Long-Term Aging Study on the Solid State Interfacial Reactions of In on Cu Substrate

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

3.1. Evolution of the Microstructure during Thermal Aging

3.2. Solid-State Aging at Room Temperature

4. Conclusions

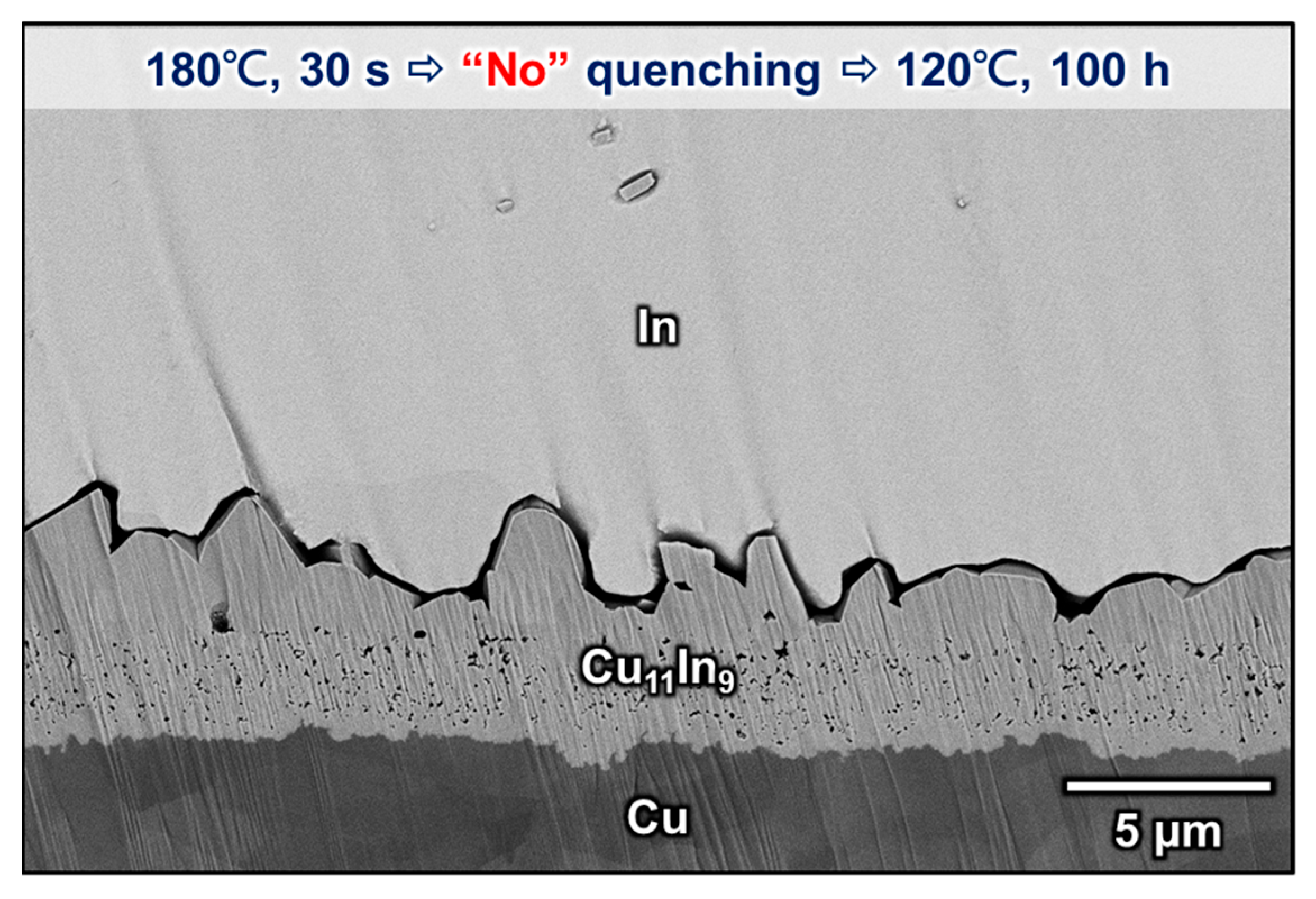

- Soldering at 180 ± 1 °C for 30 s was set as the prebonding condition in this study. A two-phase layer consisting of Cu11In9 and In and faceted Cu11In9 particles over the two-phase layer formed at the Cu/In interface after the prebonding process.

- During 120 °C and 140 °C aging, the remaining In in the two-phase layer formed during the prebonding process reacted with the Cu substrate and formed Cu11In9. Finally, only a continuous Cu11In9 layer can be observed at the interface.

- During 100 °C aging, another kind of intermetallic CuIn2 formed at the interface. As the aging time increased, Cu11In9 and In particles in the two-phase layer transformed into CuIn2 and finally formed a continuous CuIn2 layer. The peritectoid temperature of the Cu11In9 + In → CuIn2 reaction was suggested to be between 100 °C and 120 °C.

- The place where CuIn2 was first observed after quenching is at the Cu11In9/In two-phase layer, which indicates that a smaller curvature of the Cu11In9/In interface induces faster CuIn2 formation. CuIn2 formation at room-temperature storage was observed to be faster than aging at 100 °C, which indicates that a larger temperature difference with the peritectoid temperature induces faster CuIn2 formation. The curvature of the Cu11In9/In interface and the temperature difference with the peritectoid temperature of CuIn2 are two factors that influence the growth of CuIn2. These two factors influence the driving force of CuIn2 formation spontaneously.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sethi, P.; Sarangi, S.R. Internet of things: Architectures, protocols, and applications. J. Electr. Comput. Eng. 2017, 2017, 9324035. [Google Scholar] [CrossRef]

- Higurashi, E.; Suga, T. Review of low-temperature bonding technologies and their application in optoelectronic devices. Electron. Commun. Jpn. 2016, 99, 63–71. [Google Scholar] [CrossRef]

- Bernstein, L. Semiconductor Joining by the Solid-Liquid-Interdiffusion (SLID) Process. J. Electrochem. Soc. 1966, 113, 1282. [Google Scholar] [CrossRef]

- MacDonald, W.D.; Eagar, T.W. Transient Liquid Phase Bonding. Annu. Rev. Mater. Sci. 1992, 22, 23–46. [Google Scholar] [CrossRef]

- Bickel, S.; Panchenko, I.; Wahrmund, W.; Neumann, V.; Meyer, J.; Wolf, J.M. Cu-In-microbumps for low-temperature bonding of fine-pitch-interconnects. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; pp. 2092–2096. [Google Scholar]

- Panchenko, I.; Bickel, S.; Meyer, J.; Mueller, M.; Wolf, J.M. Characterization of low temperature Cu/In bonding for fine-pitch interconnects in three-dimensional integration. Jpn. J. Appl. Phys. 2017, 57, 02BC05. [Google Scholar] [CrossRef]

- Bickel, S.; Hoehne, R.; Panchenko, I.; Meyer, J.; Wolf, J.M. Cu-In fine-pitch-interconnects with enhanced shear strength. In Proceedings of the 2018 IEEE 68th Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 29 May–1 June 2018; pp. 808–813. [Google Scholar]

- Bickel, S.; Sen, S.; Meyer, J.; Panchenko, I.; Wolf, J.M. Cu-In fine-pitch-interconnects: Influence of processing conditions on the interconnection quality. In Proceedings of the 2018 7th Electronic System-Integration Technology Conference (ESTC), Dresden, Germany, 18–21 September 2018; pp. 1–6. [Google Scholar]

- Liu, B.; Tian, Y.; Feng, J.; Wang, C. Enhanced shear strength of Cu–Sn intermetallic interconnects with interlocking dendrites under fluxless electric current-assisted bonding process. J. Mater. Sci. 2017, 52, 12–1954. [Google Scholar] [CrossRef]

- Deppisch, C.; Fitzgerald, T.; Raman, A.; Hua, F.; Zhang, C.; Liu, P.; Miller, M. The material optimization and reliability characterization of an indium-solder thermal interface material for CPU packaging. JOM 2006, 58, 67–74. [Google Scholar] [CrossRef]

- Chaowasakoo, T.; Ng, T.H.; Songninluck, J.; Stern, M.B.; Ankireddi, S. Indium solder as a thermal interface material using fluxless bonding technology. In Proceedings of the 2009 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March 2019; pp. 180–185. [Google Scholar]

- Too, S.S.; Touzelbaev, M.; Khan, M.; Master, R.; Diep, J.; Keok, K.-H. Indium thermal interface material development for microprocessors. In Proceedings of 2009 the 25th Annual IEEE Semiconductor Thermal Measurement and Management Symposium, San Jose, CA, USA, 15–19 March 2019; pp. 186–192. [Google Scholar]

- Fałat, T.; Matkowski, P.; Płatek, B.; Zandén, C.; Felba, J.; Ye, L.-L.; Liu, J. Investigation on interaction between indium based thermal interface material and copper and silicon substrates. In Proceedings of 2013 Eurpoean Microelectronics Packaging Conference (EMPC), Grenoble, France, 9–12 September 2013; pp. 1–5. [Google Scholar]

- Falat, T.; Platek, B. Growth of intermetallic compound between indium-based thermal interface material and copper substrate: Molecular dynamics simulations. Mater. Sci. Pol. 2015, 33, 445–450. [Google Scholar] [CrossRef]

- Hung, H.T.; Lee, P.T.; Tsai, C.H.; Kao, C.R. Artifact-free microstructures of the Cu–In reaction by using cryogenic broad argon beam ion polishing. J. Mater. Res. Technol. 2020, 9, 12946–12954. [Google Scholar] [CrossRef]

- Madito, M.J.; Swart, H.C.; Terblans, J.J. AES and XRD study of In/Cu thin films deposited onto SiO2 by electron beam evaporation. In Proceedings of the 56th Annual Conference of the South African Institute of Physics (SAIP), Pretoria, South Africa, 12–15 July 2011. [Google Scholar]

- Keppner, W.; Klas, T.; Körner, W.; Wesche, R.; Schatz, G. Compound formation at Cu-In thin-film interfaces detected by perturbed γ-γ angular correlations. Phys. Rev. Lett. 1985, 54, 2371–2374. [Google Scholar] [CrossRef]

- Keppner, W.; Wesche, R.; Klas, T.; Voigt, J.; Schatz, G. Studies of compound formation at Cu-In, Ag-In and Au-In interfaces with perturbed γ-γ angular correlations. Thin Solid Film. 1986, 143, 201–215. [Google Scholar] [CrossRef]

- Dzionk, C.; Metzner, H.; Lewerenz, H.J.; Mahnke, H.E. Perturbed angular correlations study of thin Cu–In films. J. Appl. Phys. 1995, 78, 2392–2397. [Google Scholar] [CrossRef]

- Gossla, M.; Metzner, H.; Mahnke, H.E. Coevaporated Cu–In films as precursors for solar cells. J. Appl. Phys. 1999, 86, 3624–3632. [Google Scholar] [CrossRef]

- Wronkowska, A.A.; Wronkowski, A.; Bukaluk, A.; Trzcinski, M.; Okulewicz, K.; Skowroński, Ł. Structural analysis of In/Ag, In/Cu and In/Pd thin films on tungsten by ellipsometric, XRD and AES methods. Appl. Surf. Sci. 2008, 254, 4401–4407. [Google Scholar] [CrossRef]

- Wronkowska, A.A.; Wronkowski, A.; Skowroński, Ł. Non-destructive characterization of In/Ag and In/Cu diffusive layers. J. Alloys Compd. 2009, 479, 583–588. [Google Scholar] [CrossRef]

- Lin, Y.F.; Hung, H.T.; Yu, H.Y.; Kao, C.R.; Wang, Y.W. Phase stabilities and interfacial reactions of the Cu–In binary systems. J. Mater. Sci. Mater. Electron. 2020, 31, 10161–10169. [Google Scholar] [CrossRef]

- Okamoto, H. Cu-In (copper-indium). J. Phase Equilibria Diffus. 2005, 26, 645. [Google Scholar] [CrossRef]

- Metzner, H.; Brüssler, M.; Husemann, K.D.; Lewerenz, H.J. Characterization of phases and determination of phase relations in the Cu-In-S system by γ-γ perturbed angular correlations. Phys. Rev. B 1991, 44, 11614–11623. [Google Scholar] [CrossRef]

- Bolcavage, A.; Chen, S.W.; Kao, C.R.; Chang, Y.A.; Romig, A.D. Phase equilibria of the cu-in system I: Experimental investigation. J. Phase Equilibria 1993, 14, 14–21. [Google Scholar] [CrossRef]

- Migge, H. Thermochemistry in the system Cu–In–S at 298 K. J. Mater. Res. 1991, 6, 2381–2386. [Google Scholar] [CrossRef]

- Lindahl, K.A.; Moore, J.J.; Olson, D.L.; Noufi, R.; Lanning, B. Quantitative investigation of copper/indium multilayer thin film reactions. Thin Solid Film. 1996, 290–291, 518–524. [Google Scholar] [CrossRef]

- Kim, D.-G.; Lee, C.-Y.; Jung, S.-B. Interfacial reactions and intermetallic compound growth between indium and copper. J. Mater. Sci. Mater. Electron. 2004, 15, 95–98. [Google Scholar] [CrossRef]

- Klinger, L.; Bréchet, Y.; Purdy, G. On the kinetics of interface-diffusion-controlled peritectoid reactions. Acta Mater. 1998, 46, 2617–2621. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, H.-T.; Chang, F.-L.; Tsai, C.-H.; Liao, C.-Y.; Kao, C.R. Long-Term Aging Study on the Solid State Interfacial Reactions of In on Cu Substrate. Materials 2023, 16, 6263. https://doi.org/10.3390/ma16186263

Hung H-T, Chang F-L, Tsai C-H, Liao C-Y, Kao CR. Long-Term Aging Study on the Solid State Interfacial Reactions of In on Cu Substrate. Materials. 2023; 16(18):6263. https://doi.org/10.3390/ma16186263

Chicago/Turabian StyleHung, Han-Tang, Fu-Ling Chang, Chin-Hao Tsai, Chia-Yi Liao, and C. R. Kao. 2023. "Long-Term Aging Study on the Solid State Interfacial Reactions of In on Cu Substrate" Materials 16, no. 18: 6263. https://doi.org/10.3390/ma16186263

APA StyleHung, H.-T., Chang, F.-L., Tsai, C.-H., Liao, C.-Y., & Kao, C. R. (2023). Long-Term Aging Study on the Solid State Interfacial Reactions of In on Cu Substrate. Materials, 16(18), 6263. https://doi.org/10.3390/ma16186263