Microstructure Evolution of the Ti-46Al-8Nb-2.5V Alloy during Hot Compression and Subsequent Annealing at 900 °C

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Analysis of Microstructure and Mechanical Properties of the Hot-Compressed TiAl Alloy

3.2. Analysis of Microstructure Evolution of the TiAl Alloy after Hot-Compression and Subsequent Annealing at Service Temperature

4. Conclusions

- The stress-strain curves of Ti-46Al-8Nb-2.5V alloys during hot-compression show typical work-hardening and strain-softening features, with the peak compressive stress positively correlated with the strain rate and negatively correlated with the compression temperature. The alloy undergoes significant DRX during hot-compression, with elevated values of the strain-softening rate and a large number of fine equiaxed crystals in the microstructure;

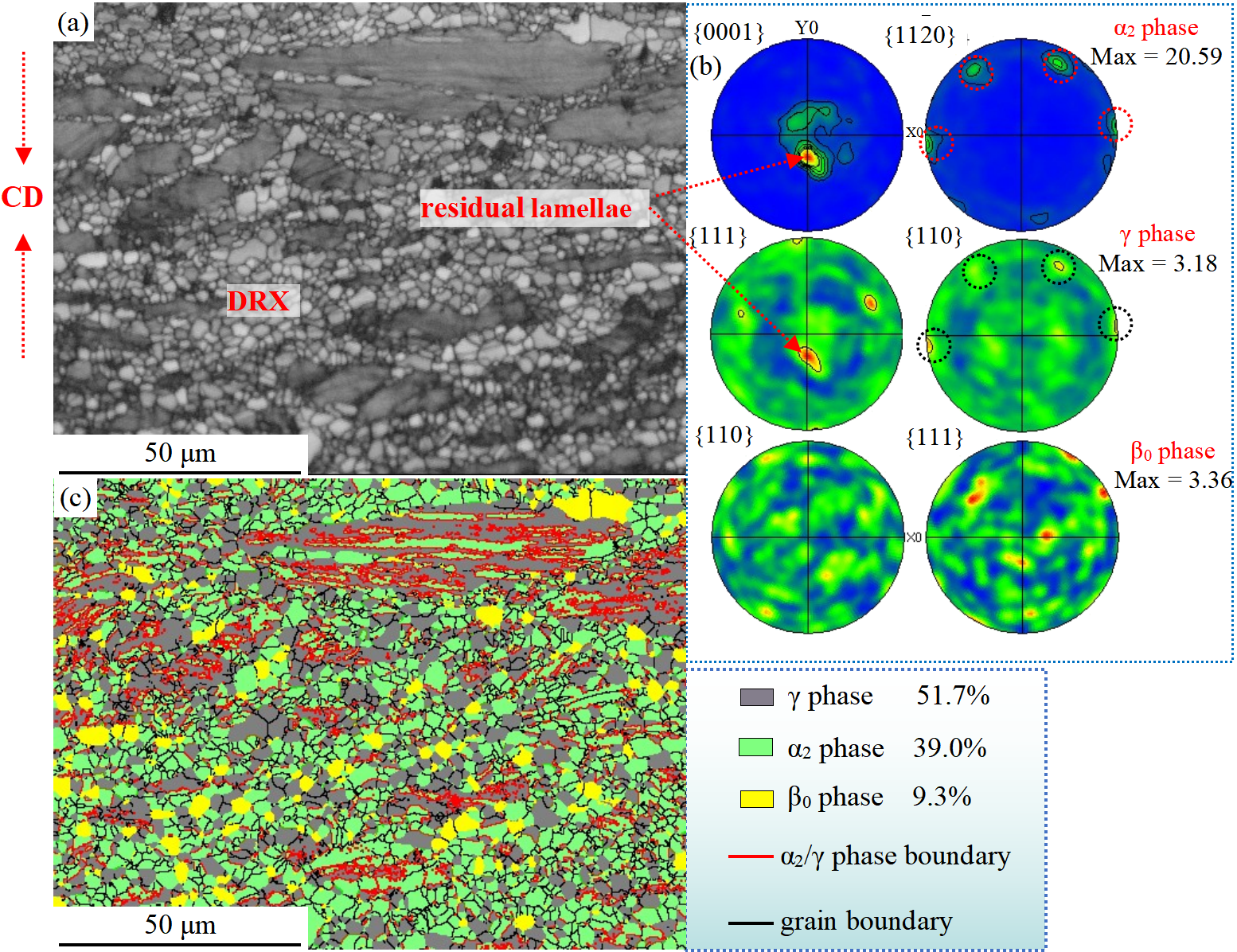

- After hot-compression, the microstructure consists of an equiaxed grain region and a residual lamellar colony region consisting of α2 and γ phases with high internal strain. The volume fractions of the α2 phase, the γ phase, and the β0 phase are 51.7%, 39.0%, and 9.3%, respectively;

- When the hot-compression samples are annealed at 900 °C for 30 min, evident phase transformations occur, and the volume fraction of the α2 phase and the β0 phase decrease to 4.6% and 6.2%, respectively. The volume fraction of the γ phase increased to 89.2%. When the annealing time is extended to 60 min, the microstructure morphology and the volume fraction of the phases did not change significantly. The compressed samples annealed at 900 °C/30 min reached a relatively stable microstructure;

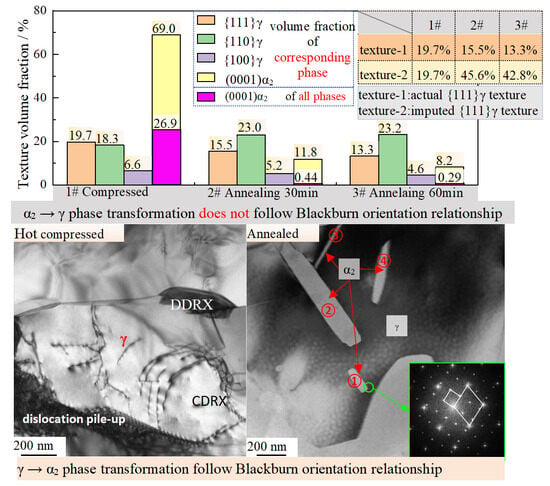

- After hot compression, the α2 phase exhibits a strong (0001)α2 basal plane texture, with a pole figure strength factor of 20.59. The grains with (0001)α2 texture account for 69% of the volume fraction of the α2 phase and 26.9% of all phases. After annealing at 900 °C, a significant α2 → γ phase transformation occurred, but the volume fraction of {111}γ texture did not increase, and the α2 → γ phase transformation did not wholly follow the Blackburn orientation relationship. Additionally, the γ → α2 phase transformation also occurred within the γ phase during the annealing process but followed the Blackburn orientation relationship.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.W. Intermetallic alloys based on gamma titanium aluminide. Jom 1989, 41, 24–30. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Tetsui, T. Effect of Microstructure on Impact Resistance and Machinability of TiAl Alloys for Jet Engine Turbine Blade Applications. Metals 2023, 13, 1235. [Google Scholar] [CrossRef]

- Chen, Y.; Niu, H.; Kong, F.; Xiao, S. Microstructure and fracture toughness of a β phase containing TiAl alloy. Intermetallics 2011, 19, 1405–1410. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Intermetallic titanium aluminides in aerospace applications–processing, microstructure and properties. Mater. High Temp. 2016, 33, 560–570. [Google Scholar] [CrossRef]

- Cao, S.Z.; Xiao, S.L.; Chen, Y.Y.; Xu, L.J.; Wang, X.P.; Han, J.C.; Jia, Y. Phase transformations of the L12-Ti3Al phase in γ-TiAl alloy. Mater. Des. 2017, 121, 61–68. [Google Scholar] [CrossRef]

- Tetsui, T. Practical use of hot-forged-type Ti-42Al-5Mn and various recent improvements. Metals 2021, 11, 1361. [Google Scholar] [CrossRef]

- Shaaban, A.; Signori, L.J.; Nakashima, H.; Takeyama, M. Effects of the addition of transition metals on phase equilibria and phase transformations in TiAl systems in between 1473 and 1073 K. J. Alloys Compd. 2021, 878, 160392. [Google Scholar] [CrossRef]

- Duan, B.; Yang, Y.; He, S.; Feng, Q.; Mao, L.; Zhang, X.; Jiao, L.; Lu, X.; Chen, G.; Li, C. History and development of γ-TiAl alloys and the effect of alloying elements on their phase transformations. J. Alloys Compd. 2022, 909, 164811. [Google Scholar] [CrossRef]

- Janschek, P. Wrought TiAl blades. Mater. Today Proc. 2015, 2, S92–S97. [Google Scholar] [CrossRef]

- Ye, X.C.; Xiao, K.Q.; Cao, R.X.; Wu, H.; Zhao, G.-W.; Li, B. Microstructure evolution and microhardness of TiAl based alloy blade by vacuum suction casting. Vacuum 2019, 163, 186–193. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Tang, B.; Song, L.; Wang, W.Y.; Liu, D.; Yang, R.; Kou, H. Decomposition and phase transformation mechanisms of α2 lamellae in β-solidified γ-TiAl alloys. Acta Mater. 2023, 242, 118492. [Google Scholar] [CrossRef]

- Zong, Y.Y.; Wen, D.S.; Guo, B.; Shan, D.B. Investigations of hydrogen-promoted α2-lamella decomposition of a γ-TiAl based alloy. Mater. Lett. 2015, 152, 196–199. [Google Scholar] [CrossRef]

- Dai, C.; Yang, Z.; Sun, J.; Lu, S.; Vitos, L. Composition and temperature dependence of α2 phase decomposition in high Nb-containing lamellar γ-TiAl alloys: Experiments and first-principles calculations. Acta Mater. 2021, 221, 117419. [Google Scholar] [CrossRef]

- Huang, Z.W.; Cong, T. Microstructural instability and embrittlement behaviour of an Al-lean, high-Nb γ-TiAl-based alloy subjected to a long-term thermal exposure in air. Intermetallics 2010, 18, 161–172. [Google Scholar] [CrossRef]

- Huang, Z.W. Thermal stability of Ti–44Al–4Nb–4Zr–0.2 Si–1B alloy. Intermetallics 2013, 42, 170–179. [Google Scholar] [CrossRef]

- Huang, Z.W. Thermal stability of Ti-44Al-4Nb-4Hf-0.2 Si-1B alloy. Intermetallics 2013, 37, 11–21. [Google Scholar] [CrossRef]

- Huang, Z.W.; Zhu, D.G. Thermal stability of Ti–44Al–8Nb–1B alloy. Intermetallics 2008, 16, 156–167. [Google Scholar] [CrossRef]

- Schuster, J.C.; Palm, M. Reassessment of the binary aluminum-titanium phase diagram. J. Phase Equilibria Diffus. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Song, L.; Lin, J.; Li, J. Phase transformation mechanisms in a quenched Ti-45Al-8.5 Nb-0.2 W-0.2 B-0.02 Y alloy after subsequent annealing at 800 °C. J. Alloys Compd. 2017, 691, 60–66. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Wu, M.; Ye, Z.H.; Wang, Q.; Gu, J.F. Atypical pathways for lamellar and twinning transformations in rapidly solidified TiAl alloy. Acta Mater. 2022, 227, 117718. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C.; Hou, Z.; Kong, F.; Chen, Y. Effects of rolling deformation on microstructure and hardness of Ti-45Al-9Nb-0.3 Y alloy. J. Rare Earths 2016, 34, 197–202. [Google Scholar] [CrossRef]

- Niu, H.Z.; Kong, F.T.; Xiao, S.L.; Chen, Y.Y.; Yang, F. Effect of pack rolling on microstructures and tensile properties of as-forged Ti-44Al-6V-3Nb-0.3 Y alloy. Intermetallics 2012, 21, 97–104. [Google Scholar] [CrossRef]

- Li, X.; Hao, X.U.; Xing, W.; Chen, B.; Shu, L.; Zhang, M.-S.; Liu, K. Microstructural evolution and mechanical properties of forged β-solidified γ-TiAl alloy by different heat treatments. Trans. Nonferrous Metals Soc. China 2022, 32, 2229–2242. [Google Scholar] [CrossRef]

- Zhang, S.; Ren, R.; Han, J.; Zhang, C. The twins of α2 phase in β-solidifying TiAl alloy during high strain rate rolling. Mater. Lett. 2023, 333, 133590. [Google Scholar] [CrossRef]

- Cao, G.H.; Russell, A.M.; Oertel, C.G.; Skrotzki, W. Microstructural evolution of TiAl-based alloys deformed by high-pressure torsion. Acta Mater. 2015, 98, 103–112. [Google Scholar] [CrossRef]

- Liang, Z.; Xiao, S.; Li, Q.; Li, X.; Chi, D.; Zheng, Y.; Xu, L.; Xue, X.; Tian, J.; Chen, Y. Creep behavior and related phase precipitation of a creep-resistant Y2O3-bearing high Nb containing TiAl alloy. Mater. Charact. 2023, 198, 112767. [Google Scholar] [CrossRef]

- Ilyas, M.U.; Kabir, M.R. Creep behaviour of two-phase lamellar TiAl: Crystal plasticity modelling and analysis. Intermetallics 2021, 132, 107129. [Google Scholar] [CrossRef]

- Xu, X.; Ding, H.; Huang, H.; Liang, H.; Ramanujan, R.; Chen, R.; Guo, J.; Fu, H. Twinning-induced dislocation and coordinated deformation behavior of a high-Nb TiAl alloy during high-cycle fatigue. Int. J. Fatigue 2023, 171, 107597. [Google Scholar] [CrossRef]

- Sun, G.; Cao, R.; Zhou, X.; Jiang, X.X.; Wang, H. Effect of stress ratio on high cycle fatigue behavior of TNM-TiAl alloy. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 3609–3621. [Google Scholar] [CrossRef]

- Tian, S.; He, A.; Liu, J.; Zhang, Y.; Zhang, S.; Zhang, Y.; Yang, Y.G.; Jiang, H. Investigation on the microstructure evolution and dynamic recrystallization mechanisms of TiAl alloy at elevated temperature. J. Mater. Res. Technol. 2021, 14, 968–984. [Google Scholar] [CrossRef]

- Yang, K.; Yang, Z.J.; Deng, P.; Chen, Y.Z.; Huang, Z.W.; Sun, H.L. Microstructure and mechanical properties of as-cast γ-TiAl alloys with different cooling rates. J. Mater. Eng. Perform. 2019, 28, 2271–2280. [Google Scholar] [CrossRef]

- Ma, T.; Li, S.; Wang, Y.; Wang, X.; Dong, D.; Zhu, D. Phase transformation and dynamic recrystallization behavior of forged beta gamma TiAl alloy in variable thermomechanical conditions. J. Mater. Res. Technol. 2022, 18, 4796–4803. [Google Scholar] [CrossRef]

- Li, J.; Hu, R.; Zhou, M.; Gao, Z.; Wu, Y.; Luo, X. High temperature micro-deformation behavior of continuous TiNb fiber reinforced TiAl matrix composite investigated by in-situ high-energy X-ray diffraction. Mater. Sci. Eng. A 2022, 846, 143255. [Google Scholar] [CrossRef]

- Yang, W.; Li, M.; Zhou, T.; Hu, L.; Shi, L.; Xiao, S.; Chen, Y. Deformation behavior and dynamic recrystallization mechanism of a novel high Nb containing TiAl alloy in (α + γ) dual-phase field. J. Alloys Compd. 2023, 945, 169250. [Google Scholar] [CrossRef]

- Niu, H.Z.; Chen, Y.Y.; Xiao, S.L.; Xu, L.J. Microstructure evolution and mechanical properties of a novel beta γ-TiAl alloy. Intermetallics 2012, 31, 225–231. [Google Scholar] [CrossRef]

- Cheng, L.; Zhu, B.; Yang, G.; Qiang, F.; Li, J. Insights into the abnormal flow softening of lamellar γ-TiAl alloys during hot-working: Experimental analysis and numerical simulation. Mater. Sci. Eng. A 2022, 852, 143695. [Google Scholar] [CrossRef]

- Zhou, M.; Hu, R.; Li, J.; Yang, C.; Liu, H.; Luo, X. Investigations of interfacial reaction and toughening mechanisms of Ta fiber-reinforced TiAl-matrix composites. Mater. Charact. 2022, 183, 111584. [Google Scholar] [CrossRef]

- Musi, M.; Kardos, S.; Hatzenbichler, L.; Holec, D.; Stark, A.; Allen, M.; Güther, V.; Clemens, H.; Spoerk-Erdely, P. The effect of zirconium on the Ti-(42–46 at.%) Al system. Acta Mater. 2022, 241, 118414. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, C.; Meng, Z.; Zhao, G.; Chen, L. Atomic diffusion mechanism and interface nanomechanics in the Al/Ti composite structures. Compos. Part B Eng. 2022, 230, 109507. [Google Scholar] [CrossRef]

- Epifano, E.; Hug, G.; Connétable, D. Insertion and diffusion of N and C in γ–TiAl: Theoretical study and comparison with O. Phys. B Condens. Matter 2022, 624, 413370. [Google Scholar] [CrossRef]

- Gao, Z.; Hu, R.; Huang, Z.; Wu, Y.; Li, J.; Zhou, M. Metastable transformation behavior in a Ta-containing TiAl-Nb alloy during continuous cooling. J. Alloys Compd. 2022, 904, 164088. [Google Scholar] [CrossRef]

- Genc, O.; Unal, R. Development of gamma titanium aluminide (γ-TiAl) alloys: A review. J. Alloys Compd. 2022, 929, 167262. [Google Scholar] [CrossRef]

- Cao, S.; Han, J.; Wang, H.; Xiao, S.; Xu, L.; Chen, Y. Effects of cycle heat treatment on the microstructure and mechanical property of as-cast γ-TiAl alloy. Mater. Sci. Eng. A 2022, 857, 144053. [Google Scholar] [CrossRef]

- Xu, R.; Li, M.; Zhao, Y. A review of microstructure control and mechanical performance optimization of γ-TiAl alloys. J. Alloys Compd. 2022, 932, 167611. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, D.L.; Jiang, D.P.; Han, X.-L.; Wang, Q.; Wu, G.-H. Microstructural characteristics and evolution of Ti2AlN/TiAl composites with a network reinforcement architecture during reaction hot pressing process. Mater. Charact. 2013, 80, 28–35. [Google Scholar] [CrossRef]

- Li, D.; Zhang, G.; Lu, G.; Liu, Y.; Wang, J.; Liu, C. Precipitation of Ti2Al phases at lamellar interfaces in a high-Nb-containing TiAl alloy during thermal exposure. J. Mater. Sci. Technol. 2022, 126, 132–140. [Google Scholar] [CrossRef]

- Gao, Y.; Kou, S.; Dai, J.; Wang, Z.-F.; Shu, S.-L.; Zhang, S.; Qiu, F.; Jiang, Q.-C. Microstructural configuration and compressive deformation behavior of a TiAl composite reinforced by Mn and in situ Ti2AlC particles. Mater. Sci. Eng. A 2021, 823, 141772. [Google Scholar] [CrossRef]

- He, L.L.; Ye, H.Q.; Xu, R.G.; Yang, D.Z. The structure of the Ti2Al phase and its relationship with TiAl and Ti3Al phases in the intermetallic compound Ti48. 3Al51. 7. Mater. Lett. 1994, 19, 17–21. [Google Scholar] [CrossRef]

- Menand, A.; Huguet, A.; Nérac-Partaix, A. Interstitial solubility in γ and α2 phases of TiAl-based alloys. Acta Mater. 1996, 44, 4729–4737. [Google Scholar] [CrossRef]

- Kawabata, T.; Tadano, M.; Izumi, O. Effect of carbon and nitrogen on mechanical properties of TiAl alloys. ISIJ Int. 1991, 31, 1161–1167. [Google Scholar] [CrossRef]

- Menand, A.; Zapolsky-Tatarenko, H.; Nérac-Partaix, A. Atom-probe investigations of TiAl alloys. Mater. Sci. Eng. A 1998, 250, 55–64. [Google Scholar] [CrossRef]

- Huguet, A.; Menand, A. Atom-probe determination of interstitial element concentration in two-phase and single-phase TiAl-based alloys. Appl. Surf. Sci. 1994, 76, 191–197. [Google Scholar] [CrossRef]

| Strain Rate | η Value | Temperature | η Value |

|---|---|---|---|

| 1 s−1 | 41.47% | 1523 K | 73.77% |

| 0.1 s−1 | 52.35% | 1473 K | 69.78% |

| 0.01 s−1 | 71.96% | 1423 K | 64.91% |

| 0.001 s−1 | 59.46% | 1373 K | 59.46% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, S.; Li, Z.; Pu, J.; Han, J.; Dong, Q.; Zhu, M. Microstructure Evolution of the Ti-46Al-8Nb-2.5V Alloy during Hot Compression and Subsequent Annealing at 900 °C. Materials 2023, 16, 6176. https://doi.org/10.3390/ma16186176

Cao S, Li Z, Pu J, Han J, Dong Q, Zhu M. Microstructure Evolution of the Ti-46Al-8Nb-2.5V Alloy during Hot Compression and Subsequent Annealing at 900 °C. Materials. 2023; 16(18):6176. https://doi.org/10.3390/ma16186176

Chicago/Turabian StyleCao, Shouzhen, Zongze Li, Jiafei Pu, Jianchao Han, Qi Dong, and Mingdong Zhu. 2023. "Microstructure Evolution of the Ti-46Al-8Nb-2.5V Alloy during Hot Compression and Subsequent Annealing at 900 °C" Materials 16, no. 18: 6176. https://doi.org/10.3390/ma16186176

APA StyleCao, S., Li, Z., Pu, J., Han, J., Dong, Q., & Zhu, M. (2023). Microstructure Evolution of the Ti-46Al-8Nb-2.5V Alloy during Hot Compression and Subsequent Annealing at 900 °C. Materials, 16(18), 6176. https://doi.org/10.3390/ma16186176