Gray Model Study of Strength and Pore Structure of Recycled Concrete Powder (RCP) Concrete Based on Low-Field NMR Technology

Abstract

:1. Introduction

2. Experimental

2.1. Raw Materials

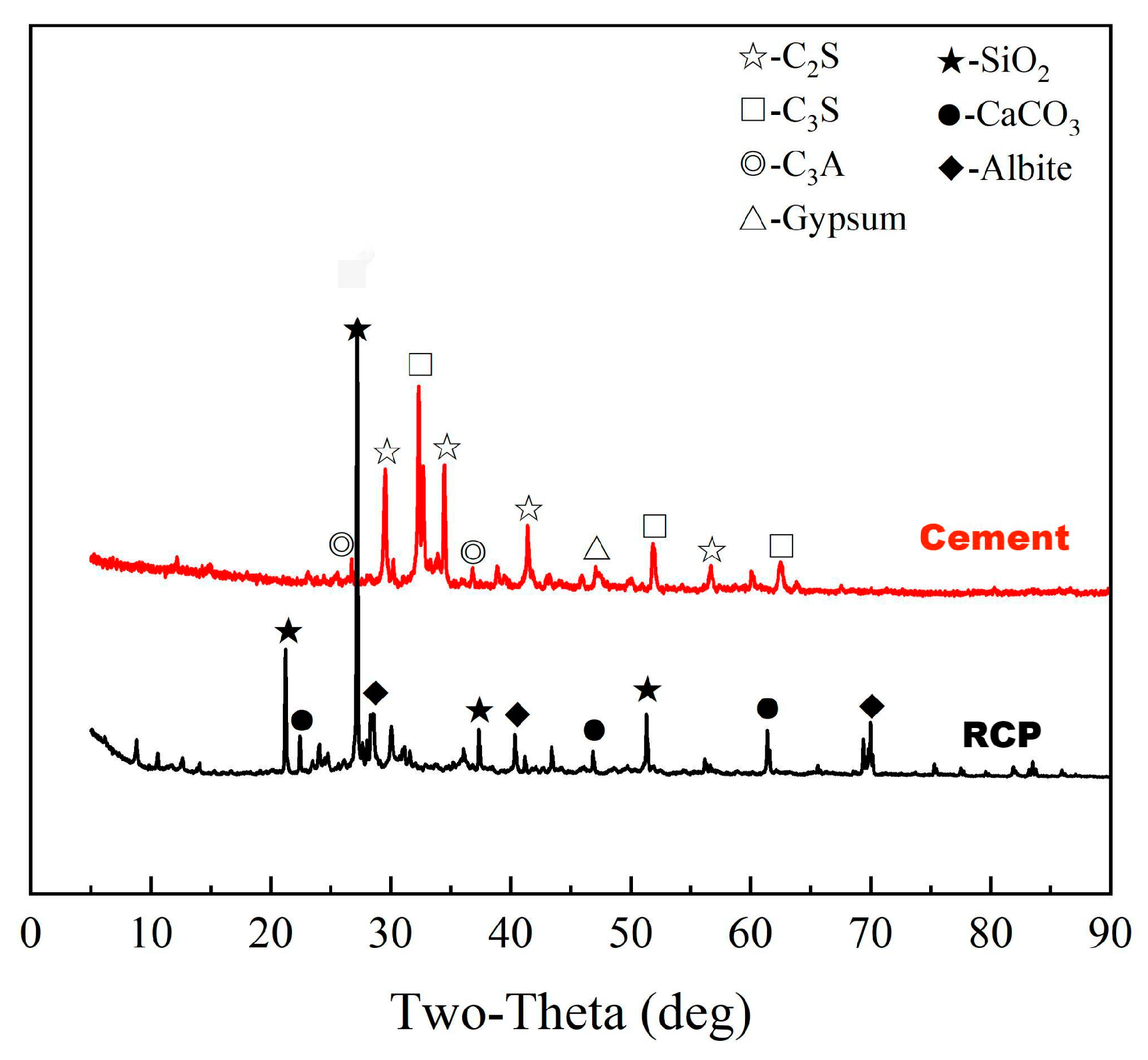

2.1.1. Cementitious Materials

2.1.2. Fine Aggregate and Coarse Aggregate

2.1.3. Others

2.2. Preparation of the Recycled Powder Concrete Samples

2.2.1. Mixing Proportions

2.2.2. Sample Preparation

2.3. Test Methods

2.3.1. Compressive Strength Test

2.3.2. Flexural Tensile Strength Test

2.3.3. Low-Field NMR Test

3. Results and Discussion

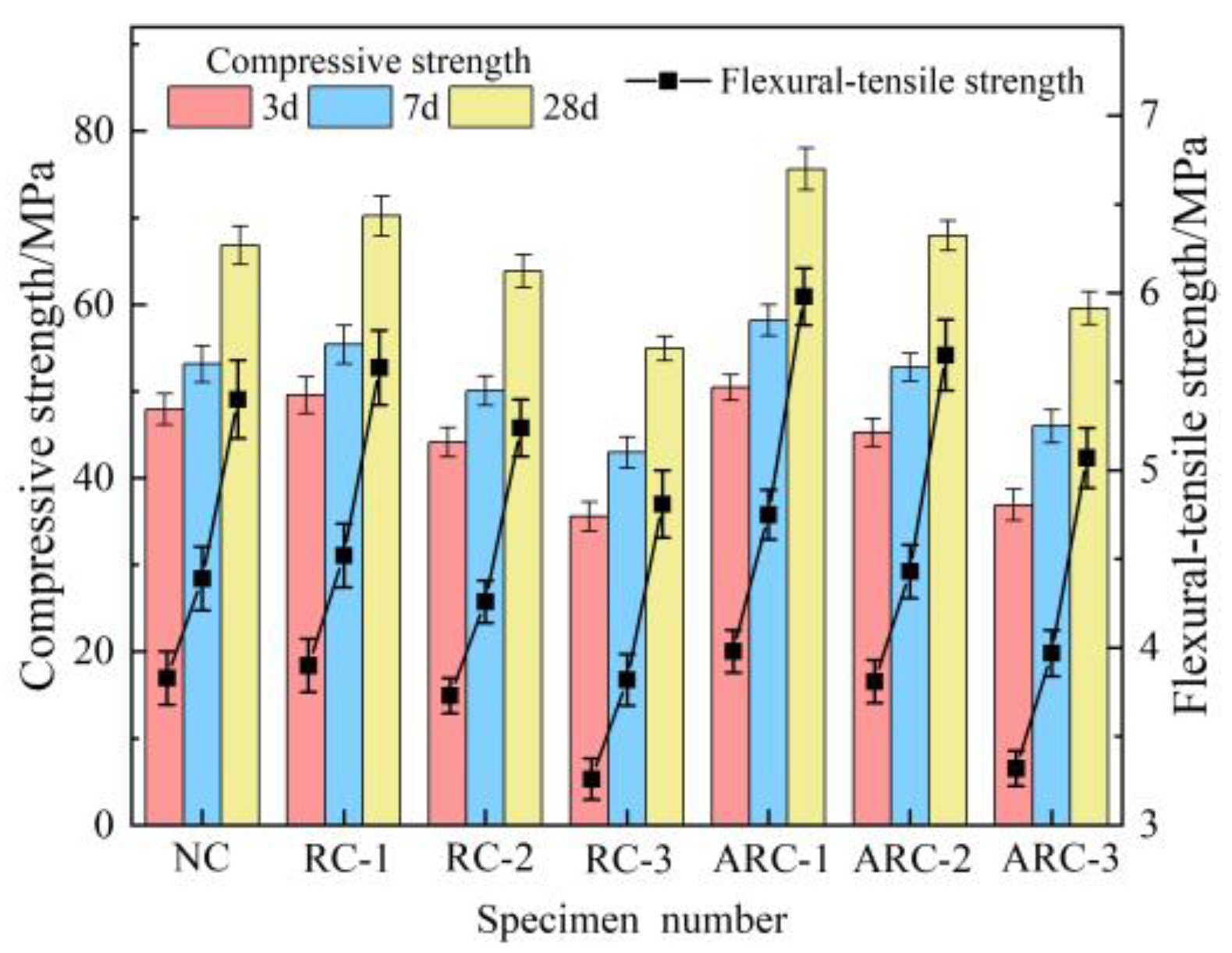

3.1. Mechanical Properties

3.2. Pore Structure Analysis

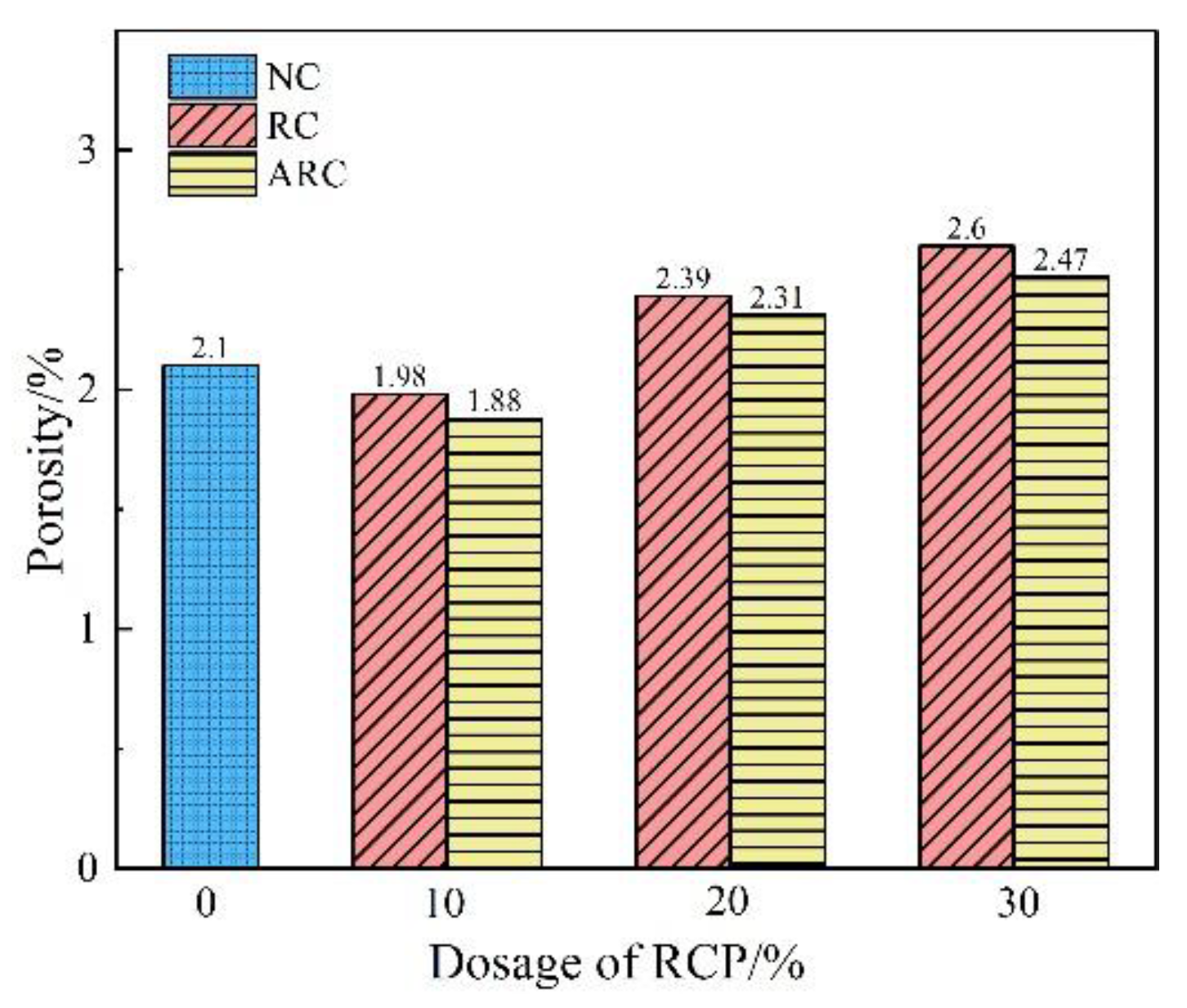

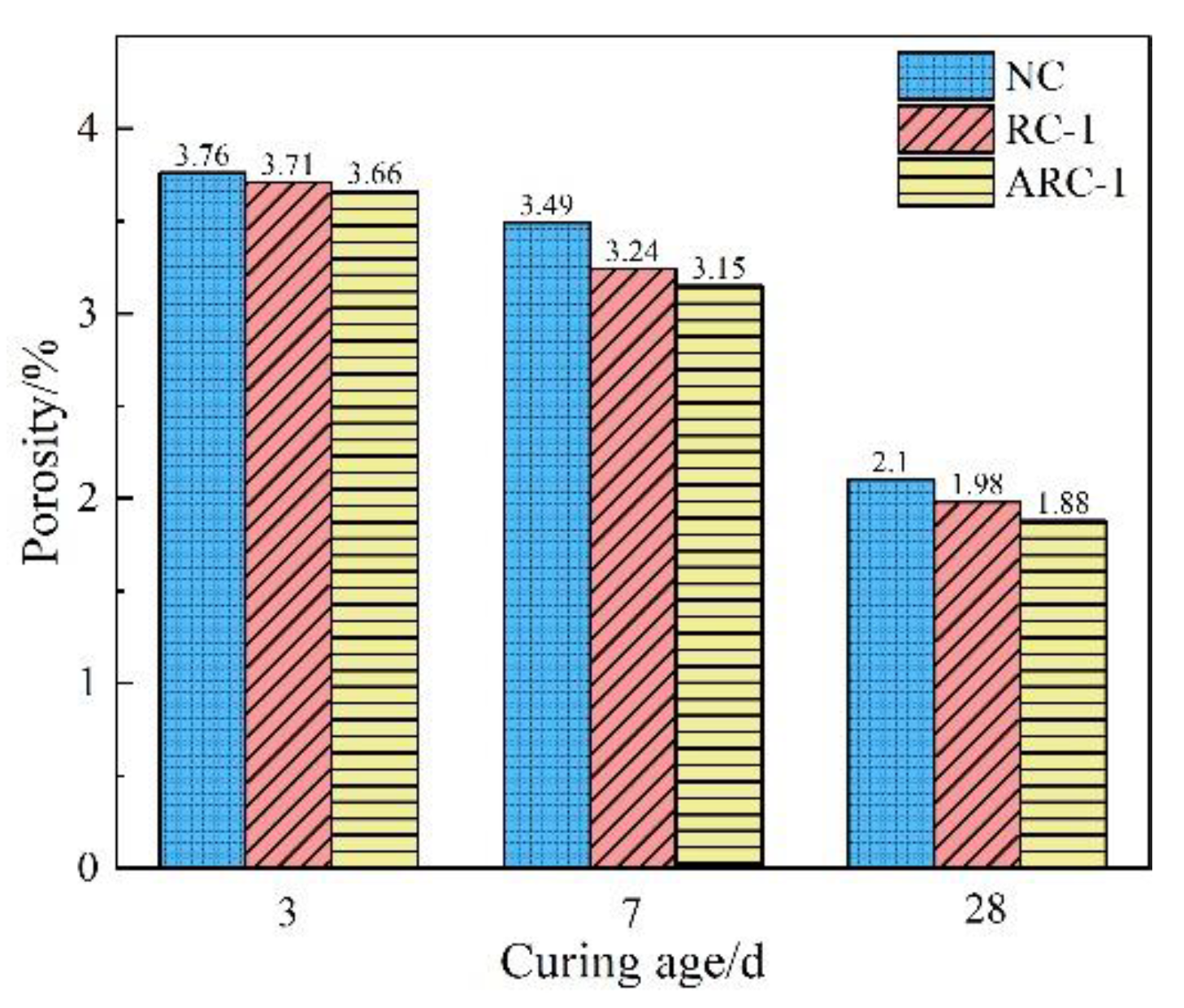

3.2.1. Porosity

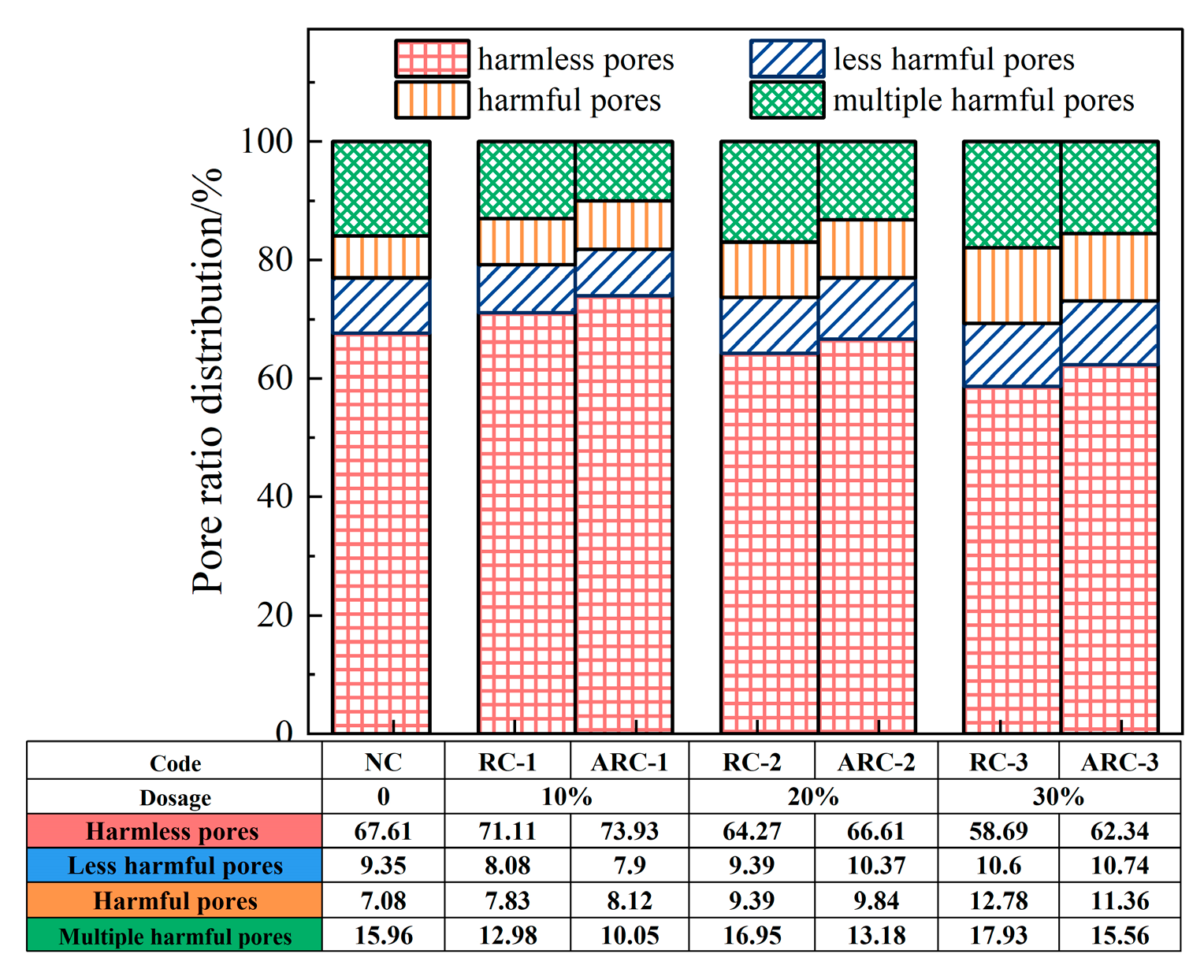

3.2.2. Pore Size Distribution

3.3. Gray Correlation Entropy Analysis

- Determine the order of fundamental parameters:

- 2.

- Dimensionless processing of data in each series:

- 3.

- Calculate the absolute difference between the reference sequence and the comparison sequence.

- 4.

- Determine the maximum and minimum values of the absolute difference, denoted as:

- 5.

- Computing the number of correlation coefficients.

- 6.

- Calculate the gray relation entropy.

- 7.

- Calculate the gray entropy correlation grade.where: —maximum entropy of difference information column, .

3.4. GM (1, N) Model

- 8.

- Determine the system characteristic data sequence A and the sequence of related factors as:

- 9.

- Find its corresponding once accumulated generating sequence (AGO).where:

- 10.

- A is the immediate neighbor of B to generate a sequence of mean values.where

- 11.

- Establish the GM (1, N) model.where is the development coefficient, is the driving term, is the driving coefficient, and is the parameter column that can be obtained by least squares , where:

4. Conclusions

- With the increase of RCP, the mechanical properties of concrete first increased and then decreased. When a reasonable amount of RCP (10%) is added, the secondary hydration reaction and micro-aggregate filling effect of RCP are beneficial to reduce the porosity of concrete and improve the mechanical properties of concrete. Excessive incorporation of RCP (30%) will cause the porosity of concrete to increase and the compactness to decrease, thereby reducing the mechanical properties of concrete.

- The incorporation of 2.5% Ca(OH)2 is beneficial to stimulate the activity of RCP, improve the pore size distribution of concrete, reduce the porosity, and improve the compactness, thus improving the mechanical properties of ARC. As the curing age increases, the RCP is fully hydrated, the pore size in the concrete is further refined, the structure becomes denser, and the mechanical properties are improved. At the same time, the effect of alkali excitation on the mechanical properties of concrete becomes higher and higher.

- The compressive strength and flexural tensile strength of RCP concrete are in the same order of gray entropy correlation degree of each pore characteristic parameter of low-field NMR, that is, harmless pore > porosity > multiple harmful pores > less harmful pore > harmful pore.

- The average relative errors of the GM (1, 4) model for predicting the compressive strength and flexural strength of RCP concrete are 1.519% and 1.423%, respectively, and the accuracy is level 2. The posterior error ratios are 0.189 and 0.255, respectively, and the accuracy is one level. The established predictive GM (1, 4) model can accurately predict the mechanical properties of RCP concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, R.; Wang, C.; Shen, J.; Ma, Z. Chloride transport and thermoactivated modification of sustainable cement-based materials with high-content waste concrete powder. J. Mater. Res. Technol. 2023, 23, 4012–4031. [Google Scholar] [CrossRef]

- Liu, J.; Teng, Y. Evolution game analysis on behavioral strategies of multiple stakeholders in construction waste resource industry chain. Environ. Sci. Pollut. Res. 2023, 30, 19030–19046. [Google Scholar] [CrossRef]

- Bian, Y.; Li, Z.; Zhao, J.; Wang, Y. Synergistic enhancement effect of recycled fine powder (RFP) cement paste and carbonation on recycled aggregates performances and its mechanism. J. Clean. Prod. 2022, 344, 130848. [Google Scholar] [CrossRef]

- Barbudo, A.; Ayuso, J.; Lozano, A.; Cabrera, M.; López-Uceda, A. Recommendations for the management of construction and demolition waste in treatment plants. Environ. Sci. Pollut. Res. 2020, 27, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 103807. [Google Scholar] [CrossRef]

- Chang, F.; Wang, D. Construction waste resource utilization and energy consumption calculation based on Internet of things. Soft Comput. 2023, 27, 7567–7578. [Google Scholar] [CrossRef]

- China Association of Building Energy Efficiency. China Building Energy Consumption and Carbon Emissions Research Report (2022); China Association of Building Energy Efficiency: Beijing, China, 2022; Available online: https://carbon.landleaf-tech.com/wp-content/uploads/2022/12/2022%E5%BB%BA%E7%AD%91%E8%83%BD%E8%80%97%E4%B8%8E%E7%A2%B3%E6%8E%92%E6%94%BE%E7%A0%94%E7%A9%B6%E6%8A%A5%E5%91%8A.pdf (accessed on 19 August 2023).

- Rodríguez, C.; Miñano, I.; Aguilar, M.Á.; Ortega, J.M.; Parra, C.; Sánchez, I. Properties of concrete paving blocks and hollow tiles with recycled aggregate from construction and demolition wastes. Materials 2017, 10, 1374. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A comprehensive review on recycled aggregate and recycled aggregate concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Reis, G.S.; Quattrone, M.; Ambrós, W.M.; Cazacliu, B.G.; Sampaio, C.H. Current applications of recycled aggregates from construction and demolition: A review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Chen, Z. Utilization of Construction Waste Recycled Powder as Filler in Asphalt Concrete. Materials 2022, 15, 5742. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wu, S.; Lyu, Z.; Shen, A.; Yin, L.; Xue, C. Pore structure characteristics and performance of construction waste composite powder-modified concrete. Constr. Build. Mater. 2021, 269, 121262. [Google Scholar] [CrossRef]

- Meng, T.; Hong, Y.; Ying, K.; Wang, Z. Comparison of technical properties of cement pastes with different activated recycled powder from construction and demolition waste. Cem. Concr. Compos. 2021, 120, 104065. [Google Scholar] [CrossRef]

- Moreno-Juez, J.; Caneda-Martínez, L.; de la Villa, R.V.; Vegas, I.; Frías, M. Durability of Construction and Demolition Waste-Bearing Ternary Eco-Cements. Materials 2022, 15, 2921. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Liu, M.; Duan, Z.; Liang, C.; Wu, H. Effects of active waste powder obtained from C&D waste on the microproperties and water permeability of concrete. J. Clean. Prod. 2020, 257, 120518. [Google Scholar]

- Wu, H.; Hu, R.; Yang, D.; Ma, Z. Micro-macro characterizations of mortar containing construction waste fines as replacement of cement and sand: A comparative study. Constr. Build. Mater. 2023, 383, 131328. [Google Scholar] [CrossRef]

- Wu, H.; Yang, D.; Wang, C.; Ma, Z. Effects of construction waste powder on micro–macro properties of green high-strength cement paste with low water-to-binder ratio. Constr. Build. Mater. 2023, 385, 131493. [Google Scholar] [CrossRef]

- Yu, Y.; Hu, H.; Pei, Q.; Yang, X.; Song, S.; Yang, P. Study on mechanical properties and microstructure of recycled aggregate-mixed powder concrete. J. Funct. Mater. 2022, 53, 8147–8152+8175. [Google Scholar]

- Duan, Z.; Hou, S.; Xiao, J.; Li, B. Study on the essential properties of recycled powders from construction and demolition waste. J. Clean. Prod. 2020, 253, 119865. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Naghizadeh, A. Alternative cleaner production of masonry mortar from fly ash and waste concrete powder. Constr. Build. Mater. 2023, 374, 130859. [Google Scholar] [CrossRef]

- Ma, Z.; Hu, R.; Shen, J.; Wang, C.; Wu, H. Chloride diffusion and binding capacity of sustainable cementitious materials with construction waste powder as cement replacement. Constr. Build. Mater. 2023, 368, 130352. [Google Scholar] [CrossRef]

- Gao, Y.; Cui, X.; Lu, N.; Hou, S.; He, Z.; Liang, C. Effect of recycled powders on the mechanical properties and durability of fully recycled fiber-reinforced mortar. J. Build. Eng. 2022, 45, 103574. [Google Scholar] [CrossRef]

- Xiao, J.; Hao, L.; Cao, W.; Ye, T. Influence of recycled powder derived from waste concrete on mechanical and thermal properties of foam concrete. J. Build. Eng. 2022, 61, 105203. [Google Scholar] [CrossRef]

- Liu, M.; Wu, H.; Yao, P.; Wang, C.; Ma, Z. Microstructure and macro properties of sustainable alkali-activated fly ash mortar with various construction waste fines as binder replacement up to 100%. Cem. Concr. Compos. 2022, 134, 104733. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fan, M.X.; Zhou, Y.X.; Ji, D.; Li, J.; Yu, R. Development of a sustainable alkali activated ultra-high performance concrete (A-UHPC) incorporating recycled concrete fines. J. Build. Eng. 2023, 67, 105986. [Google Scholar] [CrossRef]

- Liang, G.; Liu, T.; Li, H.; Wu, K. Shrinkage mitigation, strength enhancement and microstructure improvement of alkali-activated slag/fly ash binders by ultrafine waste concrete powder. Compos. Part B Eng. 2022, 231, 109570. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, J.; Yin, Z. Experimental study on mechanical properties and pore structure deterioration of concrete under freeze–thaw cycles. Materials 2021, 14, 6568. [Google Scholar] [CrossRef]

- Li, M.; Tan, H.; He, X.; Jian, S.; Li, G.; Zhang, J.; Deng, X.; Lin, X. Enhancement in compressive strength of foamed concrete by ultra-fine slag. Cem. Concr. Compos. 2023, 138, 104954. [Google Scholar] [CrossRef]

- Yuan, H.; Zhu, L.; Wang, X.; Yang, H. Effect of microstructure on the mechanical properties of steel fiber-reinforced recycled concretes. Materials 2022, 15, 4018. [Google Scholar] [CrossRef]

- Li, Y.; Wang, P.; Wang, F.; Zheng, X.; Gao, Y. Compressive strength and composite pore structure parameters of iron ore tailings ball concrete. Constr. Build. Mater. 2022, 347, 128611. [Google Scholar] [CrossRef]

- Zhang, S.; Zheng, S.; Wang, E.; Dai, H. Grey model study on strength and pore structure of self-compacting concrete with different aggregates based on NMR. J. Build. Eng. 2023, 64, 105560. [Google Scholar] [CrossRef]

- Sun, Z.; Ma, Z.; Ma, M.; Cai, W.; Xiang, X.; Zhang, S.; Chen, M.; Chen, L. Carbon peak and carbon neutrality in the building sector: A bibliometric review. Buildings 2022, 12, 128. [Google Scholar] [CrossRef]

- JTG/T F30-2014; Technical Guidelines for Construction of Highway Cement Concrete Pavements. People’s Transportation Publishing House: Beijing, China, 2014.

- JTG 3420-2020; Test Methods of Cement and Concrete for Highway Engineering. People’s Transportation Publishing House: Beijing, China, 2020.

- Tian, H.; Wei, C.; Wei, H.; Zhou, J. Freezing and thawing characteristics of frozen soils: Bound water content and hysteresis phenomenon. Cold Reg. Sci. Technol. 2014, 103, 74–81. [Google Scholar] [CrossRef]

- Diamantopoulos, G.; Katsiotis, M.; Fardis, M.; Karatasios, I.; Alhassan, S.; Karagianni, M.; Papavassiliou, G.; Hassan, J. The role of titanium dioxide on the hydration of Portland cement: A combined NMR and ultrasonic study. Molecules 2020, 25, 5364. [Google Scholar] [CrossRef]

- Liu, S.; Lu, S.; Yin, L.; Yan, C.; Lu, L.; Zhou, J. Mechanical strength model of engineered cementitious composites with freeze–thaw damage based on pore structure evolution. Cem. Concr. Compos. 2022, 134, 104706. [Google Scholar] [CrossRef]

- Yu, X.; Li, R.; Dong, X.; Li, G.; Zhang, S. Effect of Mechanical Force Grinding on the Properties of Recycled Powder. J. Synth. Cryst. 2017, 46, 688–692. [Google Scholar]

- Letelier, V.; Ortega, J.M.; Muñoz, P.; Tarela, E.; Moriconi, G. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037. [Google Scholar] [CrossRef]

- Kim, Y.J.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Zhu, X.; Tang, D.; Yang, K.; Zhang, Z.; Li, Q.; Pan, Q.; Yang, C. Effect of Ca(OH)2 on shrinkage characteristics and microstructures of alkali-activated slag concrete. Constr. Build. Mater. 2018, 175, 467–482. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Wei, J. The role of various powders during the hydration process of cement-based materials. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Ma, Q.; Yang, W.; Duan, Z.; Liu, H.; Hua, M.; Deng, Q. Influence of Alkali-Activators on Acid Rain Resistance of Geopolymer-Recycled Pervious Concrete with Optimal Pore Size. Materials 2022, 15, 8368. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z. High Performance Concrete; China Railway Publishing House: Beijing, China, 1999. [Google Scholar]

- Zhang, M.; Yao, X.; Guan, J.; Li, L.; Wang, J.; Qing, L. Study of concrete strength and pore structure model based on grey relation entropy. Materials 2021, 14, 432. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Zhao, C.; Dai, J. Prediction of compressive strength of recycled aggregate concrete based on gray correlation analysis. Constr. Build. Mater. 2021, 273, 121750. [Google Scholar] [CrossRef]

- Ji, Y.; Xu, W.; Sun, Y.; Ma, Y.; He, Q.; Xing, Z. Grey correlation analysis of the durability of steel fiber-reinforced concrete under environmental action. Materials 2022, 15, 4748. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Jiang, J.; Xu, Z. Study of the Frost Resistance of HDFC Based on a Response Surface Model and GM (1, 1) Model. Adv. Mater. Sci. Eng. 2022, 2022, 8420785. [Google Scholar] [CrossRef]

| Strength Grade | Apparent Density (g/cm3) | Specific Surface Area (m2/kg) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 d | 28 d | 3 d | 28 d | |||

| 42.5 | 3.03 | 360 | 95 | 265 | 24.8 | 45.97 | 4.4 | 8.07 |

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | Ignition Loss | |

|---|---|---|---|---|---|---|---|

| Cement | 23.44 | 55.01 | 7.19 | 2.96 | 2.24 | 2.87 | 2.86 |

| RCP | 50.6 | 19.9 | 14.2 | 5.9 | 3.16 | 1.03 | - |

| Apparent Density (kg/m3) | Stacking Density (kg/m3) | Void Ratio (%) | Mud Content (%) | Crushing Value (%) | Fineness Modulus | |

|---|---|---|---|---|---|---|

| Fine Aggregate | 2640 | 1510 | 41 | 2.3 | - | 2.7 |

| Coarse Aggregate | 2860 | 1450 | 45 | 0.8 | 8 | - |

| No. | Water-Cement Ratio | RCP | Cement | Water | Sand | Coarse Aggregate | Water Reducer | Ca(OH)2 |

|---|---|---|---|---|---|---|---|---|

| NC | 0.37 | - | 319 | 118 | 667 | 1295 | 3.19 | - |

| RC-1 | 0.37 | 31.9 | 287.1 | 118 | 667 | 1295 | 3.19 | - |

| RC-2 | 0.37 | 63.8 | 255.2 | 118 | 667 | 1295 | 3.19 | - |

| RC-3 | 0.37 | 95.7 | 223.3 | 118 | 667 | 1295 | 3.19 | - |

| ARC-1 | 0.37 | 31.9 | 287.1 | 118 | 667 | 1295 | 3.19 | 0.798 |

| ARC-2 | 0.37 | 63.8 | 255.2 | 118 | 667 | 1295 | 3.19 | 1.595 |

| ARC-3 | 0.37 | 95.7 | 223.3 | 118 | 667 | 1295 | 3.19 | 2.393 |

| Magnetic Field Intensity/T | Master Frequency/MHz | Scanned Area/mm | TE /ms | TW /ms | NS | NECH | PRG |

|---|---|---|---|---|---|---|---|

| 0.5 ± 0.08 | 21.3 | 0~60 | 0.35 | 1000 | 4 | 13,000 | 3 |

| Specimen Number | Comparison Sequence/% | Reference Sequence/MPa | |||||

|---|---|---|---|---|---|---|---|

| Porosity | Harmless Pores | Less Harmful Pores | Harmful Pores | Multiple Harmful Pores | Compressive Strength | Flexural Tensile Strength | |

| NC | 2.1 | 67.61 | 9.35 | 7.08 | 15.96 | 66.82 | 5.4 |

| RC-1 | 1.98 | 71.11 | 8.08 | 7.83 | 12.98 | 70.21 | 5.58 |

| RC-2 | 2.39 | 64.27 | 9.39 | 9.39 | 16.95 | 63.86 | 5.24 |

| RC-3 | 2.6 | 58.69 | 10.6 | 12.78 | 17.93 | 54.95 | 4.81 |

| ARC-1 | 1.88 | 73.93 | 7.9 | 8.12 | 10.05 | 75.62 | 5.98 |

| ARC-2 | 2.31 | 66.61 | 10.37 | 9.84 | 13.18 | 67.94 | 5.65 |

| ARC-3 | 2.47 | 62.34 | 10.74 | 11.36 | 15.56 | 59.57 | 5.07 |

| Pore Characteristic Parameters | Compressive Strength | Flexural Tensile Strength | ||

|---|---|---|---|---|

| Gray Relation Entropy | Gray Entropy Correlation Grade | Gray Relation Entropy | Gray Entropy Correlation Grade | |

| porosity | 1.9396 | 0.9968 | 1.9399 | 0.9969 |

| harmless pores | 1.9438 | 0.9989 | 1.9439 | 0.9990 |

| less harmful pores | 1.9030 | 0.9779 | 1.9046 | 0.9788 |

| harmful pores | 1.8709 | 0.9615 | 1.8770 | 0.9646 |

| multiple harmful pores | 1.9153 | 0.9843 | 1.9199 | 0.9866 |

| Accuracy Class | Mean Relative Deviation | Posterior Difference Ratio |

|---|---|---|

| first | 0.01 | 0.35 |

| second | 0.05 | 0.5 |

| third | 0.1 | 0.65 |

| fourth | 0.2 | 0.8 |

| Sequence Number | Experimental Value | Predicted Value | Residual Error | Relative Error | Mean Relative Deviation | Posterior Difference Ratio |

|---|---|---|---|---|---|---|

| 1 | 66.82 | 66.82 | 0 | 0 | 1.519% | 0.189 |

| 2 | 70.21 | 72.546 | 2.336 | 3.496% | ||

| 3 | 63.86 | 63.105 | −0.755 | −1.076% | ||

| 4 | 54.95 | 55.437 | 0.487 | 0.762% | ||

| 5 | 75.62 | 76.540 | 0.92 | 1.675% | ||

| 6 | 67.94 | 66.283 | −1.657 | −2.191% | ||

| 7 | 59.57 | 60.543 | 0.973 | 1.432% |

| Sequence Number | Experimental Value | Predicted Value | Residual Error | Relative Error | Mean Relative Deviation | Posterior Difference Ratio |

|---|---|---|---|---|---|---|

| 1 | 5.4 | 5.4 | 0 | 0 | 1.423% | 0.255 |

| 2 | 5.58 | 5.757 | 0.177 | 3.274% | ||

| 3 | 5.24 | 5.186 | −0.054 | −0.959% | ||

| 4 | 4.81 | 4.842 | 0.032 | 0.602% | ||

| 5 | 5.98 | 6.052 | 0.072 | 1.494% | ||

| 6 | 5.65 | 5.520 | −0.130 | −2.178% | ||

| 7 | 5.07 | 5.152 | 0.082 | 1.455% |

| Specimen Number | Porosity/% | Harmless Pores/% | Multiple Harmful Pores/% | Compressive Strength/MPa | Flexural Tensile Strength/MPa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | |

| NC | 3.76 | 3.49 | 60.51 | 62.56 | 22.66 | 18.47 | 47.92 | 53.16 | 3.83 | 4.39 |

| RC-1 | 3.71 | 3.24 | 62.84 | 64.22 | 20.54 | 17.7 | 49.57 | 55.38 | 3.9 | 4.52 |

| RC-2 | 3.88 | 3.68 | 57.27 | 60.27 | 23.95 | 19.95 | 44.13 | 50.06 | 3.73 | 4.26 |

| RC-3 | 4.12 | 3.99 | 50.69 | 58.69 | 27.93 | 23.93 | 35.56 | 42.95 | 3.26 | 3.82 |

| ARC-1 | 3.66 | 3.15 | 64.12 | 66.91 | 20.74 | 16.06 | 50.44 | 58.18 | 3.98 | 4.75 |

| ARC-2 | 3.8 | 3.47 | 59.61 | 63.61 | 22.18 | 18.18 | 45.25 | 52.77 | 3.81 | 4.43 |

| ARC-3 | 4.06 | 3.76 | 53.34 | 60.34 | 25.56 | 21.56 | 36.89 | 45.98 | 3.32 | 3.97 |

| Sequence Number | Experimental Value | Predicted Value | Mean Relative Deviation | Posterior Difference Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | |

| 1 | 47.92 | 53.16 | 47.92 | 53.16 | 3.082% | 1.706% | 0.119 | 0.171 |

| 2 | 49.57 | 55.38 | 48.12 | 52.6 | ||||

| 3 | 44.13 | 50.06 | 42.94 | 49.29 | ||||

| 4 | 35.56 | 42.95 | 37.12 | 43.11 | ||||

| 5 | 50.44 | 58.18 | 52.83 | 57.28 | ||||

| 6 | 45.25 | 52.77 | 43.79 | 53.52 | ||||

| 7 | 36.89 | 45.98 | 38.22 | 46.92 | ||||

| Sequence Number | Experimental Value | Predicted Value | Mean Relative Deviation | Posterior Difference Ratio | ||||

|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | 3 d | 7 d | |

| 1 | 3.83 | 4.39 | 3.83 | 4.39 | 2.336% | 1.696% | 0.166 | 0.148 |

| 2 | 3.9 | 4.52 | 3.99 | 4.37 | ||||

| 3 | 3.73 | 4.26 | 3.64 | 4.21 | ||||

| 4 | 3.26 | 3.82 | 3.35 | 3.76 | ||||

| 5 | 3.98 | 4.75 | 4.14 | 4.67 | ||||

| 6 | 3.81 | 4.43 | 3.74 | 4.49 | ||||

| 7 | 3.32 | 3.97 | 3.42 | 4.08 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Yu, Z.; Zhang, J.; Yang, H.; Song, W. Gray Model Study of Strength and Pore Structure of Recycled Concrete Powder (RCP) Concrete Based on Low-Field NMR Technology. Materials 2023, 16, 6058. https://doi.org/10.3390/ma16176058

Hou Y, Yu Z, Zhang J, Yang H, Song W. Gray Model Study of Strength and Pore Structure of Recycled Concrete Powder (RCP) Concrete Based on Low-Field NMR Technology. Materials. 2023; 16(17):6058. https://doi.org/10.3390/ma16176058

Chicago/Turabian StyleHou, Yongli, Zhengxing Yu, Jianhua Zhang, Hongrui Yang, and Weiqing Song. 2023. "Gray Model Study of Strength and Pore Structure of Recycled Concrete Powder (RCP) Concrete Based on Low-Field NMR Technology" Materials 16, no. 17: 6058. https://doi.org/10.3390/ma16176058

APA StyleHou, Y., Yu, Z., Zhang, J., Yang, H., & Song, W. (2023). Gray Model Study of Strength and Pore Structure of Recycled Concrete Powder (RCP) Concrete Based on Low-Field NMR Technology. Materials, 16(17), 6058. https://doi.org/10.3390/ma16176058