Thermodynamic and Microstructural Analysis of Lead-Free Machining Aluminium Alloys with Indium and Bismuth Additions

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Chemical Composition of Fabricated Alloys

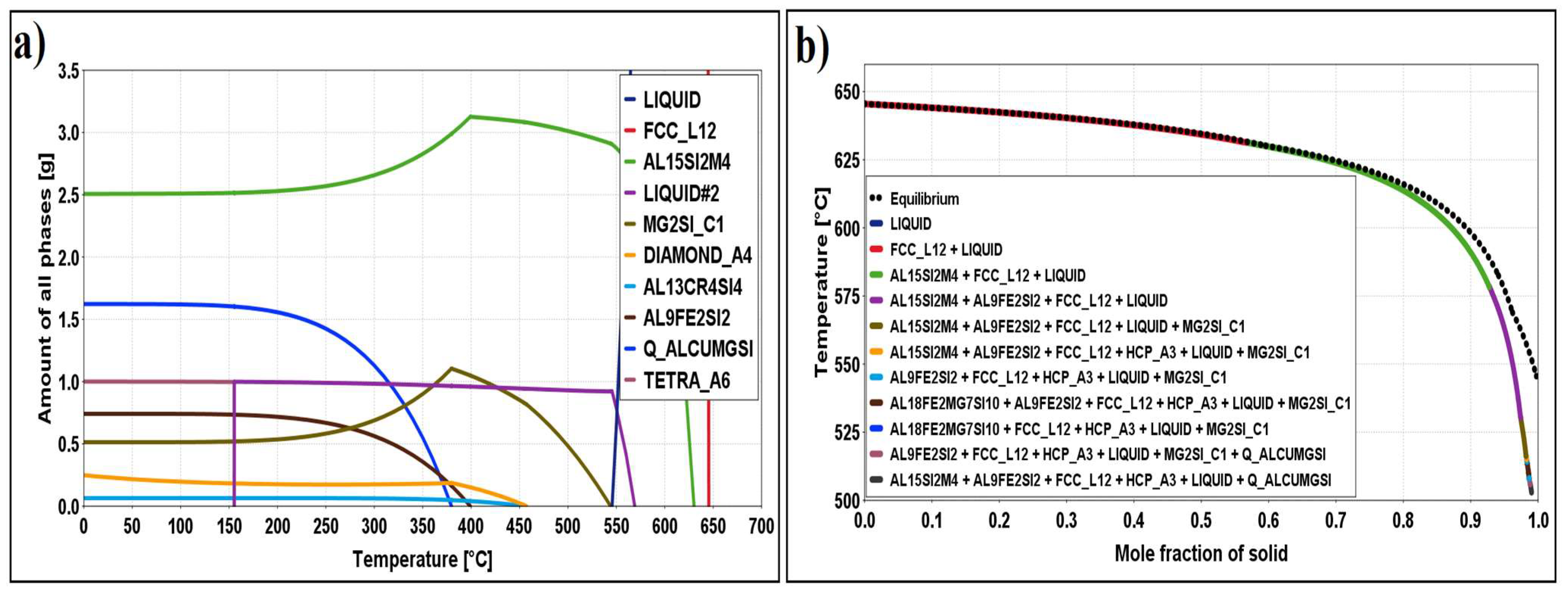

3.2. Thermodynamic Calculations

3.3. Microstructural Characterization

4. Conclusions

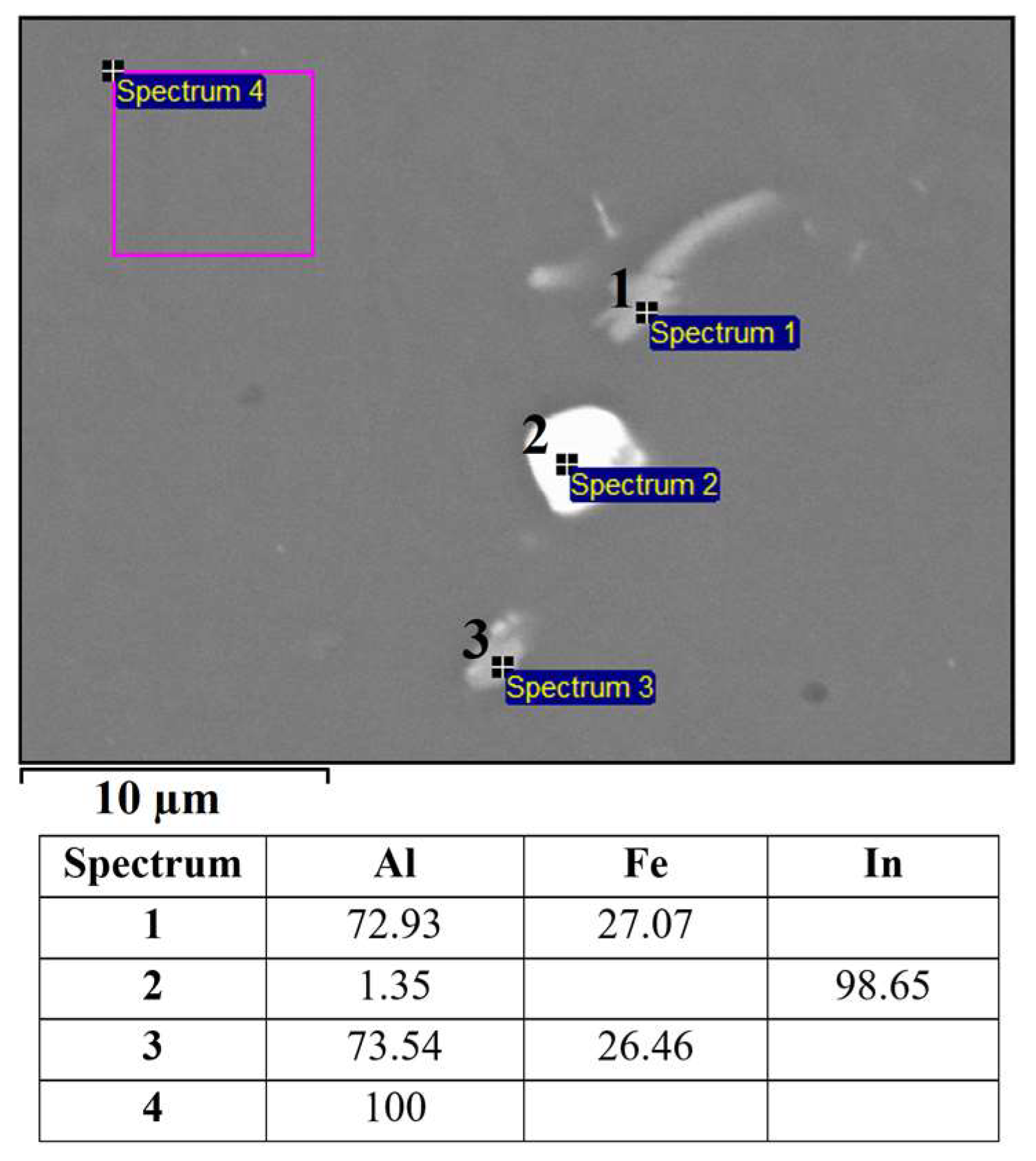

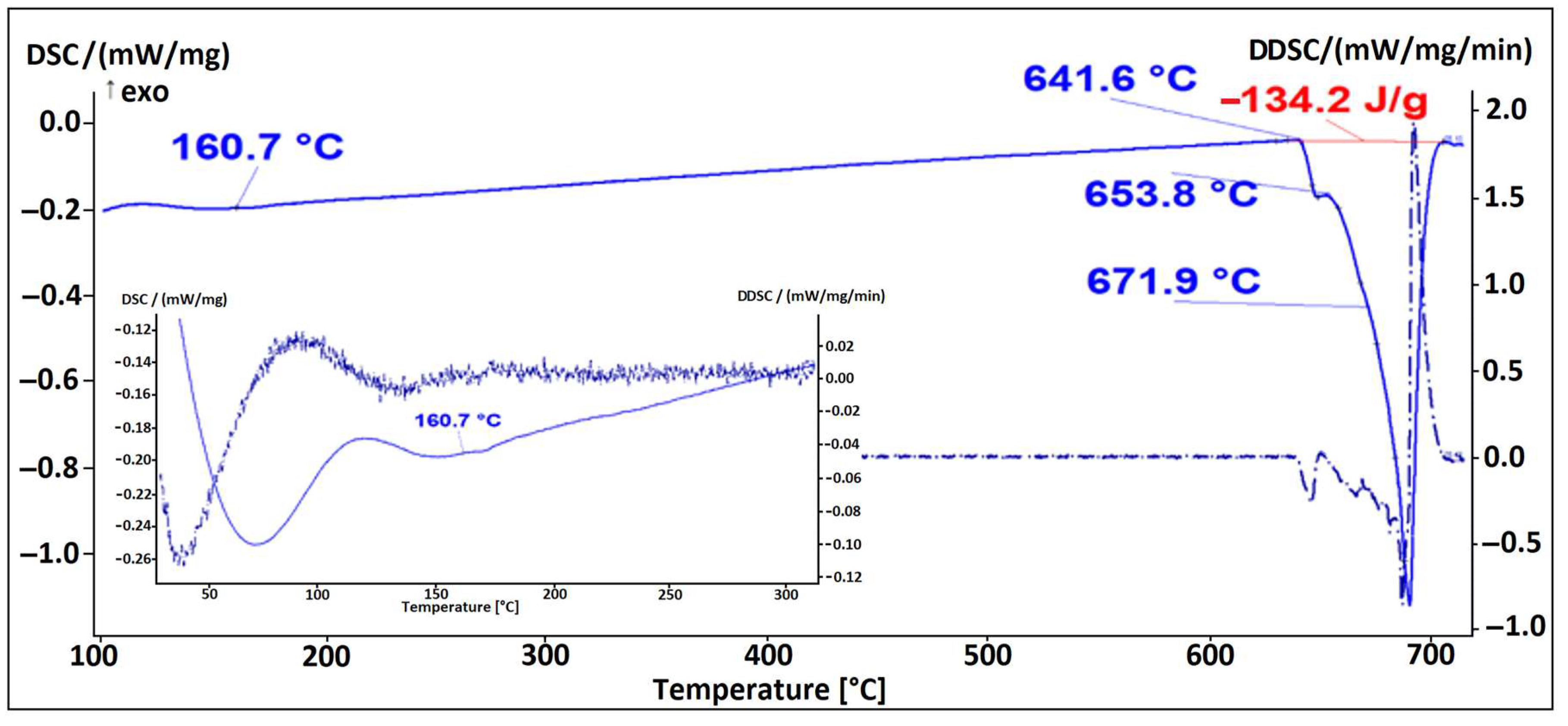

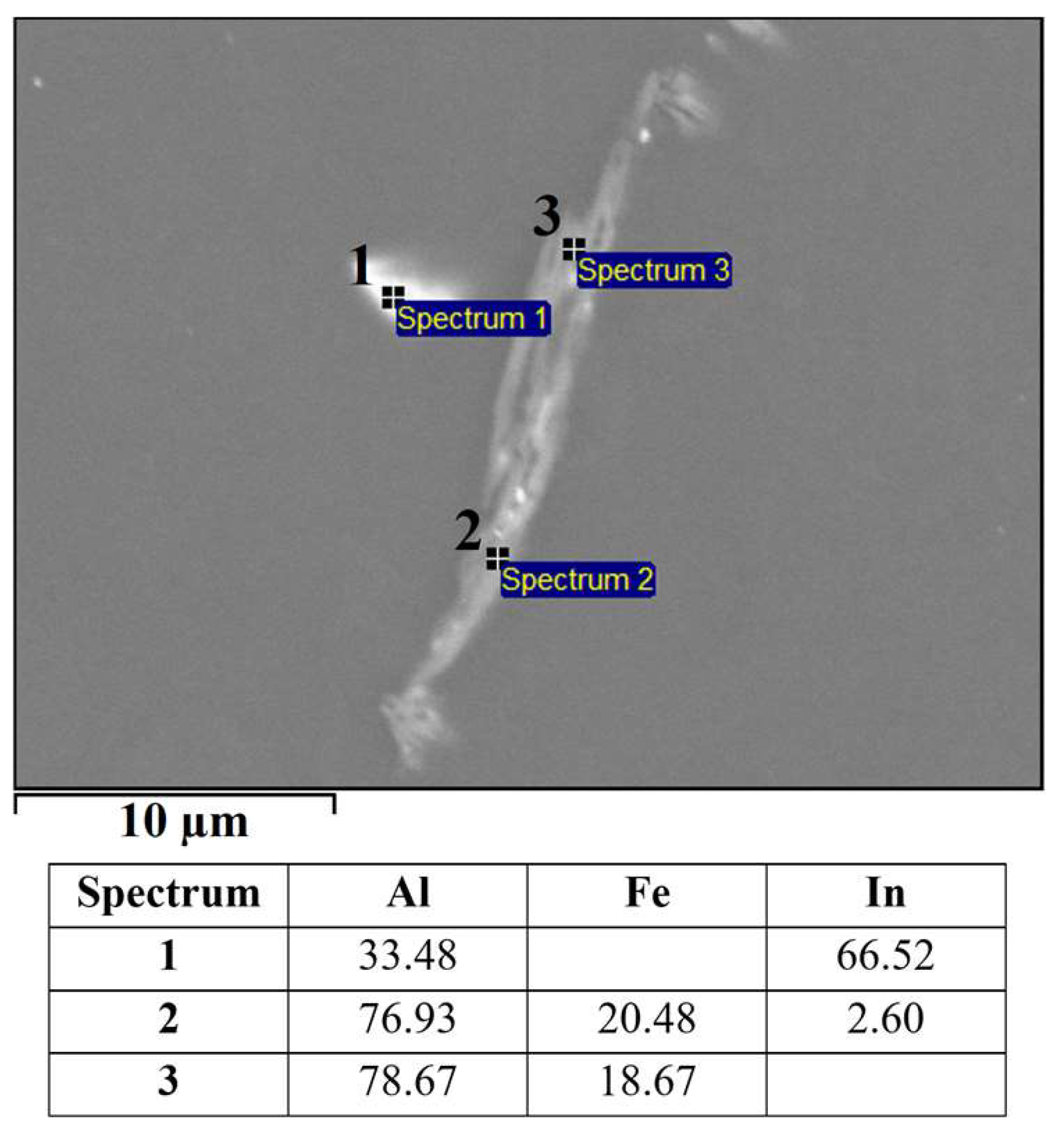

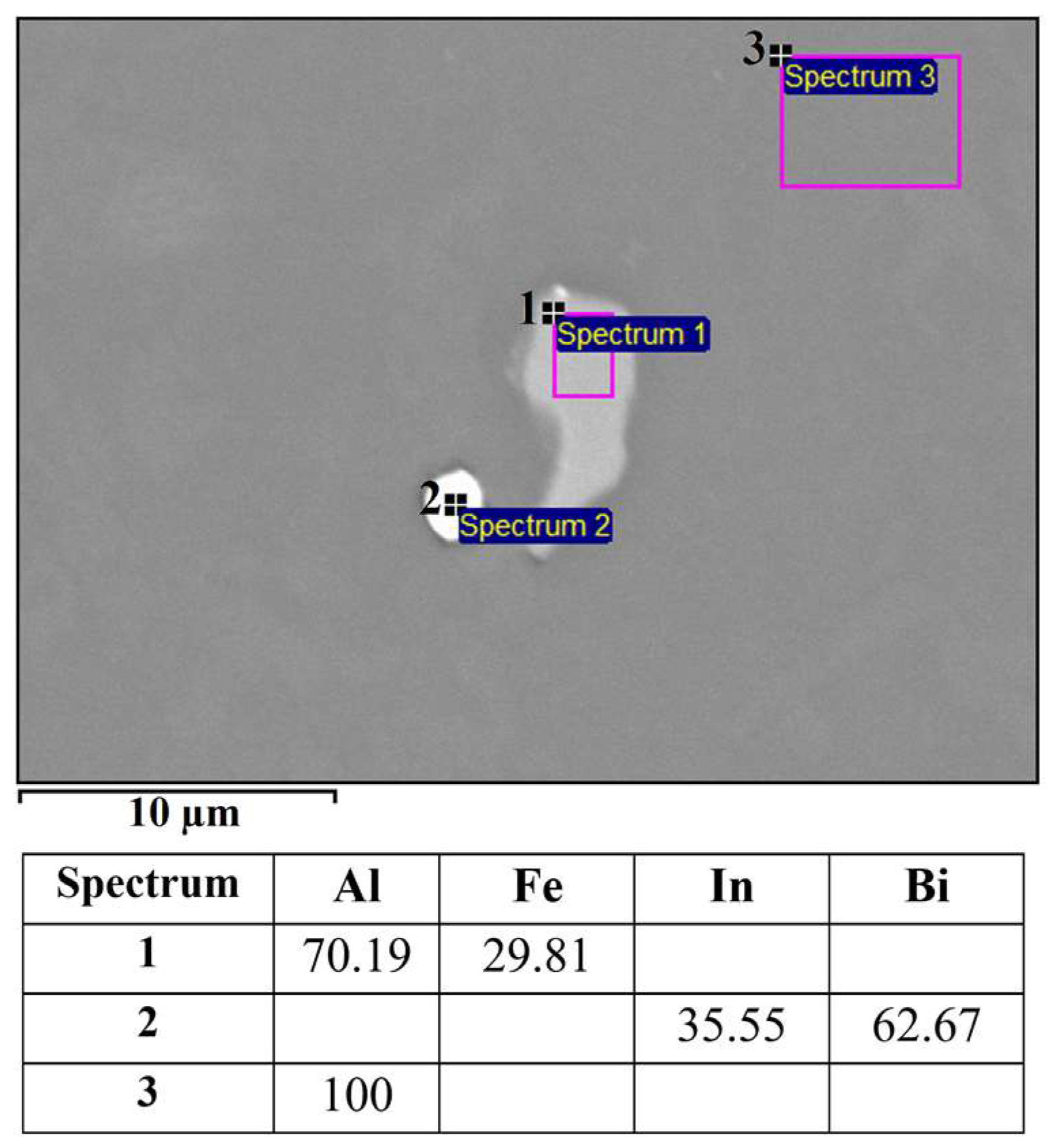

- The microstructure of the alloy EN AW 1370-In consisted of α-Al, Al13Fe4, and pure indium particles, as confirmed via EDS analysis. Differential scanning calorimetry revealed endothermic peaks corresponding to the melting points of pure indium and two eutectics: ternary (α-Al + Al13Fe4 + (Al,In)) at 641.8 °C and binary (α-Al + Al13Fe4) at 653.8 °C, while the α-Al solid solution exhibited a melting point of 671.9 °C.

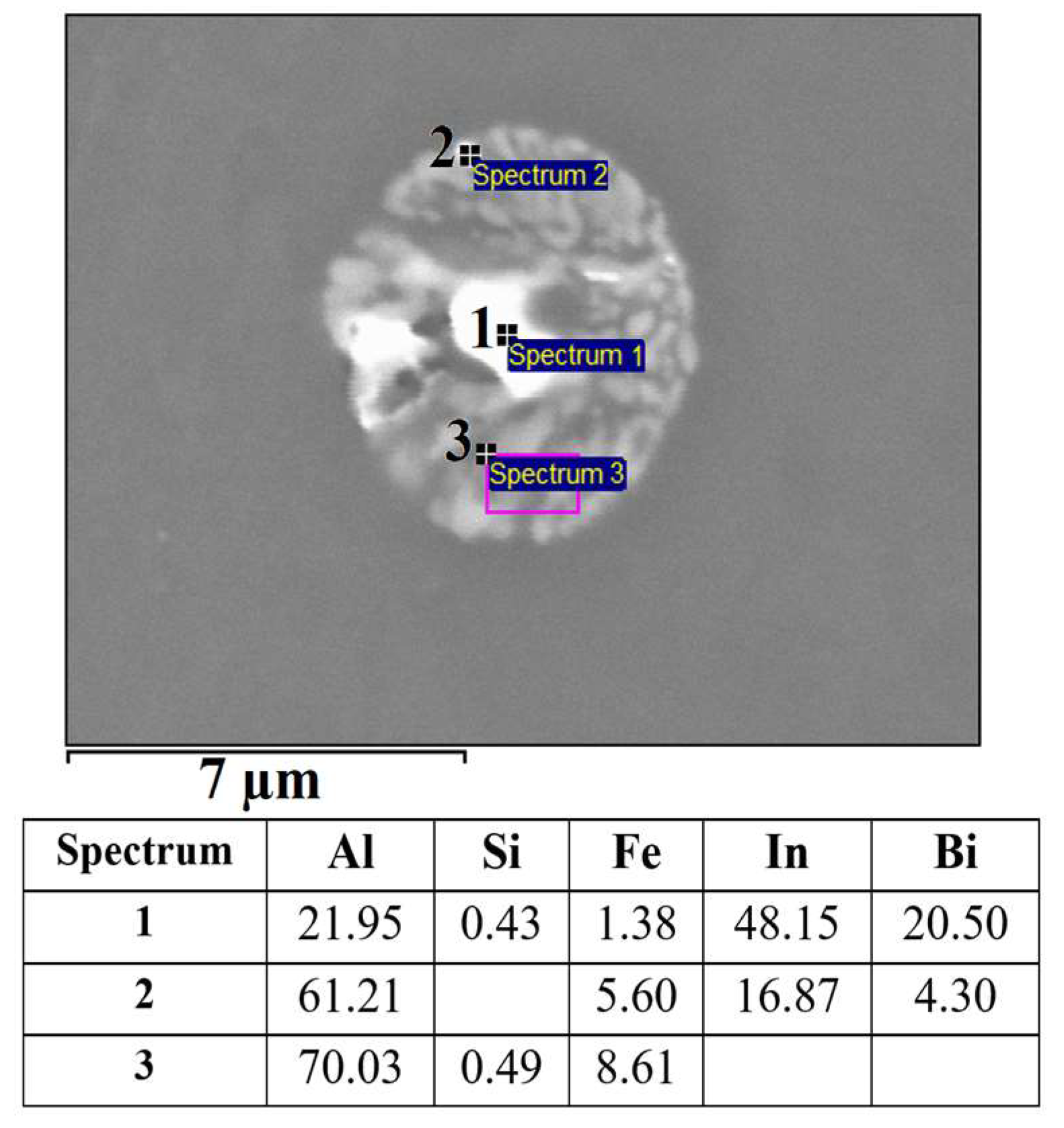

- The microstructure of the alloy EN AW 1370-BiIn consisted of α-Al, Al13Fe4, and a BiIn phase. Thermodynamic calculations suggest the possibility of a ternary eutectic (α-Al + Al8Fe2Si2+ (Al, In, Bi)). On the DSC heating curve, the melting of the BiIn phase was found to occur at 113.7 °C, which is very close to the BiIn phase melting point (109.7 °C) in the equilibrium Bi–In phase diagram. The melting points of the eutectics (α-Al + Al8Fe2Si2 + (Al, In, Bi)) and (α-Al + Al13Fe4) were detected at 646.4 °C and 658.5 °C, respectively, while the α-Al solid solution exhibited a melting point of 683.7 °C.

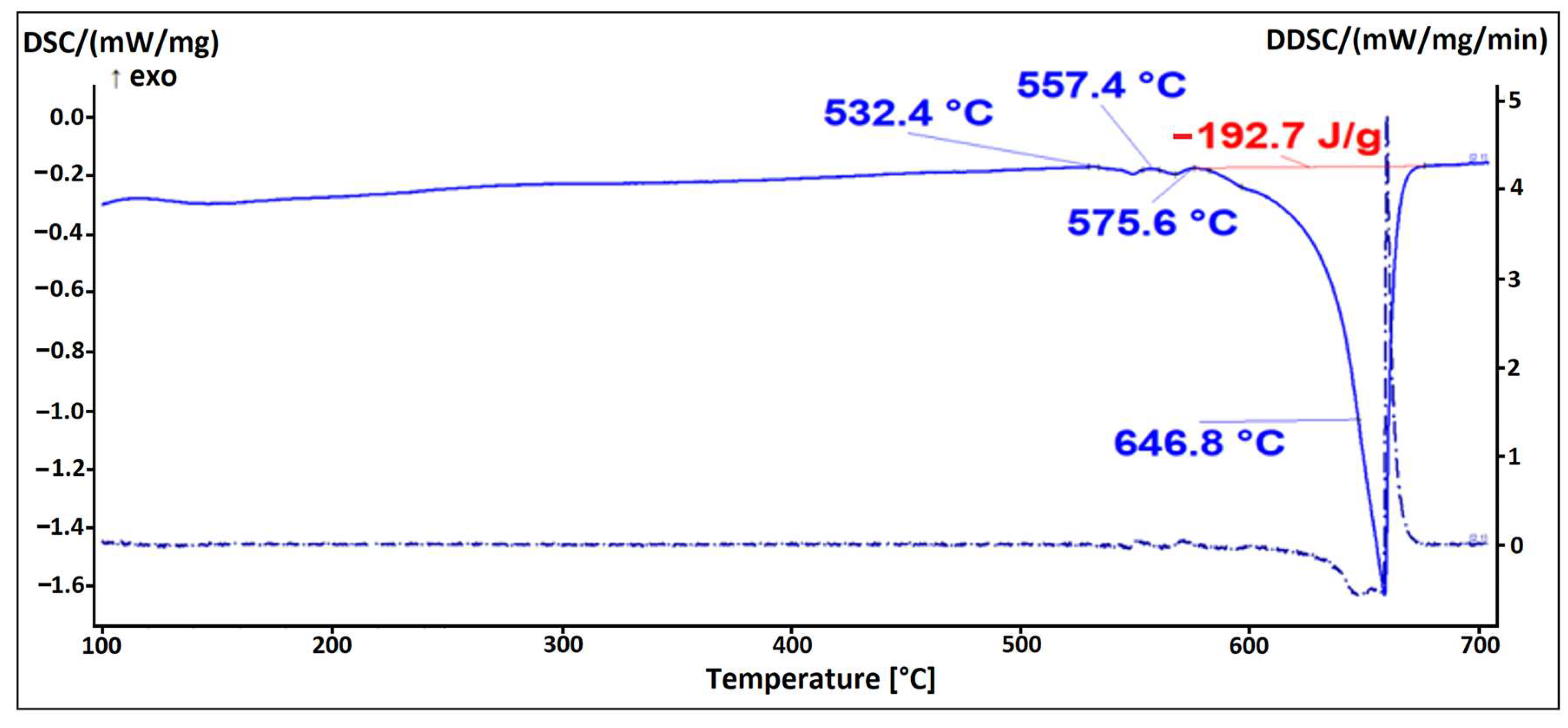

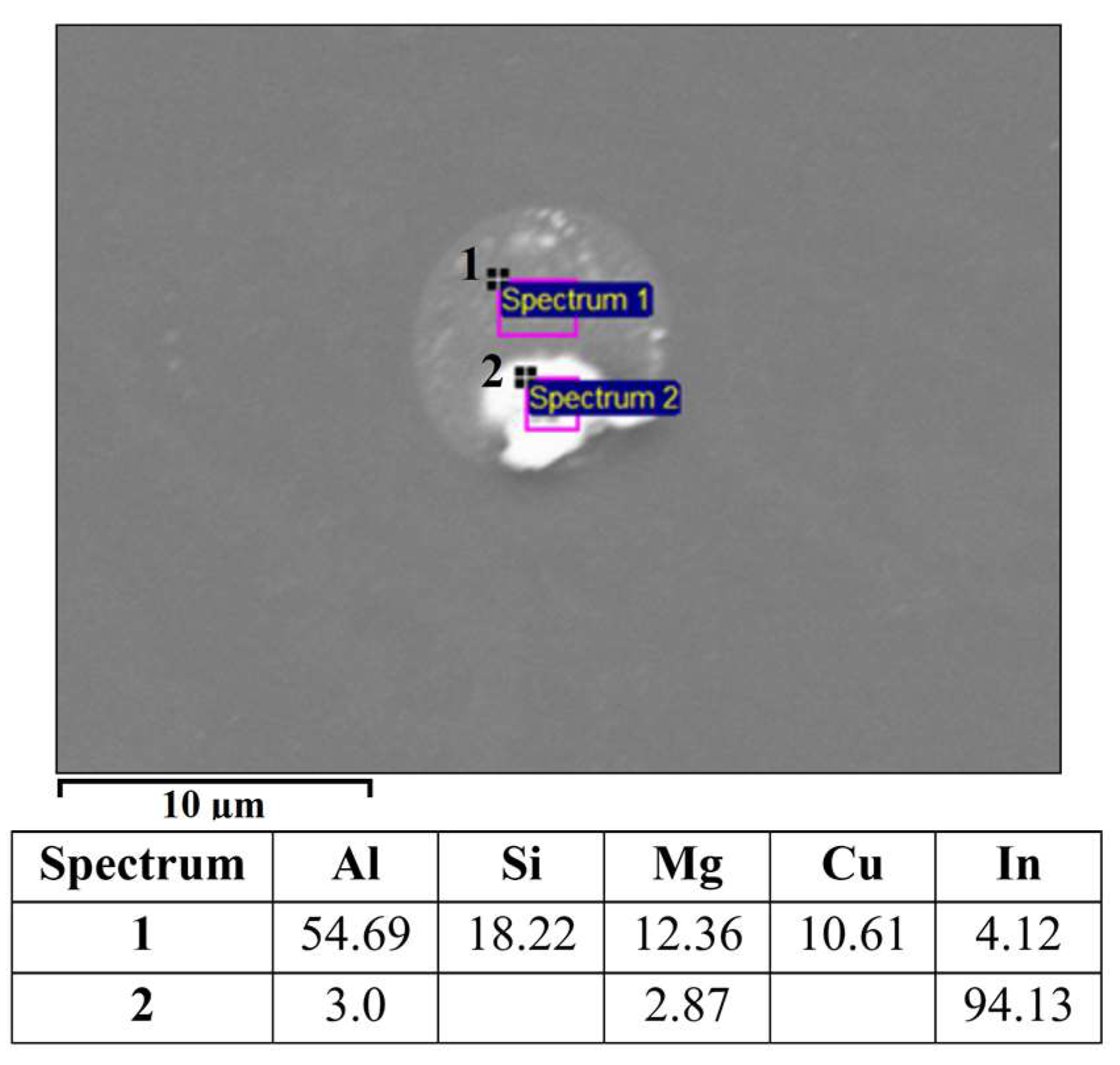

- The microstructure of the alloy EN AW 6026-In exhibited a higher degree of complexity and comprising an α-Al matrix, (α-Al + Al5Cu2Mg8Si6), (α-Al + Mg2Si), and (α-Al + Al15Si2(FeMn)4) binary eutectics as well as particles of elemental indium. Unfortunately, the DSC method could not reliably detect the melting or solidification of indium particles, due to their small number and the low enthalpy of indium. On the DSC heating curve, the initial prominent endothermic peak was seen at 532.4 °C, indicating melting of the (α-Al + Al5Cu2Mg8Si6) eutectic. Other endothermic peaks were observed at temperatures of 557.4 °C and 575.6 °C, indicating the melting of the (α-Al + Mg2Si) and (α-Al + Al15Si2(FeMn)4) eutectics, while the α-Al solid solution exhibited a melting point at 646.8 °C.

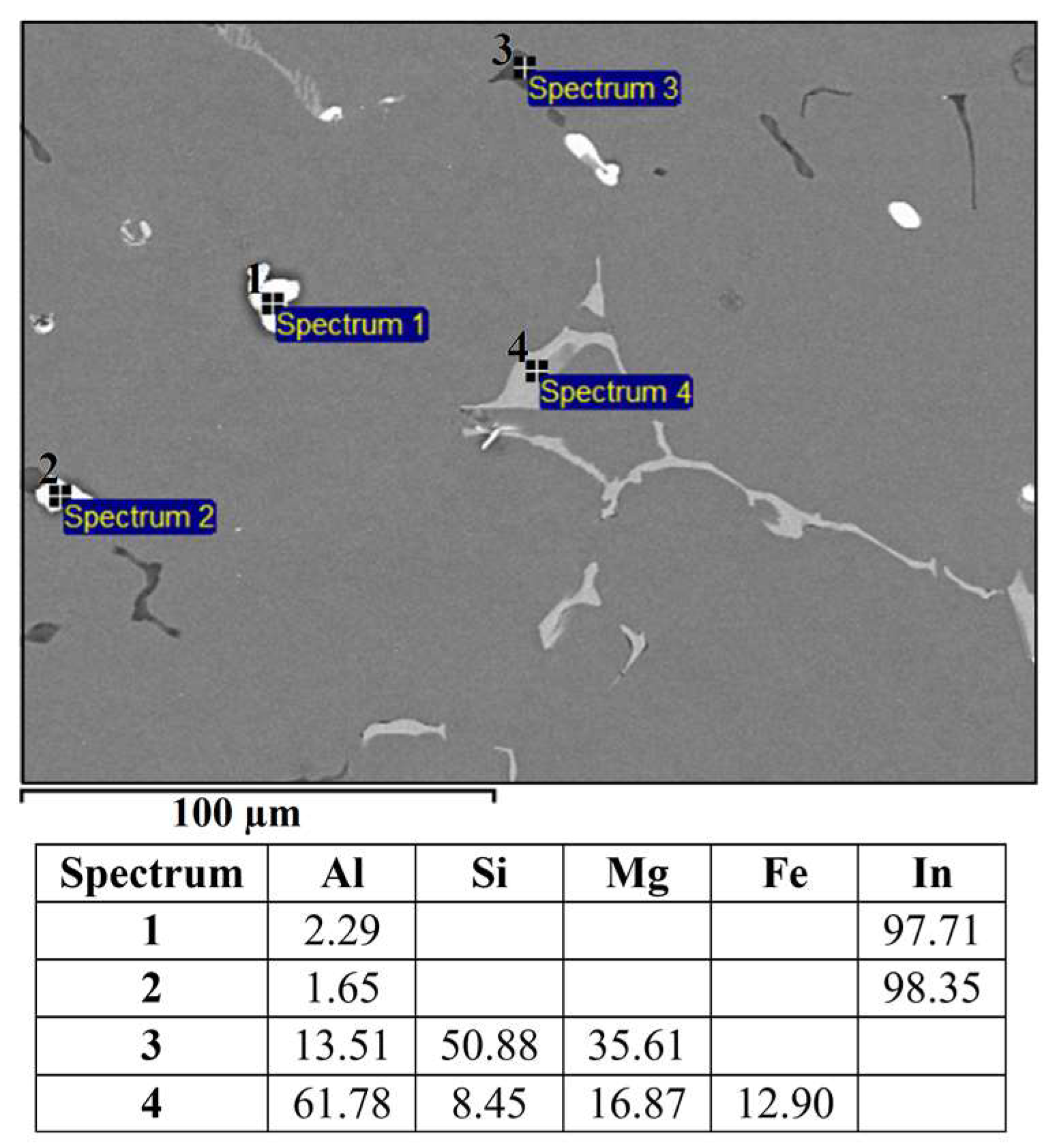

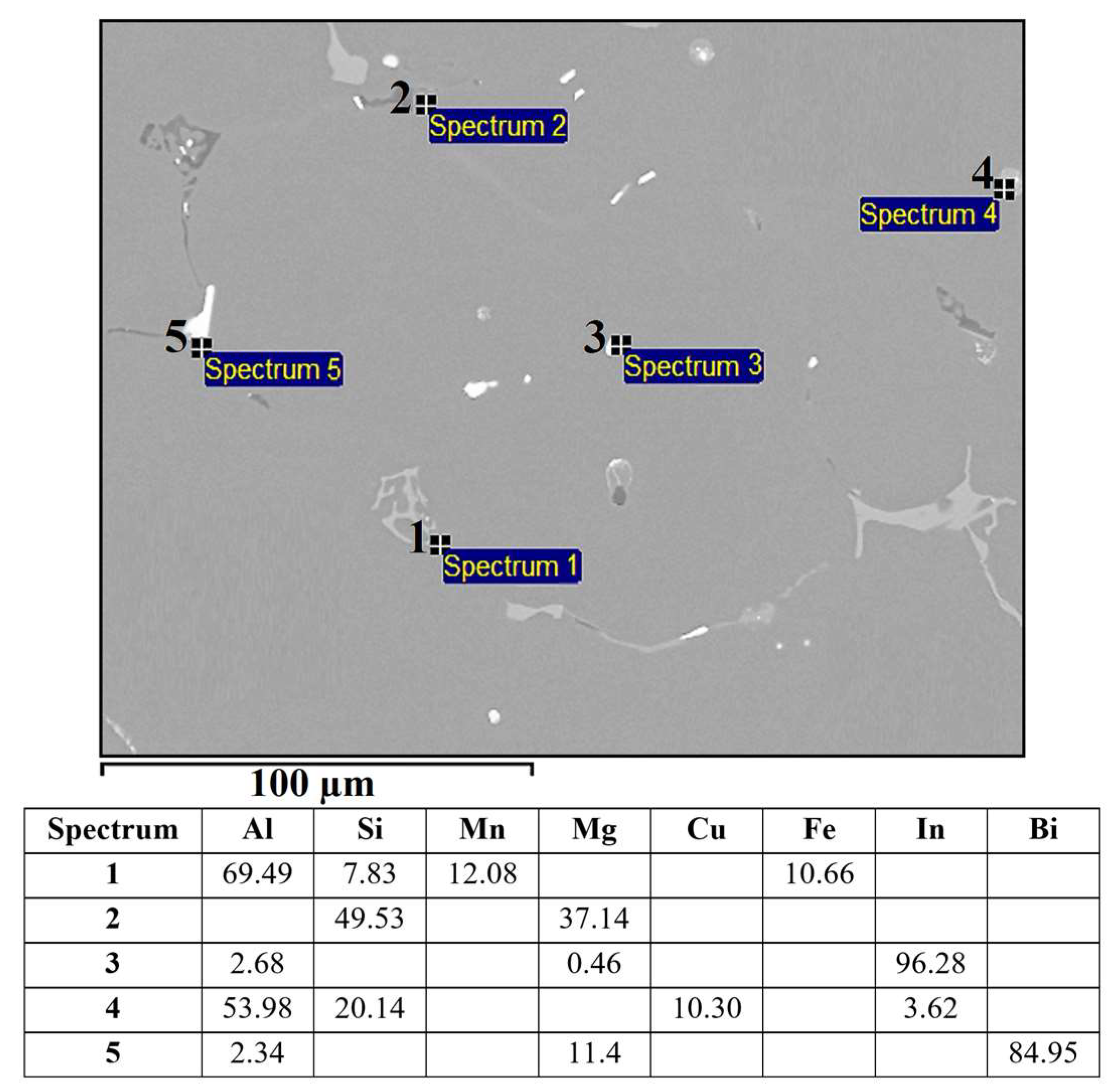

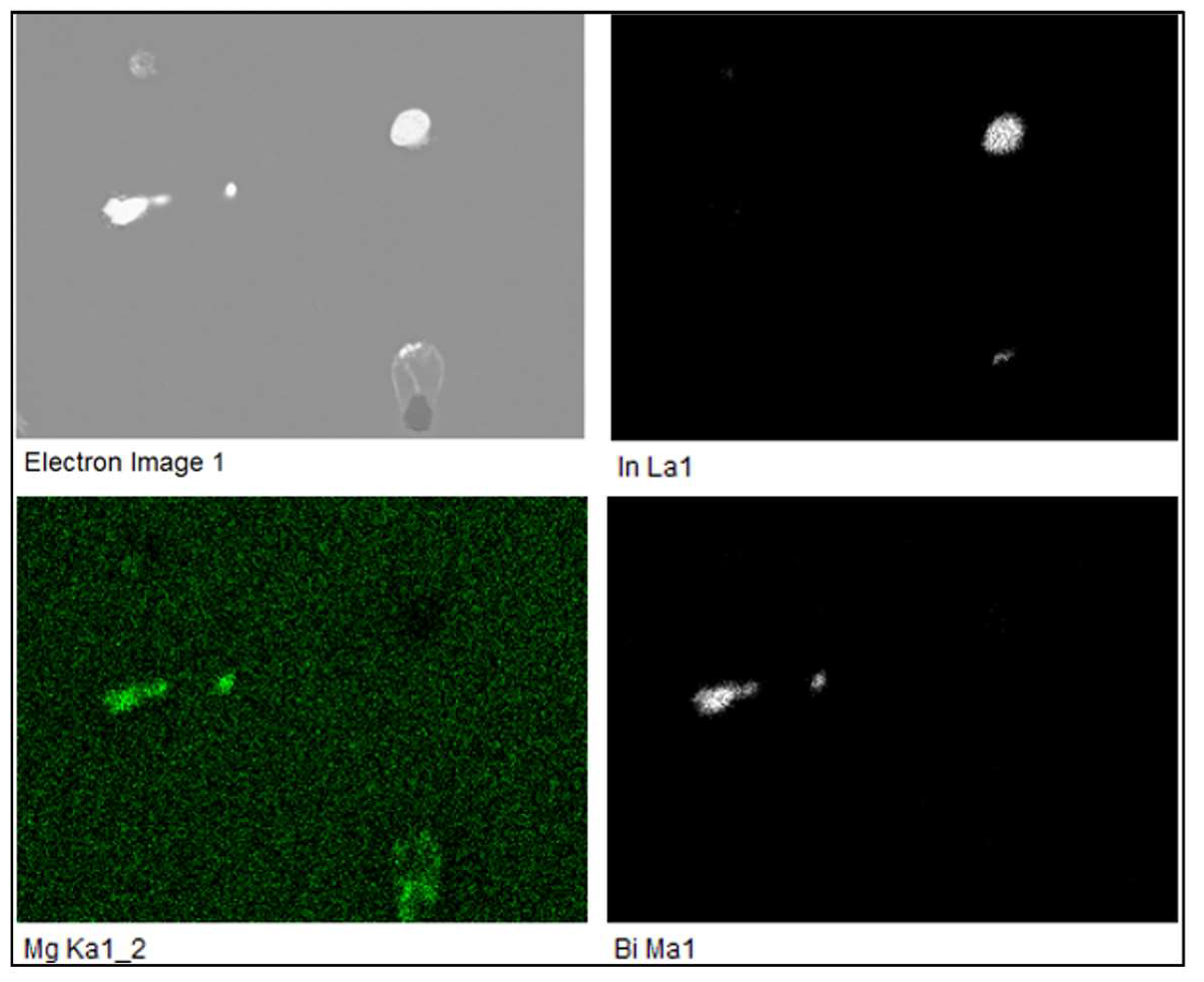

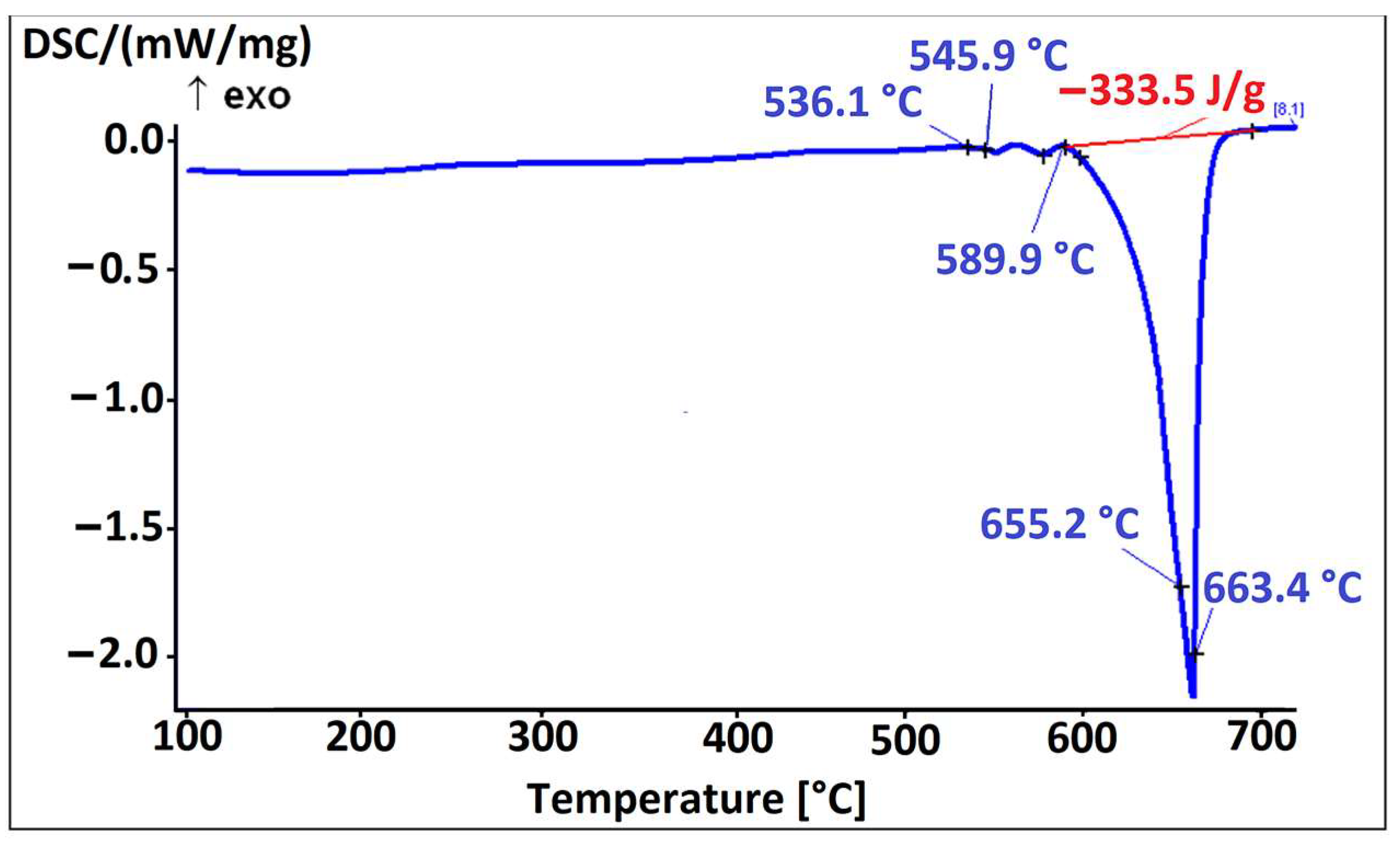

- The microstructure of the alloy EN AW 6026-BiIn consisted of the α-Al matrix; (α-Al + Al5Cu2Mg8Si6), (α-Al + Mg2Si), (α-Al + Mg3Bi2), and (α-Al + Al15Si2(FeMn)4) binary eutectics; and indium in elemental form. EDS mapping demonstrated that indium formed particles in elemental form and did not interact with other elements, while bismuth reacted with magnesium to form the Mg3Bi2 phase and prevent the formation of the BiIn phase. The DSC heating curve did not exhibit any endothermic peaks indicating the presence of the BiIn phase nor any prominent endothermic peaks corresponding to the melting of the indium particles. Instead, phase changes were observed at temperatures of 536.1 °C, 545.9 °C, 589.9 °C, and 655.2 °C and were attributed to the melting of the following eutectics (α-Al + Al5Cu2Mg8Si6), (α-Al + Mg2Si), (α-Al + α-Mg3Bi2), and (α-Al + Al15Si2(FeMn)4), while the α-Al solid solution melted at 663.4 °C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fujda, M.; Matvija, M.; Horňak, P. Effect of Pre-Straining and Natural Aging on the Hardening Response during Artificial Aging of EN AW 6082 and Lead Free EN AW 6023 Aluminium Alloys. Mater. Sci. Forum 2019, 952, 82–91. [Google Scholar] [CrossRef]

- Dubey, R.; Jayaganthan, R.; Ruan, D.; Gupta, N.K.; Jones, N.; Velmurugan, R. Energy absorption and dynamic behaviour of 6xxx series aluminium alloys: A review. Int. J. Impact Eng. 2023, 172, 104397. [Google Scholar] [CrossRef]

- Santos, M.C., Jr.; Machado, A.R.; Sales, W.F.; Barrozo, M.A.S.; Ezugwu, E.O. Machining of aluminum alloys: A review. Int. J. Adv. Manuf. Technol. 2016, 86, 3067–3080. [Google Scholar] [CrossRef]

- Varshney, D.; Kumar, K. Application and use of different aluminium alloys with respect to workability, strength and welding parameter optimization. Ain Shams Eng. J. 2021, 12, 1143–1152. [Google Scholar] [CrossRef]

- Karlík, M.; Faltus, J.; Nejezchlebová, J.; Haušild, P.; Harcuba, P. Characterisation of Al-Cu and Al-Mg-Si Free-Cutting Alloys. Mater. Sci. Forum 2014, 794–796, 1181–1186. [Google Scholar] [CrossRef]

- Timelli, G.; Bonollo, F. Influence of tin and bismuth on machinability of lead free 6000 series aluminium alloys. Mater. Sci. Technol. 2011, 27, 291–299. [Google Scholar] [CrossRef]

- Official Journal of the European Union. Directive 2002/95/EC of the European Parliament and of the Council of 27th January 2003 on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment; Artesyn Technologies, Inc.: Boca Raton, FL, USA, 2005. [Google Scholar]

- Official Journal of the European Union. Directive 2000/53/EG of the European Parliament and of the Council of 18th September 2000 on End-of Life Vehicles (ELV). Off. J. Eur. Union 2020, 269, 34–43. [Google Scholar]

- Shalaby, R.M.; Abdelhakim, N.A.; Kamal, M. Effect of Rapid Solidification on Mechanical Properties of Free Machining Lead Free Aluminum Alloys for Improved Machinability. J. Adv. Phys. 2017, 13, 5155–5166. [Google Scholar]

- Smolej, A.; Breskvar, B.; Sokovic, M.; Dragojevic, V.; Slacek, E.; Smolar, T. Properties of aluminium free-cutting alloys with tin, Part I. Aluminium 2002, 78, 284–288. [Google Scholar]

- Barekar, N.S.; Skalicky, I.; Barbatti, C. Enhancement of chip breakability of aluminium alloys by controlling the solidification during direct chill casting. J. Alloys Compd. 2020, 862, 158008. [Google Scholar] [CrossRef]

- Santos, C.M.; Machado, A.R.; Barrozo, M.A.S. Temperature in Machining of Aluminum Alloys; Open access peer-reviewed chapter; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Dasch, J.M.; Ang, C.C.; Wong, C.A.; Waldo, R.A.; Chester, D.; Cheng, Y.T.; Powell, B.R.; Weiner, A.M.; Konca, E. The effect of free-machining elements on dry machining of B319 aluminum alloy. J. Mater. Process. Technol. 2009, 209, 4638–4644. [Google Scholar] [CrossRef]

- He, C.; Luo, B.; Zheng, Y.; Bai, Z.; Ren, Z. Effect of Sn on microstructure and corrosion behaviors of Al-Mg-Si alloys. Mater. Charact. 2019, 156, 109836. [Google Scholar] [CrossRef]

- Smolej, A.; Breskvar, B.; Sokovic, M.; Dragojevic, V.; Slacek, E.; Smolar, T. Properties of aluminium free-cutting alloys with tin, Part II. Aluminium 2002, 78, 388–391. [Google Scholar]

- Røyset, J.; Sæter, J.A.; Ustad, T.; Reiso, O. Effects of Sn Addition on Microstructure, Extrudability, Mechanical Properties and Machinability of a 6082 Alloy. Mater. Sci. Forum 2002, 396–402, 1205–1210. [Google Scholar] [CrossRef]

- Abdelhakim, N.A.; Shalaby, R.M.; Kamal, M. A Study of Structure, Thermal and Mechanical Properties of Free Machining Al-Zn-Sn-Bi Alloys Rapidly Solidified from Molten State. World J. Eng. Technol. 2018, 6, 637–650. [Google Scholar] [CrossRef][Green Version]

- Faltus, J.; Karlík, M.; Haušild, P. Influence of the chemical composition on the structure and properties of lead-free machinable AA 6023 (Al-Mg-Si-Sn-Bi) alloy. In Proceedings of the 13th International Conference on Aluminum Alloys (ICAA13): TMS (The Minerals, Metals & Materials Society), Pittsburgh, PA, USA, 3–7 June 2012; pp. 1545–1550. [Google Scholar]

- Rečnik, S.; Medved, J.; Kevorkijan, V.M.; Žist, S. An Advanced Industrial Methodology for Optimizing the Properties and the Process of Homogenization for Extruded AA2xxx and AA6xxx. In Light Metals; Eskin, D., Ed.; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Rečnik, S.; Bizjak, M.; Medved, J.; Cvahte, P.; Karpe, B.; Nagode, A. Mechanism of the Mg3Bi2 Phase Formation in Pb-Free Aluminum 6xxx Alloy with Bismuth Addition. Crystals 2021, 11, 424. [Google Scholar] [CrossRef]

- Sircar, S. Free-Machining Aluminum Alloy and Method of Use. U.S. Patent 6315947, 13 November 2001. [Google Scholar]

- Sircar, S. Machineable Aluminum Alloys Containing In and Sn and Process for Producing the Same. U.S. Patent 5587029, 24 December 1996. [Google Scholar]

- Binary Phase Diagrams Database; ASM International: Novelty, OH, USA, 1996.

- Sundman, B.; Kattner, R.U.; Palumbo, M.; Fries, G.S. OpenCalphad—A free thermodynamic software. Integr. Mater. Manuf. Innov. 2015, 4, 1–15. [Google Scholar] [CrossRef]

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 1.134 | 0.201 | 0.332 | 0.747 | 0.825 | 0.016 | 0.028 | 0.017 | Bal. |

| Element | Si | Fe | Cu | Mn | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|

| wt.% | 0.051 | 0.144 | 0.047 | 0.007 | 0.014 | 0.006 | Bal. |

| Designation | Basic Alloy | Content of Added Element in [wt.%] |

|---|---|---|

| EN AW 1370-In | EN AW 1370 | 1 wt.% In |

| EN AW 1370-BiIn | EN AW 1370 | 1 wt.% BiIn |

| EN AW 6026-In | EN AW 6026 | 1 wt.% In |

| EN AW 6026-BiIn | EN AW 6026 | 1 wt.% BiIn |

| Designation | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Bi | In | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EN AW 1370-In | 0.056 | 0.167 | / | 0.007 | 0.002 | 0.001 | 0.009 | 0.002 | / | 1.041 | Bal. |

| EN AW 1370-BiIn | 0.051 | 0.142 | / | 0.006 | 0.001 | 0.001 | 0.007 | 0.001 | 0.664 | 0.373 | Bal. |

| EN AW 6026-In | 1.145 | 0.201 | 0.319 | 0.751 | 0.822 | 0.015 | 0.024 | 0.016 | / | 1.082 | Bal. |

| EN AW 6026-BiIn | 1.113 | 0.244 | 0.324 | 0.774 | 0.832 | 0.016 | 0.021 | 0.014 | 0.684 | 0.321 | Bal. |

| LIQUID = liquid | MG2SI = Mg2Si |

| LIQUID #1 = liquid based on (Al, In, Fe, Si, Mg, ...) | DIAMOND_A4 = β-Si |

| LIQUID #2 = liquid based on (In, Al, …) | AL13CR4SI4 = Al13Cr4Si4 |

| FCC_L12 = α-Al | AL9FE2SI2 = Al9Fe2Si2 |

| FCC_L12#2 = α-Al (Bi) | Q_AlCUMGSI = Al5Cu2Mg8Si6 |

| AL15SI2M4 = Al15Si2(FeMn)4 | RHOMBO_A7 = Bi |

| AL13FE4 = Al13Fe4 | TETRA_A6 = In |

| AL8FE2SI = Al8Fe2Si | HCP_A3 = (In,Zn) |

| AL8FE2SI2 = Al8Fe2Si2 | BCT_A5 = (Al,In) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rečnik, S.; Vončina, M.; Nagode, A.; Medved, J. Thermodynamic and Microstructural Analysis of Lead-Free Machining Aluminium Alloys with Indium and Bismuth Additions. Materials 2023, 16, 6241. https://doi.org/10.3390/ma16186241

Rečnik S, Vončina M, Nagode A, Medved J. Thermodynamic and Microstructural Analysis of Lead-Free Machining Aluminium Alloys with Indium and Bismuth Additions. Materials. 2023; 16(18):6241. https://doi.org/10.3390/ma16186241

Chicago/Turabian StyleRečnik, Simon, Maja Vončina, Aleš Nagode, and Jožef Medved. 2023. "Thermodynamic and Microstructural Analysis of Lead-Free Machining Aluminium Alloys with Indium and Bismuth Additions" Materials 16, no. 18: 6241. https://doi.org/10.3390/ma16186241

APA StyleRečnik, S., Vončina, M., Nagode, A., & Medved, J. (2023). Thermodynamic and Microstructural Analysis of Lead-Free Machining Aluminium Alloys with Indium and Bismuth Additions. Materials, 16(18), 6241. https://doi.org/10.3390/ma16186241