4AcH

11 phase.

Figure 1g shows the XRD pattern of the precipitated calcium carbonate that was prepared from the (CH

3COO)

2Ca solution. It shows diffraction peaks at 21.00°, 24.90°, 27.05°, 32.78°, 43.85°, 50.08°, and 55.81°, which can be ascribed to the (004), (110), (112), (114), (300), (118), and (224) crystalline planes of the vaterite phase [

20,

21] (JCPDS #72-0506). As shown in

Figure 1h, the vaterite-type precipitated calcium carbonate composite also contained extra diffraction peaks at 11.71°, 17.28°, and 18.50°, which can be ascribed to the crystalline planes of C

4AcH

11, C

3AH

6 and AH

3 phases. However, the intrinsic peaks belonging to the vaterite phase at 21.00°, 24.90°, 43.85°, 50.08°, and 55.81° vanished and were greatly reduced at 27.05° and 32.78°, indicating that most of the vaterite-type precipitated calcium carbonate was converted to another phase.

Based on the above results, only two or three new characteristic peaks appeared in the four types of CaCO

3/Al(OH)

3 composites, including calcite, vaterite, C

4AcH

11, C

3AH

6 and AH

3 crystal phases. The weight percentage of each phase in four types of CaCO

3/Al(OH)

3 composites was determined using MDI Jade 6 based on the matrix-flushing theory [

22], the adiabatic principle [

23] and the RIR-value in the JCPDS card according to the XRD patterns. The mass fraction of phase

X was calculated as follows:

where

is the mass fraction of the

X phase,

is the integral intensity of the strongest peak in the

X phase,

is the

K-value of the

X phase, and

N is the number of sample phases.

Taking the CaCO3 phase as the standard phase, according to formula (1), the mass fraction of each phase can be calculated as follows:

According to the XRD patterns as shown in

Figure 1, the characteristic peaks at 11.7°, 17.3°, 18.5°, 27.0°, and 29.4° with a diffraction angle of 2θ represent the strongest diffraction peaks of C

4AcH

11, C

3AH

6, AH

3, vaterite-CaCO

3, and calcite-CaCO

3, respectively. Therefore, the relative

K value of those phases, including C

4AcH

11, C

3AH

6, AH

3, vaterite-CaCO

3, and calcite-CaCO

3, could be calculated, and the results are shown in

Table 1.

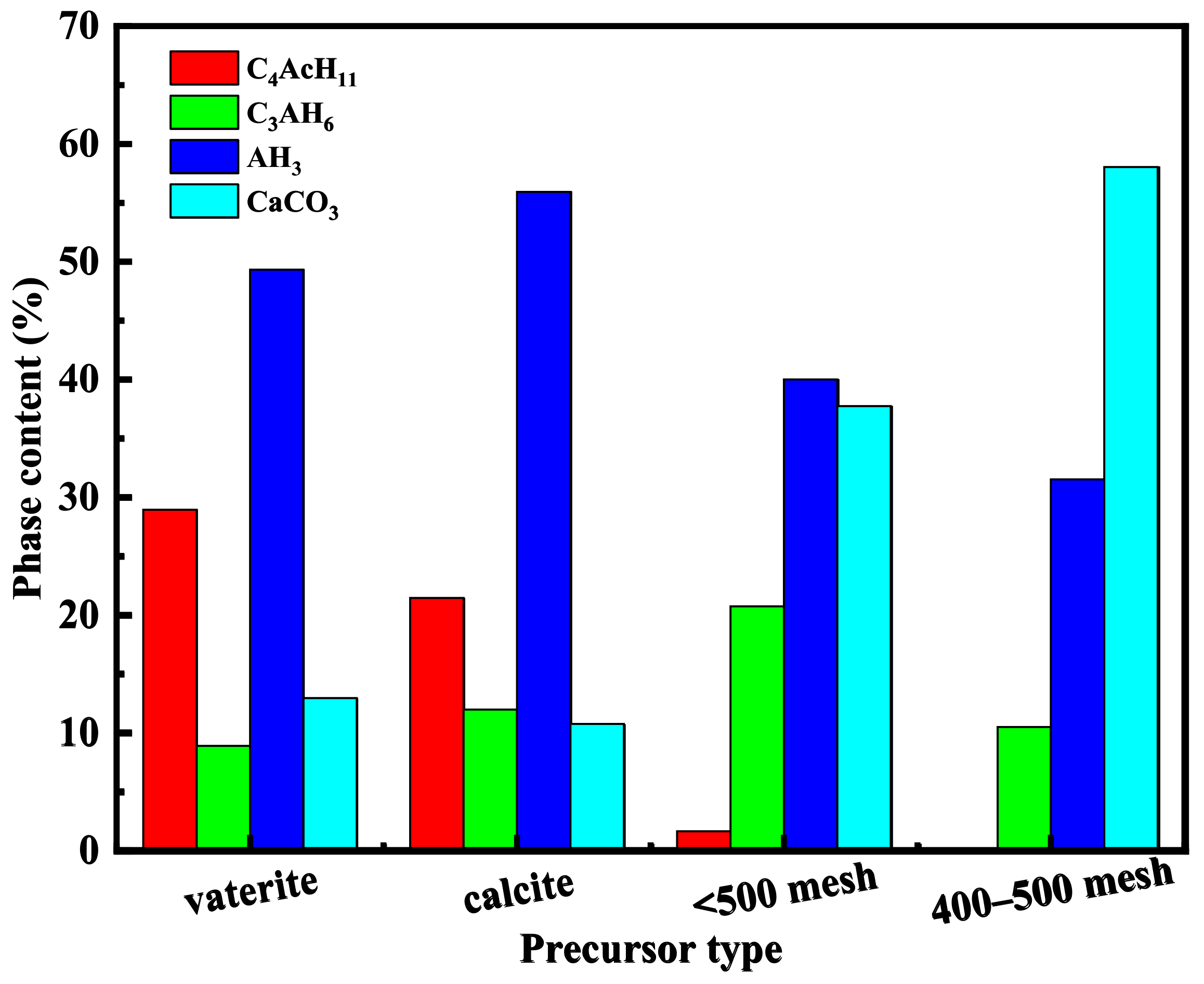

Figure 2 displays the content of each phase in four types of CaCO

3/Al(OH)

3 composites. The content of C

4AcH

11 in the composite obtained from precipitated calcium carbonate was much higher than that from the ground calcium carbonate composite, and the content of AH

3 in the precipitated calcium carbonate composites was relatively higher than that of the ground calcium carbonate composites, while the content of CaCO

3 was low. Moreover, four types of composites have C

3AH

6, while the contents of C

3AH

6 in the composite obtained from the ground calcium carbonate with a particle size of less than 500 mesh was relatively higher than that of the others. Therefore, the formed CaCO

3/Al(OH)

3 composites have a very different phase content. The CaCO

3 molecule of vaterite-type calcium carbonate is more active than those of the three other types of calcium carbonates [

24,

25], and the complex reaction between C

3AH

6 and vaterite-type calcium carbonate easily occurs compared with others. Therefore, a large number of C

4AcH

11 exist in vaterite-type calcium carbonate composite. Calcite-type precipitated calcium carbonate has more active CaCO

3 molecules in the solution than the <500 mesh ground calcium carbonate. Therefore, the content of C

4AcH

11 in calcite-type precipitated calcium carbonate composites is higher than that that in <500 mesh ground calcium carbonate composites. Additionally, with more C

3AH

6 converted to C

4AcH

11, the phase content of C

3AH

6 in calcite-type precipitated calcium carbonate composites is lower than that in <500 mesh ground calcium carbonate composites. Moreover, only a small amount of active CaCO

3 molecule is present in solution, and the phase of C

4AcH

11 could hardly be detected for 400–500 mesh ground calcium carbonate composite.

3.2. Morphological Analysis

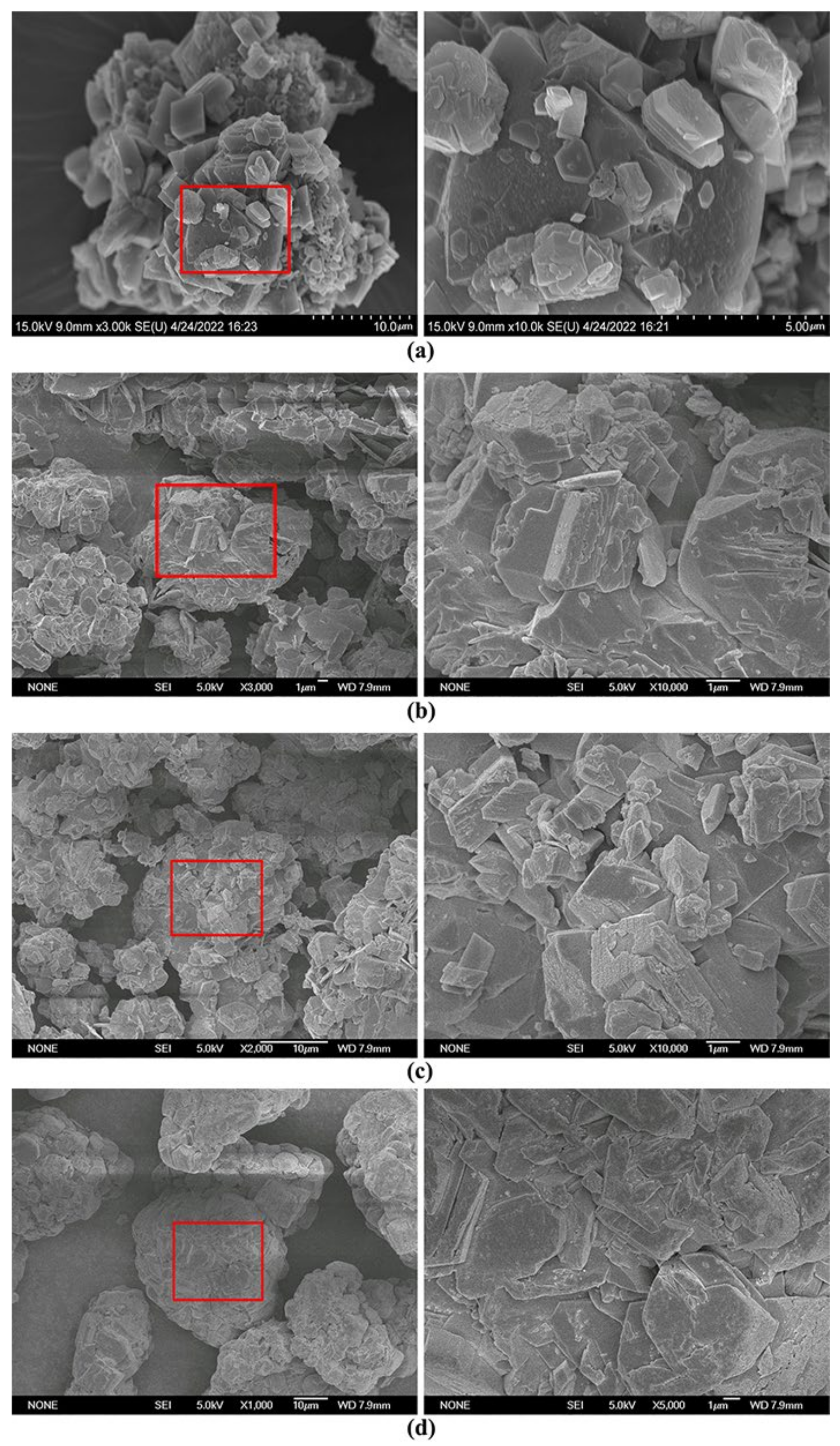

The SEM images of four calcium carbonate precursors, including vaterite-type precipitated calcium carbonate, calcite-type precipitated calcium carbonate, <500 mesh ground calcium carbonate and 400–500 mesh ground calcite carbonate are presented in

Figure 3.

Figure 3a shows that the vaterite-type precipitated calcium carbonate is composed of particles with aggregated and stacked spherical or ellipsoid structures. The single particle has a size of 1–5 μm, and the aggregate size is 20–30 μm.

Figure 3b shows that the calcite-type precipitated calcium carbonate is composed of particles with a cubic crystalline structure. These particles are uniform and interleaved with each other; the average particle size is 10–20 μm.

Figure 3c shows that the <500 mesh ground calcium carbonate is composed of polyhedron particles with different shapes and sizes. The particle size has a wide range from several microns to tens of microns. The bigger particles are stacked together in lamellar form, and many fine particles are adhered to their surfaces. In comparison with the <500 mesh ground calcium carbonate, the 400–500 mesh ground calcium carbonate is also composed of irregular polyhedrons, as shown in

Figure 3d, while the particle size distribution is much narrower with a size of 25–30 μm. Therefore, the four calcium carbonate precursors have a regular morphology and similar particle size distribution but very different morphology.

The SEM images of vaterite-type precipitated calcium carbonate composite, calcite-type precipitated calcium carbonate composite, <500 mesh ground calcium carbonate composite and 400–500 mesh ground calcium carbonate composite are shown in

Figure 4.

Figure 4a shows that the particle morphology of vaterite-type precipitated calcium carbonate composite is irregular, and the surface consists of many sheets that are stacked with each other and a small amount of granular structure. In comparison with

Figure 3a, the particle morphology changed remarkably, and the spherical and ellipsoid structure disappeared, indicating that the vaterite-type precipitated calcium carbonate has been converted into other species. Combined with XRD analysis, as shown in

Figure 1h, the formed sheet may refer to AH

3 or C

4AcH

11, and the granular structure may refer to C

3AH

6, as reported by Li [

26], Litwinek [

19] and Shang [

27].

Figure 4b shows that the surface of calcite-type precipitated calcium carbonate composite is composed of lamellar, granular, and prismatic morphology, while the cubic crystalline structure morphology cannot be found. The lamellar, prismatic morphology can refer to AH

3 or C

4AcH

11, and the granular morphology can refer to C

3AH

6.

Figure 4c shows that the <500 mesh ground calcium carbonate composites contain both large and small particles, and the surface of the large particles has a granular and columnar morphology, which can also refer to C

3AH

6 or AH

3, respectively.

Figure 4d shows that the 400–500 mesh ground calcium carbonate composites only contain large particles, and the surface of the large particles has a prismatic morphology and conical shape structure, which is very similar to the morphology of AH

3. The 400–500 mesh ground calcium carbonate particles are tightly wrapped by aluminum hydroxide.

Based on the above SEM images, the initial conclusion can be made that four types of calcium carbonate are coated with newly formed species involving C4AcH11, C3AH6, and AH3, resulting in a remarkable change on the surface of the four types of calcium carbonate. Moreover, the formed granular structure adhered to the large particles in precipitated calcium carbonate composite and <500 mesh ground calcium carbonate composites, but it cannot be clearly found in 400–500 mesh ground calcium carbonate composite. Considering that the adhered granular structure has fallen away from the surface of the calcium carbonate composites easily, the use of 400–500 mesh ground calcium carbonate is more suitable for the preparation of calcium carbonate composites.

3.3. Microstructure Analysis

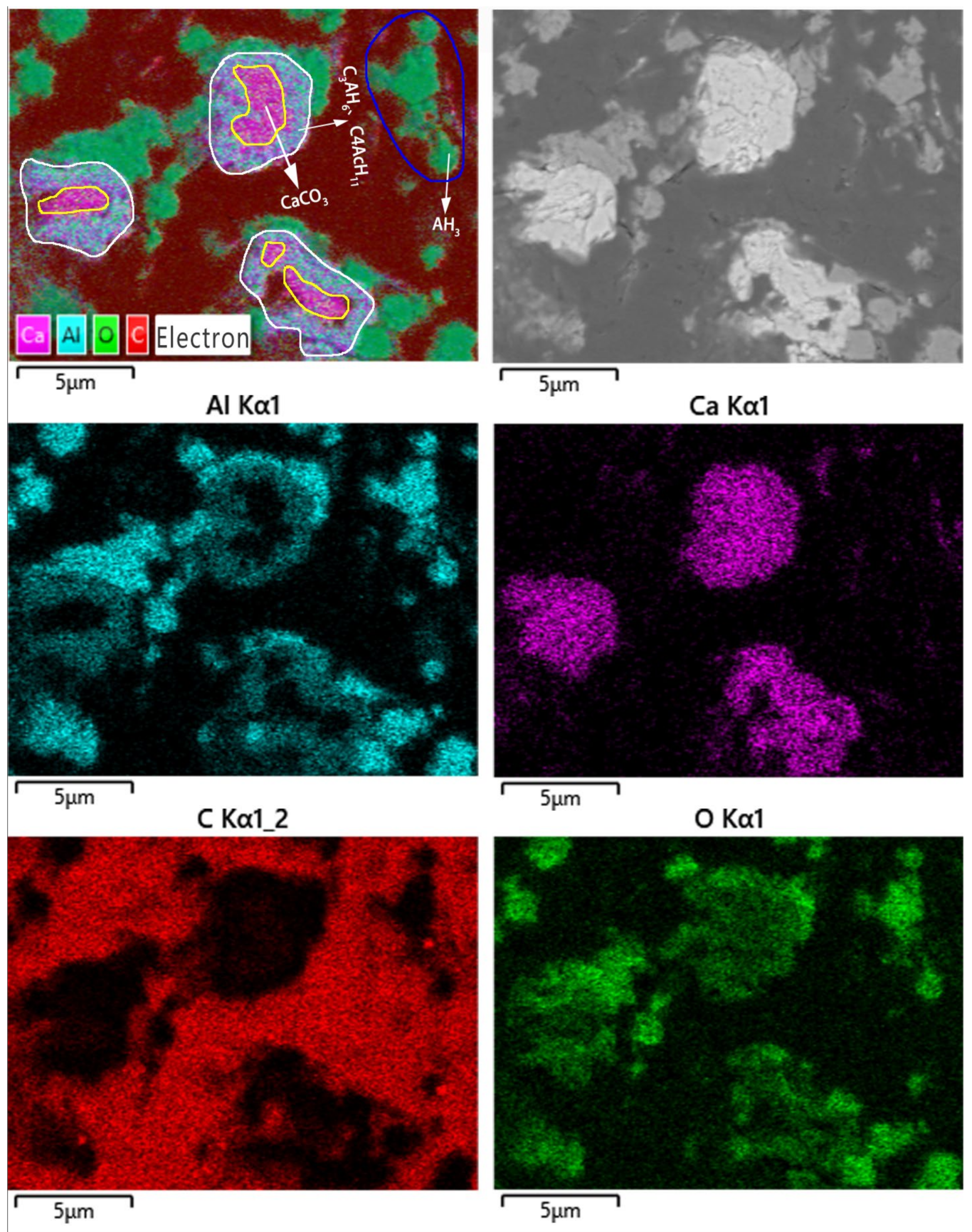

As shown in

Figure 4, with the raw calcium carbonate coated with C

4AcH

11, C

3AH

6, and AH

3 particles, the particle size of four types of calcium carbonate composites is very large, and the traditional SEM-EDS analysis cannot detect differences in their microstructures. The microstructure of the prepared calcium carbonate composites was determined by first embedding the prepared composites in resin, polishing them to expose the internal structure, and testing them via SEM-EDS.

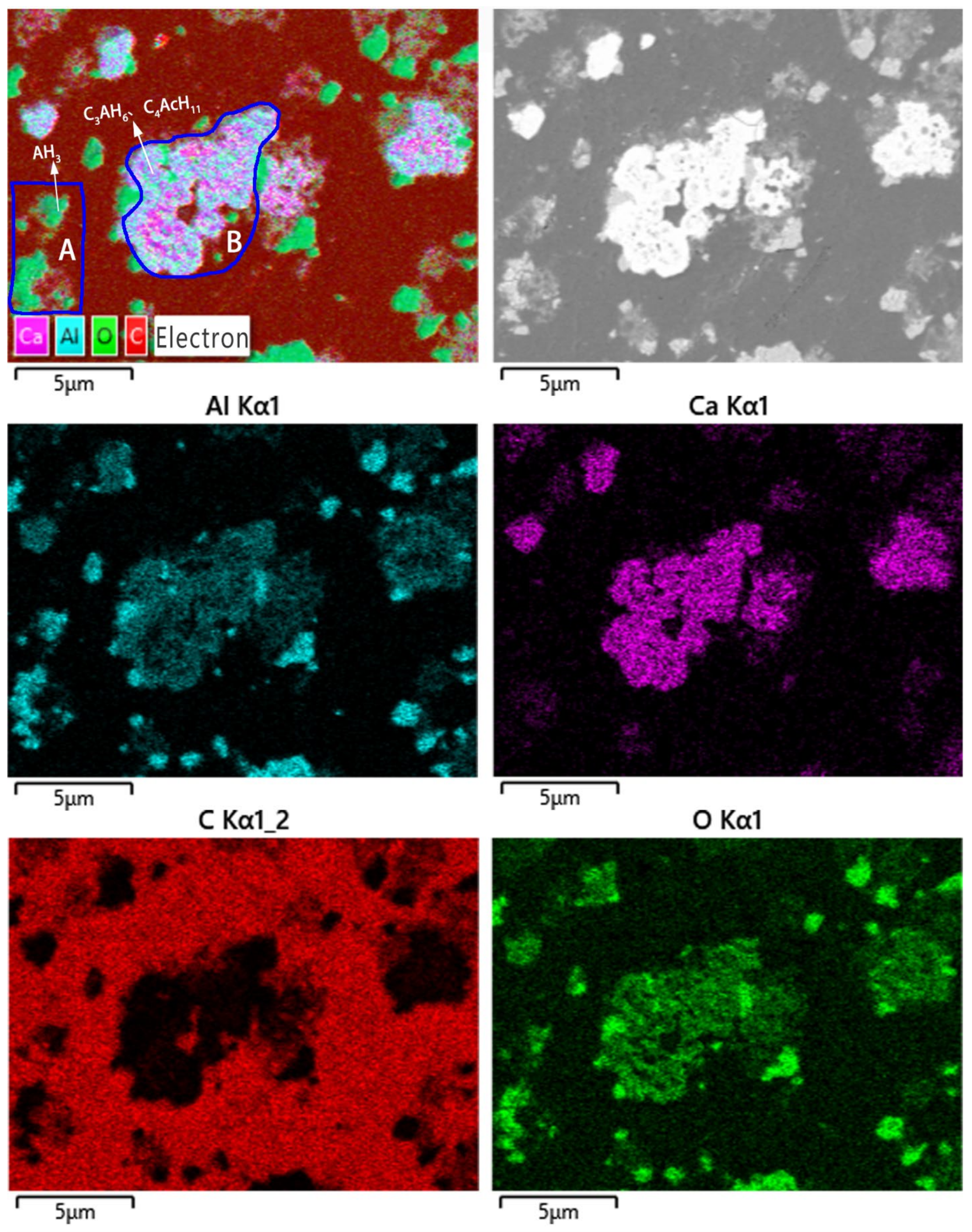

The SEM-EDS maps of vaterite-type precipitated calcium carbonate composite are shown in

Figure 5. The element distributions of Aluminum (Al), Calcium (Ca), Oxygen (O), and Carbon (C) are obviously inhomogeneous, indicating that different species wrap each other in composite. As shown in

Figure 5a, the area A has a high content of aluminum and oxygen but little content of calcium or carbon, indicating that the species phase in area A is AH

3. Additionally, area B has a high content of calcium and oxygen and a small amount of aluminum and carbon, indicating that the specie phase in area B involves C

3AH

6, C

4AcH

11, and CaCO

3. Furthermore, part of the perimeter of area B has a relatively high content of aluminum and oxygen, while the content of calcium or carbon is low in the perimeter of area A and in part of perimeter of area B. This finding indicates that the formation of AH

3 prefers to adhere to the surface of C

3AH

6 and C

4AcH

11, or has independent nucleation from the solution.

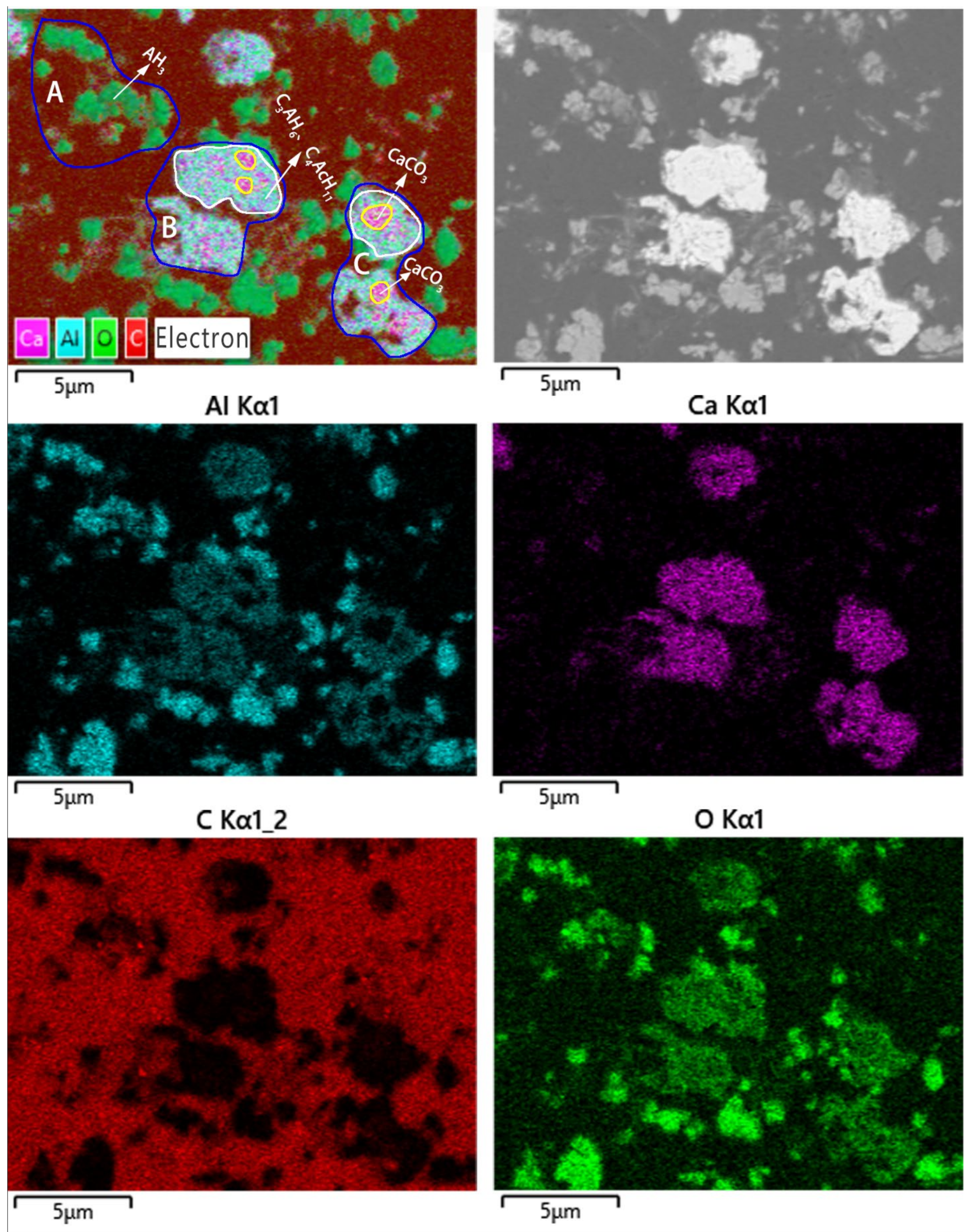

Figure 6 displays the SEM-EDS maps of calcite-type precipitated calcium carbonate composite. The element distributions of Al, Ca, O, and C are also obviously inhomogeneous. As shown in

Figure 6a, area A has a high content of Al and O but little content of Ca or C, while the areas B and C have a high content of Ca and a relatively high content of Al and O. Interestingly, the inner parts of areas B and C have low Al content but high Ca and O content. Therefore, the species phase in area A is only AH

3, and those in area B and C are C

3AH

6, C

4AcH

11, and CaCO

3, and that of CaCO

3 is coated with C

3AH

6 and C

4AcH

11. Considering the minor differences in the elemental distributions between C

3AH

6 and C

4AcH

11, their microstructures cannot be clearly recognized. Moreover, part of the perimeter of area B and C has a relatively high content of Al and O but a low content of Ca or C, indicating that the surface of the formed C

3AH

6 and C

4AcH

11 is partly coated with AH

3. Therefore, the microstructure of the formed calcium carbonate composite involves a three-tier structure, in which the innermost CaCO

3 is wrapped by C

3AH

6 and C

4AcH

11, and the outermost AH

3 adhered to the middle layer of C

3AH

6 and C

4AcH

11 with a thickness of 2–3 μm.

Figure 7 shows the SEM-EDS maps of <500 mesh ground calcium carbonate composite. It also shows that the independent precipitated AH

3 and three-tier structure particles also appeared. The Ca-rich area has relatively low Al content, while the Al-rich area usually has relatively low Ca content. Therefore, the boundary between Ca and Al elemental distribution is relatively clear. Moreover, the inner parts of the areas do not contain Al but have high Ca and O content, indicating that inner parts only contain the specie phase of CaCO

3. Therefore, those three-tier structure particles involve the unreacted CaCO

3 as a core, the formed C

3AH

6 and C

4AcH

11 as an interface, and the formed AH

3 as an overburden. However, the particle size of the CaCO

3 core increased, and the thickness of the intermediate layer decreased from 1 μm to 2 μm.

The SEM-EDS maps of 400–500 mesh ground calcium carbonate composite are displayed in

Figure 8. The elemental distribution of Ca, Al, O and C became much more regular, and the boundary between Ca and Al elemental distribution became clearer. Almost all elemental Ca is surrounded by Al, and the Ca-rich area has a very low content of Al, while the Al-rich area usually has a very low content of Ca. Additionally, both Ca- and Al-rich areas only exit in the boundary area of Ca enrichment, and the thickness of that boundary area is less than 1 μm. Based on the above XRD analysis shown in

Figure 1(2), most of the particles display an obvious and complex core-shell structure with the core being unreacted CaCO

3 and the shell involving AH

3 and C

3AH

6. Notably, a few isolated AH

3 particles were observed, as shown in

Figure 8.

Based on the above SEM-EDS maps from

Figure 5,

Figure 6,

Figure 7 and

Figure 8, the microstructures of prepared calcium carbonate composites are very different from those obtained by using varied calcium carbonate as a precursor. The prepared calcium carbonate composites mainly involve three-tier structure particles and independent precipitated AH

3 particles

. When vaterite-type precipitated calcium carbonate was used as a precursor, many inclusions involving C

3AH

6, C

4AcH

11, and CaCO

3 can be detected, and only a few AH

3 particles adhere to the surface of those inclusions. When calcite-type precipitated calcium carbonate was used as a precursor, many isolated AH

3 particles appeared and a three-tier structure with CaCO

3 as the innermost, AH

3 as the outermost and C

3AH

6 and C

4AcH

11 as the middle layers can be detected. Between the vaterite-type precipitated calcium carbonate composite and calcite-type precipitated calcium carbonate composite, more unreacted CaCO

3 particles are observed, which are used as a core in the latter, and the content of isolated AH

3 particles increased. This finding was obtained because the calcite-type precipitated calcium carbonate is more stable than the vaterite-type precipitated calcium carbonate, and the reacted vaterite-type precipitated calcium carbonate via an anti-caustic reaction may be restraining the independent precipitation of AH

3. Furthermore, when ground calcium carbonate with a particle size of less than 500 mesh and 400–500 mesh was used as a precursor, particles with a three-tier structure became more obvious, and the particle size of unreacted CaCO

3 core increased, while the thickness of the intermediate layer decreased with the increase in ground calcium carbonate particle size. This finding was obtained because the ground calcium carbonate is more stable than that of the precipitated calcium carbonate, and the anti-caustic reaction between calcium carbonate and sodium aluminate solution became more difficult with the increase in calcium carbonate particle size.

Considering the unavoidable anti-caustic reaction, the precipitated calcium carbonate, such as calcite or vaterite, is not suitable for the preparation of CaCO3/Al(OH)3 composites with a core-shell structure, while the ground calcium carbonate should be the best choice. The particle size of the ground calcium carbonate remarkably influenced the properties of the prepared CaCO3/Al(OH)3 composites, and the large particle size is favorable for the formation of the core-shell structure. However, considering that CaCO3/Al(OH)3 composites are used as a filler in plastic, rubber and man-made gems, the large particle size would impair other performances, such as compatibilization and reinforcement. Therefore, the use of ground calcium carbonate with a particle size of less than 400 mesh and greater than 500 mesh is suitable as a precursor for the preparation of core-shell CaCO3/Al(OH)3 composites.

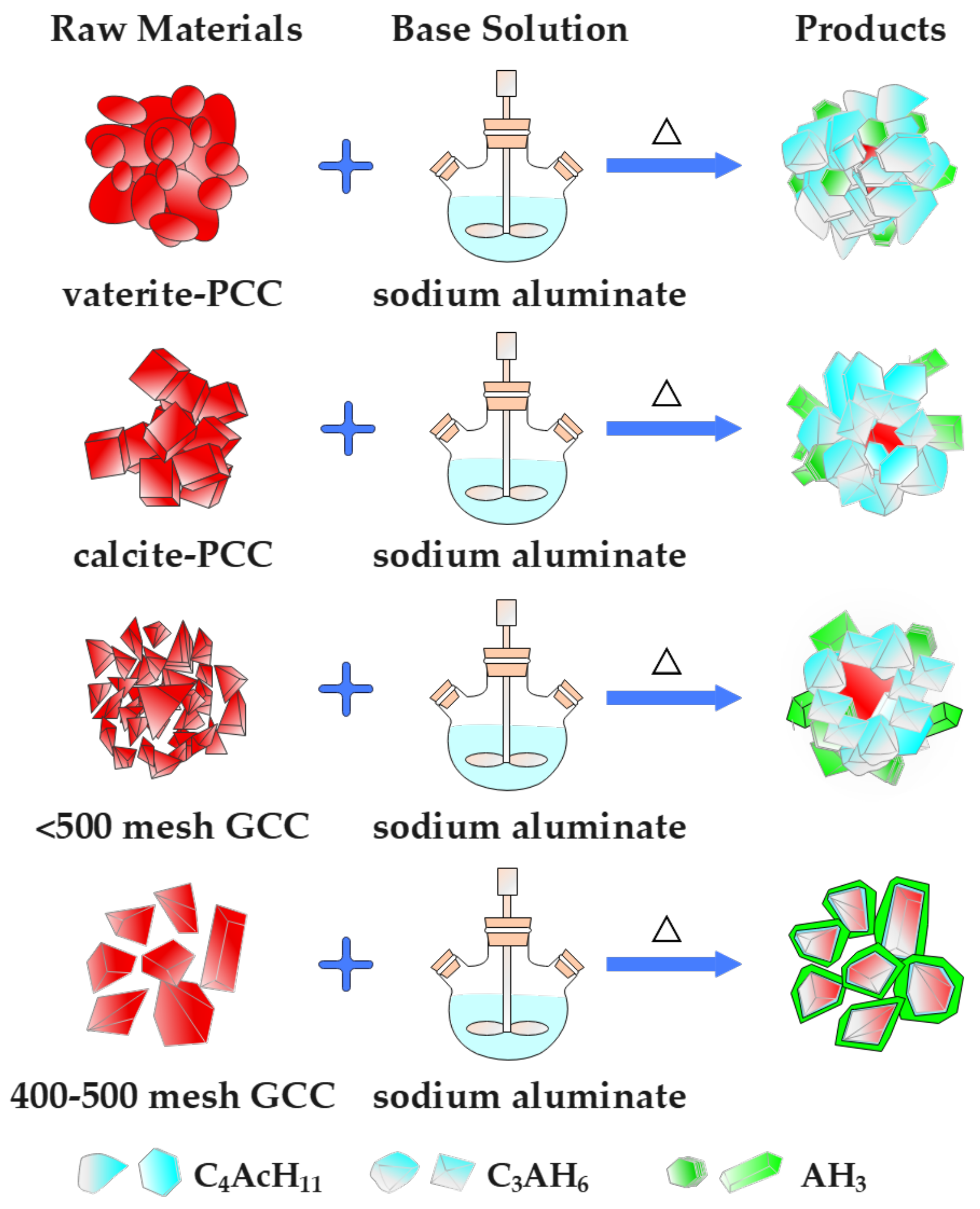

3.4. Reaction Mechanism

Based on the above analyses, the preparation of CaCO

3/Al(OH)

3 composites with the heterogeneous nucleation method could be interpreted as the following process. First, when calcium carbonate is added to the sodium aluminate solution, 3CaO·Al

2O

3·6H

2O (C

3AH

6) and Na

2CO

3 are easily generated [

28], and this process can be represented as an anti-caustic reaction:

Then, when more active CaCO

3 molecules exist in the system, the formed C

3AH

6 may be further reacted with active CaCO

3 to form a complex 3CaO·Al

2O

3·CaCO

3·11H

2O (C

4AcH

11) [

29,

30], which can be expressed in the following complex reaction:

Finally, at the end of the above anti-caustic reaction and complex reaction, the formed solid particles become the substrate of the heterogeneous nucleation of Al(OH)

3 [

31]. The nucleated Al(OH)

3 gradually separates out from the solution and adheres to the surface of those solid particles, thus forming CaCO

3/Al(OH)

3 composites. It can be represented as a seed precipitation reaction as follows:

The reaction mechanism of the formation of four types of calcium carbonate composites is shown in

Figure 9. With the addition of raw calcium carbonate to the sodium aluminate solution, four types of calcium carbonate composites were prepared after anti-caustic reaction, complexation reaction and seed precipitation reaction. Considering the differences in the surface activity of four types of calcium carbonate, the formed CaCO

3/Al(OH)

3 composites displayed very different microstructure characteristics. By using vaterite-type precipitation calcium carbonate as a precursor, the prepared composite mainly contained many inclusions formed by C

3AH

6, C

4AcH

11, and CaCO

3; using calcite-type precipitation calcium carbonate as a precursor, the prepared composite mainly involved three-tier structure particles with much smaller CaCO

3 particles as the innermost layer, AH

3 as the outermost layer and a very thick middle layer of C

3AH

6 and C

4AcH

11. When <500 mesh and 400–500 mesh ground calcium carbonates were used as precursors, respectively, the prepared composites mainly contained three-tier structure particles, while the particle size of the CaCO

3 core increased and the thickness of the middle layer decreased with the increase in the particle size of ground calcium carbonate. The 400–500 mesh ground calcium carbonate is considered to be the best precursor for the preparation of CaCO

3/Al(OH)

3 composites with a very nice core-shell structure.