The Influence of Selected Laser Engraving Parameters on Surface Conditions of Hybrid Metal Matrix Composites

Abstract

1. Introduction

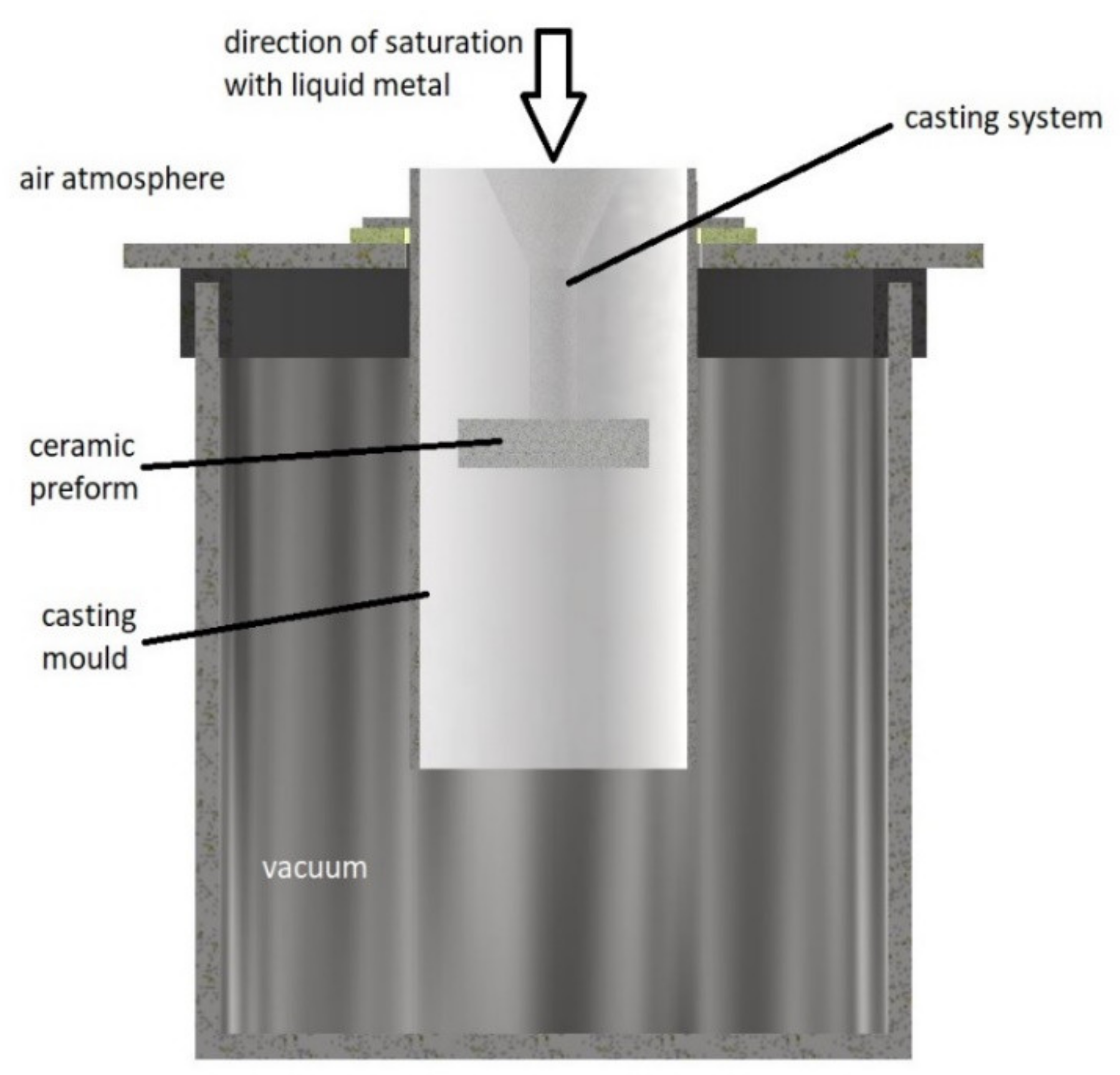

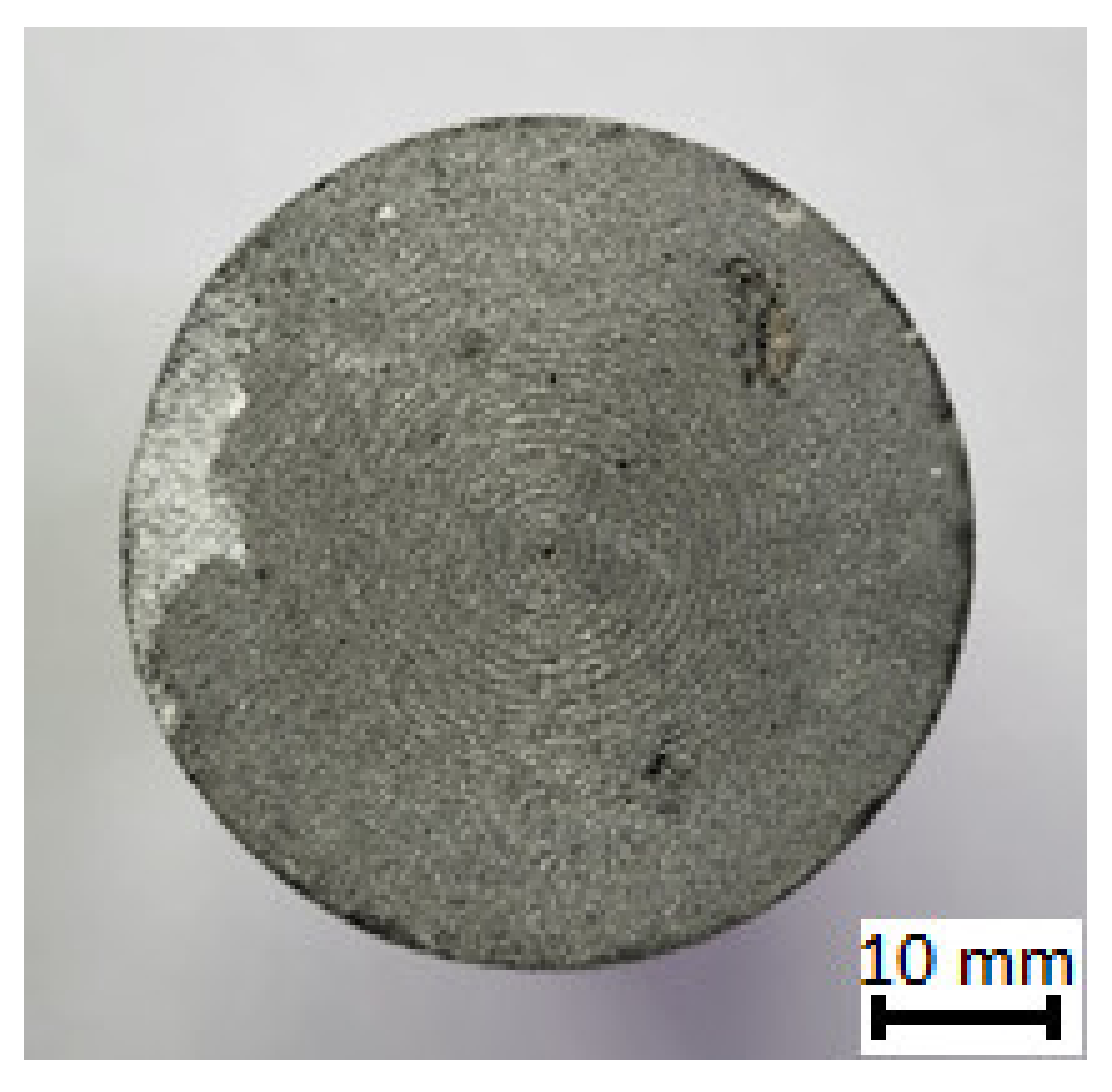

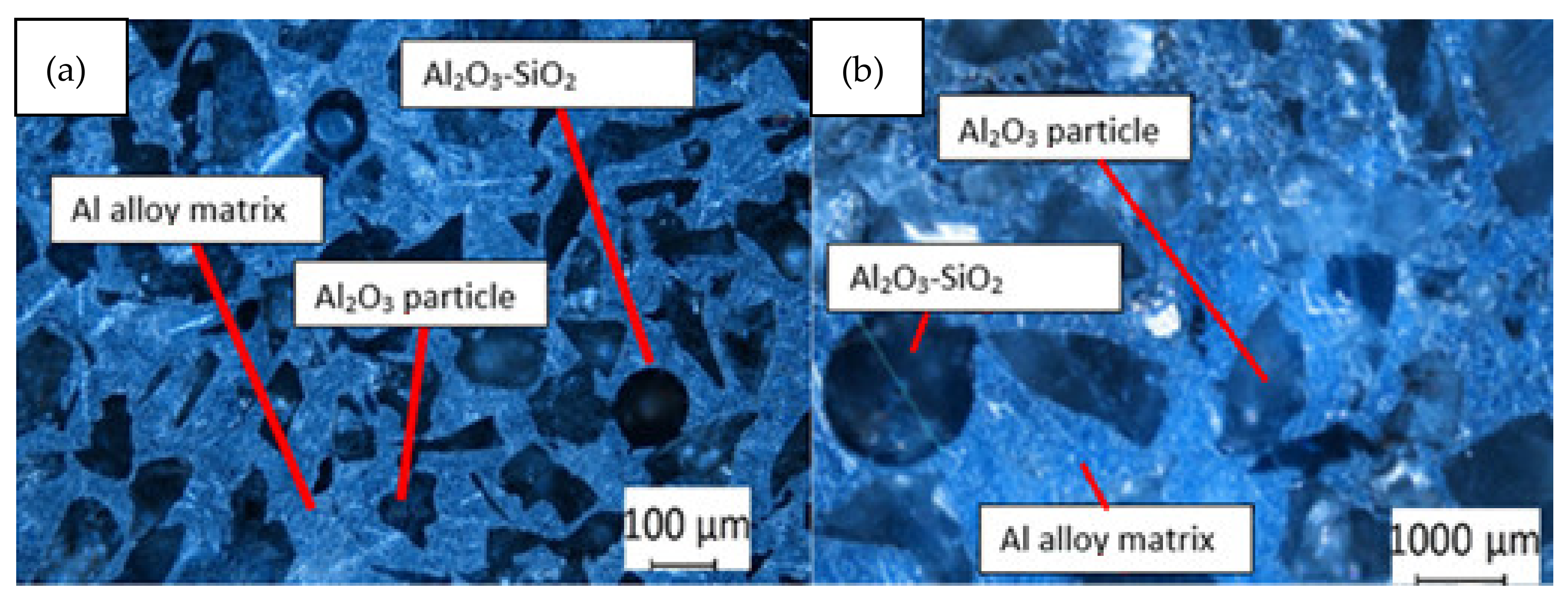

2. Materials and Methods

2.1. Hybrid Metal Matrix Composite and EN AW 1050A Aluminum Alloy (Technical Aluminum)

2.2. Laser Engraving and Measurement Processes

3. Results and Discussion

3.1. Surface Structure Optical Measurement

3.2. Geometrical Structure of the Surface after Laser Engraving of HMMC

3.3. Examples of Laser Engraving of HMMC

4. Conclusions

- The tests showed that the hybrid metal matrix composites with the AlSi12 alloy matrix is difficult to laser process because the heterogeneous structure makes it difficult to select technological parameters of the process due to different absorption of thermal energy by the matrix and reinforcement components;

- The best engraving effects were obtained at vl = 250 mm/s and Pav = 23.76 W;

- Changes in the surface structure of the metallic matrix and ceramic grains of the HMMCs are visible;

- The research was aimed at determining whether and to what extent it would be possible to obtain a clear engraving on the surface of the HMMCs. Due to the heterogeneity of the HMMCs material structure, full fusion is not achieved with lower energy of the laser beam. With appropriate beam power and higher speed of the laser head, a less melted surface is obtained and thus, a surface with less roughness;

- Engraving of HMMC composite materials AlSi12/AP/AF requires the selection of parameters allowing for minimal interference in the structure of the material surface as a result of the supplied thermal energy;

- As a result of the studies carried out, examples of laser engraving of HMMC composite with minimal impact on its structure were obtained, which are suitable for macro-assessment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| HMMC | hybrid metal matrix composite |

| AF | alumina fibers |

| AP | alumina particles |

| PCD | polycrystalline diamond |

| Pav | power of laser beam (W) |

| vl | speed of the laser head (mm/s) |

| Ra | arithmetic mean deviation from the mean line (μm) |

| Rz | highest profile height (μm) |

References

- Tuz, L. Quality of marks on metals made with the use of Nd: YAG laser engraving method. Met. Foundry Eng. 2013, 39, 51. [Google Scholar] [CrossRef][Green Version]

- Temesi, T.; Czigany, T. The Effect of Surface Treatment on the Shear Properties of Aluminium-Polypropylene Joints Manufactured by Laser Beam. Polym. Test. 2023, 117, 107882. [Google Scholar] [CrossRef]

- Saran, R.; Ginjupalli, K.; George, S.D.; Chidangil, S.; Unnikrishnan, V.K. LASER as a Tool for Surface Modification of Dental Biomaterials: A Review. Heliyon 2023, 9, e17457. [Google Scholar] [CrossRef] [PubMed]

- Fiał, C.; Pieknik, M. Wpływ Parametrów Grawerowania Laserowego Na Wygląd Wyrobów Wykonanych z Różnych Materiałów. Technol. I Jakość Wyr. 2021, 66, 134–147. [Google Scholar]

- Andrzej, M. Konstytuowanie Powierzchni I Addytywne Kształtowanie Wyrobów Obróbką Laserową; Wydawnictwo UTH: Warsaw, Poland, 2018. [Google Scholar]

- Imran, H.J.; Hubeatir, K.A.; Al-Khafaji, M.M. CO2 Laser Micro-Engraving of PMMA Complemented by Taguchi and ANOVA Methods. J. Phys. Conf. Ser. 2021, 1795, 012062. [Google Scholar] [CrossRef]

- Qi, J.; Wang, K.L.; Zhu, Y.M. A Study on the Laser Marking Process of Stainless Steel. J. Mater. Process. Technol. 2003, 139, 273–276. [Google Scholar] [CrossRef]

- Patel, S.; Patel, S.B.; Patel, A.B. A Review on Laser Engraving Process. Int. J. Sci. Res. Dev. 2015, 3, 247–250. [Google Scholar]

- Dutta Majumdar, J.; Manna, I. Laser Material Processing. Int. Mater. Rev. 2011, 56, 341–388. [Google Scholar] [CrossRef]

- Nikolidakis, E.; Antoniadis, A. FEM Modeling Simulation of Laser Engraving. Int. J. Adv. Manuf. Technol. 2019, 105, 3489–3498. [Google Scholar] [CrossRef]

- Wang, D.; Yu, Q.; Zhang, Y. Research on Laser Marking Speed Optimization by Using Genetic Algorithm. PLoS ONE 2015, 10, e0126141. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Lin, J. Laser Cleaving on Glass Sheets with Multiple Laser Beams. Opt. Lasers Eng. 2008, 46, 388–395. [Google Scholar] [CrossRef]

- Noor, Y.M.; Tam, S.C.; Lim, L.E.N.; Jana, S. A Review of the Nd: YAG Laser Marking of Plastic and Ceramic IC Packages. J. Mater. Process. Technol. 1994, 42, 95–133. [Google Scholar] [CrossRef]

- Genna, S.; Leone, C.; Lopresto, V.; Tagliaferri, V. An Experimental Study on the Surface Mechanisms Formation during the Laser Milling of PMMA. Polym. Compos. 2015, 36, 1063–1071. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, W.; Lu, L.; Zhang, J.; Qin, L.; Ma, S.; Tang, Y. Laser Micro-Milling of Microchannel on Copper Sheet as Catalyst Support Used in Microreactor for Hydrogen Production. Int. J. Hydrog. Energy 2014, 39, 4884–4894. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, J.; Huang, C. Analysis of the Machining Performance and Surface Integrity in Laser Milling of Polycrystalline Diamonds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 903–917. [Google Scholar] [CrossRef]

- Ahmadi, A.; Toroghinejad, M.R.; Najafizadeh, A. Evaluation of Microstructure and Mechanical Properties of Al/Al2O3/SiC Hybrid Composite Fabricated by Accumulative Roll Bonding Process. Mater. Des. 2014, 53, 13–19. [Google Scholar] [CrossRef]

- Akinwamide, S.O.; Abe, B.T.; Akinribide, O.J.; Obadele, B.A.; Olubambi, P.A. Characterization of Microstructure, Mechanical Properties and Corrosion Response of Aluminium-Based Composites Fabricated via Casting—A Review. Int. J. Adv. Manuf. Technol. 2020, 109, 975–991. [Google Scholar] [CrossRef]

- Mileiko, S.T. A New Look at the Application of Metal Matrix Composites in a Future Aviation Engine. J. Phys. Conf. Ser. 2021, 1891, 012029. [Google Scholar] [CrossRef]

- Rhee, H.; Whittington, W.R.; Oppedal, A.L.; Sherif, A.R.; King, R.L.; Kim, H.-J.; Lee, C. Mechanical Properties of Novel Aluminum Metal Matrix Metallic Composites: Application to Overhead Conductors. Mater. Des. 2015, 88, 16–21. [Google Scholar] [CrossRef]

- Snajdar-Musa, M.; Schauperl, Z. ECAP—New Consolidation Method for Production of Aluminium Matrix Composites with Ceramic Reinforcement. PAC 2013, 7, 63–68. [Google Scholar] [CrossRef]

- Peng, T.-Y.; Shimoe, S.; Higo, M.; Kato, M.; Hirata, I.; Iwaguro, S.; Kaku, M. Effect of Laser Engraving on Shear Bond Strength of Polyetheretherketone to Indirect Composite and Denture-Base Resins. J. Dent. Sci. 2023; in press. [Google Scholar] [CrossRef]

- Lu, J.; Wang, J.; Lin, Y.; Zheng, K.; Tian, Z.; Han, P. The Influence of Particle Surface Oxidation Treatment on Microstructure and Mechanical Behavior of 3D-SiCp/A356 Interpenetrating Composites Fabricated by Pressure Infiltration Technique. J. Mater. Res. Technol. 2023, 24, 8984–8996. [Google Scholar] [CrossRef]

- Gawdzińska, K.; Chybowski, L.; Bejger, J.A.; Krile, S. Determination of technological parameters of saturated composites based on SiC by means of a model liquid. Metalurgija 2016, 55, 659–662. [Google Scholar]

- Birsen, D.; Tütük, İ.; Acar, S.; Karabeyoğlu, S.S.; Özer, G.; Güler, K.A. Microstructure and Wear Characteristics of Hybrid Reinforced (Ex-Situ SiC–in-Situ Mg2Si) Al Matrix Composites Produced by Vacuum Infiltration Method. Mater. Chem. Phys. 2023, 302, 127743. [Google Scholar] [CrossRef]

- Pattnaik, S.; Karunakar, D.B.; Jha, P.K. Developments in Investment Casting Process—A Review. J. Mater. Process. Technol. 2012, 212, 2332–2348. [Google Scholar] [CrossRef]

- Nicholls, C.J.; Boswell, B.; Davies, I.J.; Islam, M.N. Review of Machining Metal Matrix Composites. Int. J. Adv. Manuf. Technol. 2017, 90, 2429–2441. [Google Scholar] [CrossRef]

- Zhong, Z.W. Grinding of Aluminium-Based Metal Matrix Composites Reinforced with Al2O3 or SiC Particles. Int. J. Adv. Manuf. Technol. 2003, 21, 79–83. [Google Scholar] [CrossRef]

- Dolata, A.J. Centrifugal Infiltration of Porous Ceramic Preforms by the Liquid Al Alloy—Theoretical Background and Experimental Verification. Arch. Metall. Mater. 2016, 61, 411–418. [Google Scholar] [CrossRef]

- Etemadi, R.; Pillai, K.M.; Rohatgi, P.K.; Hamidi, S.A. On Porosity Formation in Metal Matrix Composites Made with Dual-Scale Fiber Reinforcements Using Pressure Infiltration Process. Met. Mater. Trans. A 2015, 46, 2119–2133. [Google Scholar] [CrossRef]

- Szymański, P.; Gawdzińska, K.; Nagolska, D. Attempts to Prepare Precision Composite Castings by Sintering Al2O3/AlSi11 Using Underpressure. Arch. Foundry Eng. 2023, 20, 49–54. [Google Scholar] [CrossRef]

- Przestacki, D.; Szymański, P. Metallographic Analysis of Surface Layer after Turning with Lasser-Assisted Machining of Composite A359/20SiCp. Kompoz. Compos. 2011, 11, 102–106. [Google Scholar]

- Szymański, M.; Przestacki, D.; Szymański, P. Tool Wear and Surface Roughness in Turning of Metal Matrix Composite Built of Al2O3 Sinter Saturated by Aluminum Alloy in Vacuum Condition. Materials 2022, 15, 8375. [Google Scholar] [CrossRef]

- Pani, B.; Routray, S.R.; Panda, R.R.; Singh, S. A Critical Review on Hybrid Aluminum Metal Matrix Composite. J. Phys. Conf. Ser. 2020, 1706, 012195. [Google Scholar] [CrossRef]

- Nishida, Y. Recycling of Metal Matrix Composites. Adv. Eng. Mater. 2001, 3, 315–317. [Google Scholar] [CrossRef]

- Kamavaram, V.; Mantha, D.; Reddy, R.G. Recycling of Aluminum Metal Matrix Composite Using Ionic Liquids. Electrochim. Acta 2005, 50, 3286–3295. [Google Scholar] [CrossRef]

| Test No. | Laser Beam Pulse Power Pi | Speed of the Laser Head vl |

|---|---|---|

| [-] | [W] | [mm/s] |

| 1. | 6 | 50 |

| 2. | 9 | 50 |

| 3. | 12 | 50 |

| 4. | 9 | 50 |

| 5. | 9 | 150 |

| 6. | 9 | 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymański, M.; Przestacki, D.; Szymański, P. The Influence of Selected Laser Engraving Parameters on Surface Conditions of Hybrid Metal Matrix Composites. Materials 2023, 16, 6575. https://doi.org/10.3390/ma16196575

Szymański M, Przestacki D, Szymański P. The Influence of Selected Laser Engraving Parameters on Surface Conditions of Hybrid Metal Matrix Composites. Materials. 2023; 16(19):6575. https://doi.org/10.3390/ma16196575

Chicago/Turabian StyleSzymański, Michał, Damian Przestacki, and Paweł Szymański. 2023. "The Influence of Selected Laser Engraving Parameters on Surface Conditions of Hybrid Metal Matrix Composites" Materials 16, no. 19: 6575. https://doi.org/10.3390/ma16196575

APA StyleSzymański, M., Przestacki, D., & Szymański, P. (2023). The Influence of Selected Laser Engraving Parameters on Surface Conditions of Hybrid Metal Matrix Composites. Materials, 16(19), 6575. https://doi.org/10.3390/ma16196575