Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction

Abstract

:1. Introduction

2. Materials and Methods

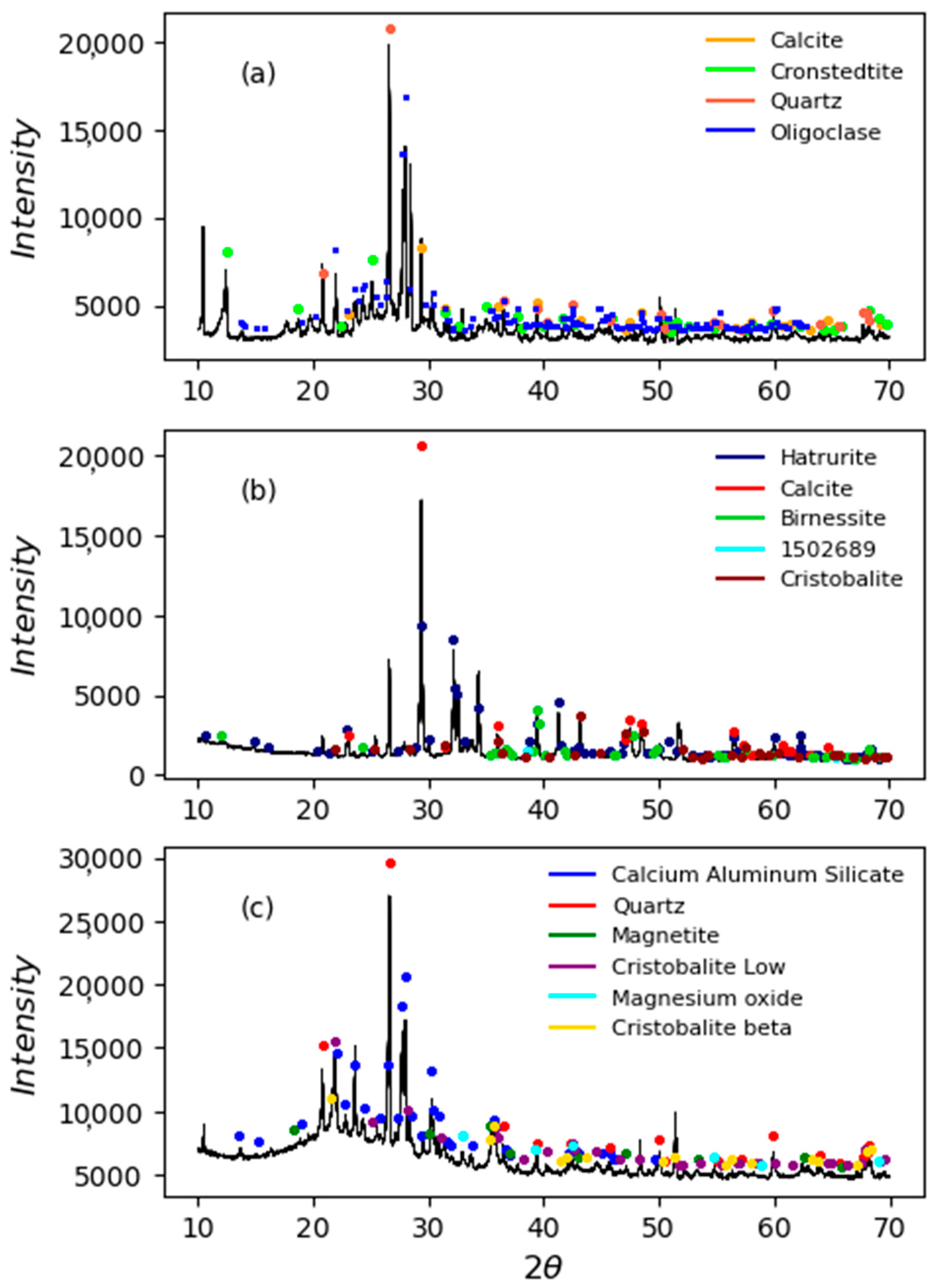

2.1. Materials

2.2. Sample Preparation

2.3. Test Methods

2.3.1. USCS Classification

2.3.2. Compaction Test

2.3.3. California Bearing Ratio (CBR) Test

2.3.4. Unconfined Compressive Strength

3. Results and Discussion

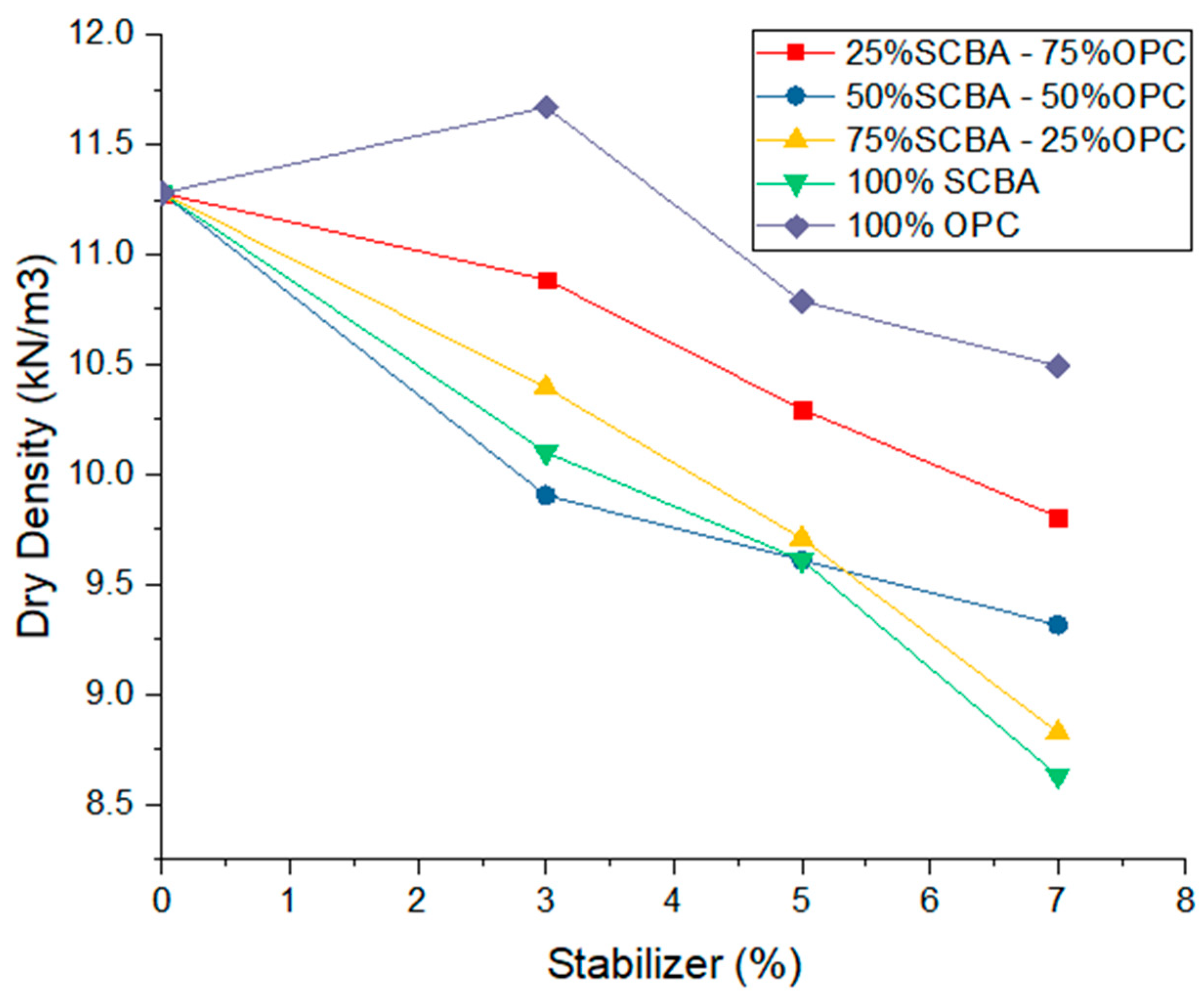

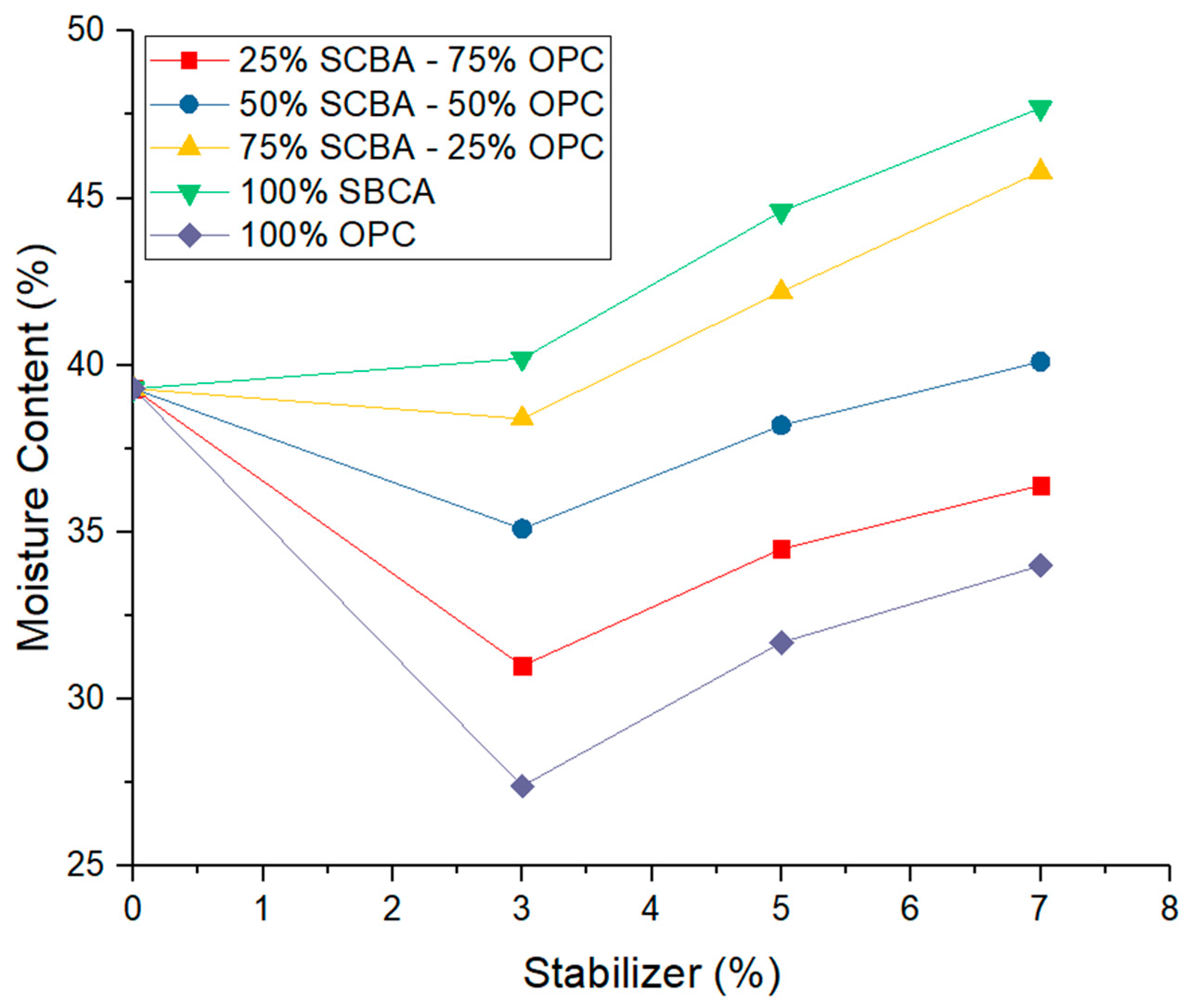

3.1. Effect on the Compaction of Stabilized Soil

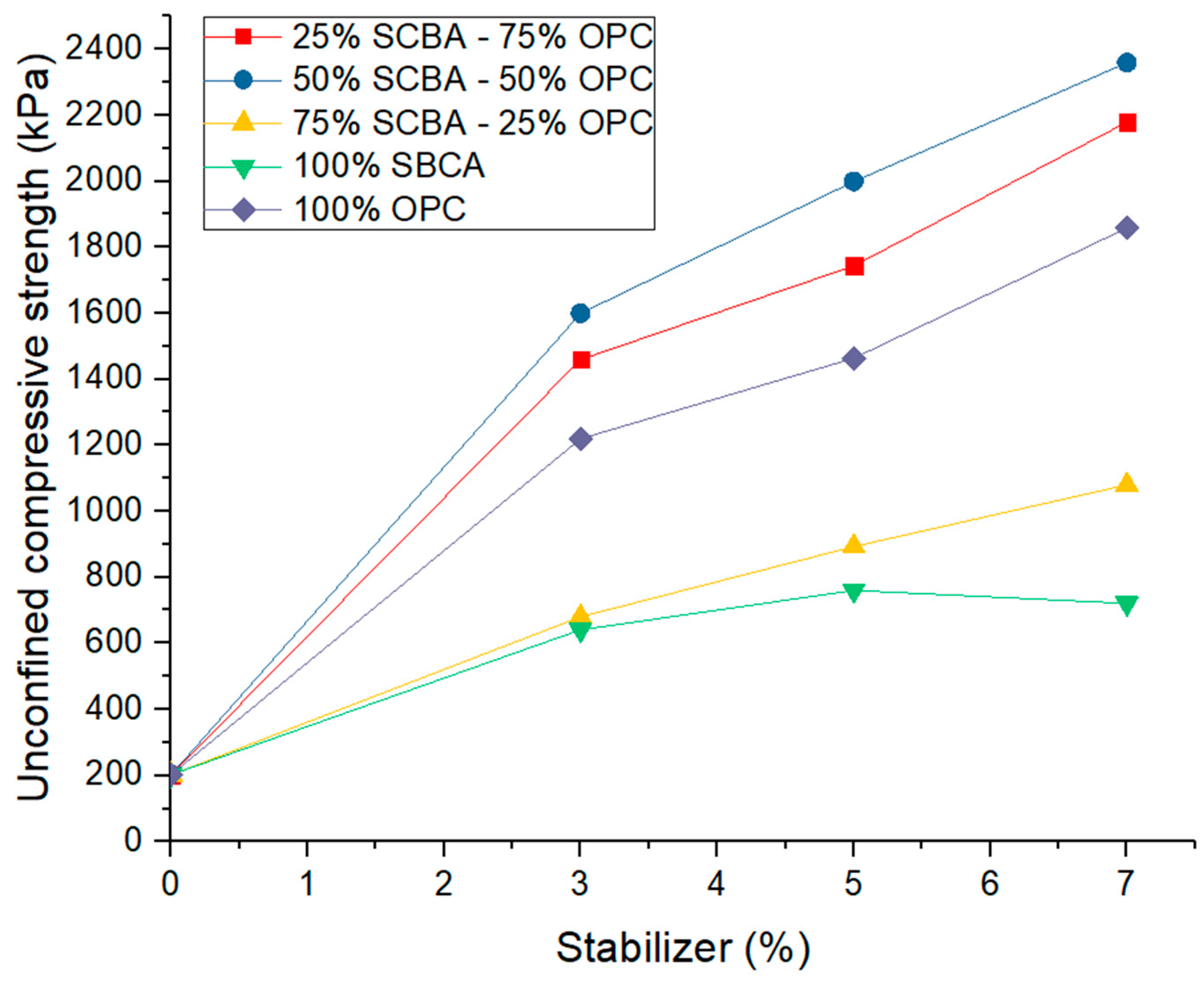

3.2. Effect on the Unconfined Compressive Strength of the Stabilized Soil

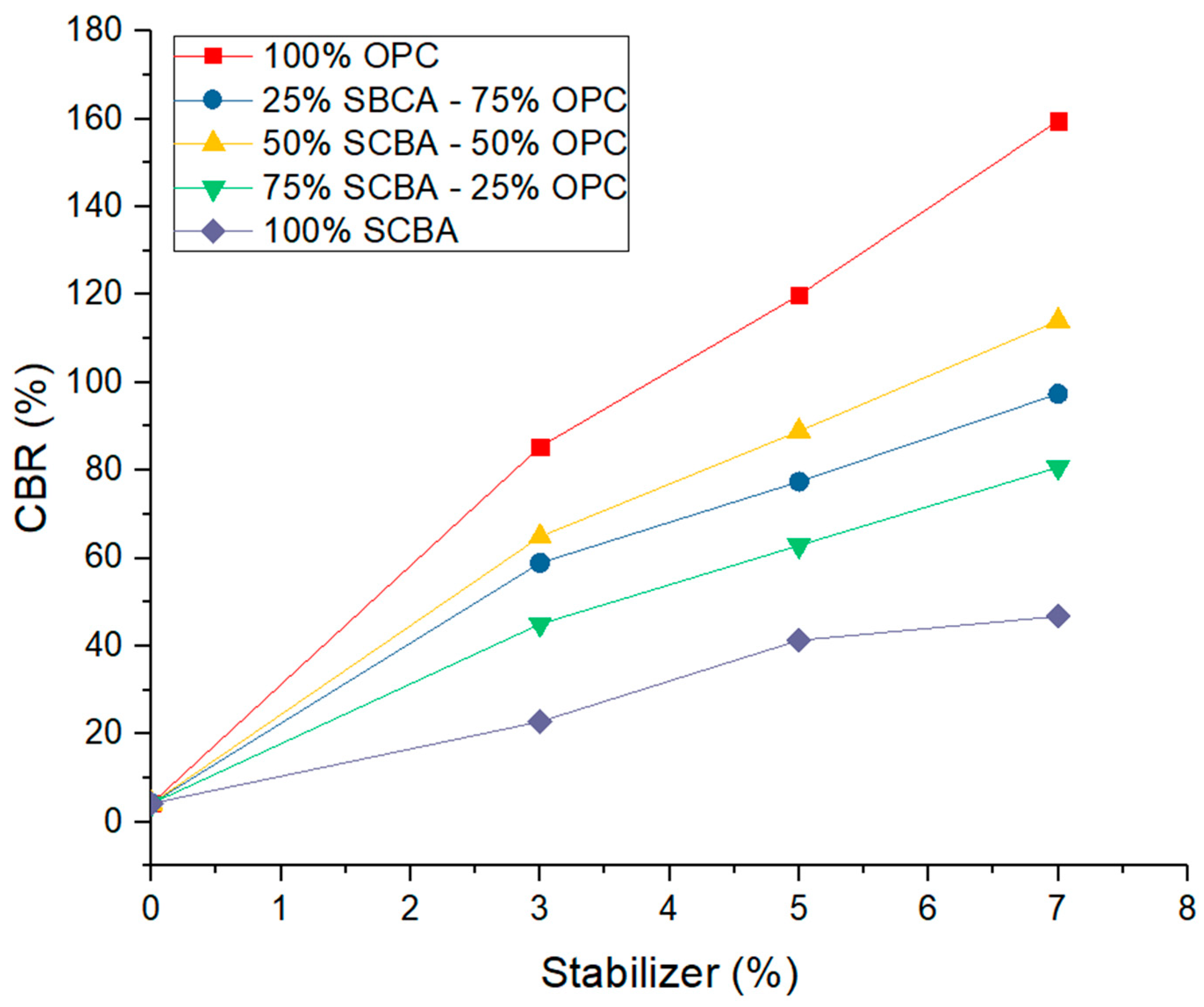

3.3. Effect on the California Bearing Ratio (CBR) of the Stabilized Soil

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Wang, F.; Li, K.; Liu, Y. Optimal water-cement ratio of cement-stabilized soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

- Solihu, H. Cement Soil Stabilization as an Improvement Technique for Rail Track Subgrade, and Highway Subbase and Base Courses: A Review. J. Civ. Environ. Eng. 2020, 10, 1–8. [Google Scholar] [CrossRef]

- Villagrán-Zaccardi, Y.; Pareja, R.; Rojas, L.; Irassar, E.F.; Torres-Acosta, A.; Tobón, J.; John, V.M. Overview of cement and concrete production in Latin America and the Caribbean with a focus on the goals of reaching carbon neutrality. RILEM Tech. Lett. 2022, 7, 30–46. [Google Scholar] [CrossRef]

- Ludwig, H.-M.; Zhang, W. Research review of cement clinker chemistry. Cem. Concr. Res. 2015, 78, 24–37. [Google Scholar] [CrossRef]

- Sargent, P. 21-The development of alkali-activated mixtures for soil stabilisation. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 555–604. [Google Scholar] [CrossRef]

- Cherian, C.; Siddiqua, S. Engineering and environmental evaluation for utilization of recycled pulp mill fly ash as binder in sustainable road construction. J. Clean. Prod. 2021, 298, 126758. [Google Scholar] [CrossRef]

- Ünsever, Y.S.; Diallo, M.L. Stabilization of Clay Soils Using Fly Ash. Black Sea J. Eng. Sci. 2019, 2, 81–87. [Google Scholar] [CrossRef]

- Vukićević, M.; Marjanović, M.; Pujević, V.; Jocković, S. The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments. Materials 2019, 12, 3018. [Google Scholar] [CrossRef]

- Amini, O.; Ghasemi, M. Laboratory study of the effects of using magnesium slag on the geotechnical properties of cement stabilized soil. Constr. Build. Mater. 2019, 223, 409–420. [Google Scholar] [CrossRef]

- Jiang, D.; Li, X.; Lv, Y.; Zhou, M.; He, C.; Jiang, W.; Liu, Z.; Li, C. Utilization of limestone powder and fly ash in blended cement: Rheology, strength and hydration characteristics. Constr. Build. Mater. 2020, 232, 117228. [Google Scholar] [CrossRef]

- Long, G.; Li, L.; Li, W.; Ma, K.; Dong, W.; Bai, C.; Zhou, J.L. Enhanced mechanical properties and durability of coal gangue reinforced cement-soil mixture for foundation treatments. J. Clean. Prod. 2019, 231, 468–482. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Tao, Z. A comprehensive review on performance of cementitious and geopolymeric concretes with recycled waste glass as powder, sand or cullet. Resour. Conserv. Recycl. 2021, 172, 105664. [Google Scholar] [CrossRef]

- Silva, A.M.D.S.E.; Pascoal, P.T.; Baroni, M.; de Vargas, A.S.; Budny, J.; Specht, L.P. Use of Phosphoric Acid and Rice Hulk Ash as Lateritic Soil Stabilizers for Paving Applications. Sustainability 2023, 15, 7160. [Google Scholar] [CrossRef]

- Fadmoro, O.F.; Kar, S.S.; Tiwari, D.; Singh, A. Environmental and Economic Impact of Mixed Cow Dung and Husk Ashes in Subgrade Soil Stabilization. Int. J. Pavement Res. Technol. 2021, 15, 835–846. [Google Scholar] [CrossRef]

- Adeyanju, E.; Okeke, C.A.; Akinwumi, I.; Busari, A. Subgrade Stabilization using Rice Husk Ash-based Geopolymer (GRHA) and Cement Kiln Dust (CKD). Case Stud. Constr. Mater. 2020, 13, e00388. [Google Scholar] [CrossRef]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Effect of coffee husk ash on geotechnical properties of expansive soil. Int. J. Curr. Res. 2017, 9, 46401–46406. [Google Scholar]

- Atahu, M.K.; Saathoff, F.; Gebissa, A. Strength and compressibility behaviors of expansive soil treated with coffee husk ash. J. Rock Mech. Geotech. Eng. 2019, 11, 337–348. [Google Scholar] [CrossRef]

- Mamuye, Y.; Geremew, A. Improving strength of expansive soil using coffee husk ash for subgrade soil formation: A case study in Jimma town. Int. J. Eng. Res. Technol. 2018, 7, 120–126. [Google Scholar] [CrossRef]

- García, R.C. El Bagazo de la Caña de Azúcar: Usos y Derivados; Universidad Veracruzana: Xalapa, Mexico, 2007. [Google Scholar]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 31 May 2023).

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M.; Nazar, S.; Jittin, V.; Ashish, D.K. Sugarcane bagasse ash as supplementary cementitious material in concrete—A review. Mater. Today Sustain. 2021, 15, 100086. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Muruganandam, L.; Srinivasan, K. An overview of the influences of mechanical and chemical processing on sugarcane bagasse ash characterisation as a supplementary cementitious material. J. Clean. Prod. 2020, 245, 118854. [Google Scholar] [CrossRef]

- Landa-Sánchez, A.; Bosch, J.; Baltazar-Zamora, M.A.; Croche, R.; Landa-Ruiz, L.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Olguín-Coca, J.; López-Léon, L.; Bastidas, J.M.; et al. Corrosion Behavior of Steel-Reinforced Green Concrete Containing Recycled Coarse Aggregate Additions in Sulfate Media. Materials 2020, 13, 4345. [Google Scholar] [CrossRef] [PubMed]

- Ariza-Figueroa, H.A.; Bosch, J.; Baltazar-Zamora, M.A.; Croche, R.; Santiago-Hurtado, G.; Landa-Ruiz, L.; Mendoza-Rangel, J.M.; Bastidas, J.M.; Almeraya-Calderón, F.; Bastidas, D.M. Corrosion Behavior of AISI 304 Stainless Steel Reinforcements in SCBA-SF Ternary Ecological Concrete Exposed to MgSO4. Materials 2020, 13, 2412. [Google Scholar] [CrossRef] [PubMed]

- Landa-Ruiz, L.; Landa-Gómez, A.; Mendoza-Rangel, J.M.; Landa-Sánchez, A.; Ariza-Figueroa, H.; Méndez-Ramírez, C.T.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Croche, R.; Baltazar-Zamora, M.A. Physical, Mechanical and Durability Properties of Ecofriendly Ternary Concrete Made with Sugar Cane Bagasse Ash and Silica Fume. Crystals 2021, 11, 1012. [Google Scholar] [CrossRef]

- Ojeda Farías, O.F.; Baltazar Zamora, M.Á.; Mendoza Rangel, J.M. Influencia de la inclusión de ceniza de bagazo de caña de azúcar sobre la compactación, CBR y resistencia a la compresión simple de un material granular tipo subrasante. Rev. Asoc. Latinoam. Control. Calid. Patol. Recuper. Construcción 2018, 8, 194–208. [Google Scholar] [CrossRef]

- Hidalgo, F.; Saavedra, J.; Fernandez, C.; Duran, G. Stabilization of clayey soil for subgrade using rice husk ash (RHA) and sugarcane bagasse ash (SCBA). IOP Conf. Ser. Mater. Sci. Eng. 2020, 758, 012041. [Google Scholar] [CrossRef]

- Abu Talib, M.K.; Noriyuki, Y. Highly Organic Soil Stabilization by Using Sugarcane Bagasse Ash (SCBA). MATEC Web Conf. 2017, 103, 07013. [Google Scholar] [CrossRef]

- Kumar Yadav, A.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. Available online: https://www.astm.org/d2166-06.html (accessed on 4 June 2023).

- Standard Test Method for Particle-Size Analysis of Soils. Available online: https://www.astm.org/d0422-63r98.html (accessed on 4 June 2023).

- D4318 Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. Available online: https://www.astm.org/d4318-17e01.html (accessed on 4 June 2023).

- Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ft-lbf/ft3 (2700 kN-m/m3)). Available online: https://www.astm.org/d1557-12r21.html (accessed on 4 June 2023).

- Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. Available online: https://www.astm.org/d1883-21.html (accessed on 4 June 2023).

- Standard Specification for Portland Cement. Available online: https://www.astm.org/c0150-07.html (accessed on 4 June 2023).

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. Available online: https://www.astm.org/c0618-22.html (accessed on 4 June 2023).

- Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Available online: https://www.astm.org/d2487-17.html (accessed on 10 June 2023).

- Landa-Ruiz, L.; Márquez-Montero, S.; Santiago-Hurtado, G.; Moreno-Landeros, V.; Mendoza-Rangel, J.M.; Baltazar-Zamora, M.A. Effect of the Addition of Sugar Cane Bagasse Ash on the Compaction Properties of a Granular Material Type Hydraulic Base. Eur. J. Eng. Technol. Res. 2021, 6, 76–79. [Google Scholar] [CrossRef]

- Suárez-Díaz, J. Resistencia al Cortante. In Deslizamientos: Vol. 1 Análisis Geotécnico, 1st ed.; División de Publicaciones UIS: Bucaramanga, Colombia, 2009; p. 77. [Google Scholar]

- Cordeiro, G.C.; Kurtis, K.E. Effect of mechanical processing on sugar cane bagasse ash pozzolanicity. Cem. Concr. Res. 2017, 97, 41–49. [Google Scholar] [CrossRef]

- Alavéz-Ramírez, R.; Montes-García, P.; Martínez-Reyes, J.; Altamirano-Juárez, D.C.; Gochi-Ponce, Y. The use of sugarcane bagasse ash and lime to improve the durability and mechanical properties of compacted soil blocks. Constr. Build. Mater. 2012, 34, 296–305. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, R.N.G.D.; Singh, S.; Sahdeo, S.K. Utilization of industrial and agricultural wastes for productions of sustainable roller compacted concrete pavement mixes containing reclaimed asphalt pavement aggregates. Resour. Conserv. Recycl. 2020, 152, 104504. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.-J.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef] [PubMed]

- Paul, Y.; Abdulrahman, B.; Kazeem, I.; Chukwuebuka, O.K.; Nyako, A.M.; Mije, F.G. A Comparative Study on the Effect of Sisal Fibre and Waste Plastic Strips in Structural Strength Improvement of Tropical Black Clay. J. Eng. Stud. Res. 2022, 28, 81–91. [Google Scholar] [CrossRef]

- García-García, D.L. Influencia de la Ceniza de Bagazo de Caña Como Sustituto de Cemento Portland en la Estabilización de un Material para Sub-Base. Bachelor’s Thesis, Facultad de Ingeniería Civil, Región Xalapa, Universidad Veracruzana, Xalapa, Mexico, 2017; p. 74. [Google Scholar]

- Landa-Sánchez, A. Efecto de la Sustitución Parcial de Cemento Portland por Ceniza de Bagazo de caña de Azúcar (CBCA) en las Propiedades Mécánicas de Material de Materianl de Base Hidráulica para la Construcción de Carreteras. Master’s Thesis, Facultad de Ingeniería Civil, Región Xalapa, Universidad Veracruzana, Xalapa, Mexico, 2017; p. 98. [Google Scholar]

- Cuervo-Mendoza, C.E. Influencia de la Adición de Ceniza de Bagazo de Caña (CBCA) en las Propiedades Geotécnicas de un Material Tipo Base Hidráulica Para Construcción de Carreteras. Master’s Thesis, Facultad de Ingeniería Civil, Región Xalapa, Universidad Veracruzana, Xalapa, Mexico, 2017; p. 80. [Google Scholar]

- Rodríguez, A.R. Manual de Calidad de los Materiales en Secciones Estructurales de Pavimentos Carreteros; Instituto Mexicano del Transporte: Querétaro, México, 1990; No. 1. [Google Scholar]

- Tang, S.W.; Cai, X.H.; He, Z.; Shao, H.Y.; Li, Z.J.; Chen, E. Hydration process of fly ash blended cement pastes by impedance measurement. Constr. Build. Mater. 2016, 113, 939–950. [Google Scholar] [CrossRef]

- Tang, S.W.; Cai, X.H.; He, Z.; Zhou, W.; Shao, H.Y.; Li, Z.J.; Wu, T.; Chen, E. The review of early hydration of cement-based materials by electrical methods. Constr. Build. Mater. 2017, 146, 15–29. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

| Property | Standard Test Method | Value |

|---|---|---|

| Soil classification (USCS) [38] | ASTM D 422, 2007 | MH |

| Liquid limit (%) | ASTM D 4318, 2010 | 83.21 |

| Plastic limit (%) | ASTM D 4318, 2010 | 51.11 |

| Plasticity index (%) | ASTM D 4318, 2010 | 32.10 |

| Dry unit weight (kN/m3) | ASTM D 1557, 2009 | 11.28 |

| Optimum moisture content (%) | ASTM D 1557, 2009 | 39.3 |

| California bearing ratio (%) | ASTM D 1883, 2007 | 4.2 |

| Compound | % of the Total Weight | ||

|---|---|---|---|

| Soil | OPC | SCBA | |

| SiO2 | 52.11 | 17.99 | 75.74 |

| Al2O3 | 19.85 | 3.88 | 4.09 |

| Fe2O3 | 10.73 | 4.76 | 8.55 |

| CaO | 7.21 | 62.28 | 2.88 |

| MgO | 4.57 | 1.71 | 0.50 |

| P2O5 | - | -- | 0.63 |

| Na2O | 0.76 | 0.23 | 1.22 |

| SO3 | - | 4.03 | 0.41 |

| K2O | 2.44 | -- | 3.88 |

| TiO2 | 1.45 | -- | 0.95 |

| MnO | - | -- | 0.38 |

| Density (g/cm3) | 1.15 | 3.15 | 2.2 |

| Specific Surface área (cm2/g) | 4390 | 850 | |

| Mixture No | Soil | OPC | SCBA | % SCBA |

|---|---|---|---|---|

| Mixture 1 | 100 | 0 | 0 | 0 |

| Mixture 2 | 97 | 3 | 0 | |

| Mixture 3 | 95 | 5 | 0 | |

| Mixture 4 | 93 | 7 | 0 | |

| Mixture 5 | 97 | 2.25 | 0.75 | 25 |

| Mixture 6 | 95 | 3.75 | 1.25 | |

| Mixture 7 | 93 | 5.25 | 1.75 | |

| Mixture 8 | 97 | 1.5 | 1.5 | 50 |

| Mixture 9 | 95 | 2.5 | 2.5 | |

| Mixture 10 | 93 | 3.5 | 3.5 | |

| Mixture 11 | 97 | 0.75 | 2.25 | 75 |

| Mixture 12 | 95 | 1.25 | 3.75 | |

| Mixture 13 | 93 | 1.75 | 5.25 |

| Mixture | Dry Unit Weight (kN/m3) | Moisture (%) | CBR (%) | Unconfined Compressive Strength (kPa) | |

|---|---|---|---|---|---|

| OPC% | SCBA% | ||||

| 0.00 | 0.00 | 11.28 | 39.3 | 4.20 | 202.0 |

| 3.00 | 0.00 | 11.55 | 27.4 | 85.4 | 1219.7 |

| 5.00 | 0.00 | 10.90 | 31.7 | 119.9 | 1463.8 |

| 7.00 | 0.00 | 10.75 | 34.0 | 159.6 | 1858.1 |

| 2.25 | 0.75 | 10.90 | 31.0 | 58.9 | 1459.6 |

| 3.75 | 1.25 | 10.51 | 34.5 | 77.4 | 1743.7 |

| 5.25 | 1.75 | 10.32 | 36.4 | 97.4 | 2179.4 |

| 1.50 | 1.50 | 9.89 | 35.1 | 64.9 | 1599.6 |

| 2.50 | 2.50 | 9.30 | 38.2 | 88.9 | 1999.5 |

| 3.50 | 3.50 | 8.81 | 40.1 | 114.1 | 2359.4 |

| 0.75 | 2.25 | 10.40 | 38.4 | 45.0 | 679.9 |

| 1.25 | 3.75 | 9.71 | 42.2 | 62.9 | 892.9 |

| 1.75 | 5.25 | 9.50 | 45.8 | 80.7 | 1079.8 |

| 0.00 | 3.00 | 10.19 | 40.2 | 22.8 | 639.9 |

| 0.00 | 5.00 | 9.61 | 44.6 | 41.3 | 759.8 |

| 0.00 | 7.00 | 9.41 | 47.7 | 46.8 | 719.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallego-Quintana, P.; Ojeda-Farias, O.F.; Alvarez-Rosario, A.; Alvarez-Sánchez, E.J.; Landa-Ruiz, L.; Terán-Torres, B.T.; Mendoza-Rangel, J.M.; Baltazar-Zamora, M.Á. Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction. Materials 2023, 16, 6395. https://doi.org/10.3390/ma16196395

Gallego-Quintana P, Ojeda-Farias OF, Alvarez-Rosario A, Alvarez-Sánchez EJ, Landa-Ruiz L, Terán-Torres BT, Mendoza-Rangel JM, Baltazar-Zamora MÁ. Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction. Materials. 2023; 16(19):6395. https://doi.org/10.3390/ma16196395

Chicago/Turabian StyleGallego-Quintana, Pedro, Omar Farid Ojeda-Farias, Alexander Alvarez-Rosario, Ervin Jesús Alvarez-Sánchez, Laura Landa-Ruiz, Bernardo T. Terán-Torres, José Manuel Mendoza-Rangel, and Miguel Ángel Baltazar-Zamora. 2023. "Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction" Materials 16, no. 19: 6395. https://doi.org/10.3390/ma16196395

APA StyleGallego-Quintana, P., Ojeda-Farias, O. F., Alvarez-Rosario, A., Alvarez-Sánchez, E. J., Landa-Ruiz, L., Terán-Torres, B. T., Mendoza-Rangel, J. M., & Baltazar-Zamora, M. Á. (2023). Analysis of the Mechanical Properties of a Stabilized Subgrade Type Soil under a Sustainable Approach for Construction. Materials, 16(19), 6395. https://doi.org/10.3390/ma16196395