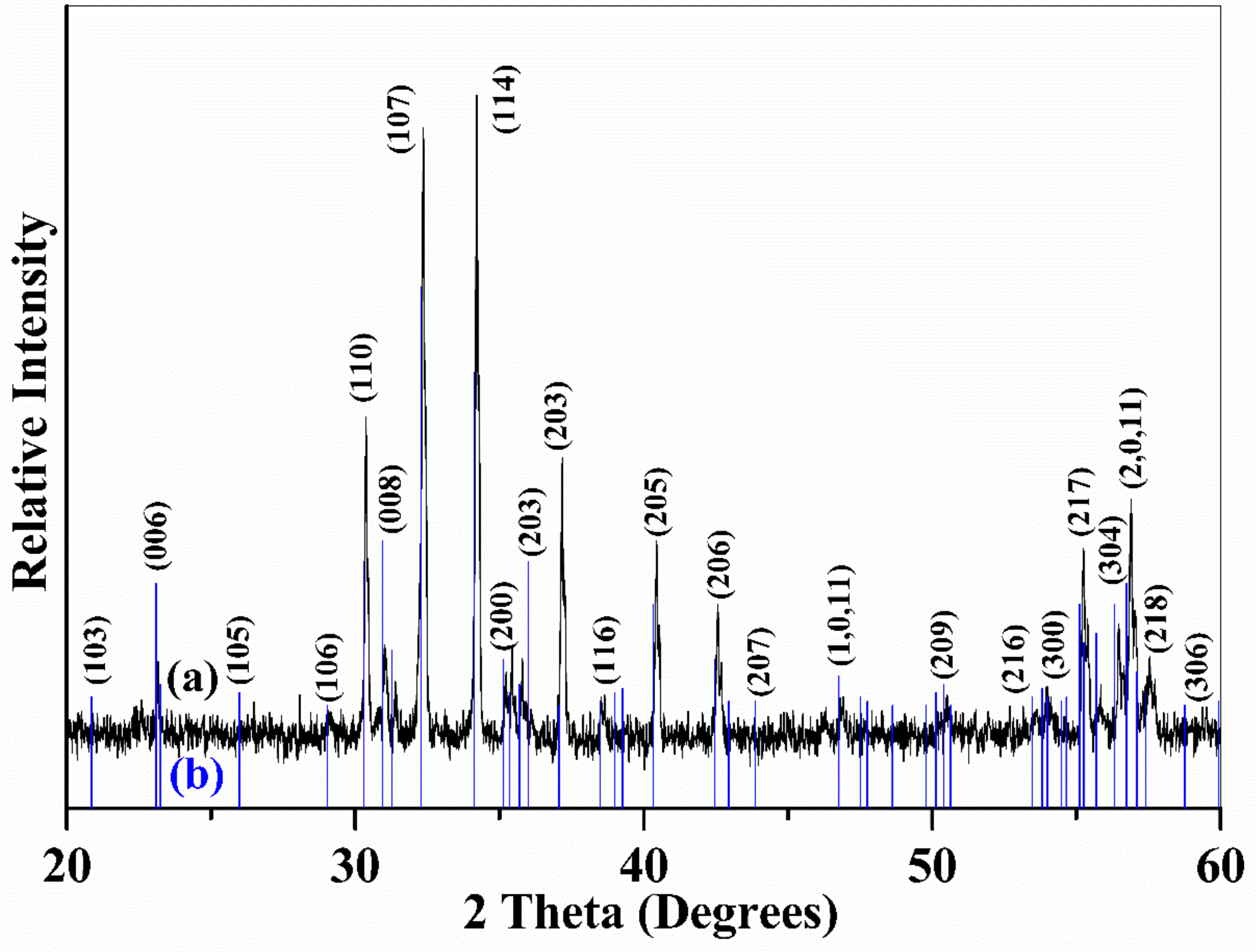

3.1. Structure Identification

The X-ray diffraction (XRD) pattern reveals that the La

0.5Sr

0.5Fe

12O

19 system shares the same crystal structure with the magnetoplumbite-5H system, which may be termed as PbFe

12O

19 or SrFe

12O

19.

Figure 1a displays the XRD pattern of sintered La

0.5Sr

0.5Fe

12O

19 ceramics. The discrete blue lines in

Figure 1b are the standard diffraction spectrum of PbFe

12O

19 (PDF#41-1373). Obviously, the overall diffraction peaks of La

0.5Sr

0.5Fe

12O

19 matches well with the standard diffraction lines, indicating that the crystal structure of the La

0.5Sr

0.5Fe

12O

19 system was the same as that of the magnetoplumbite-5H model in PbFe

12O

19 or SrFe

12O

19. There is a small lattice contraction after the substitution. The substitution of 0.5 La with 0.5 Sr won’t change the lattice volume too much since those La atoms would fit into large void spaces where the Sr atoms occupied before substitution in the unit cell of SrFe

12O

19 lattice [

24]. The decrease in the radius of La atoms compared to Sr ones is ignorable to the size of the void space. Therefore, the lattice parameters reduce very little after the replacement of La with Sr. The diffraction pattern is clean and was not indexed to second-phase impurities. However, several small peaks may be traced to the contribution of a small number of excessive Fe

2O

3 in the pattern. This result suggests that a pure solid solution of La

0.5Sr

0.5Fe

12O

19 in a single phase has been successfully fabricated after the substitution of 0.5 Sr

2+ ions with 0.5 La

2+ ions in the SrFe

12O

19 compound. According to this formula (La

0.5Sr

0.5Fe

12O

19), La ions would be bivalent (La

2+) instead of trivalent in charge. The outer shells of La atoms give the electronic structure of 5d16S2, two electrons at the 6S level and one electron at the 5d level. Therefore, La atoms may lose either two outer shell 5S electrons to become La

2+ ions in divalent or lose all three outer shell electrons (2 from 6S+1 from 5d) to be La

3+ ions. Consequently, the valence charges of 0.5La+0.5Sr would be +2, whereas 12 Fe

3+ ions provide +36 positive charges; the total positive charges are then counted to be +38, which may balance the total negative charges of −38 from 19 O

2- ions in La

0.5Sr

0.5Fe

12O

19. The charge balance in this formula would make this compound possible and may leave no vacancies in the lattice.

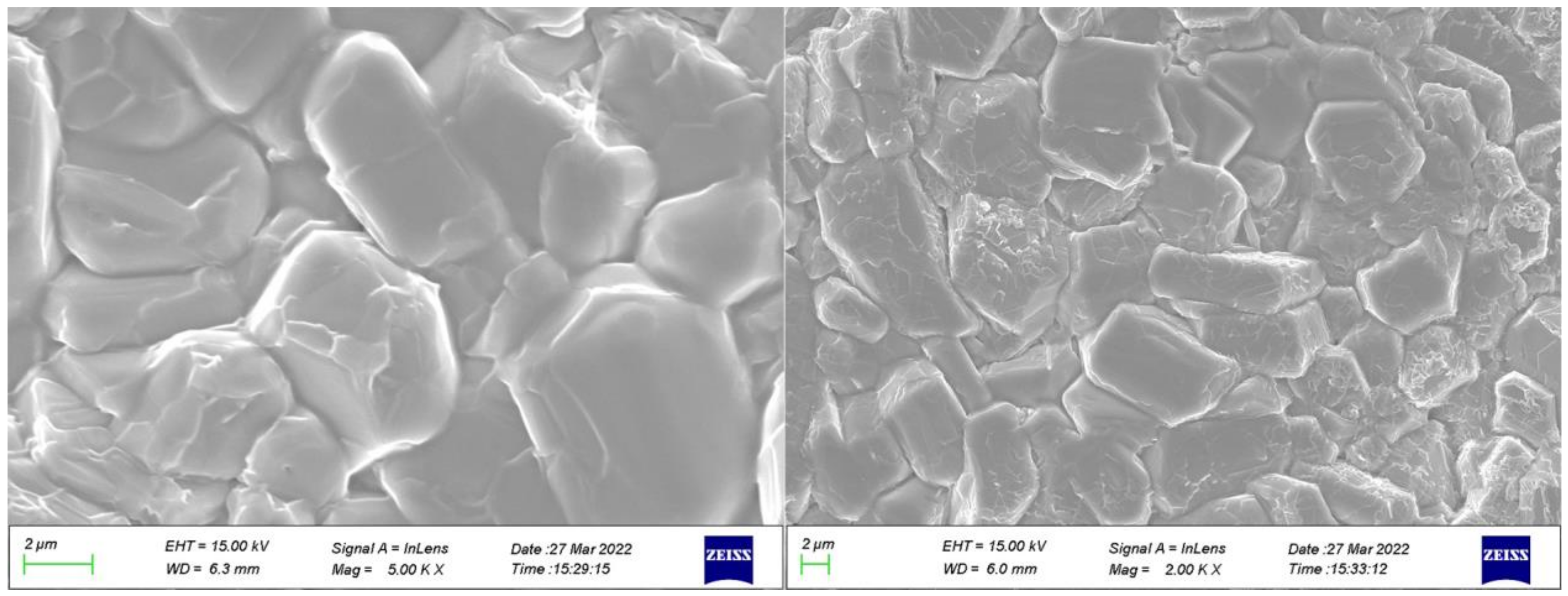

Figure 2 shows the microstructure of La

0.5Sr

0.5Fe

12O

19 ceramics measured by scanning electron microscopy (SEM, JSM-7500F, Japan Electronics Corporation (JEOL), Akishima, Japan), which shows that it has good denseness and most of the grains show a plate-like morphology. However, the grains of La

0.5Sr

0.5Fe

12O

19 are mostly irregular hexagonal plate-like structures, which is due to the substitution of Sr by La, which leads to the disruption of the hexagonal symmetry of the crystal structure of SrFe

12O

19. The [0001] direction is perpendicular to the surface of the plate grains. The plate shape indicates that the grains do not grow preferentially along the [0001] direction but preferentially along the [1000] and [0100] directions. Obviously, the grains also grow at different rates along the [1000] and [0100] directions. Therefore, the grains do not have a perfect hexahedral shape but actually grow into irregular plates.

3.2. Dielectric Relaxing and Antiferroelectrics of La0.5Sr0.5BaFe12O19 Ceramics

The temperature-dependent dielectric spectrum of pure SrFe

12O

19 ceramics has been reported in the literature [

25]. That dielectric spectrum demonstrated two-phase transition peaks, one for ferroelectrics to antiferroelectrics at 174 °C (TF-A) and the other one for antiferroelectrics to paraelectrics at 490 °C (TA-P) [

25], suggesting that SrFe

12O

19 is a ferroelectric phase at room temperature. Thereafter, by replacing 0.2 Sr ions with 0.7 La ions in SrFe

12O

19, the first phase transition peak (TF-A) shifts to the vicinity of room temperature, where the ceramic specimen shows a partial antiferroelectric feature coexisting with ferroelectric state [

26]. Herein, the substitution concentration of La ions is further increased to 0.5, aiming to move the first TF-A peak down to low-temperature region. As such full antiferroelectric state may be achieved at room temperature.

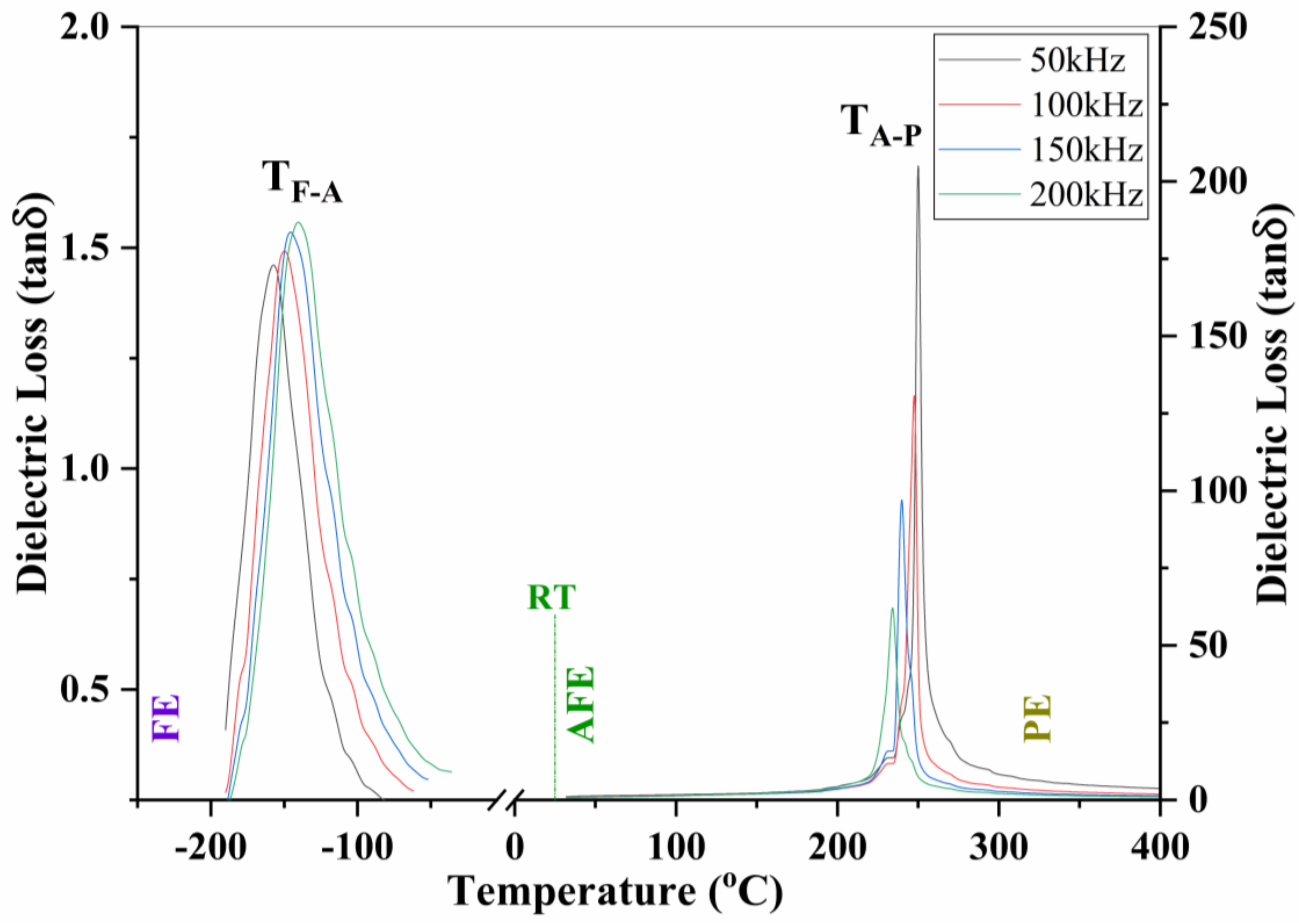

Figure 3 exhibits the temperature-dependent dielectric loss spectrum of La

0.5Sr

0.5Fe

12O

19 ceramics as a function of frequency. There also appear two-phase transition peaks. One (TF-A) locates at the low-temperature region, representing the transformation of ferroelectrics (FE) to antiferroelectrics (AFE); the other one (TA-P) stands at high-temperature region corresponding to the transition of antiferroelectrics to paraelectrics (PE). The first TF-A peak spans from −158 °C to −141 °C when the frequency increases from 50 kHz to 200 kHz, and the second TA-P peak reversely shifts from 250 °C down to 234 °C as the frequency increases from 50 kHz to 200 kHz. Both transition peaks demonstrate strong relaxing behavior upon frequencies. However, the second TA-P peak relaxes reversely to the first one due to the antiferroelectric dipolar feature. It can be seen that the ferroelectric state can only appear at the temperature region below −141 °C, while the paraelectric phase may occur above 234 °C (for 200 kHz). There is a wide space between −141 °C to 234 °C, in which antiferroelectrics remains in a thermodynamically stable state.

Upon the substitution of 0.5 Sr with 0.5 La in SrFe

12O

19, the first transition peak (TF-A) was successfully moved from 174 °C down to a low-temperature region below −140 °C, while the second TA-P peaks shifted from 490 °C down to 234 °C, leaving a broad space (−141 °C ~234 °C) at the vicinity of room temperature to accommodate full antiferroelectric state. In this way, a full antiferroelectric state at room temperature was successfully achieved, as shown in

Figure 3.

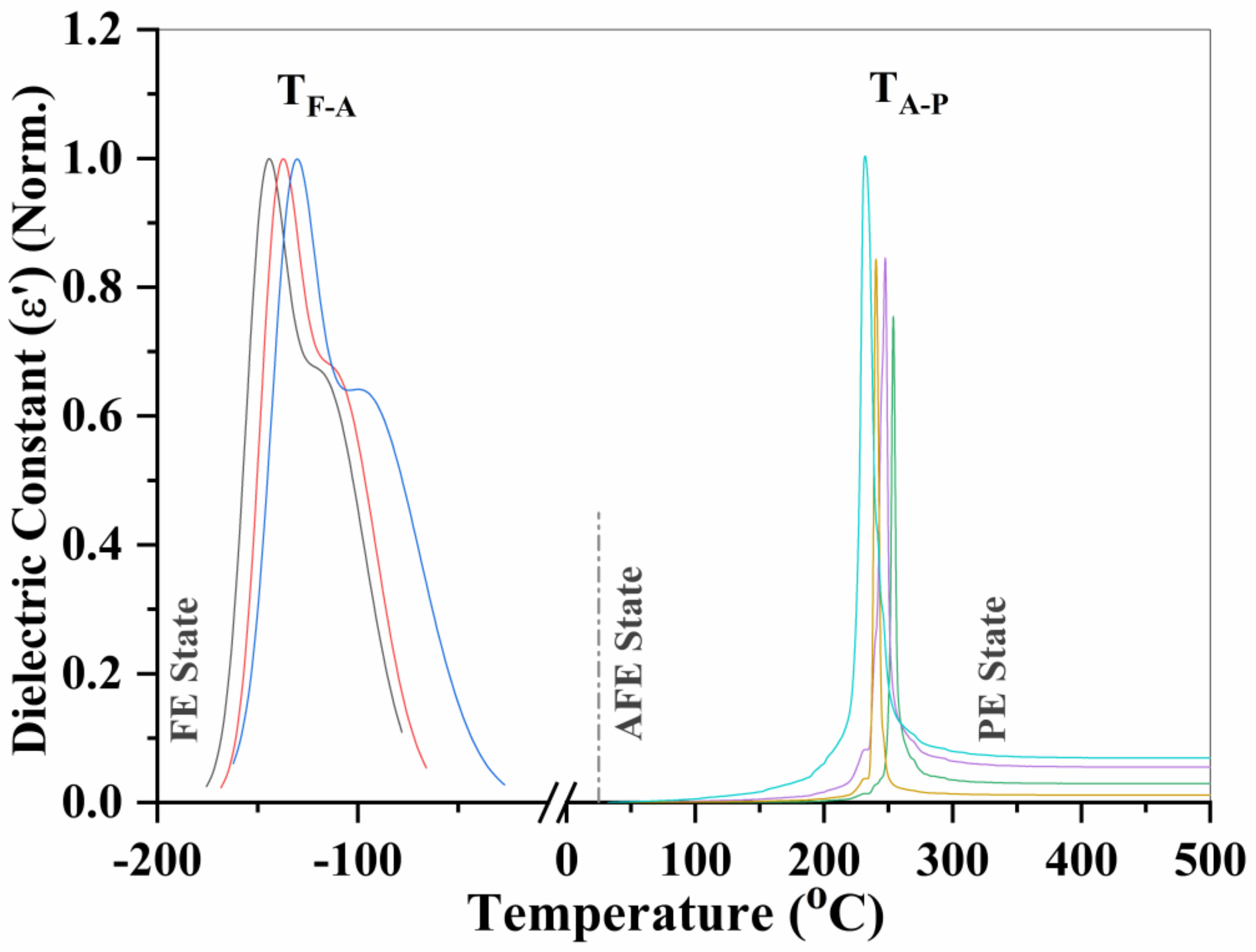

The spectrum of the real part of the dielectric constant reveals similar changes in the phase configuration of the La

0.5Sr

0.5Fe

12O

19 system. The temperature-dependent dielectric constant

spectrum is displayed in

Figure 4. The transition peak of TF-A (FE→AFE) locates at −145 °C, while that of TA-P (AFE→PE) is centered at 232 °C (200 kHz). The critical temperature of TF-A in La

0.5Sr

0.5Fe

12O

19 system moved to a very low temperature far below room temperature (RT) when 50% Sr was replaced with 50% La, leaving a wide space of −145 °C ~ 232 °C for the antiferroelectric state to survive as a stable thermodynamic phase. Consequently, the RT state of La

0.5Sr

0.5Fe

12O

19 changes to a full antiferroelectric phase after the rare earth elemental substitution. Both real and imaginary parts of dielectric constants varying with temperature revealed similar phase configurations, which was demonstrated in

Figure 4. However, there is a small retardation between the two types of spectra. The real part lags behind the imaginary one by about 18 °C because of the phase difference between the real part and the imaginary part.

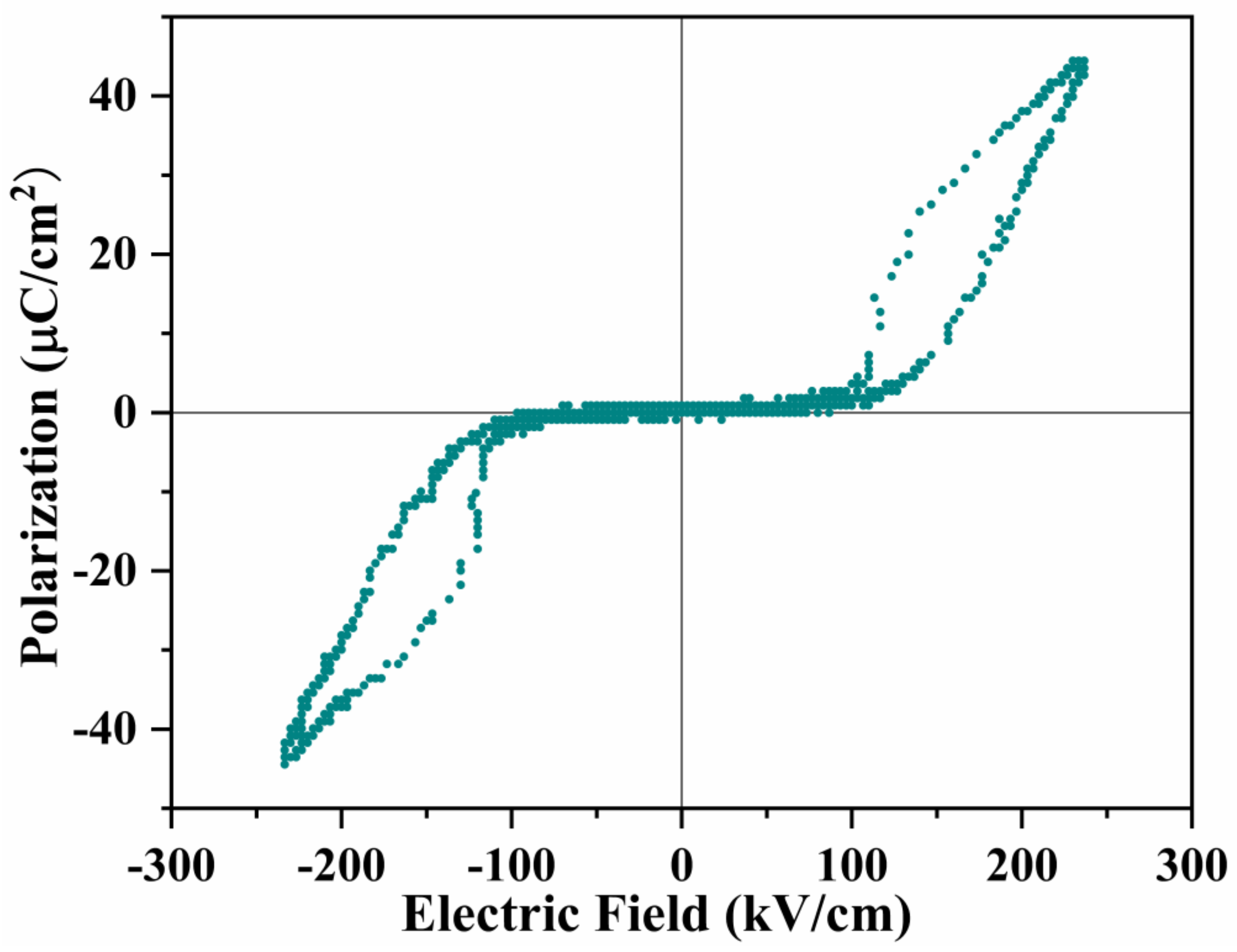

Figure 5 displays a double P-E hysteresis loop as the experimental evidence for proving the pure antiferroelectric feature of La

0.5Sr

0.5Fe

12O

19 ceramics. The polarizations in two hysteresis loops align in opposite directions upon switching the electric field. In AFEs, adjacent dipoles of the same strength in the crystal structure are initially aligned in opposite directions leading to zero overall spontaneous polarization. These initially antiparallel dipoles, however, can be forced to become parallel along the direction of a sufficiently strong external electric field to reach a FE state [

16]. Then, once the external electric field is removed, the induced FE phase can revert back to the initial AFE state, thereby generating so-called double P-E hysteresis loops. The FE loops are separated by a linear AFE component, whose polarization counteracts each other due to the antiparallel dipoles. The better the linearity. The purer is the antiferroelectric feature. It may be seen from

Figure 4 that the linear AFE component is almost overlapping with the x-axis, and the net polarization approaches zero through the cancellation of reversely aligned dipoles in the full antiferroelectric phase of the La

0.5Sr

0.5Fe

12O

19 system. Only when the external electric field is sufficiently high enough to exceed ±, EA may the antiparallel dipoles be forced to align along the same direction with the E field and thus generates the appearance of double P-E hysteresis loops. The maximum saturated polarization is estimated to be 45 μC cm

−2 at E = 235 kV cm

−1 and the remnant polarization is around 3.3 μC cm

−2, almost approaching zero. The forward switching (AFE-to-FE) field EA locates at ±109 kV cm

−1, backward switching (FE-to-AFE) field EF is around ±131 kV cm

−1, the switching hysteresis is

.

The two switching fields (EA & EF) of the La

0.5Sr

0.5Fe

12O

19 system are comparable to that of classical antiferroelectric perovskites, such as Pb (Zr

xTi

1−x) O

4 [

27,

28] and AgNbO

3 [

29] whose EA ranges from 40 kV cm

−1 to 170 kV cm

−1 and EF ranges from 100 kV cm

−1 to 230 kV cm

−1. The recoverable storage energy density of the La

0.5Sr

0.5Fe

12O

19 system is calculated from the hysteresis loops in

Figure 5 to be 6.2 J cm

−3 at 235 kV cm

−1. This value is also similar to that of PLZT perovskite capacitors (6.7 J cm

−3) [

30]. Higher energy density could be only achieved in a 700 nm La-doped PbZrO

3 thin film system by applying a very high field of up to 600 kV cm

−1 [

31] or a 500 nm Sr-doped PbZrO

3 thin film with an even higher field of 900 kV cm

−1 [

32].

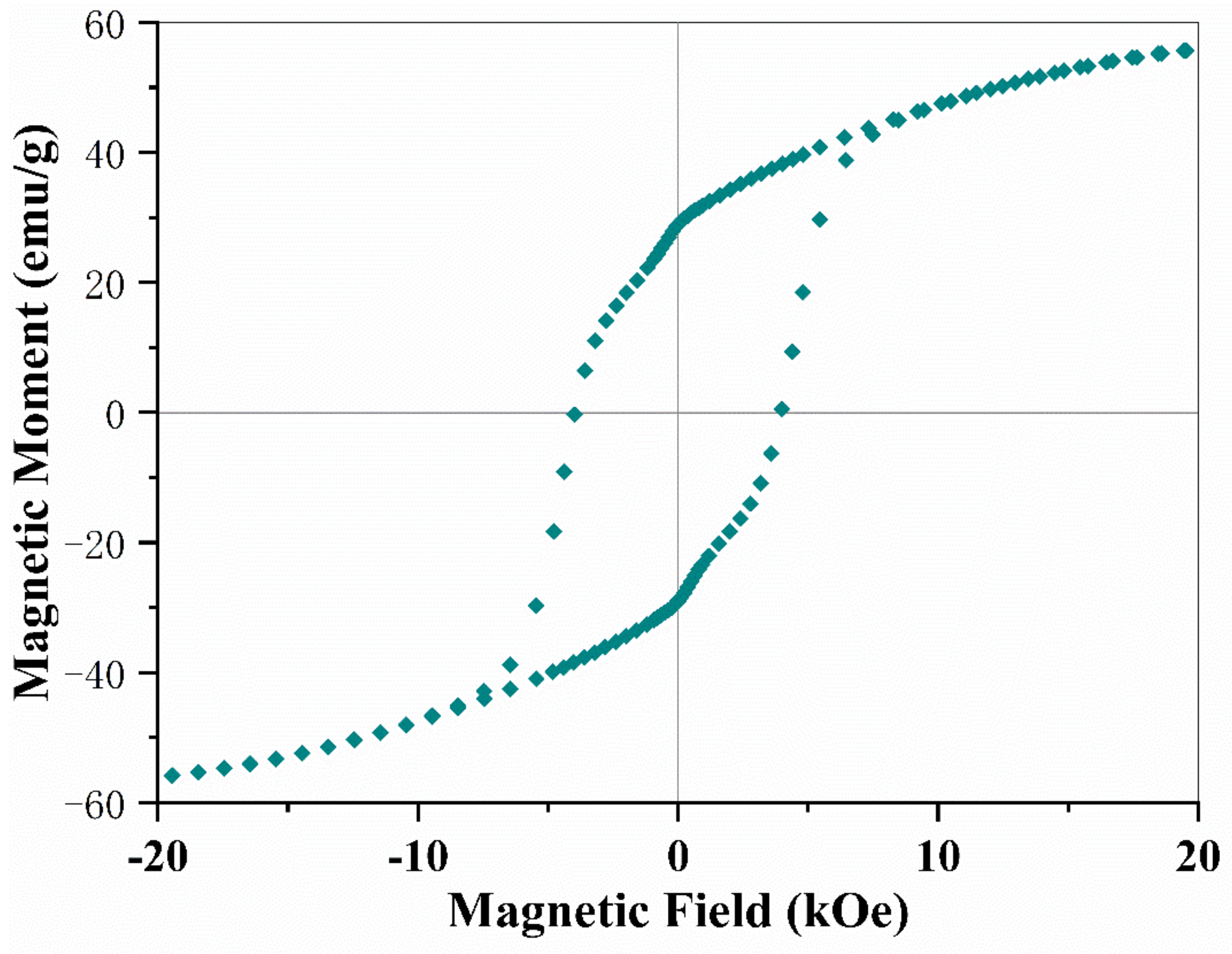

3.3. Magnetic Property of the La0.5Sr0.5Fe12O19 Ceramics

Strong magnetism is an important indexing property to identify the candidate as a multiferroic compound in addition to its ferroelectrics. The SrFe

12O

19 ceramic performances in ferrimagnetism with high remnant magnetic moments and large coercive field. The replacement of 0.5 Sr

2+ with 0.5 La

2+ may not alternate its magnetic properties too much.

Figure 6 shows an M-H hysteresis loop of La

0.5Sr

0.5Fe

12O

19 ceramic, which was measured upon a Physical Property Measurement System (PPMS). The specimen was sintered at 1350 °C and subsequently annealed in an O

2 atmosphere at 800 °C for 6 h. The remnant moment (M r) of the La

0.5Sr

0.5Fe

12O

19 ceramic specimen is around 29.5 emu g

−1, and coercive force (H c) is about 4020 O e. By comparing these parameters with that of the SrFe

12O

19 ceramic specimen sintered at 1150 °C, we found that the coercive force was enhanced from 3510 O e to 4020 O e after the replacement of 50% Sr with 50% La in the SrFe

12O

19 system, suggesting that the magnetism was improved somehow. The heavy substitution by rare earth elemental La ions generates a new type of multiferroic candidate, whose molecule formula could be termed La

0.5Sr

0.5Fe

12O

19. This novel multiferroic compound combines full antiferroelectrics and ferrimagnetism together in one single phase at room temperature.

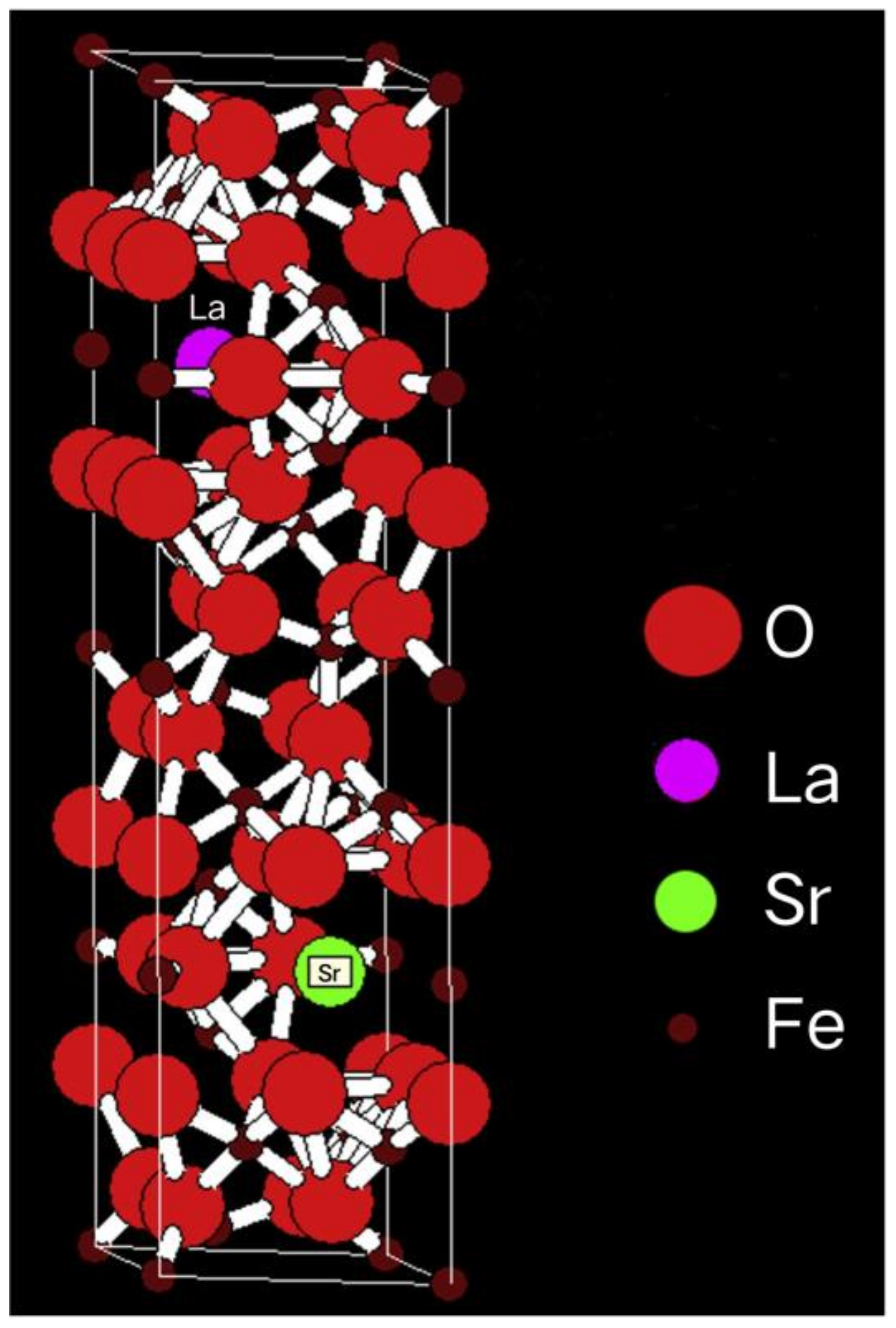

3.4. Magnetoelectric Coupling Effect in La0.5Sr0.5Fe12O19 System

The combination of FE (or AFE) and FM states in one single phase is the fundamental element of multiferroics. The magnetoelectric (ME) coupling effect, on the other hand, is the prerequisite requirement for multiferroics to be practicable. The application needs magnetically read-out and electrically write-in operation in multiple state memories. Here we will present the ME coupling performances in La

0.5Sr

0.5Fe

12O

19 ceramics. The ME coupling was tested by a setup system, and the variation of spin current and capacitor of the specimen with the external magnetic field was measured using a Keithley 2450 Source meter or Micro test LCR meter. The change in the physical parameters of the La

0.5Sr

0.5Fe

12O

19 ceramic specimen upon different magnetic fields was recorded by these instruments and output to a computer. La

0.5 Sr

0.5 Fe

12O

19 ferrite crystallizes in a hexagonal structure with 64 ions present on each unit cell, located in 11 different symmetry sites (P63/mmc space group). The crystal structure is shown in

Figure 7. 24 Fe

3+ ions are located in five different sites: including three octahedral sites (12k, 2a, and 4f2), one tetrahedral lattice site (4f1), and one hexahedral lattice site (triangular biconical lattice site) (2b) The magnetoelectric coupling in La

0.5 Sr

0.5 Fe

12O

19 is generated by three parallel (2a, 12k and 2b) and two anti-parallel (4f1 and 4f2) sublattices through the superexchange interaction between O

2− ions. The magnetoelectric coupling-induced polarization arises from the inverse Dzyaloshinskii-Moriya-type antisymmetric effect of spin-orbit coupling [

33], where two unequal obliquely tuned spin pairs are coupled, and two nonconjugated spins with a generic nonparallel configuration interact with each other. As it is in other ferrites of SmFeO

3 and DyFeO

3 [

34], the coupling between these two helical spins generates spin currents that are generating spin currents, which in turn, induce electric polarization. So, the current measured by the Keysight 2450 source meter is the spin current.

We believe that a spin current is formed in our system.

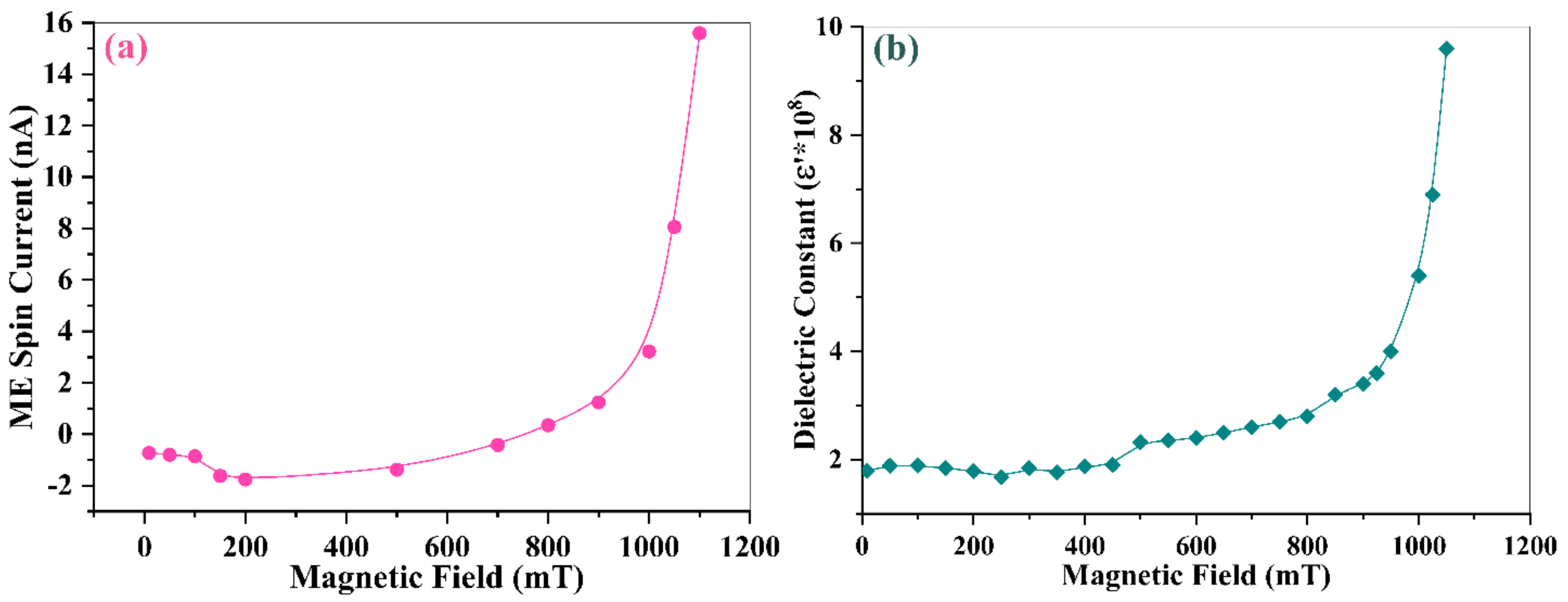

Figure 8 displays the variation of ME spin currents and the real part of dielectric constants of La

0.5Sr

0.5Fe

12O

19 ceramic specimen with increasing magnetic field. The Schottky barrier is formed between the silver electrode and the specimen surface, and the coupling voltage has no effect on the barrier height of electrons on the silver electrode side. However, the coupling voltage has a great influence on the barrier height of electrons on the specimen side, and the larger the applied voltage, the lower the barrier height. When the magnetic field is small, the resulting coupling voltage is also called smaller, and the barrier height of electrons on the silver electrode side is smaller, and the electrons flowing from the silver electrode to the sample dominate at this time, and the coupling current is negative at this time. As the magnetic field increases, the resulting coupling voltage also increases. Accordingly, the potential barrier of electrons at the silver electrode side is not affected by the voltage and remains unchanged. The height of the potential barrier of electrons at the specimen side decreases as the voltage increases. At this time, the electron flow from the specimen to the silver electrode increases continuously. At 700 mT, the two-electron flows roughly cancel, and the current is close to 0. Continue to increase the magnetic field and the electron flow from the specimen to the silver electrode. The current is positive at this time.

It can be seen from

Figure 8a that the initial spin current drops with a magnetic field below 200 m T, above which the ME coupling becomes strong enough that the spin current starts to increase with a magnetic field. The ME coupling current origins from the interaction of two neighboring conic spins, whose

gives rise to spin currents upon the external magnetic field. Within the region of 0~200 m T, the magnetic structure in the La

0.5Sr

0.5Fe

12O

19 system may arrange the conic spins to a downward orientation. Larger magnetic field strength will force more conic spins to align downwards, which is antiparallel to the direction of the magnetic field. In this region, thus, the ME coupling current becomes negative and decreases with the strength of the magnetic field. In the region of 200 m T < B < 800 m T, however, the magnetic structure changes to be the intermediate I phase, where the axis of conic spins will align to an upward direction with a large inclination angle to the z-axis (direction of magnetic field). The interaction of two such conic spins generates ME coupling current with the same inclination upward direction. The component on the z-axis of these spin currents slowly increases when the magnetic field becomes stronger, while those components in the other directions will cancel each other due to the random distribution of orientations. Therefore, the spin current within this region exhibits a slow increment with a magnetic field. When the magnetic field exceeds 800 m T, the magnetic profile switches to the intermediate II phase, where the axis of conic spins aligns with a small inclination angle to the z-axis. As the magnetic field increases, more and more conic spins will follow up the magnetic field to line upwards, aligning themselves parallel to the direction of the magnetic field. As such, the ME coupling current increases sharply with the magnetic field, as shown in

Figure 8a.

Figure 8b shows the change in the real part of dielectric constants (ε′) with a magnetic field. It can be seen that the dielectric response to the magnetic field is highly consistent with the ME coupling spin current. The stronger the magnetic field. The larger the dielectric constant. The increment of constant dielectric marches in the same step with the spin current. Above 800 m T, ε′ increases exponentially with the strength of the magnetic field. A higher magnetic field produces a larger spin current, which generates larger magnetically induced electric polarization (

P(

H)) since

(where i is the spin current, and t is the coupling time). There is a relationship between the increment of ε′ and

P(

H), which is expressed as follows [

25]:

where

t is the thickness,

ω is the frequency,

τ is relaxation time,

U is the voltage,

P(E) is the

E field-induced polarization, and

P(H) is the magnetic field-induced polarization. When

H = 0,

εr(E, H) =

εr(

E). Upon the application of an external magnetic field, an additional item of

εr(

H) as a function of

P(

H) will subjoin the item to

εr(

E), enhancing the dielectric constant to be

. Higher B induces larger

P(

H), which lifts up more

εr(

E,H) accordingly.

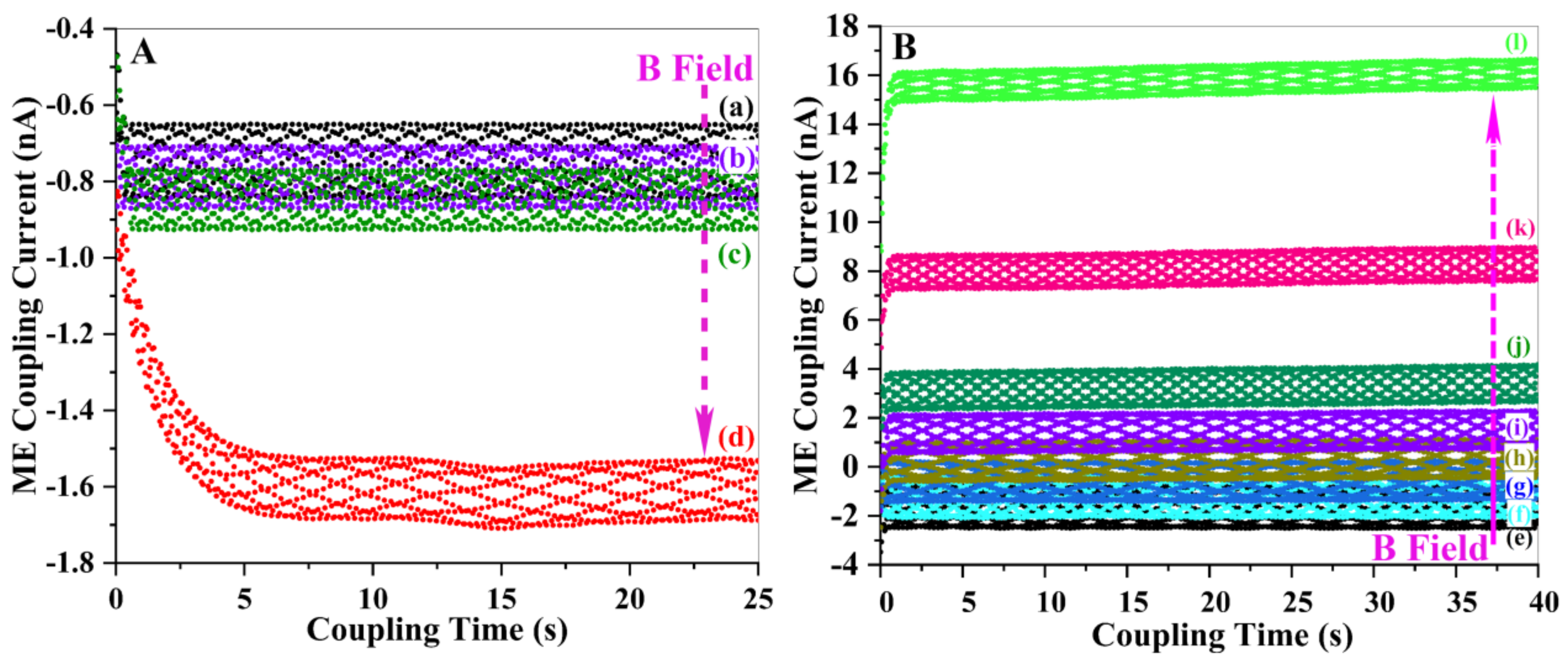

Figure 9 shows the shift of spin current waves with an external magnetic field as a function of coupling time, within the first magnetic structure region of B < 200 m T, the current wave downward shifts from −0.7 n A to −1.6 n A when the magnetic field increases from 50 m T to 200 m T due to the downward orientation of the conic spins. Within the second profile of the intermediate, I phase (200 m T < B < 800 m T), the ME current change very slowly with the magnetic field, resulting in the overlapping of the spin current waves. When the magnetic field is larger than 800 m T, the magnetic structure goes into the profile of the intermediate II phase, where the spin current enhances largely with the magnetic field. This shift pattern provides a better-visualized view to observe the change of spin current with magnetic field in La

0.5Sr

0.5Fe

12O

19 ceramics.

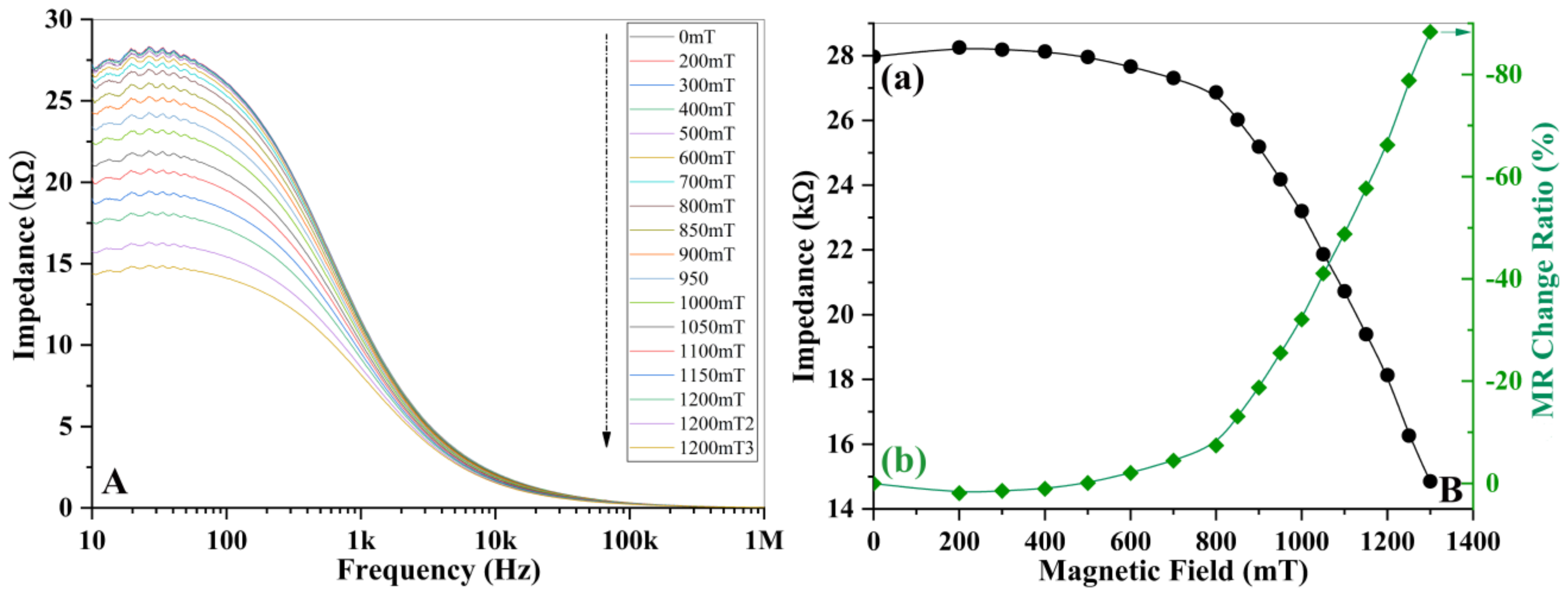

Figure 10A shows the variation of complex impedance upon the magnetic field as a function of frequency. In the low-frequency region (f < 100 Hz), the impedance (Z) reduces largely with a magnetic field. Within the high-frequency region (f > 1 kHz), the change in Z is much smaller. The magnetic field strength increases from 0mT to 1100mT, and the impedance spectrum drops from 28.3 kΩ to 14.7 kΩ, exhibiting a strong MR effect.

Figure 10B shows the stepwise change of impedance or resistance with the magnetic field at 50 Hz (a) and MR change ratio at different stepwise magnetic fields (b). Again, the impedance shows an increment with the magnetic field at the first magnetic profile (0 < B < 200 m T), then it drops gradually with B within the second profile of the intermediate I phase (200 m T < B < 800 m T). Above 800 m T, Z reduces sharply with B. The MR change ratio in

Figure 10B exhibits a reversal stepwise variation process. MR change ratio is calculated using Equation ΔZ = [Z(B) − Z(0))/Z(B)]%. The enhancement stepwise of the MR ratio above 800 m T is much larger than that below this critical field. The stronger the magnetic field, the larger the ratio. The maximum MR change ratio is around −89% at 1100 mT. The size of the MR effect that happens in this ferrite oxide is comparable to that appears in Fe/Cr/Fe trilayers film system [

35,

36] as well as Cu/Co multilayers [

37]. Obviously, the changing profile in impedance or resistance with magnetic field reversely matches the change mode in ME spin current. Both profiles follow up with the evolution process of the magnetic structure. Therefore, the orientation of the conic spins within different magnetic structure regions determines the profile of the magnetoelectric coupling effect or MR profile.