Mesoscopic Analysis of Rounded and Hybrid Aggregates in Recycled Rubber Concrete

Abstract

:1. Introduction

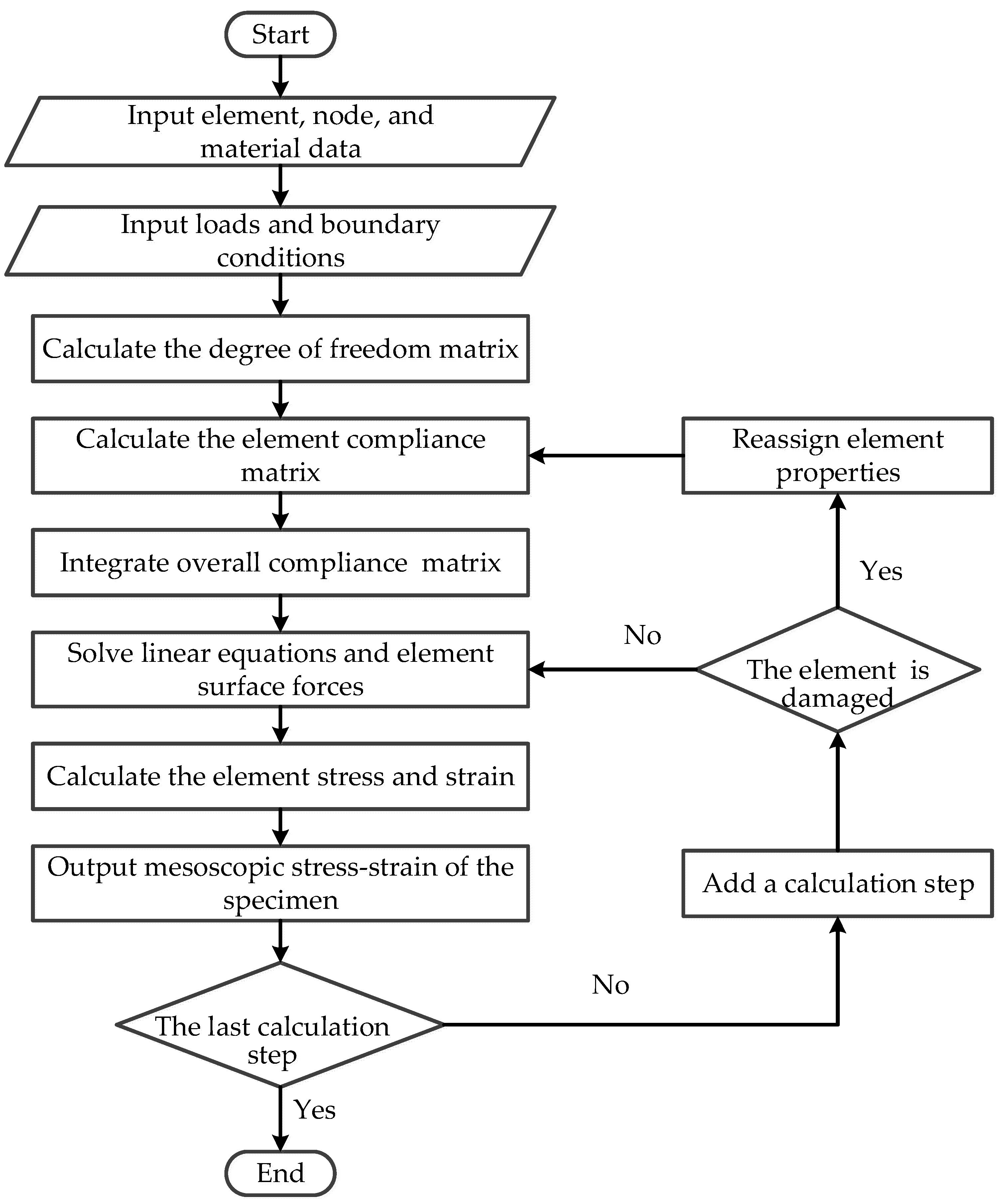

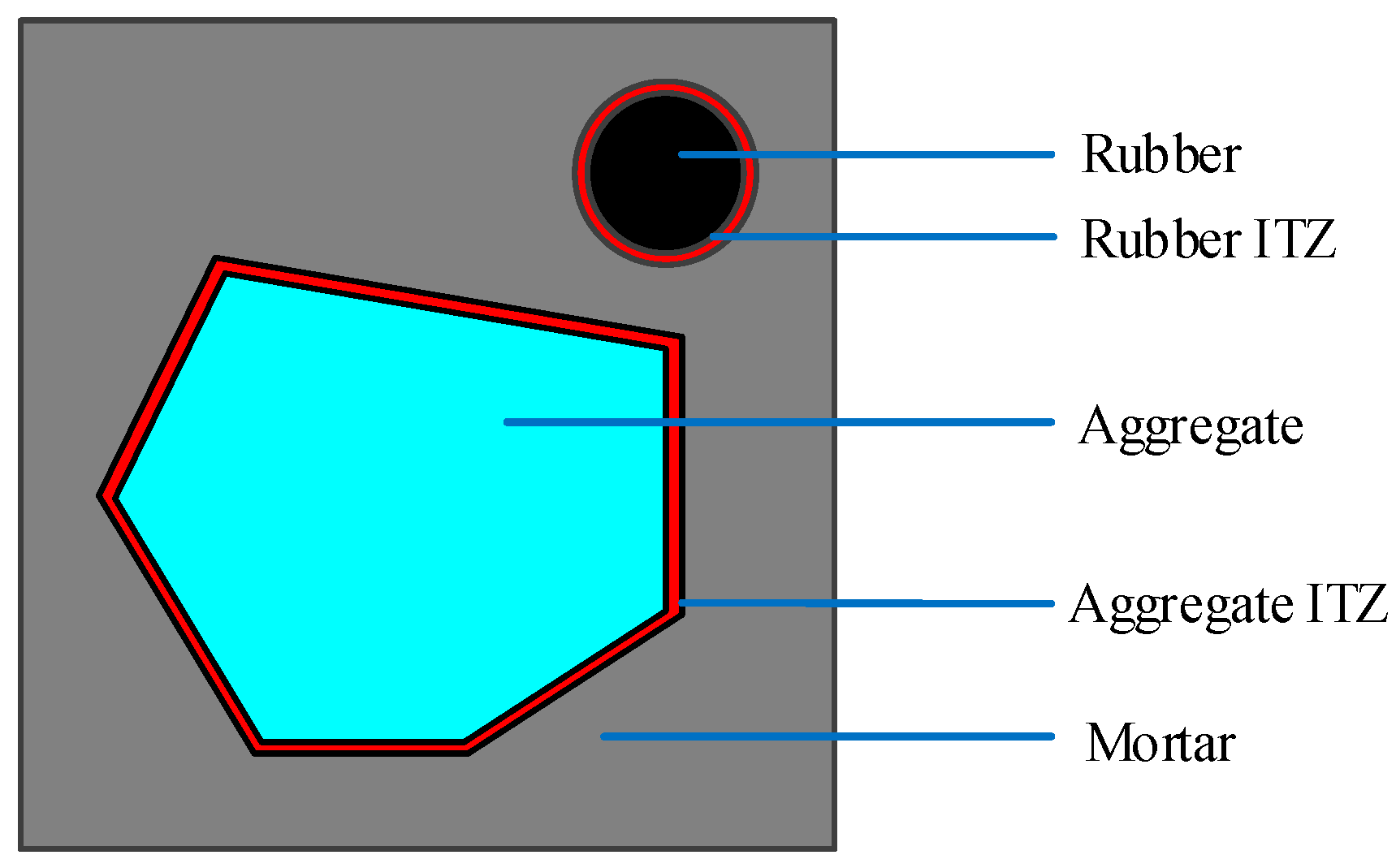

2. Two-Dimensional Mesoscopic Model of Recycled Rubber Concrete

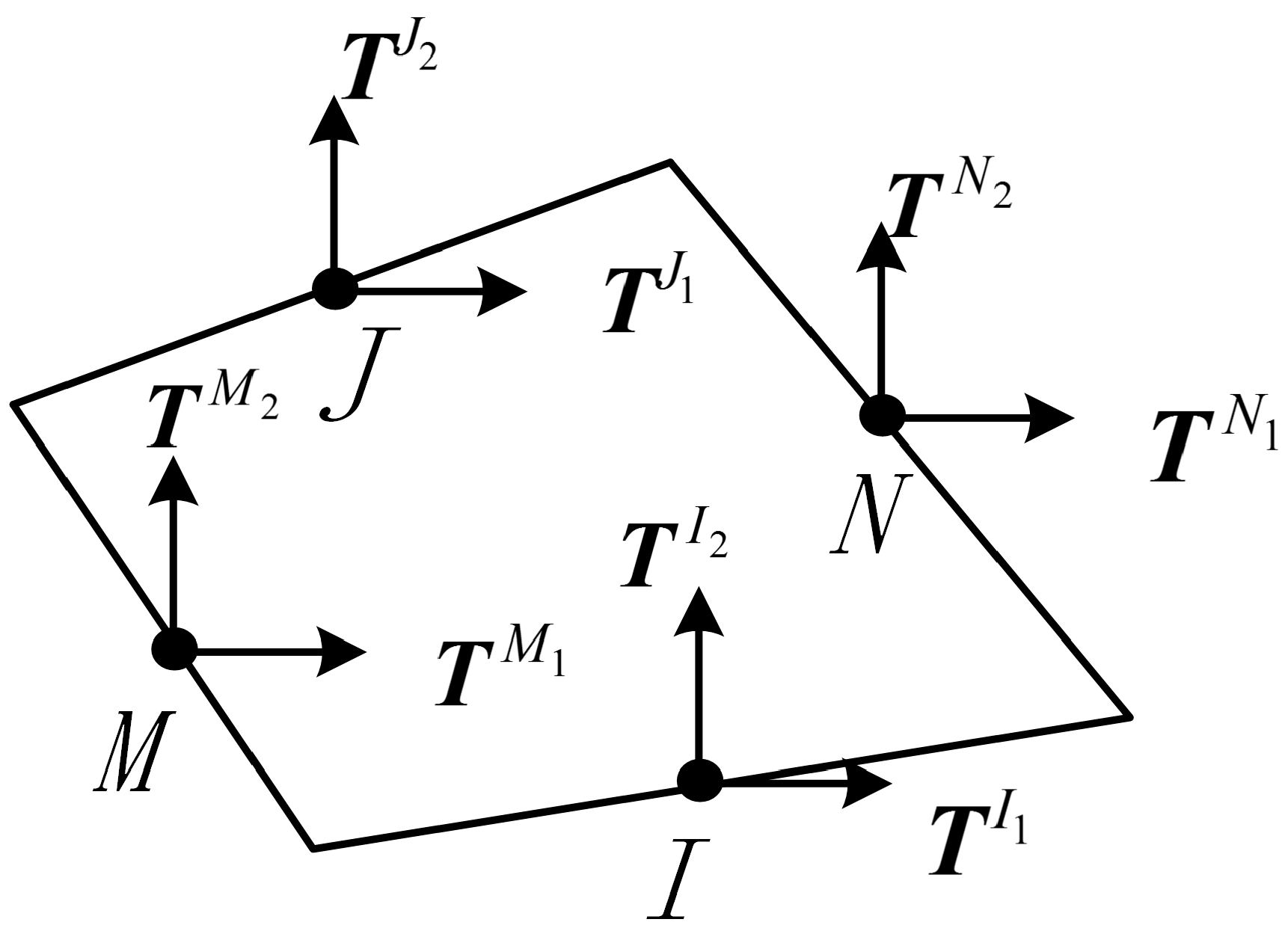

2.1. Tensor Expression of Element Compliance Matrix

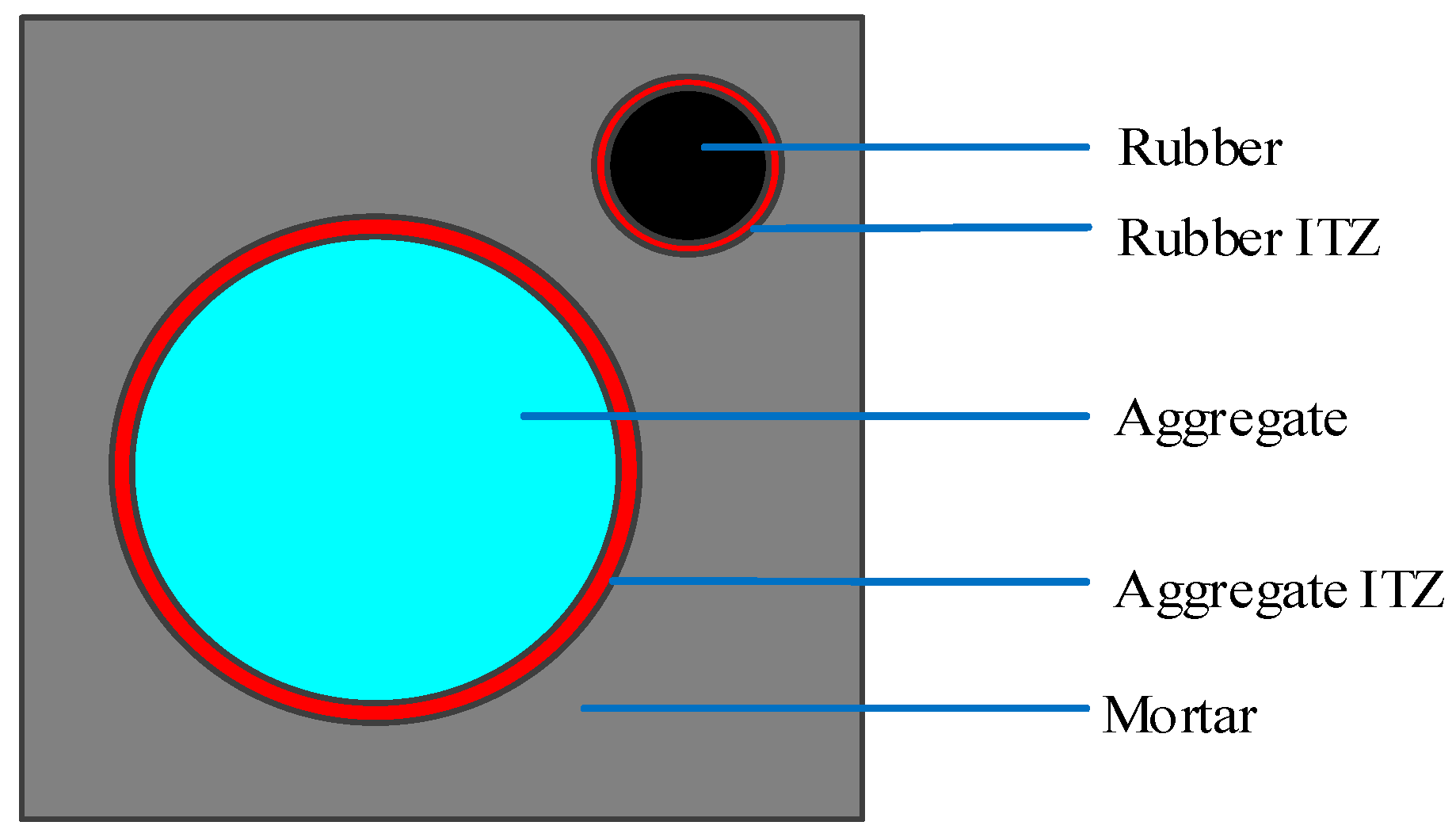

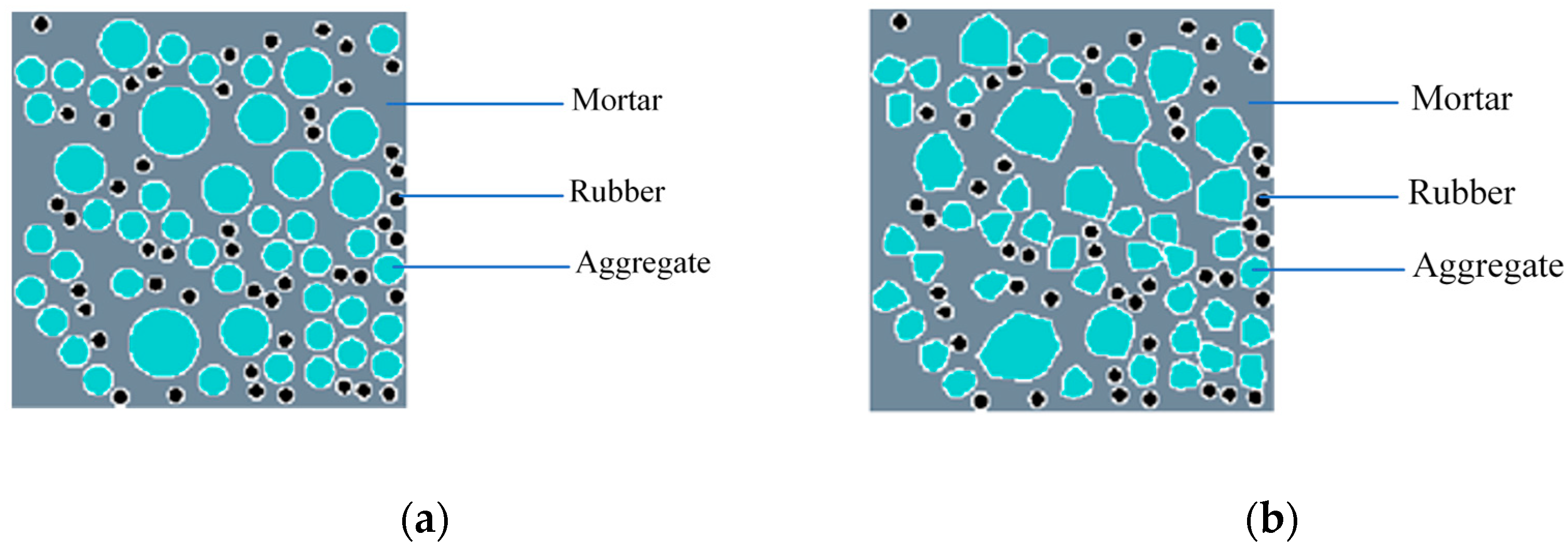

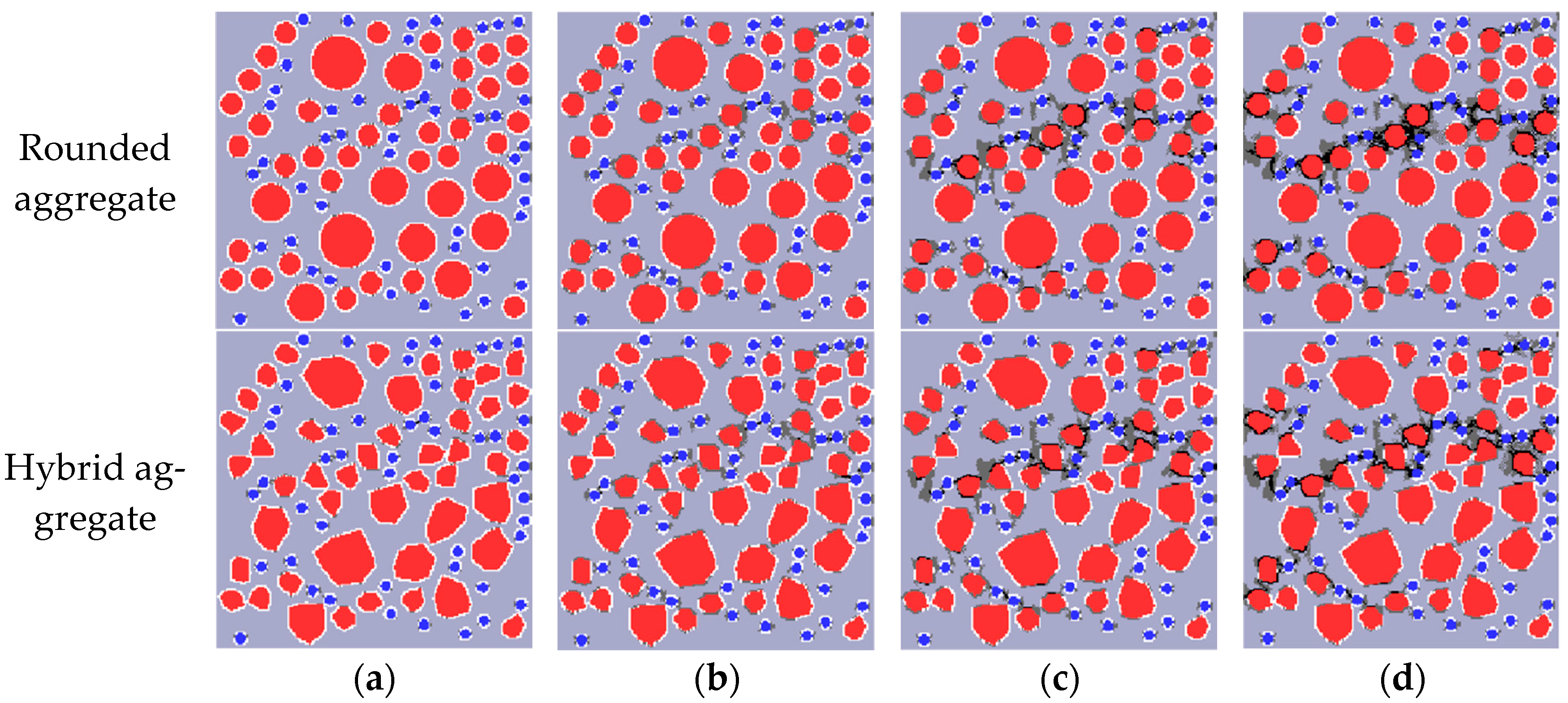

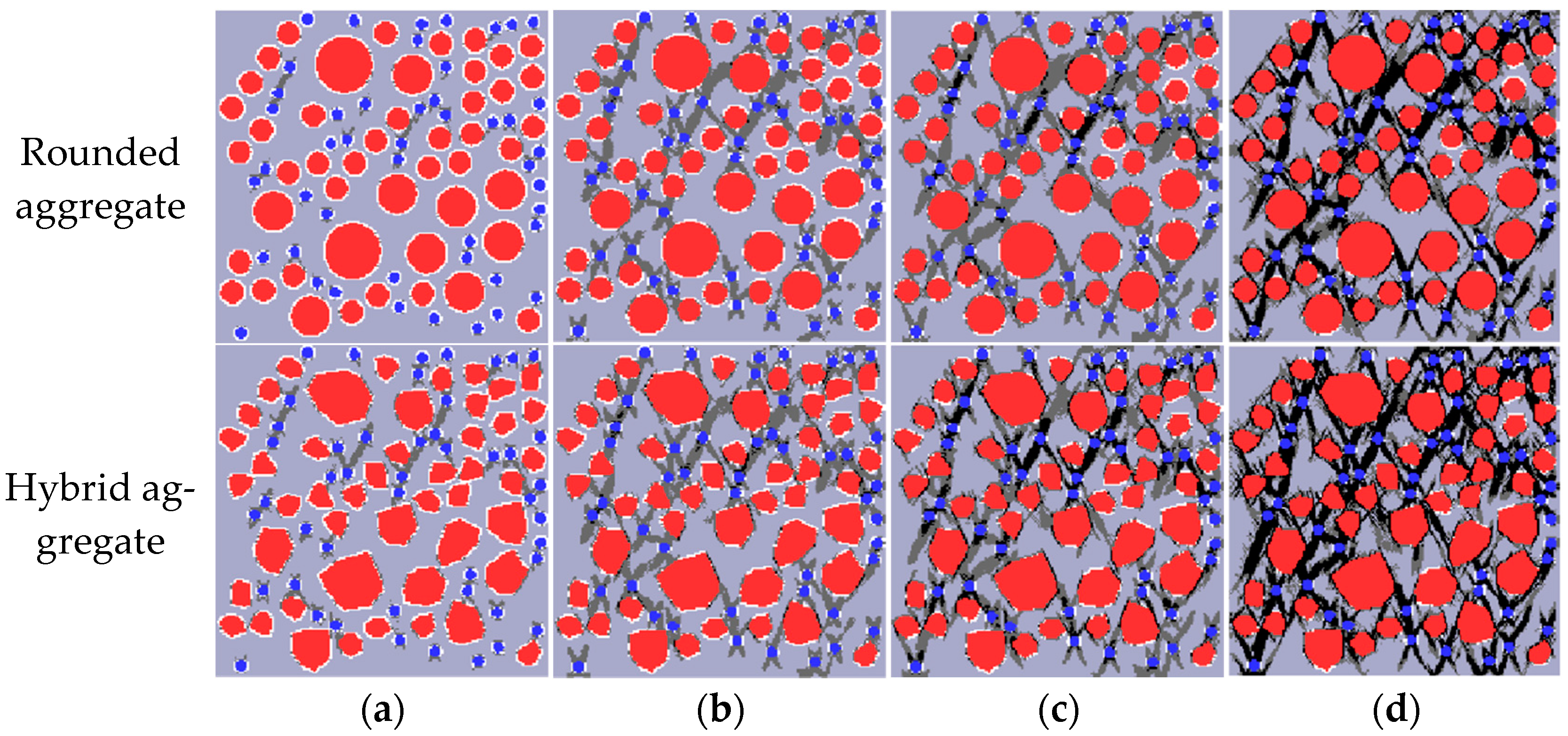

2.2. Random Rounded Aggregate Model of Recycled Rubber Concrete

- The predetermined dimensions of the rubber concrete specimen are employed to establish the boundaries and the coordinate system.

- Utilizing the Monte Carlo method, uniformly distributed random numbers and within the interval are procured.

- These two random numbers facilitate the derivation of the coordinates for aggregate placement, represented by the equationwhere denotes the cross-sectional width of the specimen and represents its cross-sectional height.

- With the derived coordinates serving as the centroid, the aggregate is strategically positioned. It is imperative to ensure the aggregate remains within the specimen’s dimensional confines. Concurrently, the stipulation demands that the distance between centers of adjacent aggregates surpasses 1.1 times the aggregate diameters’ cumulative value.

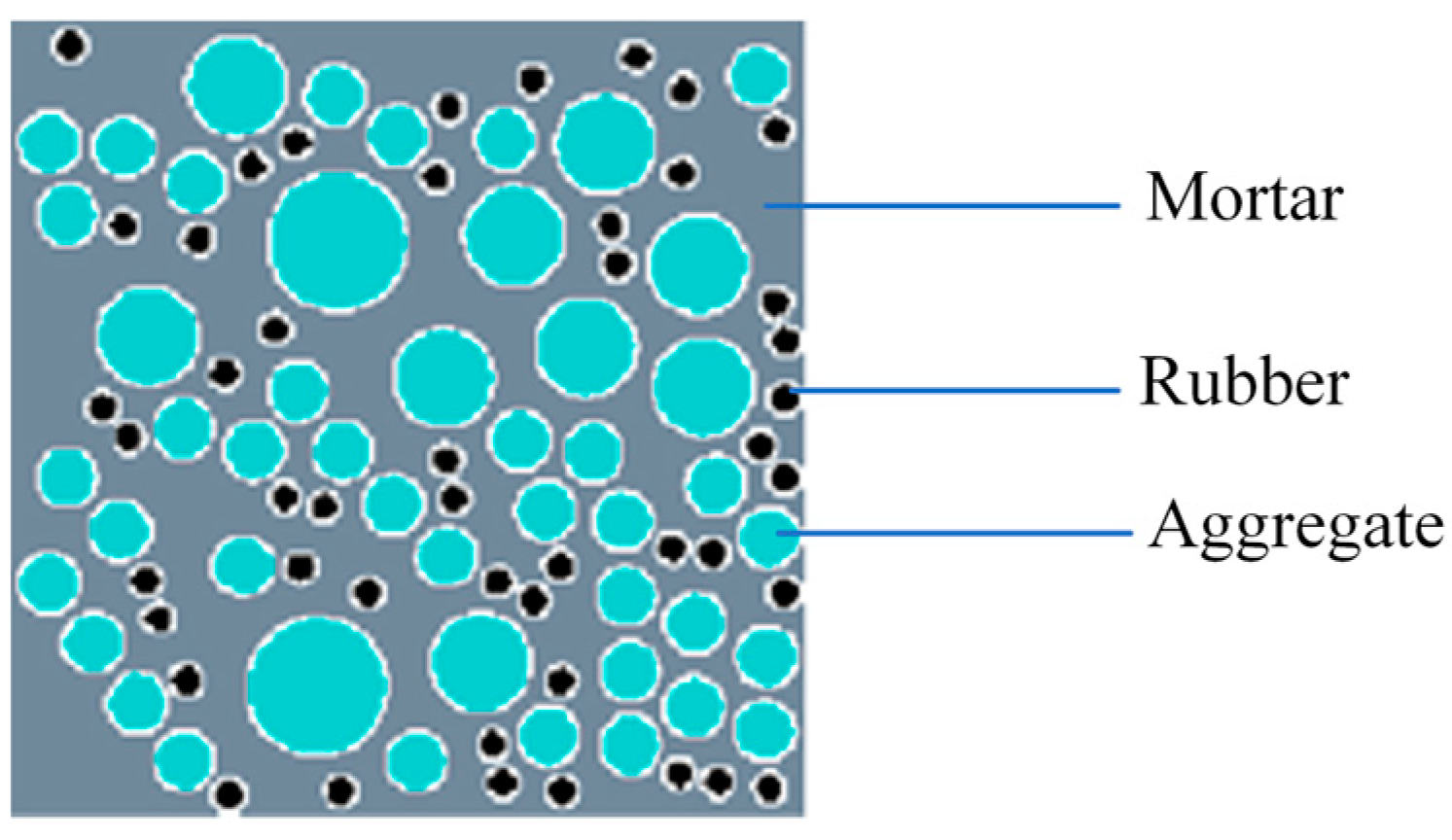

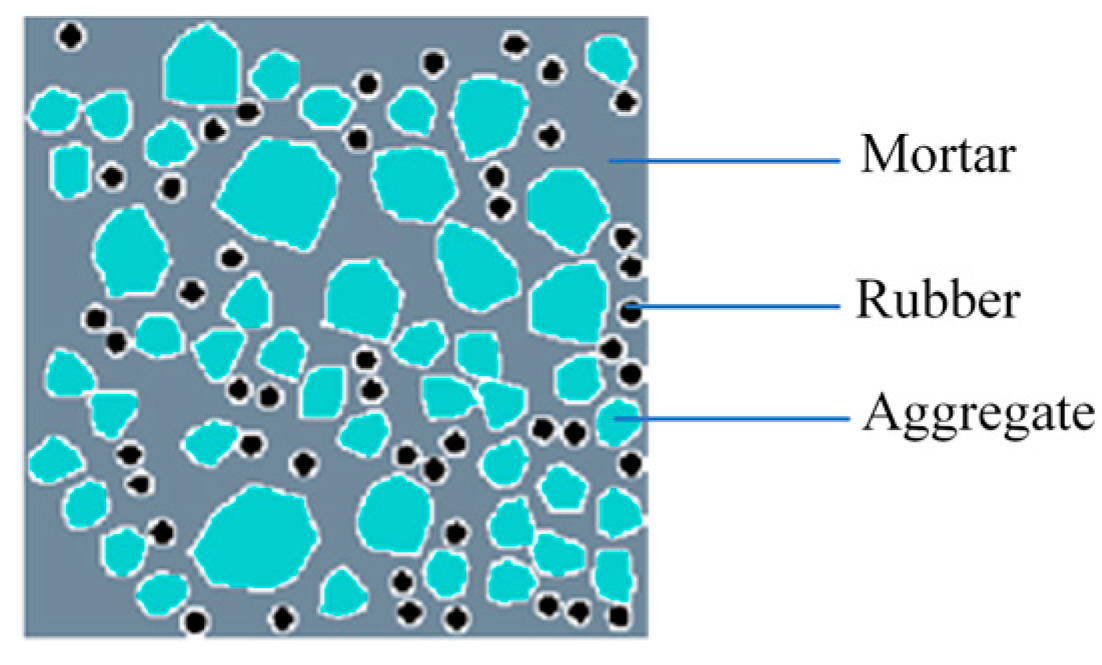

2.3. Hybrid Random Aggregate Model of Recycled Rubber Concrete

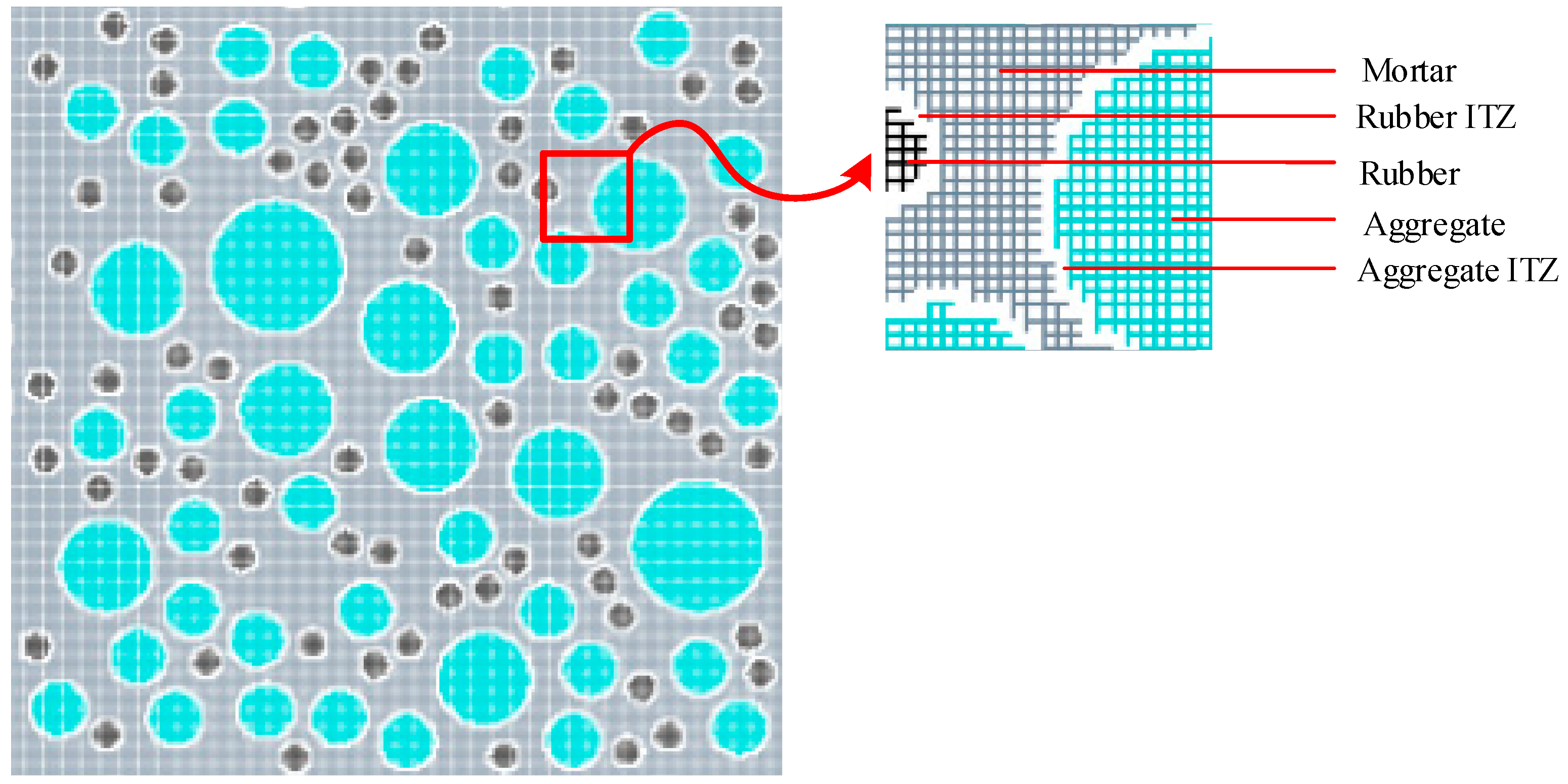

2.4. Mesh Generation and Element Attribute Determination

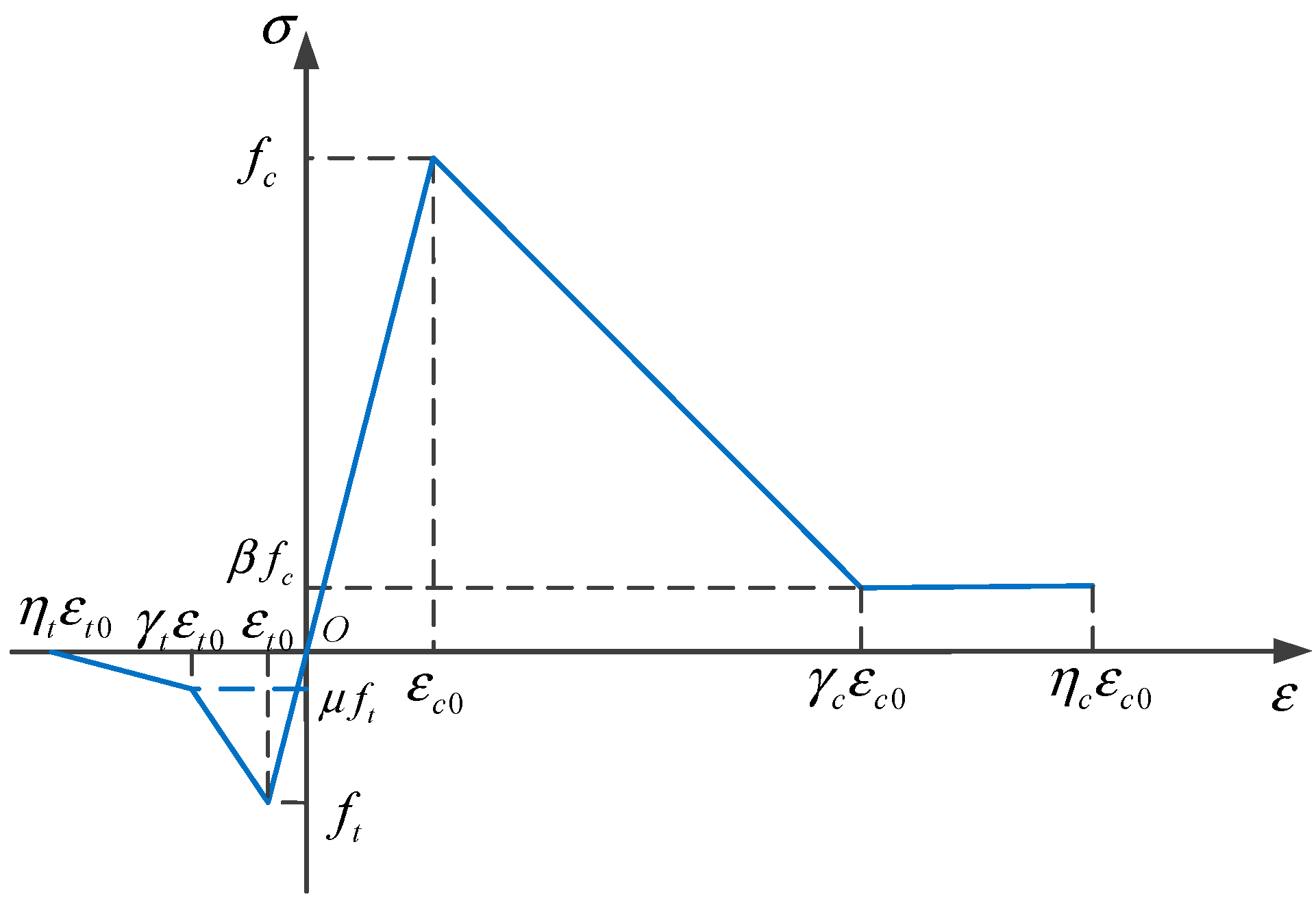

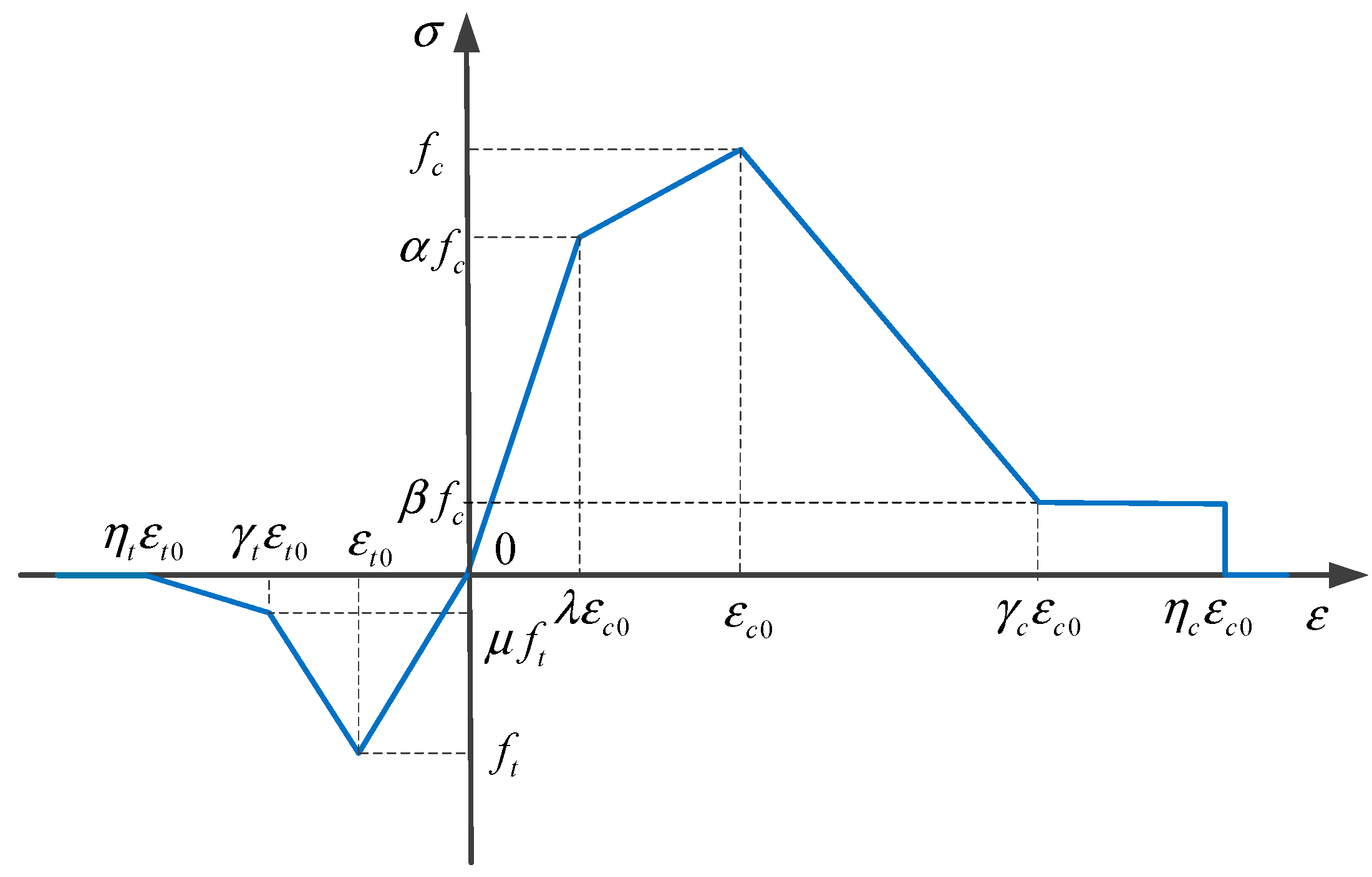

3. Damage Constitutive Model of Recycled Rubber Concrete Material

4. Numerical Simulation of Recycled Rubber Concrete

4.1. Model Parameter Selection

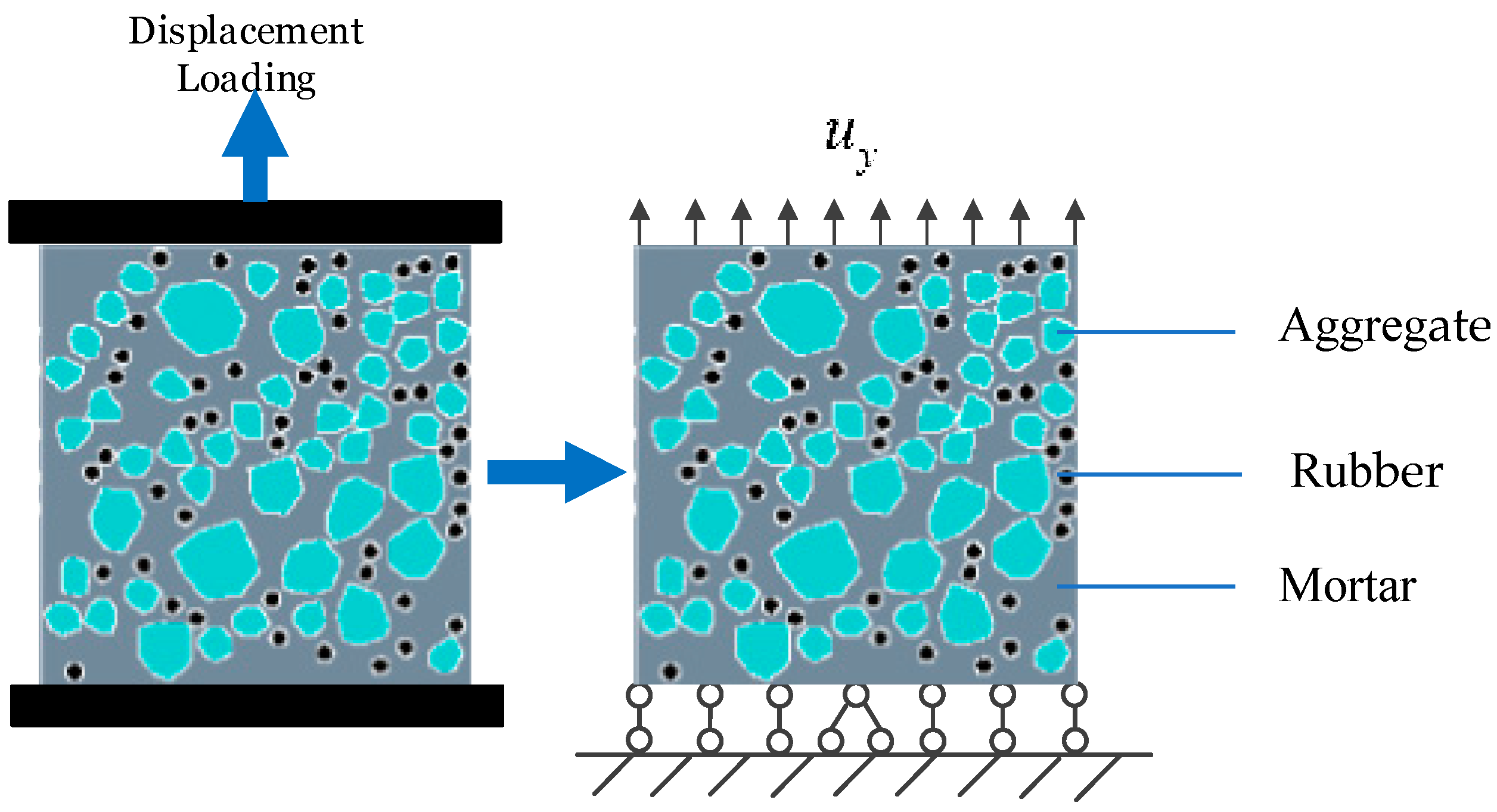

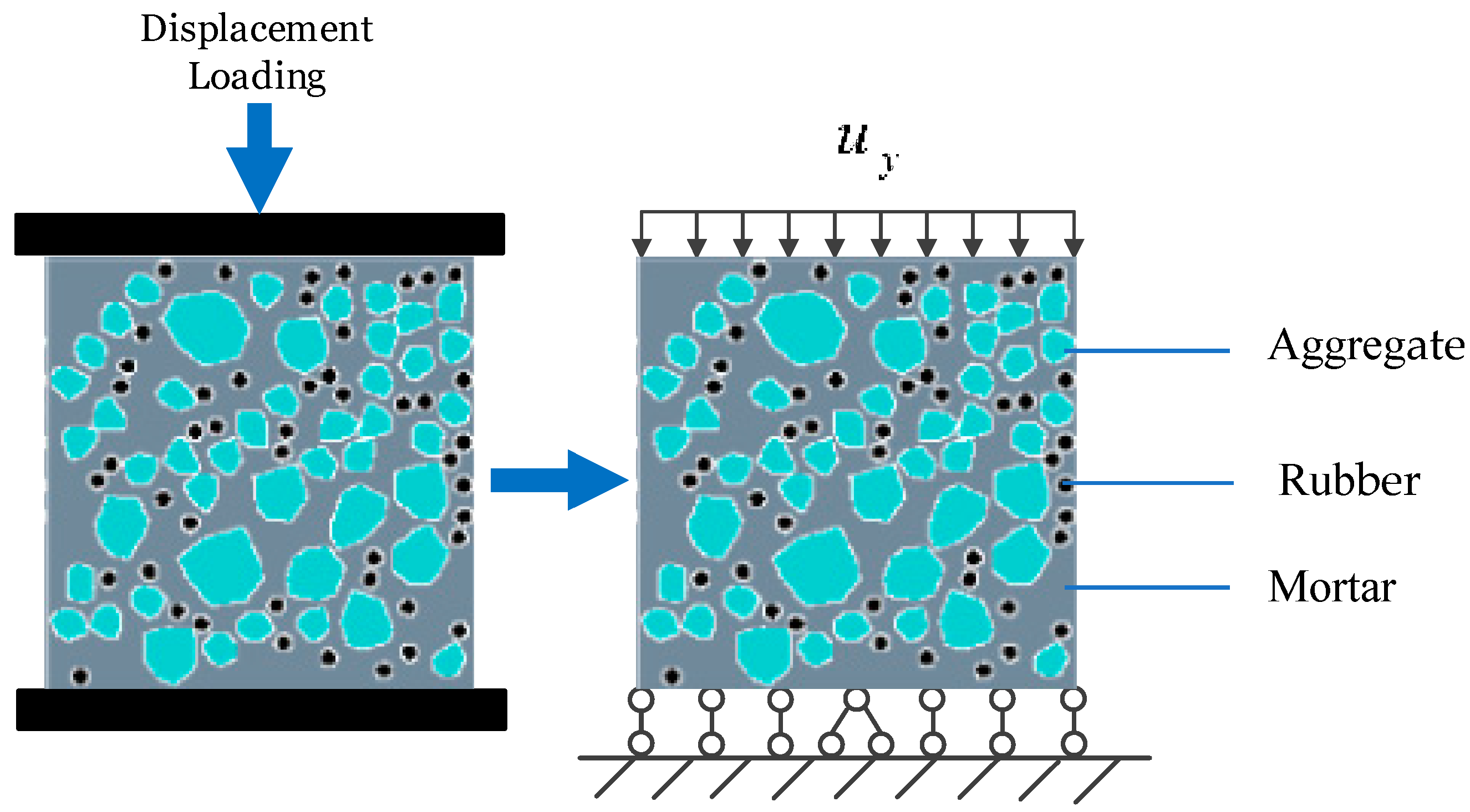

4.2. Uniaxial Tension and Compression Loading Models

5. Failure Mechanism Results of Recycled Rubber Concrete

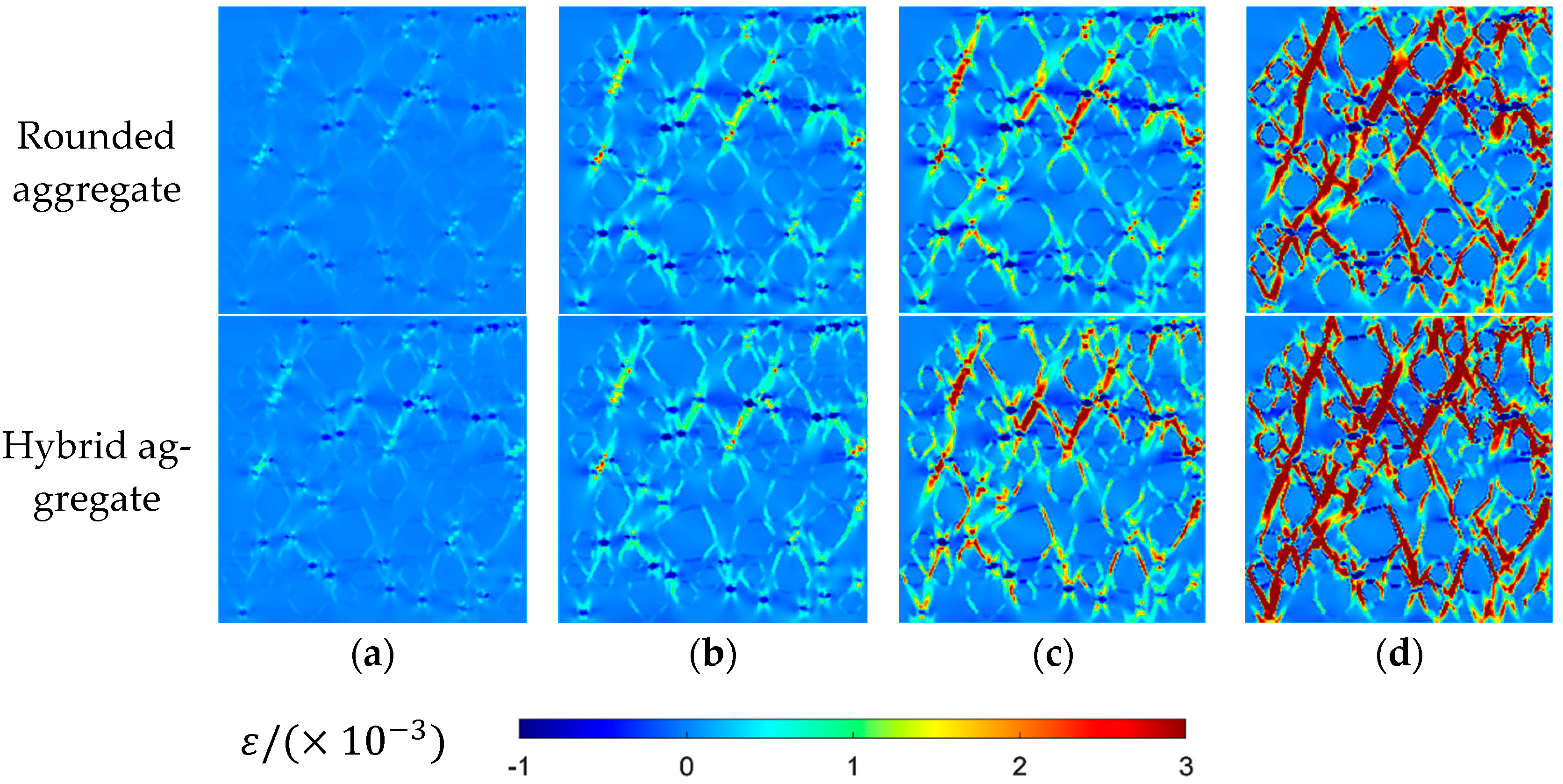

5.1. Uniaxial Tension Results

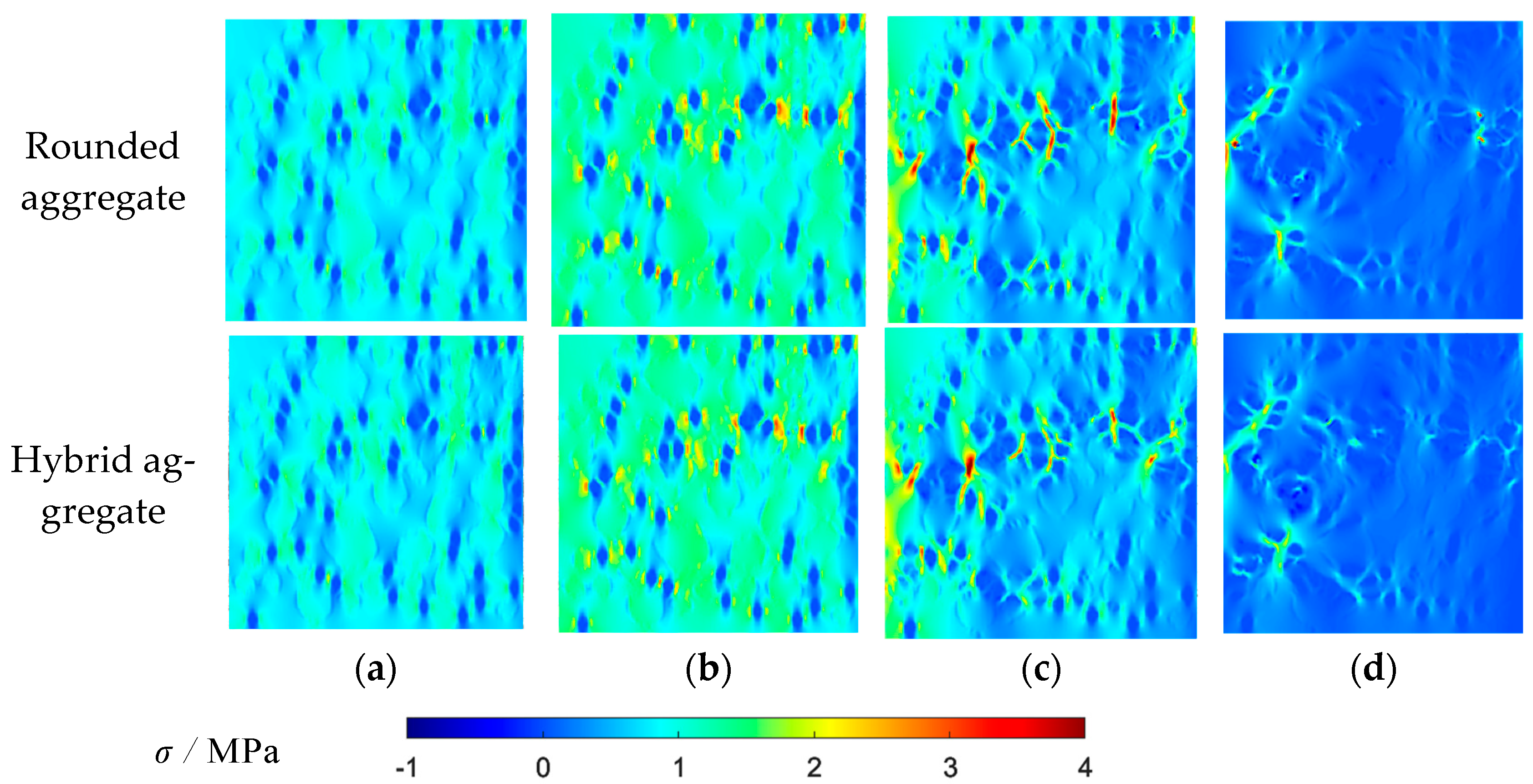

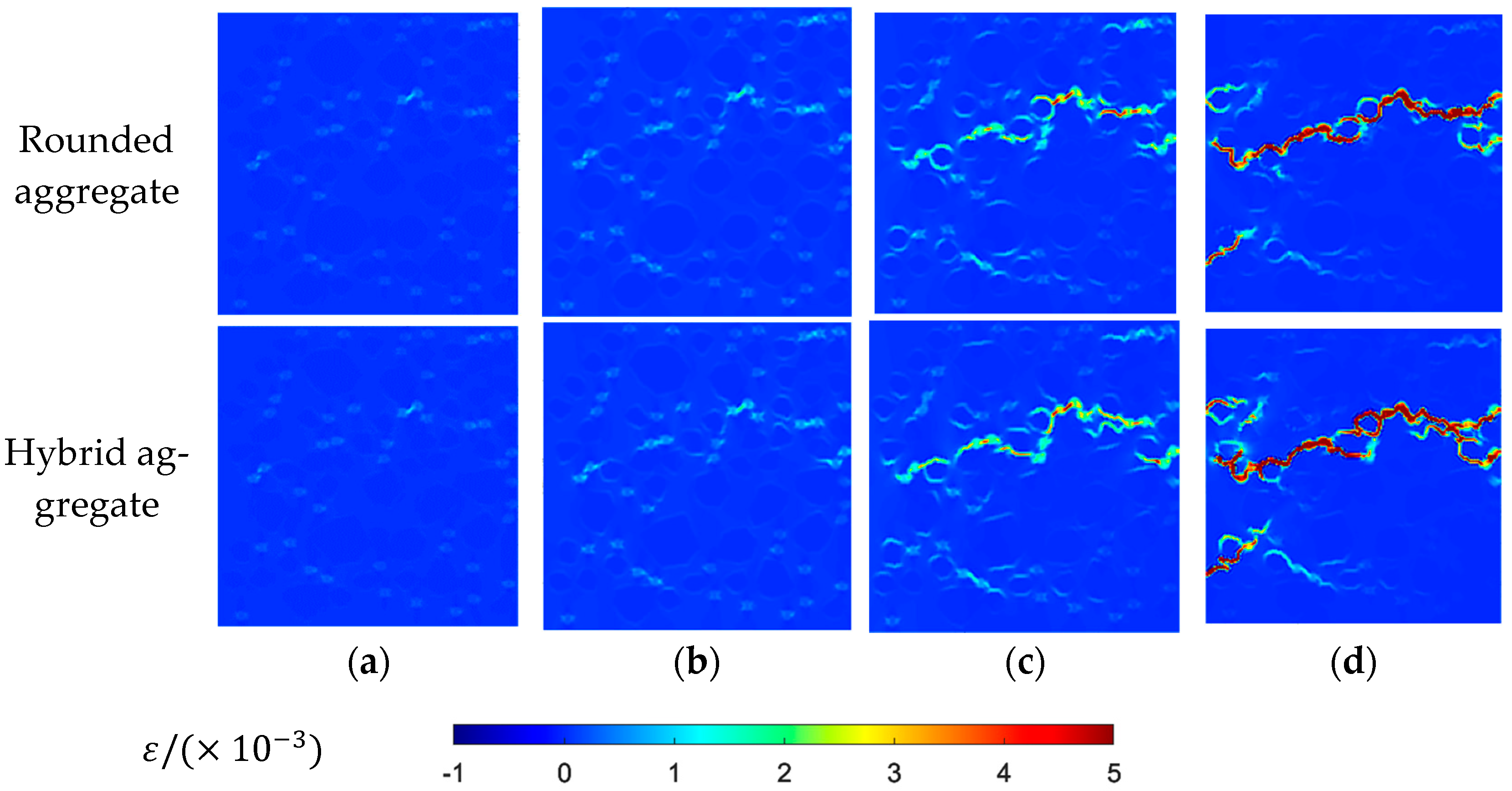

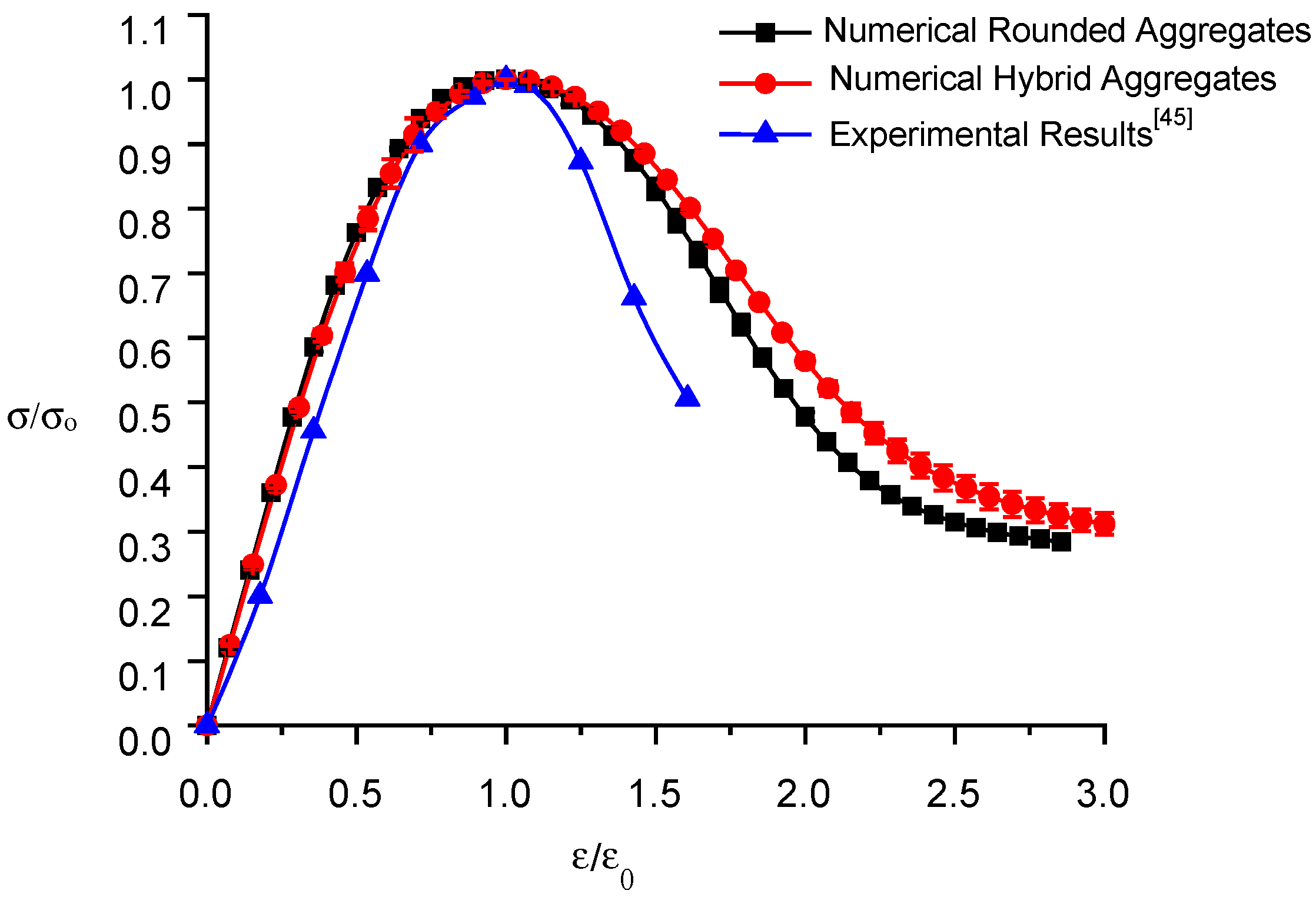

5.2. Uniaxial Compression Results

6. Conclusions

- Under tension, one or two primary cracks appear perpendicular to the load direction, while compression induces bifurcated cracks angled between 45 and 60°, akin to conventional concrete’s failure patterns.

- The more irregular the shape of aggregate and the more obvious the angle, the lower the compressive strength of rubber concrete. However, when the degree of irregularity of the aggregate is lighter, that is, when it is closer to the circle, the crack will be inhibited, and the strength will be slightly increased.

- The produced stress–strain curves, mesoscopic damage process diagrams, and principal stress and strain contour maps align closely with experimental data, reaffirming the method’s credibility.

- This study shows that the base force element method based on the complementary energy principle can be used to analyze the relationship between the microstructure and the macroscopic mechanical properties of rubber concrete materials and the failure mechanism of rubber concrete materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sofi, A. Effect of Waste Tyre Rubber on Mechanical and Durability Properties of Concrete—A Review. Ain Shams Eng. J. 2018, 9, 2691–2700. [Google Scholar] [CrossRef]

- Siddika, A.; Al, A.; Alyousef, R.; Amran, Y.H.M.; Aslani, F.; Alabduljabbar, H. Properties and Utilizations of Waste Tire Rubber in Concrete: A Review. Constr. Build. Mater. 2019, 224, 711–731. [Google Scholar] [CrossRef]

- Karakurt, C. Microstructure Properties of Waste Tire Rubber Composites: An Overview. J. Mater. Cycles Waste Manag. 2015, 17, 422–433. [Google Scholar] [CrossRef]

- Bušić, R.; Miličević, I.; Šipoš, T.K.; Strukar, K. Recycled Rubber as an Aggregate Replacement in Self-Compacting Concrete—Literature Overview. Materials 2018, 11, 1729. [Google Scholar]

- Lavagna, L.; Nisticò, R.; Sarasso, M.; Pavese, M. An Analytical Mini-Review on the Compression Strength of Rubberized Concrete as a Function of the Amount of Recycled TiresS Crumb Rubber. Materials 2020, 13, 1234. [Google Scholar]

- Martínez-barrera, G.; José, J.; Álvarez-Rabanal, F.P.; López, F.; Martínez-lópez, M.; Cruz-olivares, J. Case Studies in Construction Materials Waste Tire Rubber Particles Modi Fi Ed by Gamma Radiation and Their Use as Modi Fi Ers of Concrete. Case Stud. Constr. Mater. 2020, 12, e00321. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A Comprehensive Review on the Mechanical Properties of Waste Tire Rubber Concrete. Constr. Build. Mater. 2020, 237, 117651. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental Investigation of the Mechanical and Durability Properties of Crumb Rubber Concrete. Materials 2016, 9, 172. [Google Scholar]

- Gonen, T. Freezing-Thawing and Impact Resistance of Concretes Containing Waste Crumb Rubbers. Constr. Build. Mater. 2018, 177, 436–442. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Composite Walls Composed of Profiled Steel Skin and Foam Rubberized Concrete Subjected to Eccentric Compressions. J. Build. Eng. 2022, 46, 103715. [Google Scholar] [CrossRef]

- Youssf, O.; Mills, J.E.; Ellis, M.; Benn, T.; Zhuge, Y.; Ma, X.; Gravina, R.J. Practical Application of Crumb Rubber Concrete in Residential Slabs. Structures 2022, 36, 837–853. [Google Scholar] [CrossRef]

- Akinyele, J.O.; Salim, R.W.; Kehinde, W. The Impact of Rubber Crumb on the Mechanical and Chemical Properties of Concrete. Eng. Struct. Technol. 2016, 7, 197–204. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Long Term Behaviour of Cement Concrete Containing Discarded Tire Rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Pham, T.M.; Chen, W.; Khan, A.M.; Hao, H.; Elchalakani, M.; Tran, T.M. Dynamic Compressive Properties of Lightweight Rubberized Concrete. Constr. Build. Mater. 2020, 238, 117705. [Google Scholar] [CrossRef]

- Xu, H.; Lian, J.; Gao, M.; Fu, D.; Yan, Y. Self-Healing Concrete Using Rubber Particles to Immobilize Bacterial Spores. Materials 2019, 12, 2313. [Google Scholar] [PubMed]

- Pham, T.M.; Elchalakani, M.; Hao, H.; Lai, J.; Ameduri, S.; Tran, T.M. Durability Characteristics of Lightweight Rubberized Concrete. Constr. Build. Mater. 2019, 224, 584–599. [Google Scholar] [CrossRef]

- Mo, J.; Ren, F.; Ye, Y.; Tian, S.; Lai, C. Effect of Different Crumb Rubber Particle Sizes on the Flexural Properties of Crumb Rubber Concrete. Mater. Lett. 2022, 326, 132960. [Google Scholar] [CrossRef]

- Ai, S.; Tang, L.; Liu, Z.; Zhang, C.; Liu, Y. Damages and Failure Features of Liquid Rubber-Based Concrete in Statics Tension by 2D Dynamics Numerical Simulation. Int. J. Damage Mech. 2011, 21, 171–189. [Google Scholar] [CrossRef]

- Chen, H.; Li, D.; Ma, X.; Abd-elaal, Z.Z.E. Mesoscale Analysis of Rubber Particle Effect on Young’s Modulus and Creep Behaviour of Crumb Rubber Concrete. Int. J. Mech. Mater. Des. 2021, 17, 659–678. [Google Scholar] [CrossRef]

- Guan, Q.; Xu, Y.; Wang, J.; Wu, Q.; Zhang, P. Meso-Scale Fracture Modelling and Fracture Properties of Rubber Concrete Considering Initial Defects. Theor. Appl. Fract. Mech. 2023, 125, 103834. [Google Scholar] [CrossRef]

- Serroukh, H.K.; Li, W. Numerical Analysis of the Thermomechanical Behavior of Rubber Concrete at High Temperatures. Struct. Concr. 2023, 24, 3236–3250. [Google Scholar] [CrossRef]

- Xie, J.; Guo, Y.; Liu, L.; Xie, Z. Compressive and Flexural Behaviours of a New Steel-Fibre-Reinforced Recycled Aggregate Concrete with Crumb Rubber. Constr. Build. Mater. 2015, 79, 263–272. [Google Scholar] [CrossRef]

- Li, D.; Zhuge, Y.; Gravina, R.; Mills, J.E. Compressive Stress Strain Behavior of Crumb Rubber Concrete (CRC) and Application in Reinforced CRC Slab. Constr. Build. Mater. 2018, 166, 745–759. [Google Scholar] [CrossRef]

- Al-Balhawi, A.; Muhammed, N.J.; Mushatat, H.A.; Al-Maliki, H.N.G.; Zhang, B. Numerical Simulations on the Flexural Responses of Rubberised Concrete. Buildings 2022, 12, 590. [Google Scholar] [CrossRef]

- Pan, L.; Hao, H.; Cui, J.; Pham, T.M. Numerical Study on Dynamic Properties of Rubberised Concrete with Different Rubber Contents. Def. Technol. 2023, 24, 228–240. [Google Scholar] [CrossRef]

- Retama, J.; Ayala, A.G. Influence of Crumb-Rubber in the Mechanical Response of Modified Portland Cement Concrete. Adv. Civ. Eng. 2017, 2017, 3040818. [Google Scholar] [CrossRef]

- Hassanli, R.; Mills, J.E.; Li, D.; Benn, T. Advances in Civil Engineering Materials Experimental and Numerical Study on the Behavior of Rubberized Concrete Experimental and Numerical Study on the Behavior of Rubberized Concrete. Adv. Civ. Eng. Mater. 2017, 6, 134–156. [Google Scholar] [CrossRef]

- Xu, J.; Yao, Z.; Yang, G.; Han, Q. Research on Crumb Rubber Concrete: From a Multi-Scale Review. Constr. Build. Mater. 2020, 232, 117282. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, K.; Zhou, X. Mechanical Properties of Rubberized Concrete and Its Application in Green Buildings. Highlights Sci. Eng. Technol. 2022, 28, 435–444. [Google Scholar] [CrossRef]

- Levinson, M. The Complementary Energy Theorem in Finite Elasticity. J. Appl. Mech. Trans. ASME 1964, 32, 826–828. [Google Scholar] [CrossRef]

- Brandt, K. Derivation of Geometric Stiffness Matrix for Finite Element Hybrid Displacement Models. Int. J. Solids Struct. 1978, 14, 53–65. [Google Scholar] [CrossRef]

- Pian, T.H.H.; Chen, D.; Kang, D. A New Formulation of Hybrid/Mixed Finite Element. Comput. Struct. 1983, 81, 81–87. [Google Scholar] [CrossRef]

- Pian, T.H.H.; Sumihara, K. Rational Approach for Assumed Stress Finite Elements. Int. J. Numer. Methods Eng. 1984, 20, 1685–1695. [Google Scholar] [CrossRef]

- Nagai, K.; Sato, Y.; Ueda, T. Mesoscopic Simulation of Failure of Mortar and Concrete by 3D RBSM. J. Adv. Concr. Technol. 2005, 3, 385–402. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, Y. Advances in the Base Force Element Method; Springer: Singapore, 2019; ISBN 978-981-13-5776-3. [Google Scholar]

- Gao, Y.C. A New Description of the Stress State at a Point with Applications. Arch. Appl. Mech. 2003, 73, 171–183. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, Y.; Kamel, M.M.A.; Ying, L. Base Force Element Method Based on the Complementary Energy Principle for the Damage Analysis of Recycled Aggregate Concrete. Int. J. Numer. Methods Eng. 2020, 121, 1484–1506. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Walraven, J.C.; Reinhardt, H.W. Concrete Mechanics. Part A: Theory and Experiments on the Mechanical Behavior of Cracks in Plain and Reinforced Concrete Subjected to Shear Loading; NASA STI/Recon Technical Report N; SAO/NASA Astrophysics Data System: Washington, DC, USA, 1981. [Google Scholar]

- Wang, Y.; Peng, Y.; Kamel, M.M.A.; Ying, L. Mesomechanical Properties of Concrete with Different Shapes and Replacement Ratios of Recycled Aggregate Based on Base Force Element Method. Struct. Concr. 2019, 20, 1425–1437. [Google Scholar] [CrossRef]

- Rugsaj, R.; Suvanjumrat, C. Finite Element Analysis of Hyperelastic Material Model for Non-Pneumatic Tire. Key Eng. Mater. 2018, 775, 554–559. [Google Scholar] [CrossRef]

- Pei, X.; Huang, X.; Li, H.; Cao, Z.; Yang, Z.; Hao, D.; Min, K.; Li, W.; Liu, C.; Wang, S.; et al. Numerical Simulation of Fatigue Life of Rubber Concrete on the Mesoscale. Polymers 2023, 15, 2048. [Google Scholar] [CrossRef]

- Xie, Z.H.; Guo, Y.C.; Yuan, Q.Z.; Huang, P.Y. Mesoscopic Numerical Computation of Compressive Strength and Damage Mechanism of Rubber Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 279584. [Google Scholar] [CrossRef]

- Nagai, K.; Sato, Y.; Ueda, T. Mesoscopic simulation of failure of mortar and concrete by 2D RBSM. J. Adv. Concr. Technol. 2004, 2, 359–374. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, X.; Ma, A.; Gao, P. An Experimental Study on the Basic Mechanical Properties and Compression Size Effect of Rubber Concrete with Different Substitution Rates. Adv. Civ. Eng. 2020, 2020, 8851187. [Google Scholar] [CrossRef]

- Chen, H.; Sun, W.; Stroeven, P. Review on the Study of Effect of ITZ on Macro-Properties of Cementitious Composites. Jianzhu Cailiao Xuebao J. Build. Mater. 2005, 8, 51–62. (In Chinese) [Google Scholar]

- Guinea, G.V.; El-Sayed, K.; Rocco, C.G.; Elices, M.; Planas, J. The Effect of the Bond between the Matrix and the Aggregates on the Cracking Mechanism and Fracture Parameters of Concrete. Cem. Concr. Res. 2002, 32, 1961–1970. [Google Scholar] [CrossRef]

| Particle Size Range/mm | Average Particle Size/mm | Particles Count |

|---|---|---|

| 20–15 | 17.5 | 2 |

| 15–10 | 12.5 | 9 |

| 10–5 | 7.5 | 36 |

| Medium | Compressive Strength/MPa | Tensile Strength/MPa | Elastic Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|---|

| Aggregate | 100 | 10 | 55 | 0.16 |

| Rubber | / | / | 0.07 | 0.49 |

| Mortar | 24 | 2.95 | 18.97 | 0.22 |

| Aggregate–Mortar ITZ | 15.6 | 1.92 | 12.33 | 0.2 |

| Rubber–Mortar ITZ | 8.4 | 1.03 | 6.64 | 0.2 |

| Constitutive Parameters | Mortar | Aggregate | Aggregate–Mortar ITZ | Rubber–Mortar ITZ |

|---|---|---|---|---|

| 0.85 | 0.5 | 0.65 | 0.65 | |

| 0.2 | 0.2 | 0.2 | 0.2 | |

| 0.2 | 0.2 | 0.2 | 0.2 | |

| 0.3 | 0.5 | 0.3 | 0.3 | |

| , | 4 | 5 | 3 | 3 |

| , | 10 | 10 | 10 | 10 |

| Specimen | Numerical Simulation Results/MPa | Simulation Results Average /MPa | Experimental Results [45]/MPa |

|---|---|---|---|

| Round Aggregate Specimen 1 | 1.045 | 1.005 | 0.953 |

| Round Aggregate Specimen 2 | 1.018 | ||

| Round Aggregate Specimen 3 | 0.951 | ||

| Hybrid Aggregate Specimen 1 | 0.929 | 0.960 | 0.953 |

| Hybrid Aggregate Specimen 2 | 1.002 | ||

| Hybrid Aggregate Specimen 3 | 0.949 |

| Specimen | Numerical Simulation Result/MPa | Average Calculation Result/MPa | Experimental Result [45]/MPa |

|---|---|---|---|

| Round Aggregate Specimen 1 | 16.97 | 16.51 | 16.45 |

| Round Aggregate Specimen 2 | 16.44 | ||

| Round Aggregate Specimen 2 | 16.11 | ||

| Hybrid Aggregate Specimen 1 | 15.75 | 15.79 | 16.45 |

| Hybrid Aggregate Specimen 2 | 15.63 | ||

| Hybrid Aggregate Specimen 3 | 15.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamel, M.M.A.; Fu, Y.; Feng, X.; Peng, Y. Mesoscopic Analysis of Rounded and Hybrid Aggregates in Recycled Rubber Concrete. Materials 2023, 16, 6600. https://doi.org/10.3390/ma16196600

Kamel MMA, Fu Y, Feng X, Peng Y. Mesoscopic Analysis of Rounded and Hybrid Aggregates in Recycled Rubber Concrete. Materials. 2023; 16(19):6600. https://doi.org/10.3390/ma16196600

Chicago/Turabian StyleKamel, Mahmoud M. A., Yu Fu, Xiaowei Feng, and Yijiang Peng. 2023. "Mesoscopic Analysis of Rounded and Hybrid Aggregates in Recycled Rubber Concrete" Materials 16, no. 19: 6600. https://doi.org/10.3390/ma16196600

APA StyleKamel, M. M. A., Fu, Y., Feng, X., & Peng, Y. (2023). Mesoscopic Analysis of Rounded and Hybrid Aggregates in Recycled Rubber Concrete. Materials, 16(19), 6600. https://doi.org/10.3390/ma16196600